Kingsman IDV26, IDV43, IDV33 Installation Instructions Manual

Installation Instructions

Gas Fired Direct Vent Room Heater Inserts Listed Certified for USA. and Canada

Model Numbers:

IDV26 – Stock Numbers: IDV26N, IDV26LP, IDV26NE,IDV26LPE

Minimum Fireplace Opening Required: 33”W x 19-1/2”H x 14-1/4”D Components In

28”W x 19-1/2”H x 14-1/4”D Components Out

IDV33 - Stock Numbers: IDV33N, IDV33NE, IDV33LP, IDV33LPE

Minimum Fireplace Opening Required: 26-1/4”W x 21-3/8”H x 14-3/8”D

IDV43– Stock Numbers: IDV43N, IDV43NE, IDV43LP, IDV43LPE

Minimum Fireplace Opening Required: 30-3/4”W x 25-5/8”H x 14-3/4”D

Are Certified to: ANSI Z21.88-2014 • CSA 2.33-2014

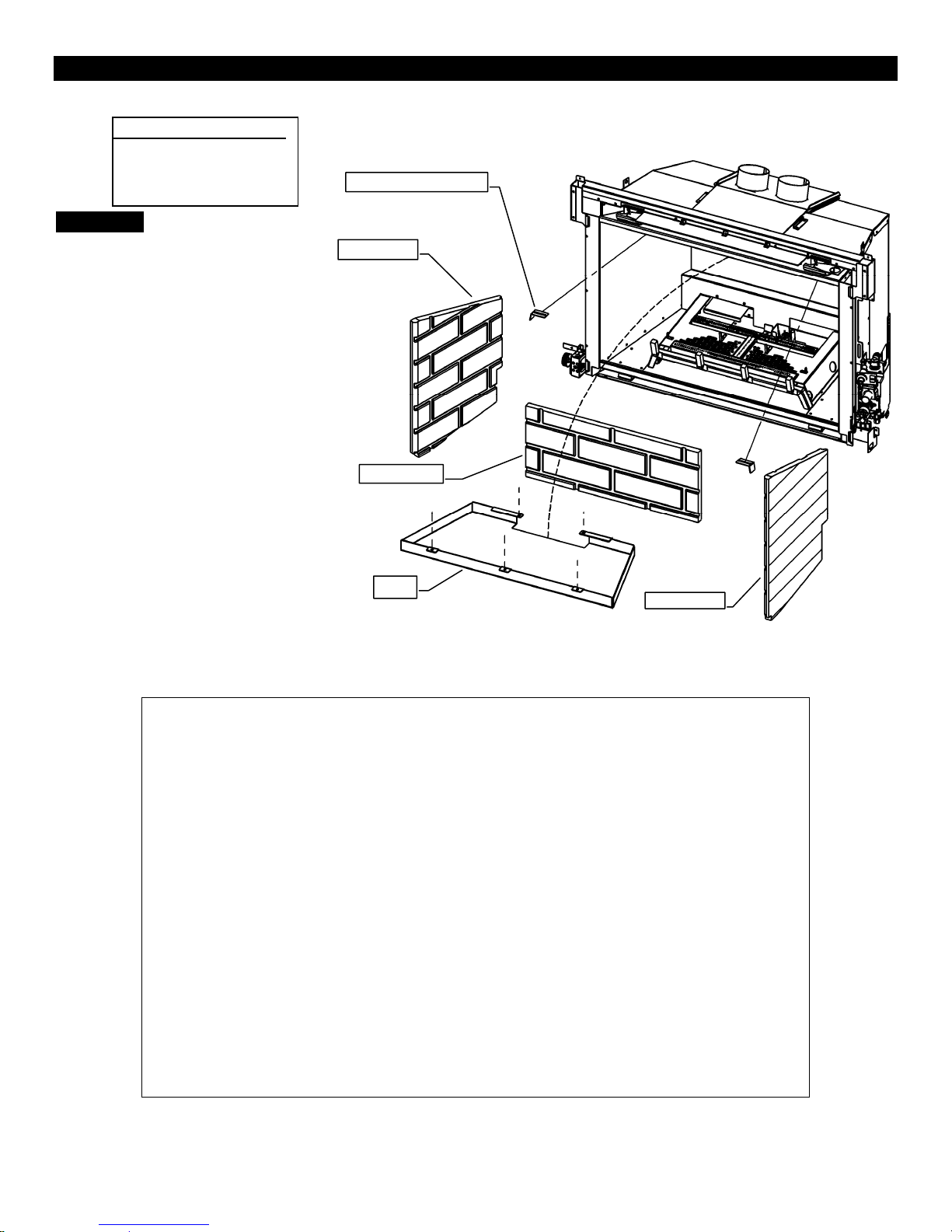

⚠WARNING: The IDV26/IDV33/IDV43 Fireplace

Insert was designed for installation in a solid fuel

fireplace that has been installed in accordance

with national, provincial/state and local building

codes and is constructed of noncombustible

materials. Do not remove any refractory materials

from any masonry solid fuel fireplace.

The IDV26/IDV33/IDV43 Fireplace Insert was

designed for installation in a zero clearance type

listed solid fuel burning factory built fireplace. It may

be necessary to remove the damper plate, refractory

liners, log grates, glass door, and screen rails/mesh.

Removal of the smoke baffle is necessary in most

cases.

A Division of R-Co. Inc.

2340 Logan Avenue

Winnipeg, Manitoba, Canada R2R 2V3

Ph: (204) 632-1962

Printed in Canada March 22, 2016

Part # 43IDV-MAN14

INSTALLER: Leave this manual with the

appliance.

CONSUMER: Retain this manual for

future reference.

This appliance may be installed in an

aftermarket, permanently located,

manufactured home (USA only) or mobile

home, where not prohibited by local codes.

This appliance is only for use with the type

of gas indicated on the rating plate. This

appliance is not convertible for use with

other gases, unless a certified kit is used.

CAPELLA

Table of Contents.....................................................................................................................................................

2-3

Pre-installation Questions and Answers..................................................................................................................

4

Operating Instructions..............................................................................................................................................

4

Safety Screen Installation……………………………………………………………………………………………………

5

Installation of IDV26 / IDV33 / IDV43 Using Steel Studs and Concrete Board over Wood Burning Fireplace…….

6

Mobile Home/Manufactured Housing Installation....................................................................................................

7

Warnings, Installations and Operations...................................................................................................................

8

Installation Requirements for the Commonwealth of Massachusetts......................................................................

9

Glass Safety / Termination Cap Safety Warning………………………………………………………………………….

10

Important Information...............................................................................................................................................

11

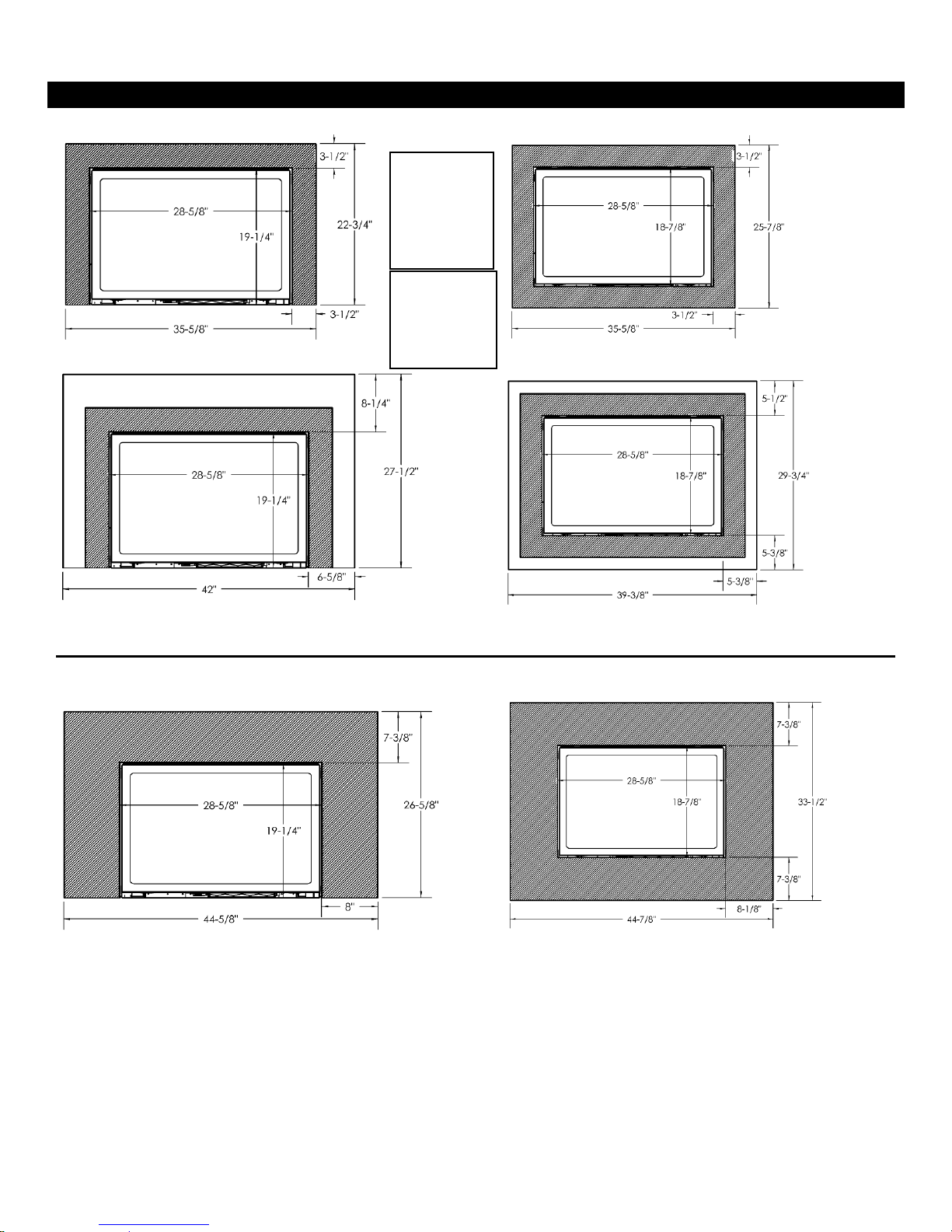

IDV26 Section

IDV26 Insert Dimensions and Sizing........................................................................................................................

12-13

I26CV Clean View and Surround Sizes...................................................................................................................

14

I26SU Universal Surround.......................................................................................................................................

15-16

I26CV Surround Installation / Clean View (CV) Attachment / Valve Access...........................................................

17

I26S1 / I26SPF1 / I26SU Surround Installation........................................................................................................

18

I26CV2 / I26CV4 / I26CVPF2 / I26CVPF4 Wide Clean View Installation………………………………………………

19

I26CV2 / I26CVPF2 Wide Clean View Installation -Components Out-....................................................................

20

IDV26PRL Porcelain Liner Panels...........................................................................................................................

21

IDV26RL Brick Liner Panels....................................................................................................................................

22

IDV26 -Millivolt- Control Components Outside the Opening- COMPONENTS OUT..........................................

23-24

IDV26 -IPI- Control Components Outside the Opening- COMPONENTS OUT.............................................

24-25

IDV26 Fan Speed Control Outside COMPONENTS OUT.......................................................................................

26

IDV26 Fan Installation / Removal / Wiring............................................................................................................

27-28

IDV26 Remote Receiver Location............................................................................................................................

29

IDV33 Section

IDV33 Insert Dimensions and Sizing.......................................................................................................................

30

I33CV Clean View and Surround Sizes...................................................................................................................

31

I33CV1 / I33CV3 Front Face and Surround Attachment Installation……………………………………………………

32

I33LK Louver Kit and Surround Sizes......................................................................................................................

33

I33LK/I43LK Front Face Attachment Installation………………………………………………………………………….

34

Surround Installation for IDV33 Fronts………………………………………………………………………………….....

