Kingsman GLMVF40MVN, VFBL4040MVN, MVFBL4040MVP, MVFBR4040MVN, GLMVF40MVP Owner's Operation And Installation Manual

...Page 1

1

Owner’s Operation and Installation Manual

MVF40 certified as a Universal Firebox ANSI Z21.91-2007

Listed Certified for USA

UNVENTED (VENT-FREE) MULTI-SIDED FIREBOX

Enclosure For Gas-Fired Decorative Type Unvented Room Heaters

Vent Free: GLMVF40MVN, GLMVF40MVP

MVFBL4040MVN, MVFBL4040MVP, MVFBR4040MVN, MVFBR4040MVP

Vent-free: Certified to USA standards: ANSI Z21.11.2 - 2007

Warning

If the information in this manual is not followed

exactly, a fire or explosion my result causing property

damage, personal injury, or loss of life.

– Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

– WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

– Installation and service must be performed by a qualified

installer, service agency, or the gas supplier.

Warning

Improper installation, adjustment,

alteration, service, or maintenance

can cause injury or property

damage. Refer to this manual for

correct installation and operational

procedures. For assistance or

additional information consult a

qualified installer, service agency, or

the gas supplier.

Warning

This is an unvented gas-fired heater.

It uses air (oxygen) from the room in

which it is installed. Provisions for

adequate combustion and ventilation

air must be provided. Refer to section

Save this manual for future reference • 2340 Logan Ave., Winnipeg, MB, Canada, Phone: (204) 632-1962 • Printed in Canada • PART #40VF-MAN

July 27, 2009

Warning

Carefully review the instructions

supplied with the decorative type

unvented log set room heater for the

minimum size requirement.

DO NOT INSTALL THE APPLIANCE

IN THIS FIREBOX UNLESS THIS

FIREBOX MEETS THE MINIMUM

DIMENSIONS REQUIRED FOR THE

INSTALLATION

Warning

FOR USE ONLY WITH

A LISTED GAS-FIRED UNVENTED

DECORATIVE ROOM HEATER

NOT TO EXCEED

40,000 BTU/H.

DO NOT BUILD A WOOD FIRE

This appliance must be

installed by a licensed

plumber or gas fitter in

the Commonwealth of

Massachusetts and meet

the requirements of 527

CMR 30 and 248 CMR.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

Page 2

2

Page 3

3

Why does my fireplace or stove give off odour?

It is normal for your fireplace to give off some odour. This is due to the curing of the paint, adhesives,

silicones and any undetected oil from the manufacturing process as well as the finishing materials used

with the installations (e.g. marble, tile and the adhesives used to adhere this product to the walls can react

with heat and cause odours).

It is recommended that you burn your gas fireplace or stove for a minimum of four hours at a time with

the fan off after the curing of the paint has been completed. These odours can last upward to 40 hours of

burn time, keep burning at a minimum of four hours per use until odours dissipate.

About curing of the paint

Your stove or fireplace has been painted with the highest quality silicone stove paint. This paint dries

quickly in 15-20 minutes when first applied at the factory. However, due to the high temperature silicone

components, the paint will cure when heat is applied to the appliance as it is first used.

The following information applies to the curing process to get the paint fully hard and durable.

Fire the appliance four successive times for 10 minutes each firing and a 5 minute cool down between

each. Be aware during log and firebox paint curing that a white deposit may be developing on the inside

of the glass doors. It is important to remove this white deposit from the glass doors with an appropriate

cleaner to prevent build-up (such as Windex or a commercial fireplace glass cleaner).

• Babies, small children, pregnant women and pets should leave the area during the cure phase.

• Ventilate well, open doors and windows.

• Do not touch during curing.

Noise coming from the fireplace?

• Noise caused by metal expanding and contracting as it heats up and cools down, similar to the sound

produced by a furnace or heating duct. This noise does not affect the operation or longevity of your

fireplace.

• Different types and thicknesses of steel will expand and contract at different rates resulting in

“cracking” and “ticking” sounds throughout the heating and cooling periods.

• You should also be aware that as temperatures change within the unit these sounds will likely reoccur. Again this is normal for steel fireboxes, and is not a defect.

Cleaning the Glass

During the first few fires, a white film may develop on the glass front, as part of the curing process. The

glass should be cleaned after the unit has cooled down or the film can bake on and become very difficult

to remove. Use a non-abrasive cleaner and do not attempt to clean the glass while it is hot.

PRE-INSTALLATION QUESTIONS and ANSWERS

Page 4

4

TABLE OF CONTENTS

SECTION PAGE

Burner System Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Local Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

For Your Safety Read Before Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Framing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Framing Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-10

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installing by Framing Fireplace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Peninsula Framing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

See-Through Framing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Bay Peninsula Framing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Corner Framing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Universal Firebox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Air for Combustion and Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Providing Adequate Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Determining Air Flow for Firebox Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Ventilation Air from Inside Building . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Ventilation Air from Outdoors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Installing Gas Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Installing MVFB 4040 Burner System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Cleaning and Servicing of Burner /ODS Pilot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Installing MVFB4040 Burner System & LOGF38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

LOGF38 Log Placement for MVFB4040 Burner System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28-29

Installing GLMVF40 Burner System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

LOGC31 Log Placement for GLMVF40 Burner Grate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31-32

Millivolt System, Lighting Instructions & Burner Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Installing Fan Kit, Screen Door, Shield + Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34-35

Illustrated Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36-38

Accessory and Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39-40

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41-42

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Page 5

5

BURNER SYSTEM OPTIONS

See chart below for required burner system:

TABLE 1 - The MVF40 is also approved as a Universal Vent Free Box. See page 20 for more information.

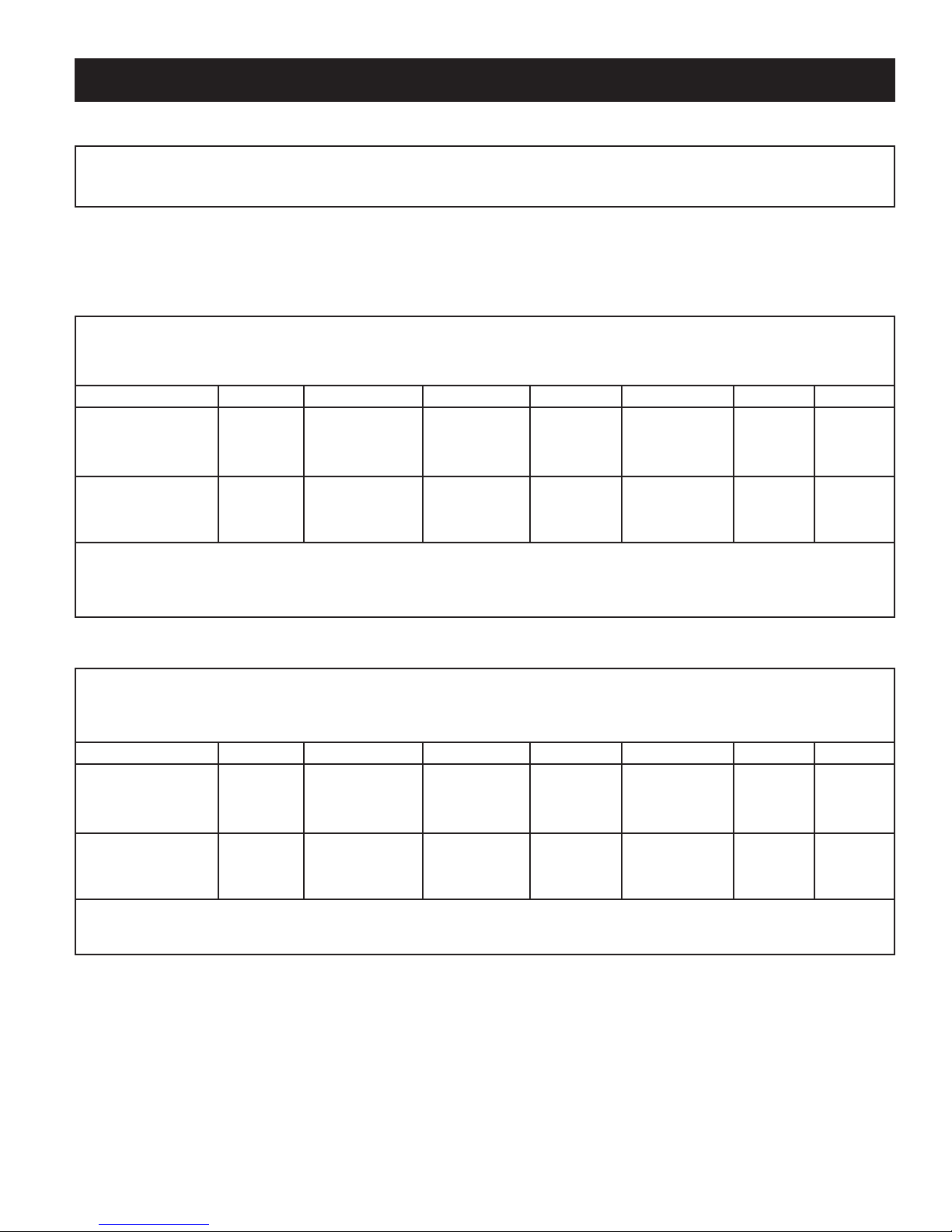

MVF40 Vent Free Firebox Required burner system: (Select from below to complete the fireplace)

OPTION 2

MVFBL/R 40 Burner Systems - control are hidden and accessed through bottom grill.

LOGF38 Log Set Fibre Five Piece - Required for MVFBL/R 4040 Burner Systems

Burner Model Valve Type Fuel Type BTU – Input Min/Max Inlet Manifold Pressure Orifice Size Primary Air

Left Hand Burner

MVFBL4040MVN Millivolt Natural Gas 26,000-38,000 5.5/10” 1.6-3.5” 32 0.25

MVFBL4040MVP Millivolt Liquid Propane 26,000-34,000 11/13” 6.3-10” 50 Full Open

Right Hand Burner

MVFBR4040MVN Millivolt Natural Gas 26,000-38,000 5.5/10” 1.6-3.5” 32 0.25

MVFBR4040MVP Millivolt Liquid Propane 26,000-34,000 11/13” 6.3-10” 50 Full Open

OPTION 1

GLMVF40 Log Grate Burner System - controls are accessed from firebox on raised grate. Pull screen are recommended.

LOGC31 Log Set 7 Piece required for GLMVF40 Burner Systems.

Burner Model Valve Type Fuel Type BTU – Input Min/Max Inlet Manifold Pressure Orifice Size Primary Air

GLMVF40MVN Millivolt Natural Gas 29,900-38,225 5.5/10” 1.6-3.5” 32 1/8” Open

GLMVF40MVP Millivolt Liquid Propane 24,200-30,500 11/13” 6.3-10” 49 1/2” Open

This appliance is equipped for (Natural or Propane) Gas.

