KINGSINE K68i, K68 Instruction Manual

roger@kingsine.com.cn

K68i / K68 Relay Tester

Instruction Manual

Version: 1.3

Kingsine Electric Automation Co., Ltd.

K68 Series Protection Relay Test Set

roger@kingsine.com.cn

Dear Customers:

Thank you for using Kingsine Series Relay Tester. We hope the technical data and information in

the manual can be provided to you for use and operation as detailed as possible. Meanwhile, we

shall be appreciated highly if experts, technicians and readers can give us your precious comments.

If you need business consultation or technical support service, please call us or visit our website.

Oversea Trade : +86-755-8341 8941

Customer Service: +86-755-8835 2590

Website : http://www.kingsine.com.cn

Email : roger@kingsine.com.cn

Note:

This manual is applicable for KINGSINE K68i and K68 Relay Tester but it is compiled to use K68i

as example. The corresponding updated software and functions instruction will be released on our

website (www.kingsine.com.cn), when updating the software and increasing the contents. In order

to obtain the latest and first-hand information, please pay more attention to the latest news on our

website. The functions and pictures mentioned in this manual will be as reference only and the

released real product is the sole standard.

1

Catalogue

roger@kingsine.com.cn

Chapter 1 Overview.............................................................................................................................3

1.1 System Description................................................................................................................3

1.2 Technical Parameters.............................................................................................................4

1.3 Amplifier for Voltage and Current .........................................................................................7

1.4 Package list ............................................................................................................................7

1.5 After service:..........................................................................................................................7

1.6 Attention:................................................................................................................................8

Chapter 2 Panel Description ................................................................................................................9

Chapter 3 Testing Operation ..............................................................................................................12

3.1 Main Menu...........................................................................................................................12

3.2 Basic Operations..................................................................................................................13

3.3 DC Relays Testing................................................................................................................15

3.4 AC Relays T esting................................................................................................................20

3.5 Distance/ Zero-sequence Relays Testing .............................................................................26

3.6 Harmonic Output Testing.....................................................................................................37

3.7 Frequency Protections Testing .............................................................................................41

3.8 Aux DC ................................................................................................................................48

Chapter 4 System Calibration, Settings & Update.............................................................................49

4.1 System Calibration...............................................................................................................49

4.2 IP Setting..............................................................................................................................55

4.3 Software Upgrade and Report Upload.................................................................................57

- 2 -

1.1 System Description

roger@kingsine.com.cn

K68 Series Relay Tester is new All-in-One protections testing systems developed

independently by KINGSINE on the basis of Windows CE system, which adopts the

embedded system, the latest high-speed DSP processor and ultra-large-scale field

programmable logic devices FPGA.

It have high-precision signal and high-efficiency and high-stability power amplifier with

the advanced level in the world by the developed digital phrase lock patented algorithm and

SPWM technology based on the advanced SOC design concept, to provide customers with

comprehensive and easy-to-use testing solutions with complete functions.

It is widely applied to power industry, metallurgy industry, petrochemical industry, railway

K68 Series Protection Relay Test Set

Chapter 1 Overview

and scientific research institution as well as industrial and mining enterprises and power

equipment factories that on a large scale.

Characteristics:

1. High power: 3 x 0…35A with a power of 450VA for Medium/Low Voltage test.

2. Phase, frequency and amplitude are independently and continuously adjustable.

3. The maximum output of DC voltage for every phase:300V

4. High Precision: 0.14% reading+0.06% range guaranteed at 0-35A & 0.14% reading+0.06%

range guaranteed at 0-300V.

5. Auto/Manual Test on all its five modules: DC Test, AC Test, Distance Test, Harmonic Test,

Frequency protection.

6. 3-Years Warranty for free repair.

7. Reliability: Self-protection by stop output plus with light flashing/sound alarming in case

of wrong-wiring, open/short-circuit, overheat & overload.

8. On-site Testing Convenience: the equipment can be put vertically or horizontally when

on-site testing.

9. The tester could upgrade by USB and can make speed data communication between

computer On 100M-T Network-card.

10. Internal design is of architectural style framework and of shock & impact resistance

external box made of high intensity aluminum alloy enables the equipment subject to rigid

vibration.

3

K68 Series Protection Relay Test Set

roger@kingsine.com.cn

K6 Series Protection Relay Tester main Tech description

Factor

(DC Module Setting)

(Interface Setting)

Binary Input 8 pairs ● ●

Binary Output 4 pairs ● ●

Model

K68 K68i

AC Current I 3*35A 3*35A

AC Voltage U 4*130V 4*300V

DC Current I 3*20A 3*20A

DC Voltage U 1*150V 1*150V

DC Voltage Ubc 1*300V 1*300V

Aux. DC

0~300V 0~300V

Aux. DC

0~260V 0~300V

1.2 Technical Parameters

Voltage generators (overload and short protection)

Setting

Range

Power

Accuracy

Rise/down time

Resolution

Setting

Range

Power

4-phase AC (L-N)

2-phase AC (L-L)

4-phase AC (L-N)

2-phase AC (L-L)

<0.14% reading + 0.06% range guaranteed at 0-300V;

<0.04% reading + 0.01% range typical at 0-300V

Current generators ( O/C protection)

3-phase AC (L-N)

1-phase AC (3L-N)

3-phase AC (L-N)

1-phase AC (3L-N)

4x 0 ... 300 V

2 x 0 ...600 V

4 x 110VA, max. at 0 ... 300V

2 x 220VA, at 0 ... 600 V

<120µs

1mV

3 x 0 ... 35A

1 x 0 ... 105A

3 x450 VA max.