35

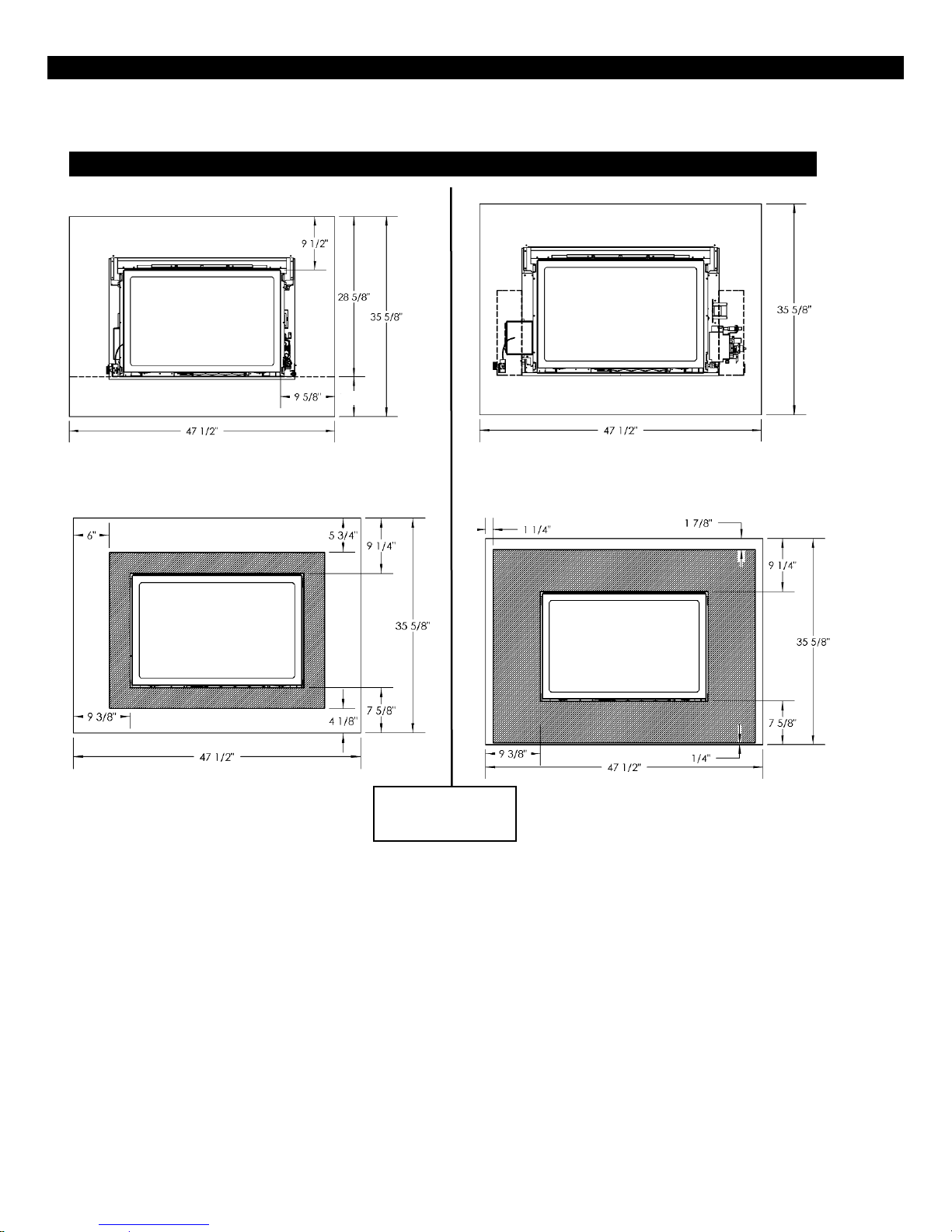

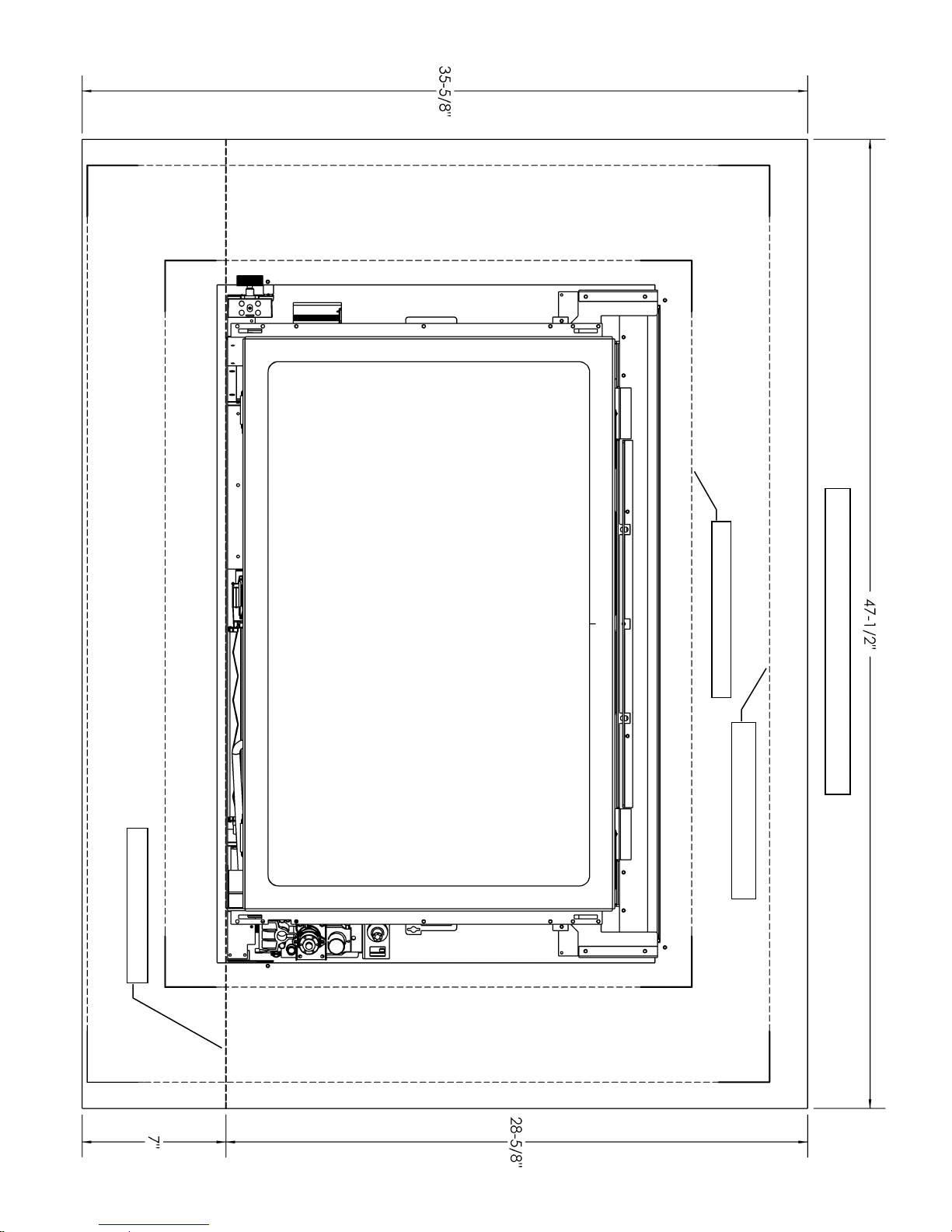

IDV43Section

IDV43 Fireplace Openings………….......................................................................................................................

36

IDV43 Fireplace Dimensions…………..…………………………………………………………………………………...

36

Clean View and Surround Coverages Chart for IDV43……………………………………………………………….....

37

I43CV1 and I43CV3 for IDV43 Fireplace……………………………………………………………………………….....

38

I43CV1 / I43CV3 Front Face and Surround Attachment Installation……………………………………………………

39

I43CV5 for IDV43 Fireplace…………………………………………………………………………………………………

40

I43CV5 Clean View and Surround Attachments – RECESSED OPENING……………………………………………

41

I43CV5 Clean View and Surround Attachments – NON RECESSED OPENING…………………………………….

42

I43CV5 Heat Shield Attachment…………………………………………………………………………………………….

43

I43US4736 Universal Surround……………………………………………………………………………………………..

44

I43LK Front Face Attachment Installation………………………………………………………………………………….

45

I43LK Louver Kit and Surround Sizes……………………………………………………………………………………...

46

Surround Installation for I43LK Fronts…………………………………………………………………………………......

47

I43LKS3BL Universal Surround…………………………………………………………………………………………….

48

Accessories for IDV33 / IDV43

IDV33 / IDV43 Fan Installation/Removal..................................................................................................................

49

IDV33 & IDV43 Brick Liners.....................................................................................................................................

50

IDV33/36PL- Liner Panels -Generation 1.................................................................................................................

50

IDV33/36PRL Removing and Installing Generation 2 Liner Panels.........................................................................

51

[Continued]

2

Clearances and Mantel Heights

I43CV Clearance to Combustible Mantels…………………………………………………………………………………

52

IDV26 / IDV33 / IDV43 Wall Coverings....................................................................................................................

53

IDV26 / IDV33 / IDV43 Clearance to Combustible Mantels.....................................................................................

54

I33CS -Mantel Clearance Shield- For IDV26 / IDV33 / IDV43…………………………………………………………..

55-56

Information and Media Accessories for IDV26 / IDV33 / IDV43

IDV26 / IDV33 / IDV43 Riser Kit and Leveling Instructions......................................................................................

57

Glass Door Information............................................................................................................................................

58

MQRSP4 / MQRSP8 Rock and Glass Support Platform Installation IDV26 / IDV33 / IDV43..................................

59

RSP10 Glass Support Platform -Installation IDV26 / IDV33 / IDV43.......................................................................

60

RSP11 Glass Support Platform -Installation IDV26 / IDV33 / IDV43.......................................................................

61

MQRSP11 With MQLOGF453………………………………………………………………………………………………

62

MQROCK2 / MQROCK3 -MQRSP4 IDV26 / IDV33 / IDV43...................................................................................

63-64

MQStone, MQRSP8 IDV26 / IDV33 / IDV43............................................................................................................

65

Glass Ember / MQ Ember Installation -MQRSP8 / RSP10- IDV26 / IDV33 / IDV43................................................

66

IDV26 LOGF26……………………………………………………………………………………………………………..

67

IDV26 LOGF27……………………………………………………………………………………………………………..

68

Log Placement – LOGF35.......................................................................................................................................

69

Log Placement – LOGF36…………………………………………………………………………………………………..

70

Burner and Gas Information

Gas Line Installation.................................................................................................................................................

71

IDV33 / IDV43 Insert Burner Component List..........................................................................................................

72

IDV33 / IDV43 Burner Installation/Removal.............................................................................................................

73

IDV26 Burner Installation/Removal..........................................................................................................................

73-74

Millivolt System, Lighting, and Burner Control.........................................................................................................

75

Burner System Maintenance....................................................................................................................................

76

Conversion Kit Instructions – PART A.....................................................................................................................

76-77

Gas Conversion for Top Convertible Pilot (Series 019065X) – PART B Millivolt……………………………………...

78

Gas Conversion for Top Convertible Pilot – Part B (series 0190XYZ) IPI……………………………………………..

79

Gas Conversion for Modulator – PART C................................................................................................................

80

Troubleshooting the Gas Control System................................................................................................................

81

Remote Control Operation…………………………………………………………………………………………………..

82

IPI System

IPI Electronic Ignition System..................................................................................................................................

83-84

IPI Electronic Ignition Parts List – Standard System……………………………………………………………………..

85

IPI Configurations 1 & 2 ……………………………………………………………………………………………………..

86

Operating the Receiver Without Batteries For GT / EGT / GTM / EGTM Remote Controls………………………….

87

Electronic Ignition Lighting Instructions....................................................................................................................

88

Venting

Venting.....................................................................................................................................................................

89

Installation of Vent Pipe...........................................................................................................................................

90

Insulation of Chimney Cavity...................................................................................................................................

91

IPI (Intermittent Pilot Ignition) Appliances Cold Climate Mode................................................................................

91

Parts List

IDV26 Parts List.......................................................................................................................................................

92

IDV33 Parts List.......................................................................................................................................................

93

IDV43 Parts List.......................................................................................................................................................

94

Parts for IDV26/ IDV33/ IDV43................................................................................................................................

95

Parts for IDV26/ IDV33 Venting...............................................................................................................................

95

Limited Lifetime Warranty........................................................................................................................................

96

3

Pre-installation Questions and Answers

Operating Instructions

1. Be sure to read and understand all the instructions in this manual before operation of appliance.

2. Ensure all wiring is correct and properly enclosed to prevent possible shock.

3. Check for gas leaks.

4. Make sure the glass door is properly installed before operation. Never operate the appliance with the glass door

removed.

5. Make sure venting and termination cap are installed and unobstructed.

6. If brick or porcelain liners are used, ensure they are installed.

7. Verify that the pilot can be seen when lighting the appliance. If not, the log or rock placement is incorrect.

8. If the unit is turned off, you must wait a minimum of 60 seconds before re-lighting it.

4

About curing of the paint

Your stove or fireplace has been painted with the highest quality silicone stove paint. This paint dries quickly in 15-20

minutes when first applied at the factory. However, due to the high temperature silicone components, the paint will cure

when heat is applied to the appliance as it is first used. The following information applies to the curing process to get the

paint fully hard and durable.

Fire the appliance four successive times for 10 minutes each firing and a 5 minute cool down between each. Be aware

during log and firebox paint curing that a white deposit may be developing on the inside of the glass doors. It is important

to remove this white deposit from the glass doors using a fireplace glass cleaner.

Babies, small children, pregnant women and pets should leave the area during the cure phase.

Ventilate well, open doors and windows.

Do not touch during curing.

Why does my fireplace or stove give off odour?

