Page 1

g

OUTDOOR FIRE PIT MANUAL

MODELS FP2085 ROUND FIRE PIT, FP2785 RECTANGULAR FIRE PIT

CERTIFIED FOR USA & CANADA

Owner’s Operation and Installation Manual

STANDARDS: CR97-003, ANSI Z21.97-2010

OUTDOOR DECORATIVE GAS APPLIANCES

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

! DANGER

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. If odor continues, keep away

from the appliance and

immediately call your gas

supplier or fire department.

! WARNING

Do not store or use gasoline or

other flammable vapors and

liquids in the vicinity of this or

any other appliance.

An LP-cylinder not connected

for use shall not be stored in the

vicinity of this or any other

appliance.

! WARNING

! DANGER

sman Fireplaces 2340 Logan Ave., Winnipeg, Mb Canada Ph: 204-632-1962 Printed in Canada P/N 27FP-MAN June 28, 2012

Kin

CARBON MONOXIDE HAZARD

This appliance can produce carbon

monoxide which has no odor.

Using it in an enclosed space can

kill you.

Never use this appliance in an

enclosed space such as a camper,

tent, car or home.

For Outdoor Use Only.

! WARNING

Improper installation,

adjustment, alteration, service

or maintenance can cause injury

or property damage. Read the

installation, operating and

maintenance instructions

thoroughly before installing or

servicing this equipment.

Page 2

Table of Contents

2

Table Of Contents........................................................................................................... 2

Introduction..................................................................................................................... 3

Assembly And Installation.............................................................................................. 4

Gas Specifications.......................................................................................................... 5

Installation In Combustible Enclosure............................................................................. 6

Installing Rectangle Fire Pit Into A Wood Enclosure..................................................... 7

Installing Wall Clearance Shield...................................................................................... 8

FP2085 Fire Pit Assembly............................................................................................... 9

FP2785 Burner Assembly............................................................................................... 10

Log Placement Instructions............................................................................................. 11

Accessories For Your Fire Pit.......................................................................................... 12

30FPB-KWK Decorative Key Way Valve Kit................................................................... 13

Kingsman Outdoor Fire Pit Media Section...................................................................... 14-15

Operating Instructions..................................................................................................... 16

Maintenance Instructions................................................................................................ 16

High Elevation Installation............................................................................................... 16

Safety Information And Lighting Instructions................................................................... 17

FP2085/FP2785 Parts List.............................................................................................. 18

Kingsman Fireplaces Gas Fire Pit – Limited Warranty.................................................... 19

Page 3

INTRODUCTION

3

Models FP2085/FP2785 are Decorative Gas Log Set for

outdoor use only. This appliance MUST NOT be used

for cooking.

WARNING: This appliance shall be used ONLY

outdoors in a well-ventilated space and shall NOT be

used inside a building, garage, or any other enclosed

area.

WARNING: This log set must NOT be installed in an

unvented appliance.

WARNING: THIS UNIT IS NOT FOR USE WITH

SOLID FUEL.

The installation must conform with Local codes ore in

the absence of local codes, with the National Fuel Gas

Code ANSI Z223.1 or CAN/CGA-B149.1, National Gas

Installation Code or CAN/CGA-B149.2, Propane

installation Code.

The appliance and its individual shut off valve must be

disconnected from the gas supply piping system during

any pressure testing of the system at test pressures in

excess of 1/2 psig (3.5kPa).

This appliance must be isolated from the gas supply

piping system by closing its individual manual shut off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/2

psig (3.5kPa).

For the state of Massachusetts a T-handle gas shut-off

valve must be used on a gas appliance. This T-handle gas

shut-off valve must be listed and approved by the state of

Massachusetts. This is in reference to the state of

Massachusetts state code CMR238.

The following clearances to combustible construction

must be maintained: Bottom - 0 inches Sides (all

around)-24 inches (610 mm), and Top-7 feet (2.12 m).

Always keep the appliance area clear and free from

combustible materials, gasoline, and other flammable

vapors and liquids.

Do not locate appliance where it can get excessively

wet.

Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to

inspect the unit and to replace any part of the control

system and any gas control which has been underwater.

When an appliance is for connection to a fixed piping

system, the installation must conf orm with local codes,

or in the absence of local codes with the National Fuel

Gas Code, ANSI Z223.1/NFPA 54, or International Fuel

Gas Code.

For appliances for fixed fuel piping system and equipped

with an appliance gas pressure regulator,

the appliance and its individual shutoff valve must be

disconnected from the gas supply piping

system during any pressure testing of that system at test

pressures in excess of 1/2 psi (3.5 kPa).

Children and adults should be alerted to the

hazards of high surface temperatures and should

stay away to avoid burns or clothing ignition.

Young children should be carefully supervised

when they are in the area of the appliance.

Clothing or other flammable materials should not

be hung from the appliance, or placed on or near

the appliance.

Any guard or other protective device removed for

servicing the appliance must be replaced prior to

operating the appliance.

Installation and repair should be done by a

qualified service person. The appliance should be

inspected before use and at least annually by a

qualified service person. More frequent cleaning

may be required as necessary. It is imperative the

control compartment, burners and circulating air

passageways of the appliance be kept clean.

Inspect the fuel supply connection (including the

hose for LP models) before each use of the

appliance.

If it is evident there is excessive abrasion or wear,

or the hose is cut, it must be replaced prior to the

appliance being put into operation.