1 x 900VA, at 0 ... 105A

Accuracy

<0.14% reading + 0.06% range guaranteed at 0-35A;

<0.05% reading + 0.02% range typical at 0-35A;

4

K68 Series Protection Relay Test Set

roger@kingsine.com.cn

Rise/down time

Resolution

Voltage and Current Synchronism

Range

Accuracy / drift

Frequency

Harmonic superimpose

Resolution

Range

Phase

Accuracy / drift

Resolution

Range

Timer

Accuracy / drift

<50µs

1mA

Generators, general

≤10μS

0 ... 1000 Hz

Error < 0.001Hz at 0 ... 50Hz

2-9 orders

0.001Hz

0° ... 360°±0.2°

Error < 0.2 °

0.01°

0.1mS ... 9999.999S

Error<0.1ms

Voltage ranges

Current ranges

Accuracy

Resolution

Ranges

Accuracy

Number

Resolution

Time range

Ranges

DC generators (over-load protection)

0 ... 300V/180VA

0 ... 20A (60A on 3-phase-paralleling)/300VA

<0.14% reading + 0.06% range guaranteed at 0…20A;

<0.05% reading + 0.02% range typical at 0…20A;

1mA; 1 mV

Aux DC supply

0~300V/0.5A

Error<0.5%

Binary inputs

8 pairs (extendible to 64channel)

0.1ms

0.1mS -9999.999S

10V ... 250V

Binary outputs

Number

Ranges

DC-250V/3,AC-250V/3A

4 Pairs

Power supply

Nominal input voltage

Power

5

220V±10% VAC, 1-phase

1000VA/Max.15A

K68 Series Protection Relay Test Set

roger@kingsine.com.cn

Nominal frequency

Working temperature

Storage temperature

Humidity range

Box

Weight

Dimensions

Interface

50/60±10% Hz

Environmental conditions

-5°C... 55 °C

-20°C... 75 °C

5 ... 90 %, non-condensing

Alloy aluminum

24KG

360(D)×140 (W) ×460 (H) mm

RJ 45, USB,RS232, PS/2,VGA

6

K68 Series Protection Relay Test Set

roger@kingsine.com.cn

1.3 Amplifier for Voltage and Current

Current generator and voltage generator have no current booster and no voltage booster, but direct

coupling mode is adopted by them, which enables the power supply’s frequency output range to be

from 0Hz to 1000Hz, outputting DC and all AC voltage or AC current in all frequency. Such as

square waveform, varying waveform in proportion with the exponential function as well as mixed

Reclosing waveform. Basically it meets the transient testing requirements of the protection device,

thereby achieving the simple simulating test on various protection devices.

Power amplifier circuit has the perfect protective function against over-current, over-voltage and

over-temperature so that keep the high-power components of the set from damage in the test. When

the power amplifier is charged, the internal circuits of protection relay will real-time monitor/detect

the output current value from the voltage circuit and determine whether the detected current values

are overload. When there is overload or short-circuit in the circuit voltage, the power of the power

amplifier will shut down automatically and the test will stop, giving out the warning signal.

1.4 Package list

Relay-Tester mainframe 1set

Operation software 1set

Twisted-pair 2pc

Special testing cables 1kit

Power cord 1pc

Instruction Manual 2pcs

Aluminum alloy packaging box 1pc

1.5 After service:

The Host will have free maintenance for three years. While the 3-year guarantee for free repair shall

be subject to the condition that the ‘products’ shall not be modified or improperly used within three

years after being sold. In order to improve continually on the reliability and performances of the

hardware and software of the test device, welcome all customers to bring forward valuable

comments and suggestions on this product. We will be happy to work with you and explore and

strive to meet your requirements.

7

K68 Series Protection Relay Test Set

roger@kingsine.com.cn

1.6 Attention:

z There are good Grounding picture in the right bottom of each interface menu.

The grounding link is abnormal if showing picture

In order to insure the test security and the accuracy of testing result, please check the power

supply whether the grounding is proper.

z It is prohibited to connect the host instrument with 380V three-phase AC or DC power supply.

z Before testing, the grounding line jack must be reliably grounding; otherwise it might damage

the Relay Tester.

z The voltage circuit can not be short circuit or overload, and the load of the current circuit

should meet Impedance values under the given technical parameters so that avoid the overload

affecting the testing results.

z In case that there is overload or short-circuit in the voltage generator, the Relay Tester will

automatically shut down the power of the amplifier power and give out warning signal.

