Page 1

OUTDOOR LINEAR FIRE PIT MANUAL

⚠ DANGER

If you smell gas:

1. Shut off gas to the

appliance.

2. Extinguish any open flame.

3. If odor continues, keep

away from the appliance

and immediately call your

gas supplier or fire

department.

⚠ WARNING

Do not store or use gasoline

or other flammable vapors and

liquids in the vicinity of this or

any other appliance.

An LP-cylinder not connected

for use shall not be stored in

the vicinity of this or any other

appliance.

⚠ WARNING

For Outdoor Use Only.

⚠ WARNING

Improper installation,

adjustment, alteration, service

or maintenance can cause

injury or property damage.

Read the installation,

operating and maintenance

instructions thoroughly before

installing or servicing this

equipment.

⚠ DANGER

CARBON MONOXIDE HAZARD

This appliance can produce carbon

monoxide which has no odor.

Using it in an enclosed space can

kill you.

Never use this appliance in an

enclosed space such as a camper,

tent, car or home.

Kingsman Fireplaces 2340 Logan Ave., W innipeg, Mb Canada Ph: 204-632-1962 Printed in Canada P/N 24LFP-MAN April 4, 2017

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

This appliance is designed as an “attended appliance”. Adults

must be present when the unit is operating. DO NOT leave this

unit burning when unattended. If this product is left burning

unattended it may cause damage or serious injury.

OLTN / OLTW

OUTDOOR FIRE TABLE

OFP S1 / S2

OUTDOOR FIREPLACE

OB

OUTDOOR BURNER

OFS

OUTDOOR FIRE STAND

VALVE

OUTDOOR BURNERS: OB24MAN, OB24MAP, OB24MVN, OB24MVP,

OB36MAN, OB36MAP, OB36MVN, OB36MVP,

OB48MAN, OB48MAP, OB48MVN, OB48MVP,

OB72MVN, OB72MVP, OB96MVN, OB96MVP

-CERTIFIED FOR USA & CANADA- ANSI Z21.97-2014 • CSA 2.41-2014 OUTDOOR DECORATIVE GAS APPLIANCES

NOTE: LP MANUAL (MAP) VALVE SYSTEMS ARE SHIPPED WITH AN ACCOMPANYING ORIFICE FOR NG CONVERSION.

ALL MILLIVOLT VALVE SYSTEMS ARE SHIPPED AS NG SYSTEMS (MVN) AND REQUIRE A CONVERSION KIT FOR LP CONVERSION.

OUTDOOR FIRE STANDS (c/w Burner): OFS24MAN, OFS24MAP, OFS36MAN, OFS36MAP, OFS48MAN, OFS48MAP

OUTDOOR FIRE TABLES (Burner Required): OLTN24, OLTW24, OLTN36, OLTW36, OLTN48, OLTW48

OUTDOOR FIREPLACES (Burner Required): OFP4336S1, OFP4336S2, OFP5548S1, OFP5548S2, OFP7972S1, OFP7972S2

Page 2

Warnings, Installations and Operations

WARNING

FOR SAFE INSTALLATION AND OPERATION OF YOUR GAS FIREPLACE PLEASE NOTE THE FOLLOWING:

1. when an appliance is for connection to a fixed piping system, the installation must conform with local codes or,

in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1 • NFPA 54; National Fuel Gas

Code; Natural Gas and Propane Installation Code, CSA B149.1; or Propane Storage and Handling Code, CSA

B149.2, as applicable.

2. This appliance, when installed, must be electrically grounded in accordance with local codes or, in the absence

of local codes, with the National Electrical Code, ANSI/NFPA 70; or the Canadian Electrical Code, CSA C22.1,

if applicable.

3. THIS UNIT IS NOT FOR USE WITH SOLID FUEL.

4. Always keep the appliance clear and free from combustible materials, gasoline, and other flammable vapors

and liquids.

5. Inspect the fuel supply connection (including the hose for LP models) before each use of the appliance. See

Lighting Instructions for removal of Access Panel.

6. If it is evident there is excessive abrasion or wear, or the hose is damaged, it must be replaced prior to the

appliance being put into operation. Locate the hose out of pathways where people may trip over it or in areas

where the hose may be subject to accidental damage

7. Locate the hose out of pathways where people may trip over it or in areas where the hose may be subject to

accidental damage.

8. Children and adults should be alerted to the hazards of the high surface temperatures of this appliance and

should stay away to avoid burns or ignition of clothing.

9. Young children should be carefully supervised when they are in the area of the appliance.

10. Clothing or other flammable material should not be placed on or near the appliance. This appliance should not

be used as a drying rack for clothing.

11. Any safety screen or guard removed for servicing an appliance must be replaced prior to operating the

appliance.

12. Installation and repair should be done by a qualified service person. The appliance should be inspected before

use and at least annually by a professional service person. More frequent cleaning may be required due to

excessive lint from carpeting, et cetera. It is imperative that control compartments, burners and circulating air

passageways of the appliance be kept clean.

13. Do not use this appliance if any part has been under water. Immediately call a qualified service technician to

inspect the unit and to replace any part of the control system and any gas control which has been underwater.

2

This gas appliance must be installed by a qualified installer in accordance with local building codes, or in the absence of

local codes, with the current CAN/CSA-B149.1 or .2 Installation Code (in Canada) or the current National Fuel Gas Code

Z223.1- NFPA 54 when installed in the United States.

This appliance, when installed, must be electrically connected and grounded in accordance with local codes, or in the

absence of local codes, with the current CSA C22.1 Canadian Electrical Code or with the National Electrical Code;

ANSI/NFPA 70 when installed in the United States.

In the Commonwealth of Massachusetts, the installer or service

agent shall be a plumber or gas fitter licensed by the

Commonwealth of Massachusetts.

For the State of Massachusetts, flexible connectors shall not

exceed 36 inches in length.

For the state of Massachusetts a T-handle gas shut-off valve

must be used on a gas appliance.

Page 3

Table of Contents

INTRODUCTION

Warnings, Installations and Operations……….........

2

Table of Contents………………………………..........

3

Pre-installation Questions and Answers……...........

4

Important Information About Outdoor

Fireplaces………………………………………...........

4

Locating Your Appliance / Outdoor Spaces…..........

5

Clearance Specifications……………………….........

6

Outdoor Burners Basic Models and

Applications………………………………………........

7

24 / 36 / 48 / 72 / 96 OUTDOOR BURNERS

Burner Systems for Custom Applications, OB /

OFS / OLTN / LTW / OFP Models……....................

8

Clearance to Combustibles for Outdoor Burners,

Outdoor Fire Stands, Outdoor Fire

Tables......................................................................

8

Dimensions - OB24 / OB36 / OB48 / OB72 / OB96

Outdoor Burners.......................................................

9

OB Burners – Unpacking and Setup – Manual

Valve Systems.........................................................

10

OB Burners – Unpacking and Setup – Millivolt

Valve Systems.........................................................

11

CUSTOM ENCLOSURES

Custom Enclosures-OB24 / 36 / 48 / 72 / 96............

12

Custom Enclosures – Optional LED Lighting...........

13

Enclosures for LP (Propane) Gas Supply

Systems...................................................................

14

OUTDOOR FIRE STANDS

Outdoor Fire Stands (OFS) Dimensions - OFS24 /

OFS36 / OFS48.......................................................

15

Outdoor Fire Stands (OFS) Unpacking and Setup...

16

OUTDOOR FIRE TABLES

Outdoor Fire Tables (OLTN / OLTW) Dimensions –

OLTN24 / OLTW24..................................................

17

Outdoor Fire Tables (OLTN / OLTW) Dimensions –

OLTN36 / OLTW36..................................................

18

Outdoor Fire Tables (OLTN / OLTW) Dimensions –

OLTN48 / OLTW48..................................................

19

Outdoor Fire Tables – Assembly..............................

20

Outdoor Fire Tables– Burner Installation.................

21

Outdoor Fire Tables – Optional LED Lighting..........

22

Outdoor Fire Tables – 20lb Cylinder Installation......

23

OUTDOOR FIREPLACES

Outdoor Fireplaces (OFP) OFP4336S1 &

OFP4336S2 Dimensions..........................................

24

Outdoor Fireplaces (OFP) OFP5548S1 &

OFP5548S2 Dimensions..........................................

25

Outdoor Fireplaces (OFP) OFP7972S1 &

OFP7972S2 Dimensions..........................................

26

Outdoor Fireplaces (OFP) – Handling Unit..............

27

Adjustable Support Guide -Hearth Flush With

Fireplace Opening....................................................

28

Outdoor Fireplace (OFP) Optional Framing (S1 &

S2)............................................................................

29

Outdoor Fireplace (OFP) Clearances and Mantels..

30

Surround Installation OFP43SS / OFP55SS /

OFP79SS.................................................................

31

Weather Cover Installation OFP43WC / OFP55WC

/ OFP79WC..............................................................

32

Outdoor Fireplace (OFP) Wind Guard Glass...........

33

About Stainless Steel Parts And Accessories..........

33

Outdoor Fireplace (OFP) Optional LED Lighting......

34

Outdoor Fireplace (OFP) Burner Removal &

Installation................................................................

35

ACCESSORIES AND OPTIONS

Glass Media for Outdoor Burners............................

36

Optional Media Accessories.....................................

36-37

Optional Wind Guards..............................................

38

MAINTENANCE

Burner System Maintenance....................................

39

General Maintenance Instructions...........................

40

BURNER LIGHTING / GAS INSTALLATION

Manual Lighting Instructions....................................

41

Millivolt Lighting Instructions....................................

42

Gas Line Installation.................................................

43

LP Cylinder Requirements / LP Conversion Kits......

44

Gas Conversion - Manual Systems..........................

45

Gas Conversion Part A – Millivolt Systems..............

46

Gas Conversion Part B – Top Convertible Pilot.......

47

Gas Conversion Part C – Valve Modulator..............

48

Optional Electronic Spark Assist..............................

49

Troubleshooting the Gas Control System................

50

PARTS LISTS

Plumbing Parts.........................................................

51

Outdoor Burners- Parts List......................................

52-53

Limited Warranty......................................................

54

3

Page 4

Pre-installation Questions and Answers

Important Information About Outdoor Fireplaces

-Operating Instructions-

1. Be sure to read and understand all the

instructions in this manual before

operation of appliance.

2. Ensure all wiring is correct and properly

enclosed to prevent possible shock.

3. Check for gas leaks.

4. If brick or porcelain liners are used,

ensure they are installed.

5. Verify that the pilot can be seen when

lighting the appliance. If not, the log or

rock placement is incorrect.

6. If the unit is turned off, you must wait a

minimum of 60 seconds before relighting it.

4

About curing of the paint

Your stove or fireplace has been painted with the highest quality silicone

stove paint. This paint dries quickly in 15-20 minutes when first applied at

the factory. However, due to the high temperature silicone components,

the paint will cure when heat is applied to the appliance as it is first used.

The following information applies to the curing process to get the paint

fully hard and durable.

Fire the appliance four successive times for 10 minutes each firing and a

5 minute cool down between each. Be aware during log and firebox paint

curing that a white deposit may be developing on the inside of the glass

doors. It is important to remove this white deposit from the glass doors

using a fireplace glass cleaner.

Babies, small children, pregnant women and pets should leave

the area during the cure phase.

Ventilate well, open doors and windows.

Do not touch during curing.

Why does my fireplace or stove give off odour?

It is normal for your fireplace to give off some odor at first. This is due to the curing of the paint, adhesives, silicones and

any undetected oil from the manufacturing process as well as the finishing materials used with the installations (e.g.

marble, tile and the adhesives used to adhere this product to the walls can react with heat and cause odours).

It is recommended that you burn your gas fireplace or stove for a minimum of four hours at a time with the fan off (if a fan

is present) after the curing of the paint has been completed. These odours can last upward to 40 hours of burn time; keep

burning at a minimum of four hours per use until odours dissipate.

Noise coming from the fireplace?

Noise is caused by the expansion and contraction of metal as the appliance heats up and cools down. This is normal and

is similar to the sounds produced by a furnace or heating duct. This noise does not affect the operation or longevity of

your fireplace.

Note to the Installer:

Be sure appliance is working properly and its operation (including remote control operation, if included) is fully explained

to and understood by the customer.

Before you build in this appliance:

Do not insulate around the appliance. Heat buildup could lead to component failure.

Pay attention to all clearances to combustibles and specifications stated in this manual.

Drainage- If this appliance is installed in a location where it will be exposed to water and moisture, drainage is an

important consideration.

Inadequate drainage will cause rust, which is not covered by the warranty.

Information about outdoor fireplaces

Outdoor fire burning appliances may not function properly at all times regardless of the circumstances.

Wind can greatly affect flame performance. If used in windy conditions a wind guard is recommended.

Outdoor units require adequate ventilation in order to burn properly.

Restricted access to air is not only dangerous for persons near the appliance, but the appliance also will not

function correctly.

This appliance consumes air, burns fuel, and emits heat and exhaust gases.

Only approved media and accessories listed in this manual should be used with this appliance.

