Page 1

Mapping Registers for

extending I/O or Instrument

Max. 10MHz High Speed Pulse

Counter

Max. 300KHz High Speed

Pulse Output

MxxT Series

User Manual

Ver 2.0

Date Issued: 2019-11-28

King Pigeon Hi-Tech. Co., Ltd.

www.IOT-Solution.com

Industrial

Ethernet Remote I/O Module

Page 2

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

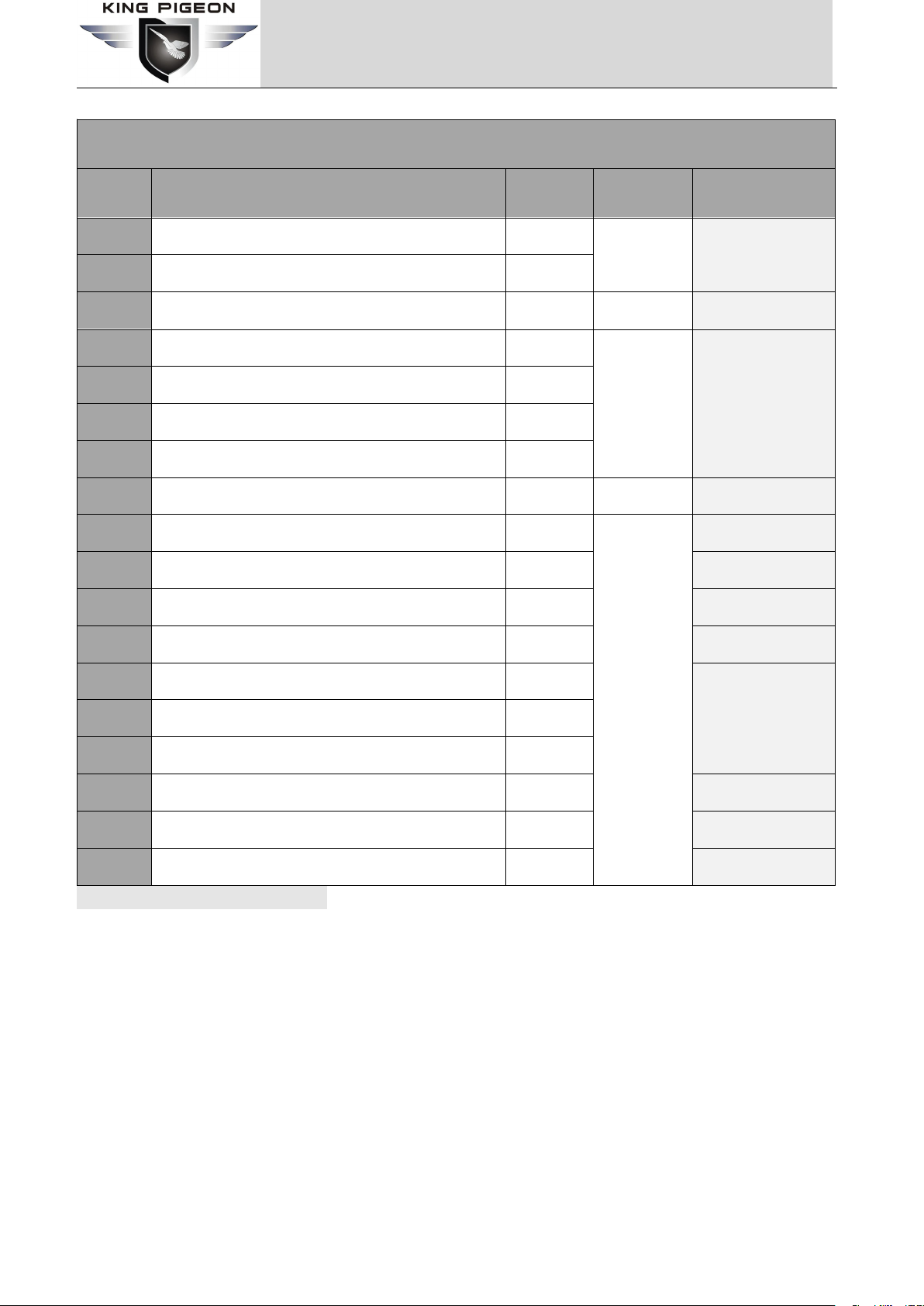

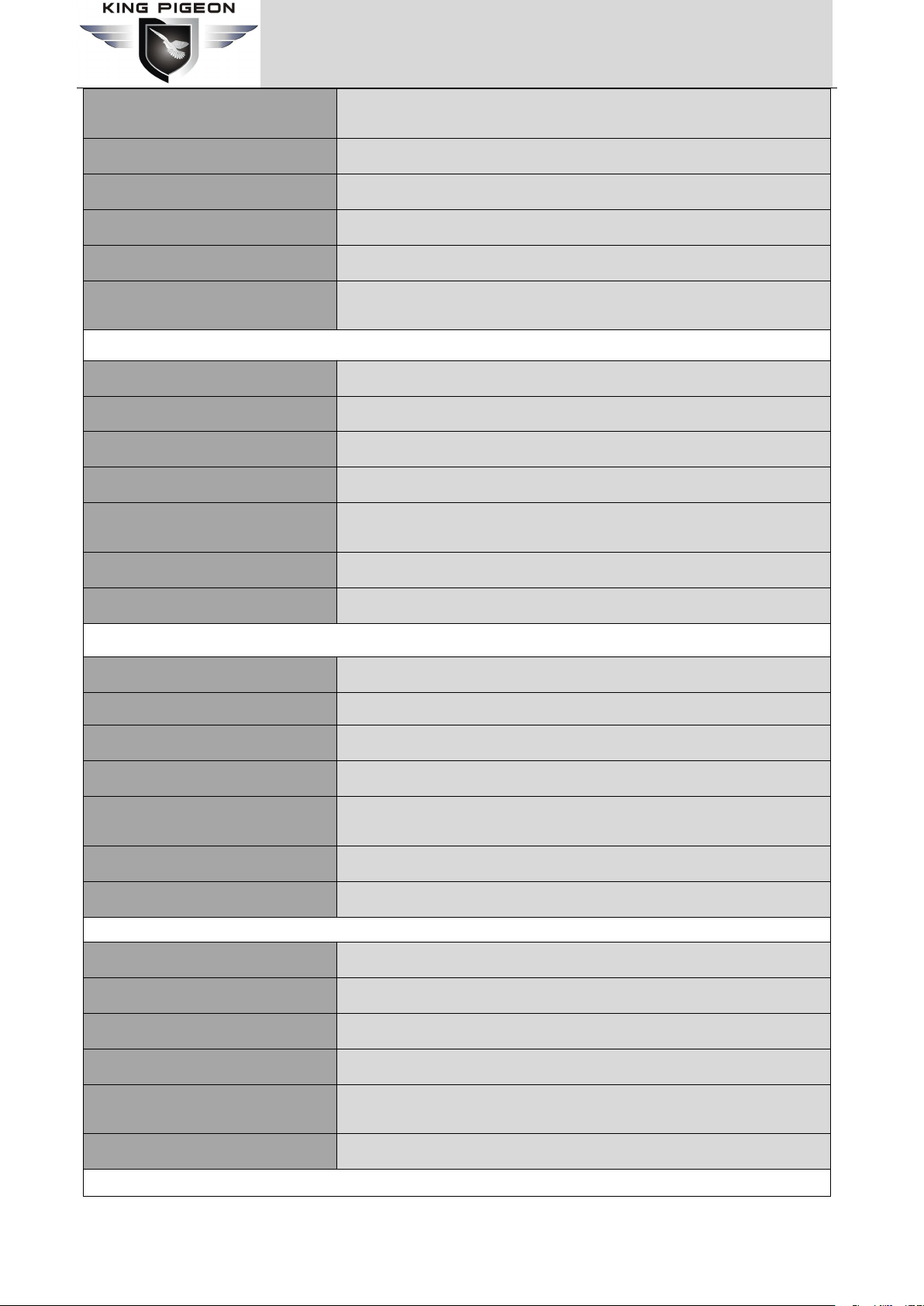

Modbus TCP Ethernet Remote I/O Module Model List

Model

Descriptions

DC Output

DC Input

Typical Power

Consumption

M100T

1 RJ45,1 RS485, 2 DI, 2 AI, 2 DO

1 DC

9~36VDC

160mA@12V

M110T

1 RJ45,1 RS485, 4 DI, 4 DO

1 DC

M120T

1 RJ45,1 RS485, 4 DI, 4 AI, 2AO(0-10V), 4 DO

1 DC

24~36VDC

90mA@24V

M130T

1 RJ45,1 RS485, 8 DI, 4 DO

1 DC

9~36VDC

150mA@12V

M140T

1 RJ45,1 RS485, 8 DI, 8 DO

1 DC

M150T

1 RJ45,1 RS485, 8 DI, 4 AI, 4 DO

1 DC

M160T

1 RJ45,1 RS485, 8 DI, 48 AI, 8 DO

1 DC

M200T

1 RJ45,1 RS485, 2AO(0-10V)

1 DC

24~36VDC

90mA@24V

M210T

1 RJ45,1 RS485, 4 DI

1 DC

9~36VDC

160mA@12V

M220T

1 RJ45,1 RS485, 4 DO

1 DC

160mA@12V

M230T

1 RJ45,1 RS485, 4 AI

1 DC

160mA@12V

M240T

1 RJ45,1 RS485, 4 RTD, 2/3 wire PT100/PT1000

1 DC

100mA@12V

M310T

1 RJ45,1 RS485, 8 DI

1 DC

150mA@12V

M320T

1 RJ45,1 RS485, 8 DO

1 DC

M330T

1 RJ45,1 RS485, 8 AI

1 DC

M340T

1 RJ45,1 RS485, 8 RTD, 2/3 wire PT100/PT1000

1 DC

100mA@12V

M410T

1 RJ45,1 RS485, 16 DI

1 DC

160mA@12V

M420T

1 RJ45,1 RS485, 16 DO

1 DC

110mA@12V

Special instructions for ordering:

1) If the model provides digital input, the DIN default type: wet contact, optional: dry contact. The input type

cannot be changed after manufacturer delivered. The DIN1 default is high-speed count mode; it can be

changed to low-speed count mode by open the shell and change the internal jumper. If require dry contact

input, please note when ordering, if DIN1 require high-speed pulse count mode then must be wet contact.

2) If the model provides digital output, the DO type is SINK, DO1 supports high-speed pulse output; DO2 can be

used to control the direction of the stepper motor. Also can connect external relay if need.

3) The model number: M240T, M340T support thermal resistance temperature transmitter default type: PT100,

optional: PT1000, if you need PT1000 type of thermal resistance, please note when ordering.

4) All models support the register mapping, can extend I/O or meters via Modbus RTU protocol.

5) Each model’s I/O port qty is referred to the above table only. As MXXT series use same housing, those I/O

port hardware terminal blocks on the device which not described in the table is not valid.

Page2of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 3

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

Table of Contents

DATE

FIRMWARE VERSION

HARDWARE VERSION

DESCRIPTION

2017-04-17

V1.0

2019-11-18

V2.0

New version

This user manual has been designed as a guide to the installation and operation of MxxT Series Ethernet Remote I/O

Module.

Statements contained in the manual are general guidelines only and in no way are designed to supersede the

instructions contained with other products.

We recommend the advice of a registered electrician before any Installation work.

King Pigeon Hi-Tech.Co., Ltd, its employees and distributors, accept no liability for any loss or damage including

consequential damage due to reliance on any material contained in this manual.

King Pigeon Hi-Tech.Co., Ltd, its employees and distributors, accept no liability for any Network upgrading or due to

the technology specifications contained in this manual.

【UPGRADE HISTORY】...................................................................................................................................................3

1. Brief introduction......................................................................................................................................................... 4

2.Standard Packing List.....................................................................................................................................................5