Maximum current load in each phase is up to 0.55A for the voltage generator.

z In case that the large current has been output for a long time, and as a result, the power

amplifier’s temperature is at high degrees, the Relay Tester will automatically shut down the

power of the amplifier power and give out warning signal, User shall stop test right until the

amplifier power gets cool.

z Binary Input’s potential is directional. So better to use idle contact as usual.

z Negative terminals A, B, C of Binary input are all connected together, but not connected with

the public terminal ‘N’ of voltage / current output terminal and the ground wire (such as panel,

machine box) that is the suspending ground. Binary Input’s terminal is compatible with the idle

contact and the potential (10-250V). However, Binary Input’s terminal has directionality for the

input of the charged contact, as shown in the Figure below, A, B, C and R are connected with

the high potential (+),the negative terminal are connected with the lower potential (-) of the

charged contact, and then the computer can detect the overturn of the contact state. If the

connections are in reverse, what will always be detected will be the closed state.

z If there is emergency in the process of the test, the Power Amplifier button must exit rapidly

and then to shut down the power of the host of Relay Tester.

8

K68 Series Protection Relay Test Set

roger@kingsine.com.cn

Chapter 2 Panel Description

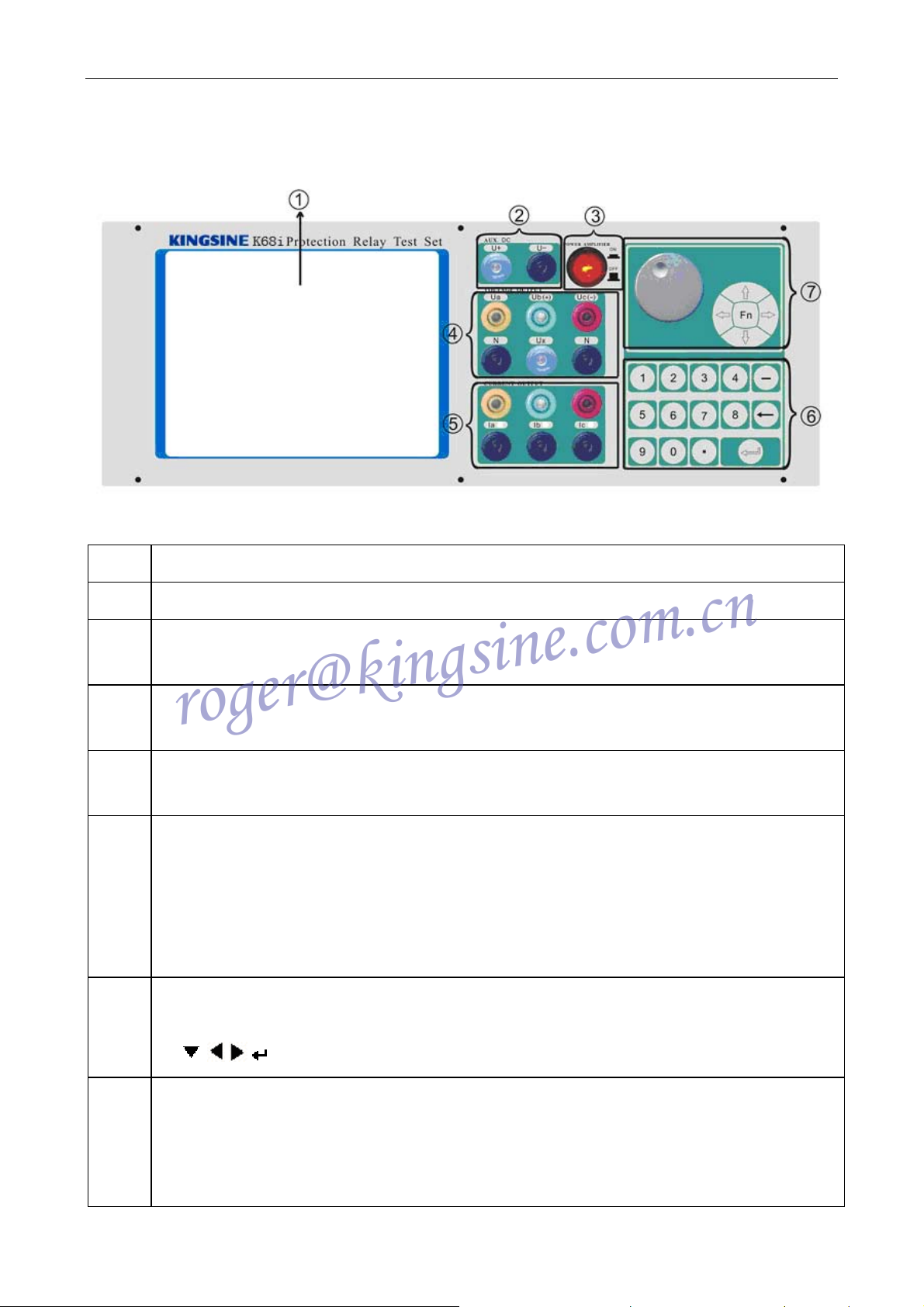

(1)

(2)

(3)

(4)

(5)

(6)

Fig. 2-1 Panel Description

6.4” TFT LCD screen

U(+) and U(-) are for Aux. DC supply,

Power amplifier button: Press the button to start amplifier, while amplifier stop

working the moment the button revert.