Page 5

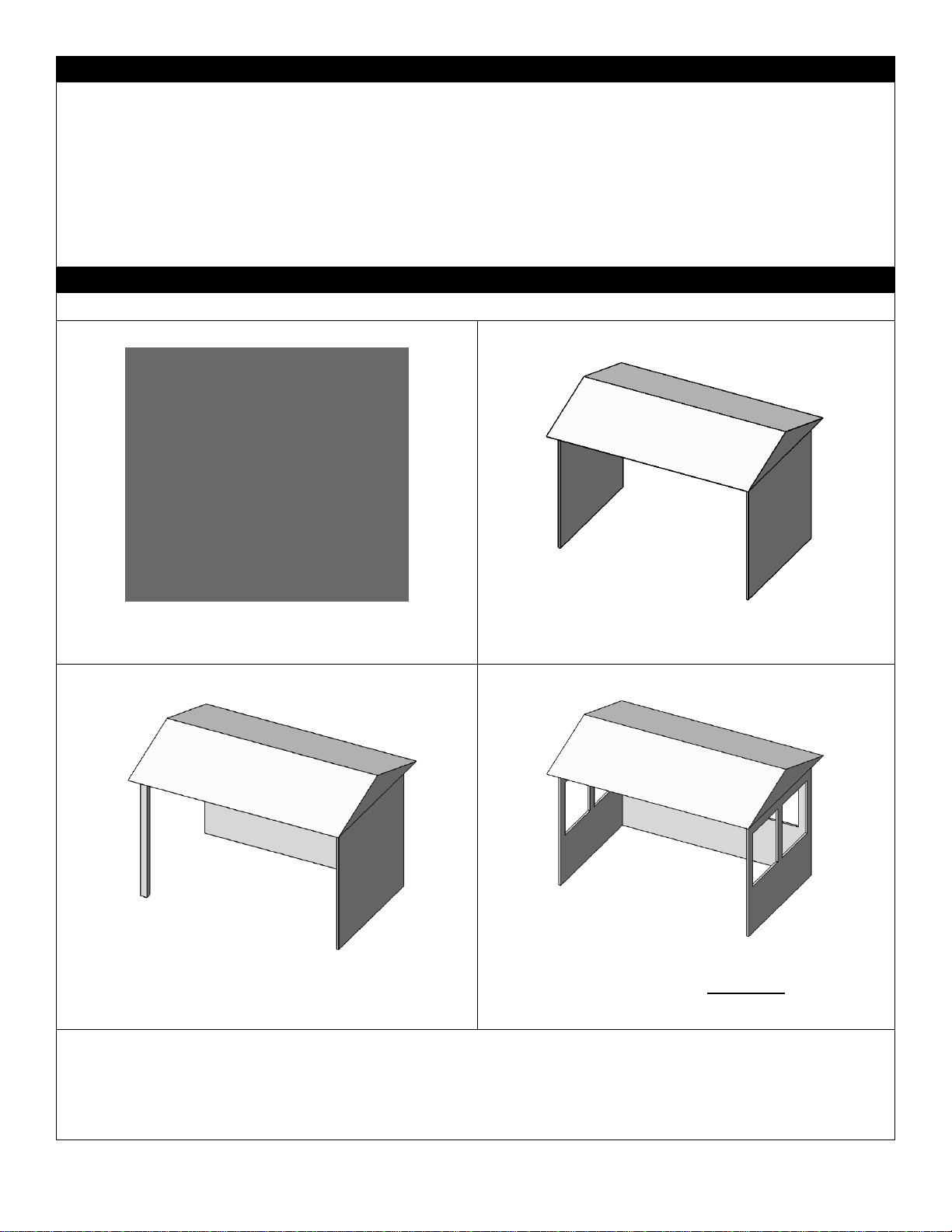

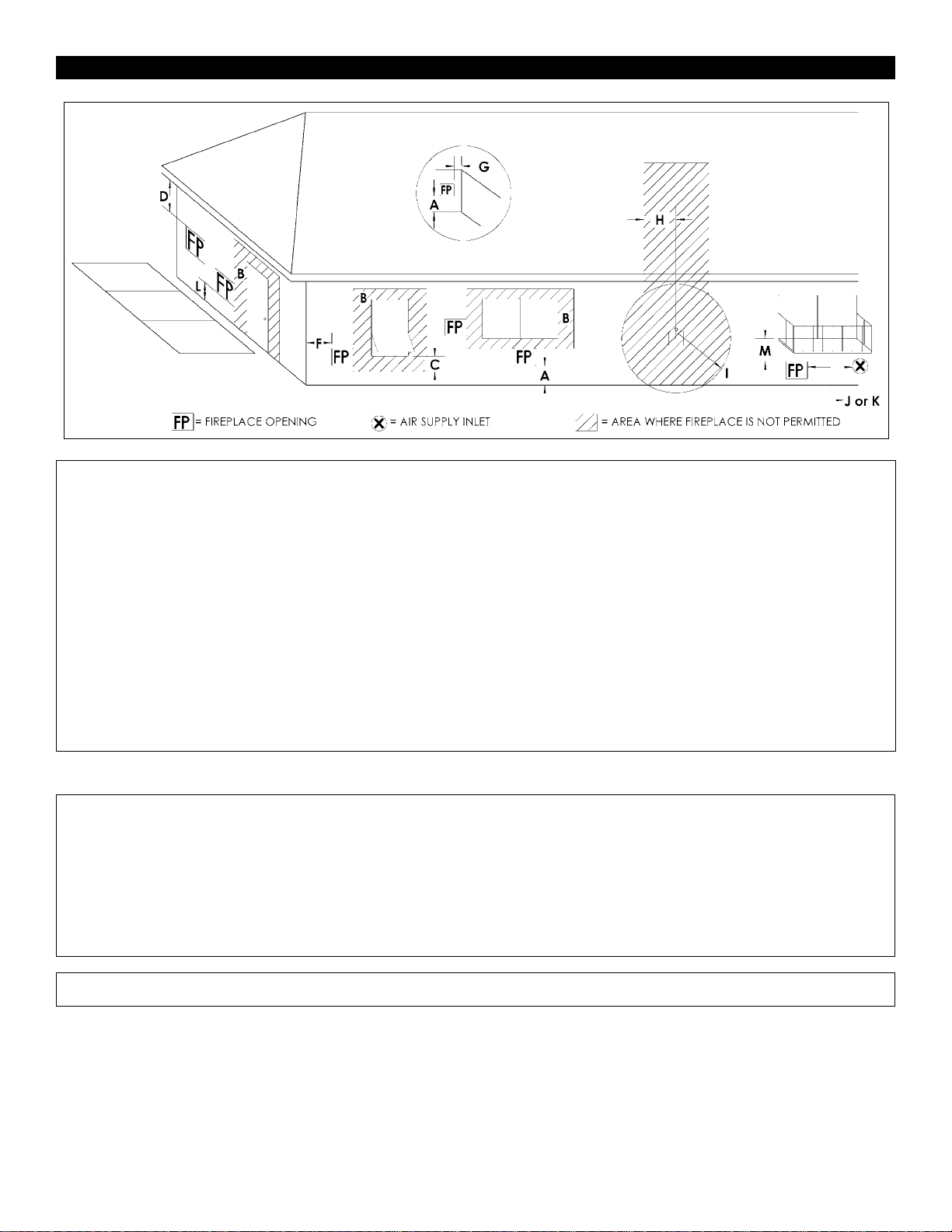

Locating Your Appliance

Note: Ventilation and air flow comes from openings in the walls and ceiling. Open floor space around the appliance

must not be considered ventilation and air flow space.

This unit requires combustion air and will produce exhaust gases. Install in an open-air situation with natural

ventilation and without stagnant areas.

Avoid installing in tight spaces and corners.

Be aware of combustibles (i.e. furniture) near appliance. Clearance is Minimum 36”.

By definition, an outdoor space is not enclosed. Any area in which these appliances are used shall comply with

the structures shown below.

Locating Your Appliance – Outdoor Spaces

This appliance may be installed within the following structures:

1.

Walls on all sides (Minimum area of 96 square feet), but

with no overhead cover and at least one permanent

opening (doorway) at ground level.

2.

Within a partial enclosure that includes an overhead cover

and no more than two side walls.

3.

These side walls may be parallel, as in a breezeway, or at

right angles to each other.

4.

Within a partial enclosure that includes an overhead cover

and three side walls, as long as 30 percent or more of the

horizontal periphery of the enclosure is permanently open.

All models can be installed safely in a screened porch area within the following guidelines:

Minimum porch area is 96sq. feet with one side fully open.

A minimum of two (2) walls can be screened, but must be open to outside ventilation, with a minimum screen area of 64

sq. feet, and a minimum side wall height of 78” inches.

5

Page 6

Clearance Specifications

A =

2in………….

Clearances above grade, veranda, porch,

deck or balcony.

I =

3ft (USA)……..

6ft (Canada)

Clearance to service regulator

vent outlet and electric service.

B =

12in…………

36in…………

Clearances to window or door that may be

opened, or to permanently closed window.

Vinyl windows or siding.

J =

9in (USA)…….

12in (Canada)

Clearance to non-mechanical air

Supply inlet to building or the

combustion air inlet to any other

appliance.

C =

12in…………

Clearance below an operable window.

K =

3ft (USA)…….

6ft (Canada)

Clearance to a mechanical air

supply inlet

D =

47in…………

60in…………

Vertical clearance to unventilated soffit or

to or to ventilated soffit located above the

fireplace.

Vinyl clad soffits.

L*=

54in………......

(See note 1)

Clearance above paved sidewalk

or a paved driveway located on

public property.

G =

3-1/2in…….

48in………..

Clearance to inside corner.

Vinyl windows or siding.

M**=

47in…………..

Clearance under veranda, porch,

deck, balcony or overhang.

H =

3ft. (Canada)

Not to be installed above a gas

meter/regulator assembly within 3ft

horizontally from the center line of the

regulator.

Not allowed….

Vinyl.

* A fireplace shall not open directly above a sidewalk or paved

driveway which is located between two single family

dwellings and services both swellings.

**Only permitted if veranda, porch, deck or balcony is fully

open on a minimum of 2 sides beneath the floor, or if the

screened porch guidelines are followed.

Note 1: Local codes or regulations may require different

clearances.

This appliance can be installed safely in a screened porch area

within the following guidelines:

Minimum porch area is 96sq. feet with one side fully open.

A minimum of two (2) walls can be screened, but must be open to

outside ventilation, with a minimum screen area of 64 sq. feet,

and a minimum side wall height of 78” inches.

Note: There may be some odor and small amounts of soot associated with burning the fireplace in a screened porch. Ensuring good

cross draft ventilation and routine maintenance of the fireplace will maximize comfort and cleanliness.

6

NOTE: Diagrams & Illustrations not to scale.

Page 7

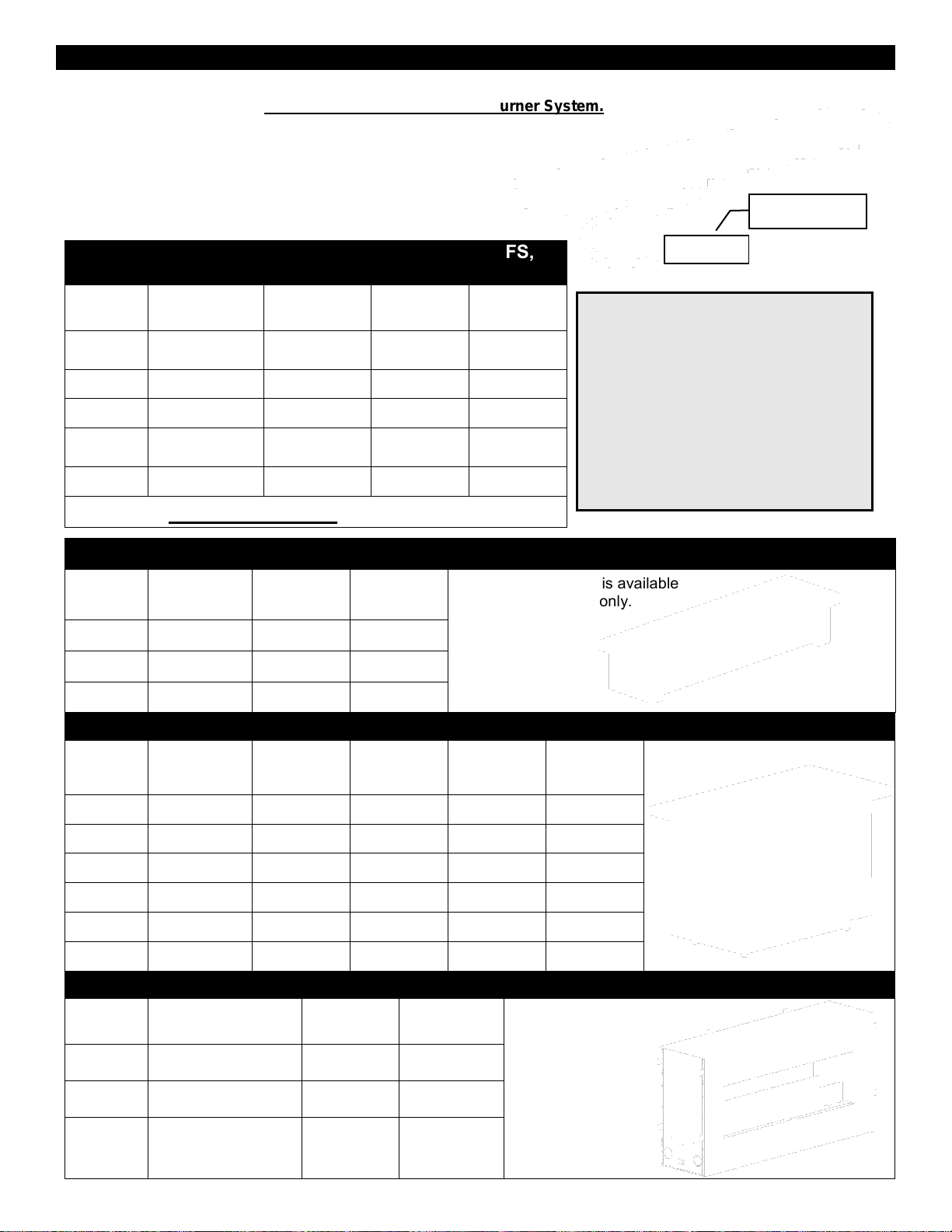

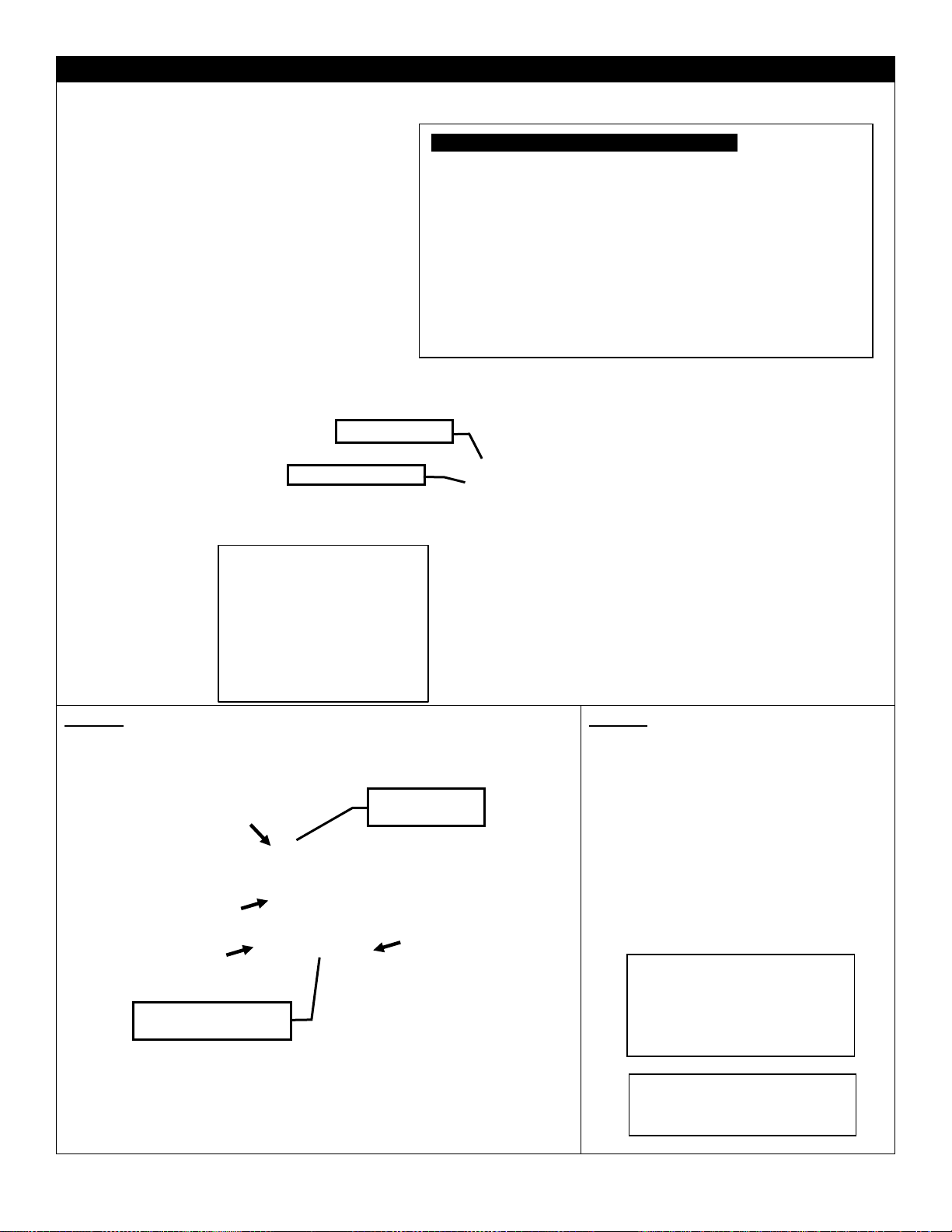

Outdoor Burners Basic Models and Applications

The Outdoor Burners (OB24, OB36, OB48, OB72, and OB96) are the basic component of the Barbara Jean

Series. These burners are a Complete Certified and Listed Burner System.