3. Mainly Features............................................................................................................................................................5

4. Technical Specifications................................................................................................................................................6

5. Physical Layout and Installation Diagram.................................................................................................................... 9

5.1 Physical layout.................................................................................................................................................9

5.2 Led Instruction...............................................................................................................................................10

5.3 Interface Instructions for installation............................................................................................................10

5.4 Typically Wiring Instruction:..........................................................................................................................11

5.5 Setup the DIN1 High Speed Pulse Count & Low Speed Pulse Count Mode:................................................. 12

6. Initialize/Reset the Module........................................................................................................................................12

7. Settings&Operation....................................................................................................................................................12

7.1 Ready to set up:.............................................................................................................................................12

7.2 Selection Description.....................................................................................................................................13

7.3 Basic Setting..................................................................................................................................................14

7.4 Network Settings...........................................................................................................................................15

7.5 Slave Settings................................................................................................................................................ 16

7.6 Register list....................................................................................................................................................18

7.7 System Log.....................................................................................................................................................19

8. Modbus Protocol........................................................................................................................................................20

8.1 Read Input Coil (Function Code 2: Read Coil)...................................................................................................20

8.2 Read and Write Holding Coil............................................................................................................................ 21

8.3 Read Input Register.......................................................................................................................................... 21

8.4 Read and Write Holding Register.....................................................................................................................23

8.5 Mapping Register----Transit BIT Register Address...........................................................................................24

8.6 Mapping Register----Transit 16-Bit Register Address...................................................................................... 24

9. Warranty.....................................................................................................................................................................24