UB and UC are applied for programmable DC output of DC module. UN terminal is

electrically connected.

Both AC current and DC current can be output from Current output terminals. IN

terminal is electrically connected.

Functional keyboard: the numeric keys from 0 to 9 are worked for changing the

data of the testing menu. When inputting the data, user should firstly point to the

data position which to be modified with the mouse, and then click the confirm

button. Previous data get cleared and then input new data. After the input please

click confirm button.

Rotary encoder: clockwise move cursor to left and anticlockwise move cursor to left

(7)

(8)

and pressing down or Fn Key for enter. It can be substituted for the button

, , , on the function keyboard.

▲,

Binary Input contact:

1) Public terminal TN corresponds to binary Input contact A, B, C, and TN is electrically

connected.

2) Binary contact are compatible with idle contact and charged contact, Potential +

9

K68 Series Protection Relay Test Set

roger@kingsine.com.cn

terminal of charged contact is supposed to connect to public terminal TN (HN).

10

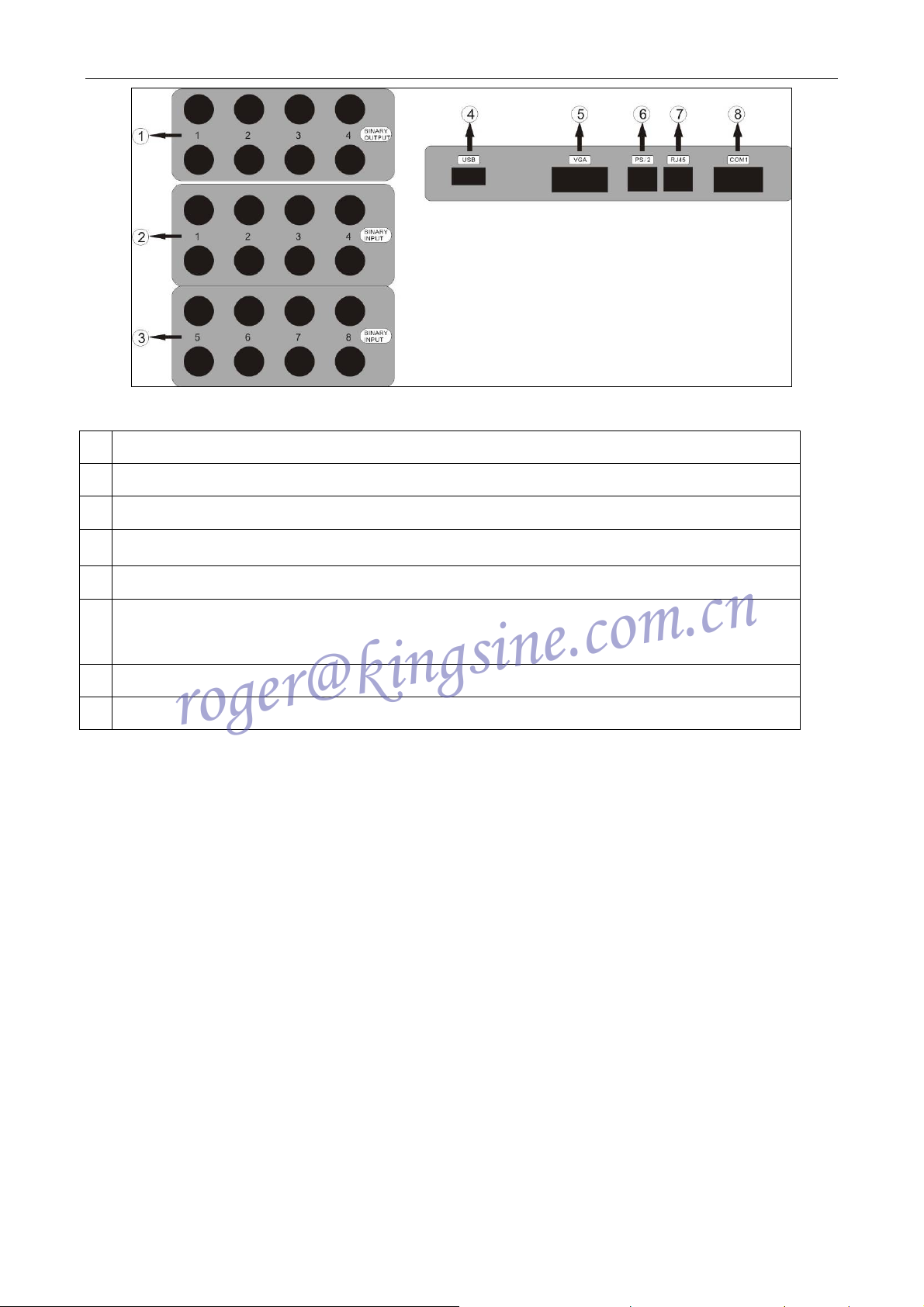

1 Binary Output

roger@kingsine.com.cn

2 Binary Input

3 Binary Input

