OPERATION MANUAL

User’s Guide

King-Long XMQ6900 Series Tourist Bus

Xiamen King Long United Automotive Industry Co., Ltd.

Foreword

1-1

FOREWORD

King-Long XMQ6900 series tourist bus keeps features of superior economy,

security and comfort. It has stable performance, strong power, luxury interior

trimming and high speed, which could meet applications of passenger inter-city

transportation, touring and business affairs, etc.

As for the specifications introduced in relate to information of the driving

and operation, service and maintenance of the XMQ6900 series tourist bus,

please read them carefully and make proper operation, maintenance and repair so

as to ensure it in good condition. Special hint: without authorization of Xiamen

King Long United Automotive Industry Co., Ltd, never modify the electrical

deployment of the whole vehicle, and should not lap the power supply line in

disorder. Improper usage and repair may have a strong impact on service

performance of the complete vehicle, and thus the manufacturer , Xiamen King

Long United Automotive Industry Co., Ltd. will not takes the responsibility for

the damages caused by them.

Any problem in service, please contact our special maintenance network or

after-sales department. We will ensure timely and complete maintenance as well

as original parts supply.

In order to satisfy all kinds of different demand of the consumers, we strive

to improve the quality of the product continuously to optimize our products. We

should not give any further notice for any modification of the product in advance .

The contents on the instruction book can only be used as reference. If there are

facts not comply with the manual, will be subject to the actual state of the

products because for some device and items, the vehicle will be finally equipped

only if they have been taken as optional configurations.

Final interpretive right of the instruction book belongs to the Engineering

Academy of Xiamen King Long United Automotive Industry Co., Ltd.

Xiamen King Long United Automotive Industry Co., Ltd.

MAY. 2016

Contents

1-2

Contents

Vehicle’s Picture

1. Foreword---------------------------------------------------------------------------------------------------------1-1

Contents

Contents--------------------------------------------------------------------------------------------------------------1-2

2. Technical parameters and complete vehicle description

Technical parameters ----------------------------------------------------------------------------------------------2-1

Introduction to data plate------------------------------------------------------------------------------------------2-2

Product quality assurance -----------------------------------------------------------------------------------------2-3

Technical document ------------------------------------------------------------------------------------------------2-3

Vehicle body structure----------------------------------------------------------------------------------------------2-4

Schematic illustration of the driver zone-------------------------------------------------------------------------2-5

3 . Operation Instruction

Instrument instruction----------------------------------------------------------------------------------------------3-1

Illustration of switch and indicators----------------------------------------------------------------------------3-2

Air conditioner control panel--------------------------------------------------------------------------------------3-3

Transmission operation---------------------------------------------------------------------------------------------3-4

ABS operation-------------------------------------------------------------------------------------------------------3-5

ECAS operation-----------------------------------------------------------------------------------------------------3-6

Open or close the passenger door---------------------------------------------------------------------------------3-7

Door emergency switch--------------------------------------------------------------------------------------------3-8

Adjustment of the driver's seat------------------------------------------------------------------------------------3-9

Horn button---------------------------------------------------------------------------------------------------------3-10

Adjustment of the steering wheel-------------------------------------------------------------------------------3-11

Ignition switch-----------------------------------------------------------------------------------------------------3-12

Lamplight operating handles-------------------------------------------------------------------------------------3-13

Wiper operating handle-------------------------------------------------------------------------------------------3-14

Passenger control panel-------------------------------------------------------------------------------------------3-16

Safety hatch--------------------------------------------------------------------------------------------------------3-17

Contents

1-2

Safety hammer-----------------------------------------------------------------------------------------------------3-18

Relays & Fuses----------------------------------------------------------------------------------------------------3-19

Switch control box------------------------------------------------------------------------------------------------3-20

4 . Vehicle starting and driving

Check oil level of the engine--------------------------------------------------------------------------------------4-1

Check level of the coolant-----------------------------------------------------------------------------------------4-2

Check fuel pre-filter with water separator-----------------------------------------------------------------------4-3

Check fuel level-----------------------------------------------------------------------------------------------------4-4

Check vehicle lighting, intermittent lights and brake lights-------------------------------------------------4-5

Check the level of AdBlue and the daily maintenance of SCR system--------------------------------------4-6

Drain water in air tank----------------------------------------------------------------------------------------------4-7