【UPGRADE HISTORY】

Page3of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 4

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

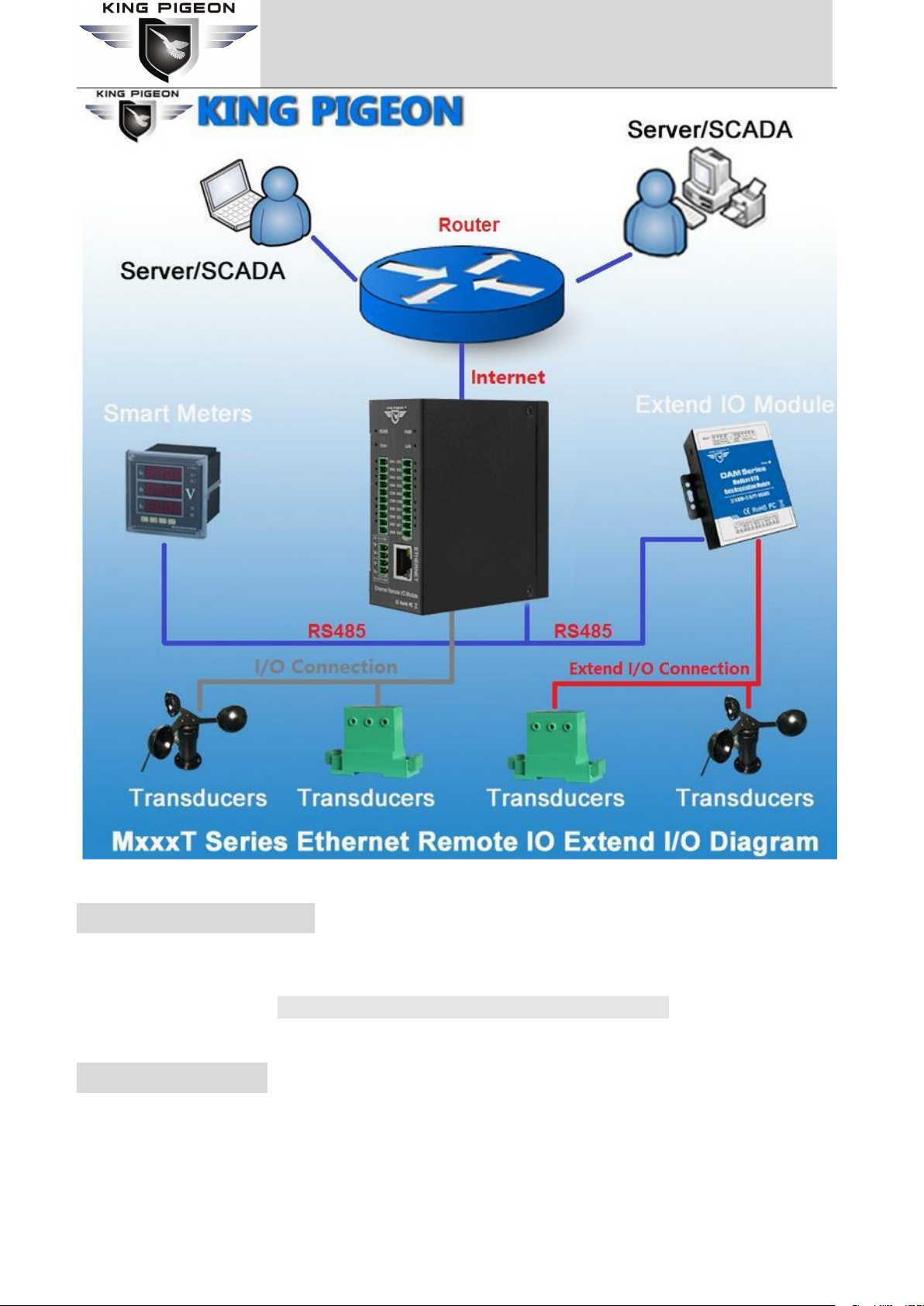

1. Brief introduction

The MxxxT Ethernet Remote I/O Module is an industrial class, isolated designed, high reliability, high stability and

high precision data acquisition module, embedded 32-Bit High Performance Microprocessor MCU, Integrated 1

Industrial 10/100M adaptive Ethernet module inside. It provides multi I/O, supports standard Modbus TCP,

supports modbus master and slave, can be integrated into SCADA, OPC server, and other automation systems. It is

design for working in the harsh industrial application environment, widely used in a variety of industrial

automation, security monitoring system, automatically measurement and control system.

The MxxxT Ethernet Remote I/O module provides a RS485 interface, through the RS485 bus, it can cascade

Modbus I/O devices or Modbus meters, e.g.: a variety of digital input or digital outputs, analog inputs or outputs,

thermal resistance IO module combination, save costs. At the same time, the Ethernet Remote I/O module has

register mapping function, the cascade Modbus I/O data are automatically collected to the register mapping area,

the TCP Client polling without waiting then can get a quick response to meet the industrial timely requirements.

The MxxxT Ethernet Remote I/O module provides different I/O ports for variety applications. Includes

optical-isolated digital inputs, compatibles dry contact and wet contact, supports max 700KHz high speed pulse

counter, digital outputs supports 10Hz~300Khz high speed pulse output or relay outputs, isolated 12bits analog

inputs, supports 0~5V, 0~10V, 4~20mA, 0~20mA analog signal, 12bits analog outputs, supports 0~10VDC signal

output, resistance thermal detector inputs compatibles 2/3 wires PT100 and PT1000. All of the I/O ports are high

sampling frequency and special filtering strategy to ensure its reliability.

The MxxxT Ethernet Remote I/O module can work at wide working voltage range, the range is 12 ~ 36VDC with

anti-reverse protection design. Also, it provides 1channel 12~36VDC power output for external device to save

wiring cost.

Page4of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 5

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

2.Standard Packing List

Ethernet Remote I/O Module X 1, Card type Manual X 1, 35mm Standard DIN rail fixed Bracket*1.

Note: The package does not include AC/DC Adaptor.

3. Mainly Features

Standard Modbus TCP protocol and Modbus RTU over TCP communication protocol;

Embedded 32-Bit High Performance Microprocessor MCU, inbuilt watchdog;

Power supply 12~36VDC with over voltage and phase-reversal protection;

Page5of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 6

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

Management and configuration via LAN connection configuration software for easy operation and

