USER MANUAL

MODEL: TIG200DP ACDC

Preface

This manual includes hardware description and operation introduction of the equipment. For your and

other people’s safety, please read the manual carefully.

Pay attention

Pay attention to the words after the signs below.

Sign Description

The words after this sign means there is great potential danger,

which may cause major accident, damage or even death, if it is not

followed.

The words after this sign means there is some potential danger,

which may cause hurt or property lose, if it is not followed.

The words after this sign means there is potential risk, which may

cause equipment fault or break, if it is not followed.

Version

The contents of this manual are updated irregularity for updating of product. The manual is only used as

operation guide, except for other promises. No warranties of any kind, either express or implied are

made in relation to the description, information or suggestion or any other contents of the manual.

The images shown here are indicative only. If there is inconsistency between the image and the actual

product, the actual product shall govern.

Content

1 Safety warning..........................................................................................................1

2 Product......................................................................................................................5

2.1 Introduction........................................................................................................5

2.2 Technical data....................................................................................................6

3 Installation................................................................................................................7

4 Operation..................................................................................................................9

4.1 panel layout........................................................................................................9

4.2 Operation interface specification...................................................................10

5 INSTRUCTION NOTES ...........................................................................................18

5.1 Operation environment...................................................................................18

5.2 SAFTY...............................................................................................................18

6 MAINTENANCE AND CHECK TROUBLE..............................................................19

6.1 Maintenance .................................................................................................19

6.2 Check Fault......................................................................................................19

Appendix Circuit diagram........................................................................................... 23

1

1 Safety warning

The safety notes listed in this manual is to ensure correct use of the machine and to keep you and

other people from being hurt.

The design and manufacture of welding machine considers safety. Please refer to the safety

warning listed in the manual to avoid accidents.

Different damage would be caused by wrong operation of the equipment as follows. Please read

the user manual carefully to reduce such damage.

Sign Description

Any contact of electric parts may cause fatal electric shock or burnt.

Gas and fumes are harmful to health.

Operation in narrow space may cause choke .

Spark and hot workpiece after welding may cause fire.

Bad connected cable may cause fire.

Incompletion connection of workpiece side circuit may cause fire.

Never weld on the case of tinder stuff, or it may cause explode.

Never weld airtight containers such as slot, pipe etc., or it may break.

Arc ray may cause eye inflammation or skin burnt.

Spark and residue will burn your eyes and skin.

Toppling over of the gas cylinder will cause body hurt.

Wrong use of the gas cylinder will lead to high-pressure gas eruption

and cause human hurt.

Never let fingers, hair, clothes or etc. near the moving parts such as

the fan.

The wire shoot out of the torch may stab eyes, face and other naked

parts.

Never stand in front of the swang equipment or under it, or it may fail

and cause injury.

2

Please follow the rules below to avoid heavy accidents.

Never use the equipment to do other things but welding.

Follow related regulations for the construction of the input-driven power source, choice of place,

usage of high-pressure gas, storage, configuration, safe-keeping of workpiece after welding

and disposal of waste, etc.

Nonessentials do not enter the welding area.

People using heart pacemaker is not allowed to get close to the welding machine or area

without doctor’s permission. The magnetism created by energizing the welding machine can

have a bad effect to the pacemaker.

Install, operation, check and maintain the equipment by profession personnel.

Understanding the contents of the user manual for safety.

Please follow the rules below to avoid electric shock。

Keep away from any electric parts.

Earth the machine and workpiece by professional personnel.

Cut off the power before installation or checking, and restart 5 minutes later. The capacitance is

chargeable device. Please ensure it has no voltage before start again even if the power source

is cut off.

Do not use wire with inadequate section surface or damage insulation sleeve or even exposed

conductor.

Do ensure well isolation of wire connection.

Never use the device when the enclosure is removed.

Never use broken or wet insulation gloves.

Use firenet when work at high position.

Check and maintain regularly, don’t use it until the broken parts are fixed well.

Turn off the power when not in used.

Follow the national or local related standard and regulations when using the AC welding

machine at narrow or high position.

Please follow the below notes to avoid fire and explode, etc.

No combustible in welding area.

Keep off combustible when welding.

Keep hot workpiece after welding away from flammable gas.

Do move away the combustible around when weld the dooryard, ground and wall,.

The wire connection of base metal should be as close to the welding place as possible.

Never weld those facilities with gas pipe or airtight slot.

Put fire extinguisher around the welding area to prevent fire.

The gas and fumes are harmful to health, please wear protective device

according to regulations.

Wear exhaust equipment and breathe preventive facilities to prevent gas poisoning or choke.

Use suggested part exhaust equipment and breathe preventive facilities to prevent hurt or

poisoning by gas and other powder, please.

To prevent oxygen-deficiency, air out the gas-filled room which is full of CO

2 and argon on the

bottom, When operating on trunks, boilers, cabins, etc.

Please accept the supervisor’s inspection when operating in narrow space. Air the room and

wear breathe preventive facilities.

3

Never operate in degrease, washing or spray space.

Using breathe preventive facilities when weld shielded steel for it will cause poisonous dust and

gas.

The arc, spark, residue and noise are harmful to health, please wear

protective appliance.

Eye protection against arc is recommended when welding or supervise welding.

Please wear preventive spectacles.

Welder’s gloves, welder’s goggles, long sleeve clothes, leather apron, and other standard

protection equipments must be worn for welding operation.

A screen to protect other people against the arc must be set in the welding place.

Please follow the notes below to avoid gas cylinder toppling over or

broken.

Use the gas cylinder correctly.

Use the equipped or recommended gaseous regulator.

Read the manual of gaseous regulator carefully before using it, and pay attention to the safety

notes.

Fix the gas cylinder with appropriative holder and other relative parts.

Never put the cylinder under high temperature or sunshine environment.