Field conversion is not permitted.

Page 6

SAFETY INFORMATION WARNINGS

6

WARNINGS

Important: Read this owner’s manual carefully and completely

before trying to assemble, operate, or service this firebox.

Improper use of this firebox can cause serious injury or death

from burns, fire, explosion, electrical shock, and carbon monoxide

poisoning.

Early signs of carbon monoxide poisoning resemble the

flu, with headaches, dizziness, and / or nausea. If you have these

signs, the heater may not be working properly. Get fresh air at

once! Turn off gas appliance. Have appliance serviced. Some

people (such as pregnant women, persons with heart or lung

disease, persons with anemia and those at high altitudes) are more

affected by carbon monoxide than others. Make certain you read

and understand all warnings.

1. Use correct gas type for your appliance. Do not convert from

one gas type to another.

2. If this appliance is for use with Propane gas, do not place

propane supply tank(s) inside any structure. Locate propane

supply tank(s) outdoors.

3. If you smell gas:

– Shut off gas supply.

– Do not try to light any appliance.

– Do not touch any electrical switch; do not use any phone in

your building.

– Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

– If you cannot reach your gas supplier, call the fire

department.

4. Do not use this appliance for burning trash or cooking. Never

place matches, paper, garbage, or any other material on top

of logs or logs into flame.

5. Warning: Always operate appliance with front fireplace

screens closed.

6. Make sure any safety screen or guard removed for servicing

is in place before running appliance.

7. Never run appliance in a small, closed room. Open the door

into next room to help ventilate.

8. If appliance shuts off, do not relight until you provide fresh

outside air. If appliance keeps shutting off, have it serviced.

9. Do not run appliance:

– where flammable liquids or vapors are used or stored.

– under dusty conditions.

10. Surface of appliance becomes very hot when operating. Keep

children and adults away from hot surface. Appliance will

remain hot for some time after shutdown. Allow surface to

cool before touching.

11. Do not use this appliance if any part has been submerged

under water. Immediately call a qualified technician to

inspect the appliance and to replace any part of the control

system and gas control which has been under water.

12. The installation must conform with local codes or, in the absence

of local codes, with the National Fuel Gas Code, ANSI Z223.1.

13. Never install the appliance:

– in a bedroom, bathroom, mobile home, or recreational

vehicle.

– where curtains, furniture, clothing, or other flammable

objects are less than forty-two inches (42”) from the front

of the appliance.

– in high traffic areas.

– in windy or drafty areas.

14. Disconnect the appliance and its individual shut off valve

from the gas supply piping system during any pressure

testing of that system at test pressures in excess of 1/2 psig,

(3.5kPa).

15. Isolate the appliance from the gas supply piping system by

closing its individual manual shut off valve during any

pressure testing of the the gas supply piping system at test

pressure equal or less than 1/2 psig,(3.5kPa).

16. Do not use any type of after-market blower that fits inside the

fireplace. Drafts created by these type of blowers may cause

sooting.

17. Turn off appliance and let cool before servicing. Only a

qualified service person should install, service and repair

appliance

DANGER

CARBON MONOXIDE POISONING

MAY LEAD TO DEATH!

NOTE: It is recommended that a Carbon Monoxide (CO)

Detector be installed in or near bedrooms and on all levels of

your home. Place a detector about 15 feet (4.5 meters) outside

the room that houses your gas appliance.

This appliance is equipped for

(Natural or Propane) Gas.

Field conversion is not permitted.

Warning: Failure to position parts in accordance

with these diagrams or failure to use only part

specifically approved with this heater may result in

property damages or personal injury.

Page 7

7

WARNING

If you do not follow these instructions exactly, a fire or

explosion may result causing property damage,

personal injury or loss of life.

18. Inspect the appliance before use and at least annually by a professional service person. Frequent cleaning may be required due to

excessive lint from carpeting, bedding material, etc. It is important that control compartment, burner and circulating air passage of

the appliance be kept open.

19. When operated for the first time, there will be some smell from the appliance. This will diminish and disappear after a few hours of

operation.

20. Warning: Do not allow fans to blow directly into the fireplace. Avoid any drafts that alter flame patterns.

21. Warning: Do not use a blower insert, heat exchanger insert or other accessory not approved for use with this heater.

22. The firebox canopy must not be replaced with a canopy which may be provided with the decorative type UNVENTED room heater.

23. Warning: Do not operate ceiling fans in same room as the vent free appliance.

24. Due to high temperatures, the appliance should be located out of traffic and away from furniture and draperies.

25. Children and adults should be alerted to the hazard of high surface temperature and should stay away to avoid burns or clothing

ignition.

26. Young children should be carefully supervised when they are in the same room with the appliance.

27. Do not place clothing or other flammable material on or near the appliance.

28. Any safety screen or guard removed for servicing an appliance must be replaced prior to operating the heater (see 1.2.3).

29. Installation and repair should be done by a qualified service person. The appliance should be inspected before use and at least

annually by a professional service person. More frequent cleaning may be required due to excessive lint form carpeting, bedding

material, etc. It is imperative that control compartments, burners and circulating air passageways of the appliance be kept clean.

30. “Warning: Any change to this heater or its controls can be dangerous.”

31. Must be installed by a licensed gasfitter in the Commonwealth of Massachusetts. Complies to code 527 CMR

32. Unvented gas fired appliances may be used only for supplemental heat and/or decorative purposes and under no

circumstances shall they provide a primary heat source.

33.

Warning: Failure to keep the primary air opening(s) of the burner(s) clean may result in sooting and property damage.

LOCAL CODES

Install and use fireplace with care. Follow all local codes.

In the absence of local codes, use the latest edition of

The National Fuel Gas Code ANSI Z223.1, also known as

NFPA 54*. Firebox must be electrically grounded in

accordance with the National Electrical Code,

ANSI/NFPA 70 (latest edition).

*Available from:

American National Standards Institute, Inc. National Fire Protection Association, Inc.

1430 Broadway Batterymarch Park

New York, NY 10018 Quincy, MA 02260

FOR YOUR SAFETY READ BEFORE LIGHTING

A. This appliance has a pilot which must be lighted by hand. When lighting the pilot, follow these instructions exactly.

B. Before lighting, smell all around the appliance area for gas. Be sure to smell next to the floor because some gas is

heavier than air and will settle on the floor.

What to do if you smell gas

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

C. Use only your hand to push in or turn the gas control knob. Never use tools. If the knob will not push in or turn by hand,

don’t try to repair it, call a qualified service technician or gas supplier. Force or attempted repair may result in a fire or

explosion.

D. Do not use this appliance if any part has been under water. Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and any gas control which has been under water.