K68 Series Relay Tester

Fig. 2-2 Panel Description

4

USB interface,is meant to be external connective to various

5 VGA interface, is meant to be external connective to various VGA display

6 PS/2 mouse or keyboard, is meant to be external connective to PS/2 mouse or

keyboard at one time

7 RJ45 interface, is meant to have data transmission between network and computer;

8 COM4

11

K68 Series Relay Tester

roger@kingsine.com.cn

Chapter 3 Testing Operation

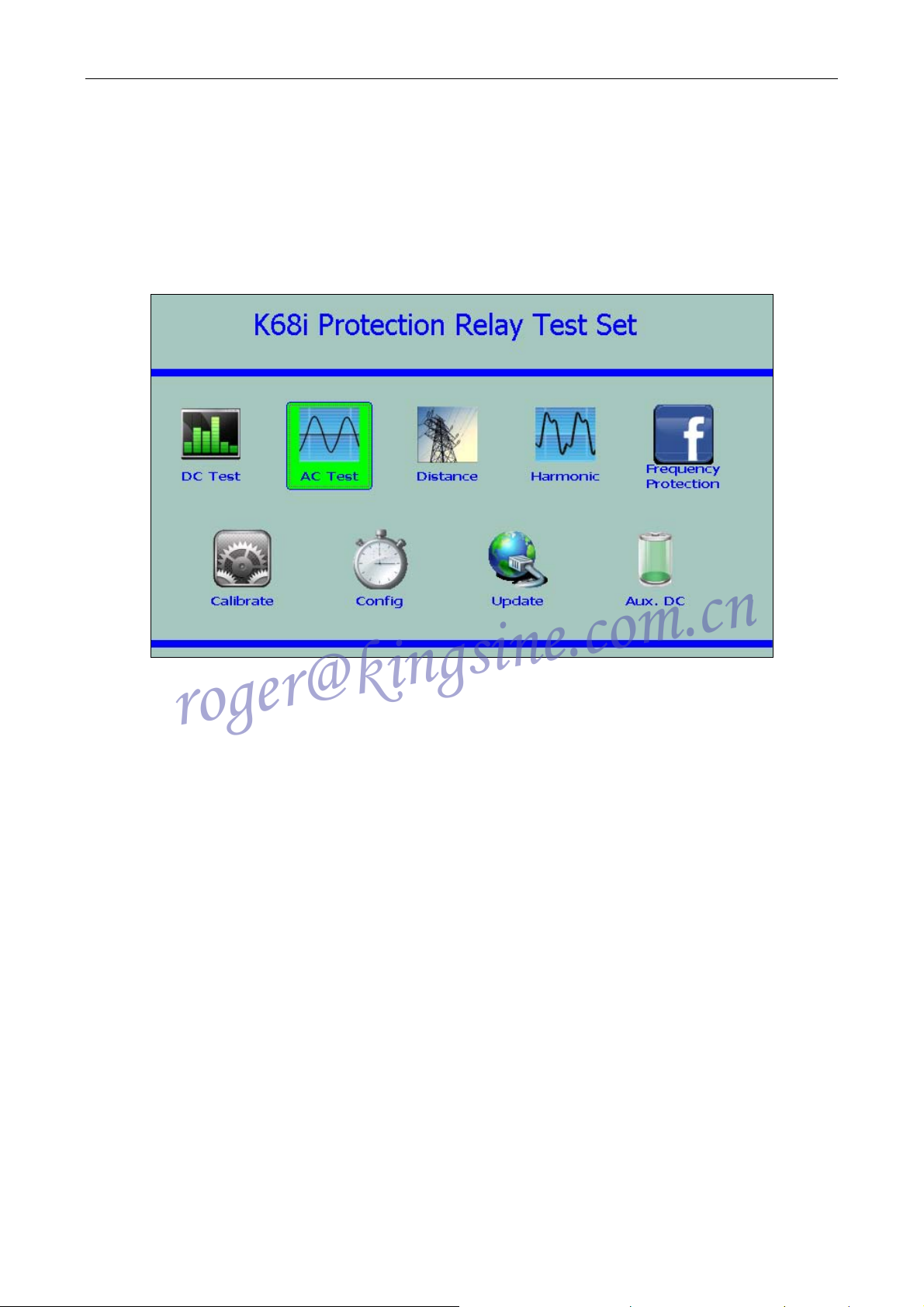

3.1 Main Menu

The main interface of user Operation is shown as below after set software start running:

Fig 3.1-1 Main menu

Users may choose to enter the function modules required with the Rotary encoder or mouse and can

also switch to choose the function modules with the first shortcut key or the direction key on the left

of the external keyboard and then press ‘Enter’ to enter.

DC Test DC Relays Testing

AC Test AC Relays Testing

Distance test the Property of the whole set on circuit protection, such as the

distance relays and zero-sequence relays

Harmonic control Relay Tester and output AC and DC and harmonic to test

automatically and manually, and the oscillogram is used for real-time

monitor of every output channel.

