S

S

LAP

LAP

U

U

SER

SER

M

M

ANUAL

ANUAL

Table of Content

A. Content

B. Introduction

C. Specification

D. Design Consideration of KingRex SLAP

E. Important safety instruction

F. Safety caution

G. Operation environment presentation

G.1 Front panel

G.2 Rear panel

H. Installation

H.1 Inspection

H.2 Placement

H.3 Battery charging

H.4 Connect the loads

I. Operating method

I.1 Switch on

I.2 Battery replacement

J. Troubleshooting

K. Storage

L. Maintenance

M. Service

N. Our best wishes

Content

SLAP*1

DC cord * 1

AC cord * 1

User manual * 1

Warranty card *1

Introduction

SLAP is designed with automatic monitoring by TI UC3906IC which is a SLA battery charger controller. It is

using 3 stage charging management to prevent overcharging and this design could extend the life of SLA

battery.

The LED indicator of front panel could show all charging and discharging stage at PSU on mode. The front

LED indicator could start monitoring the charging stage. If the "PSU OFF", the charging process is still

working but it can not be show the monitoring status through the LED as it won't light

-1-

Specification

Rated input voltage AC 90~260V, 47~67Hz

Battery type 12 volt nominal SLA

Battery size 12V/7Ah

Charging current 80mA~ 750mA

Charging type Lead Acid Chemistry

Constant current/ constant voltage/float

Stage 1: current 750mA

Stage 2: current 400mA

Charging current

Weight

Cooling Natural convection, no fan

Protections AC input fuse, DC output fuse

MTBF 30,000 hours by MIL-STD calculation

LED Indications

Stage 3: float charge current 200~400mA

“Charged” light turns on and float charge starts when the

charge current is approx 80mA when the battery charge

voltage is above 14 volts.

Charging Red

Charged Green

In use Green

Battery low Red & green blinking

-2-

Design consideration of KingRex SLAP

Design consideration for the KingRex SLAP

The slightest demand, the greatest satisfaction

After introduction of the T20 series audio amplifier to the public, KingRex sought the next evolutionary step in

sonic excellence while preserving the existing value for our customers. Currently we provide two power supply

solutions for our T 20 series amplifiers, a power adaptor(switching type) and a power supply unit – PSU (linear

power type). We believe these two products match most audiophile demands because of their reasonable price and

excellent quality but also they sound good. Nevertheless, to satisfy the highest level of audiophile expectation for

low noise and distortion, we have developed a pure power source – the SLAP (Sealed Lead-Acid battery power

supply unit)

What are the differences between switching power, linear power, and battery power?

All amplifiers need a continuous current supply during operation. If the demands of the amplifier exceed the

capabilities of the power of the power supply during transient conditions deep bass passages then detail loss,

smearing and distortion can occur. The three most common power sources: switching power adaptor, linear

power supply, and battery power supply unit.

The switching power adaptor is the most convenient and common power source however it is not a good

selection for the music connoisseur who prefers sonic performance over convenience as it has the most noise

and distribution due to the high-frequency switching and harmonics in its design.

The linear power supply is a better choice for audiophiles. It has less noise and distortion than the switching

power adaptor, however, during the AC to DC conversion and rectification process, there is still minute amounts

of unavoidable noise and distortion. That’s because the AC power is required to traverse significant circuitry

such as transformer, diodes, voltage regulators, and other components.

To eliminate any potential for noise during the rectification and filtering process we have eliminated it

(during operation) and created the SLAP.

-3-

Why the SLAP(battery power) is better than a PSU(linear power supply)?

Pure DC is the best power source for the Hi End audio equipment. However, it is difficult to provide pure DC for

high watt power amplifiers as the large capacitor (battery) size required to meet the transient and bass demands

require careful design considerations for practical use consideration.

The power voltage and current supply is very important for operating the power amp which if not properly

designed, will affect the sonic performance directly.