Page 8

8

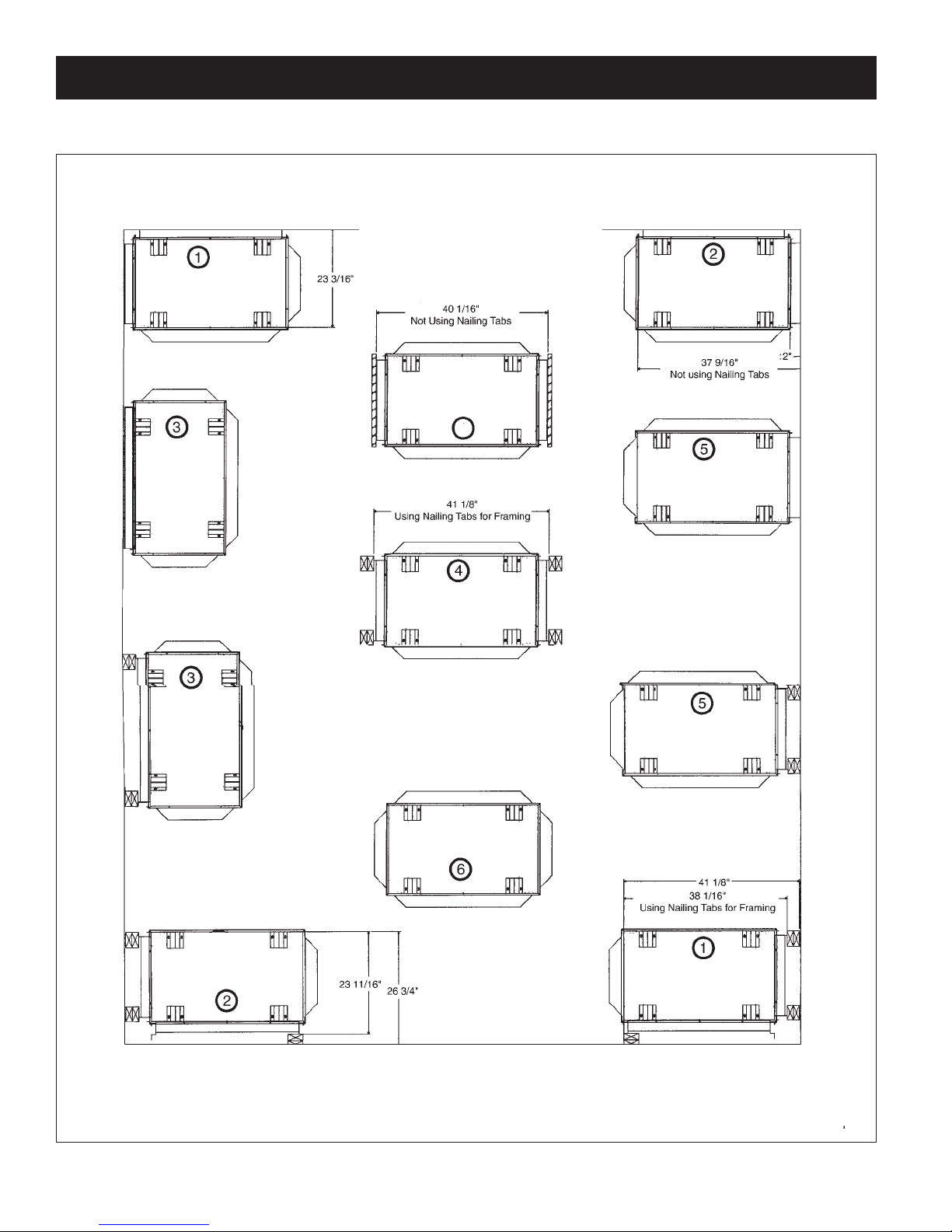

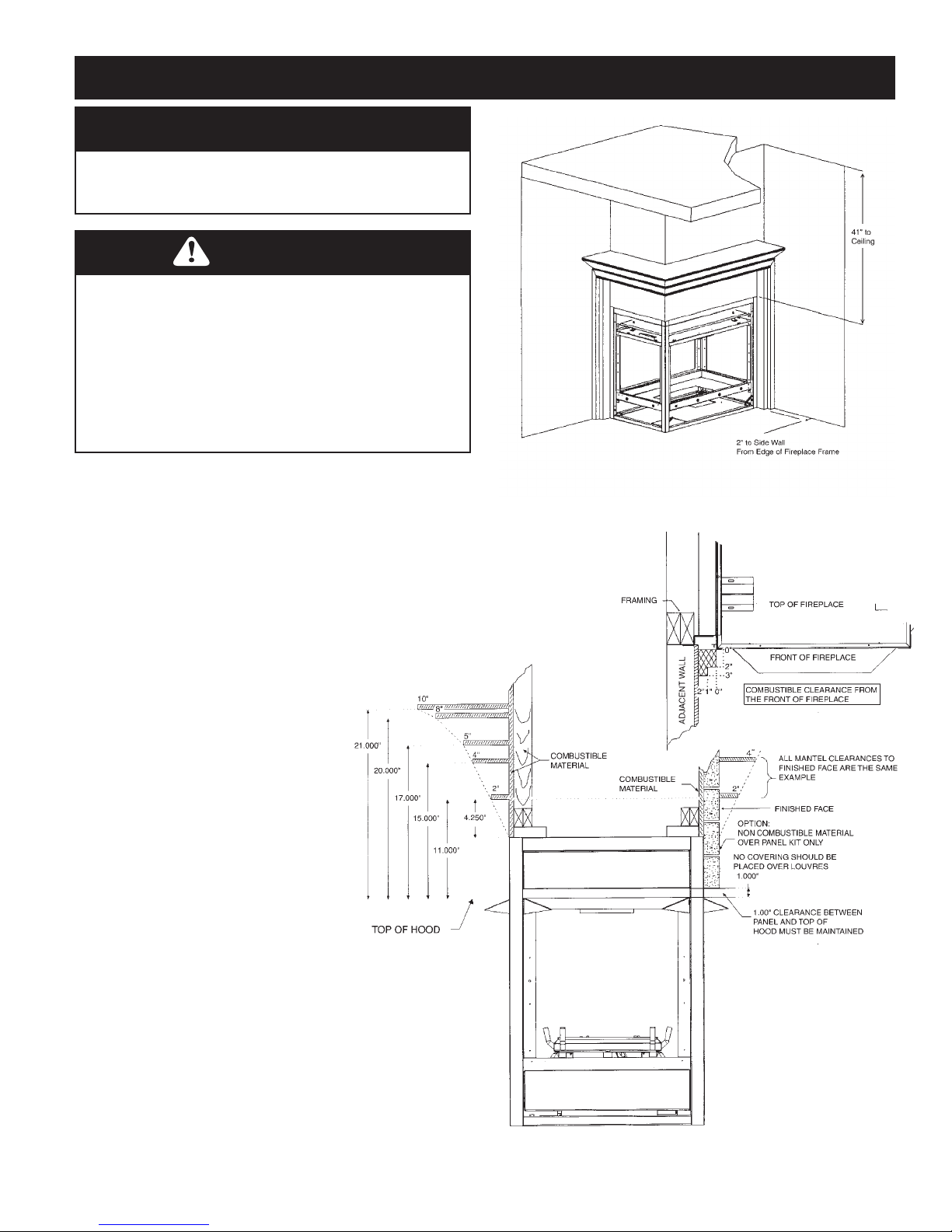

FRAMING SPECIFICATIONS

See Page 9 for required parts for installation.

FIGURE 1

Framing Clearances to Fireplace:

Bottom – 0 / Sides – 0 to standoffs / Top – 0 to standoffs / Adjacent side wall – 2” / Front of fireplace to ceiling – 41”.

Right Corner Top View

Without 2 x 4 Framing

Left Corner Top View

using 2 x 4 Framing

See Thru top View

Without 2 x 4 Framing

See Thru Top View using

2 x 4 Framing

Island Top View

PLACEMENT AND FRAMING

Note: When not using nailing tabs

you may place Heatshield directly

against existing wall and screw

unit to the floor using holes located

in the bottom of unit

Bay Peninsula

without

2 x 4 Framing

Bay Peninsula

Using 2 x 4

Framing

Right Corner Top View

Using 2 x 4 Framing

Peninsula Top View

Using 2 x 4 Framing

Peninsula Top View

Without 2 x 4 Framing

Left Corner Top View

Without 2 x 4 Framing

4

Page 9

9

FRAMING PARTS

REQUIRED PARTS FOR INSTALLATIONS OF MULTI-SIDED FIREPLACE

MVF40 Multi-Sided Vent Free Firebox

Choose Your installation (as shown on Page 8, and see below for required parts.)

1. RIGHT CORNER INSTALLATION

MVF40CK Corner Kit - One Large Side Open, One Small Side Open

Choose Natural Gas or Liquid Propane Burner:

Choose Grill Kits or Panel Kits:

MGCKBP Grill Kit Corner - Classic Polish Brass (Two Sets)

MGCKBA Grill Kit Corner - Classic Antique Brass (Two Sets)

MGCKBC Grill Kit Corner - Classic Chrome (Two Sets)

MGCKBL Grill Kit Corner - Black (Two Sets)

MGCKPB Grill Kit Corner - Polish Brass (Two Sets)

MGCKAB Grill Kit Corner - Antique Brass (Two Sets)

MGCKCR Grill Kit Corner - Chrome (Two Sets)

MVF40PCK Panel Kit for Corner Kit - Black (Two Sets)

2. LEFT CORNER INSTALLATION

MVF40CK Corner Kit - One Large Side Open, One Small Side Open

Choose Natural Gas or Liquid Propane Burner:

Choose Grill Kits or Panel Kits:

MGCKBP Grill Kit Corner - Classic Polish Brass (Two Sets)

MGCKBA Grill Kit Corner - Classic Antique Brass (Two Sets)

MGCKBC Grill Kit Corner - Classic Chrome (Two Sets)

MGCKBL Grill Kit Corner - Black (Two Sets)

MGCKPB Grill Kit Corner - Polish Brass (Two Sets)

MGCKAB Grill Kit Corner - Antique Brass (Two Sets)

MGCKCR Grill Kit Corner - Chrome (Two Sets)

MVF40PCK Panel Kit for Corner Kit - Black (Two Sets)

BURNER SYSTEM & LOG SET (REQUIRED FOR MVF40 FIREBOX)

OPTION 1

GLMVF40MVN Vent Free Multiview Burner System – Millivolt Valve 38,000 BTU/HR Natural Gas

GLMVF40MVP Vent Free Multiview Burner System – Millivolt Valve 35,000 BTU/HR Liquid Propane

LOGC31 Log Set LOGC31 required for GLMVF40 Burner System

OPTION 2

MVFBL4040MVN Vent Free Left Burner System – Millivolt Valve 38,000 BTU/HR Natural Gas

MVFBL4040MVP Vent Free Left Burner System – Millivolt Valve 35,000 BTU/HR Liquid Propane

LOGF38 Log Set required for MVFB40 R/L Burner System

This appliance is equipped for (Natural or Propane) Gas.

Field conversion is not permitted.

BURNER SYSTEM & LOG SET (REQUIRED FOR MVF40 FIREBOX)

OPTION 1

GLMVF40MVN Vent Free Multiview Burner System – Millivolt Valve 38,000 BTU/HR Natural Gas

GLMVF40MVP Vent Free Multiview Burner System – Millivolt Valve 35,000 BTU/HR Liquid Propane

LOGC31 Log Set LOGC31 required for GLMVF40 Burner System

OPTION 2

MVFBR4040MVN Vent Free Right Burner System – Millivolt Valve 25,900/38,225 Natural Gas

MVFBR4040MVP Vent Free Right Burner System – Millivolt Valve 24,200/30,500 Liquid Propane

LOGF38 Log Set required for MVFB40 R/L Burner System

Page 10

10

FRAMING PARTS (continued)

3. BAY PENINSULA INSTALLATION

MVF40BK Bay Peninsula Kit - One Large Side Open, Two Small Sides Open

Choose Natural Gas or Liquid Propane Burner:

Choose Grill Kits or Panel Kits:

MGBKBP Grill Kit Bay Peninsula - Classic Polish Brass (Three Sets)

MGBKBA Grill Kit Bay Peninsula - Classic Antique Brass (Three Sets)

MGBKBC Grill Kit Bay Peninsula - Classic Chrome (Three Sets)

MGBKBL Grill Kit Bay Peninsula - Black (Three Sets)

MGBKPB Grill Kit Bay Peninsula - Polish Brass (Three Sets)

MGBKAB Grill Kit Bay Peninsula - Antique Brass (Three Sets)

MGBKCR Grill Kit Bay Peninsula - Chrome (Three Sets)

MVF40PBK Panel Kit Bay Peninsula Kit - Black (Three Sets)

4. SEE-THROUGH INSTALLATION

MVF40SK See Through Kit - Two Large Sides Open

Choose Natural Gas or Liquid Propane Burner:

Choose Grill Kits or Panel Kits:

MGSKBP Grill Kit See-Through - Classic Polish Brass (Two Sets)

MGSKBA Grill Kit See-Through - Classic Antique Brass (Two Sets)

MGSKBC Grill Kit See-Through - Classic Chrome (Two Sets)

MGSKBL Grill Kit See-Through - Black (Two Sets)

MGSKPB Grill Kit See-Through - Polish Brass (Two Sets)

MGSKAB Grill Kit See-Through - Antique Brass (Two Sets)

MGSKCR Grill Kit See-Through - Chrome (Two Sets)

MVF40PSK Panel Kit See-Through - Black (Two Sets)

BURNER SYSTEM & LOG SET (REQUIRED FOR MVF40 FIREBOX)

OPTION 1

GLMVF40MVN Vent Free Multiview Burner System – Millivolt Valve 38,000 BTU/HR Natural Gas

GLMVF40MVP Vent Free Multiview Burner System – Millivolt Valve 35,000 BTU/HR Liquid Propane

LOGC31 Log Set LOGC31 required for GLMVF40 Burner System

OPTION 2

MVFBR4040MVN Vent Free Right Burner System – Millivolt Valve 25,900/38,225 Natural Gas

MVFBR4040MVP Vent Free Right Burner System – Millivolt Valve 24,200/30,500 Liquid Propane

MVFBL4040MVN Vent Free Left Burner System – Millivolt Valve 38,000 BTU/HR Natural Gas

MVFBL4040MVP Vent Free Left Burner System – Millivolt Valve 35,000 BTU/HR Liquid Propane

LOGF38 Log Set required for MVFB40 R/L Burner System

BURNER SYSTEM & LOG SET (REQUIRED FOR MVF40 FIREBOX)

OPTION 1

GLMVF40MVN Vent Free Multiview Burner System – Millivolt Valve 38,000 BTU/HR Natural Gas

GLMVF40MVP Vent Free Multiview Burner System – Millivolt Valve 35,000 BTU/HR Liquid Propane