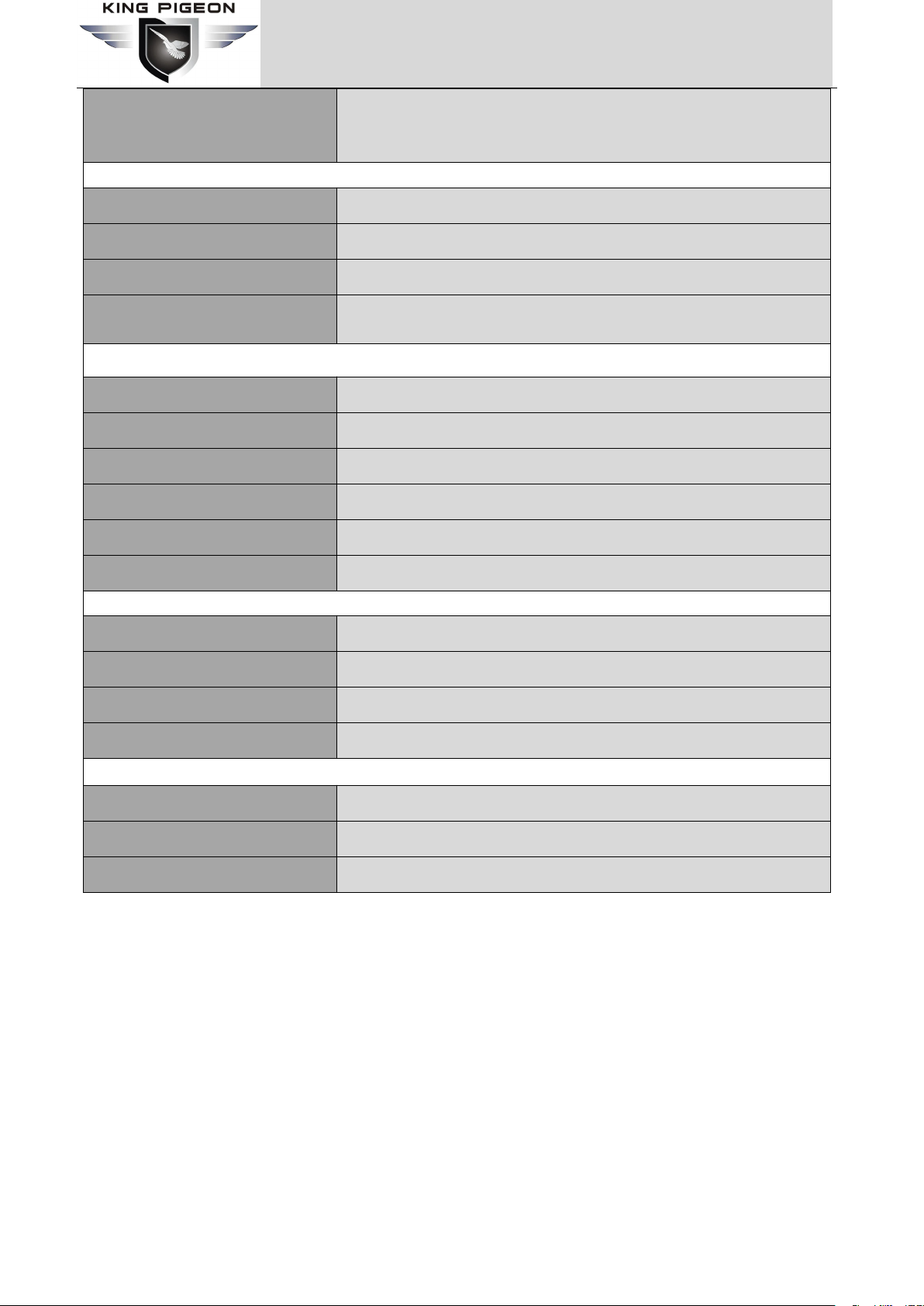

• Digital Input

Type

Wet Contact (NPN or PNP), Dry Contact. Default wet contact, if need dry

contact ,pleases tell us when order

I/O Mode

DI or Pulse Counter

Dry Contact

• On: short to GND, logic=1

• Off: open, logic=0

Wet Contact (DI to COM)

• On: 10 to 30 VDC,logic=1

• Off: 0 to 3 VDC,logic=0

Pulse Counter Frequency

Only the 1stChannel can be used as pulse counter, Compatibles DI and

counter simultaneously. Counter value will save if power off.

High Speed Mode: Max. 700Khz(Default);

Low Speed Mode: Max. 10KHz (Optional, can open the cover to choose

low speed mode.)

Digital sampling frequency

500Hz,3 times ACK

Digital filtering strategy

Support Anti-Shake Mechanism

Isolation

Optical Isolated,3k VDC or 2kVrms

• Digital Output

Type

Sink or pulse or relay(default is sink,can control ≤24V DC ≤0.5A relay

directly ,otherwise must connect external relay)

I/O Mode

Sink or Pulse Output

maintenance;

Integrated 10/100M adaptive Ethernet port, With 15KV ESD protection;

Optical isolated digital input(Compatible Dry or Wet type), supports max 700KHz high speed pulse counter;

DO supports Sink output,DO1 can be used as high-speed pulse output, supports 10Hz~300KHz ;

Isolated analog input, 12-bit resolution, supports 0~20mA,4~20mA,0-5VDC, 0-10VDC;

Analog output, 12-bit resolution, supports 0-10VDC;

RTD input, supports PT100 and PT1000 resistance sensor, compatible 2 or 3 wires;

High sampling frequency and special filtering strategy to ensure reliability;

1 RS485 Serial port, supports Modbus RTU Master/Slave, can extend I/O modules;

Supports register mapping function and extend I/O inquiry strategy;

Provides 1 channel VDC power source output for external device, saving wiring cost;

LED instructions work status, with reset button to reset, easy on-site installation and commissioning;

Using metal shell, protection class IP30. Metal shell and system security isolation, especially suitable for

industrial applications in the field;

Small size, L82 * W40 * H99mm, compatible wall installation and DIN35mm industrial rail installation.

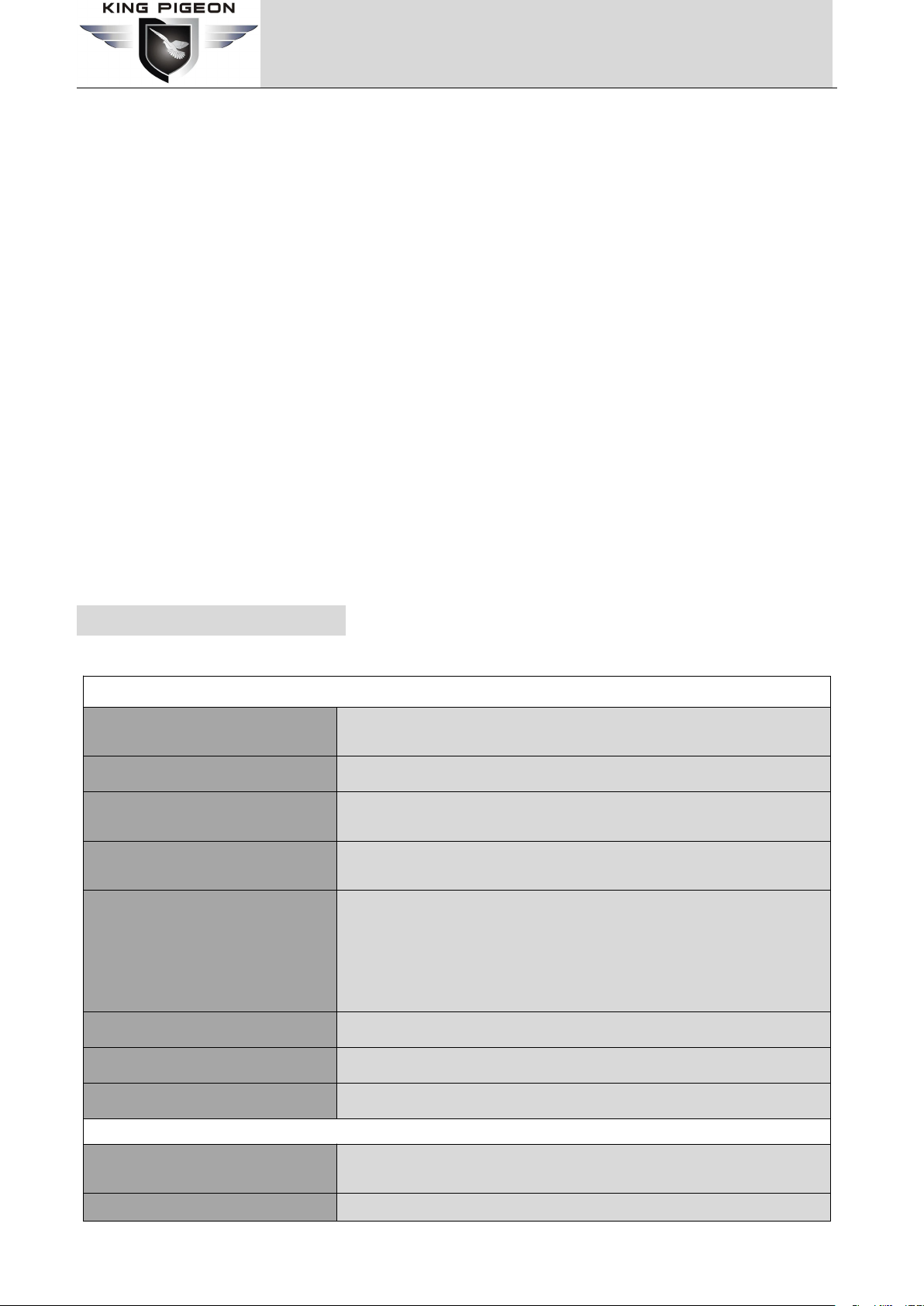

4. Technical Specifications

Page6of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 7

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

Pulse Output Frequency

10Hz~300KHz(Only the 1stChannel is Sink type can be used as high speed

pulse output)

Over-Voltage Protection

50V DC

Over-Temperature Shutdown

175°C (typical), 150°C (min.)