It is normal for your fireplace to give off some odor at first. This is due to the curing of the paint, adhesives, silicones and

any undetected oil from the manufacturing process as well as the finishing materials used with the installations (e.g.

marble, tile and the adhesives used to adhere this product to the walls can react with heat and cause odours).

It is recommended that you burn your gas fireplace or stove for a minimum of four hours at a time with the fan off (if a fan

is present) after the curing of the paint has been completed. These odours can last upward to 40 hours of burn time; keep

burning at a minimum of four hours per use until odours dissipate.

Noise coming from the fireplace?

Noise is caused by the expansion and contraction of metal as the appliance heats up and cools down. This is normal and

is similar to the sounds produced by a furnace or heating duct. This noise does not affect the operation or longevity of

your fireplace.

It is also normal for the fan to make some noise when it comes on. This noise can be reduced somewhat by turning down

the speed of the fan with the variable speed control. Be aware, however, that this will reduce the volume of heated air

circulated into the room by the fan.

Note to the Installer:

Be sure appliance is working properly and its operation (including remote control operation, if included) is fully explained

to and understood by the customer.

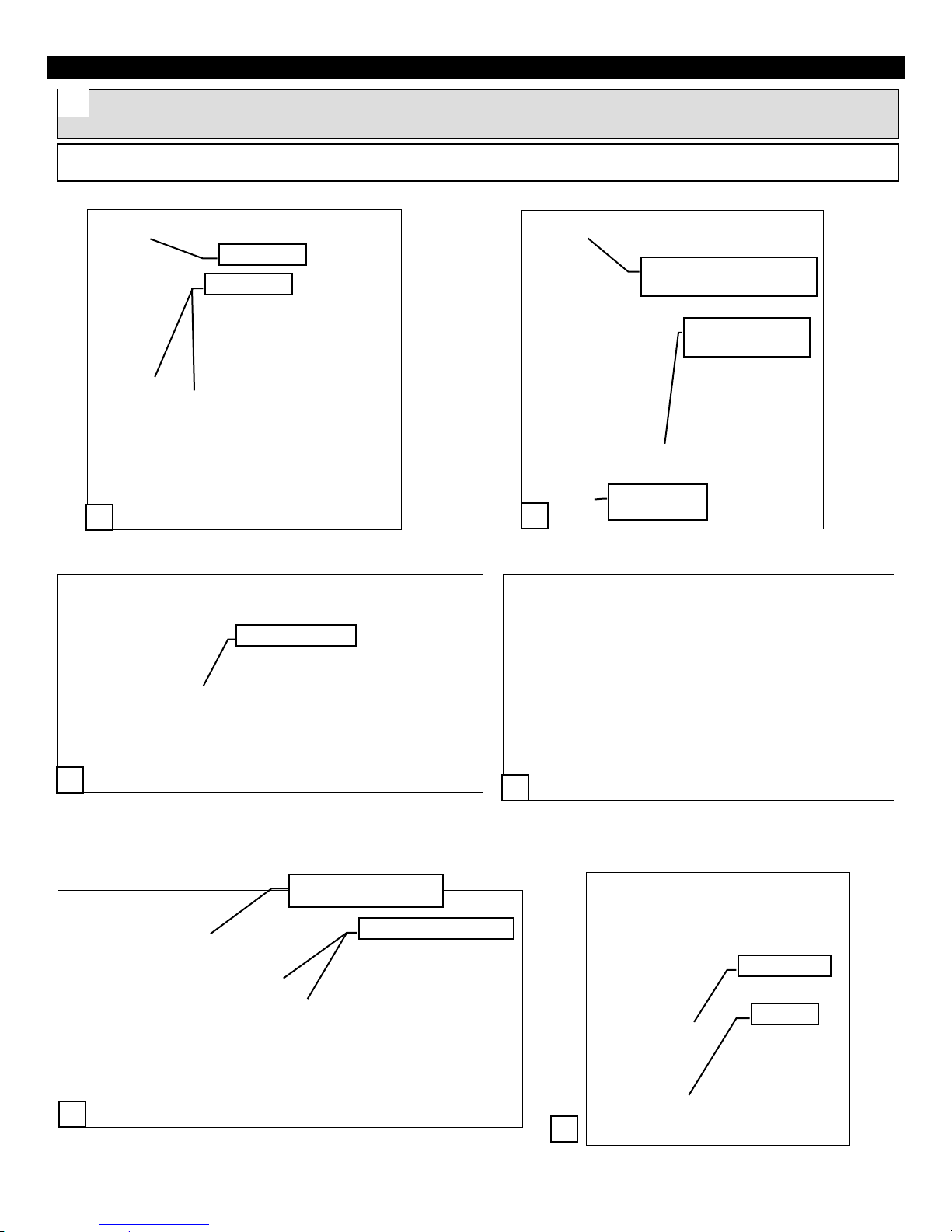

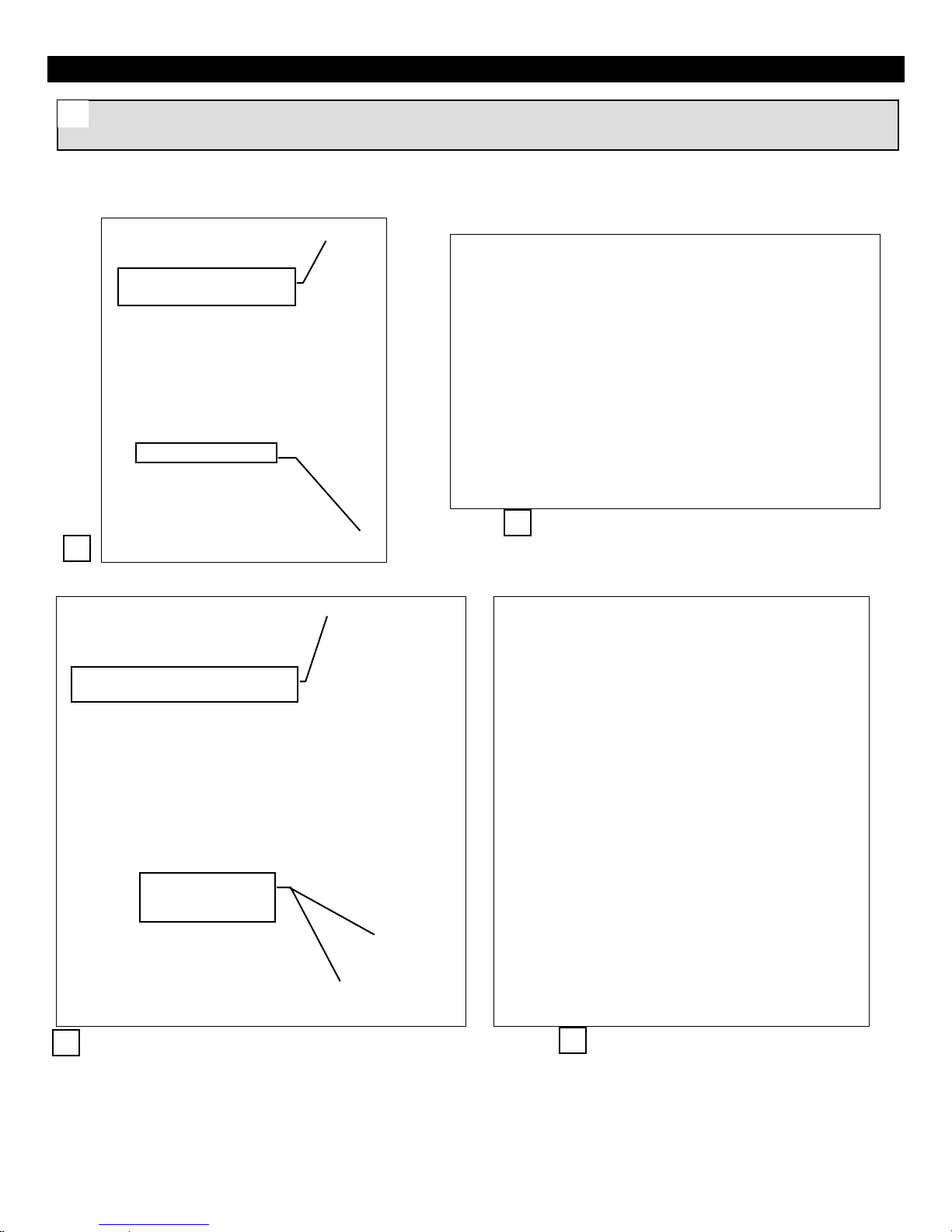

Safety Screen Installation Inserts

Screen with Side & Horizontal Angles

Hook Lower Clip onto glass door frame.

Press down and push upper clip under top glass door frame.

Fireplace with screen.

⚠WARNING:

Wait until unit is COMPLETELY

cool before touching glass or

attempting to install or remove

Child Safety Screens.

To install screens

hook bottom clip

onto glass door

frame, then press

down and push

upper clip under

top glass door

frame, then

release. Clip will

hook onto frame.

To remove

Safety

Screens

WAIT UNTIL

FIREPLACE IS

COMPLETELY

COOL.

Press down on

upper clips and

remove screen

from fireplace

glass door.

TOP VIEW

Upper Clip

Lower Clip

Upper Clip

NOTE: Screens are

symmetrical from top to

bottom.

CLIPS

Contents of Kit:

[1] Safety Screen

SIDE VIEW

5

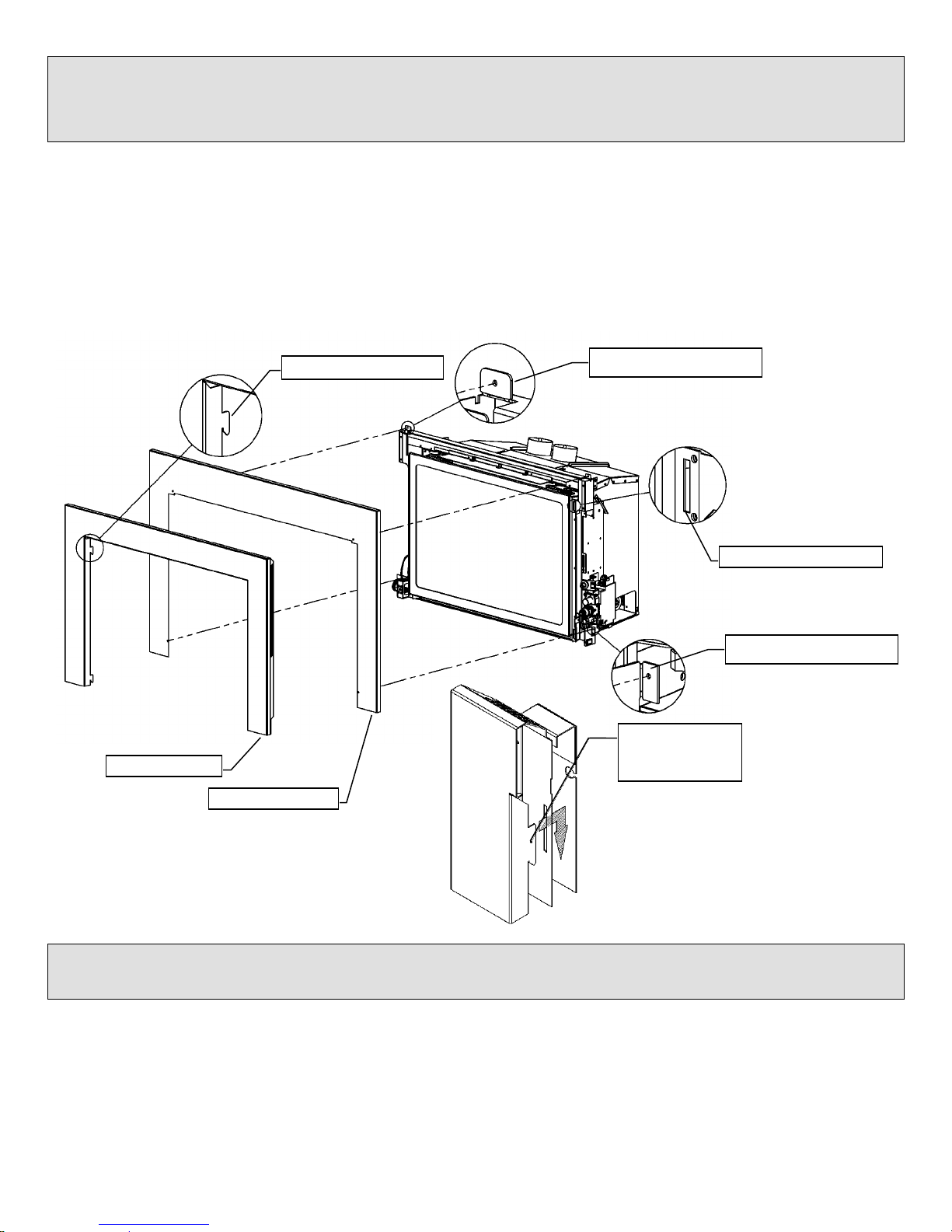

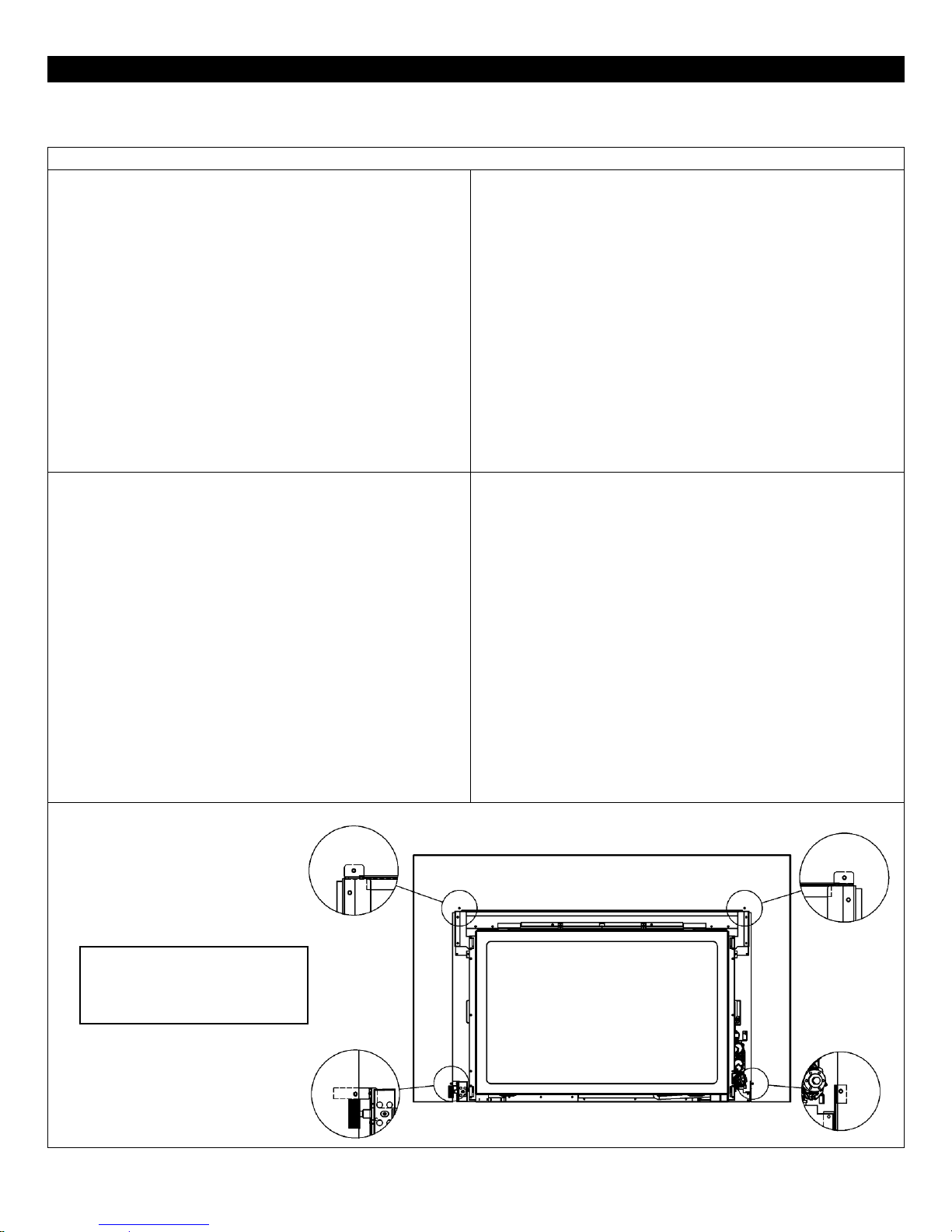

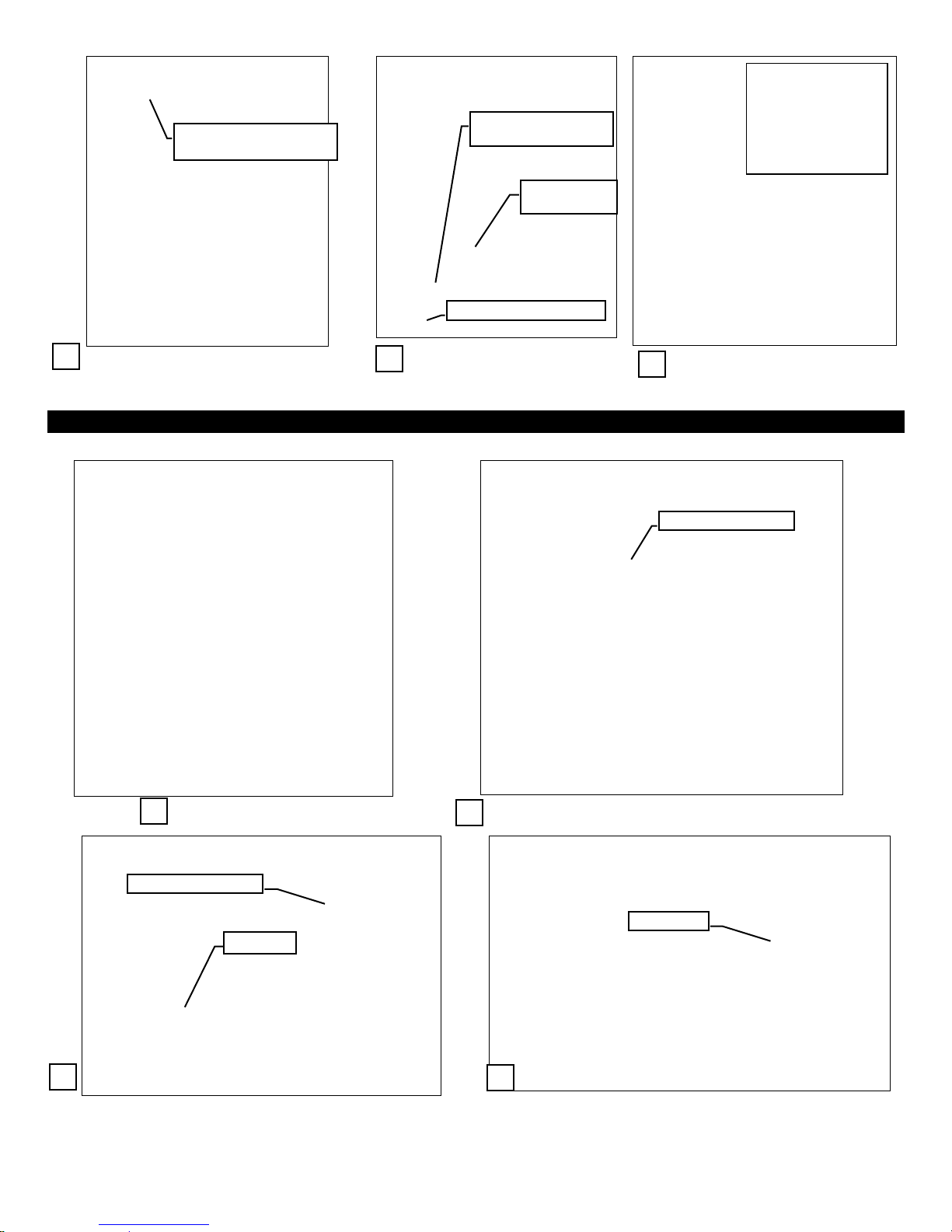

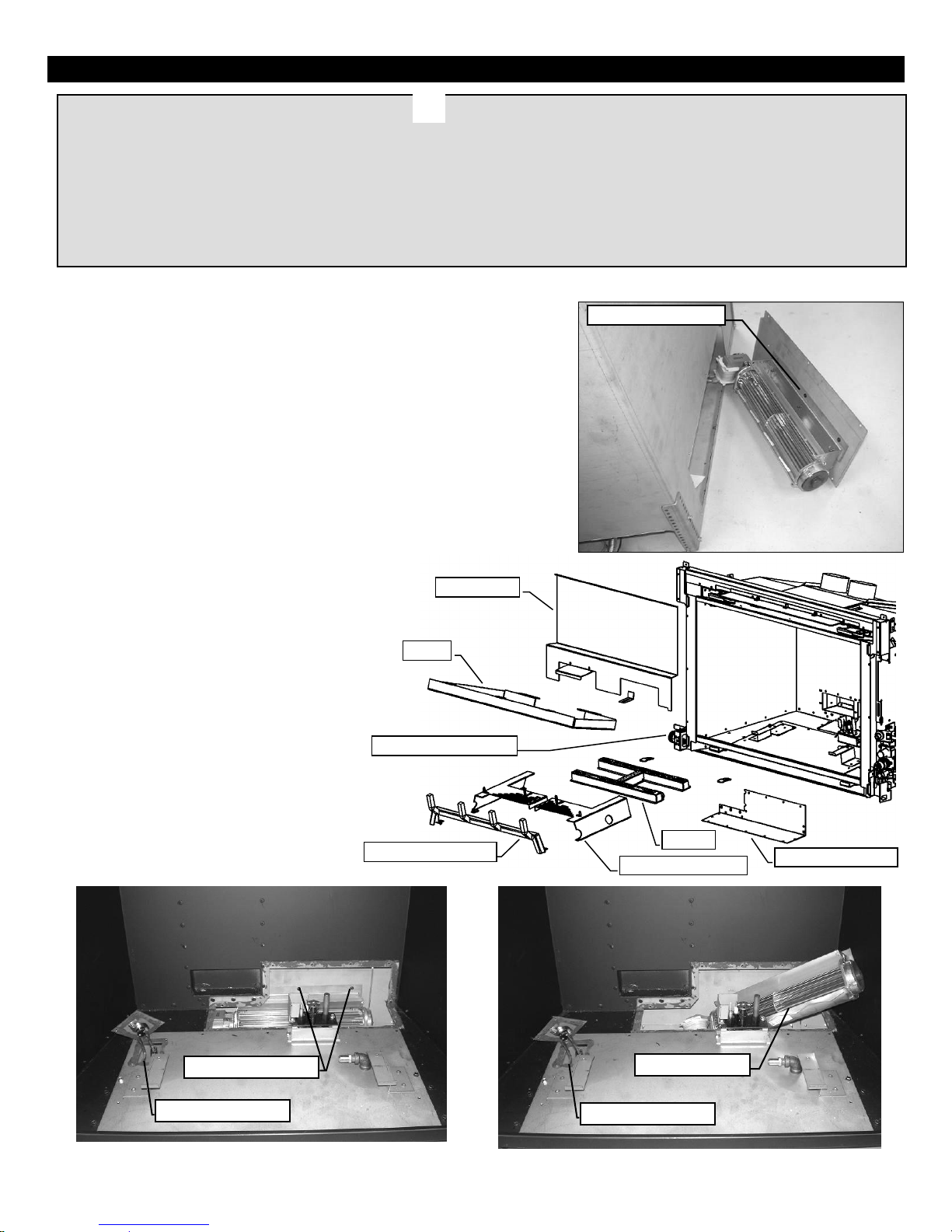

Installation of IDV26 / IDV33 / IDV43

Using Steel Studs and Concrete Board over Wood Burning Fireplace

USE STEEL STUDS

USE CONCRETE BOARD ON

FRONT AND AROUND STEEL

STUD ENCLOSURE FOR INSERT

MUST BE SEALED TO AVOID HEAT

ENTERING OLD ENCLOSURE

EXISTING ZERO CLEARANCE

WOOD BURNING / MASONRY

FIREPLACE

MUST BE SEALED TO AVOID HEAT

ENTERING OLD ENCLOSURE

6

Brick facing may be removed and replaced with non-combustible materials such as steel studs and

concrete board. The opening between the firebox and non-combustive materials must be sealed so

as the heat cannot run between the face of the wood fireplace and the re-facing materials.

Insert must be pulled out so the appliance is flush with the finishing materials and the clean view kit is

proud of the finished non-combustible enclosure (wood burning fireplace).