Cylinders must be stored outdoors in a well

ventilated area out of the reach of children.

Disconnected cylinders must have threaded valve

plugs tightly installed and must not be stored in a

building, garage or any other enclosed area.

Storage of this appliance indoors is permissible

only if it has been disconnected from its fuel supply

(natural gas line or LP gas cylinder).

LP GAS WARNINGS

The LP gas supply cylinder used with LP models

must be constructed and marked in accordance

with the specifications for LP-gas cylinders of the

U.S. Department of Transportation (DOT).

The pressure regulator and hose assembly supplied

with LP models must be used. Replacement

pressure regulators and hose assemblies must be

those specified in this manual.

The LP gas cylinder supply system must be

arranged for vapor withdraws.

The LP -gas cylinder used must include a collar to

protect the cylinder valve.

When an LP model is not in use, the LP-gas must

be turned off at the supply cylinder.

Fuel Supply line must not come into contact with

surfaces having temperatures in excess of 140°F. LP

gas cylinder must be kept a minimum of 4.5 feet from

the appliance.

You must use an approved LP cylinder retention

device (See Gas Specifications for an example).

Page 4

ASSEMBLY

4

The log set (LOGC85) and the burner assembly

shipped

A. Remove the gas log set and burner assembly and

B. Place the burner assembly on a flat, stable surface in

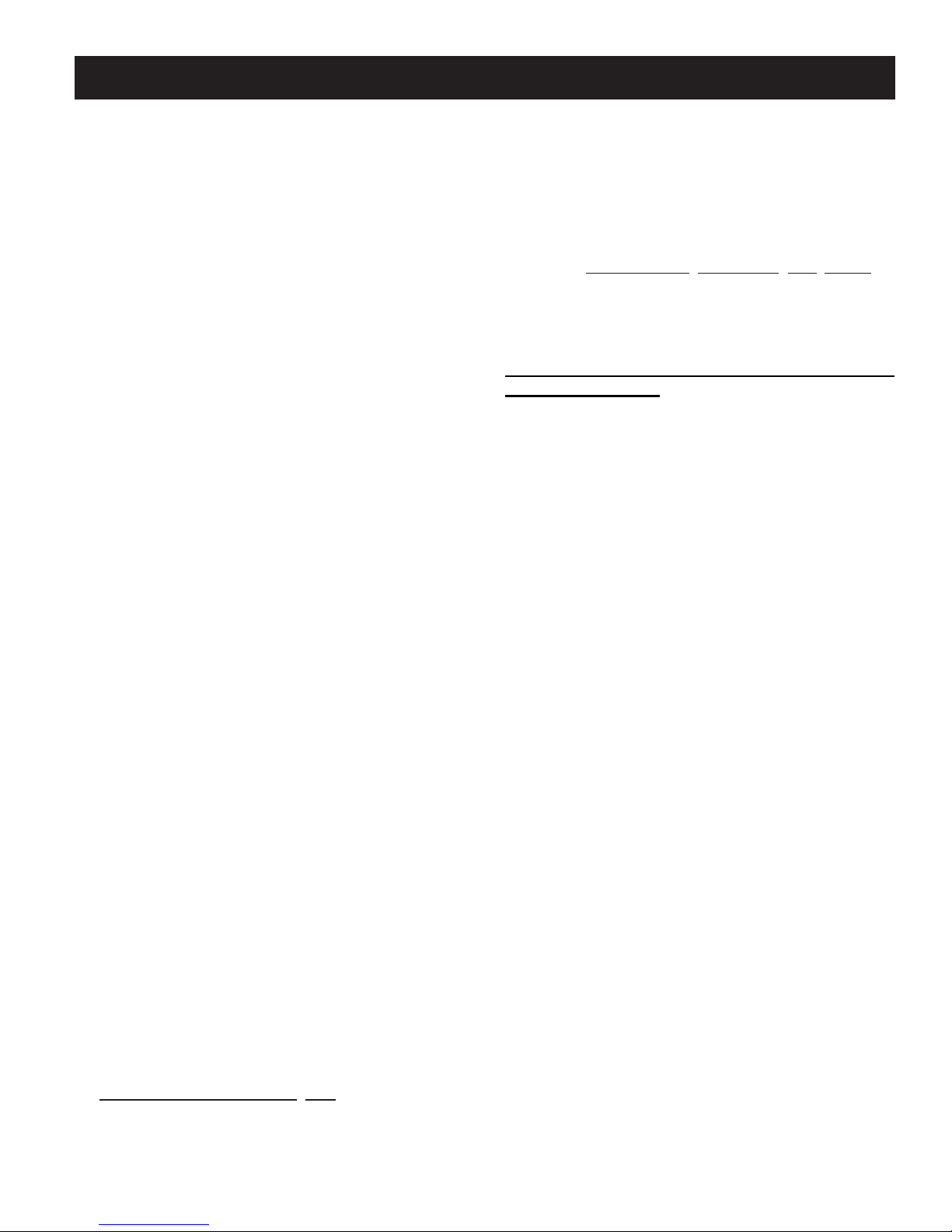

C. NATURAL GAS MODELS: Connect the incoming

LP-GAS

1. Make sure tank valve is in its full off position. (Turn

2. Check tank valve features to ensure it has proper

3. Inspect hose shipped with the unit for damage. Never

4. After inspecting the LP hose shipped with the unit,

NOTE: Fuel Supply line must not come into contact

5. When connecting regulator assembly to the tank

6. Locate the hose out of pathways where people may

separately.

check for damage. DO NOT install damaged

components. The logs are fragile use care when

handling.

an outdoor location such as a patio or a deck. This

location must be adjacent to the gas supply line

(natural gas) or LP-gas supply cylinder. NOTE:

Minimum clearances to combustible construction

must be maintained.