Frequency Frequency protection and test the action value, action time, df/dt

action value, the closed value of voltage and the lockout value of

current of various frequency relays and Low Frequency Decrease

Load automatic device.

Remarks: The Main menu contains the information: name, version number, function modules,

12

K68 Series Relay Tester

roger@kingsine.com.cn

company name, website and telephone of the current system. The reference of the first edition of

K68i Instruction such as software upgrade or content supplement. The real function should refer to

the set latest version as software upgrading.

3.2 Basic Operations

(1) Run

Click ‘Run’ button and begin to this test.

(2) +

Click ‘+’ manual increase button and the chosen variable are increased gradually in

accordance with the set step length.

(3) -

Click ‘-’ Manual decrease button, and the chosen variable is decreased gradually in

accordance with the set step length.

(4) PgDn

Click ‘PgDn’ button, and switch to another Parameter Setup interface.

(5) Save

Click ‘Saver’ button, spring out ‘Save parameter’ interface. In the interface of ‘Save

parameter’, save the tested parameters or import the tested parameters previously saved

and delete parameters.

(6) Report

When springing out ‘Report processing’ interfaces, save, View or delete a report.

(7) Bin. Input

Binary Input: the potential of the electric volume of the input switch has directionality,

under the normal circumstance, you had better use the dead contact. A, B, C negative

terminals of Binary Input terminals are all connected together, and not connected with

the public terminal ‘N’ of voltage and current output terminal and the ground wire (such

as panel, machine box) that is the suspending ground. Binary Input terminal is

compatible with the dead contact and the potential (10-250V). However, the input with

electric contact has directionality (refer to the attentions in 1.6 above for the detail).

(8) Bin. Output

Binary Output: the impulse signal can be triggered from the Relay Tester, to start some

functions of the protection device and reach synchronous or delay timing.

(9)Load

13

Switch the light load and heavy load of the Relay Tester. Under the normal

roger@kingsine.com.cn

circumstances, the Relay Tester outputs light load; when the impedance value is greater

with load or the greater current is output in the Relay Tester; it is proposed to switch the

state of the heavy load before testing.

(10)Exit

Exit this module and Return to the Main menu of the system.

(11)Fn

Press ‘Fn’ function key can jump the Cursor to the bottom function control key and step

to next key.