Keep your face away from the gas cylinder exit when opening it.

Put on the gas shield when it is not used.

Never put the torch on the gas cylinder. The electrode can not meet the gas cylinder.

Any touch of the switch part will cause injury, please note the following.

Never use the machine when the enclosure is off.

Install, operate, check and maintain the machine by professional person.

Keep your fingers, hair, clothes etc. away from the switch parts such as the fan.

The wire end may deal damage, please note the following.

Never look into the electric conduction hole when checking the wire feeding is normal or not, ,

or the shooting wire may stab your eyes and face.

Keep your eyes, face or other naked parts away from the end of torch when feeding the wire

manually or pressing the switch.

For better work efficiency and power source maintenance, please

note the following.

Precautions against toppling over.

Never use the welding equipment for pipe thawing.

Lift the power source from side when use the up-down forklift truck to avoid toppling over.

When using the crane for lift, tie the rope to the ears with an angle no more than φ15 to the

vertical direction.

When lifting the welding machine which equipped with gas cylinder and wire feeder, download

them from the power source and ensure the horizontal of the machine. Do fix the gas cylinder

with belt or chain when moving it to avoid body hurt.

4

Ensure fastness and insulation when lifting the wire feeder through the swing ring for welding.

Electromagnetic interference needing attention.

It may need extra preventive measures when the equipment is used in particular location.

Before the installation, please estimate the potential electromagnetism problems of the

environment as follows.

a) Upper and lower parts of the welding equipments and other nearby power cable, control

cable, signal cable and phone cable.

b) Wireless electric as well as TV radiation and reception equipment.

c) Computer and other control equipments.

d) Safety-recognition equipment etc. Such as supervise of industrial equipments.

e) Health of people around. Such as personnel using the heart pacemaker or audiphone.

f) Equipments for adjustment and measurement.

g) Anti-disturb capability of other used equipments .Users should ensure these equipments and

the environment are compatible, which may need extra preventive measures.

h) Practical state of the welding and other activities.

Users should observe the following dos and don’ts to decrease radiation interference.

a) Connect the welding equipments to the power supply lines.

b) Maintain the welding equipments regularly.

c) The cable should be short enough to be close to each other and the ground.

d) Ensure the safety of all the welding metal parts and other parts nearby.

e) The workpiece should be well earth.

f) Shield or protect the other cable and equipments to decrease the effects of disturbances. The

welding equipments can be complete shielded in some special conditions.

Users are responsible for interference due to welding.

5

2 Product

2.1 Introduction

Congratulations for your purchase.

The welding machine is a rectifier adopting the most advanced inverter technology.

The development of inverter gas-shielded welding equipment profits from the development of the inverter

power supply theory and components. Inverter gas-shielded welding power source utilizes high-power component

IGBT to transfer 50/60HZ frequency up to 50KHZ, then reduce the voltage and commutate, and output

high-power voltage via PWM technology. Because of the great reduce of the main transformer’s weight and

volume; the efficiency increases by 30%. The appearance of inverter welding equipment is considered to be a

revolution for welding industry.

AC/DC series welding machine are the AC/DC two-way machines, which are developed by our company

newly. Its biggest characteristics is that DC function can be used to weld stainless steel, alloyed steel, carbon steel,

copper and other color metals and AC function can be used to weld aluminum and aluminum alloy materials, such

as welding of scooters, bicycles. Main models are TIG200DP ACDC。

AC/DC series machine adopts our company’s exclusive HF inverter technology. Compared with traditional

machine, it is compact in volume, light in weight, effective in transfer, power-saving; com pared with imported

machine, it is low in price, strong in power net adaptability. What’s more, it adopts twice inverter technology, has

characteristics of pure square wave output, good arc force, wide cleaning range and continuous arc with small

current, which guarantee excellent welding result.

AC/DC series are also with pedal current adjustment device . With that welder can free their hands to adjust

current by foot; And at the beginning of welding and at the moment of adding wire, it can increase current to heat

quickly; At the end of welding it can decrease current that is good for welding lines shape. With the help of pedal

it can improve welding efficiency, reduce welding difficulty and guarantee welding quality.

Thanks for purchasing our company product and hope for your precious advice. We will dedicate to

produce the best products and offer the best service.