Remember, you must have easy access to the

gas valve control knob AFTER the appliance is

installed and connected to the gas supply .

THE ON/OFF GAS VALVE IS USED TO

THE BURNER ON AND OFF

gas supply line to the on/off gas valve of the

appliance (Figure 1). Make certain ALL gas

connections are tight, turn the on/off valve at the unit

slowly to the on position and use soap water to test

for leaks. DO NOT USE AN OPEN

MODELS:

clockwise to stop).

external mating threads. (Tank Valve Marked: USE

WITH TYPE 1 )

attempt to use damaged or plugged equipment. See

your local LP Gas Dealer for

connect the end with the female fitting on the hose to

the male fitting on the on/off gas valve at the end of

the flex tube and make sure it is tight.

with surfaces having temperatures in excess of

140°F. LP gas cylinder must be kept a minimum

of 4.5 feet from the appliance. You must use an

approved LP cylinder retention device (See Gas

Specifications for an example).

valve, hand tighten nut clockwise to a positive stop.

DO NOT use a wrench to ti

may damage quick closing coupling nut and result in

a hazardous condition.

trip over it or in areas where the hose may be subject

to accidental damage.

.

repairs.

ghten. Use of a wrench

FLAME

AND INSTALLATION

are

TURN

.

7. Open tank valve fully (counter-clockwise). Turn the

on/off valve at the unit slowly to the on position and

use a soapy water solution to check all connections

for leaks before attempting to light the appliance. If a

leak is found, turn tank valve off and do not use the

appliance until repairs can be made by a local LP G as

Dealer. DO NOT attem

8. Never

components that have been damaged or exposed

to

attempt

an accidental fire.

pt to make repairs yourself.

to use this appliance or

ENCLOSURES FOR SELF-CONTAINED LP-GAS

SUPPLY SYSTEMS

If you build an enclosure for an LP gas cylinder you must

follow these specifications. You must also follow local

codes.

An enclosure for an LP-gas cylinder shall be ventilated by

openings at both the upper and lower levels of the

enclosure.

following:

a. One side of the enclosure shall be completely open; or

b. For an enclosure having four sides, a top, and a

bottom:

1. At least two ventilation openings shall be provided in

the sidewalls of the enclosure, located within 5 in (217

mm) of the top of the enclosure, equally sized, spaced at

a minimum of 90 degrees (1.57 rad), and unobstructed.

The opening(s) shall have a total free area of not less

than 1 in2Clb (14.2 cm2Ckg) of stored fuel capacity.

2. Ventilation opening(s) shall be provided at floor level of

the enclosure and shall have a total free area of not less

than

ventilation openings at floor level are in a side wall, there

shall be at least two openings. The bottom of the

openings shall be 1 in (25.4 mm) or less from the floor

level and the upper edge no more than 5 in (127 mm)

above the floor level. The openings shall be equally

sized, spaced at a minimum of 90 degrees (1.57 rad),

and unobstructed.

3. Every opening shall have minimum dimensions so as

to permit the entrance of a

4. Ventilation openings in sidewalls shall not

communicate directly with other enclosures of the

appliance.

The cylinder valve shall be readily accessible for hand

operation. A door on the enclosure to gain access to the

cylinder valves is acceptable, provided it is non-locking

and can be opened without the use of tools. Designs

using a cover to gain access to the cylinder and cylinder

valve shall be provided with handles or equivalent at a

minimum of 180 degrees apart to facilitate lifting of the

cover.

This shall be accompanied by one of the

1/2 in2Clb (7.1 cm2Ckg) of stored fuel capacity. If

1/8 in (3.2 mm) diameter rod.

any

Page 5

5

The enclosure for the LP-gas cylinder shall isolate the

cylinder from the burner compartment to provide:

a. Shielding from radiation;

b. A flame barrier; and

c. Protection from foreign material.

There shall be a minimum clearance of 2 in (50.8 mm)

between the floor of the non-disposable LP-gas cylinder

enclosure and the ground.

The design of the appliance shall be such that:

a. A non-disposable LP-gas cylinder can be connected,

disconnected, and the connections inspected and tested

outside the cylinder enclosure; and

b. Those connections which could be disturbed when

installing the cylinder in the enclosure can be leak tested

inside the enclosure.

Be certain to mount or set the LP-gas cylinder on a flat

stable surface and retain it to prevent it from tipping.

Purge the gas supply line of any trapped air prior to the

WARNING: During the initial purging and subsequent

Place the logs on the burner assembly. See log

Test fire the unit after referring to the SAFETY

INFORMATION and LIGHTING INSTRUCTIONS.

If

!Warning

!WARNING:

DO NOT LEAVE

DO

NOT LEAVE

FIRE PIT UNATTENDED

UNATTENDED WHEN

WHEN IN USE

USE

GAS

FP2085N FP2085LP

SPECIFICA

TIONS

FIREPIT

IN

first firing of the unit.

lightings, NEVER allow gas valve to remain in

"OPEN" position without first placing a burning match

on the top of the burner.

placement instructions.