They consist of: -Burner

-Valve Control (Manual or Millivolt)

-Label

These burners can be placed into Custom Enclosures

which meet the specifications stated in the manual.

Burners for Custom Applications and Optional OFS,

OFT, and OFP Installations

LISTED

BURNER

MAP

Manual-LP

MAN

Manual-NG

MVP

Millivolt-LP

MVN

Millivolt-NG

OB24-

✔ c/w NG Orifice

✔

Conversion Kit

Required

✔

OB36-

✔ c/w NG Orifice

✔

Conversion Kit

Required

✔

OB48-

✔ c/w NG Orifice

✔

Conversion Kit

Required

✔

OB72-

N/A

N/A

Conversion Kit

Required

✔

OB96-

N/A

N/A

Conversion Kit

Required

✔

The following Approved Accessories can also be ordered:

Outdoor Fire Stand (OFS) Approved Accessory (Burner is Included)

LISTED

BURNER

OFS

Fire Stand

MAP

Manual-LP

MAN

Manual-NG

Outdoor Fire Stand is available

with a Manual Valve only.

OB24-

OFS24-

✔

✔

OB36-

OFS36-

✔

✔

OB48-

OFS48-

✔

✔

Outdoor Fire Tables (OLTN / OLTW) Approved Accessory (Burner is ordered separately)

LISTED

BURNER

OFT

Outdoor

Fire Table

MAP

Manual-LP

MAN

Manual-NG

MVP

Millivolt-LP

MVN

Millivolt-NG

Outdoor Fire Table

OB24-

OLTN24

✔

✔

Conversion Kit

Required

✔

OB24-

OLTW24

✔

✔

Conversion Kit

Required

✔

OB36-

OLTN36

✔

✔

Conversion Kit

Required

✔

OB36-

OLTW36

✔

✔

Conversion Kit

Required

✔

OB48-

OLTN48

✔

✔

Conversion Kit

Required

✔

OB48-

OLTW48

✔

✔

Conversion Kit

Required

✔

Outdoor Fireplace (OFP) Approved Accessory (Burner is included)

LISTED

BURNER

OFP

Outdoor Fireplace

MVP

Millivolt-LP

MVN

Millivolt-NG

Outdoor Fireplace

OB36-

OFP4336

S1 or S2

Conversion

Kit Required

✔

OB48-

OFP5548

S1 or S2

Conversion

Kit Required

✔

OB72-

OFP7972

S1 or S2

Conversion

Kit Required

✔

Label is attached

to Valve

VALVE

Burner systems may be connected

together in series (i.e. OB36MAP &

OB48MAP). See Custom Enclosures

section.

ALL LP MANUAL (MAP) VALVE SYSTEMS

ARE SHIPPED WITH AN ACCOMPANYING

ORIFICE FOR NG CONVERSION.

ALL MILLIVOLT VALVE SYSTEMS ARE

SHIPPED AS NG SYSTEMS (MVN) AND

REQUIRE A CONVERSION KIT FOR LP

CONVERSION.

7

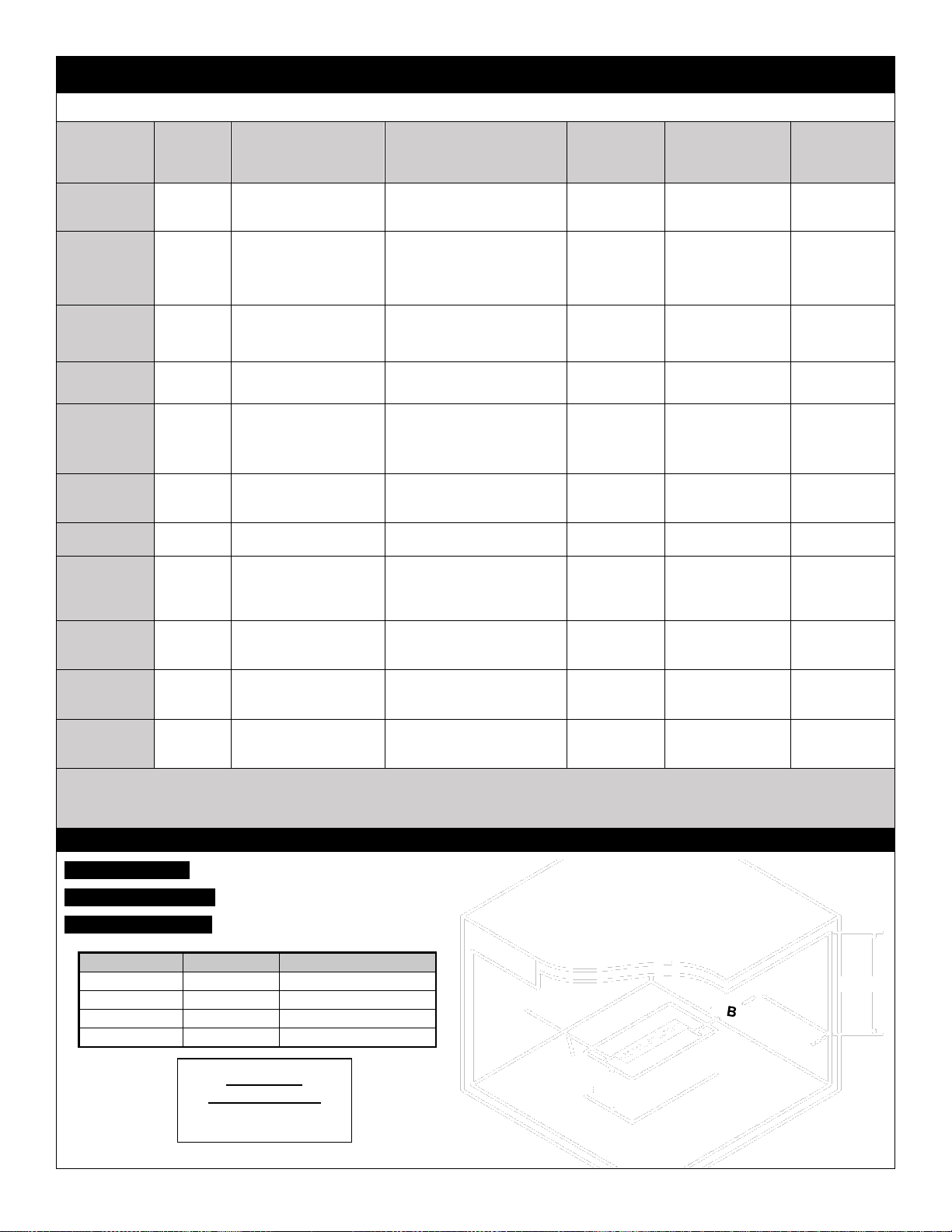

Page 8

-Burners-

Burner Systems for Custom Applications, OB / OFS / OLTN / OLTW / OFP Models

Burner

System c/w

Valve

Valve

System

Stocked Burner

Conversion Kit shown

Burner (OB) Dimensions

for Custom Applications

(Add 1/8” per side for

tolerance)

Outdoor

Fire Stand

(OFS)

Outdoor Fire

Table

(OLTN or OLTW )

Outdoor

Fireplace

(OFP)

OB24MAP

Dante

Manual

LP Burner

(c/w NG Orifice)

7-1/2” wide x 26” long

x 2” tall

OFS24MAP

OLTN24

OLTW24

N/A

OB24MAN

Dante

Manual

NG Burner

For LP order

24OB-CKLP5 or

24OB-CKLP10

7-1/2” wide x 26” long

x 2” tall

OFS24MAN

OLTN24

OLTW24

N/A

OB24MVN

SIT

Millivolt

NG Burner

For LP order 24OB-

CKLP

7-1/2” wide x 26” long

x 2” tall

N/A

OLTN24

OLTW24

N/A

OB36MAP

Dante

Manual

LP Burner

(c/w NG Orifice)

7-1/2” wide x 38” long

x 2” tall

OFS36MAP

OLTN36

OLTW36

N/A

OB36MAN

Dante

Manual

NG Burner

For LP order

36-48OB-CKLP5 or

36-48OB-CKLP10

7-1/2” wide x 38” long

x 2” tall

OFS36MAN

OLTN36

OLTW36

N/A

OB36MVN

SIT

Millivolt

NG Burner

For LP order

36OBCKLP

7-1/2” wide x 38” long

x 2” tall

N/A

OLTN36

OLTW36

OFP4336S1

OFP4336S2

OB48MAP

Dante

Manual

LP Burner

(c/w NG Orifice)

7-1/2” wide x 50” long

x 2” tall

OFS48MAP

OLTN48

OLTW48

N/A

OB48MAN

Dante

Manual

NG Burner

For LP order

36-48OB-CKLP5 or

36-48OB-CKLP10

7-1/2” wide x 50” long

x 2” tall

OFS48MAN

OLTN48

OLTW48

N/A

OB48MVN

SIT

Millivolt

NG Burner

For LP order

48OB-CKLP

7-1/2” wide x 50” long

x 2” tall

N/A

OLTN48

OLTW48

OFP5548S1

OFP5548S2

OB72MVN

SIT

Millivolt

NG Burner

For LP order

72OB-CKLP

7-1/2” wide x 74” long

x 2” tall

N/A

N/A

OFP7972S1

OFP7972S2

OB96MVN

SIT

Millivolt

NG Burner

For LP order

96OB-CKLP

7-1/2” wide x 98” long

x 2” tall

N/A

N/A

N/A

Burner systems may be connected together in series (i.e. OB36MAP & OB48MAP). See Custom Enclosures section.

LP MANUAL (MAP) VALVE SYSTEMS ARE SHIPPED WITH ACCOMPANYING ORIFICE FOR NG CONVERSION.

MILLIVOLT SYSTEMS ARE SHIPPED AS NG SYSTEMS (MVN) AND REQUIRE A CONVERSION KIT FOR LP CONVERSION.

Locating Your Appliance –Minimum Clearances to Combustibles

Outdoor Burners (OB24 / 36 / 48 / 72 / 96)

Outdoor Fire Stands (OFS24 / 36 / 48)

Outdoor Fire Tables (OLTN / OLTW24 / 36 / 48)

Clearance

Dimension

Measured From:

A: Side wall

24”

Side of Burner Tray

B: End wall

12”

End of Burner Tray

C: Ceiling

49-1/2”

Top of Burner Tray

D: Floor

8”

Top of Burner Tray

A

C

D

WARNING

-RISK OF FIRE-

All minimum clearances

must be adhered to.