7

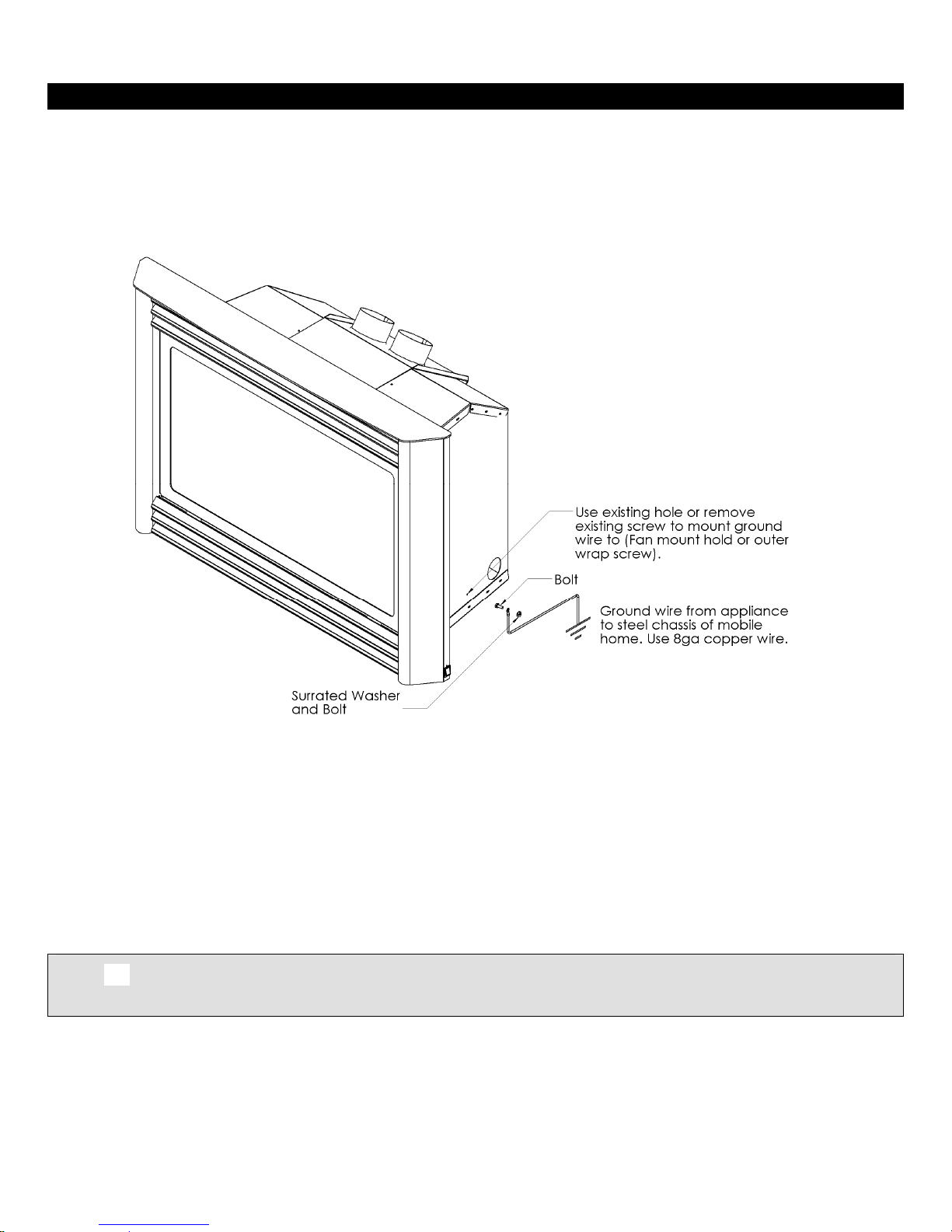

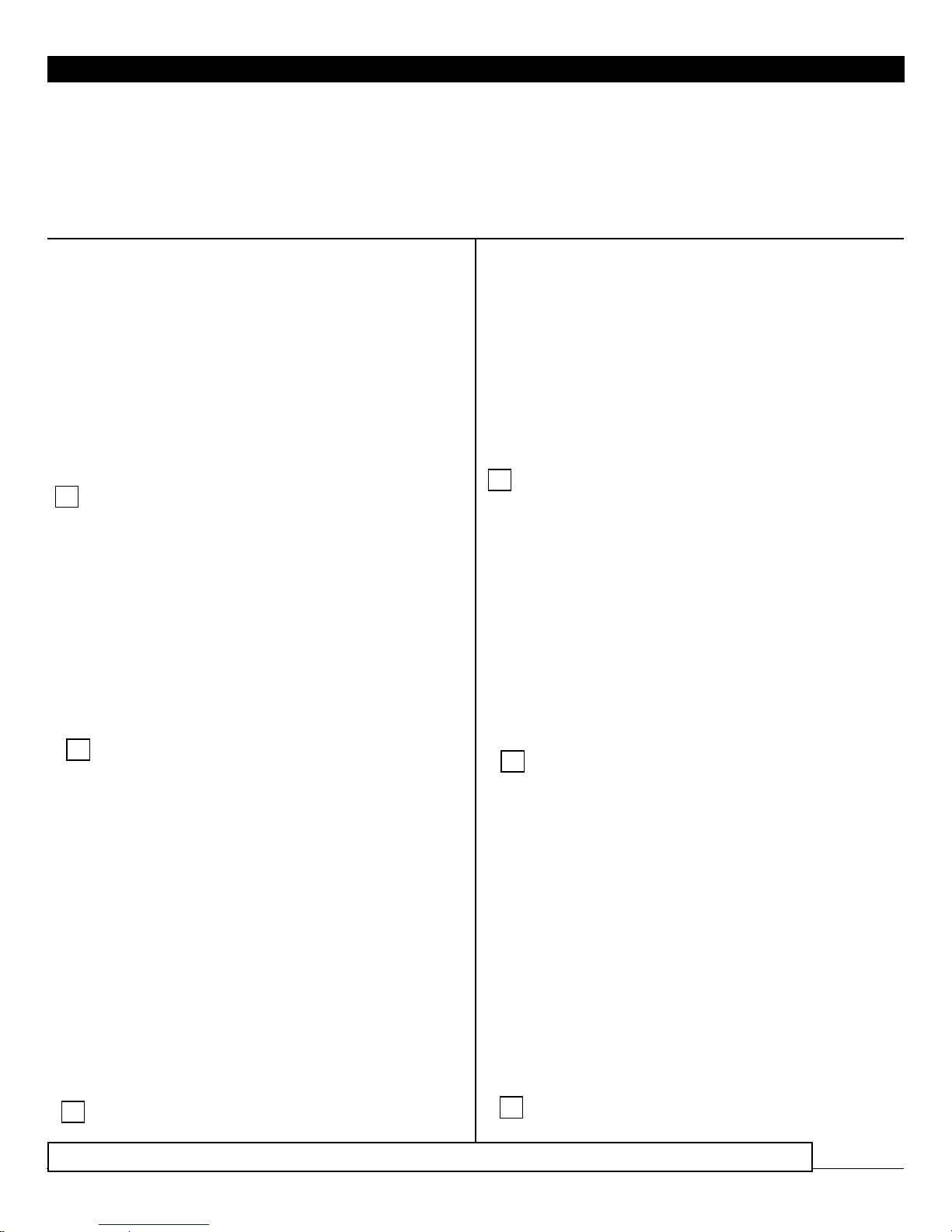

Mobile Home/Manufactured Housing Installation

This Direct Vent System Appliance must be installed in accordance with the manufacturer’s installation instructions and

the Manufactured Home Construction and Safety Standard Title 24 CFR, Part 3280, or the current Standard for Fire

Safety Criteria for Manufactured Home Installation, Sites, and Communities ANSI/NFPA 501A, and with CAN/CSA Z240

MH Mobile Home Standard in Canada.

THIS APPLIANCE MAY BE INSTALLED IN MANUFACTURED (MOBILE) HOMES AFTER FIRST SALE.

Please follow the current ANSI/NFPA 70 National Electrical Code in the USA and CAN/CSA C22.1 Canadian National

Electrical Code in Canada.

An appliance must be grounded to the steel chassis of the home with 8ga. copper wire using a serrated or star washer to

penetrate paint or protective coating to insure grounding.

Use carriage bolt at the attachment point (see diagram above) to secure the appliance to the floor.

Bedroom approved.

Warning: Do not compromise the structural integrity of the manufactured home wall, floor or ceiling,

during installation of appliance or venting.

For required venting components see venting installation in appropriate section of this manual.

Warnings, Installations and Operations

WARNING

FOR SAFE INSTALLATION AND OPERATION OF YOUR GAS FIREPLACE PLEASE NOTE THE FOLLOWING:

1. Do not clean when the glass is hot.

2. Do not use abrasive cleaners.

3. Using a substitute glass will void all product warranties.

4. For safe operation, glass doors must be closed.

5. When purging the gas line, the glass front must be removed.

6. Do not strike or abuse glass. Take care to avoid breakage.

7. Do not alter gas orifice.

8. No substitute materials may be used other than factory

supplied components.

9. This appliance gives off high temperatures and should be

located out of heavy traffic areas and away from furniture and

draperies.

10. Children and adults should be alerted to the hazards of the high

surface temperatures of this appliance and should stay away to avoid burns or ignition of clothing.

11. Young children should be carefully supervised when they are in the same room as the appliance. Toddlers, young children

and others may be susceptible to accidental contact burns. A physical barrier is recommended if there are at risk individuals

in the house. To restrict access to a fireplace or stove, install an adjustable safety gate to keep toddlers, young children and

other at risk individuals out of the room and away from hot surfaces.

12. Under no circumstances should any solid fuels (wood, paper) be used in this appliance.

13. Under no circumstances should this appliance be modified. Any parts that have to be removed for servicing should be

replaced prior to operating this appliance.

14. Any safety screen, guard, or barrier removed for servicing an appliance must be replaced prior to operating the appliance.

15. Installation and repair should be done by a qualified service person. The appliance should be inspected before use and at

least annually by a professional service person. More frequent cleaning may be required due to excessive lint from

carpeting, bedding material, et cetera. It is imperative that control compartments, burners and circulating air passageways

of the appliance be kept clean. Make sure that the gas valve and pilot light are turned off before you attempt to clean this

unit.

16. Clothing or other flammable material should not be placed on or near the appliance. This appliance should not be used as a

drying rack for clothing nor should Christmas stockings or decorations be hung from it.

17. Do not use this heater if any part has been under water. Immediately call a qualified service technician to inspect the heater

and to replace any part of the control system and any gas control which has been under water.

18. Do not operate appliance unless completely installed as per installation instructions.

19. Failure to position the parts in accordance with these diagrams or failure to use only parts specifically approved with this

appliance may result in property damage or personal injury.

20. WARNING: Do not operate appliance with the glass front removed, cracked or broken. Replacement of the glass

should be done by a licensed or qualified service person.

21. The appliance area must be kept clear and free from combustible materials, gasoline, and other flammable vapors and

liquids.

22. The front of the fireplace gives off high temperatures that could ignite combustible material which is kept close to the front of

the unit.

23. Ensure that power to the Fireplace is turned off before servicing.

24. Do not operate this Fireplace without the glass front or with a broken glass.

25. Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer to the

owner’s information manual provided with this appliance. For assistance or additional information consult a qualified

installer, service agency, or the gas supplier.

26. Operation of this appliance when not connected to a properly installed and maintained venting system or tampering with the

blocked vent shutoff system can result in carbon monoxide (CO) poisoning and possible death.

27. This appliance is equipped with a three-prong (grounding) plug for your protection against shock hazard and should be

plugged directly into a properly grounded three-prong receptacle. Do not cut or remove the grounding prong from this plug.

8

Installation Regulations

This gas appliance must be installed by a qualified installer in accordance with local building codes, or in the absence of local codes, with the current

CAN/CSA-B149.1 or .2 Installation Code (in Canada) or the current National Fuel Gas Code Z223.1- NFPA 54 when installed in the United States.

This appliance, when installed, must be electrically connected and grounded in accordance with local codes, or in the absence of local codes, with the

current CSA C22.1 Canadian Electrical Code or with the National Electrical Code; ANSI/NFPA 70 when installed in the United States.

In the U.S.A. Thermostats are not permitted for Vented Gas Fireplaces (ANSI Z21.50b-Decorative).

Gas fired appliances may be used only for supplemental heat and/or decorative purposes and under no circumstances shall they

NOTE: It is recommended that a Carbon Monoxide (CO) Detector be installed in or near bedrooms and on all levels of your home.

Place a detector about 15ft [4.5m] outside the room that houses your gas appliance.

Certified for installation in a bedroom or bed/sitting room. In Canada must be installed with listed millivolt thermostat.

In the U.S.A. Thermostats are not permitted for Vented Gas Fireplaces (ANSI Z21.50b-Decorative).

In USA see local codes.

9

provide a primary heat source.

This appliance must not be connected to a chimney flue serving a separate solid-fuel burning appliance.

Operations and Maintenance Instructions

For safe installation and operation note the following:

• Venting systems should be periodically examined by a qualified agency.

• The flow of combustion and ventilation air must not be obstructed.

• The Burner/Log Assembly has been engineered and permanently adjusted for proper flame control.

• Periodically remove the logs from the grate assembly and vacuum any loose particles from the grate and burner areas. See Log

Placement page to remove logs. Vacuum burner parts and replace logs.

• Never use your gas fireplace as a cooking device.

• Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. Verify

proper operation after servicing.

Installation Requirements for the Commonwealth of Massachusetts

In the Commonwealth of Massachusetts, the installer or service agent shall be a plumber or gas fitter licensed by the Commonwealth.