LP-Gas outdoor firepits

a

couple

the

off the

couple

propane

to the

of

hours,

flame decreasing

control valve

of

hours before lighting again

tanks. The

volume

of gas

are used continuously after

you

could

see the possibility of

in size. If this

and the tank

propane

being taken

happens,

valve

and wait a

or switch

tank is

freezing

out of the tank.

turn

up due

FP2785N FP2785LP

Fuel Natural Gas Liquid Propane

Maximum Supply Pressure 10 IN. W.C./2.47 KPa 13 IN. W.C./3.24 KPa

Figure 1

The above photo shows an

example of an approved LP

cylinder retention device.

SS FLEX

4.5’ MIN

Page 6

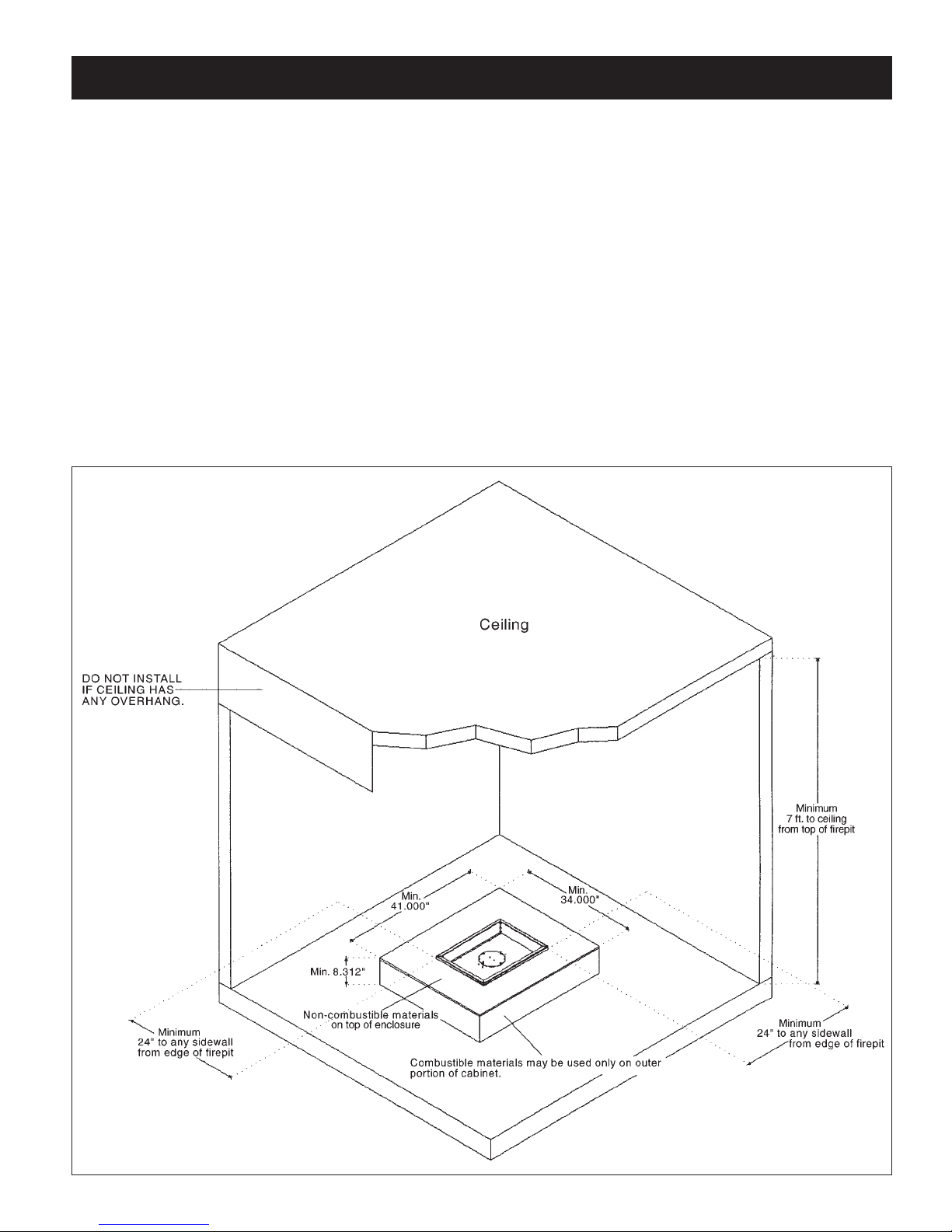

CLEARANCES FOR ROUND FIREPIT (FP2085)

1. The round firepit (FP2085) cannot be built into a

combustible cabinet of any type. Only noncombustible materials may be placed around firepit.

(eg. bricks, concrete, river rock, etc.)

2. Clearance to combustible side wall is 24” minimum.

Non-combustible walls 14” to side wall.

3. Minimum clearance to any ceiling with no overhang

is to be 7 feet from top of firepit.

4. Clearance to a combustible floor is 0”.

INSTALLATION IN COMBUSTIBLE ENCLOSURE

6

CLEARANCES FOR RECTANGLE FIREPIT (FP2785)

1. The rectangle firepit (FP2785) may be built into a

combustible enclosure. You must maintain minimum

enclosure dimensions of 321/2” x 391/2” I.D. The top

of enclosure must be of a non-combustible material

such as concrete board or wonder board.