6

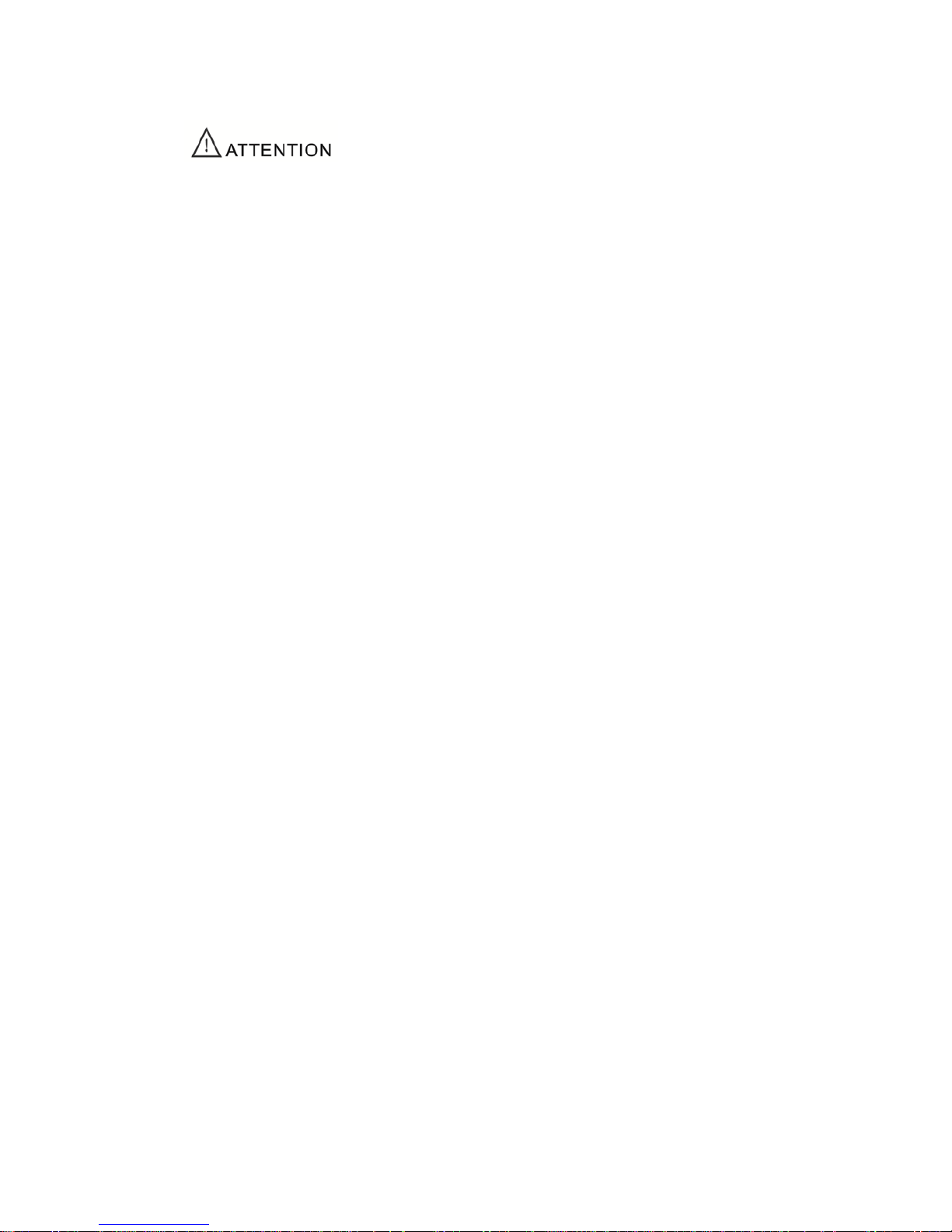

2.2 Technical data

model

parameters

TIG200DP ACDC

Power voltage(V) AC230V±15%

Frequency (HZ) 50/60

TIG 26.8

Rated input current (A)

MMA 36.5

TIG 18

Rated output voltage (V)

MMA 27.2

TIG 200

Rated output current(A)

MMA 180

No-load voltage(V) 59

Arcing way HF

Pre-flow(S) 0.1-1

Current descending time(S) 0-25

Post flow time(S) 0-10

TIG 60

Duty cycle (%)

MMA 40

No-load loss(W) 40

Efficiency (%) 80

Power factor 0.73

Insulation grade F

Housing protection grade IP21

weight(kg) 14.2

Dimensions (mm) 475×200×410

7

3 Installation

The welder is fitted with power voltage compensation device. When power voltage changes

with

in a range of 15% of rated voltage, it can go on with the operation.

If a longer cable wire is used, , we suggest using cable with greater cross section in order to

reduce line loss voltage; if a connecting cable is too long, it may exert a great effect upon the arc

starting of the welder and other performance of the system, such as weakened high-frequency arc

starting or failure of the system to work regularly. So we suggest that you use recommended

configuration length.

1、Make sure that the vent of the welder is not covered or plugged to avoid failure of the

cooling system.

2、Protective gas source should be connected well. Gas supply passage should include gas

cylinder, argon decompression flow-meter and gas pipe. The connecting portion of the gas

pipe should be tied up with a hose clamp or other objects to prevent leakage and air intake.

3、The shell should be grounded reliabl y with a conducting wire with a sectional area not less

than 6mm2.

4、The quick plug of the loop cable is inserted into the quick socket of welder surface plate with

the polarity of “+” and tightened clockwise. The ground wire pliers at the other end hold up

the work piece.

5、When the pedal switch is used to control, Connect the 2-core aviation plug and 3-core

aviation plug of the pedal switch with the 2-core aviation socket and 3-core aviation socket.

6、Based on the input voltage class of the welder, the power line should be connected to the

distribution box of corresponding voltage class and non-corresponding connection should

never occur . Make sure that error in power voltage is within a permissible range.

7、Manual welding correctly as shown in the figure. Connect the copper nut from the other end

of the welder with the gas electric integration from the front panel, and tightened clockwise

firmly.

After completion of the above job, installation of the welder comes to an end and welding

can begin.