LOGC31 Log Set LOGC31 required for GLMVF40 Burner System

OPTION 2

MVFBR4040MVN Vent Free Right Burner System – Millivolt Valve 25,900/38,225 Natural Gas

MVFBR4040MVP Vent Free Right Burner System – Millivolt Valve 24,200/30,500 Liquid Propane

MVFBL4040MVN Vent Free Left Burner System – Millivolt Valve 38,000 BTU/HR Natural Gas

MVFBL4040MVP Vent Free Left Burner System – Millivolt Valve 35,000 BTU/HR Liquid Propane

LOGF38 Log Set required for MVFB40 R/L Burner System

Page 11

11

5. PENINSULA INSTALLATION

MVF40PK Peninsula Kit - Two Large Sides Open, One Small Side Open

Choose Natural Gas or Liquid Propane Burner:

Choose Grill Kits or Panel Kits:

MGPKBP Grill Kit Peninsula - Classic Polish Brass (Three Sets)

MGPKBA Grill Kit Peninsula - Classic Antique Brass (Three Sets)

MGPKBC Grill Kit Peninsula - Classic Chrome (Three Sets)

MGPKBL Grill Kit Peninsula - Black (Three Sets)

MGPKPB Grill Kit Peninsula - Polish Brass (Three Sets)

MGPKAB Grill Kit Peninsula - Antique Brass (Three Sets)

MGPKCR Grill Kit Peninsula - Chrome (Three Sets)

MVF40PPK Panel Kit Peninsula - Black (Three Sets)

6. ISLAND INSTALLATION

MVF40IK Island Kit - Four Sides Open

Choose Natural Gas or Liquid Propane Burner:

Choose Grill Kits or Panel Kits:

MGIKBP Grill Kit Island - Classic Polish Brass (Four Sets)

MGIKBA Grill Kit Island - Classic Antique Brass (Four Sets)

MGIKBC Grill Kit Island - Classic Chrome (Four Sets)

MGIKBL Grill Kit Island - Black (Four Sets)

MGIKPB Grill Kit Island - Polish Brass (Four Sets)

MGIKAB Grill Kit Island - Antique Brass (Four Sets)

MGIKCR Grill Kit Island - Chrome (Four Sets)

MVF40PIK Panel Kit Island Kit - Black (Four Sets)

Required For all Burners

LOGF38 Log Set - Five Piece Fibre Split Oak - For MVFB40 Burners

LOGC31 Log Set - Seven Piece - For GLMVF40 Burners

*Note that we suggest Left Burner as your first choice, you can choose a Right Burner if a (*) is notated beside part number

FRAMING PARTS (continued)

BURNER SYSTEM & LOG SET (REQUIRED FOR MVF40 FIREBOX)

OPTION 1

GLMVF40MVN Vent Free Multiview Burner System – Millivolt Valve 38,000 BTU/HR Natural Gas

GLMVF40MVP Vent Free Multiview Burner System – Millivolt Valve 35,000 BTU/HR Liquid Propane

LOGC31 Log Set LOGC31 required for GLMVF40 Burner System

OPTION 2

MVFBR4040MVN Vent Free Right Burner System – Millivolt Valve 25,900/38,225 Natural Gas

MVFBR4040MVP Vent Free Right Burner System – Millivolt Valve 24,200/30,500 Liquid Propane

MVFBL4040MVN Vent Free Left Burner System – Millivolt Valve 38,000 BTU/HR Natural Gas

MVFBL4040MVP Vent Free Left Burner System – Millivolt Valve 35,000 BTU/HR Liquid Propane

LOGF38 Log Set required for MVFB40 R/L Burner System

BURNER SYSTEM & LOG SET (REQUIRED FOR MVF40 FIREBOX)

OPTION 1

GLMVF40MVN Vent Free Multiview Burner System – Millivolt Valve 38,000 BTU/HR Natural Gas

GLMVF40MVP Vent Free Multiview Burner System – Millivolt Valve 35,000 BTU/HR Liquid Propane

LOGC31 Log Set LOGC31 required for GLMVF40 Burner System

OPTION 2

MVFBR4040MVN Vent Free Right Burner System – Millivolt Valve 25,900/38,225 Natural Gas

MVFBR4040MVP Vent Free Right Burner System – Millivolt Valve 24,200/30,500 Liquid Propane

MVFBL4040MVN Vent Free Left Burner System – Millivolt Valve 38,000 BTU/HR Natural Gas

MVFBL4040MVP Vent Free Left Burner System – Millivolt Valve 35,000 BTU/HR Liquid Propane

LOGF38 Log Set required for MVFB40 R/L Burner System

Page 12

12

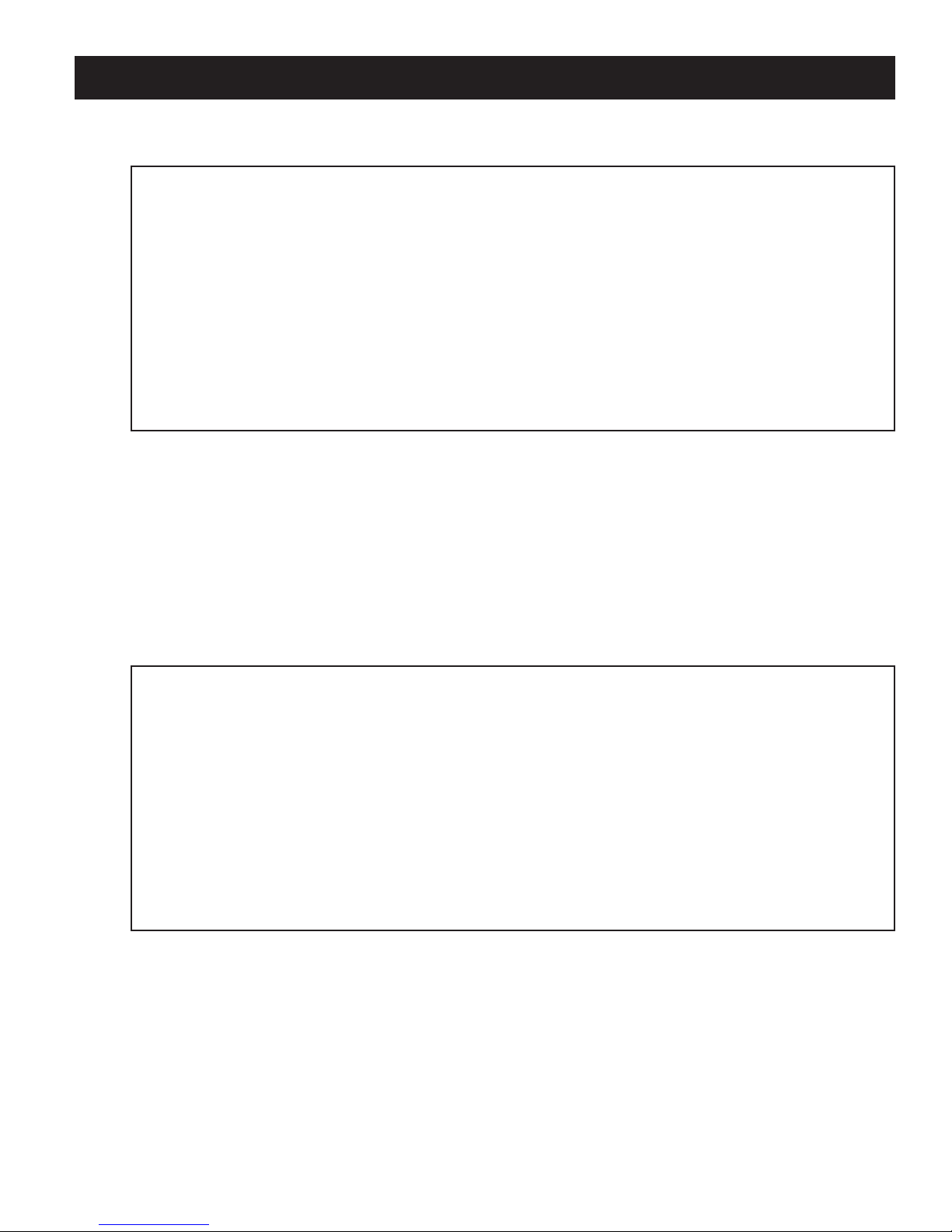

NOTE: Non combustible materials such as tile, marble,

and brick may overlap any facing on the appliance, but

should never cover any necessary openings like

louvered grills.

WARNING: Do not allow any combustible materials

to overlap the firebox front facing.

DIMENSIONS

FIGURE 2

Page 13

13

INSTALLING – Clearances

IMPORTANT: Vent-free gas log heaters add moisture to

the air. Although this is beneficial, installing firebox in

rooms without enough ventilation air may cause mildew to

form from too much moisture. See Air for Combustion and

Ventilation, pages 20 through 23.

IMPORTANT: Make sure the firebox is level.

If firebox is not level, log set will not work properly

.