2. Clearance to combustible side wall is 24” minimum.

Non-combustible walls 14” to side wall.

3. Minimum clearance to any ceiling with no overhang

is to be 7 feet from top of firepit.

4. Clearance to a combustible floor is 0”.

Page 7

1. Minimum size of wood enclosure must be no less

than 32.5” I.D. x 39.5” I.D.

2. Non-combustible material (eg. Wonder Board) for the

top of enclosure must be used, along with using metal

gussets.

3. Non-combustible materials such as tile or brick may

be used to finish on top of Wonder Board. Do not use

any combustible materials to finish top, eg. wood or

plastic products.

4. You must have an opening in the enclosure to have

access to the on/off valve.

INSTALLING RECTANGLE FIREPIT INTO A WOOD ENCLOSURE

7

Page 8

1. Using a non-combustible material (eg. Wonder Board)

cut two shields, 1 Large 44” x 30 min. and 1 Small 37”

x 30” min.

2. Mount six 1” non-combustible spacers to wall, this

will maintain a 1” air space behind shields Fig:1Ref:F.

Non-combustible spacer (eg. Metal Bracket, Wonder

Board) should be no wider than 1” and 30” long.

3. Screw non-combustible shield to spacer. Shield must

be placed 1” below top of firepit Fig:2-Ref:D. Inside

corners of shields should not touch combustible wall.

Shield must extend 3” past end of firepit Fig:1-Ref:E.

4. Note: Firepit cabinet or other structures must NOT

obstruct wall shield air space on ends, top or bottom.

If a cabinet is built around firepit, the end face of

cabinet must not extend past bottom face of clearance

shield by more than 1/2” Fig:2-Ref::D.

INSTALLING WALL CLEARANCE SHIELD

SINGLE CLEARANCE SHIELD

NON-COMBUSTIBLE CORNER CLEARANCE SHIELD

1. Side of unit must be more than 24” from a

combustible wall for a single shield to be used, and

can have a distance of no less than 14” to a wall shield.

2. All specifications as in corner installation must be

used, including shield must extend a minimum of 3”

past sides of firepit Fig:1-Ref:E.

8

Page 9

FP2085

9

Item No.

Qty

. Part No.

1 1 27FP-106 Burner

2 1 20FP-102 Burner Pan

3 1 20FP-101

4 1 20FP-103 Heat Shield

5 1 27FP-115 Gasket

6 1 27FP-200 Mixing Tube Asm

1 27FP-201

1 4000-208

1 Air Shutter

Description

SS FLEX (27FP-902FF)

FIREPIT

Frame

ASSEMBLY

Item No.

10 2 8-32 x 1.00 Screw

11 2 10-32 x .500 Screw

12 2 10-32 Locknut

13 2

14 2

15 2

Qty

.Part No.

7 1 1000-255 Orifice

8 1 125 x 375 Flare

9 1 27FP-104 Orifice Retainer

8-18 x .312 TC

8-18 x .500 DT

8-32 Locator

Screw

Screw

Pin

Description

#26

#40

Page 10

FP2785

10

Item No.

Qty

. Part No.

1 1 27FP-106 Burner

2 1 27FP-105 Burner Pan

3 1 27FP-115 Gasket

4 1 27FP-200 Mixing Tube Asm

1 27FP-201

1 4000-208

1 Air Shutter

5 1 1000-255 Orifice

SS FLEX (27FP-902FF)

Description

BURNER

Item No.

ASSEMBLY

Qty

.Part No.

6 1 125 x 375 Flare

7 1 27FP-104

8 2 10-32 x .500 Screw

9 2 8-32 Locator Pin

10 2 8-32 x 1.00 Screw

11 2 10-32 Locknut

12 2

13

8-18 x .312 TC

2 8-18 x .500 TC

Screw

Screw

#26

#40

Description

Orifice Retainer

Brkt

Page 11

After setting up your model and hooking up the gas connection, make sure that logs are not broken. Identify

the logs using the pictures below and place logs as indicated, lining up with mounting pegs in logs.

LOG PLACEMENT INSTRUCTIONS

STEP 1 STEP 2

STEP 3

STEP 5

STEP 4

This picture depicts the typical flame pattern of this

burner system.

11

Page 12

Accessories For Your Fire Pit

12

Fire Pit Covers:

27FP-113A For FP2785 Rectangular Fire Pit

(SUPPLIED WITH UNIT)

Non-Combustible Enclosures For Firepits

FP20COV For FP2085 Round Fire Pit

NOTE: Any non-combustible enclosure must have a minimum of [5] 1-1/2” holes for drainage.

Fire Pit Bowl for FP2085 Round Fire Pit:

KINGSMAN OUTDOOR FIRE BOWLS FOR THE 2085 FIRE PIT

Fire Bowl Includes:

Key Way Valve and Connectors

1/4 Lava Rock (10 Lbs)

Leg Extension & Filler Strip Ring

SS Flex Connector

Fire Pit not included

FPB30SG Fire Bowl - Smooth Grey

FPB30TB Fire Bowl -Textured Black

FPB30COVB Cover for Fire Bowl - Charcoal

30FPB-KWK Decorative Key Way Valve Kit

This Valve Kit can be used when installing your Fire Pit In a non-Combustible enclosure.

MUST BE INSTALLED BY A

QUALIFIED SERVICE

TECHNICIAN.