CEILING

8

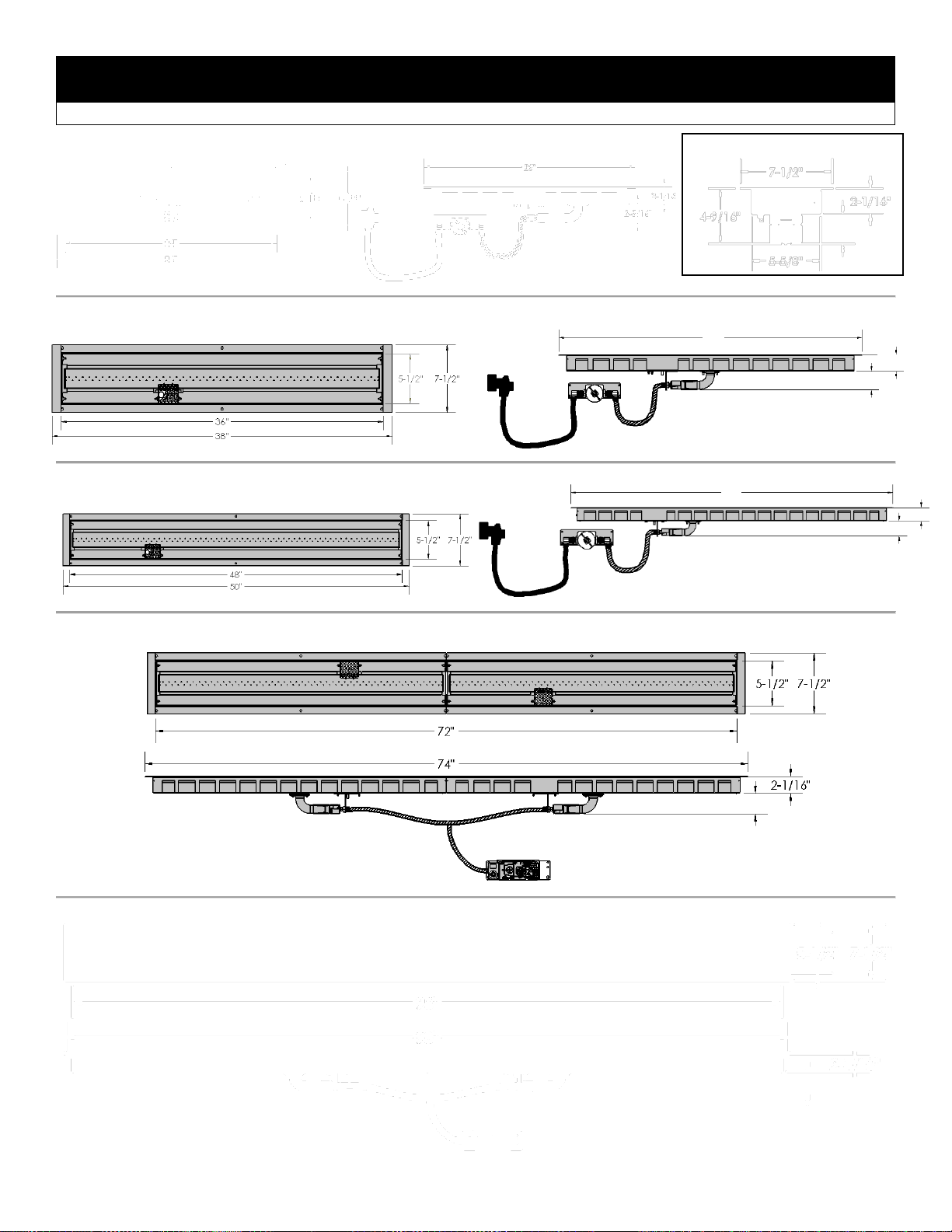

Page 9

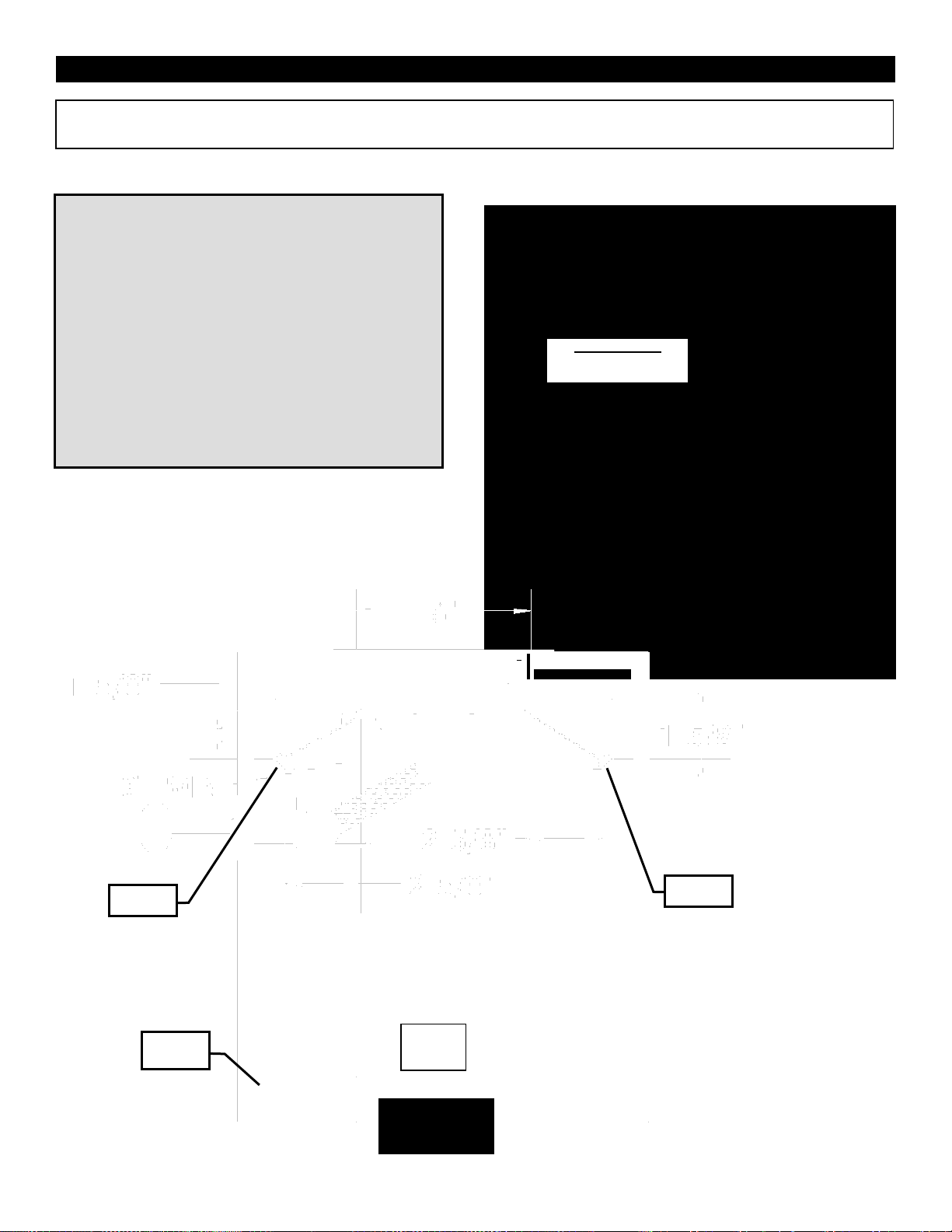

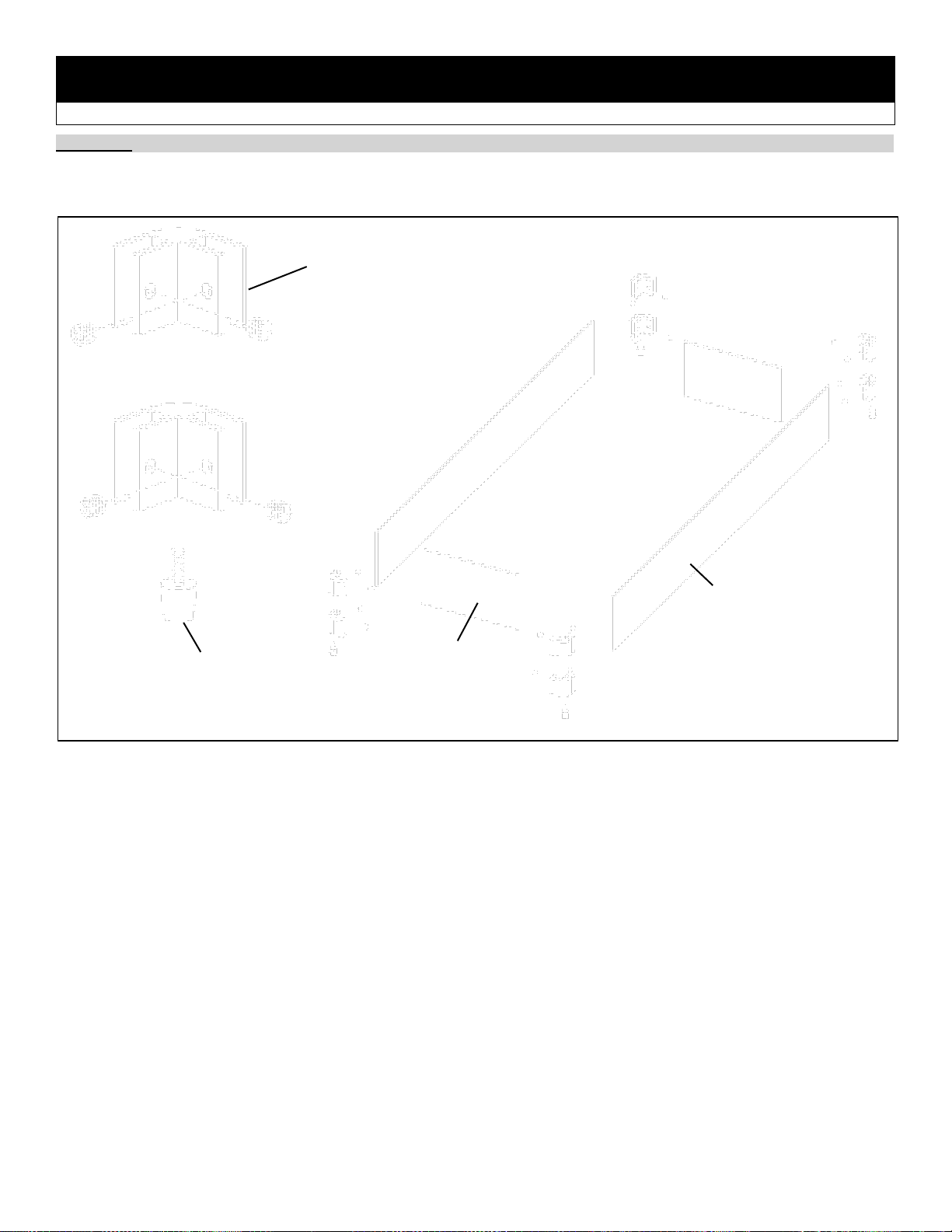

Certified Burners with Label

Dimensions OB24 / OB36 / OB48 / OB72 / OB96 (Outdoor Burners)

END VIEW- ALL BURNERS

2-1/16”

2-5/16”

38”

2-5/16”

2-1/16”

50”

2-5/16”

2-5/16”

2-5/16”

9

OB24 BURNER

OB36 BURNER

OB48 BURNER

OB72 BURNER

OB96 BURNER

Page 10

OB Burners – Unpacking and Setup – Manual Valve Systems

.

STEP 1: Insert Burner Orifice into mixing sleeve and attach Orifice

Retainer Bracket with [2] 1/2” DT Screws. Then insert Electrode Mount

Plate and Sparker into Burner and install with [2] 1/2” DT Screws.

STEP 2: Install Burner with attached Valve

System into structure.

For Outdoor Fire Tables (OFT) refer to

OFT Burner Installation Instructions.

For Outdoor Fireplaces (OFP) refer to OFP

Burner Installation Instructions.

Refer to Custom Enclosures Section for

Custom Enclosures.

NOTE: Filler Strips must be installed

before media is placed into burner.

Parts List: OB24 / OB36 / OB48 MAP/MAN

[1] Burner, c/w [1] Pilot Shield, [2] Ends, [3] Filler Strips

[1] Manual Valve System (c/w Regulator and 5ft Hose for LP

Systems)

[1] Push Button Igniter c/w wire and Sparker

[1] Valve Key

[1] Key Way Installation Tool

[1] Brass Orifice for NG Conversion (LP Systems)

[1] Tank Retainer (LP Systems)

[1] Hardware Bag: [8] 1/2” DT Screws, [4] #6 Black Screws, [2]

#10 Woodscrews

[3] Filler Strips (See Below)

Orifice Retainer

Bracket

Electrode Mount Plate

and Sparker

24OB – 23-9/16”

36OB – 35-9/16”

48OB – 47-9/16”

24OB – 10-5/8”

36OB – 10-5/8”

48OB – 10-5/8”

24OB – 10-5/8”

36OB – 22-5/8”

48OB – 34-5/8”

FILLER STRIPS:

Long Flange Up

Short Flange Down

Qty [4] 1/2” DT Screws

to attach Valve

NG Conversion Orifices

(Included with MAP Burners)

OB24MAP - #40

OB36MAP - #31

OB48MAP - #30

Air Shutter = 1/16”- NG

Air Shutter = Full Open- LP

10

Page 11

OB Burners – Unpacking and Setup – Millivolt Valve Systems

STEP 1 (For OB72 & OB96 only):

Connect Burners using [2] 10-24 x

1/2” bolts. Set Cover Clip over joined

burner ends.

STEP 2: Insert Orifice(s)

into mixing sleeve(s) and

install bracket(s) with [4]

1/2” DT Screws. Then

insert Pilot Assembly into

one Burner and attach with

[2] 1/2” DT Screws.

Attach Pilot Opening Cover

in the other Burner with [2]

1/2”DT Screws.

Air Shutter = 1/16”- NG

Air Shutter = Full Open- LP

STEP 3: Install Burner with attached Valve System into structure.

For Outdoor Fire Tables (OFT) refer to OFT Burner Installation Instructions page.

For Outdoor Fireplaces (OFP) refer to OFP Burner Installation Instructions page.

For Custom Enclosures refer to Custom Enclosures Section.

NOTE: Filler Strips must be installed before media is placed into burner.

Parts List: OB72 / OB96MVN

[2] Burners, c/w [2] Pilot Shields, [2] Ends, [6] Filler Strips

[1] Millivolt Valve System (c/w [2] Orifice Assemblies and [1] Pilot

Assembly)

[1] Piezo Button Igniter c/w wire and Sparker

[1] On/Off Rocker Switch (installed on valve)

[1] Pilot Opening Cover

[1] Hardware Bag: [12] 1/2” DT Screws, [8] #6 Black Screws, [2]

10-24 x 1/2” Bolts c/w Star Nuts

[6] Filler Strips

[1] Cover Clip

24OB – 23-9/16”

36OB – 35-9/16” (x 2 for OB72)

48OB – 47-9/16” (x 2 for OB96)

24OB – 10-5/8”

36OB – 10-5/8” (x 2 for OB72)

48OB – 10-5/8” (x 2 for OB96)

24OB – 10-5/8”

36OB – 22-5/8” (x 2 for OB72)

48OB – 34-5/8” (x 2 for OB96)

Connect Electrode

Wire to Piezo.

Connect On/Off

Switch to TP and

TH Terminals.

Connect Electrode Wire to

Piezo.

Connect On/Off Switch to

TP and TH Terminals.

Install Pilot Assembly and

Orifice Bracket [4 Dt Screws].

Cover Clip

Pilot Assembly is

installed from

bottom of Burner

Tray – but can be

serviced from the

Top.

Parts List: OB24 / OB36 / OB48MVN

[1] Burner, c/w [1] Pilot Shield, [2] Ends, [3] Filler Strips

[1] Millivolt Valve System (c/w Orifice Assembly and Pilot Assembly)

[1] Piezo Button Igniter c/w wire and Sparker

[1] On/Off Rocker Switch (Installed on valve)

[1] Hardware Bag: [8] 1/2” DT Screws, [4] #6 Black Screws

[3] Filler Strips (See Below)

Orifice

Retainer

Bracket

Pilot Opening

Cover

FILLER STRIPS:

[Qty 4] 1/2”

DT Screws

to attach

valve to

appliance

Long Flange Up

Short Flange

Down

[Qty 2] 1/2”

DT Screws

[Qty 2] 1/2”