8

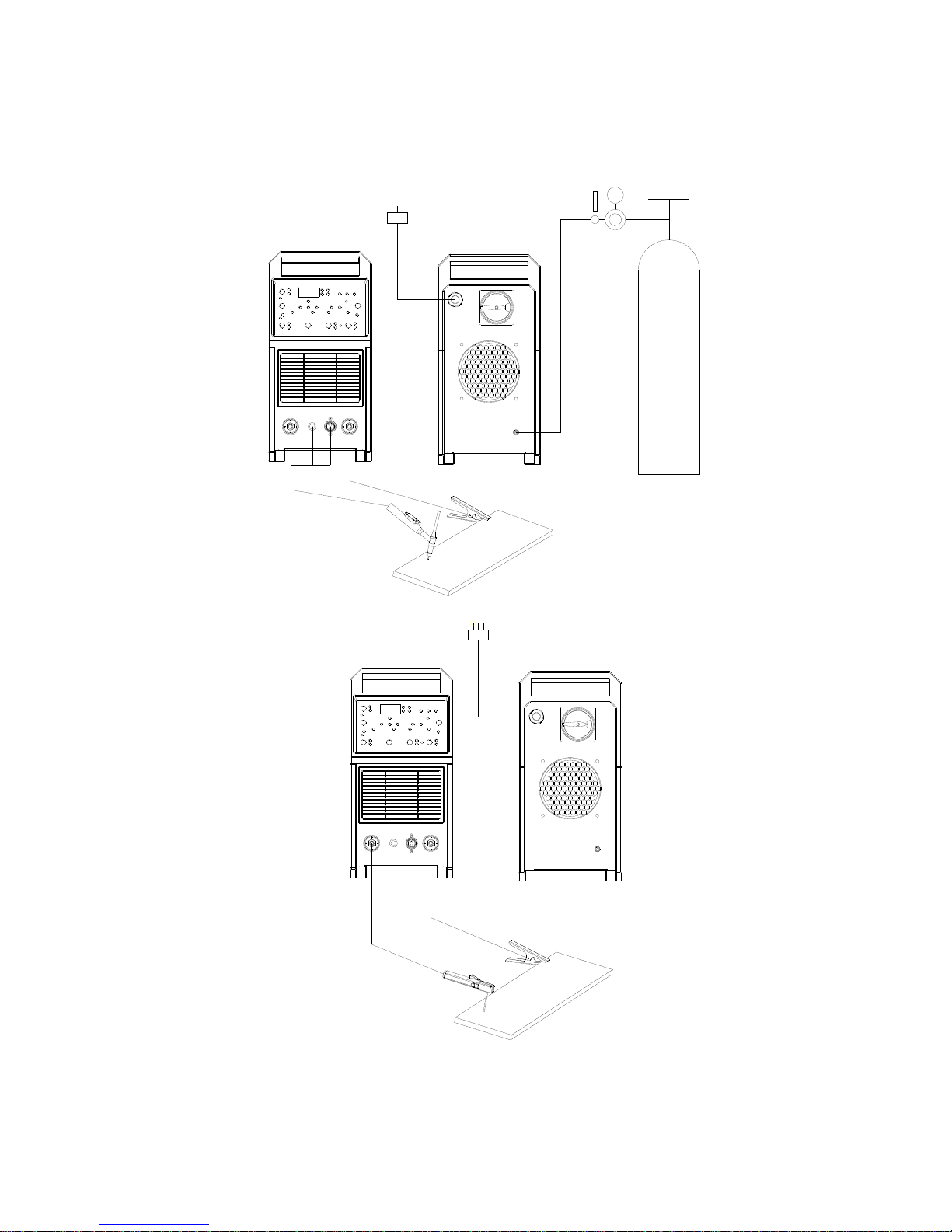

Installation diagram

E

l

e

c

t

r

o

d

e

h

o

l

d

e

r

E

a

r

t

h

c

l

a

m

p

W

o

r

k

p

i

e

c

e

E

l

e

c

t

r

o

d

e

h

o

l

d

e

r

E

a

r

t

h

c

l

a

m

p

W

o

r

k

p

i

e

c

e

Gas

cylinder

Ar meter

9

4 Operation

4.1 Panel Layout

1 Digital Display Meter 7 Abnormal Indicator Light

2 STICK/TIG Selector Button 8 Remote Control Indicator Light

3 Move Left Selector Menu Button 9 Move Right Selector Menu Button

4 2T/4T Selector Button 10 AC/DC Selector Button

5

Parameter Adjustment Knob (Pressed

in the knob tuning parameters is for

coarse adjustment, not pressed in is

for fine tuning.)

11 Pulse /No pulse Button

6 Unit of parameter Indicator Light 12

The panel picture above is for reference only. If any difference with the real machine, please follow with

the real machine.