Page 13

30FPB-KWK Decorative Key Way Valve Kit

This Valve Kit can be used when installing your Fire Pit in a Non-Combustible Enclosure.

!WARNING

THE INSTALLATION OF THIS KIT MUST ONLY BE UNDERTAKEN BY A QUALIFIED AN D CER TIFIED GAS

APPLIANCE INSTALLER.

PARTS LIST:

1. 90° Ball Valve c/w Key Way Assembly (27FPCPBVS)

2. 1/2” MPT x 1/8” FPT Bushing (30FPBP110DA)

3. Tee 1/8” NPT (30FPB-P107A)

4. Hex Plug 1/8” MPT (30FPB-P118A)

5. Brass Connector 3/8” Tube OD x 1/8” MPT

(27FP-P904FF)

6. Valve Mount Bracket (20FP-117)

7. Key Way Installation Tool (20FP-116)

8. SS Flex Connector (27FP-902FF)

9. 3/8” Tube OD Union Coupling (30FPB-P426)

PROCEDURE:

1. Determine a suitable location for Valve if not supplied.

NOTE: Mounting surface of Valve should be

approximately 1” to 1-1/2” thick if you wish to use

supplied Valve Mount Bracket.

2. Drill a 1-1/8” hole (preferably with a core style masonry

bit) at this location.

3. Remove Key Way and Valve Mount Bracket from

Valve Body.

4. Remove existing valve from Fire Pit assembly.

5. Connect Key Way Valve Body to Fire Pit Connector.

6. Place Key Way into 1-1/8” hole.

7. Place Valve Mount Bracket onto Valve.

8. Manually start threads of Key Way onto Valve body.

9. Using supplied tool, tighten Key Way onto Valve.

10. Proceed with installation of Fire Pit and Fuel Supply.

Remove Existing Valve on Fire Pit

To Fire Pit

1 (Key)

7

4

5

3

! WARNING

Always check for gas leaks with a soap and water

solution. DO NOT USE OPEN FLAME FOR LEAK

TESTING.

USE PIPE THREAD SEALANT

1 (Key Way)

6

1 (Valve Body)

To Fire Pit

2

8

9

Fuel Supply

(LP Hose Shown)

Page 14

Kingsman Outdoor Fire Pit Media Section

14

MEDIA REQUIREMENTS OPTIONS: (When not using LOGC85 Log Set)

20 LBS of Glass Required for Fire Pits, if using the Fire Bowl add an additional 10 - 15LBS

One bag of MQSTONE may be used for the Fire Pit, if using the Fire Bowl an additional bag may be used.

One bag of 1/4" Lava Rock is required for the Fire Pit and an additional bag for the Fire Bowl may be used to fill the

entire Bowl with the same material.

REQUIRED AMOUNT OF MEDIA

ACCESSORY ITEM

*MLR1410 - 1/4" Lava

Rock 10 LBS

FP2785 Rectangular

Fire Pit

ROCKS

10 LBS

(1 BAG)

-MQ DEALERS ONLY-

FP2085 Round Fire

Pit Only

10 LBS

(1 BAG)

*Fire Bowl Includes: ¼” Lava Rock – 10LBS

FP2085 Round Fire

Pit With Fire Bowl

20 LBS

*(2 BAGS)

MQSTONE Decorative Stones

NOTE: The MQSTONE requires a Glass or Lava Rock Base.

MQG5W -1/2” White

Glass 5LBS

MQG5C - 1/2”Bronze

Glass 5LBS

MQG5A - 1/2”Cobalt

Blue Glass 5LBS

MQG5B -1/2” Black

Glass 5LBS

MQG10C - 1/4"

Reflective Bronze

Glass 10 LBS

MQG10B - 1/4" Black

Glass 10 LBS

1 BAG 1 BAG 2 BAGS

GLASS

20LBS

(4 BAGS)

20LBS

(4 BAGS)

20LBS

(4 BAGS)

20LBS

(4 BAGS)

20LBS

(2 BAGS)

20LBS

(2 BAGS)

Media Examples Shown Below.

20LBS

(4 BAGS)

20LBS

(4 BAGS)

20LBS

(4 BAGS)

20LBS

(4 BAGS)

20LBS

(2 BAGS)

20LBS

(2 BAGS)

30-35LBS

(6-7 BAGS)

30-35LBS

(6-7 BAGS)

30-35LBS

(6-7 BAGS)

30-35LBS

(6-7 BAGS)

30-35LBS

(3-4 BAGS)

30-35LBS

(3-4 BAGS)

FP2085 Without Media

¼” Lava Rock (1 Bag – 10LBS)

Page 15

15

¼” Lava Rock & ¾” Lava Rock (Supplied with Fire Pit).

(1/4” Lava Rock is used as Base.)

MQSTONE with ¼” Lava Rock Base – (10LBS)

NOTE: MQSTONE Requires a Glass or Lava Rock Base.

¼” Reflective Bronze Glass - (20LBS)

MQSTONE with ¼” Bronze Glass Base – (20LBS)

Page 16

OPERATING INSTRUCTIONS

U.L. Listed gas fireplaces are tested and approved for

elevations from 0 to 4,500 feet in Canada and U.S.A.

When installing this fireplace at an elevation above 4,500

feet (in Canada), check with local authorities.

Consult your local gas utility for assistance in

determining the proper orifice for your location.