Load Current

Max.500 mA per channel

Digital sampling frequency

500Hz

Isolation

If DO is Sink type, then no isolation. If it is Relay, then is electrical

isolation.

• Analog Input

Type

mA/V

Resolution

12 bits

Current-type input impedance

124Ohm

Input Range

0~5VDC , 0~10VDC, 0~20 mA, 4~20mA,

Accuracy

±0.1% FSR @ 25°C

±0.3% FSR @ -10 and 60°C

Sampling frequency

20Hz

Isolation

Electrical isolation

• RTD Input

Sensor Type

PT100 or PT1000(default PT100,If need PT1000,please tell us when order)

Measurement Range

-50 ~ +300℃

Resolution

0.1°C or 0.1 ohm

Input Connection

2 or 3-wire

Accuracy

±0.1% FSR @ 25°C

±0.3% FSR @ -10 and 60°C

Sampling frequency

20Hz

Isolation

No

• Analog Output

Type

0-10V DC

Resolution

12 bits

Output Range

0 to 10 VDC

Load Current

1A (max.)

Accuracy

±0.1% FSR @ 25°C

±0.3% FSR @ -10 and 60°C

Isolation

No

• Working Power Requirements

Page7of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 8

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

Input Voltage

9~36VDC for no-AO output model,

24~36VDC for AO output model;

Peak Voltage:+40VDC, Power consumption: Less than 2W,

• LAN

Ethernet

10/100 Mbps adaptive Ethernet module, RJ45 ports

Protection

15KV ESD Protection

Protocols

Modbus TCP Master or Slave, TCP/IP

TCP Connection

Can be TCP client and server. As TCP server, support max 5 TCP client

connection

• Serial Port

RS485

MODBUS RTU Master or Slave.

Protection

15KV ESD Protection

Modbus Slave address

1~247

Polling Frequency

Default is 50mS,range:30-65535mS

Baud Rate

2400,4800,9600,19200,38400,57600,115200,128000Bps;

Mapping registers

Bit registers: 300, 16-Bit register: 300. Total 600 mapping registers.

• Physical Characteristics

Wiring

I/O cable max. 14 AWG

Dimensions

82x 40 x 99 mm

Weight

300 g

Mounting

DIN rail or wall-mounted

• Environmental Limits

Operating Temperature

Standard Models: -20 to 70°C (-4 to 158°F)

Storage Temperature

-40 to 85°C (-40 to 185°F)

Ambient Relative Humidity

5 to 95% (non-condensing)

Page8of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 9

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

5. Physical Layout and Installation Diagram

5.1 Physical layout

35mm Standard DIN rail fixed Bracket:

Page9of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 10

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

5.2 Led Instruction

LED Indicator Instruction

Power Indicator: Power on the device,PWR will always on.

Link Indicator: MODBUS TCP connection successful will always on.

RS485 Indicator: Flicks while receiving data on RS485 Serial port.

RS485 Indicator: Flicks while sending data on RS485 Serial port.

Digital input status indicator, turn on or input high level, or will close.

Digital Output status indicator, turn on or output high level, or will close.

Interface Definition Instruction

DC in 9~36V

+

DC9~36V positive input, 1A, for power on the Unit. If need to use the AO port,

then please power on it by DC24~36v.

–

DC12~36V negative input.

DC Out 9~36V

+

DC Power output positive for external device, output voltage= input voltage.

5.3 Interface Instructions for installation

See below interface definition, please connect the correct wires.

Page10of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 11

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

GND

DC Power output negative external device, output voltage= input voltage

Reset

Reset button. Recovery the parameters to factory default value.

ETHERNET

Ethernet port.

RS485

A

RS485 data A

B

RS485 data B

GND

RS485 data ground if required.

Digital Input

DINx+

The x channel digital input positive

GND

Digital input negative

Digital Output

DOx+

The x channel Digital Output High Level or Relay NO port.

GND

Sink output: GND (For output type is SINK.)

COM

Relay output: COM.(For output type is Relay)

Analog Input

AINx+

The x channel Analog input positive.

GND

Analog input negative.

Analog Output

AOx+

The x channel Analog output positive.

GND

Analog output negative.

RTD Input

RTDx+

The x channel Resistance Thermal input positive.

RTDx -

Resistance Thermal input negative.

COM

Resistance Thermal input COM port.

5.4 Typically Wiring Instruction:

Tips:

Resistance Thermal Detector (RTD) compatibles 2-wire or 3-wire, please reference abovementioned wiring instruction. If

the sensor near the module and the wire resistance is small can be ignored, can be used 2-wire wiring, if the distance is far

and the wire resistance affect the value, should be used 3-wire way connection.

Page11of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 12

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

5.5 Setup the DIN1 High Speed Pulse Count & Low Speed Pulse Count Mode:

High speed mode:

Short-circuit the upside 2 pins of

JP2&JP3’s with Caps.

Low speed mode:

Short-circuit the downside 2 pins

of

JP2&JP3’s with Caps.

The DIN1 can be used as pulse counter, default is high speed mode, the max. Frequency is 700Khz. it can be change

to low speed pulse count mode by open the shell, and change the JP2&JP3’s jump Caps to the right side2PINs, see

below pictures.

6. Initialize/Reset the Module

The device can be reset to factory default if mistake programmed. Please follow below steps to initialize it. After

initialized, the parameters will set as factory default.

1) Switch off the device

2) Press and hold the RESET button;

3) Power ON the Unit, waiting for 3 seconds, all the 4 lights( PWR, Link, RS485, Error Led Indicators) will turn on,

then loose the RESET Button, the other lights will flick for 5 times then turn off, while the PWR Led indicator

keeps on.

4) Turn off and Restart the device then recovery to factory default settings, and will enter to work mode. All of

the parameters will be reset to factory default.

7. Settings&Operation

The MxxT Ethernet Remote I/O module provides a standard Ethernet RJ45 interface, through the direct line

connect to the router, switches, HUB and other interconnect switching equipment, or through the cross-line

connect to PC and other terminal devices. The user can program parameters, firmware upgrades and debugging

through the WEB configuration interface. In the actual use, the Master will communicate it by MODBUS to read

and write the local register address and mapped registers of the slave I / O.

Below are the steps to setup the parameters by software, please follow it step by step.

7.1 Ready to set up:

1) Through the direct line connect to the router, switches, HUB and other interconnect switching equipment, or

through the crossover cable connect to PC and other terminal devices, And make sure the device and computer are

Page12of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 13

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

in the same LAN.

2) Powered on the device, the PWR LED indicator will turn on and the device will initialize within several second.

3) At the PC, open the software, click “search device”, Double click the device you find and enter password(default

is 1234). After password verification, you can set parameters.

Tips:

* If the first connection is through a crossover cable to the PC, the device IP will be 192.168.1.110. You need to change the

computer IP to 192.168.1. * to find the device..

7.2 Selection Description

System Settings

[Login Password]: Parameter setting can be done after login. The default password is 1234.

[Change Password]: Modify the device password. After modification, you need to log in with the new password.