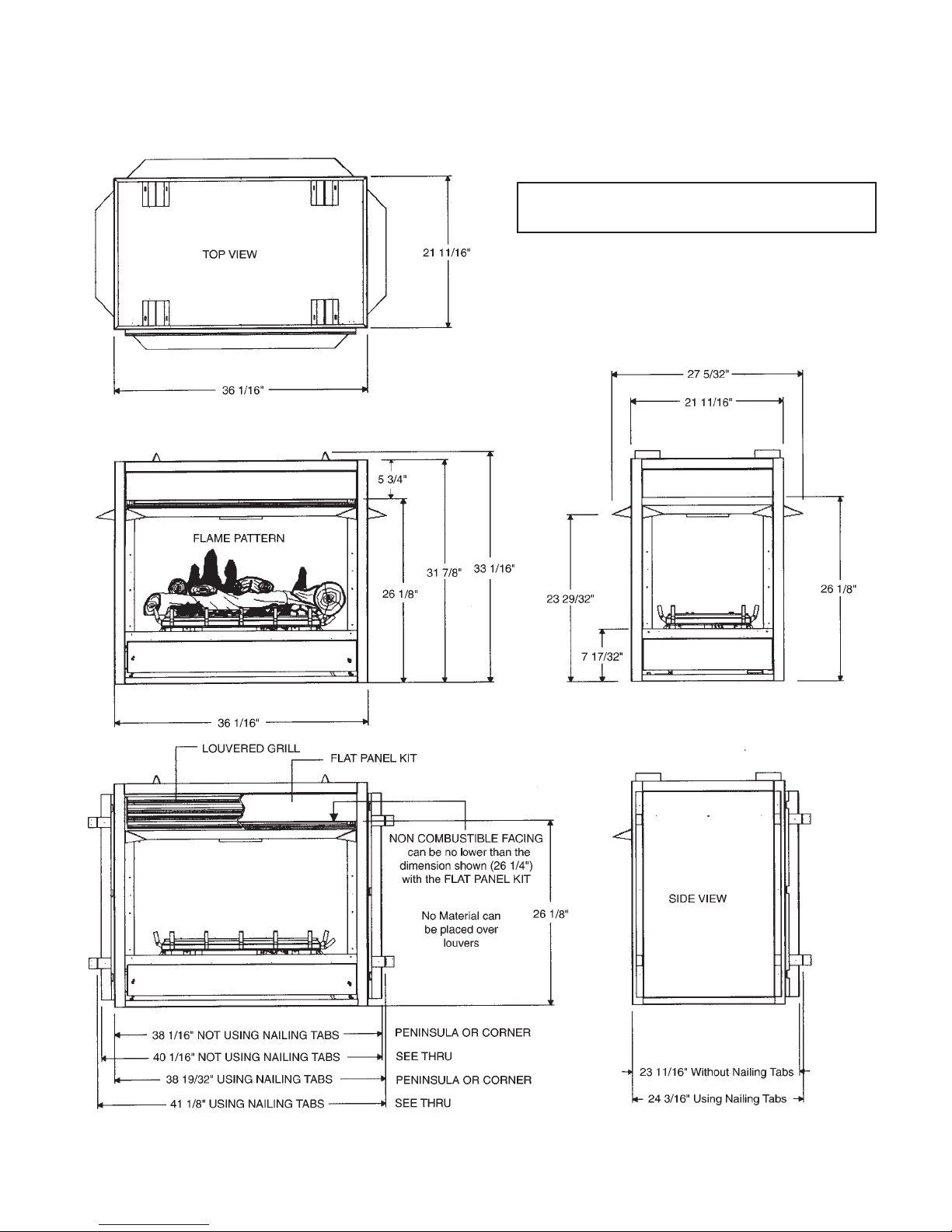

INSTALLATION CLEARANCES

Carefully follow the instructions below. This will

ensure safe installation.

Minimum Wall and Ceiling Clearances

A. Clearances from the firebox to

adjacent wall should not be less than

2 inches. (Ref. Page 8)

B. Clearance from the top of the

fireplace front to the ceiling should

not be less than 41 inches.

C.

Clearance from the bottom of firebox

to the floor is 0 inches. Bottom of unit

must be flush with top of combustible

floor covering.

D. Clearance from side of fireplace to

enclosure is 0 inches.

E. Clearance from top of fireplace

standoffs is 0 inches.

F. Clearance from opens side of fireplace

is 36”.

These fireboxes can be installed as freestanding

units against a wall with the approved, optional

cabinet mantels or as a built-in unit. The

clearances are the same for either installation method.

NOTICE

A qualified service person must install firebox. Follow

all local codes.

WARNING

Never install the firebox

• in a bedroom or bathroom

• in a recreational vehicle

• where curtains, furniture, clothing, or other

flammable objects are less than 36 inches from the

front, top, or sides of the firebox

• in high traffic areas

• in windy or drafty areas

FIGURE 3 – Minimum Clearances - Top and Sides

of Room Heater to Ceiling and Walls.

FIGURE 4 – Mantel Clearances.

Page 14

14

INSTALLING – Framing

INSTALLING BY FRAMING

FIREPLACE

Built-in installation of this firebox involves installing firebox

into a framed-in enclosure. Optional brass trim accessories are

available. The brass trim will extend past sides of firebox.

This will cover the rough edges of the wall opening. If

installing a mantel above the firebox, you must follow the

clearances shown in Figure 4, page 12. Follow the instructions

below to install the firebox in this manner

.

1. Frame in rough opening. The firebox framing should be

constructed of 2 x 4 lumber or heavier. Use dimensions in

Figure 1, 2 ,3 and 4, pages 8, 10 and 11. Adjust framing

so that firebox is flush with finished wall surface.

2.

Install gas piping to firebox location. See Installing Gas

Line on page 24 and Connecting to Gas Supply in log set

owners manual. IMPOR

TANT: If installing blower

accessory see page 31.

3.

Carefully insert firebox into rough opening.

4. Attach firebox to wall studs using nails or wood screws

through holes in nailing flange.

5. If using optional Brass Surround Kit, install the trim after

final finishing and/or painting of wall. See instructions

included with brass trim accessory for attaching Surround.

6. Install and properly test gas log heater. Follow installation

instructions included with the vent-free gas log heater that

is being installed.

IMPORTANT: When finishing your firebox, combustible

materials such as wall board, gypsum board, sheet rock,

drywall, plywood, etc. may be butted up next to the sides and

top of the firebox. Combustible materials should never overlap

the firebox front facing.

IMPORTANT: Non-combustible materials such as brick, tile,

etc. may overlap the front facing, but should never cover any

necessary openings like louvered slots.

CAUTION

Log heaters installed in this firebox create warm air

currents. These currents move heat to wall surfaces next

to firebox. Installing firebox next to vinyl or cloth wall

coverings or operating firebox where impurities in the

air (such as tobacco smoke) exist, may discolor walls.

WARNING

Do not allow any materials to overlap the firebox front

facing.

WARNING

Never modify or cover the louvered slots on the front

of the firebox.

WARNING

Use only non-combustible mortar or adhesives when

overlapping the front facing with non-combustible

facing material.

WARNING

Do not allow non-combustible materials to cover any

necessary openings like louvered slots.

CAUTION

Do not install the firebox on carpet or vinyl.

WARNING

Maintain the minimum clearances. If you can, provide

greater clearances from floor, ceiling, and adjoining wall.

WARNING

Ensure the minimum clearances shown in Figures 3 and

4 on page 12 are maintained. Left and right clearances

are determined when facing the front of the heater

.

Page 15

15

INSTALLING – Mantel Cabinets

NOTICE

A qualified service person must install firebox. Follow

all local codes.

NOTICE

Installation and repair should be done by a qualified

service person well trained in the installation of such

appliances. You will also need a building permit from

your local Building Commissioner before installing this

appliance, otherwise your insurance company may not

cover this appliance.

DANGER

CARBON MONOXIDE POISONING

MAY LEAD TO DEATH!

WARNING

Any changes to this heater or its controls can be

dangerous.

CAUTION

Use new black pipe only. Internally tinned copper

tubing can be used in some areas when permitted by

local codes. Only use pipe of 1/2” or greater diameter

to allow full gas volume to heater. Excessive pressure

loss will occur if the pipe is too small.

A manual shutoff valve, union and plugged

1

⁄8” NPT

pressure tap pointer must be installed upstream of the

heater.

A sediment trap must be installed upstream of the heater

to prevent moisture and contaminants from passing

through the pipe to the heater controls and burners. Failure

to do so could prevent the heater from operating

reliably.

Page 16

16

PENINSULA FRAMING SPECIFICATIONS

FRAMING

Using 2x4s frame to local building codes.

DO NOT install against a vapour barrier or

exposed insulation.

Framing measurements have been adjusted to

accommodate a 1/2” thick finished wall.

FIGURE 5.

Combustible materials may be installed flush

with top and sides of fireplace.

It is not necessary to install a hearth with this

fireplace system. Objects placed in front of

the fireplace should be kept a minimum of

24” away from the front face.

Gas line installation should be performed

only after Fireplace installation. Fireplace

bottom supplies you with two 6”x8”

rectangular holes. The use of these holes

depends on valve and Fireplace location on

riser or upper floor.

NOTE

If the unit is installed in a non conventional manner not using

2x4 framing the nailing tabs may be removed and the heat

shields may be placed directly against a combustible wall or

partition.

When the unit is installed without nailing tabs the unit must

be secured to the floor using the holes located in the bottom

of the fireplace.

FIREPLACE ASSEMBLY

1. Mount Door Cover on one end. Figure #6.

Position Door Cover over opening as shown

in diagram and using 4 self tapping screws

secure onto fireplace. Check to see that door

cover is properly sealed.

2. Hang Heat Shield on top edge of

Fireplace and secure with self tapping

screws. Heat Shield must be centered

allowing a 1/2” clearance both sides of

Fireplace for finishing material.

3. The heat shield is equipped with nailing

tabs if 2x4 framing is used as shown in

diagram Level Fireplace and nail or screw

into place.

When not using 2x4 framing secure Unit

with screws at bottom (SEE ABOVE

NOTE:)

Note: Framing dimension shown is to accept

1/2” Facing Material. The dimension shown may

be reduced depending on the thickness of

facing material up to 1”

Figure 6

Figure 5

Screw Attachment

Points (4)

NOTE: The standoffs are non load bearing. When

installing a cabinet, a maximum weight of 250 lbs

can be installed on the 1/2” drywall lip (located

around the perimeter of the appliance).

Page 17

17

SEE-THROUGH FRAMING SPECIFICATIONS

FRAMING

Using 2x4s frame to local building codes.

DO NOT install against a vapour barrier or exposed insulation.

Framing measurements have been adjusted to accommodate a

1/2” thick finished wall. FIGURE 7.

Combustible materials may be installed flush with top and sides

of fireplace.

It is not necessary to install a hearth with this fireplace system.

Objects placed in front of the fireplace should be kept a minimum

of 24” away from the front face.

Gas line installation should be performed only after Fireplace

installation. Fireplace bottom supplies you with two 6” x 8”

rectangular holes. The use of these holes depends on valve and

Fireplace location on riser or upper floor.

NOTE

If the unit is installed in a non conventional

manner not using 2x4 framing the nailing tabs

may be removed and the Heat Shields may be

placed directly against a combustible wall or

partition.

When the unit is installed without nailing tabs

the unit must be secured to the floor using the

holes located in the bottom of the fireplace.

FIREPLACE ASSEMBLY

1. Mount Door Cover on one end. Figure #8.

Position Door Cover over opening as shown in

diagram and using 4 self tapping screws secure onto

fireplace. Check to see that door cover is properly

sealed.

2. Hang Heat Shield on top edge of Fireplace and

secure with self tapping screws. Heat Shield must be

centered allowing a 1/2” clearance both sides of

Fireplace for finishing material.

3. The Heat Shield is equipped with nailing tabs if

2x4 framing is used as shown in diagram. Level

Fireplace and nail or screw into place.

When not using 2x4 framing secure Unit with screws

at bottom (SEE ABOVE NOTE:)

Figure 7

Figure 8

Page 18

18

BAY PENINSULA FRAMING SPECIFICATIONS

FRAMING

Using 2x4s frame to local building codes.

DO NOT install against a vapour barrier or

exposed insulation.

Framing measurements have been adjusted to

accommodate a 1/2” thick finished wall.

FIGURE 9.

Combustible materials may be installed flush with

top and sides of fireplace.

It is not necessary to install a hearth with this

fireplace system. Objects placed in front of the

fireplace should be kept a minimum of 24” away

from the front face.

Fireplace bottom supplies you with two 6” x 8”

holes. The use of these holes depends on valve and

Fireplace location on riser or upper floor.

NOTE

If the unit is installed in a non conventional manner

not using 2x4 framing the nailing tabs may be

removed and the Heat Shields may be placed

directly against a combustible wall or partition.