The output stage of a power amplifier during peak power operation will draw a instantaneous high current from

the DC voltage rails. DC voltage is supplied by the rectifier diodes, which convert AC to DC, to and through the

filtering capacitors, which smooth the ripple voltage and also act as a power reservoir. Performance of the power

supply largely depends on the capacity of these components. When the output power of the amp is relatively low,

the demand on the current is small and steady, the supply will be stable and will not deteriorate. When the output

power is relatively high, more DC current will be drawn from the capacitors, putting a strain on the rectifier diodes

and causing AC ripple voltage. When a ripple voltage exists, it will cut short the recharging time of the capacitors

and develop a 120Hz pulse noise that in turn interfere the output stage transistors, inducing distortion within the

audible frequencies. The best solution to overcome this is by adopting a power supply capable of extremely large

current(probably 5 to 10 times of what is required to meet normal demand) and very large capacitors to sustain the

supply. Under such circumstances, a reliable battery power supply can fulfill the dual role of large current and large

capacitor.

The battery power supply provides the required current for operation while maintaining a very large reserve for

transient and bass heavy passages. The SLAP uses YUASA NP7-12 (12V/7AH) sealed lead-acid battery which has

a maximum output of 105A w/o pulse noise which is a very good match for the under 20 Watt output of Class T or

Class D amplifiers.

-4-

Is there any further reason to choose battery power?

There is another reason to choose battery power over switching or linear AC designs and that is to prevent power

interruption and transmission line noise from being passed to the audio gear. During the path of an AC power

source, transfer from power plant through the high-voltage transmission lines to the substation and ultimately the

end user, various levels of step up and down as well as all kinds of spurious noise such as radio waves,

electromagnetic waves, high tension noise, automobile spark plug, lighting, electric motor noise etc., gets passed

to your Audio equipment. Even if your AC power is run through a line filter to reduce the noise, the AC power

source still could be one possible noise source.

The SLAP battery power supply unit will be the best solution for fully isolated power source from AC

environment as the internal AC power is only used for charging. The AC power source will be totally isolated

one switching button by the main power control board.

What other design features are there in the SLAP?

The SLAP has an integrated auto charging/discharging power management system. It auto-detects the battery

voltage and auto adjust the charging current which protect the battery from over-charging or over-heating. For

discharging protection, we have designed a low voltage detection circuit that automatically shuts down when the

voltage drops below 10.5V protecting the amplifier from low voltage situations.

Operation of the SLAP is very user friendly. Users only need to press one button for automatic operation of all

functions. Charging and discharging status are shown by one dual color LED light.

-5-

Key features:

The SLAP is utilizes the TI UC3906IC which is a SLA battery charge controller.

1. 3 stage charging management to prevents- overcharging extending battery life.

2. Front panel dual color LED indicator for monitoring power status-The LED indicator on front

panel could display the charge status while the SLAP is in the on mode.

3. AWG 18 copper wire is used for all internal connections.

4. DC output terminal use a 3 pin XLR connector made by CONTECH a US firm. The maximum

current capability is 6 amps.

5. AC input fuse and DC output fuse for safety consideration.

6. Battery Low Voltage monitoring circuit to ensure extended automatically shuts the system

down when voltage drops below 10.5. This protects the battery and the amplifier.

Appearance

The cabinet is of a rigid construction with an elegant appearance. The size is 185*146*156mm

with 6mm thick aluminum face plate. The stylish design stable platform will provide the user with

a reliable product for years to come. All the components used in SLAP are of the highest quality

and have been selected through intensive listening sessions.

-6-

Important safety instructions

Thank you for choose KINGREX SLAP. It provides you with better protection for connected equipment.

We sincerely hope you could keep the user manual for whole SLAP life.

Please read this user manual very carefully. It provides safety, installation, and operating instructions

that will help you derive the over all performance and fully extend the life that the SLAP has to offer.

Please save this manual! It includes important instructions for the safely use SLAP and for obtaining

factory service should the proper operation of the SLAP come into question.