DT Screws

11

Page 12

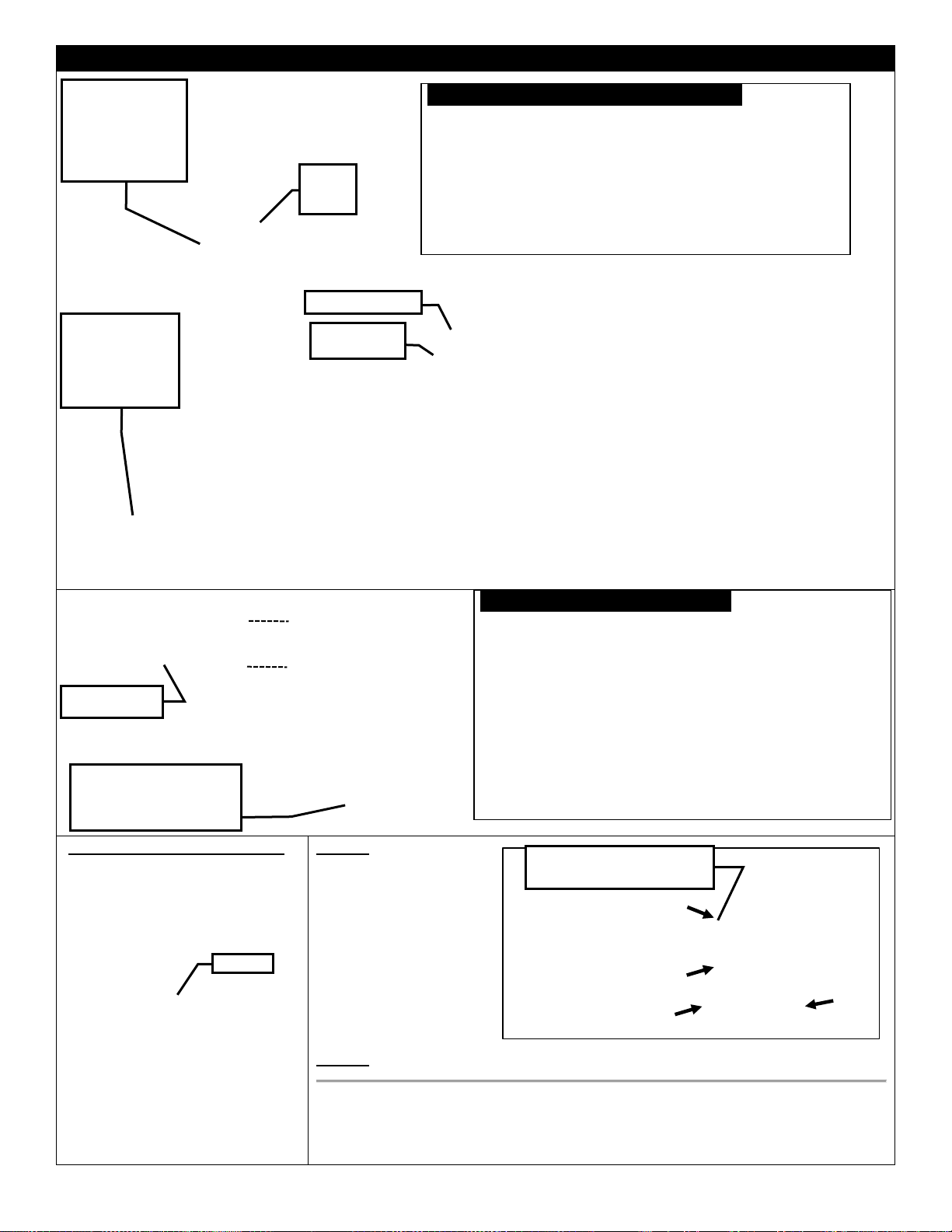

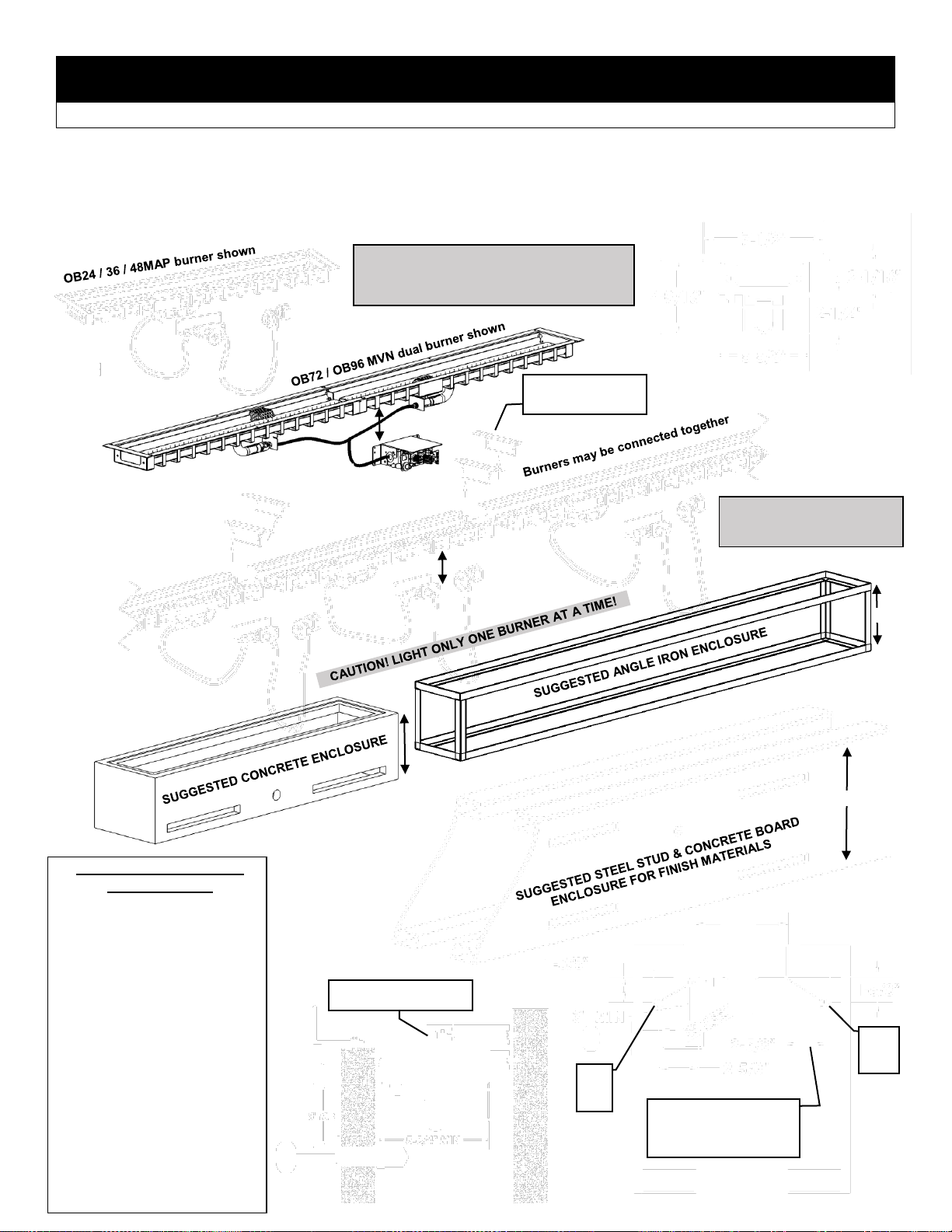

-Custom Enclosures-

OB24 / 36 / 48 / 72 / 96 (Must be non-combustible)

Multiple burners can be connected together in series. ENCLOSURES MUST BE NON-COMBUSTIBLE. Enclosures

3” MIN

3” MIN

5-3/4”

Required Openings for

Stock Burners

OB24 – 5-3/4” x 24-1/2”

OB36 – 5-3/4” x 36-1/2”

OB48 – 5-3/4” x 48-1/2”

OB72 – 5-3/4” x 72-1/2”

OB96 – 5-3/4” x 96-1/2”

Burners may be connected

together in any combination.

When connecting additional

burners, add desired lengths

(24”, 36”, 48”, 72”, 96”) plus

Required Opening for total

opening (e.g. 24” + 72-1/2” +

24” = 120-1/2”).

NOTE: Flame height will be

noticeably higher on OB48

burners. This can be manually

adjusted.

Remove ends when

connecting burners.

END VIEW

ALL BURNERS

Maximum height of

media is 1” above tray.

LED Light Strips must be

at least 1-5/8” below and

2-5/8” away from Burner

Tray.

LED

Light

Strip

LED

Light

Strip

8” MIN

8” MIN

8” MIN

Burner Tray must

be supported.

REFER TO Enclosures for LP

(Propane) Gas Supply

Systems

NOTE: All Gas Controls and

connections must be readily

removable, supported, or accessible.

12

shown are suggestions only. Refer to Clearance to Combustibles section of manual.

NOTE: all manual valve systems are shipped as LP systems (MAP) with accompanying orifice for NG conversion.

All millivolt valve systems are shipped as NG systems (MVN) and require a conversion kit for LP conversion.

NOTE: For propane installations see Enclosures for LP (Propane) Gas Supply Systems.

Page 13

Optional LED Lighting – Custom Enclosures

Please follow the current ANSI/NFPA 70 National Electrical Code in the USA and CAN/CSA C22.1 Canadian

National Electrical Code in Canada.

⚠ WARNING

Electrical Grounding Instructions

This appliance is equipped with a three prong (grounding)

plug for your protection against shock hazard and should be

plugged directly into a properly grounded three-prong

receptacle. Do not cut or remove the grounding prong from

this.

The fireplace receptacle must be connected to an

external GFI protected outlet installed near the fireplace.

Before Servicing

1. Ensure all power supply is shut off.

2. Label all wires prior to disconnecting when servicing

control. Wiring errors can cause improper and

dangerous operation.

SIDE VIEW

CUSTOM

ENCLOSURE

-Junction Box-

Must be connected to

an external GFI outlet

JUNCTION

BOX

LED

CONTROL

BOX

LED LIGHT

STRIP

LED LIGHT

STRIP

13

NOTE: If appliance is directly connected to an electrical supply, it must be anchored using anchor points provided in

bottom of appliance. Use cord and wire restraints provided also.

Page 14

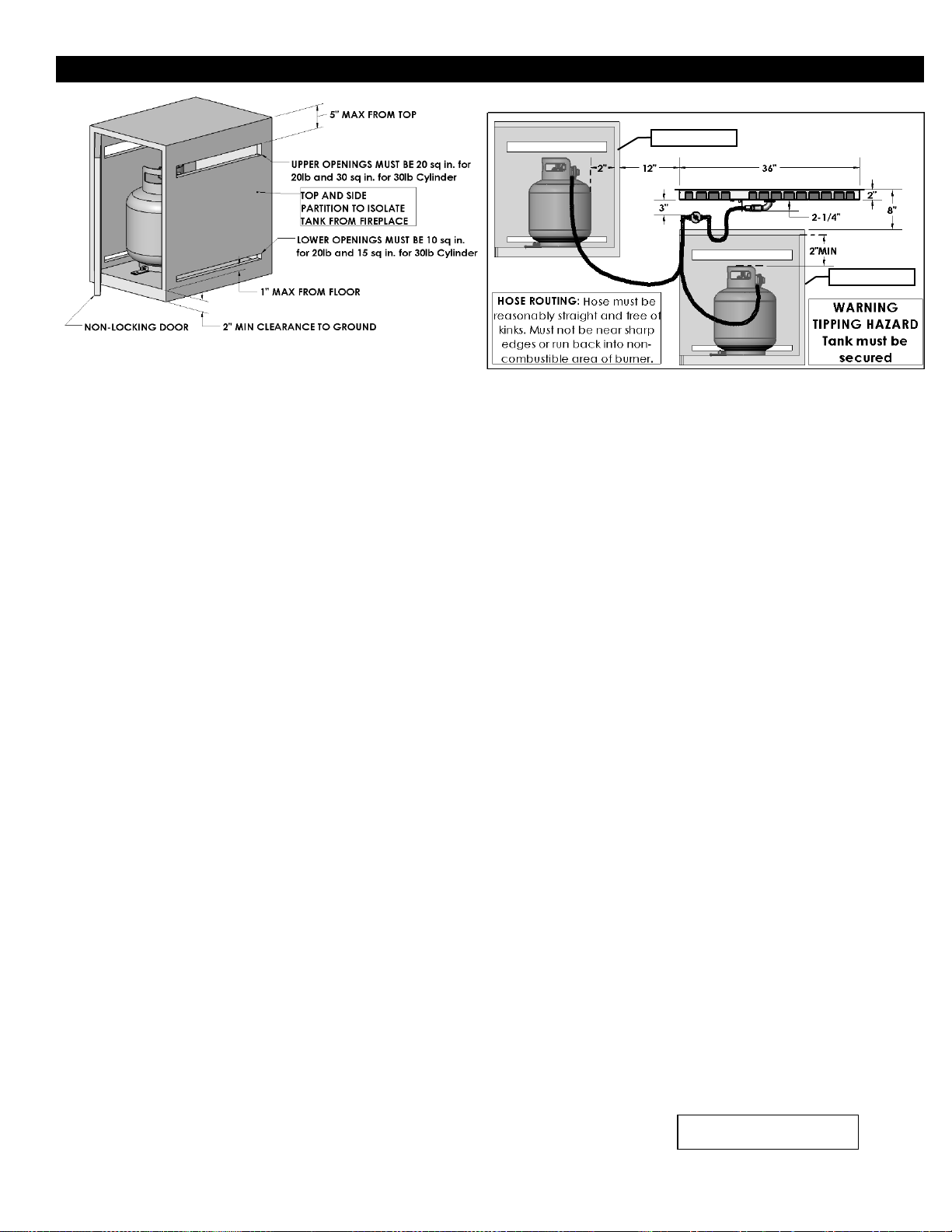

Enclosures for LP (Propane) Gas Supply Systems

LP cylinder with retention

device attached.

Combustible

Combustible

14

If you build an enclosure for an LP gas cylinder you must

follow these specifications. You must also follow local

codes.

An enclosure for an LP-gas cylinder shall be ventilated by

openings at both the upper and lower levels of the

enclosure. This shall be accompanied by one of the

following:

a. One side of the enclosure shall be completely open; or

b. For an enclosure having four sides, a top, and a bottom:

1. At least two ventilation openings shall be provided in the

sidewalls of the enclosure, located within 5 in (217 mm) of

the top of the enclosure, equally sized, spaced at a

minimum of 90 degrees (1.57 rad), and unobstructed. The

opening(s) shall have a total free area of not less than

1square inch per pound (14.2 cm2Ckg) of stored fuel

capacity.

2. Ventilation opening(s) shall be provided at floor level of

the enclosure and shall have a total free area of not less

than 1/2 square inches per pound (7.1 cm2Ckg) of stored

fuel capacity. If ventilation openings at floor level are in a

sidewall, there shall be at least two openings. The bottom

of the openings shall be 1 in (25.4 mm) or less from the

floor level and the upper edge no more than 5 in (127

mm) above the floor level. The openings shall be equally

sized, spaced at a minimum of 90 degrees (1.57 rad),

and unobstructed.

3. Every opening shall have minimum dimensions so as to

permit the entrance of a 1/8 in (3.2 mm) diameter rod.

4. Ventilation openings in sidewalls shall not communicate

directly with other enclosures of the appliance.

The cylinder valve shall be readily accessible for hand

operation. A door on the enclosure to gain access to the

cylinder valves is acceptable, provided it is non-locking and

can be opened without the use of tools. Designs using a

cover to gain access to the cylinder and cylinder valve shall

be provided with handles or equivalent at a minimum of 180

degrees apart to facilitate lifting of the cover.

The enclosure for the LP-gas cylinder shall isolate the

cylinder from the burner compartment to provide:

a. Shielding from radiation;

b. A flame barrier; and

c. Protection from foreign material.

There shall be a minimum clearance of 2 in (50.8 mm)

between the floor of the non-disposable LP-gas cylinder

enclosure and the ground.

The design of the fireplace shall be such that:

a. A non-disposable LP-gas cylinder can be connected,

disconnected, and the connections inspected and tested

outside the cylinder enclosure; and

b. Those connections which could be disturbed when

installing the cylinder in the enclosure can be leak tested

inside the enclosure.

Be certain to mount or set the LP-gas cylinder on a flat

stable surface and retain it to prevent it from tipping.

Purge the gas supply line of any trapped air prior to the

first firing of the unit.

WARNING: During the initial purging and subsequent

lightings, NEVER allow gas valve to remain in "OPEN"

position without first placing a burning match on the top

of the burner.

Test fire the unit after referring to the SAFETY

INFORMATION and LIGHTING INSTRUCTIONS.

If

LP-Gas outdoor fire

pits

are used

continuously after a

couple

of

hours,

you

could

see the

possibility of the

decreasing

this

happens,

the

control valve

the tank

wait a

valve

couple

flame

in size. If

turn off

and

and

of

hours

before lighting again

or switch

tanks. The

tank is

to the

being taken

propane

propane

freezing

volume

up due

of gas

out of the

tank.

Page 15

Fire Stands – Approved Accessory

OFS Series Dimensions (Outdoor Fire Stand)

OFS24MAP / OFS24MAN

15

OFS36MAP / OFS36MAN

OFS48MAP / OFS48MAN

Page 16

OFS Outdoor Fire Stands – Unpacking and Setup

Parts List: OFS24 / OFS36 / OFS48 – MAP/MAN

[1] OFS Outdoor Fire Stand c/w Burner, Valve System and 10ft LP

Hose & Regulator (Installed)

[3ea] Filler Strips

[1] Push Button Igniter (AAA Battery not included) c/w Wire and

Sparker (Installed)

[1] Valve Key

[1] Key Way Installation Tool

[1] Brass Orifice for NG Gas Conversion (LP Systems)

[1] Tank Retainer, [2ea] Wood Screws (LP Systems)

OFS24 Shown – Ready for Media Placement.

See Media Section of Manual for Options.