10

4.2 Operation interface specification

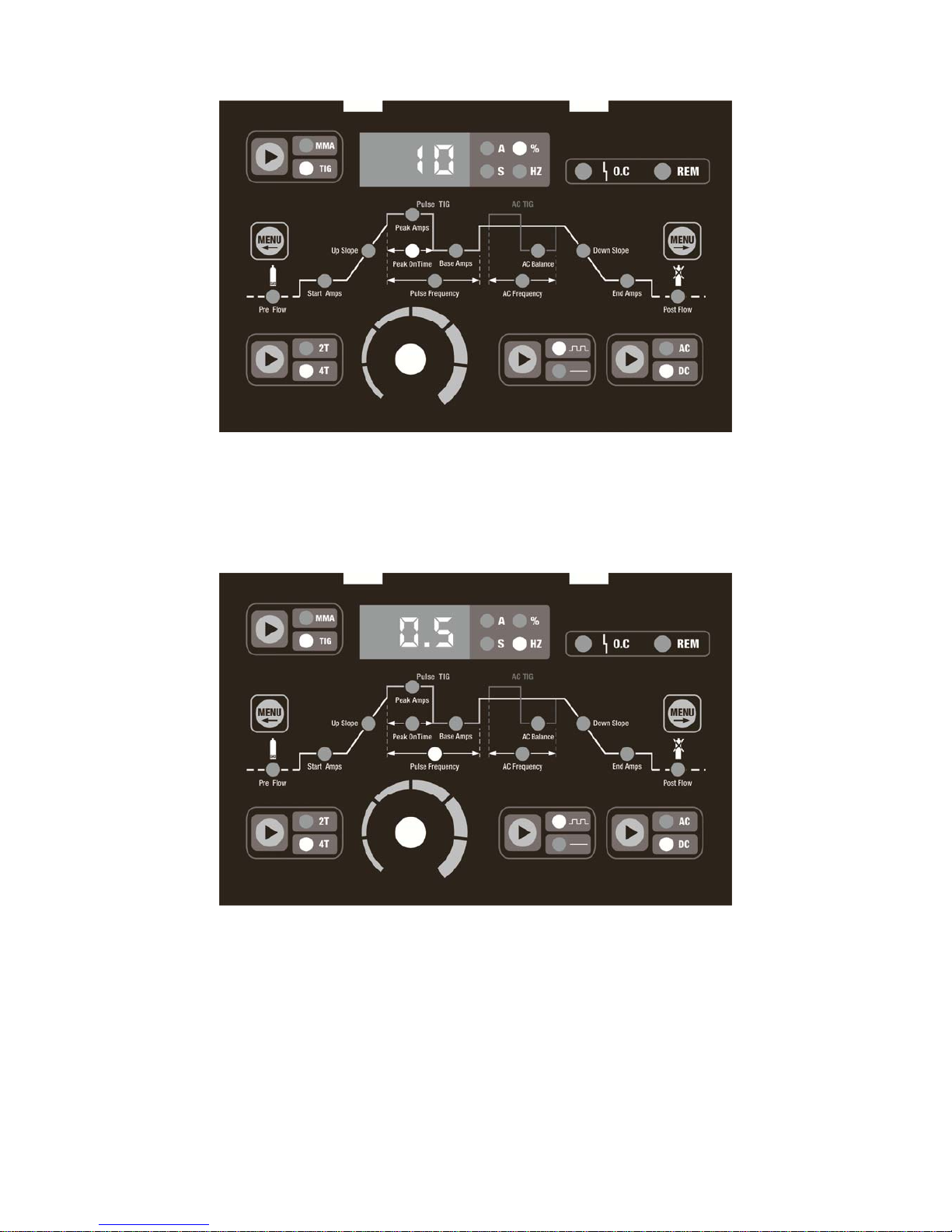

Picture2

The picture 2 shows the digital display meter reads “LL”when the machine starts working.

Picture3

The picture3 shows when under TIG mode, the Peak Amps indicator light on, adjust the parameter knob, meter

reads 10-200A ajustable, press the Move Left/Right Selector Menu Button to choose other parameter settings.

11

Picture 4

The picture 4 shows when under 4T mode, press the Move Left Selector Menu Button to Up Slope indicator light

on, adjust the parameter knob, the meter reads 0-10s adjustable.

Picture 5

The picture 5 shows press the Move Left Selector Menu Button to Start Amps indicator light on, adjust the

parameter knob, the meter reads 10-200A adjustable.

12

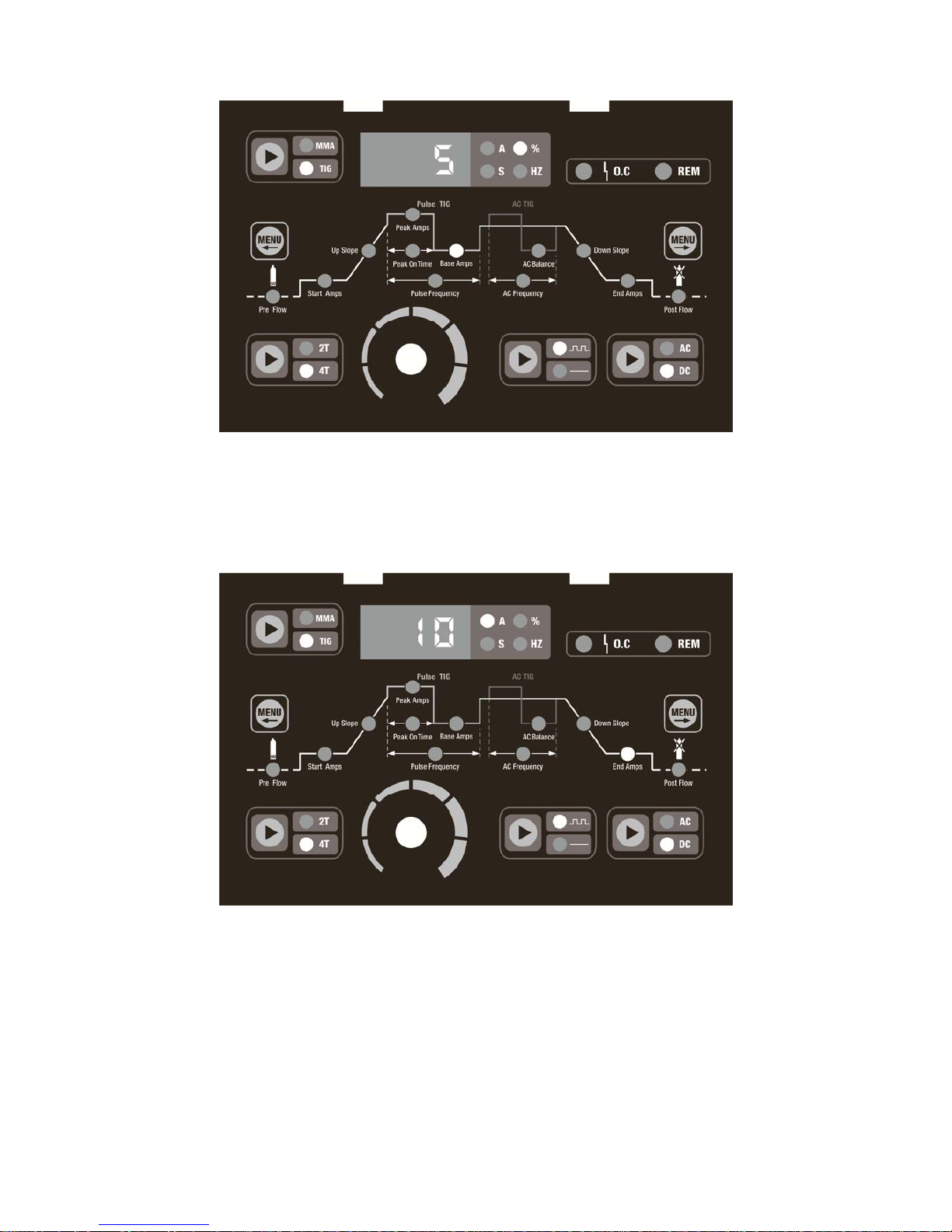

Picture 6

The picture 6 shows when under pulse mode, press the Move Right Selector Menu Button to Peak On Time

indicator light on, adjust the parameter knob, the meter reads 10-90% adjustable.