Please save or recycle the packaging materials! The SLAP’s shipping materials were designing with

great care to provide protection from transportation related damage. These materials are invaluable if

you ever have to return the SLAP for service. Damage sustained during transit is not covered under

the warranty.

Safety caution!

To reduce the risk of electric shock, disconnect the SLAP from the mains supply before installing an

amplifier . Reconnect the power cord only after signaling interconnections have been made.

1. Do not dispose of batteries in a fire, the battery may explore.

2. Do not open or mutilate the battery, released electrolyte is harmful to the skin and eyes.

A battery can present a risk of electric shock and high short circuit current. The following precaution

should be observed when working on batteries

1. Remove watches, rings or other metal objects.

2. Use tools with insulated handles.

- Caution: Risk of electric shock - hazardous live parts inside this unit are energized from the

battery supply even when the input AC power is connected.

- Caution: Risk of electric shock, do not remove cover. No user serviceable parts inside, Refer

servicing to qualified service personnel.

- Warning: To reduce the risk of fire, replace only with the same type and rating of fuse.

- Warning: To reduce the risk of fire or electric shock, install in temperature and humidity controlled

indoor area of conductive contaminants.

-7-

Operation environment presentation

FRONT PANEL

States indicator (RED/GREEN DOUBLE COLOUR LED)

Charging stage : (CHARGER ON , PSU ON)

a. Red - Charging

A 7Ah SLA battery could be fully charged after 24hours charging. But it should depend on individual

one status. Normally the difference will within 1~2 hours. New battery will need some extra hours for its

first few charging.

After 10 hours charging, the capacity should be filled 70~75% by 750mA charger current

After 15 hours charging, the capacity should be filled 90~95% by 200~400 mA charger current

After reaching the 90~95% volume of the SLA content, the SLA battery charger will decrease the

charging current from 200~400mA into 80mA(maintain charge)

b. Green- Charging completed and still keeping maintain charge(80mA). (Advantage: Battery

charging should be high current while it began. During this stage which could also called bulk

charge stage)

It will be stoped after the volume is full. However, after stop bulk-charge, the battery will start

outputing which will cause the interior battery power volume decreasing from 100% to 90~95%. If it

still keep float-charge which could maintain charge at 80mA, it could keep battery capacity at 100%.

(in some reference the float charge also called standby charge)

Discharging stage: (CHARGER OFF, PSU ON)

a. Green: DC output On

b. Green Red Blink : Low voltage(the battery voltage is under 10.5V). DC output cut!

-8-

Operation environment presentation

REAR PANEL

- AC POWER INPUT: FROM:90-260V AC 47-63HZ

- CHARGER ON SWITCH: ENABLE SLAP TO CHARGE MODE

- PSU ON SWITCH: ENABLE SALP DC OUTPUT ON

- AC FUSE SLOT: 2A/250V FUSE

- FUSE FOR DC OUTPUT: 3A/250V

- DC OUTPUT: BATTERY DC POWER OUTPUT

PSU ON, CHARGER ON >>>>>DC OUT OFF

PSU ON, CHARGER OFF>>>>>DC OUT ON

PSU OFF, CHARGER OFF>>>>>DC OUT OFF

-9-

Installation

Inspection

Inspect the SLAP upon receipt. The packaging is recyclable; save it for reuse or dispose of it properly.

Placement

Install the SLAP in a protected area with adequate air flow and free of excessive dust. Do not operate

the SLAP where the temperature and humidity is outside the specified limits.

Charge the battery

The SLAP charges its battery when CHARGER ON SWITCH IS ON, charge the battery for 24 hours in

the initial use.

Connect the loads

Plug the loads(Amplifier) into the DC output connectors on the rear of the SLAP. To use the SLAP as a

PSU ON switch, make sure all of the loads are switched on).

USE KINGREX DC CABLE ONLY !!!