When the unit is installed without nailing tabs the

unit must be secured to the floor using the holes

located in the bottom of the fireplace.

FIREPLACE ASSEMBLY

1. To mount Door Cover, Figure #10. Position Door Cover

over opening as shown in diagram and using 6 self tapping

screws secure onto fireplace. Check to see that door cover is

properly sealed.

2. Hang Heat Shield on top edge of Fireplace and secure with

self tapping screws. Heat Shield must be centered allowing a

1/2” clearance both sides of Fireplace for finishing material.

3. The Heat Shield is equipped with nailing tabs if 2x4

framing is used as shown in diagram. Level Fireplace and nail

or screw into place.

When not using 2x4 framing secure Unit with screws at

bottom (SEE ABOVE NOTE:)

NOTE: Use 8-18 x 3/4 DT screws for bottom of door cover.

NOTE: Holes for mounting sides of Heat Shield are not

pre-punched.

Note: Framing dimension shown is to

accept 1/2” facing material. The dimension

shown may be reduced depending on the

thickness of facing material up to 1”

Bay Peninsula Fireplace Shown

Figure 10

Figure 9

NOTE: The standoffs are non load bearing. When

installing a cabinet, a maximum weight of 250 lbs

can be installed on the 1/2” drywall lip (located

around the perimeter of the appliance).

Page 19

19

CORNER FRAMING SPECIFICATIONS

FRAMING

Using 2x4s frame to local building codes.

DO NOT install against a vapour barrier or exposed insulation.

Framing measurements have been adjusted to accommodate a

1/2” thick finished wall. FIGURE 11.

Combustible materials may be installed flush with top and sides

of fireplace.

It is not necessary to install a hearth with this fireplace system.

Objects placed in front of the fireplace should be kept a

minimum of 24” away from the front face.

Fireplace bottom supplies you with two 6” x 8” rectangular

holes. The use of these holes depends on valve and Fireplace

location on riser or upper floor.

NOTE

If the unit is installed in a non conventional

manner not using 2x4 framing the nailing tabs

may be removed and the Heat shields may be

placed directly against a combustible wall or

partition.

When the unit is installed without nailing tabs the

unit must be secured to the floor using the holes

located in the bottom of the fireplace.

FIREPLACE ASSEMBLY

1. Mount Door Cover on one end. Figure #12. Position

Door Cover over opening as shown in diagram and using

4 self tapping screws secure onto fireplace. Check to see

that door cover is properly sealed.

2. Hang Heat Shield on top edge of Fireplace and secure

with self tapping screws. Heat Shield must be centered

allowing a 1/2” clearance both sides of Fireplace for

finishing material.

3. The Heat Shield is equipped with nailing tabs if 2x4

framing is used as shown in diagram. Level Fireplace and

nail or screw into place.

When not using 2x4 framing secure Unit with screws at

bottom (SEE ABOVE NOTE:)

NOTE: Use 8-18 x 3/4 DT screws for bottom of door cover

NOTE: Holes for mounting sides of heat shield are not

pre-punched.

Figure 12

Corner Fireplace Shown

Figure 11

Page 20

20

UNIVERSAL FIREBOX

The MVF40 is approved as a Zero Clearance Universal Firebox, when using as a Universal Firebox the bottom burner pan

must be used. (Part # 38VF-134).

When installing another manufacturer’s log and burner system, follow the manufacturer’s assembly instructions.

For framing, see pages 12 through 18 depending on type of installation. (eg. SEE THRU, ISLAND, PENINSULA, CORNER,

AND BA

Y PENINSULA) Follow all clearances to combustibles in this manual and see below for installation of the Bottom

Firebox Pan (Part # 38VF-134) that must be used.

The Firebox canopy must not be replaced with a canopy which may be provided with the decorative type unvented room heater.

USE ONLY KINGSMAN DECORATIVE COMPONENT AND REPLACEMENT PARTS.

Figure 13

Warning: Fireplace screen must be closed

while appliance is in operation.

Page 21

21

AIR FOR COMBUSTION AND VENTILATION

Today’s homes are built more energy efficient than ever. New materials, increased insulation, and new construction methods

help reduce heat loss in homes. Home owners weather strip and caulk around windows and doors to keep the cold air out

and the warm air in. During heating months, home owners want their homes as airtight as possible.

While it is good to make your home energy

efficient, your home needs to breathe. Fresh air must enter

your home. All fuel-burning appliances need fresh air for

proper combustion and ventilation.

Exhaust fans, fireboxes, clothes dryers, and fuel burning

appliances draw air from the house to operate. You must

provide adequate fresh air for these appliances. This will

insure proper venting of vented fuel-burning appliances.

PROVIDING ADEQUATE VENTILATION

The following are excerpts from National Fuel Gas Code. NFPA 54/ANSI Z223.1, Section 5.3, Air for Combustion and

Ventilation:

All spaces in homes fall into one of the three following ventilation classifications:

1. Unusually Tight Construction, 2. Unconfined Space, 3. Confined Space.

The information on pages 20 through 24 will help you classify your space and provide adequate ventilation.

Unusually T

ight Construction

The air that leaks around doors and windows may provide enough fresh air for combustion and ventilation. However, in

building of usually tight construction, you must provide additional fresh air.

Unusually tight construction is defined as construction where:

a. walls and ceilings exposed to the outside atmosphere have a continuous water vapor retarder with a rating of one

perm (6 x 10-11 per pasec-m2) or less with openings gasketed or sealed and

b. weather stripping has been added on openable windows and doors and

c. caulking or sealants are applied to areas such as joints around window and door frames, between sole plates and

floors, between wall-ceiling joints, between wall panels, at penetrations for plumbing, electrical, and gas lines, and

at other openings.

If your home meets any of the three criteria above, you must provide additional fresh air.

See Ventilation Air From Outdoors, page 24.

Confined and Unconfined Space

The National Fuel Gas Code (ANSI Z223.1, 1992 SEction 5.3) defines a confined space as a space whose volume is less than

50 cubic feet per 1,000 btu per hour (4.8 m3 per kw) of the aggregate input rating of all appliances installed in that space.

Rooms communicating directly with the space in which the appliances are installed*, through openings not furnished with

doors, are considered a part of the unconfined space.

*Adjoining rooms are communicating only if there are doorless passageways or ventilation grills between them.

DETERMINING AIR FLOW FOR FIREBOX LOCATION

Determining if You Have a Confined or Unconfined Space

Use the work sheet on the next page to determine if you have a confined or unconfined space.

Space: Includes the room in which you will install firebox plus any adjoining rooms with doorless

passageways or ventilation grills between the rooms.

WARNING

This firebox shall not be installed in a confined space

unless provisions are provided for adequate combustion

and ventilation air. Read the following instructions to

insure proper fresh air for this and other fuel-burning

appliances in your home.

Page 22

22

AIR FOR COMBUSTION AND VENTILATION Cont.

1. Determine the volume of the space (length x width x height).

Length x Width x Height = ______________ cu. ft. (volume of space)

Example: Space size 22ft. (length) x 18 ft. (width) x 8 ft. (ceiling height) = 3168 cu. ft. (volume of space)

If additional ventilation to adjoining room is supplied with grills or openings, add the volume of these rooms to the total

volume of the space.

2. Divide the space volume by 50 cubic feet to determine the maximum Btu/Hr the space can support.

______________ (volume of space) ÷ 50 cu. ft. = 63.3 or 63,300 (maximum Btu/Hr the space can support)

3. Add the Btu/Hr of all fuel burning appliances in the space.

Vent-free firebox __________________ Btu/Hr

Gas water heater* __________________ Btu/Hr

Gas furnace __________________ Btu/Hr

Vented gas heater __________________ Btu/Hr

Gas firebox logs __________________ Btu/Hr

Other gas appliances* + __________________ Btu/Hr

Total = __________________ Btu/Hr

Example: Gas water heater 40,000 Btu/Hr

Vent-free firebox with log heater + 39,000 Btu/Hr

Total = 79,000Btu/Hr

* Do not include direct-vent gas appliances. Direct-vent draws combustion air from the outdoors and vents to the

outdoors.

4. Compare the maximum Btu/Hr the space can support with the actual amount of Btu/Hr used.

__________________ Btu/Hr (maximum the space can support)

__________________ Btu/Hr (actual amount of Btu/Hr used)

Example: 63,300 Btu/Hr (maximum the space can support)

79,000 Btu/Hr (actual amount of Btu/Hr used)

The space in the above example is a confined space because the actual Btu/Hr used is more than the maximum Btu/Hr the

space can support. You must provide additional fresh air. Your options are a follows:

A. Rework work sheet, adding the space of an adjoining room. If the extra space provides an unconfined space, remove

door to adjoining room or add ventilation grills between rooms, See Ventilation Air from Inside Building, page 22.

B.

Vent room directly to the outdoors. See ventilation Air

from Outdoors, page 23.

C.

Install a lower Btu/Hr firebox, if lower Btu/Hr size

makes room unconfined.

If the actual Btu/Hr used is less than the maximum Btu/Hr

the space can support, the space is an unconfined fined

space. You will need no additional fresh air ventilation.

WARNING

If the area in which the firebox and gas log heater may be

operated is smaller than that defined as an unconfined

space, provide adequate combustion and ventilation air by

one of the methods described in the National Fuel Gas

Code, ANSI Z223.1, 1992, Section 5.3.

Page 23

23

AIR FOR COMBUSTION AND VENTILATION Cont.

VENTILATION AIR FROM INSIDE BUILDING

This fresh air would come from an adjoining unconfined space. When ventilating to an adjoining unconfined space, you

must provide two permanent openings: one within 12” of the ceiling and one within 12” of the floor on the wall connecting

the two spaces. You can also remove doors into adjoining

rooms. Follow the National Fuel Gas Code NFPA 54/ANSI

Z223.1, Section 5.3, Air for Combustion and Ventilation for

required size of ventilation for required size of ventilation

grills or ducts.

WARNING

Rework worksheet, adding the space of the adjoining

unconfined space. The combined spaces must have

enough fresh air to supply all appliances in both spaces.

Ventilation Grills into

adjoining room

Option 1

Ventilation Grills

into adjoining room

Option 2

Remove Door into

adjoining room

Figure 14

Page 24

24

AIR FOR COMBUSTION AND VENTILATION Cont.

Ventilation Air From Outdoors

Provide extra fresh air by using ventilation grills or ducts. You must provide two permanent openings: one within 12” of the

ceiling and one within 12” of the floor. Connect these items directly to the outdoors or spaces open to the outdoors. These

spaces include attics and crawl spaces.

IMPORTANT: Do not provide openings for inlet or outlet air into attic if attic has a thermostat-controlled power vent.

Heated air entering the attic will activate the power vent.