Picture 7

The picture 7 shows press the Move Right Selector Menu Button to Pulse Frequency indicator light on, adjust the

parameter knob, the meter reads 0.5-200 HZ adjustable.

13

Picture8

The picture 8 shows press the Move Left Selector Menu Button to Pre flow indicator light on, adjust the parameter

knob, the meter reads 0.1-1S adjustable.

Picture9

The picture 9 shows press the Move Right Selector Menu Button to Post flow indicator light on, adjust the

parameter knob, the meter reads0-10S adjustable.

14

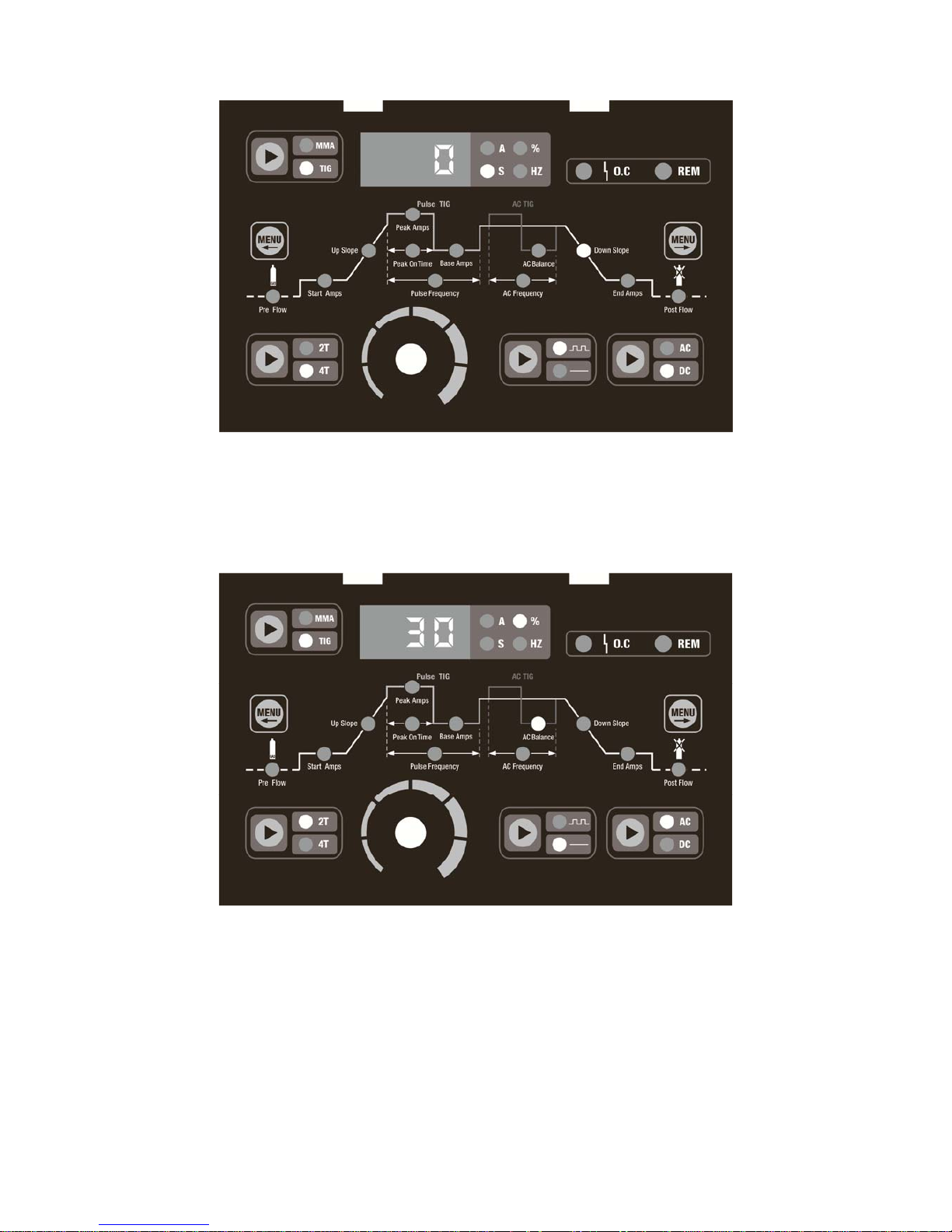

Picture10

The picture10 shows press the Move Right Selector Menu Button to Base Amps indicator light on, adjust the

parameter knob, the meter reads 5-95% adjustable.

Picture11

The picture11 shows press the Move Right Selector Menu Button to End Amps indicator light on, adjust the

parameter knob, the meter reads 10-200A adjustable.

15

Picture12

The picture12 shows press the Move Right Selector Menu Button to Down Slope indicator light on, adjust the

parameter knob, the meter reads 0-25S adjustable.

Picture13

The picture13 shows when choose under AC mode, press the Move Right Selector Menu Button to AC balance

indicator light on, adjust the parameter knob, the meter reads 30-70% adjustable.

16

Picture14

The picture14 shows when choose under AC mode, press the Move Right Selector Menu Button to AC Frequency

indicator light on, adjust the parameter knob, the meter reads 40-200HZ adjustable.

Picture15

The picture15 shows when choose under MMA mode, adjust the parameter knob, the meter reads 20-180A

adjustable, only AC/DC mode can be choosed, other buttons can’t be used.

17

Picture16

The picture16 shows when the temperature is too high or abnormal the digital display show"Err", abnormal light

O.C lights up, this time no output, will have to wait until the temperature reducing or restart the machine to return

to normal.