-10-

Operating method

Switch on

With SLAP plugged in, press and PSU On then DC output , when Battery low to 10.5V, DC output will

auto cut off and front panel LED light will flashing green & read lights. For protect Battery not into deep

discharging (Deep discharging will damage the SLA battery. By pressing the CHARGE ON switch,

SLAP into charge mode (red light), Charge complete, front panel led will be green light)

Battery Replacement

Your battery should run any where from 2-3 years before eve needing to be replaced. Please follow the

instructions below for easy battery replacement.

1. Unplug unit from AC power source and disconnect all connected equipment.

2. Open the upper case- using a phillips screw driver, and hex screw driver to open the front panel

upside screw.

3. Using a phillips screw driver to unlock the main circuit board.

4. Carefully lift off main circuit board, using a phillips screw driver to unlock the battery.

5. Remove the 2 connecting wires from the battery.

6. You can now easily remove the battery from the unit.

i. Caution: Do not dispose of battery in fire.

ii. Caution:Do not attempt to open the battery.

iii. Caution: The following precautions should be taken, please remove watches, rings, etc… when

replacing the battery and use tools with insulated handles.

7. Place your new battery in the same position/direction and reconnect the wires red wire-position(+) and

black wire negative(-)

8. Please follow steps6. 5,4 and 3 (in that order) to reconnect the entire unit.

9. Please follow manual instructions in order to properly reconnect with your equipment.

-11-

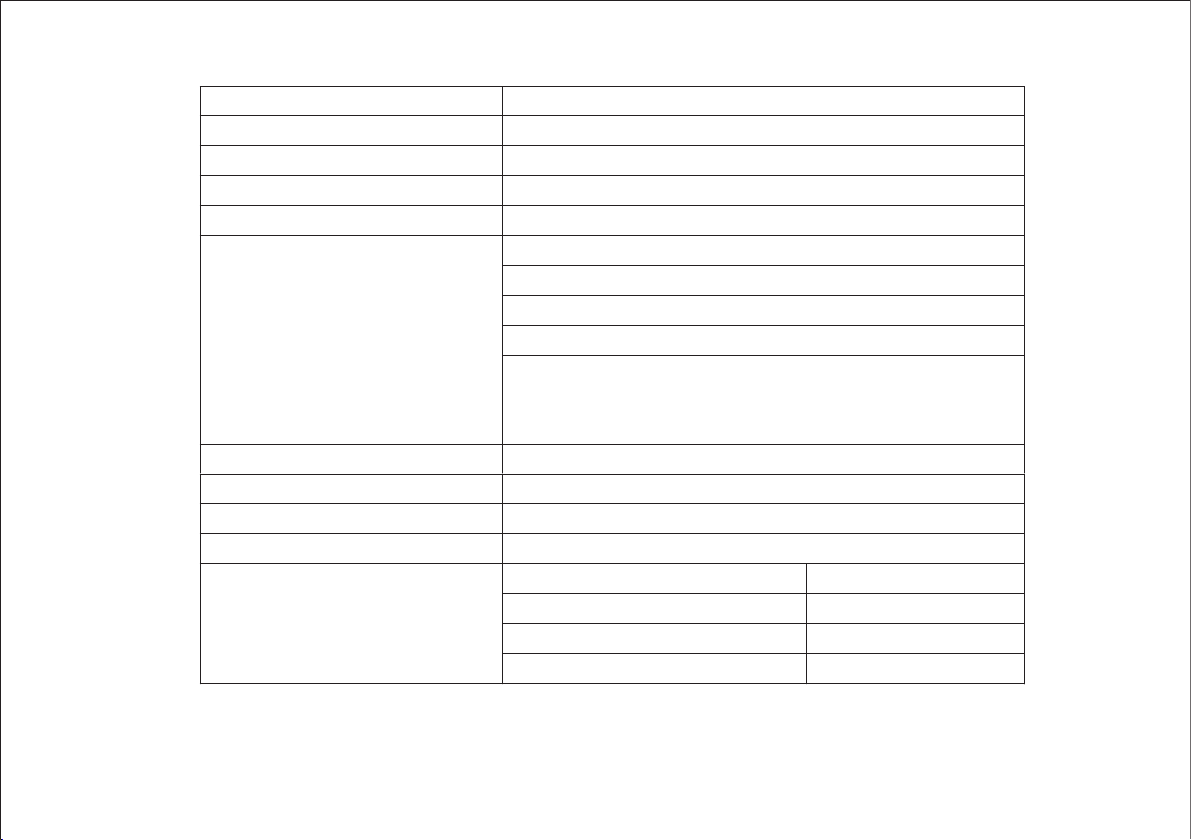

Trouble Shooting

Storage

Storage conditions

Store the SLAP covered and upright in a cool, dry location, with its battery fully charged.

Before storing, charger the SLAP for at least 15 hours

Extended storage

During extended storage in environments where the ambient temperature is -15 to +30 (+5 to +86 ),

charge the SLAP’s battery every 6 months.

During extended storage in environments where the ambient temperature is +30 to +45 (+86 to +113

), charge the SLAP‘ s battery every 3 months.

PROBLEM POSSIBLE CAUSE ACTION TO TAKE

SLAP NOT ON ,

LED NOT LIGHT

SLAP ON LED

GREEN BUT NO

DC OUTPUT

CHARGE ON,

CHARGE SW NO

LIGHT FRONT

LED CAN NOT

CHANGE TO RED

PSU NOT ON PRESS PSU ON SWITCH

DC FUSE BURN, DC OUTPUT

CABLE BROKEN

AC POWER LINE BROKEN, OR

AC FUSE BRUN

-12-

REPLACE DC FUSE (3A) CHECK

DC CABLE BY DMM

RAPLACE AC FUSE (2A), AND