[Save Data]: Save the parameter configuration to the device.

[Loading Data]: Read the parameter configuration of the device. Please read the current configuration before

setting the parameters.

[Restart]: Click this item to restart the device.

[Close]: Click this item to close the configuration software.

Device Search

[Login Password]: Click this item to search device.

File Operation

[Load File]: Import the previously exported configuration file parameter information to the configuration

Page13of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 14

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

software.

[Save File]: Export the current parameter information on the configuration software to a computer configuration

file,convenient for next configuration.

Language Selection

[Chinese]: Click to switch language to Chinese.

[English]: Click to switch language to English.

7.3 Basic Setting

Device ID: Default is 1, can be 1~247.

Device Information: Max 32 characters,this is the description of the module, e.g.: installation address, usage

instructions and so on.

AIN Setting: 0~5V,0~10V,0~20mA,4~20mA are optional,After selecting the specific mode, you also need to set the

AIN switch to the corresponding position on the hardware; [Maximum value] and [Minimum value] are

the sensor range, and [Current value] will be automatically converted to the real value according to the

set range.

DIN Input Status: :The state of the digital input. When the state of the digital input is closed, the corresponding

value in the list is 1, otherwise it is 0.

DIN1 Counter Default Trigger Direction: Can be set as rising edge or falling edge, need restart to take effect

DO Output Status: The Digital output status,When the status of the digital output is closed, the corresponding,

value in the list is 1, otherwise it is 0.

Double-click the value of a specific DO to change it, and the corresponding DO will immediately

output related actions;

Click [Turn On] or [Turn Off], all DO will output related actions immediately.

DO1 Pulse Output ,DO2 Direction Control: :Tick”Enable”,stands for DO1 is used as pulse output and DO2 is used as

direction control after the device restarts.

Page14of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 15

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

PT100/PT1000 Temperature Value: :It is the corresponding thermal resistance PT100 / 1000 channel converted

temperature value.

AO Output Test: :[AO1], [AO2] correspond to AO1 and AO2 channels. Adjust the DAC value of AO output by sliding

the slider. The output values of AO1 and AO2 cannot preset. In actual use, it is set by the host computer, 12-bit

accuracy,range is 0 ~ 4095, corresponding to the output voltage 0 ~ 10VDC, and the maximum load is 1A.

Note: After setting, please click "System Settings"-"Loading data" option to save the set parameters.

7.4 Network Settings

Got the IP address Auto: Tick it stands for: the device automatically obtains the IP address in the LAN. Only when

the router in the LAN allows the dynamic allocation of IP addresses can be used.

User Specifies the IP Address: Tick it stands for the user setup a fixed IP address for the module.

IP Address,Gateway,Netmask,Primary DNS,Secondary DNS: Only can be set After choose”User specifies the IP

address”.

Modbus TCP listening port: 1~65535,default is 502,listen TCP Client establish connection port,supports max 5 TCP

Client connection.

Modbus over TCP Active Connection Settings:Tick it stands for device will connect to the server automatically ,or

will not connect.

Server 1/2 IP/Domain,Server 1/2 Port: The device will connect to server 1 first, and connect to server 2 when the

connection fails.

Register Packets: Registration packet sent by the device to the server when connecting to the server.

Register ACK Packets: If this option is set, when registering to connect to the server, the server must deliver the

Page15of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 16

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

corresponding data to the device, otherwise the device considers the registration connection failed.

Heartbeat Packets: Heartbeat content to avoid network offline

Heartbeat ACK Packets: Once set,When receiving the heartbeat packet, the server must send the corresponding

data to the device. If the device does not receive this data for 3 consecutive times, it will

disconnect.

Disconnect Packets: The device will actively disconnect when receiving this data from the server.

Server Strategy: Can choose” Send once when login server,Plus it in front of every packet,Both of them”.

Heartbeat time: 1~9999 seconds,default is 60s.

Re transmission times: 1~9,default is 3.stands for when the device sends data to the server, the server does not

respond and will send it repeatedly 3 times.

Connection time: 1~999,default is 180s.

TCP Slave Setting: TCP client/slave IP,slave port.supports max 5 slaves.

Note: After setting, please click "System Settings"-"Loading data" option to save the set parameters.

7.5 Slave Settings

This series of products provide a serial port and network port to make it have powerful expansion functions. In the

device's internal storage area, 300 BIT-bit registers(Boolean) and 300 16-bit register mapping areas are provided.

(those 300 register can be 16-bit,32-bit or 64-bit,32-bit takes 2 16-bit address,64-bit takes 4 16-bit address

etc).This storage area is used to store slave data, which can reduce the communication response waiting time of

the entire network device and improve communication efficiency.

,

Page16of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 17

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

RS485 Settings

If the slave is only provides RS-232 interface, please use the RS-232/RS-485 converter connected to the 485

network. It is strongly recommended to use the isolated RS485 converter to improve system reliability. In a BUS, all

of the equipments ‘data A + should be connected together, and data B- should be connected together, cannot be

reversed, RS485 signal to the GND terminal should be shorted together, and connect to the module’s ground only.

RS-485 network generally allows up to 32 nodes in parallel devices, more than 32 systems need to use RS485

repeater to expand. RS-485 communication line should be STP(shielded twisted pair), the shield should be

single-ended ground; RS485 communication distance can be up to 1200 meters, when a bus connected to a lot of

RS485 devices, or use high baud rate higher communication distance Will be correspondingly shortened

accordingly, then you can use RS485 repeater to expand. RS-485 network has a variety of topology, the general use

of linear connection, that is, start from near to far, connecting devices to the master one by one. In the far end can

be connected to 120 ~ 300Ω / 0.25 watts of terminal matching resistance (depending on the communication

quality to determine).

Mode Selection : Master or Slave optional.

Baud rate : 2400,4800,9600,14400,19200,38400,57600,115200,128000 optional.

Data Bit: 7,8 bit.

Parity Bit: None, Even and Odd optional.

Stop Bit: 0.5Bit,1Bit,1.5Bit,2Bit optional.

Over time: Wait for the command reply time, the next command will be sent after timeout, default 200ms

Interval: Polling time, each command sending interval time, default is 50ms, please increase the time

appropriately when there are too many slaves.

Retry counts: command reply timeout retry times, default is 3 times.

Mapping Registers--Read Coil & Registers: Mapping registers between the slaves and module

After configuration, the module will Read the Modbus slaves automatically by the corresponding read coil and

register function codes according to the mapped registers.

Slave address : slave device ID,range 1~247.

Function code : Sets the type of action host to slave.Including 02 read input coil, 01 read hold coil, 04 read input

register, 03 read hold register,the values of the input coil and holding coil are automatically

allocated to the mapping storage area of the relay bit register, and the values of the input

register and holding register are automatically allocated to the mapping storage area of the relay

16 bit register.

Slave Start addr : The starting register address for slave data reading.

Number of registers : How many register need to read.

Mapped Addr(100-399) : Stand for mapping the slave start register data to the device start mapping address,

Can be set 100-399,The mapping addresses of the transit Bit and 16-bit registers are

separate, each occupying 300. The mapping addresses of the same type must not be the

same, and the mapping addresses for reading and writing cannot be the same.

Collection Target : Optional RS485, ports 1 ~ 5, corresponding to TCP slaves 1 ~ 5 respectively.

Add : After editing a slave information, click” Add” to map the register address of the cluster device to the

mapping storage area of this device.