FIGURE 15 - Ventilation Air from Outdoors

Page 25

25

INSTALLING – Gas Line

INSTALLING GAS LINE

Early signs of carbon monoxide poisoning resemble the flu, with

headaches, dizziness, and / or nausea. If you have these signs, the

heater may not be working properly. Get fresh air at once! Turn off

gas appliance. Have appliance serviced. Some people (such as

pregnant women, persons with heart or lung disease, persons with

anemia and those at high altitudes) are more affected by carbon

monoxide than others. Make certain you read and understand all

warnings.Place Burner Base or Grate Assembly in center of firebox

and connect flexible gas line to incoming black iron pipe gas line.

Do not connect appliance before pressure testing gas piping.

Damage to gas valve may result and an unsafe condition may be

caused.

Prepare incoming black iron gas line with Teflon tape or pipe joint

compound (check with local codes about the use of Teflon tape).

Compounds used on threaded joints of gas piping shall be resistant

to the action of Liquefied Petroleum (LP or Propane) and should be applied lightly to ensure excess sealant does not enter the gas line.

Complete your gas installation by connecting incoming gas line to regulator. Secure all joints tightly with wrench but do not over-

tighten. If a flexible gas line is used, take care not to kink connector. The burner pressure is controlled by the regulator. Check pressure

at the pressure test point, which is located on the side of the gas control near the pilot outlet. Make sure that the pressure tap is

completely closed after checking gas pressure. The pressure should be checked with the appliance burning and the control set on high.

IMPORTANT: Loosen the pipe adapter on the flex tube before installing to the system piping.

CHECK GAS TYPE: The gas supply must be the same as stated on the heater’s rating plate. If the gas supply is different, Do Not

Install the heater. Contact your dealer for the correct model.

For the state of Massachusetts a T-handle gas shut-off valve must

be used on a gas appliance. This T-handle gas shut-off valve must

be listed and approved by the state of Massachusetts. This is in

reference to the state of Massachusetts state code CMR238.

CAUTION

All gas piping and connections must be tested for leaks

after installation is completed. To test, turn gas valve on,

then apply a soap and water solution to all connections

and joints. If bubbles appear, leak can be detected and

corrected. Never use an open flame for leak testing.

Never operate any appliance if a leak is detected!

CAUTION

Any safety screen or guard removed for servicing an

appliance must be replaced prior to operating the heater.

FIGURE 16, 16a – Installing gas line and manual shutoff valve

FIGURE 16a – This is one option for installing shutoff

valve. Check local codes for shutoff location regulations.

NOTICE

A qualified gas appliance installer must connect the

fireplace to the gas supply. Consult all local codes.

Page 26

26

FIGURE 18 – Manual and Millivolt Pilot Flames

FIGURE 19 – Millivolt Models

1. Remove the Universal Bottom before installing Kingsman Multiview Burner system by removing 4 screws.

2. Position burner assembly as per unit configuration (eg. left corner, right corner, peninsula, etc.)

3. Tilt burner assembly so valve is at an angle to the fireplace and lower into position.

4. Line the 4 holes on the burner assembly as shown on the diagram with the 4 holes on the fireplace and screw into place

with 1/2” DT Screws.

5. Install log support plates as shown in the lower diagram. (Make sure the log support plate with the cut out is placed on

the side where the ODS Pilot is located.)

NOTE: When installing Burner assembly into a corner installation it is very important that the NON FLAME END of the

burner assembly is facing the side of the enclosure that is built in.

FIREBOX BOTTOM ODS PILOT

LOCATION

NON FLAME END

OF BURNER

ASSEMBLY

(SEE NOTE)

BURNER

INSTALLATION

HOLES

Figure 17

UNIVERSAL

BOTTOM

NOTE: LOG LOCATOR

PIN ORIENTATION

INSTALLING – MVFB4040 Burner Systems

Warning: Failure to position parts in accordance with these diagrams or failure to use only part specifically

approved with this heater may result in property damages or personal injury.

CLEANING AND SERVICING OF

BURNER / ODS PILOT

It is recommended to annually inspect and clean the unit to

prevent malfunction and / or sooting. This operation should

be performed by your dealer or a qualified technician.

1. Remove fireplace hood and screen. (Refer to Installation

of Door Screen and Hood, page 30.)

2.

Remove log set, handling carefully by holding gently at

each end. (Refer to Log Placement, page 26.) Gloves are

recommended to prevent skin irritation from ceramic.

Annual Cleaning / Inspection

•

Do not use cleaning fluids to clean logs or any part of the

heater.

• Use a soft bristle brush or a vacuum with brush attachment.

• Vacuum loose particles and dust from burner ports, valve

and blower compartments.

• Vacuum any accumulation of lint from primary mixing

tube.

• Inspect ODS pilot for operation, accumulation of lint at the

air inlet holes.

• Verify flame pattern and log placement for proper

operation.

• Verify that all ports ignite and cross over smoothly from rear

to front burner.

WARNING

Turn off heater and allow to cool before cleaning. Only a

qualified service technician should service and repair appliance.

Failure to keep primary air openings clear, may result in

sooting and property damage.

Page 27

27

INSTALLING – MVFB4040 Burner Systems and LOGF38

WARNING

The positioning of the logs is critical for the safe

and clean operation of this heater. Sooting and other

problems can occur if the logs are not properly and

firmly positioned in the heater. Never add additional

logs or embellishments such as pine cones, vermiculite,

volcanic rock or rock wool to the heater.

Log Installation

The Kingsman log set has been numbered for ease of installation.

1. Place log #1 onto plate with the ODS Pilot extending through

the notch area. Position holes on under side of Log #1 with the 2

vertical tabs on the plate and lower onto plate.

2. Place log #4 onto plate opposite of plate with the ODS Pilot

3. Position Log #5 onto end Pin of Log #4 as shown in diagram

4. Position Log #3 onto center Pin of Log #4 as shown in diagram.

5. Position log #2 onto Pin of Log #1 and position Log #2 up

against Log #4.

NOTE LOG #5 IS TO BE POSITIONED ON THE NON FLAME SIDE.

Crushed Rock Installation

Place crushed rock onto firebox bottom making sure not to

place any rock onto the burner or burner ports as this will

cause carboning, delayed ignition, and will raise Carbon

Monoxide to very dangerous levels.

Side Brick Panel Installation (Long Side)

1. Remove side brick clip located on top of Firebox.

2. Slide Side Brick Panel into Firebox through the small side

opening and center from left to right and push tight against side

wall of Firebox.

3. Place Brick Clip back into position and tighten

Back Brick Panel Installation (Short Side)

1. Remove back brick clip located on top of Firebox.

2.Slide Back Brick Panel into Firebox through the large side

opening and center form left to right and push tight against side

wall of Firebox.

3. Place Brick Clip Back into position and tighten.

Optional Back and Side Brick Panel Installations

NOTE: BRICK CLIPS CAN BE REPOSITIONED DEPENDING ON TYPE OF INSTALLATION

Figure 21

Figure 20

Page 28

28

Log Tabs

Step (1) If using the MVF40 chassis, omit this step (go to step

2). If using MDV30 or MDV38, break glowing embers into

thumbnail size and place along the perimeter of the burner.

Do not place on middle burner (as illustrated). Care should be

taken not to block burner ports.

Step (2) Take Log #4 and place onto burner using the two log

tabs (located on burner pan) as a guide.

Log Pin

Log Pin

Step (3) Take Log #1 and place onto burner using the two log

tabs (located on burner pan) as a guide.

LOGF38 PLACEMENT FOR MVFB4040 BURNER SYSTEM

Page 29

29

Step (4) Place Log #5 onto Log #4 using the log pin as a

guide. Ensure Log #5 rests on the shape of Log #4.

Log Pin

Step (5) Place Log #3 onto both Log #1 and Log #5 using the

log pins as a guide.

Log Pin

Step (6) Place Log #2 onto both Log #1 and #4 using the log

pins as a guide. Ensure Log #2 does not cover burner.

LOGF38 PLACEMENT FOR MVFB4040 BURNER SYSTEM

Page 30

30

INSTALLING – GLMVF40 Burner System

1. Install Optional Brick Liners before installing GLVF40 Burner system.

2. Remove the Universal Burner Bottom before installing Kingsman Multiview Burner system by removing 4 screws.

3. Position burner assembly as per unit configuration. Front of Gas Valve should always be accessible after installation.

4. Tilt burner assembly so valve is at an angle to the Fireplace and lower into position.

5. Center Burner assembly inside Fireplace and fasten with 2 supplied screws.

6. Place 8 Grate Bars into Burner System by sliding them into square openings.

NOTE: After installation of Burner, make sure Log support plates are still in their proper position.

Warning: Failure to position parts in accordance with these diagrams or failure to use only part specifically

approved with this heater may result in property damages or personal injury.

Page 31

31

LOGC31 PLACEMENT for GLMVF40 BURNER GRATE

Step (1) Place notched area of Log #1 against the O.D.S.

Pilot as shown. Place Log31C-A and Log31C-B along the

grate bar as shown.

Step (2) Place flat area of Log #2 against Tab 2 and over top

of Log #1. Locate log mounting hole on Log #3. Position hole

on Tab 3 as shown. Do not place log over the center burner

tube.

Step (3) Locate the 2 mounting holes on the bottom of Log #4

and position them onto Tabs 4A and 4B. Place V area of Log

#5 on the grate bar and then rest Log #5 on the flat area of

Log #2.

Step (4) Place the flat area of Log #6 on the burner pan. Lean

against Logs #4 and #5. Locate flat notched areas of Log #2

and Log #3. Place Log #7 onto these with charred branch in

the down position.

Page 32

32

Step (5) Place ember rocks on ember plates. (Warning: Do not place ember rocks on the burner tubes).

Step (6) Place lava rock on the bottom of the fire box

surrounding the burner system. Sprinkle vermiculite over top

of the Lava Rock.

LOGC31 PLACEMENT for GLMVF40 BURNER GRATE

Page 33

33

CAUTION

Do not wire 120 Volt power to Millivolt switches or

thermostats.

MILLIVOLT LIGHTING INSTRUCTIONS

Page 34

34

INSTALLING – Screen Door, Shield + Hood

Hinged grill

1. In the bottom inside corner of post there

are Teardrop slots. As shown in Ref: B.

2. On the Grill there are screws in both

ends. To install, slide the head into one of

the teardrop slots, then slide Grill to

opposite side. These screws may have to

be adjusted for proper alignment, and

length.

3. Install 2 springs on both ends of grill.

Refer to Ref: C. for proper installation.

Hinged bottom panel

1. Ref:E Install two 8-32 x 1/2” screws and

nuts, from the inside of panel with nut to

the outside. Tighten one side only.

2. Thread of loose screw should not

protrude past face of nut.

3. The end of the panel, with tightened

screw can now be slid into teardrop hole

Ref: B

4. Align opposite side of panel with

teardrop Ref:B and tighten screw.