CHECK AC POWER CABLE

Trouble Shooting

Maintenance

For cleaning the cabinet, use a dry cloth and wipe dust away. If needed, moisturize the cloth with a

small amount of window cleaning dissolvent. Do not use excessive amounts of solvents, and do not

let any of solvent spill into amplifier. The front panel is made of aluminum it can be cleaned by using

normal mild solvents and clean paper tissue or cloth. Do not use any other the scratch the mirror

display at the front.

Service

The simplicity of the KingRex SLAP is very few parts can be breaking down. Should you ever require

service, you can either contact your dealer or national distributor, who can solve any problems locally.

You are also very welcome to contact KingRex Technology Co., LTD directly if you need any

information or help. Our contact information is listed on the last page of this user guide.

Our best wishes

We only use the best “raw materials” trimmed and rafted to perfection by the best engineers and

sound enthusiasts for all audiophiles.

The guidance lines in this manual will assure you of an exquisite sound experience hope it will provide

clear instruction to operate our products.

We hope you years of proud ownership and happy listening. We feel confident that you will cherish

this amplifier for both its amazingly clear reproduction as well as for its splendid craftsmanship,

elegant appearance, and convenient size.

Hope you won’t mind to share with us if there is any problem or question. Please do not hesitant to

contact with us. We look forward to hearing from you~

-13-

KingRex Warranty

KingRex Warranty

PRODUCT

SERIAL NUMBER

PURCHASING

COMPANY

PURCHASE DATE

Client Information

Name

NOTICE INFORMATION :

※The warranty content of our service

The breakdown of product is not artificial. The warranty for exchange new

product is only one month after purchasing and the free fixing service is only for

one year after purchasing. After the warranty, we still offer repairing service

(change for service & components).

※ The warranty is annulment by following condition:

The damage of machine by artificial damage, improper using, repair or refit by

yourself, nature disaster, lightening strike, leaking water, using power voltage

didn’t follow designated, unable provide warranty certification, unmatched model

NO. Empty or alter content of warranty, cannot recognize content of warranty

certification.

Address

KINGREX TECHNOLOGY CO., LTD

2F, NO.232 LIANCHENG RD.,JHONGHE CITY,TAIPEI TAIWAN 235

-14-

Loading...

Loading...