Del : Select an edited slave information, click this item to delete the corresponding slave information.

Mapping Registers--Write Coil & Registers: Mapping registers between the slave and module

After configuration, the module will write the Modbus slaves automatically by the corresponding Function codes

according to the mapped registers.

Slave address : slave device ID,range 1~247.

Page17of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 18

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

Function code : Sets the type of action host to slave.including 05/15 write holding coil and 06/16 write holding

register, where the value of the holding coil is automatically allocated to the mapping storage area

of the relay bit register, and the value of the holding register is automatically allocated In the

mapped memory area of the transit 16-bit register.

Slave Start addr : The starting register address for slave data writing.

Number of registers : How many register need to write.

Mapped Addr(100-399) : Stand for mapping the slave start register data to the device start mapping address,

Can be set 100-399,The mapping addresses of the transit Bit and 16-bit registers are

separate, each occupying 300. The mapping addresses of the same type must not be the

same, and the mapping addresses for reading and writing cannot be the same.

Collection Target : Optional RS485, ports 1 ~ 5, corresponding to TCP slaves 1 ~ 5 respectively.

Add : After editing a slave information, click” Add” to map the register address of the cluster device to the

mapping storage area of this device.

Note: After setting, please click "System Settings"-"Loading data" option to save the set parameters.

7.6 Register list

The mapped register list in the Web page is only readable and cannot be written. It is used to display the current

value of the register in the mapping area, which is convenient for user debugging. There are 300 registers for the

Bit Type register, used to store one bit can represent the state of the data, e.g.: input coil, holding coil value. 300

registers for the 16-bit type register, used to store input register and holding register data. 300 BIT-bit

registers(Boolean) and 300 16-bit register mapping areas are provided. (those 300 register can be 16-bit,32-bit or

64-bit,32-bit takes 2 16-bit address,64-bit takes 4 16-bit address)The module will automatically assign and stored

them according to the coil or register set in Mapping Registers page.

Page18of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 19

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

7.7 System Log

This device supports the system log function, which is convenient for users to analyze the operation of the device.

The Record types includes below:

Normal power on, nth boot.

Caused by hardware failure,nth boot

Caused by memory failure,nth boot

Caused by CPU bus failure ,nth boot

Caused by command failure ,nth boot

Factory data restart ,nth boot

Server mode connection request, allow connection

Server mode connection request, exceeding the number of connections, forbidden to connect

Server mode, close connection received

Server mode, no data for a long time, close the connection

Client mode, successful connection to the server

Client mode, the server closes the connection

Client mode, no data for 10 minutes disconnect

Client mode, data transmission error, disconnection

Page19of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 20

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

Client mode, receiving disconnected packets

Read Input Coil (Function Code 2: Read Coil)

Channel

Register Address

Data Type

Description

DIN 1

0

1Bit

DIN1 Value, Read Only,0=Open,1=Close.

DIN 2

1

1Bit

DIN2 Value, Read Only,0=Open,1=Close.

DIN 3

2

1Bit

DIN3 Value, Read Only,0=Open,1=Close.

DIN 4

3

1Bit

DIN4 Value, Read Only,0=Open,1=Close.

DIN 5

4

1Bit

DIN5 Value, Read Only,0=Open,1=Close.

DIN 6

5

1Bit

DIN6 Value, Read Only,0=Open,1=Close.

DIN 7

6

1Bit

DIN7 Value, Read Only,0=Open,1=Close.

DIN 8

7

1Bit

DIN8 Value, Read Only,0=Open,1=Close.

DIN 9

8

1Bit

DIN9 Value, Read Only,0=Open,1=Close.

DIN 10

9

1Bit

DIN10 Value, Read Only,0=Open,1=Close.

DIN 11

10

1Bit

DIN11 Value, Read Only,0=Open,1=Close.

DIN 12

11

1Bit

DIN12 Value, Read Only,0=Open,1=Close.

DIN 13

12

1Bit

DIN13 Value, Read Only,0=Open,1=Close.

Client mode, 3 failed connections

Ethernet slave mode, successfully connected to the server

Ethernet slave mode, the server closes the connection

Ethernet slave mode, no data disconnection in 10 minutes

Ethernet slave mode, data error disconnected

Ethernet slave mode, 3 failed connections

8. Modbus Protocol

This device supports standard Modbus communication protocol:

1) As a TCP client, it supports Modbus RTU over TCP and Modbus TCP protocols to communicate with the server;

2) As a TCP server, it supports Modbus TCP protocol to communicate with TCP clients;

3) As RS485 master, support Modbus RTU protocol to communicate with slaves;

4) As RS485 slave, support Modbus RTU protocol to communicate with the host.

The device's register address, Modbus function code, data type, purpose, and precautions are described in the

following table.

8.1 Read Input Coil (Function Code 2: Read Coil)

Page20of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 21

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

DIN 14

13

1Bit

DIN14 Value, Read Only,0=Open,1=Close.

DIN 15

14

1Bit

DIN15 Value, Read Only,0=Open,1=Close.

DIN 16

15

1Bit

DIN16 Value, Read Only,0=Open,1=Close.

Notice

This Table corresponds to all MxxT series models, some of the models do not exist in the

corresponding channel then its register address is empty. For example, if DIN1 and DIN2

are available for M100T, the DIN3 to DIN16 registers are empty.

8.2 Read and Write Holding Coil

Read and Write Holding Coil (Function Code 1, Function Code, Function Code 15.)

Channel

Register Address

Data Type

Description

DO 1

0

1Bit

DO1 Value, Read/Write, 0=Open,1=Close.

DO 2

1

1Bit

DO2 Value, Read/Write, 0=Open,1=Close.

DO 3

2

1Bit

DO3 Value, Read/Write, 0=Open,1=Close.

DO 4

3

1Bit

DO4 Value, Read/Write, 0=Open,1=Close.

DO 5

4

1Bit

DO5 Value, Read/Write, 0=Open,1=Close.

DO 6

5

1Bit

DO6 Value, Read/Write, 0=Open,1=Close.

DO 7

6

1Bit

DO7 Value, Read/Write, 0=Open,1=Close.

DO 8

7

1Bit

DO8 Value, Read/Write, 0=Open,1=Close.

DO 9

8

1Bit

DO9 Value, Read/Write, 0=Open,1=Close.

DO 10

9

1Bit

DO10 Value, Read/Write, 0=Open,1=Close.

DO 11

10

1Bit

DO11 Value, Read/Write, 0=Open,1=Close.

DO 12

11

1Bit

DO12 Value, Read/Write, 0=Open,1=Close.

DO 13

12

1Bit

DO13 Value, Read/Write, 0=Open,1=Close.

DO 14

13

1Bit

DO14 Value, Read/Write, 0=Open,1=Close.

DO 15

14

1Bit

DO15 Value, Read/Write, 0=Open,1=Close.

DO 16

15

1Bit

DO16 Value, Read/Write, 0=Open,1=Close.

Notice

This Table corresponds to all MxxT series models, some of the models do not exist in the

corresponding channel then its register address is empty. For example, if DIN1 and DIN2

are available for M100T, the DIN3 to DIN16 registers are empty.

(Function Code 1: Read Coil, Function Code 5: Write Single Coil, Function Code 15: Write multi Coils.)

8.3 Read Input Register

(Function Code 4: Read Input Register.)

Page21of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 22

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

Read Input Register (Function Code 4: Read Input Register.)