When installed in the Commonwealth of Massachusetts or where applicable codes; the unit shall be installed with a CO detector per the

requirements listed below.

1. For direct-vent appliances, mechanical-vent heating appliances or domestic hot water equipment, where the bottom of the vent

terminal and the air intake is installed below four feet above grade the following requirements must be satisfied:

A. If there is not one already present, on each floor level where there are bedroom(s), a carbon monoxide detector and alarm

shall be placed in the living area outside the bedroom(s). The carbon monoxide detector shall comply with NFPA 720.

B. A carbon monoxide detector shall be located in the room that houses the appliance or equipment and shall:

Be powered by the same electrical circuit as the appliance or equipment such that only one service switch services

both the appliance and the carbon monoxide detector;

Have battery back-up power;

Meet ANSI./UL 2034 Standards and comply with NFPA 720; and

Have been approved and listed by a Nationally Recognized Testing Laboratory as recognized under 527 CMR.

C. A Product-approved vent terminal must be used, and if applicable, a Product-approved air intake must be used.

Installation shall be in strict compliance with the manufacturer’s instructions. A copy of the installation instructions shall

remain with the appliance or equipment at the completion of the installation.

D. A metal or plastic identification plate shall be mounted at the exterior of the building, four feet directly above the location of

vent terminal. The plate shall be of sufficient size to be easily read from a distance of eight feet away, and read “Gas Vent

Directly Below”.

2. For direct-vent appliances, mechanical-vent heating appliances or domestic hot water equipment where the bottom of the vent

terminal and the air intake is installed above four feet above grade the following requirements must be satisfied:

A. If there is not one already present, on each floor level where there are bedroom(s), a carbon monoxide detector and alarm

shall be placed in the living area outside the bedroom(s). The carbon monoxide detector shall comply with NFPA 720.

B. A carbon monoxide detector shall:

Be located in the room that houses the appliance or equipment;

Be either hard-wired or battery powered or both; and

Shall comply with NFPA 720.

A Product-approved vent terminal must be used, and if applicable, a Product-approved air intake must be used. Installation shall be in

strict compliance with the manufacturer instructions. A copy of the installation instructions shall remain with the appliance or equipment

at the completion of the installation.

For the state of Massachusetts a T-handle gas shut-off valve must be used on a gas appliance. This T-handle gas shut-off valve must be listed and

approved by the state of Massachusetts. This is in reference to the state of Massachusetts state code CMR238.

-Glass Safety- All Units

-Termination Cap Safety- All Units

WARNING:

WHEN THE HORIZONTAL VENT TERMINATION IS ACCESSIBLE

A CERTIFIED GUARD (SAFETY CAGE) SHALL BE INSTALLED.

10

IT IS THE RESPONSIBILITY OF THE

HOME OWNER TO ENSURE THAT

NO ONE TOUCHES A HOT

APPLIANCE.

If the barrier becomes damaged, the barrier

shall be replaced with the manufacturer’s

barrier for this appliance.

Any safety screen, guard, or barrier removed for

servicing the appliance, must be replaced prior

to operating the appliance.

Children and adults should be alerted to the

hazards of the high surface temperatures of this

appliance and should stay away to avoid

burns or ignition of clothing.

Do not clean when the glass is hot.

Young children should be carefully supervised when they are in the same room as the appliance. Toddlers,

young children and others may be susceptible to accidental contact burns.

A physical barrier is recommended if there are at risk individuals in the house. To restrict access to a fireplace or

stove, install an adjustable safety gate to keep toddlers, young children and other at risk individuals out of the

room and away from hot surfaces.

Do not leave the fireplace remote control where it is accessible to children.

SAFETY CAGES ARE AVAILABLE FOR ALL HORIZONTAL VENT TERMINATIONS.

CHECK WITH YOUR DEALER.

TERMINATION CAP IS HOT! Do not place flammable materials on or within 24 inches of termination caps.

It is imperative that the vent termination be located observing the minimum clearances as shown in manual.

There must not be any obstruction such as bushes, garden sheds, fences, decks or utility buildings within 24"

from the front of the termination plate.

Do not locate termination where excessive snow or ice build-up may occur. Be sure to check vent termination

area after snow falls and clear to prevent accidental blockage of venting system. When using snow blowers,

make sure snow is not directed towards vent termination area.

Venting terminal shall not be recessed into a wall or siding.

Important Information

11

INSTALLATIONS

The following label (supplied with the gas fireplace insert) must be attached with rivets or screws to the inside of the

firebox of the fireplace into which it is installed:

Cutting any sheet-metal parts of the fireplace, in which the gas fireplace insert is to be installed, is prohibited.

If the factory-built fireplace has no gas access hole(s) provided, an access hole of 1.5 in (37.5 mm) or less may be drilled

through the lower sides or bottom of the firebox in a proper workmanship like manner. This access hole must be plugged

with non-combustible insulation after the gas supply line has been installed.

The fireplace flue damper can be fully blocked open or removed for installation of the gas fireplace inse rt.

Ensure that existing chimney cleanouts fit properly.

refractory, glass doors, screen rails, screen mesh and log grates can be removed from the fireplace before installing the

gas fireplace insert.

Smoke shelves, shields and baffles may be removed if attached by mechanical fasteners.

Trim panels or surrounds must not seal ventilation openings in the fireplace.

The fireplace and fireplace chimney must be clean and in good working order and con stru cted of non-combustible

materials.

MAINTENANCE

If for any reason the vent air intake system is disassembled, re-install and re-seal per the inst ructions provided for the

initial installation. See “Installation of Vent Pipe” section.

It is recommended to annually inspect and clean the Burner System to prevent malfunction a nd / or sooting. This

operation should be performed by your dealer or a qualified technician. Refer to Burner System Maintenance section.

Venting systems should be periodically examined by a qualified age ncy.

Periodically remove the logs from the grate assembly and vacuum any loose particles from the grate and burner areas.

See Log Placement page to remove logs. Vacuum burner parts and replace logs.

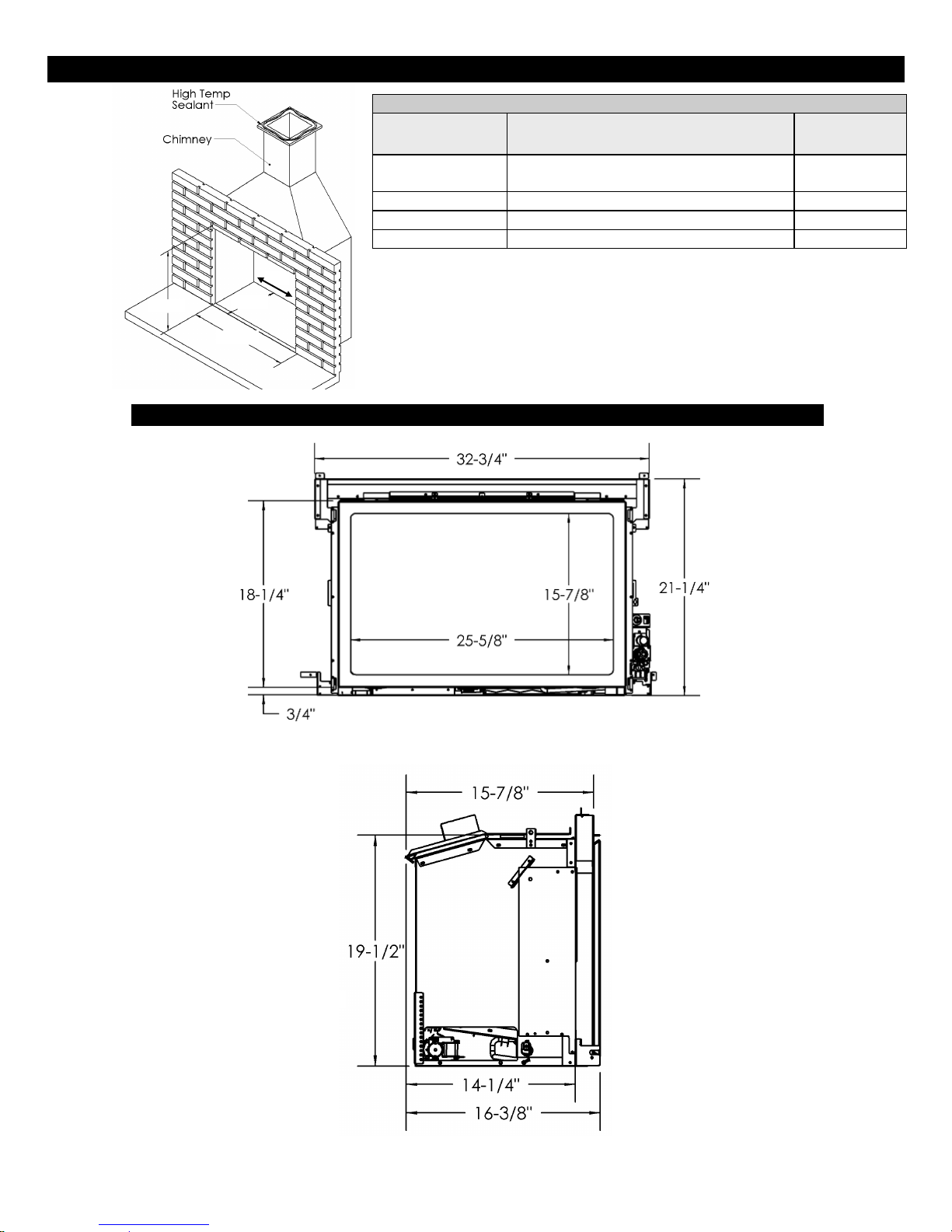

IDV26 Insert Dimensions and Sizing

Minimum Opening Dimensions

Dimension

Components In

Components

Out

“A” Front Width:

33” Centered in existing fireplace

*31” Not Centered in existing fireplace

28”

“B” Height:

19-1/2”

19-1/2”

“C” Depth:

14-1/4”

14-1/4”

“D” Back Width:

22”

22”

Note: Valve Control Components can be placed either inside the opening

(Components In) or outside the opening (Components Out).

Units are shipped with Control Components in.

For instructions on changing to Components Out refer to Control Components

Outside the Opening- COMPONENTS OUT.

“C”

“A”

“B”

Base Model IDV26

Front View

Left Side View

“D”

12

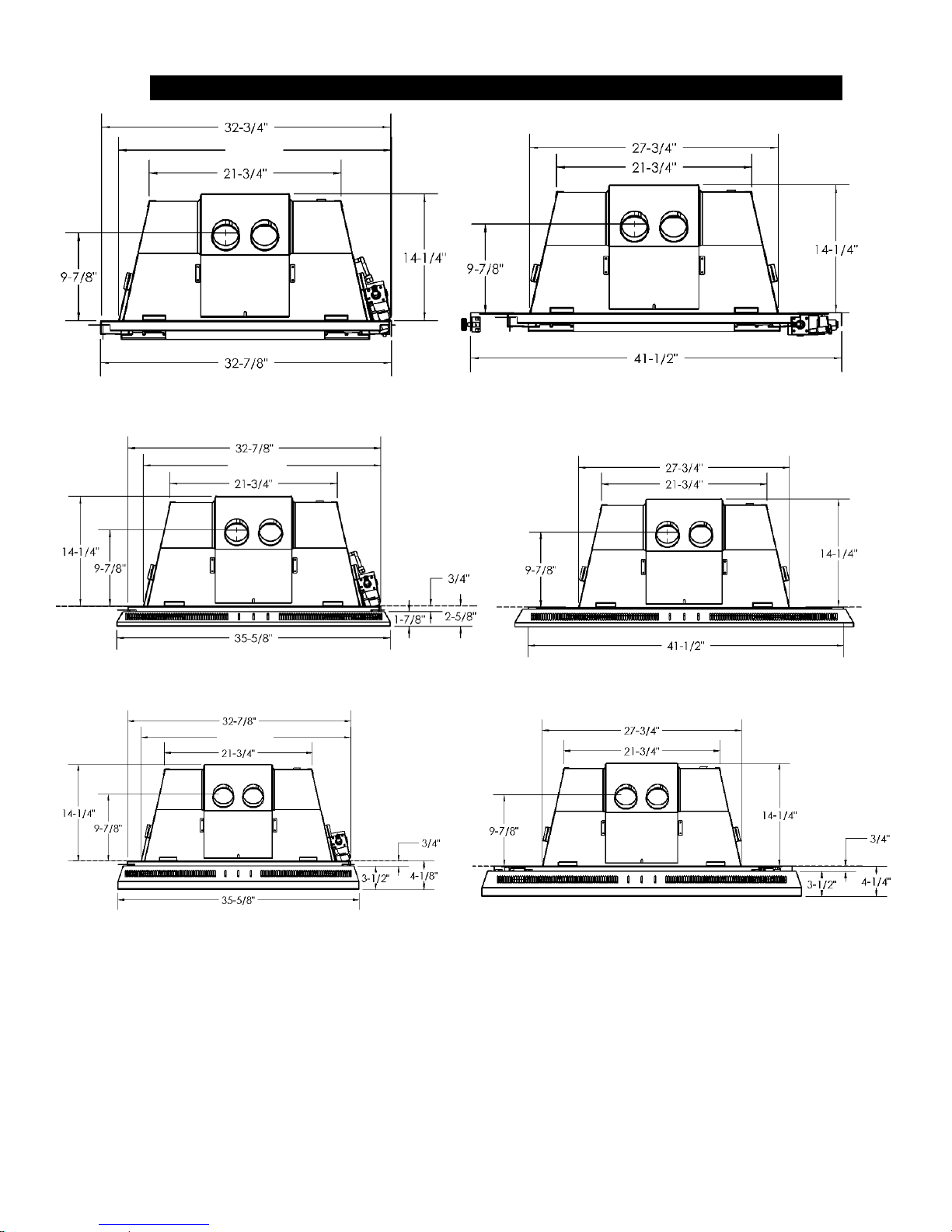

Top View- Components In

(As Shipped)