Upon completing the gas line connection, a small amount

of air will be in the lines. When first lighting the burner,

it will take a few minutes for the lines to purge

themselves of this air. Once the purging is complete, the

burner will light and operate as indicated in the

instruction manual. Subsequent lighting of the appliance

will not require such purging.

WARNING: Read and follow the Safety and Lighting

Instructions page in this manual and on labels on the

appliance. IF YOU DO NOT FOLLOW THESE

INSTRUCTIONS PRECISELY, A FIRE OR

EXPLOSION MAY RESULT AND YOU MAY BE

SERIOUSLY INJURED!

16

MAINTENANCE INSTRUCTIONS

1. The appliance should be inspected before initial use

and inspected and cleaned at least annually by a

qualified field service person.

2. Tampering is DANGEROUS and voids all

warranties. Any component that is found to be faulty,

must be replaced with an approved component.

To obtain proper operation, it is imperative that the

3.

burner flame characteristics are steady, not lifting or

floating. Check the burner flame patterns with

Log Placement Instructions Section.

4. Periodically remove the logs and examine the burner.

If dirty, clean with a soft brush. Also examine the

area around the burner air shutter. Any dirt or lint in

this area should be removed. This will ensure long

life and trouble free operation. Re-install the logs as

shown in the log placement instructions. When the

appliance is put back in service, check the burner

flame patterns with Log Placement Instructions Section.

5. Periodically check the hose connecting the LP-gas

cylinder to ensure it is not damaged in any way.

HIGH ELEVATION INSTALLATION

Page 17

SAFETY INFORMATION AND LIGHTING INSTRUCTIONS

1. Turn the on/off valve to the off position at the unit

for natural gas unit. For LP unit, turn the on/off

valve to the off position at the unit and then turn the

valve on the LP tank to the off position clockwise.

2. Replace the top cover.

TO TURN OFF GAS APPLIANCE

5. If the burner does not light before the match goes

out, immediately turn the gas to off.

6. Wait at least five (5) minutes to clear out any gas.

If you have unsuccessfully tried to light the burner,

wait longer. Then smell for gas, including near the

floor. If you smell gas, STOP! Follow “B” in the

safety information above. If you don’t smell gas,

repeat step 4.

1. STOP! Read the safety information above.

2. Remove the top cover.

3. Find the manual gas control valve.

4. Place a burning match on top of burner in the

middle where ports are present. DO NOT HOLD

THE MATCH IN HAND. For Natural Gas unit

turn on the on/off valve slowly at the unit. For LP

unit turn the valve on the LP tank counterclockwise all the way and then turn on the on/off

valve slowly at the unit.

• If you cannot reach your gas supplier, call the fire

department.

C. Use only your hand to turn the gas control knob or

valve. Never use tools. If the valve will not turn by

hand, don’t try to repair it, call a qualified service

technician. Force or attempted repair may result in

a fire or explosion.

D. Do not use this appliance if any part has been

underwater. Immediately call a qualified service

technician to inspect the appliance, and to replace

any part which has been underwater.

A. This appliance must be lit by hand. When lighting,

follow these instructions exactly.

B. Before LIGHTING, smell all around the appliance

area for gas. Be sure to smell next to the floor,

because some gas is heavier than air and will settle

on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone

in your building.

• Immediately call your gas supplier from a neighbours

phone. Follow the gas suppliers instructions.

WARNING: If you do not follow these instructions exactly, a fire or explosion may result

causing property damage, personal injury or loss of life.

FOR YOUR SAFETY READ BEFORE LIGHTING

LIGHTING INSTRUCTIONS

17

Page 18

FP2085/FP2785 Parts List

18

KINGSMAN FIRE PITS:

Listed for Canada and USA

NUMBER DESCRIPTION

FP2085N Round 20” Diameter - 65,000 BTU - Natural Gas c/w 10LBS ¾” Lava Rock

FP2085LP Round 20” Diameter - 65,000 BT U - Liquid Propane c/w 10LBS ¾” Lava Rock

FP2785N Rectangular 27” x 20” - 65,000 BTU - Natural Gas c/w Cover & 10LBS ¾” Lava Rock

FP2785LP Rectangular 27” x 20” - 65,000 BT U - Liquid Propane c/w Cover& 10LBS ¾” Lava Rock

LOG SET

LOGC85 Log Set - Four piece Cast oak

MEDIA OPTIONS

MLR1410 Media - 1/4" Lava Rock 10 lbs

MEDIA OPTIONS – MQ DEALER ONLY

MQSTONE Decorative Stones

MQG5W Decorative Glass 1/2” White

MQG5A Decorative Ember Glass 1/2” Cobalt Blue

MQG5C Decorative Ember Glass - 1/2” Bronze

MQG5B Decorative Ember Glass - 1/2” Black

MQG10C Media - 1/4" Reflective Bronze Glass 10 lbs

MQG10B Media - 1/4" Black Glass 10 lbs

FIRE PIT ACCESSORIES OPTIONS

FP20COV Cover for Round Fire Pit

27FP-113A Cover for Rectangular Fire Pit (SUPPLIED WITH UNIT)

30FPB-KWK Decorative Key Way Valve and Connectors

MUST BE INSTALLED BY A QUALIFIED SERVICE TECHNICIAN

OUTDOOR FIRE BOWLS FOR THE 2085 FIRE PIT

Fire Bowl Includes Key Way Valve and Connectors, 1/4 Lava Rock (10 Lbs), Leg Extension, Filler Strip Ring and SS

Flex Connector. Fire Pit not included.