K68 Series Relay Tester

14

K68 Series Protection Relay Test Set

roger@kingsine.com.cn

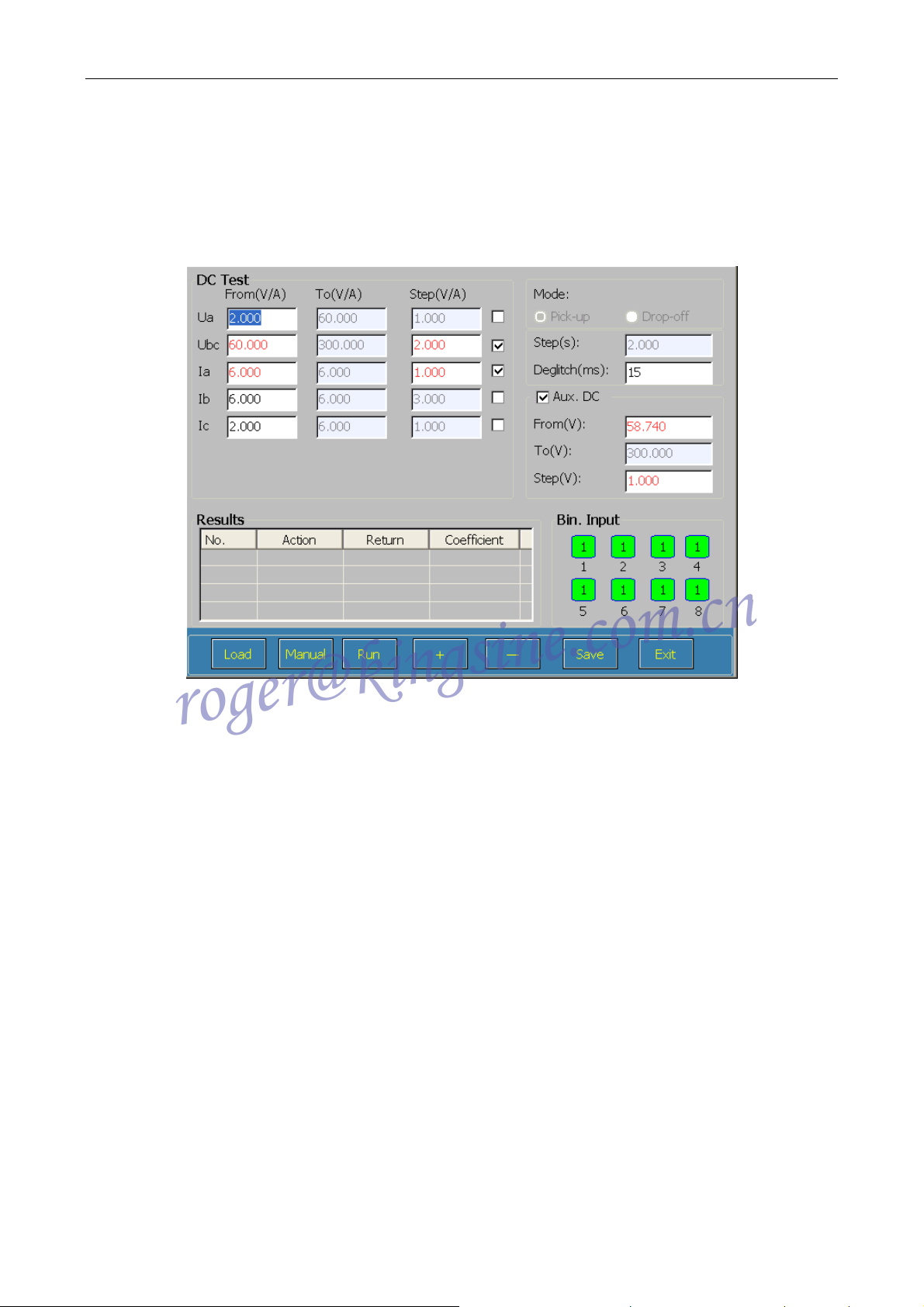

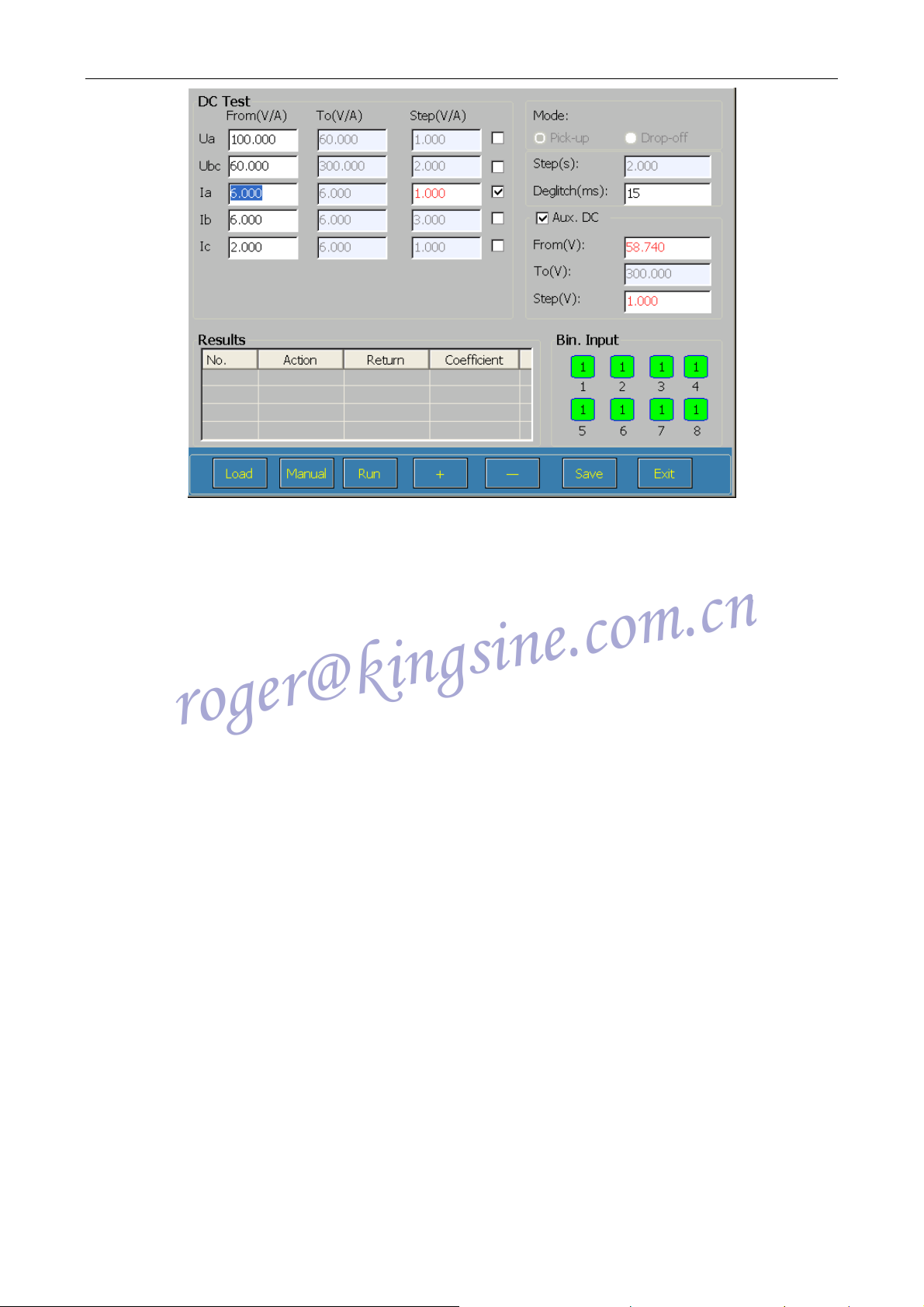

3.3 DC Relays Testing

Click‘DC Test’ module of the Main menu and enter Direct Current interface, This Module test

manually and automatically action value and return time of AC current/Voltage relay as shown in