Channel

Register Address

Data Type

Description

AIN1

0(High)

32 Bit Int

ABCD

AIN1 Value, Read Only,

Real value= Current value stored in register/100

1(Low)

AIN2

0(High)

32 Bit Int

ABCD

AIN2 Value, Read Only,

Real value= Current value stored in register/100

1(Low)

AIN3

0(High)

32 Bit Int

ABCD

AIN3 Value, Read Only,

Real value= Current value stored in register/100

1(Low)

AIN4

0(High)

32 Bit Int

ABCD

AIN4 Value, Read Only,

Real value= Current value stored in register/100

1(Low)

AIN5

0(High)

32 Bit Int

ABCD

AIN5 Value, Read Only,

Real value= Current value stored in register/100

1(Low)

AIN6

0(High)

32 Bit Int

ABCD

AIN6 Value, Read Only,

Real value= Current value stored in register/100

1(Low)

AIN7

0(High)

32 Bit Int

ABCD

AIN7 Value, Read Only,

Real value= Current value stored in register/100

1(Low)

AIN8

0(High)

32 Bit Int

ABCD

AIN8 Value, Read Only,

Real value= Current value stored in register/100

1(Low)

RTD1 ADC

0

16 Bit int

RTD1 ADC Value, Read Only.

RTD 2 ADC

1

16 Bit int

RTD2 ADC Value, Read Only.

RTD 3 ADC

2

16 Bit int

RTD3 ADC Value, Read Only.

RTD 4 ADC

3

16 Bit int

RTD4 ADC Value, Read Only.

RTD 5 ADC

4

16 Bit int

RTD5 ADC Value, Read Only.

RTD 6 ADC

5

16 Bit int

RTD6 ADC Value, Read Only.

RTD 7 ADC

6

16 Bit int

RTD7 ADC Value, Read Only.

RTD 8 ADC

7

16 Bit int

RTD8 ADC Value, Read Only.

RTD1 Temp

8

16 Bit int

After converted RTD1 Value, Read Only.

Real value= Current value stored in register/10.

RTD 2 Temp

9

16 Bit int

RTD2 ADC Value, Read Only.

Real value= Current value stored in register/10.

RTD 3 Temp

10

16 Bit int

RTD3 ADC Value, Read Only.

Real value= Current value stored in register/10.

RTD 4 Temp

11

16 Bit int

RTD4 ADC Value, Read Only.

Real value= Current value stored in register/10.

RTD 5 Temp

12

16 Bit int

RTD5 ADC Value, Read Only.

Real value= Current value stored in register/10.

RTD 6 Temp

13

16 Bit int

RTD6 ADC Value, Read Only.

Real value= Current value stored in register/10.

RTD 7 Temp

14

16 Bit int

RTD7 ADC Value, Read Only.

Real value= Current value stored in register/10.

Page22of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 23

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

RTD 8 Temp

15

16 Bit int

RTD8 ADC Value, Read Only.

Real value= Current value stored in register/10.

Reserved

16~25

16 Bit unsigned

Reserved

Product Model

26

16 Bit unsigned

Product Model Number

Product LOT

27

16 Bit unsigned

Product LOT

Product SN

28

16 Bit unsigned

Product Serial Number

Power On Times

29

16 Bit unsigned

Power On Times

Hardware Version

30

16 Bit unsigned

Hardware Version

Firmware Version

31

16 Bit unsigned

Firmware Version

Notice

This Table corresponds to all MxxT series models, some of the models do not exist in the

corresponding channel then its register address is empty. For example, only AIN1 and

AIN2 are available for M100T, the AIN3 to AIN8 registers are empty.

8.4 Read and Write Holding Register

Read and Write Holding Register (Function Code 3,Function Code 6, Function Code 16)

Channel

Register

Address

Data Type

Description

AO 1

0

16 Bit unsigned

AO1/AO2 output value, resolution 12bits, Range = 0 4095 corresponds to output voltage 0-10V, Maximum

loading is 1 Ampere.

AO 2

1

16 Bit unsigned

DIN1 Pulse

Counter Trigger

2

16 Bit unsigned

0= Falling, 1=Rising, can be changed in operation, after

opto-coupler isolation will become low level trigger.

DIN1 Pulse Counter

3(High)

32 Bit unsigned

ABCD

Counting does not affect the normal input, DIN1

high-speed mode pulse frequency up to 700KHz,

low-speed mode the frequency up to 10KHz. Can change

the High-speed or low-speed by internal switch. Default

is high-speed mode.

4(Low)

DO1 Pulse Counter

5(High)

32 Bit unsigned

ABCD

Read Only, automatically clear the value.

6(Low)

DO1 Pulse

Frequency

7

16 Bit unsigned

1-30000, unit:10Hz, means the DO1 output frequency

range is 10Hz-300KHz. Can be changed in operation.

DO1 Pulse

Duty Ration

8

16 Bit unsigned

Range=10-90, stands for pulse Duty Ration is 10%-90%.

Cannot be 0% and 100%. Can be changed in operation.

Recommend set as 20% while driving the motor.

DO2 Pulse

Output Direction

9

16 Bit unsigned

=1 stands for output high level, =0stands for output low

level. Can be changed in operation.

DO1 Pulse

Output Quantity

10(High)

32 Bit unsigned

ABCD

Range=0-4294967295. Only can be changed after

finished present operation.

11(Low)

(Function Code 3: Read Holding Register, Function Code 6: Write single Holding Register, Function Code 16: Write

multi Holding Registers)

Page23of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 24

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

DO1 Pulse

Output Control

12

16 Bit unsigned

0=No Action, 1=Output specified pulse quantity. 2=

Continuous output pulse. Complete the action

automatically reset to zero, the user can read the

register to determine whether the action is complete.

Reserved

13~31

16 Bit unsigned

Reserved

Notice

This Table corresponds to all MxxT series models, some of the models do not exist in

the corresponding channel then its register address is empty. For example,

M240T,M340T without AO,DIN,DO.

8.5 Mapping Register----Transit BIT Register Address

Transit BIT Register Address (Function Code 1, Function Code 5, Function Code 15.)

Transit BIT Register Address

Data Type

Description

100~399

1Bit

The BIT type mapping registers in the internal memory

of the module. Used to store the serial port slave and

TCP Client exchange data.

Notice

Cannot Read and write the same address.

Transit 16-Bit Register Address(Function Code 3:, Function Code 6, Function Code 16)

Transit 16-Bit Register Address

Data Type

Description

100~399

16 Bit

The 16-Bit type mapping registers in the internal

memory of the module. Used to store the serial port

slave and TCP Client exchange data.

Notice

Cannot Read and write the same address.

(Function Code 1: Read Coil, Function Code 5: Write Single Coil, Function Code 15: Write multi Coils.)

8.6 Mapping Register----Transit 16-Bit Register Address

(Function Code 3: Read Holding Register, Function Code 6: Write single Holding Register, Function Code 16: Write

multi Holding Registers)

9. Warranty

1) This module is warranted to be free of defects in material and workmanship for one year.

2) This warranty does not extend to any defect, malfunction or failure caused by abuse or misuse by the

Operating Instructions. In no event shall the manufacturer be liable for any module altered by purchasers

Page24of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Page 25

Industrial Ethernet Remote I/O Module

IoT Data Acquisition Module

The End!

Any questions please help to contact us feel free.

Http://www.iot-solution.com

Page25of

25

King Pigeon Hi-Tech. Co., Ltd. Ver 2.0

Loading...

Loading...