Picture17

The picture17 shows In TIG mode, when connectting the foot pedal to the machine, the REM indicator is on, the

machine is converted to REM mode automatically. At this time: Start Amps, Peak Amps, End Apms these three

current parameters are controlled by the foot pedal, other parameters are controlled by the knob on the front panel.

18

5 INSTRUCTION NOTES

5.1 Operation environment

1)Welding operation should be carried out in a relatively dry environment with air humidity

usually less than 90%.

2)Ambient temperature should be kept between -10C ~40C.

3)Welding in the sun or rain should be avoided and water or rainwater should never be seeped into

the welder interior.

4)Welding in the dusty area or under a corrosive gas environment should be avoided.

5)Gas protection welding operation in an environment with strong air flow should be avoided.

5.2 SAFTY

In this welder over-voltage, over-current and overheat protection circuits have been installed

beforehand. When the grid voltage, output current and machine temperature surpass the set

standards, the machine will stop automatically. But excessive use (for example, when the

voltage is too high) can still lead to the breakdown of the welder. So you have to pay attention to

the following items:

1)Good ventilation!

This machine is a small type welder. In operation a high working current flows in and natural

ventilation is unable to meet the welder’s requirement for cooling. So a fan is fitted to

effectively cool the welder to keep it work smoothly.

Operators should make sure that the vent is not covered or plugged, the distance of the welder

from its surrounding objects is not less than 0.3 m and good ventilation is kept all the time. All

these are very important for better operation of the welder and longer service life of the welder.

2)No overload!

Operators should bear in mind that maximum permissible load current (relative to the selected

load duration factor) be observed at any time and welding current should never surpass the

maximum permissible load current.

Over-current will shorten the service life of the welder remarkably and even burn it down.

3)No over-voltage!

Power voltage is shown in the main performance parameter table. In general, the voltage

auto-compensation circuit in the welder will ensure the welding current remain within the

permissible range. If power voltage surpasses the permissible value, the welder will be broken

down. Operators should fully know this and adopt corresponding preventive measures.

4)Behind each welder there is a grounding screw with the grounding mark. Before operation the

shell of the welder should be grounded reliably by a cable wire with a sectional area bigger than

6mm

2

so as to release static electricity or prevent any accident due to leakage.

5)If the welding machine exceeds the standard load duration factor in operation, it may probably

go into a protective state suddenly and stop work, which indicates it has exceeded the standard

19

load duration factor. Excessive heating triggers the temperature control switch and makes the

welding machine stop operation. Under such circumstances you needn’t turn off the power so

that the cooling fan may work continuously for cooling. When the temperature drops to the

standard range, welding may be restarted.

6 MAINTENANCE AND CHECK TROUBLE

6.1 Maintenance

1 Dust should be removed with dry and clean compressed air regularly. If the welder is used in a

heavily polluted environment with dense smoke and polluted air, dust must be removed from the

welder each month.

2 The pressure of compressed air should be reasonable so that damage is not done to small

elements in the welder.

3 Regularly check the connection of electric circuit in the welder and make sure circuit be

connected properly and joint is secured (especially inserted joint or element). If the cases of

rusting or loosening are found, the rust layer or oxidized film should be removed with abrasive

paper and then the joint should be connected again and tightened firmly.

4 Entry of water or steam into the interior of the welder should be avoided. If this condition

occurs, the welder should undergo drying treatment. Then the welder is measured for insulation

by a megohm-meter (including the area between connecting points and the areas between the

connecting points and shell). Welding can go on only when evidence shows no abnormality.

5 If the welder is not to be used for a long time, it should be replaced in the original package and

kept in a dry environment.

6.2 Check Fault

Phenomena enumerated here may have something to do with the parts, gas, environmental factors

and power supply you use and efforts should be made in improving the environment to avoid

occurrence of such cases.

Black welding spot

——This shows the welding spot is oxidized without being protected effectively and you can

make the following inspection :

1. Make sure that the valve of argon cylinder has been opened with sufficient pressure. As a rule, if

the pressure within the cylinder is lower than 0.5MPa, then it is necessary to refill the cylinder.

2. Check if the argon flow-meter is turned on with sufficient flow. You can select different flow

rates in light of varying welding current, but too small flow may lead to inadequate gas stiffness

and thus failure to cover all the welded spots. We suggest argon flow should never be lower than

3l/min no matter how weak the current will be.

3. The easiest way to check gas delivery is to touch the nozzle of welding torch to see whether the

20

gas passage of the welding torch is blocked.

4. Poor sealing of gas passage or lower gas purity will also give rise to welding quality trouble.

5. Strong air flow in the environment may also lead to deterioration of welding quality.

B、Difficulty in arc starting with easy arc breaking:

1. Make sure that the tungsten electrode in use is of good quality as discharge ability of inferior

tungsten electrode may fail the requirement;

2. Tungsten electrode without sharpening treatment is also unable to start arc and leads to unstable

arc.

C、Output current can’t reach the rated value:

Deviation of power voltage from the rated value will lead to unconformity of output current

value with the set value. When power voltage is lower than the rated value, maximum output

current of the welder may also be lower than the rated value.

D、Unstable current in the operation of the welder:

This may be attributed to the following factors:

1. Change in grid voltage;

2. Interference from the power grid or other power equipments.

E、:Severely burn of the tungsten needle

The duty cycle is adjusted too large, causing emission from the workpiece to the tungsten electron

for too long, resulting in severe heat of the tungsten needles.

F、The oxide film can’t be torn when welding aluminum:

1. the welding gear is selected wrong.

2. The duty cycle is adjusted too small;

3. The secondary inverter has field pipe damage.

G、The abnormal pilot lamp is on:

1、The light is on when the welder work abnormally, please turn off the power switch and then

reboot the machine, it can continue to use if it return to normal,

2、If the light is on repeatedly, please refer to the professional or the manufacturer for repair.