END VIEW – Outdoor Fire Stand

FILLER STRIPS:

24OB – 23-9/16”

36OB – 35-9/16”

48OB – 47-9/16”

ALL UNITS – 10-5/8”

24OB – 10-5/8”

36OB – 22-5/8”

48OB – 34-5/8”

OFP Bottom View

(MAP System Shown)

INCLUDED WITH MAP (PROPANE)

BURNER SYSTEMS ONLY

Long Flange at Top

Short Flange at Bottom

BURNER END VIEW

Valve Control

Push Button Igniter – Unscrew and insert AAA

Battery here.

16

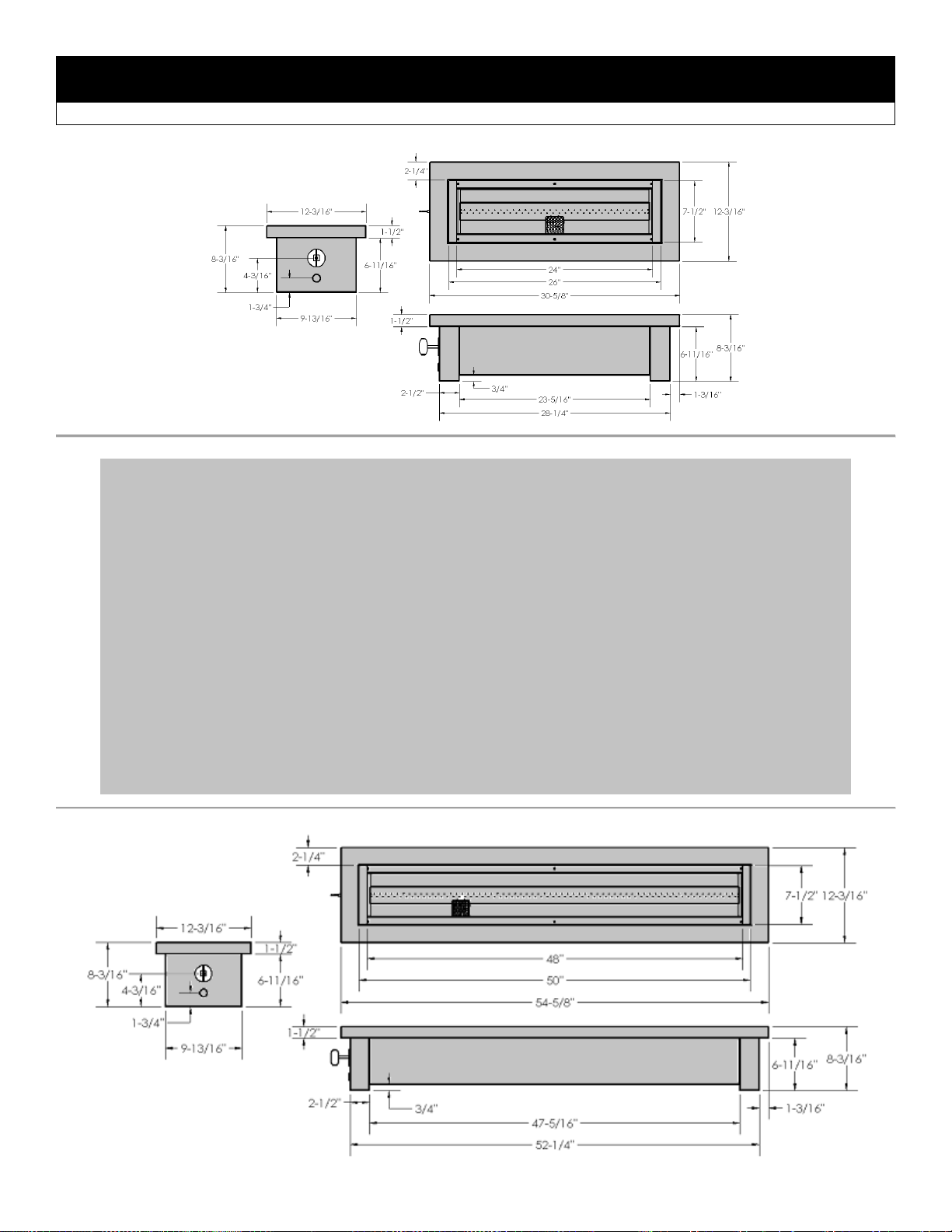

Page 17

Fire Tables –Approved Accessory

OLTN24 and OLTW24 Dimensions (Outdoor Fire Table)

OLTN24

BURNER OPTIONS:

OB24MAP (c/w #40 Orifice for NG)

OB24MAN (Order 24OB-CKLP5 for LP)

OB24MVN (Order 24OB-CKLP for LP)

OLTW24

BURNER OPTIONS:

OB24MAP (c/w #40 Orifice for NG)

OB24MAN (Order 24OB-CKLP5 for LP)

OB24MVN (Order 24OB-CKLP for LP)

17

Page 18

Fire Tables –Approved Accessory

OLTN36 and OLTW36 Dimensions (Outdoor Fire Table)

OLTN36

BURNER OPTIONS:

OB36MAP (c/w #31 Orifice for NG)

OB36MAN (Order 36-48OB-CKLP5 for LP)

OB36MVN (Order 36OB-CKLP for LP)

OLTW36

BURNER OPTIONS:

OB36MAP (c/w #31 Orifice for NG)

OB36MAN (Order 36-48OB-CKLP5 for LP)

OB36MVN (Order 36OB-CKLP for LP)

18

Page 19

Fire Tables –Approved Accessory

OLTN48 and OLTW48 Dimensions (Outdoor Fire Table)

OLTN48

BURNER OPTIONS:

OB48MAP (c/w #30 Orifice for NG)

OB48MAN (Order 36-48OB-CKLP5 for LP)

OB48MVN (Order 48OB-CKLP for LP)

OLTW48

BURNER OPTIONS:

OB48MAP (c/w #30 Orifice for NG)

OB48MAN (Order 36-48OB-CKLP5 for LP)

OB48MVN (Order 48OB-CKLP for LP)

19

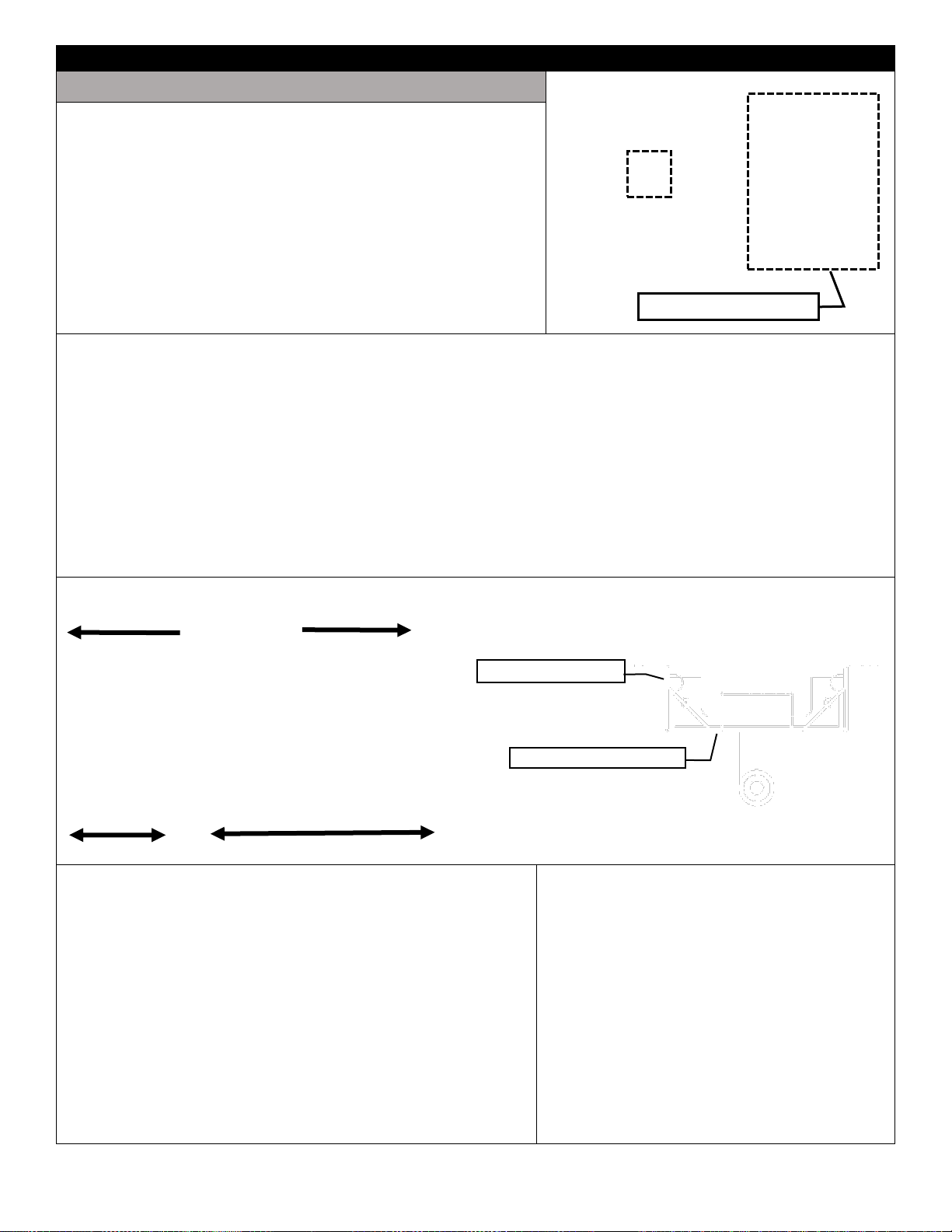

Page 20

Fire Tables -Assembly-

OUTDOOR FIRE TABLES: OLTN24, OLTW24, OLTN36, OLTW36, OLTN48, OLTW48

Tools Required: 1/4” Hex Driver c/w 4” Extension or 1/4” Hex Screwdriver

NOTE: Two people are required to lift this assembly.

Step One: Lay Table Top upside down on a flat non-

abrasive surface.

Step Two: Form Tank Shield into shape and attach to

one end of Table Top with [4] DT Screws. NOTE: There

will be two Tank Shields for 36” and 48” models.

Step Three:

Carefully

place Table

Body onto

Table Top

and attach

with [4 or 6]

bolts.

NOTE: Tank

Brace &

Tank Shield

must be on

the same

side as the

Tank Mount Hole.

Step Four: Install Tank

Brace with Washer and

Thumbscrew.

Carefully lift and place

Fire Table upright.

Install Doors using [2]

DT Screws each.

NOTE: Doors may be

installed on either left

or right side.

Burner Lid

Tank Shield

Table Top

Table Top

Table Body

Tank

Mount

Hole

Tank

Guard

Table Top

Outer Trim Ring

Table Top

Table Body

Tank Shield

Door

Door

Parts List:

BOX 1:

[1ea.] Burner Lid

[1ea.] Outer Trim Ring

[1ea.] Table Top

[1ea.] Tank Shield, [2ea.] for 36” & 48”

BOX 2:

[1 ea.] Table Body

[2 ea.] Door

[1 ea.] Tank Brace

Hardware:

[8 ea.] DT Screws, [12ea.] for 36” & 48”

[4 ea.] Bolts 8-32 x 1”, [6ea.] for 36” & 48”

Tank

Brace

Tank Brace

Tank

Shield

20

Page 21

OLTN and OLTW Burner Installation

Place Burner and Valve assembly into opening in table top. Attach Valve Mount Bracket on valve to Mount Plate on

OB Burner and Valve Assembly

Valve Mount Bracket

Valve Mount Plate

DT Screw

DT Screw

DT Screw

DT Screw

#6 Black Screws

#6 Black Screws

Push Button Igniter

Location

Valve Key storage

on inside of door

ON/OFF Switch

Location

Electronic Spark

Module

4 DT Screws

to attach

Valve to

Appliance

See Electronic Spark Assist Page

Piezo

Igniter

On/Off

Switch

21

table.

MANUAL VALVE SETUP OPTIONAL ELECTRONIC SPARK ASSIST

Page 22

Optional LED Lighting - OLTN / OLTW Outdoor Fire Tables

Please follow the current ANSI/NFPA 70 National Electrical Code in the USA and CAN/CSA C22.1 Canadian

National Electrical Code in Canada.

⚠ WARNING

Electrical Grounding Instructions

This appliance is equipped with a three prong (grounding)

plug for your protection against shock hazard and should be

plugged directly into a properly grounded three-prong

receptacle. Do not cut or remove the grounding prong from

this.

The fireplace receptacle must be connected to an

external GFI protected outlet installed near the fireplace.

Before Servicing

1. Ensure all power supply is shut off.

2. Label all wires prior to disconnecting when servicing

control. Wiring errors can cause improper and

dangerous operation.

SIDE VIEW

OLTN / OLTW

JUNCTION

BOX

TOP VIEW

OLTN / OLTW

-Junction Box-

Must be connected to

an external GFI outlet

ANCHOR

POINT

ANCHOR

POINT

LED

CONTROL

BOX

ANCHOR

POINT

ANCHOR

POINT

LED LIGHT

STRIP

LED LIGHT

STRIP

LED

CONTROL

BOX

22

NOTE: If appliance is directly connected to an electrical supply, it must be anchored using anchor points provided in

bottom of appliance. Use cord and wire restraints provided also.

Page 23

20lb Cylinder Installation - Fire Table - Custom Installations

Fire Tables -20LB Cylinder In Unit-

⚠ Only a 20LB LP Cylinder may be used inside the Fire Table Enclosure.

NOTE: Cylinders acceptable for use inside this appliance must be compatible with the retention means shown here.

The LP gas supply cylinder used with LP models

must be constructed and marked in accordance

with the specifications for LP-gas cylinders of the

U.S. Department of Transportation (DOT)

Specifications for LP-Gas Cylinders, or the

Standard for Cylinders, Spheres and Tubes for

Transportation of Dangerous Goods and

Commission, CAN/CSA-B339, as applicable.

The LP gas supply cylinder used with LP models

must be provided with a listed overfilling

prevention device.

The pressure regulator and hose assembly

supplied with LP models (PN# 27FP-900FF) must

be used. Replacement pressure regulators and

hose assemblies must be those specified in this

manual.

Always check for gas leaks with a soap and water

solution. DO NOT USE OPEN FLAME FOR LEAK

TESTING.

When an LP model is not in use, the LP-gas must

be turned off at the supply cylinder.

CUSTOM INSTALLATIONS

TANK RETAINER - Included with all MAP Burners and LP

Conversion Kits

1. Connect foot ring of 20lb

Cylinder to Tank Retainer with

thumbscrew.

2. Fasten Tank Retainer to

mounting surface.

3. Concrete anchor

required for concrete

surface (not supplied).

Foot Ring Drops

into Round Hole

Replace Tank Brace.

Slide over Protective

Collar of 20lb cylinder

and tighten.

Tank Retainer for Custom

Installations.

NOT USED ON FIRE TABLES.

Installation of 20lb Cylinder

into Fire Tables:

Remove Top Clamp.

Connect 20lb cylinder to

regulator.

Place 20lb cylinder into

Fire Table as shown.

Secure 20lb cylinder with

Tank Brace as shown.