Fig. 3.3-1:

Fig. 3.3-1 DC Relays Testing

3.3.1 Interface Introduction to the set

There are 3 areas in the Main:

① Left upper area of the interface: You can set the starting value, the final value and step size for

each variable value of the tested AC and DC voltage and current. There are a 4 voltage

channels and 3 current channels in the area, including DC 0-150V voltage output from

UA, UB, UC port and DC 0-300V voltage output from Ub (+) and Uc (-) port. And

0-20A DC current is output from IA, IB, and IC. Click ‘√’of the option box of

‘variable’ with the mouse, as indicates the variables will the variable tested.

② On the left upper area of the interface: The setup area for testing parameters:

③ On the lower area of the interface: It displays the open or close state of Binary Input or Binary

Output and it is the display column of tested results.

15

K68 Series Protection Relay Test Set

roger@kingsine.com.cn

Fig. 3.3-2 DC Relays Testing

3.3.2 Parameter setup of the set:

Variable : including Amplitude Value, phase and frequency, one of which can be chosen as a

variable and eight channels(five-way voltage and three-way current)of which can also

be chosen as variable output.

Test mode: including Automatic test and manual testing mode.

Auto: Control Action value, Return Value and Return Coefficient of the testing variables through

setting variable mode, automatic test time and variable step size. When testing, the

variable will increase or decrease by degrees from the starting value to the final value in

accordance with automatic time and step size; when doing an excessive test, set step

size to the positive and the starting value set must be less than the final value; when

doing an inadequate test, set step size to the negative and the starting value set must be

more than the final value. Note: Click ‘Stop’ button to stop the test and then amend the

parameters to retest if a new test is required by changing the parameters in the

automatic test.

Manual : Control the test manually by variable step size of ‘+’ Manual increase or‘-’ Manual

decrease. When testing, the change of the variable will not be controlled by the change

time and not be limited by the final value, step size will not be set to the negative, and

the test of increase or decrease by degrees can be done by +Manual increase and

-Manual decrease; when Binary Input receives the action signal and then the test stops,

16

K68 Series Protection Relay Test Set

roger@kingsine.com.cn

meanwhile, action time and action value are recorded. After testing, the setup

parameters will be changed to re-test without clicking ‘Stop’ button to stop the test, for

the parameter can be changed directly.

Mode : Only adapt to Automatic test, including ‘Action stops’ and ‘Action returns’ mode.

Pick-up: Variables change to strop from the starting value to the final value in accordance with step

size or receive the protection signal to stop the testing process in the process of the

change. Action time and Action value will be automatically recorded and action value

or Return Value of the variable can be tested.

Drop-off : Voltage or current variables change from the starting value to the final value in

accordance with step size, when the protection action signal is received, the variable

will begin to return to the starting value until return signal is received, when Action

stops, action time, action value, return value and return coefficient will be recorded.

Action value, return value and return coefficient will be automatically tested.

Steps(s): when automatically testing, the time of step size changes once for the variable, the

automatic time generally set should be more than Action time and Return Time of the

relay, Maximum Automatic testing time is set to 1000s. When manually testing, users

can grasp the changing time.

Deglitch(s): JitterBuffer time, Deglitch(s) generally can be set to 15ms, it functions when the tested

result is affected due to the jitter of the protection access point in the process of testing

during automatic test, only after the lasting period when the access point is closed or

disconnected meets the set time, the located state is authorized.

3.3.3 Testing process

Click ‘DC Test’ module with the mouse and enter the interface shown in Fig. 3.3-3:

17

K68 Series Protection Relay Test Set

roger@kingsine.com.cn

Fig. 3.3-3 Direct Relays Testing

1) Testing connection

Connect the testing terminals of the relay or the protection device to be tested with the

corresponding output port of the current or voltage by wire and connect the contact of the

relay or the output contact of the protection device with Binary Input port of the Relay Tester

by wire. (Note: DC voltage is output from Ub (+) and Uc (-) port and DC current is output

from IA and In).

2) Parameter setup

A. Set testing mode, including Manual test and Automatic test.

B. Set variables and the starting value and the final value of variables.

C. Set Binary Input (Digital input) and time mode.

D. Set ‘Light load’ or ‘Heavy load’ according to the testing load bulk of the Relay Tester.

E. Save Parameters.

F. Run.

G. Report processing and choose whether to save the report.

3) T esting process

Click on ‘Run’ button to begin the test and click ‘stop’ key if pausing the test in

Operation. In the process of manual test, the parameters of the variable can be changed. If it is

the automatic test, the parameters cannot be changed. Manually press ‘+’ and ‘-’ to make the

relay operate if it is the manual test, when action value and action time are recorded. When

clicking ‘stop’, the test ends and Save Report dialog box is automatically sprung out. Press

18

K68 Series Protection Relay Test Set

roger@kingsine.com.cn

‘Save’ to save results and ‘View’ to preview the selected testing report.

19

Loading...

Loading...