5. Ref:C for spring installation.

Fixed grill and panel

1. In both top and bottom inside corners of

post there are vertical slots, as shown in

Ref: A & B

2. Grills & panels have tabs on both ends.

To install slide the tabs into slots on one

side of post, top side up (Ref:D)

3. Clip opposite side of flat panel into

opposite post. Extra force may be required

to push grill or panel over to clip it in.

Repeat for other fixed grills and panels.

Curtain & Hood Installation

Curtain:

1. Slide curtain onto rods.

2. Slide round end of rod into side post Ref:B

Using two 1/2” DT screws, mount flattened

end of rod to the bottom side of rod hanger

brackets Ref:A, Repeat this step for opposite

side.

3. Mount curtain rod on short side of

fireplace Ref: C. Insert one end into slot on

the inside of post, slide it all the way in, then

slide back to insert into other side of post.

Hood

1. Ref:D Loosen pre-installed 1/2” DT screws

with 1/4” wrench. Slide slotted area of hood

under screws.

2. Tighten screws to finish installation, repeat

this step for all hoods if applicable.

Figure 23

Figure 24

Warning: Fireplace screen

must be closed while

appliance is in operation.

Page 35

35

INSTALLING – Fan Kit

WARNING

Electrical Grounding Instruction - This

appliance is equipped with a three pronged (grounding) plug for your

protection against shock hazard and

should be plugged directly into a

properly grounded three-prong

receptacle.

WARNING

A qualified electrician must connect

electrical wiring to junction outlet for

built-in installation. Follow all codes.

WARNING

Label all wires prior to disconnection

when servicing controls. Wiring errors

can cause improper and dangerous

operation. Verify proper operation and

servicing.

Installation of Optional Fan Kit

Use Part number Z36FK fan assembly. NOTE that

the thermodisc will not be used, bypass these two

wires by stripping the ends and tie together with a

marrette (as shown Fig. 27).

Fan Installation

1. To install fan locate #8 screws in bottom of fireplace Ref A. Fan and fan shield should always be mounted at the end of

the fireplace with the small clearance shield mounted (corner kit peninsula kit & see-through kit)

2. Slide teardrop hole on fan housing over the two #8 screws, slide fan away from screws and release.

Fan Shield installation

1. Slide shield under firebox nearest fan.

2. Install two 1/2” DT screws from inside of firebox into fan shield.

3. If fireplace has been installed with fan shield mounted opposite to the side with clearance shield. It must be removed and

installed on the appropriate side.

Fan shield location

* Caution: Fan shield must be mounted

directly in front of fan.

Alternate

Fan & Shield

location

Suggested Location for 120V

Junction Box for Fan Kit

Suggested Location for 120V

Power Cable

Fan Shield

Clearance Shield

Fan

Ref: A

Ref: A

Optional in unit

variable speed

control location

WALL MOUNTED

VARIABLE SPEED

CONTROL

Figure 25

Figure 26

Figure 27

Page 36

36

ILLUSTRATED PARTS LIST

MVFB 4040MVN - (LEFT OR RIGHT) PARTS LIST

Natural Gas

MVFB 4040MVP - (LEFT OR RIGHT) PARTS LIST

Liquid Propane

Ref# Description Qty: Part #

1 Brass Cap Orifice 1 1000-255

2 Brass Nipple 1/8 x 1 1 1000-253

3 ELBOW 1/8” 1 2000-213

4 MP NIPPLE 1/8 X 2.0 1 3000-921

5 Reducing Elbow 1/8 x 3/8 1 1000-257

6 Nipple 3/8 x 3.5 1 1000-212

7 Street Elbow 3/8 1 1000-245

8 COS Pilot NG 1 33VF-P8214

9 Compression Sleeve 1 33VF-P603VE

10 Compression Nut 1 33VF-P613VE

11 ALT TUBE 3/16 X 11.5 1 33VF-P316VE

12 Connector 1 33VF-P683VE

13 Regulator 1 33VF-P245M

14 Connector 1 33VF-P683VE

15 Alt Tube 3/16 x 3 1 33VF-P316VE

16 COS Valve 820 Nova NG 1 33VF-P637SI

Ref# Description Qty: Part #

1 Brass Cap Orifice 1 1000-255

2 Brass Nipple 1/8 x 1 1 1000-253

3 Elbow 1/8” 1 2000-213

4 MP Nipple 1/8 X 2.0 1 3000-921

5 Reducing Elbow 1/8 x 3/8 1 1000-257

6 Nipple 3/8 x 3.5 1 1000-212

7 Street Elbow 3/8 1 1000-245

8 COS Pilot LP 1 33VF-P8404

9 Compression Sleeve 1 33VF-P603VE

10 Compression Nut 1 33VF-P613VE

11 Alt Tube 3/16 X 16.5 1 33VF-P316VE

12 COS Valve 820 Nova NG 1 33VF-P636SI

1

16

15

14

13

12

11

10

7

4

8

5

2

9

6

3

1

12

11

10

7

4

8

5

2

9

6

3

#32 Brass Cap Orifice

Set Primary to 1/4”

Natural Gas

#50 Brass Cap Orifice

Set Primary all Full Open

Propane

Page 37

37

ILLUSTRATED PARTS LIST Cont.

MVF 40 BURNER ASSEMBLY

28

27

26

29

30

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

7

4

8

5

2

9

6

3

1

Ref# Description Qty: Part #

1 Brass Cap Orifice 1 1000-255

2 Brass Nipple 1/8 x 1 1 1000-253

3 ELBOW 1/8” 1 2000-213

4 MP NIPPLE 1/8 X 2.0 1 3000-921

5 Reducing Elbow 1/8 x 3/8 1 1000-257

6 Nipple 3/8 x 3.5 1 1000-212

7 Street Elbow 3/8 1 1000-245

8 COS Pilot NG 1 33VF-P8214

9 Compression Sleeve 1 33VF-P603VE

10 Compression Nut 1 33VF-P613VE

11 ALT TUBE 3/16 X 11.5 1 33VF-P316VE

12 Connector 1 33VF-P683VE

13 Regulator 1 33VF-P245M

14 Connector 1 33VF-P683VE

15 Alt Tube 3/16 x 3 1 33VF-P316VE

16 COS Valve 820 Nova NG 1 33VF-P637SI

17 Piezo 1 1000-214

18 Valve Bkt 1 38VF-112

19 Pan Bottom 1 38VF-104

20 Burner Bkt 4 38VF-105

21 ODS Bracket 1 38VF-106

22 Burner ASSy 1 N/A

23 Log Holder (LH) 1 38VF-113

24 Log Holder (RH) 1 38VF-114

25 Grate Assembly 1 N/A

26 Log #5

27 Log #4

28 Log#2

29 Log #1

30 Log #3

Natural Gas System Shown

Page 38

38

GLMVF40 ILLUSTRATED PARTS LIST

24

20

16

15

14

13

5

5

4

5

3

2

19

6

1

12

9

10

11

13

14

15

16

17

18

17

16

21

22

23

17

18

17

16

23

22

21

19

24

20

19

8

7

Enlarged View

ITEM NO. QTY. PART NO. (NG) PART NO. (LP) DESCRIPTION

1 1 40GL-PAN 40GL-PAN Burner Pan

2 1 40GL-BRN 40GL-BRN Burner Assembly

3 4 4200-132 4200-132 Burner Hold Down

4 1 39GL-107 39GL-107 ODS Log Support Plate

5 3 39GL-117 39GL-117 Log Support Plate

6 1 39GL-108 39GL-108 ODS Pilot Burner

7 1 39GL-104 39GL-104 Orifice Bracket

8 1 39GL-112 39GL-112 Base Cover

9 1 39GL-102 39GL-102 Control Panel

10 1 1000-216 1000-216 Rocker Switch

11a 1 1000-214 1000-214 Piezo igniter

11b 1 1000-215 1000-215 Pal Nut for Piezo igniter

12 8 39GL-105 39GL-105 Grate Bar

13 1 350-P217SI 350-P217SI 1 1/2” On/Off Extension Knob

14 1 350-P218SI 350-P218SI 1 1/2” Hi/Lo Extension Knob

15 1 33VF-P637SI 33VF-P636SI Vent free Gas Valve

16 1 33VF-P316VE 33VF-P316VE Alt Tubing 3/16”

17 2 33VF-P683VE Connector (Natural Gas Only)

18 1 33VF-P245M Regulator (Natural Gas Only)

19 1 33VF-P8214 33VF-p8404 ODS Pilot System

20 1 4000-P963VE 4000-P963VE 3/8 Make x 3/8 Flare Adapter

21 1 350-P3875D 350-P3875D 10” - 3/8 Flex Connector

22 1 3100-466PA 3100-466PA 3/8 Flare x 1/8 Fipt Adapter

23 1 1000-253 1000-253 1/8 Closed Nipple

24 1 1000-255 (#32) 1000-255 (#49) Orifice

Page 39

39

ACCESSORY AND PARTS LIST

Product No. Description

MVF40 KINGSMAN MULTI-SIDED VENT FREE FIREPLACE:

Listed for USA as a Universal Firebox

Choose your View: (Required for each unit)

MVF40CK Corner Kit - One Large Side Open, One Small Side Open

MVF40SK See-Through Kit - Two Large Sides Open

MVF40PK Peninsula Kit - Two Large Sides Open, One Small Side Open

MVF40BK Bay Peninsula Kit - One Large Side Open, Two Small Sides Open

MVF40IK Island Kit - Four Sides Open

Choose Grill Kits or Panel Kits: (Required for View Chosen Above)

MGCKBP Grill Kit Corner - Classic Polish Brass (Two Sets)

MGCKBA Grill Kit Corner - Classic Antique Brass - (Two Sets)

MGCKBC Grill Kit Corner - Classic Chrome (Two Sets)

MGCKBL Grill Kit Corner - Black (Two Sets)

MGCKPB Grill Kit Corner - Polish Brass (Two Sets)

MGCKAB Grill Kit Corner - Antique Brass (Two Sets)

MGCKCR Grill Kit Corner - Chrome (Two Sets)

MVF40PCK Panel Kit for Corner Kit - Black (Two Sets)

MGSKBP Grill Kit See-Through - Classic Polish Brass (Two Sets)

MGSKBA Grill Kit See-Through - Classic Antique Brass (Two Sets)

MGSKBC Grill Kit See-Through - Classic Chrome (Two Sets)

MGSKBL Grill Kit See-Through - Black (Two Sets)

MGSKPB Grill Kit See-Through - Polish Brass (Two Sets)

MGSKAB Grill Kit See-Through - Antique Brass (Two Sets)

MGSKCR Grill Kit See-Through - Chrome (Two Sets)

MVF40PSK Panel Kit See-Through - Black (Two Sets)

MGPKBP Grill Kit Peninsula - Classic Polish Brass (Three Sets)