Tank Brace

23

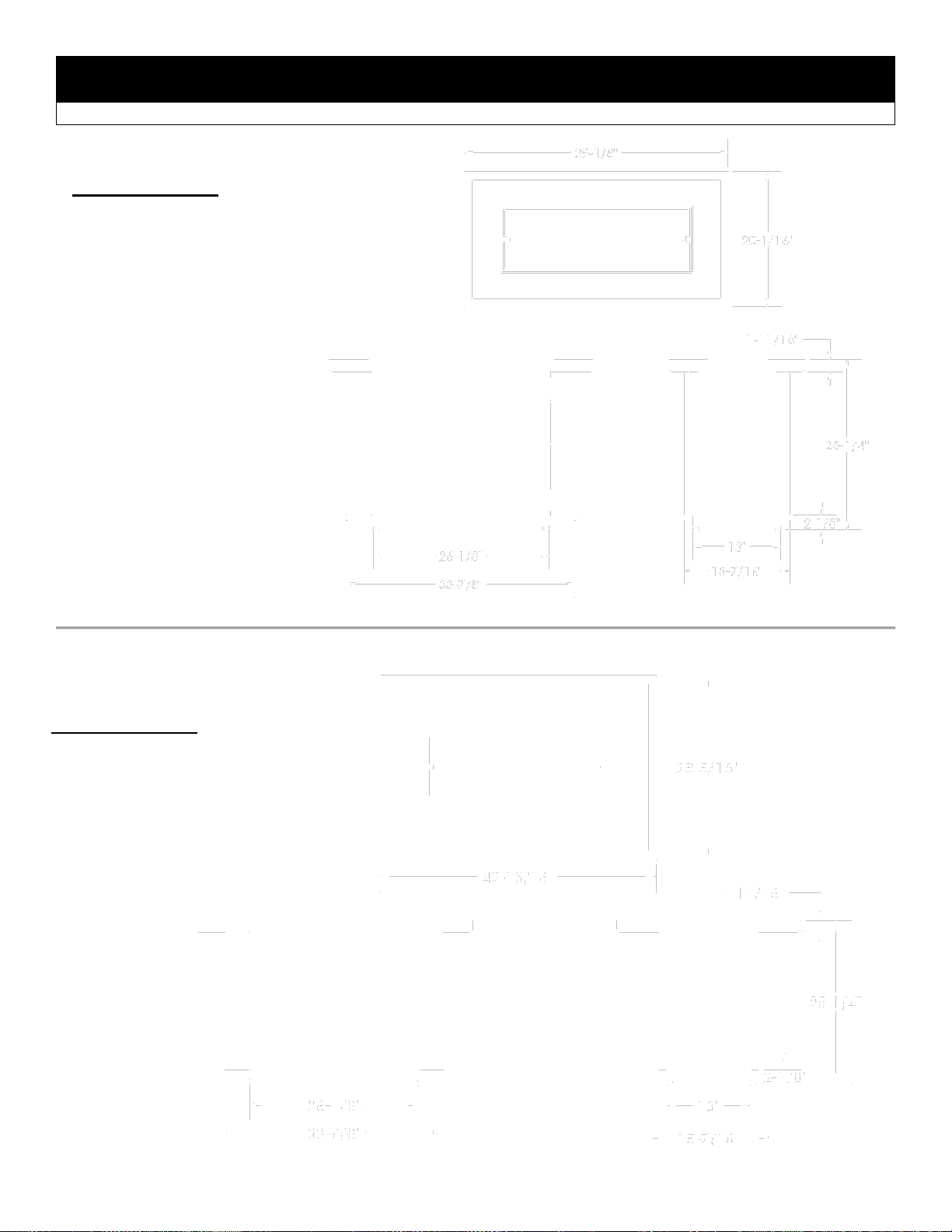

Page 24

Outdoor Fireplaces

OFP4336S1 and OFP4336S2 Dimensions (Outdoor Fire Place)

OFP4336S1 (Millivolt/Natural Gas)

Convert to LP with Conversion Kit

36OB-CKLP

OFP4336S2 (Millivolt/Natural Gas)

Convert to LP with Conversion Kit

36OB-CKLP

24

Page 25

Outdoor Fireplaces

OFP5548S1 and OFP5548S2 Dimensions (Outdoor Fire Place)

OFP5548S1 (Millivolt/Natural Gas)

Convert to LP with Conversion Kit

48OB-CKLP

OFP5548S2 (Millivolt/Natural

Gas) Convert to LP with

Conversion Kit 48OB-CKLP

25

Page 26

Outdoor Fireplaces

OFP7972S1 and OFP7972S2 Dimensions (Outdoor Fire Place)

OFP7972S1

(Millivolt/Natural

Gas) Convert to LP

with Conversion Kit

72OB-CKLP

OFP7972S2

(Millivolt/Natural

Gas) Convert to LP

with Conversion Kit

72OB-CKLP.

26

Page 27

Outdoor Fireplaces – Handling Unit – OFP4336 / OFP5548 / OFP7972

2 x 4

2 x 4

Lift Here

Lift Here

Lift Here

27

⚠ CAUTION: UNIT IS EXTREMELY HEAVY

Ensure that fireplace is properly supported when handling.

Tab cutouts on the faces of the appliance can be used to assist with handling and locating fireplace.

Cutouts are for Hand use or 2 x 4 use.

Lift Tabs are for crane use.

Page 28

OFP4336 / 5548 / 7972 S1 or S2 – Adjustable Support Guide

-Hearth Flush With Fireplace Opening-

Adjustable Support Guides on the sides of the fireplace can be used to assist installation.

NOTE: Support Guide is

NOT load bearing. Bottom

of fireplace MUST be

supported.

Set Support Guides at

desired height and

attach with DT

Screws.

Support Guide

Support Guide

Set to desired height.

Ledge Stone

Base

Support Guide

Support Guide

Base

Bottom of fireplace must be

supported.

28

Page 29

Outdoor Fireplaces

OPTIONAL FRAMING: OFP4336 / OFP5548 / OFP7972 (S1 & S2)

4336 / 5548 / 7972-S1 Single Sided Framing

4336 / 5548 / 7972-S2 See Through Framing

1/2” Plywood

Non-Combustible Facing

1/2” Plywood

Exterior Facing

Fold Nailing Tabs

back onto framing.

Fold Nailing Tabs

back onto

framing.

SIDE

OF

UNIT

RIGHT

SIDE OF

UNIT

Back of Unit

Install Non-combustible Header

Panel.

Fold Standoffs into position and

fasten in place with Screws.

Use Nailing Tabs to fasten Unit to

framing.

Use Nailing Tabs to fasten Unit

to framing.

29

Page 30

Outdoor Fireplaces CLEARANCES: OFP4336 / OFP5548 / OFP7972 (S1 & S2)

The sides and top of the front face of these appliances must be covered with non-combustible materials only.

Sides and Top of Front Faces of OFP4336 / OFP5548 / OFP7972 S1 and

S2 Fireplaces can be covered by Non-combustible materials only (i.e. brick,

stone, tile, concrete board, etc.).

Mantel Dimensions are from front

face or Non-Combustible Facing

Materials covering fireplace.

FLOOR INSTALLATION

ELEVATED INSTALLATION

Clearance

Dimension

Measured From:

A: Side wall

8-1/2”

Side of fireplace opening

B: Ceiling

61”

Bottom of Unit

C: Ceiling

35”

Top of fireplace opening

D: Mantel Height- Bottom

35-1/2”

Bottom of Unit

E: Mantel Height- at 10” Depth

45-1/2”

Bottom of Unit

Combustibles In Front of Unit

36”

Face or Facing of Fireplace

Top, Sides and Back of Appliance

0”

Standoffs

ALCOVE

Alcove Depth- All Units

36”

Face or Facing of Fireplace

Alcove Width- OFP4336S1 & S2

60” = Fireplace Opening (43”) plus Side wall Dim A (8-1/2”) x 2

Alcove Width- OFP5548S1 & S2

72” = Fireplace Opening (55”) plus Side wall Dim A (8-1/2”) x 2

Alcove Width- OFP7972S1 & S2

96” = Fireplace Opening (79”) plus Side wall Dim A (8-1/2”) x 2

A

A B D C E

COMBUSTIBLE

COMBUSTIBLE

WARNING

-RISK OF FIRE-

All minimum clearances

must be adhered to.

ALCOVE

DEPTH

WIDTH

Fireplace

Opening

SIDE VIEW

⚠ WARNING

Combustible Objects on Non-Combustible Mantel

Combustible objects must not be placed on a Non-

combustible Mantel unless the mantel meets the

dimensional requirements for a Combustible Mantel.

Determine whether your mantel conforms to the

requirements of a Combustible Mantel.

COMBUSTIBLE

NON-COMBUSTIBLE

COMBUSTIBLE

NON-COMBUSTIBLE

OFP4336 / OFP5548 / OFP7972 S1 SHOWN

30

Page 31

Surround Installation OFP43SS / OFP55SS / OFP79SS

Parts List:

-Surround Frame [1 pc]

-Side Filler Panels [2 pc] (1LH & 1RH)

-Stainless Steel Screws ([2] for OFP43SS,

[3] for OFP55SS & OFP79SS)

STEP 1: Place bottom of Side Filler into gap at corner of

opening.

STEP 2: Push Side Filler into place. Repeat procedure for

other side.

STEP 3: Hook Surround Frame onto Lower Edge of

fireplace opening.

STEP 4: Push Surround Frame into place and attach with

screws into top lip of opening.

LEFT

RIGHT

TOP

RIGHT

CORNER

HOOK ONTO LOWER EDGE

31

Page 32

Weather Cover Installation OFP43WC / OFP55WC / OFP79WC

PARTS LIST: 1 Weather Cover

-WEATHER COVER CAN BE USED WITH OR WITHOUT SURROUND-

STEP 1: Insert left side of Weather Cover into fireplace

opening.

STEP 2: Insert right side of Weather Cover into fireplace

opening. Slide to the right until gap is closed.

Weather Cover is installed.

16-1/16”

44” for OFP36WC

56” for OFP48WC

80” for OFP72WC

32

Page 33

OFP4336 / OFP5548 / OFP7972 Wind Guard Glass Installation

Wind Guard Glass must be installed for safety and in order for unit to function properly.

Stainless Steel Parts And Accessories

Wind Guard

Glass

Glass Mount

Bracket

33

Step one: Place Wind Guard Glass into Glass Mount Brackets.

Step two: Center Wind Guard Glass in appliance and tighten screws in Glass Mount Brackets. Do NOT over tighten.

NOTE: The protective wrap on stainless steel parts is best removed at room temperature. A hair dryer may be

helpful.

Cleaning Stainless Steel

Stainless steel tends to oxidize or stain in the presence of chlorides and sulfides, particularly in coastal areas and other

harsh environments, such as the warm, highly humid atmosphere around pools and hot tubs. These stains could be

perceived as rust, but can be easily removed or prevented. To provide stain prevention and removal, wash all stainless

steel surfaces every 3-4 weeks or as often as required with fresh water and/or stainless steel cleaner.

Notes on Cleaning Stainless Steel Surfaces: Do not use abrasive cleaners or steel wool on any painted, or stainless

steel parts. Doing so will scratch the finish. Exterior surfaces should be cleaned with warm soapy water. Use a stainless

steel or a non-abrasive cleaner. Always wipe in the direction of the grain.

Over time, stainless steel parts discolor when heated, usually to a golden or brown hue. This discoloration is normal and

does not affect the performance of the appliance.

Page 34

Optional LED Lighting – OFP Outdoor Fireplaces

Please follow the current ANSI/NFPA 70 National Electrical Code in the USA and CAN/CSA C22.1 Canadian

National Electrical Code in Canada.

⚠ WARNING

Electrical Grounding Instructions

This appliance is equipped with a three prong (grounding) plug for

your protection against shock hazard and should be plugged directly

into a properly grounded three-prong receptacle. Do not cut or

remove the grounding prong from this.

The fireplace receptacle must be connected to an external GFI

protected outlet installed near the fireplace.

Before Servicing

1. Ensure all power supply is shut off.

2. Label all wires prior to disconnecting when servicing control.

Wiring errors can cause improper and dangerous operation.

SIDE VIEW

OFP

TOP VIEW

OFP

-Junction Box-

Must be connected to

an external GFI outlet

JUNCTION

BOX

ANCHOR

POINT

ANCHOR

POINT

ANCHOR

POINT

ANCHOR

POINT

LED

CONTROL

BOX

LED LIGHT

STRIP

LED LIGHT

STRIP

LED

CONTROL

BOX

LED LIGHT

STRIP

LED LIGHT

STRIP

34

NOTE: If appliance is directly connected to an electrical supply, it must be anchored using anchor points provided in

bottom of appliance. Use cord and wire restraints provided also.

Page 35

OFP4336 / OFP5548 / OFP7972 -Burner Removal / Installation

⚠ THE FOLLOWING MUST BE PERFORMED BY QUALIFIED INSTALLERS ONLY.

To remove burner:

1. Disconnect gas supply. Caution: only a qualified person should do this.

2. Remove Access Cover.

3. Remove Screws in Burner Tray and Valve Bracket.

TO INSTALL BURNER, REVERSE ABOVE STEPS.

ACCESS

COVER

VALVE LOCATION

Remove

Screws in

Burner Tray

BURNER

AND VALVE

ASSEMBLY

Remove

Screws from

Valve

Bracket

35

Page 36

Glass Media for Outdoor Burners

Choose Glass Media ‐ 5 lbs. per Foot of Burner (i.e.: 24" burner = 10lbs)

Product

Number

Description

Spread glass evenly in burner tray.

Pilot Shield must not be covered, as a delayed ignition

can occur (See photo below).

MQG5ZG

Glass Media ‐ ZIRCON Glacier Ice ‐ 5 lbs.

MQG5A

Glass Media ‐ 1/2" Cobalt Blue ‐ 5 lbs.

MQG5B

Glass Media ‐ 1/2" Black ‐ 5 lbs.

MQG5C

Glass Media ‐ 1/2" Bronze ‐ 5 lbs.

MQG5W

Glass Media ‐ 1/2" White ‐ 5lbs.

Use of any other glass can alter the performance of the unit

and is not covered under warranty.

Discoloration of glass media may occur if placed on the

burner, this is not covered under warranty.

Optional Media Accessories

MQRBD3 – Driftwood Log Set – 5 piece

Place Logs Randomly as shown. Do not cover Pilot.

MQRBD4 – Driftwood Log Set – 3 piece

Place Logs Randomly as shown. Do not cover Pilot.

Pilot Area

Must Not Be

Covered.

Maximum height of glass

media is 1” above burner tray.

SIDE VIEW

36

Page 37

MQROCK2 – Rock Set, Contemporary Collection – Natural

MQROCK3 – Rock Set, Contemporary Collection – MultiColored

MQSTONE – Decorative Stones – 80 Piece Set

MQSTONE10 – Decorative Stones – 10 Piece Set

Place Rocks and Stones randomly. Do not cover Pilot.

Not all Rocks or Stones will be used on all models.

RBCB1 – Canonballs – Assorted Size and colors- 14 pieces

Place Canonballs randomly. Do not cover Pilot. Not all Canonballs will be used on all models.

37

Page 38

Optional Wind Guards

Fire Tables / Fire Stands / Custom Applications

Parts List: [4] Bottom Feet, [8] Corner Brackets c/w neoprene tipped screws, [2] Glass End Panels, [2] Glass Side Panels

Corner Bracket

c/w Neoprene

Screws

Bottom Foot

Glass Side

Panel

Glass End

Panel

38

O24WG – 24” Wind Guard

O36WG – 36” Wind Guard

O48WG – 48” Wind Guard

O72WG – 72” Wind Guard

O96WG - 96” Wind Guard

Wind can greatly affect flame performance. If used in windy conditions a wind guard is recommended.