Components In Components Out

Top View- Components In

With I26CV1

Top View- Components Out

30-7/8”*

30-7/8”*

Top View- Components Out

With I26CV2

Top View- Components In

With I26CV3

Top View- Components Out

With I26CV4

30-7/8”*

13

Top View Dimensions

I26CV Clean View and Surround Sizes

Clean View Kit I26CV1, I26CV3

Picture Frame Clean View Kit

I26CVPF1, I26CVPF3

Clean View Kit I26CV1, I26CV3 with

Rectangular Surround I26S1

Picture Frame Clean View Kit I26CVPF1, I26CVPF3,

with Picture Frame Surround I26SPF1

Clean View Kit I26CV2, I26CV4

Picture Frame Clean View Kit

I26CVPF2, I26CVPF4

Dimensions

are to

Inside Edge

of Clean

View.

Note: If a

completely tight

fit to the wall is

desired, CV

requires I26S1

or I26SPF1.

14

*The Clean Views and Surrounds in this section must be used with Valve Control Components inside the opening (as shipped).

*The Clean Views in this section can be used with Valve Control Components inside or outside the opening, HOWEVERif controls are outside, these Clean Views MUST be used to cover valve controls.

IDV26 I26SU Universal Surround

Components In Components Out

Picture Frame Clean View Kit I26CVPF1 or

I26CVPF3 With Universal Surround I26SU

Picture Frame Clean View Kit I26CVPF2 or

I26CVPF4 With Universal Surround I26SU

I26SU must be trimmed to fit around

Valve Control Components.

7”

Dimensions are to

Inside Edge of

Clean View.

15

A Universal Surround is available for the IDV26. This is provided as a flat sheet which mounts onto the unit and is to be

cut to size and formed by the installer. Flat Surround Shown dimensioned.

I26SU installed on unit.

Refer to Worksheet on next page to trim for use as a 3-sided surround or for a custom layout.

I26SU UNIVERSAL SURROUND

I26CVPF1 or I26CVPF3

I26CVPF2 or I26CVPF4

BOTTOM OF UNIT

16

I26CV - Surround Installation

-Clean View (CV) Attachment

-Valve Access

NOTE: The Clean View Surround needs to be removed in order to access the Glass Door, access the valve, and

service the unit.

Surround Mount Tab

Surround Mount Tab

Clean View Mount Tab

Clean View Mount Slot

Clean View Kit

Optional Surround

Insert Tab into

Slot to mount the

Clean View Kit.

17

1. Optional Surround Kit (I26S, I26SPF, I26SU) is fastened to the insert by pulling up [4] Surround Mount Tabs on the

unit and using [4] #6 screws provided with surround.

2. Insert the Clean View (I26CV1 or I26CV3, I26CV2 or I26CV4, I26CVPF1 or I26CVPF3, I26CVPF2 or I26CVPF3)

Mounting Tab into the Clean View Mounting Slots (four [4] places) and lower the Clean View kit into place.

3. Valve Access: To access valve simply remove Clean View. Replace Clean View as per item [2] above once

adjustments to valve have been completed.

Valve positioned as per manufacturer’s instructions.

I26S1 / I26SPF1 / I26SU Surround Installation

Bend Up All 4 Mount Tabs

Top Left

Top Right

Bottom Left

Bottom Right

Place Surround onto unit and

line up holes in mount tabs with

holes in Surround. Attach with

screws provided.

18

Component List: I26S1 / I26SPF1 / I26SU Surround, [Qty 4] #6 Black Combo Screws

I26CV2 / I26CV4 / I26CVPF2 / I26CVPF4 Wide Clean View Installation

Component List:

Fan Control Switch Bracket

On/Off Switch Bracket

Remove Fan Control Switch From Current Position.

Remove On/Off Switch and original mount bracket.

Attach Fan Control Switch Extension Bracket using [2] #6

Combo Screws as shown.

Attach On/ Off Switch Extension Bracket using [2] #6

Combo Screws as shown.

Mount Switch & route wiring as shown.

Mount Switch & route wiring as shown.

-Components Out-

Insert Mount Tabs into slots in unit and lower Clean View into place. Refer to Clean View Attachment.

1

1

2

2

3

3

19

I26CV2 / I26CV4 / I26CVPF2 / I26CVPF4 Clean View

On/ Off Switch Extension Bracket

Fan Control Switch Extension Bracket

[4] #6 Black Combo Screws

Components In (As Shipped):

Fan Control Switch Bracket

On/Off Switch Bracket

NOTE: If Ground is attached to Side Component Plate,

remove and fasten to side of appliance with a DT Screw.

Remove Fan Control Switch From Current Position.

Attach Fan Control Switch Extension Bracket using [2] #6

Combo Screws.

Mount Switch & route wiring as shown.

Remove On/Off Switch and original mount bracket.

Attach On/ Off Switch Extension Bracket using [2] #6

Combo Screws as shown.

Mount Switch & route wiring as shown.

Insert Mount Tabs into slots in unit and lower Clean View into place. Refer to Clean View Attachment.

Components Out

1

2

2

3

3

20

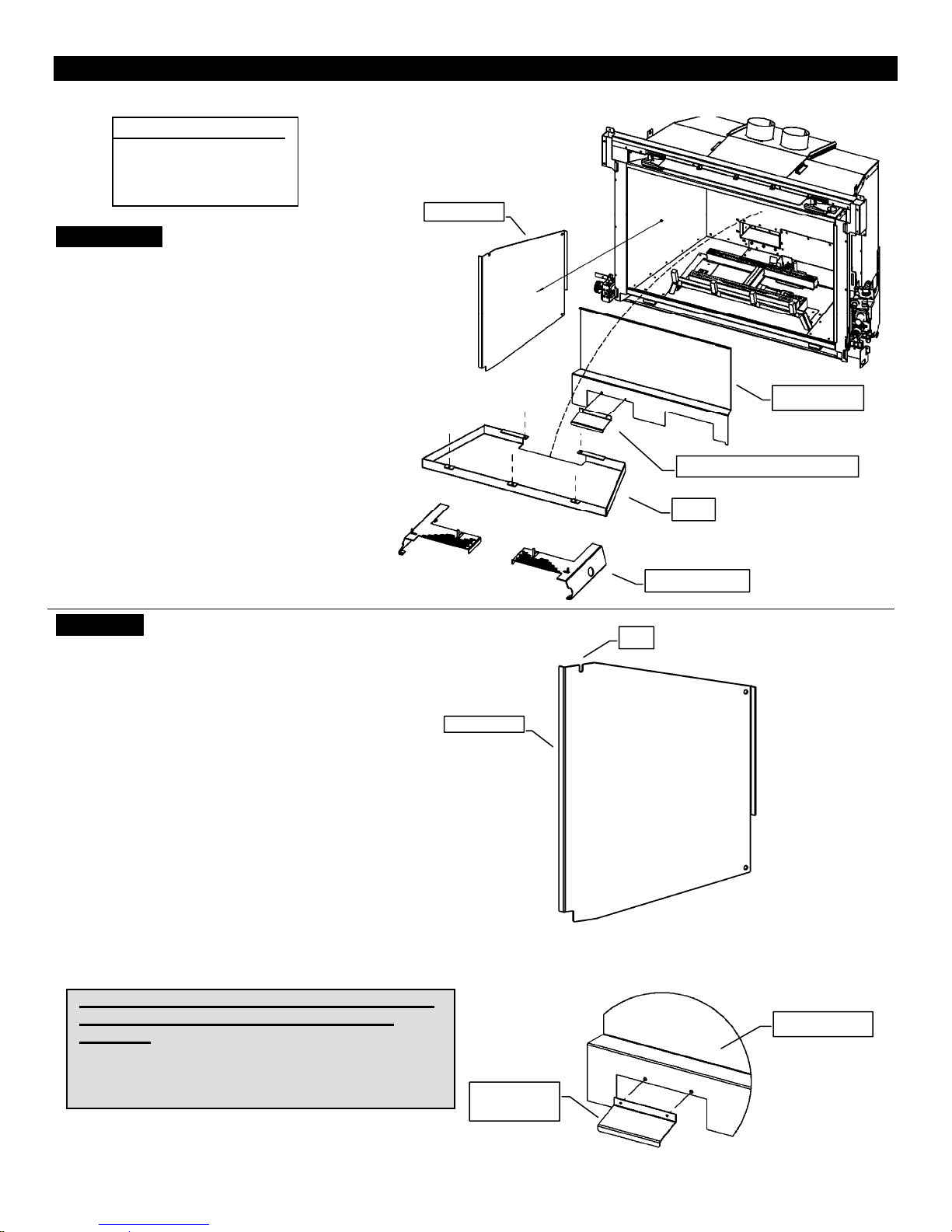

IDV26PRL - Porcelain Liner Panels-

21

IDV26PL Parts List:

-1 Back Panel

-1 Right Side Panel

To Remove:

-1Left Side Panel

1. Remove Log Supports. Remove

the [5] screws in the firebox top

holding the Baffle in place.

2. Remove Back Panel. Unscrew and

remove the Back Panel.

tilt to remove. NOTE: If you will be

installing a porcelain Back Liner,

unscrew Back Panel Air Deflector

and install on porcelain Back Liner.

3. Remove Side Panels (if present).

Remove screw. Tilt and slide Side

Panels out of fireplace.

Slide and

Side Panel

Back Panel

Back Panel Air Deflector

Baffle

To Install:

1. Install Side Panels. If you are using Side

Panels, install them first. Tilt and slide

Side Panels into place. Secure with screw

in side of firebox.

2. Install Back Panel. Ensure that Back

Panel Air Deflector is in place on Back

Panel (See Illustration). Place Back Panel

up against the back of the Firebox and

reinstall the [2] Screws in firebox top.

Then slide lower Liner Retainer Clip

(located on bottom of firebox behind

burner) up to bottom of Back Panel &

tighten.

3. Replace Baffle. Replace Baffle and

proceed with Log or Rock/Glass Tray

setup.

Note: Warping and Discoloration of Porcelain or

Painted Metal Liners Is Not Covered Under

Warranty.

Both Porcelain and Painted Metal Liners may discolor

and warp during normal operation of your appliance.

This is normal, and not considered a defect

.

Side Panel

Back Panel

Air Deflector

Log Supports

Top

Back Panel

IDV26RL - Brick Liner Panels-

22

IDV26RL Parts List:

-1 Back Panel

-1 Right Side Panel

-1Left Side Panel

To Install:

1. Remove the Baffle.

Remove the [5] screws in

the firebox top holding the

Baffle in place. Remove

the [2] Liner Retainer Clips

in the firebox top also.

2. Install Back Panel. Place

Back Panel on the rear

ledge inside the firebox.

3. Install Side Panels. Twist

and rotate Side Panels into

place. Secure with Liner

Retainer Clips in top of

firebox..

Liner Retainer Clip

Side Panel

Back Panel

4. Replace Baffle. Replace

Baffle and proceed with

Log or Rock/Glass Tray

setup.

Baffle

Side Panel

IDV26 -Millivolt- -Control Components Outside the Opening- -COMPONENTS OUT-

Remove [2] 3/8” nuts holding valve onto Component

Panel. Unhook valve from Component Panel.

Remove Component Panel, Switch Bracket, and Side Plate.

Remove knockout with side cutters, if present.

Discard knockout.

Optional- Connect flex (Not included. Order PN#

FP15GC) to inlet side of valve. This can then be

connected to the gas supply and routed through the

channel inside the fireplace.

Route valve connections through the opening.

Mount Component Panel on opposite side of valve.

NOTE: It is not necessary to disconnect pilot lines and gas supply line from valve to complete this procedure. Care

should be taken to ensure that the gas and pilot lines are not damaged during handling. These lines are fragile.