Faults

Resolvable Methods

1. Power indicator is not

lit ,fan does not work

and no welding output

1. Power switch is out of work .

2. Check if electrify wire net (which is connected to input cable )is in

work. .

3. Check if input cable is out of circuit .

21

2.ower indicator is

lit ,fan does not work

or revolve several

circles ,no welding

output

1. Maybe connect wrong to 380V power cause machine is in protection

circuit ,connect to 400V power and operate machine again .

2. 400V power is not stable,(input cable is too slender)or input cable is

connected to electrify wire net cause machine is in protection

circuit .Add the section of cable and tighten input connector

firmly .Close machine 2-3 minutes then open it again.

3. Cable is loosed from switch to power panel ,tighten them again .

4. Open and close power switch constantly in short time cause machine

is in protection circuit Close machine 2-3 minutes then open it again .

5. Main circuit 24V relay of power panel is not close or has

damaged .Check 24Vpower source and relay .If relay has damaged

replace it with same model.

3. Fan is working ,

indicator is not lit and

sound of HF

arc-striking can not be

heard ,wiping welding

can not strike arc.

1. Positive and negative electrodes of VH-07 insert component voltage

should be about DC310V from power panel to MOS board .

(1) If circuit is broken and silicon bridge is poor contact .

(2) If some of four high electrolytic(about 470UF/450V) of power

panel capacitor is leaking .

2. There is a green indicator in auxiliary power of MOS board ,if it is not

on ,auxiliary power is out of work .Check fault spot and connect with

seller .

3. Check if connectors is poor contact .

4. Check control circuit and find out reasons or connect with seller.

5. Check if control cable of torch is broken.

4. Abnormal indicator is

not on ,sound of HF

arc-striking can be

heard ,but there is no

welding output .

1. Check if torch cable is broken .

2. Check if grounding cable is broken or not connected to welding piece .

3. Output terminal of positive electrode or torch electrify is loosed from

inter-machine .

5.bnormal indicator is

not lit ,sound of HF

arc-striking can not be

heard ,wiping welding

can strike arc .

1. Primary cable of arc-striking transformer is not connected to power

panel firmly ,tighten it again.

2. Arc-striking tip is oxidized or too far ,give a good polish to it or

change it is about 1 mm between arc-striking tip .

3. Switch(sticking/argon-arc welding) is damaged ,replace it .

4. Some of HF arc-striking circuit components is damage ,find out and

replace it .

6.bnormal indicator is

lit but there is no

welding output .

1. Maybe it is overheated protection ,please close machine first ,then

open the machine again after abnormal indicator is out .

2. Maybe it is overheated protection ,wait for 2-3 minutes (argon-arc

welding does not has overheated protection function .)

3. Maybe inverter circuit is in fault ,please pull up the supply power plug

of main transformer which is on MOS board (VH-07 insert which is

near the fan)then open the machine again.

(1) If abnormal indicator is still lit ,close machine and pull up supply

power plug of HF arc-striking power source (which is near the

VN-07 insert of fan ),then open machine :

a. If abnormal indicator is still lit ,some of fieldistor of MOS

board is damaged ,find out and replace it with same model .

b. If abnormal indicator is not lit , rise transformer of HF

arc-striking circuit is damaged ,replace it .

(2) If abnormal indicator is not lit ,

a. Maybe transformer of middle board is damage ,measure

inductance volume and Q volume of main transformer by

inductance bridge(L=0.9-1.6mH Q>35) .If volume is too

low ,please replace it .

b. Maybe secondary rectifier tube of transformer is

damaged ,find out faults and replace rectifier tube with same

22

model .

4. Maybe feedback circuit is broken .

7. When welding

aluminum, can not

break oxidized film

1. Wrong welding value

2. Pulse duty too low

3. Twice inverter MOSFET broken

8. Stick is burnt out Pulse duty is too high, reduce it.

23

Appendix Circuit diagram

switch

300VDC

PZ01-057

PM01-041

EARTH

Port

Port

PD01-032

L

123

VH-03

EARTH

L

fan

Electromagnetism valve

negative output terminal

positive output terminal

C

D

AB

PK01-123

torch switch socket

1

CON8

1

CON7

AC115/230V

12CON11

VH-02

1

2

3

CON13

VH-03(2)

EARTH

1

3

CON12

VH-03( 2)

temperature switch

5

4

2

PH09-010

12CON9

VH-02

1

2

3

4

CON6

XH-04

1

2

3

4

5

6

CON15

XH-06

1

2

3

4

CON10

VH-04

1

2

3

4

CON2

VH-04

123456789

CON1

VH-09(8)

123456789

CON1

VH-09(8)

1

2

3

CON16

VH-03( 2)

1

2

3

CON4

XH-03

PK06-009

1

2

3

CON1

XH-03

PCO N 1

PCO N 2

PCON7

PCON8

PCO N 3

PCO N 4

PCON4

PCON5

PCON1

PCON2

PCON5

PCON6

PCON6

PCON3

1

2

3

CON1

1

2

3

CON5

VH-03

1

2

CON6

VH-02

1

2

CON8

VH-02

1

2

3

4

CON2

VH-04

123

4

CON4

VH-04

123456789

10

CON12

COM2X10

123456789

10

CON2

COM2X10

1

2

3

4

CON4

XH-04

1

2

3

CON3

XH-03

1

2

3

4

CON9

XH-04

A

B

DC

1

2

3

4

5

CON2

VH-05

12345

CON3

VH-05

1

2

3

CON2

VH-03( 2)

1

2

3

CON5

VH-03( 2)

resis tance

1

3

1

PCO N 1

1

PCO N 2

Loading...

Loading...