NOTE: Painted finishes damaged or discolored by heat are not covered under warranty.

Page 39

Burner System Maintenance

It is recommended to annually inspect and clean the Burner System to prevent malfunction and / or sooting. This operation

-CAUTION-

Before servicing the burner system ensure that the gas supply is turned OFF and disconnect all electrical

connections to the appliance. Allow the appliance to cool to room temperature. Note that the pilot assembly

may be hot in an intermittent or standing-pilot system—even if the main burner was never on. Exercise

caution when working within the area.

-ALL WORK SHOULD BE PERFORMED BY A QUALIFIED AND CERTIFIED TECHNICIAN-

Pilot Area Must Not Be Covered.

Pilot Must Maintain This

Relationship With Burner.

*Pilot Shield should be visually inspected monthly

for signs of deterioration due to flame exposure.

Replace if necessary.

39

should be performed by your dealer or a qualified technician.

Monthly Flame Inspection

It is recommended to turn on the unit at least once a month and inspect the flame pattern to ensure there are no problems with

the burner tube (Flame should appear similar to the above picture).

The pilot flame should also be inspected monthly to ensure proper operation.

Page 40

OB24 / OB36 / OB48 General Maintenance Instructions

40

The appliance should be inspected before initial use and inspected and cleaned at least annually by a qualified field service person.

Tampering is DANGEROUS and voids all warranties. Any component that is found to be faulty, must be replaced with an approved

component.

To obtain proper operation, it is imperative that the burner flame characteristics are steady, not lifting or floating. Check the burner

flame patterns with Burner System Maintenance Section.

Periodically remove media and examine the burner. If dirty, clean with a soft brush. Also examine the area around the burner air

shutter. Any dirt or lint in this area should be removed. This will ensure long life and trouble free operation. Replace media (rocks, logs,

glass, etc.) as shown in manual. When the appliance is put back in service, check the burner flame patterns with Burner System

Maintenance Section.

Periodically check the hose connecting the LP-gas cylinder to ensure it is not damaged in any way.

FOR SAFE INSTALLATION AND OPERATION NOTE THE FOLLOWING:

The Burner/Log Assembly has been engineered and permanently adjusted for proper flame control.

Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. Verify proper

operation after servicing.

Cylinders must be stored outdoors in a well ventilated area out of the reach of children. Disconnected cylinders must have threaded

valve plugs tightly installed and must not be stored in a building, garage or any other enclosed area.

Storage of this appliance indoors is permissible only if it has been disconnected from its fuel supply (natural gas line or LP gas

cylinder).

The LP gas cylinder supply system must be arranged for vapor withdraws.

The LP gas cylinder used must include a collar to protect the cylinder valve.

When an LP model is not in use, the LP gas must be turned off at the supply cylinder.

The appliance and its individual shut off valve must be disconnected from the gas supply piping system during any pressure testing of

the system at test pressures in excess of ½ psi (3.5 kPa).

The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure

testing of the gas supply piping system at test pressures equal to or less than ½ psi (3.5 kPa).

CLEANING

It is recommended to annually inspect and clean the unit to prevent malfunction and / or sooting. This operation should be performed by

your dealer or a qualified technician.

Carefully remove media (log set, Rocks, Glass, etc.). Gloves are recommended.

Warning: Turn off Unit and allow to cool before cleaning. Only a qualified service technician should service and repair appliance.

• Do not use cleaning fluids to clean logs.

• Use a soft bristle brush or a vacuum with brush attachment.

• Vacuum loose particles and dust from burner and valve

• Inspect Burner Plate, Pilot, Valve, and Mixing Sleeve for spider webs or other blockages.

• Replace media. Refer to the appropriate page in this manual for proper placement of contents, such as logs.

Page 41

Safety Information and Manual Lighting Instructions

FOR YOUR SAFETY READ BEFORE LIGHTING

Manual Lighting Instructions

Push Button Ignition (if equipped)

To Turn Off Gas Appliance

41

⚠WARNING: If you do not follow these instructions exactly, a fire or explosion may result causing property damage,

personal injury or loss of life.

A. This appliance must be lit by hand. When lighting,

follow these instructions exactly.

B. Before LIGHTING, smell all around the appliance

area for gas. Be sure to smell next to the floor,

because some gas is heavier than air and will settle

on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

C. Use only your hand to turn the gas control knob or

valve. Never use tools. If the valve will not turn by

hand, don’t try to repair it, call a qualified service

technician. Force or attempted repair may result in a

fire or explosion.

D. Do not use this appliance if any part has been

underwater. Immediately call a qualified

technician to inspect the appliance, and to replace

part which has been underwater.

service

any

1. STOP! Read the safety information above.

2. Remove the top cover.

3. Find the manual gas control valve.

4. Place a burning match on top of burner in the

middle where ports are present. DO NOT HOLD

THE MATCH IN HAND. For Natural Gas unit

turn on the on/off valve slowly at the unit. For LP

unit turn the valve on the LP tank

counterclockwise all the way and then turn on

the on/off valve slowly at the unit.

1. STOP! Read the safety information above.

2. Remove the top cover.

3. Find the manual gas control valve and push

button igniter.

4. Push and hold the button on the igniter and

ensure sparking is occurring at the probes inside

the burner tray.

5. Turn ON gas supply and manual key valve.

5. If the burner does not light before the match

goes out, immediately turn the gas to off.

6. Wait at least five (5) minutes to clear out any

gas. If you have unsuccessfully tried to light the

burner, wait longer. Then smell for gas, including

near the floor. If you smell gas, STOP! Follow

“B” in the safety information above. If you don’t

smell gas, repeat step 4.

6. Gas should ignite within 10 seconds or less. If

the burner does not light turn the gas to off.

7. Wait at least five (5) minutes to clear out any

gas. Then smell for gas, including near the floor.

If you smell gas, STOP!

8. If you don’t smell gas, repeat step 4.

1. Turn the on/off valve to the off position at the

unit for natural gas unit. For LP unit, turn the

on/off valve to the off position at the unit and

then turn the valve on the LP tank to the off

position clockwise.

2.

Replace the top cover.

Page 42

Millivolt System, Lighting, and Burner Control

FOR YOUR SAFETY READ BEFORE LIGHTING

BEFORE LIGHTING

A This appliance has a pilot which must be lighted by hand. When

lighting the pilot, follow these instructions exactly.

B Smell all around the appliance area for gas. Be sure to smell next

to the floor because some gas is heavier than air and will settle on

the floor.

WHAT TO DO IF YOU SMELL GAS

Do not try to light an appliance.

Do not touch any electrical switch; do not use any phone in your

building.

Immediately call your gas supplier from a neighbour’s phone. Follow the

gas supplier’s instructions.

If you cannot reach your gas supplier, call the fire department.

C Use only your hand to push or turn the gas control knob. Never use

tools. If the knob will not push in or turn by hand, don’t try to repair it.

Call a qualified technician. Force or attempted repair may result in a fire

or explosion.

D Do not use the appliance if any part has been under water. Immediately

call a qualified service technician to inspect the appliance and to

replace any part of the control system which has been under water.

LIGHTING INSTRUCTIONS

1. Stop! Read the safety information above this label.

2. Set the thermostat to lowest setting.

3. Turn off all electrical power to the appliance.

4. Locate valve under the burner assembly.

5. If the control knob is not already in the off position, i.e. the word

“OFF” in the 9 o’clock position, then push in the gas control knob

slightly and turn clockwise to “OFF”. NOTE: Knob cannot be

turned from “PILOT” to “OFF” unless knob is pushed in slightly. Do

not use force.

6. Wait five [5] minutes to clear out any gas. If you then smell gas.

STOP! Follow “B” in the safety information above on this label. If

you don’t smell gas then go to the next step.

7. Now push in the control knob slightly and turn counter-clockwise

to the “PILOT” position.

8. Push in the control knob all the way and hold it. With the other

hand push in the red igniter button until you hear a click. Now

observe closely the pilot burner located on the rear center-left

hand side of the main burner.

If a flame has appeared then continue to depress the control knob for 20

seconds. If the flame did not appear then continue to depress the red

igniter button every 5 seconds until a flame is established. NOTE: If

after 30 seconds a flame has not yet been established then turn the

control knob back to the off position and repeat steps 5, 6 & 7.

9. Once the pilot has been established hold the control knob in the

depressed position for approximately 25 seconds before releasing. If

the flame goes out then repeat steps 7 and 8.

If the knob does not pop up when released, stop and immediately call

your service technician or gas supplier.

If the pilot will not stay lit after several tries, turn the gas control to

“OFF” and call your service technician.

10. Now turn the control knob to the “ON” position. The burner will not light

unless the wall switch thermostat or remote control is turned “ON” or in

the case of the thermostat there is a call for heat.

11. Close the access door and turn all electrical power back to the

appliance.

12. The pilot must be turned off when the unit is not in use.

TO TURN OFF THE APPLIANCE

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance if service is to be

performed.

3. Open the control access door.

4. Push in the gas control knob slightly and turn clockwise to the “OFF”

position. Do not force.

5. Replace control access panel.

Recommended Maximum Lead Length (Double Wire)

When Using Wall Switch or Thermostat

Wire Size

Max. Length

14ga

100ft [30.4m]

16ga

64ft [19.5m]

18ga

40ft [12.1m]

20ga

25ft [7.6m]

22ga

15ft [4.5m]

CAUTION: DO NOT WIRE 120V POWER TO

MILLIVOLT SWITCHES OR THERMOSTAT.

NOTE: Only one on/off device (manual on/off, remote control, or hard wired thermostat) should be connected to the

appliance at any one time, this is most important when installing an insert or stove as the on/off rocker switch is installed at

the factory.

WARNING: If you do not follow these instructions exactly, a fire or explosion may result causing property

damage, personal injury or loss of life.

To Wall Switch,

Thermostat*, Or

Remote Receiver

*In the U.S.A. Thermostats are not permitted for Vented Gas Fireplaces (ANSI Z21.50b-2009 -Decorative).

42

Page 43

MAP / MAN -MANUAL VALVE (DANTE)

MVN / MVP -MILLIVOLT VALVE

Models →

OB24MAN

OB24MAP

OB36MAN

OB36MAP

OB48MAN

OB48MAP

OB24MVN

OB24MVP

OB36MVN

OB36MVP

OB48MVN

OB48MVP

OB72MVN

OB72MVP

OB96MVN

OB96MVP

Fuel

Natural Gas

Propane

Natural Gas

Propane

Natural Gas

Propane

Natural Gas

Propane

Natural Gas

Propane

Natural Gas

Propane

Natural Gas

Propane

Natural Gas

Propane

Gas Control

Dante Adjustable

Millivolt Adjustable

Max / Min

(Btu)

40,000

40,000

60,000

60,000

63,500

60,000

27,500Lo

40,000Hi

31,500Lo

40,000Hi

39,000Lo

60,000Hi

48,000Lo

60,000Hi

54,000Lo

80,000Hi

61,000Lo

80,000Hi

83,000Lo

120,000Hi

91,000Lo

115,000Hi

110,000Lo

156,000Hi

125,000Lo

157,000Hi

Orifice Size

(0-4500ft)

#40

#50

#31

#43

#30

#43

#31

#49

#25

#43

#14

#37

#19 [2ea]

#43 [2ea]

#10 [2ea]

#37 [2ea]

Air Shutter

1/16” Open

Fully Open

1/16” Open

Fully Open

1/16” Open

Fully Open

1/16” Open

Fully Open

1/16” Open

Fully Open

1/16” Open

Fully Open

1/16” Open

Fully Open

1/16” Open

Fully Open

Gas Inlet Size

Dante, 3/8” NPT

S.I.T. 820 Nova, 3/8” NPT

S.I.T. 820 Nova, 1/2” NPT

Gas Supply

Pressure

Minimum

Normal

Maximum

Minimum

Normal

Maximum

Natural Gas

7” (Unregulated)

7” (Unregulated)

7” (Unregulated)

5.5”

7”

10”

Liquid

Propane

11” Hose Regulator

11” Hose Regulator

11” Hose Regulator

11”

11”

13”

Manifold

Pressure High

N/A

N/A

3.5” w.c. [0.87KPa] NG

10” w.c. [2.61KPa] LP

Manifold

Pressure Low

N/A

N/A

1.6” w.c. [0.40KPa]

6.3” w.c. [1.57KPa]

IMPORTANT: Always check for gas leaks with a soap and water solution. DO NOT USE OPEN FLAME FOR LEAK TESTING.

For the state of Massachusetts a T-handle gas shut-off valve must be used on a gas appliance. This T-handle gas shut-off valve must be listed and approved by the state of Massachusetts.

This is in reference to the state of Massachusetts state code CMR238.

43

1. The gas pipeline can be brought in through either the left side or the bottom of the appliance. A knockout is provided at either location to allow for the gas pipe installation and testing of any gas

2. The gas control inlet is 3/8” NPT. Typical installation layout for rigid pipe is shown at right.

3. When using copper or flex connector, use only approved fittings. Always provide a union so that gas line can be easily

4. When a vertical section of gas pipe is required for the installation, a condensation trap is needed. See CAN/CGA-B149.1 or .2

5. For natural gas, a minimum of 3/8” iron pipe with gas minimum pressure of 4.5” w.c. must be used for supply from the gas

6. Ports are accessible for test gauge connection both on the inlet and outlet of the gas valve.

7. Turn the gas supply ON and check for leaks. DO NOT USE OPEN FLAME FOR THIS PURPOSE. Use an approved leak

8. The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure

9. The appliance must be isolated from the gas supply piping system by closing its individual shutoff valve during any pressure

Note: The gas line connection may be made of 1/2” rigid pipe, 1/2” copper pipe or an approved flex connector. Since some

municipalities have additional local codes, it is always best to consult your local authorities and the current CAN/CGA - B149.1 or .2

installation code in Canada or the National Fuel Gas code ANSI Z223.1 in the U.S.A.

disconnected for burner or fan servicing. See gas specification for pressure details and ratings.

for code details.

meter. Consult with the local gas utility if any questions arise concerning pipe sizes.

testing solution.

testing of that system at test pressures in excess of 1/2psig [3.5 KPa].

testing of the gas supply piping system at test pressures equal to or less than 1/2psig [3.5 KPa].

This gas appliance should be installed by a qualified installer in accordance with local building codes and with current CAN/CGA - B149.1 or .2 installation codes for Gas Burning appliances and

equipment in Canada and the National Fuel Gas Code ANSI Z223 in the U.S.A.

connection.

Gas Line Installation and Specifications

Page 44

LP Cylinder Requirements

NOTE: Cylinders acceptable for use inside this appliance must be compatible with the retention means shown here.

The LP gas supply cylinder used with LP models must be constructed

and marked in accordance with the specifications for LP-gas cylinders

of the U.S. Department of Transportation (DOT) Specifications for LP-

Gas Cylinders, or the Standard for Cylinders, Spheres and Tubes for

Transportation of Dangerous Goods and Commission, CAN/CSA-

B339, as applicable.

The LP gas supply cylinder used with LP models must be provided