Warning: Failure to position the parts in accordance with these diagrams or failure to use only parts specifically

approved with this appliance may result in property damage or personal injury.

Route Through Opening

Remove Knockout

Remove Nuts

Unhook Tab

Unscrew Component Panel

[1] Screw

Remove Side Plate

[4] Screws

Switch Bracket

[2] Screws

Hook Tab

Refasten Nuts

1.

2.

3.

4.

5.

6.

Route Through Opening

(Optional)

23

This procedure must be done Before the unit is inside the enclosure.

Fasten Component Panel at top.

Replace Side Plate. Attach

Component Panel and

Extended Switch Bracket.

Procedure is complete.

IDV26 -IPI- -Control Components Outside the Opening- -COMPONENTS OUT-

Ready to begin.

Remove All Components from Component Panel.

Remove Component Panel from fireplace.

Remove Side Plate and knockout if present (see millivolt

section). Place Component Panel on other side of valve.

Optional- Connect flex (Not included. Order PN#

FP15GC) to inlet side of valve. This can then be connected

to the gas supply and routed through the channel inside the

fireplace. (see millivolt section).

Fasten Component Panel

[2] Screws

Replace Side

Plate

Extended Switch Bracket

Attach Component

Panel

Component Panel

Component Panel

IPI Module

7.

8.

9.

1.

2.

3.

4.

Side Plate

NOTE: Some

screws may need to

be cut flush to the

component mount

plates for a tight fit

against wall.

24

*Refer to Millivolt section for more detailed photos & instructions.

Replace Side Plate. Fasten Component Panel at top &

bottom. Attach Component Panel and Extended Switch

Bracket (see millivolt section).

Procedure is complete.

MILLIVOLT- COMPONENTS OUT

IPI- COMPONENTS OUT

5.

6.

Fasten to Component

Panel with Zip Tie.

NOTE: Some screws may need to be cut flush to

the component mount plates for a tight fit against

wall.

25

IDV26 Fan Speed Control Outside COMPONENTS OUT

Left Side of Fireplace

Connect Fan Switch to Extension Bracket.

Install Component Panel and Fan Switch Extension in new

position.

Remote Receiver Location.

Warning: Failure to position the parts in accordance with these diagrams or failure to use only parts specifically

approved with this appliance may result in property damage or personal injury.

Remove Component Panel

[1] DT Screw

Remove Fan Switch

1.

2.

3.

Install Fan Switch

Extension Bracket

[3] Screws

Replace Component Panel in New

Position [2 Screws]

4.

26

NOTE: It is not necessary to disconnect fan wiring to complete this procedure.

This procedure must be done before the unit is inside the enclosure.

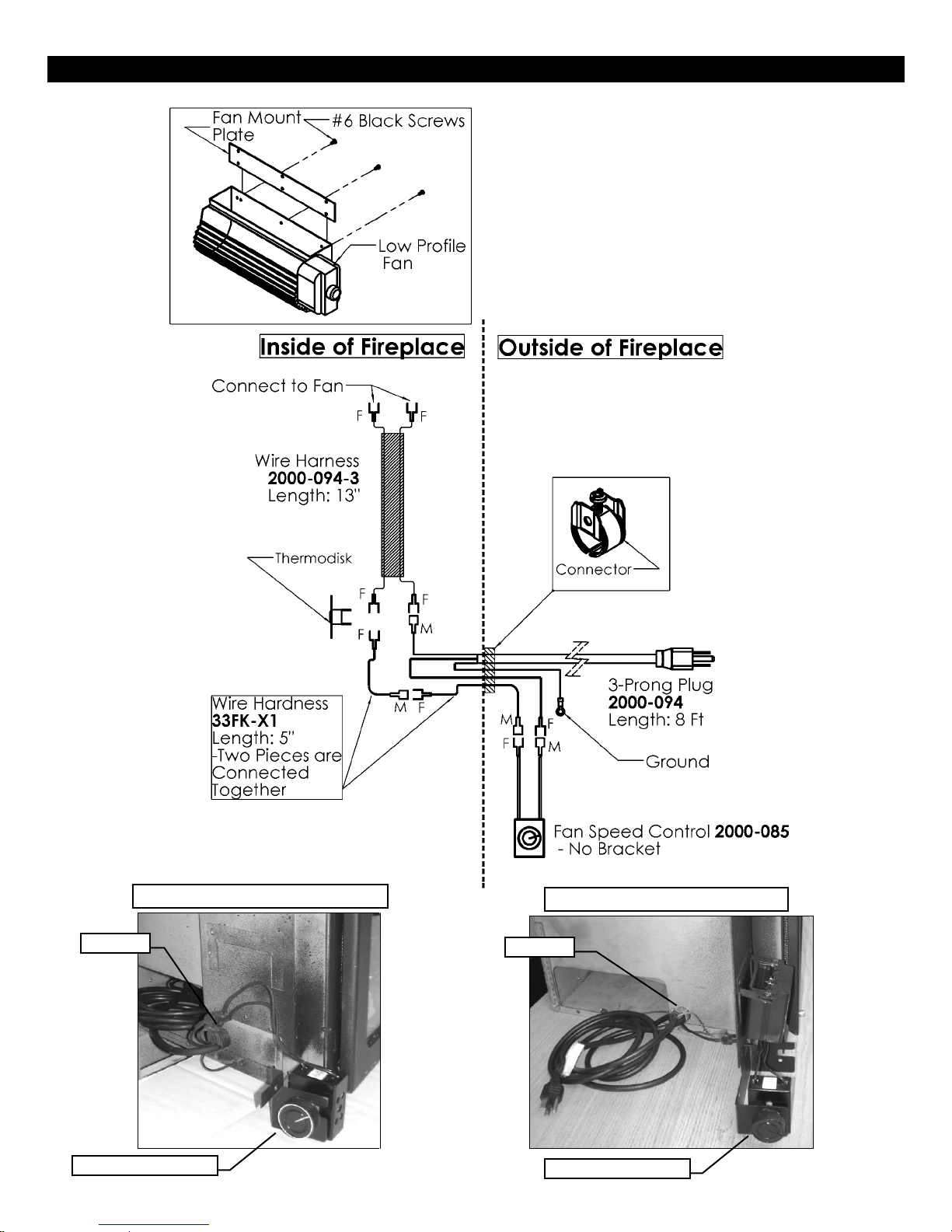

IDV26 Fan Removal / Installation

1. Remove Grate Bar Assembly, Burner Trim

Plates, and Burner. Then remove the [5]

screws in the firebox top holding the Baffle

in place. Remove the Baffle. Then

unscrew and remove the Back Panel.

2. Remove Fan Access Cover (15 screws). It

is located on the back and bottom right

hand corner. The fan area will now be

exposed (See photo below).

3. Unscrew the [2] screws and remove fan.

Fan needs to be twisted and rotated

slightly. (See photo below).

4. Replace all components and seal Fan

Access Cover and Thermodisk Plate with

Millpac.

5. Verify proper operation after servicing.

WARNING

Electrical Grounding Instructions

This appliance is equipped with a three prong (grounding) plug for your protection against shock hazard and should be plugged directly

into a properly grounded three-prong receptacle. Do not cut or remove the grounding prong from this.

Before Servicing

1. Ensure all power supply is shut off.

2. Label all wires prior to disconnecting when servicing control. Wiring errors can cause improper and dangerous operation.

3. For fan servicing: Vacuum and clean lint/dirt build-up on the fan blades and motor.

When resealing the Fan Access Panel, use High Temp Silicone or Millpac.

Fan Access Cover

Back Panel

Baffle

Burner

Burner Trim Plates

Variable Speed Switch

Grate Bar Assembly

Thermodisk Location

Remove [2] Screws

Thermodisk Location

Twist and Rotate

#6 Black Screws.

27

The fan can be accessed from the back of the unit (which is easiest on an uninstalled unit) or through the inside

of the firebox.

To remove or install the fan from the back of the unit, remove the

Fan Access Cover from the back of the fireplace. The fan will be attached

to this cover (See right).

Thermodisk Location: Note the location of the Thermodisk in the

photograph below.

Variable Speed Switch Location: Note the location of the Variable

Speed Switch in the illustration below.

To remove or install the fan through the inside of the firebox, refer

to the procedure below.

IDV26 Fan - Wiring IDV26

Components In –Left Side of Unit

Components Out- Left Side of Unit

Variable Speed Switch

Variable Speed Switch

Connector

Connector

28

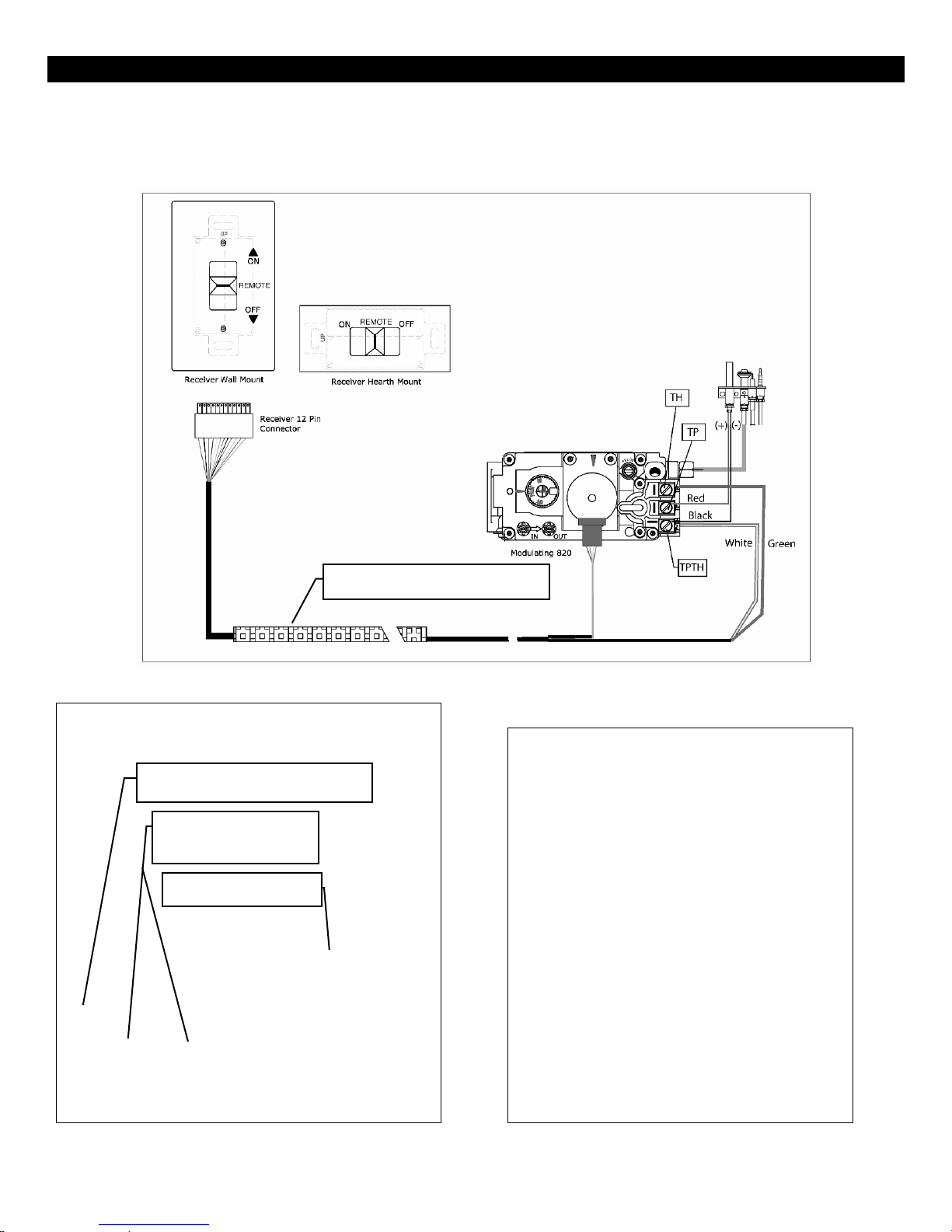

IDV26 Remote Receiver Location All Units

Route Wiring Harness 1001-P904SI

Under Fan Inside Fireplace.

Route Wiring Harness 1001-P904SI

Under Fan Inside Fireplace.

Restrain Harness With [2]

Zip Ties Through Holes

Provided in Fireplace.

Pull up Mount Tabs &

Mount Remote Receiver

29

Connecting to the Gas Valve

The wiring harness for the Proflame GTM system has two wires labeled “TH” & “TPTH”. Connect the wires to the gas

valve as labeled. (TH to TH and TPTH to TPTH). Additionally there is a connector labeled “Motor”. Connect this “Motor”

connector to the stepper motor on the gas valve (if present).

Left Side of Fireplace

Components In (As Shipped) Components Out Remote Receiver Location.

Loading...

Loading...