FPB30TB Fire Bowl - Textured Black

FPB30SG Fire Bowl - Smooth Grey

FPB30COVB Cover for Fire Bowl - Charcoal

FPB30COVG Cover for Fire Bowl - Grey

KINGSMAN FIRE PITS REPLACEMENT PARTS

27FP-900FF LP Reg & 5ft Hose (I4T60GRQC)

27FP-901FF Ball Valve with Manometer (BVTM5042-6)

27FP-902FF SS Gas Connector 16” (ACS-375-16)

27FP-P904FF Brass Connector 48-6A

27FP-P486D Connector 3/8 to ½ 48-6D

1000-255 Brass Orifice

27FP-115 Gasket

REPLACEMENT PARTS FOR MANOMETER SUB-ASSEMBLY OF 30FPB-KWK KEY WAY VALVE KIT

30FPB-P107A Tee 1/8 107-A @ 1.280

30FPB-P110DA Bushing ½-1/8 110-DA @ .72

30FPB-P118A Plug 118-A @ .22

Page 19

Kingsman Fireplaces Gas

gives

you

Save this certificate. It

to

state.

In the

event

your unit

service, please

distributor

Fill in the

warranty

have the

is

available

installation

for your files.

needs servicing contact

model

for

support

date and

specific

and

and we, in turn

model

GENERAL TERMS

This

limited warranty applies

inside

the

continental United States, Alaska, Hawaii

operated

trade

During

defective

replacement

In lieu of

credit equal

a

credit

a

warranty claim

In

warranty, reasonable

the date of

Any

warranty

W e will not be

riot. fire,

chlorine, fluorine,

any

matching

and

in

application

use of

W e shall not be

of this

there

this

connections

provinces

long an

limited warranty

remedies provided

Model No.:

in

accordance

practices.

the first year after

in

materials

part.

providing a replacement

to the

is

given

establishing

manufacture

labor, material, freight and/or handling charges associated

will be your

flood,

unauthorized alteration

or

application

service

connection

limited warranty.

to the unit (f) any

with

(i)

electricity

supplemental electric

unit.

We

is no

implied condition

with this

do not

implied Warranty

or

distributor’s component purchase price from

in lieu of a

and the unit

the date of

proof of the

responsibility.

responsible

or Acts of God (b)

or any

service

liable

have

not

No one is

unit.

allow

are in

by law .

Date Installed:

*You

must retain

the

original records

only

while

with the

workmanship.

plus

other damaging chemicals (other

of the unit or the unit's

or fuel costs or any

for any

made

the

or

additions

printed instructions

installation,

part, we

replacement

being replaced must

installation

original installation

thirty

(30) days.

In this

for and you the user will pay for: (a)

damages caused

or

repair

expenses incurred

or

maintenance

heat.

incidental, consequential,

and do not

of

fitness

authorized

Any

implied warranties

exclusion

condition

to and not a

that can

legal rights, and you may also have other rights which may vary from

your

dealer

serial number from

support

and

serial numbers

the unit

we will

The part to be

part, the

for any

of the unit

for a

or

limitation

lasts so the

remains

and

and in

provide a replacement

replaced must

may,

at our

rating plate from

be

made available

purpose including determination

date

warranty

(h)

increase

make

particular

to

establish

the word

by

affecting

components

for

erecting disconnecting

damage repairs, inoperation

in

any

representation

use or

change

modification

this

shall last for one year after the

of

incidental

above limitations

the

installation

Fire Pit – Limited Warranty

or

contractor

each unit

the

distributor's

of the unit in the

at the site of the

Canada.

compliance

option, provide

us

must

be

with any

"installation" means original

damages caused

operating

than in a

its

stability

(e)

damages caused

electricity

or

special damages

purpose.

limited warranty

or

of or

subtraction from

Serial No.:

date of your unit.

who

readily available.

efforts.

space provided below

original installation

The

warranty applies

with

for any

be

returned

the

distributor's component purchase price from

toward

the unit

or fuel cost

consequential damages

the

the unit

presented*, otherwise

being replace must

to our

repair

where there

normal residential environment)

or

performance

or

or

warranty

We

make

or to

or

exclusions

installed

applicable

component

purchase

distributor

or

inefficiency resulting from faulty installation

whatsoever including additional

or

or

service

If your

only if the unit is installed and

installation,

part of your unit

to our

distributor

of any new unit

for disposition.

of the

starting

or

replacement pursuant

by

accident, abuse, negligence, misuse,

is a

(d)

damages caused

by

failing

dismantling

expenses

of

fitness

no

express warranties except

create

for us any

original installation. Some states

may not

an

statutory warranties

your

unit. When

dealer needs assistance,

and

retain

this limited

and only if the unit

building codes

found

in

exchange

which

be

submitted

date for the term of this limited

the

effective

installation.

corrosive atmosphere

to

provide proper

the unit (g)

in

connection

for a

or do not

apply

date will be

to this limited

(c)

damages caused

by improper

parts

or

with any use or failure

particular

other obligation

to you. The

use or

allow limitations

and

other

requesting

is installed

and good

to be

for the

we

distribute.

on

based

containing

maintenance

supplies

or unusual

purpose

as

stated

or liability in

and

on how

provisions

rights and

state

the

us

or a

upon

by

used

or

and

in

of

this

If

Loading...

Loading...