Check engine oil pressure------------------------------------------------------------------------------------------4-8

Check Pneumatic pressure-----------------------------------------------------------------------------------------4-9

Check Tachometer working order-------------------------------------------------------------------------------4-10

Steering wheel play------------------------------------------------------------------------------------------------4-11

Check tire for abrasion and pressure and tire nut for fixture------------------------------------------------4-12

Air cleaner----------------------------------------------------------------------------------------------------------4-13

General leakages (water, oil, fluids and fuel) -----------------------------------------------------------------4-14

Fastening and state of seat belts---------------------------------------------------------------------------------4-15

Check emergency devices and driver’s tools (fire extinguisher) -------------------------------------------4-16

Windshield wipers and conditions of wiper blades and arms-----------------------------------------------4-17

Electrical rearview mirror----------------------------------------------------------------------------------------4-18

Power steering system--------------------------------------------------------------------------------------------4-19

General state and tension of drive belts------------------------------------------------------------------------4-21

Check level of battery electrolyte-------------------------------------------------------------------------------4-22

Procedures for engine start up-----------------------------------------------------------------------------------4-23

Engine shut down-------------------------------------------------------------------------------------------------4-24

Engine start up and shut down in the engine compartment--------------------------------------------------4-25

Starting the vehicle------------------------------------------------------------------------------------------------4-26

Parking the vehicle------------------------------------------------------------------------------------------------4-27

Contents

1-2

5 . Vehicle maintenance and service

General knowledge------------------------------------------------------------------------------------------------5-1

Maintenance of engine and chassis subassembly-------------------------------------------------------------5-2

Body maintenance ------------------------------------------------------------------------------------------------5-3

ABS/EBS maintenance-------------------------------------------------------------------------------------------5-4

Electrical system maintenance and notices --------------------------------------------------------------------5-5

Tire transposition---------------------------------------------------------------------------------------------------5-6

Adjustment of the brake pedal freeplay-------------------------------------------------------------------------5-8

Bus cleaning--------------------------------------------------------------------------------------------------------5-9

Cleaning air filter -------------------------------------------------------------------------------------------------5-10

Cleaning outside of radiator -------------------------------------------------------------------------------------5-11

Coolant specification ---------------------------------------------------------------------------------------------5-12

Fuel recommendation---------------------------------------------------------------------------------------------5-13

Oil quality and specification recommendation----------------------------------------------------------------5-14

Breaking-in of a new vehicle------------------------------------------------------------------------------------5-15

Daily Maintenance Operation-----------------------------------------------------------------------------------5-16

Maintenance per 5000km----------------------------------------------------------------------------------------5-17

Maintenance per 10000km---------------------------------------------------------------------------------------5-18

Maintenance per 20000km---------------------------------------------------------------------------------------5-19

Maintenance per 40000km -----------------------------------------------------------------------------------5-20

Maintenance per 80000km -------------------------------------------------------------------------------5-21

Maintenance more than 80000km-------------------------------------------------------------------------------5-22

Maintenance period chart-----------------------------------------------------------------------------------------5-23

The introduction for the lubricate point location--------------------------------------------------------------5-24

6 . Common trouble and its eliminating method

Engine Common trouble and elimination------------------------------------------------------------------------6-1

Propeller shaft-------------------------------------------------------------------------------------------------------6-3

Transmission---------------------------------------------------------------------------------------------------------6-4

Rear axle------------------------------------------------------------------------------------------------------------6-5

Front axle and steering system-----------------------------------------------------------------------------------6-6

Contents

1-2

Braking system-----------------------------------------------------------------------------------------------------6-7

Electrical equipment and the starting system ---------------------------------------------------------------6-8

Air conditioner system--------------------------------------------------------------------------------------------6-9

7 . Appendix

Driver's tool table--------------------------------------------------------------------------------------------------7-1

Tightening moment of the bolts and the nuts in major position ------------------------------------------7-2

Illustration for spare tyre dismounting & mounting-----------------------------------------------------------7-3

The operation tips for maintenance free battery---------------------------------------------------------------7-4

Table of lubricant, power steering oil, and grease-------------------------------------------------------------7-5

Air braking schematic diagram ----------------------------------------------------------------------------------7-6

Electrical elementary diagram of vehicle --------------------------------------------------------------------7-7

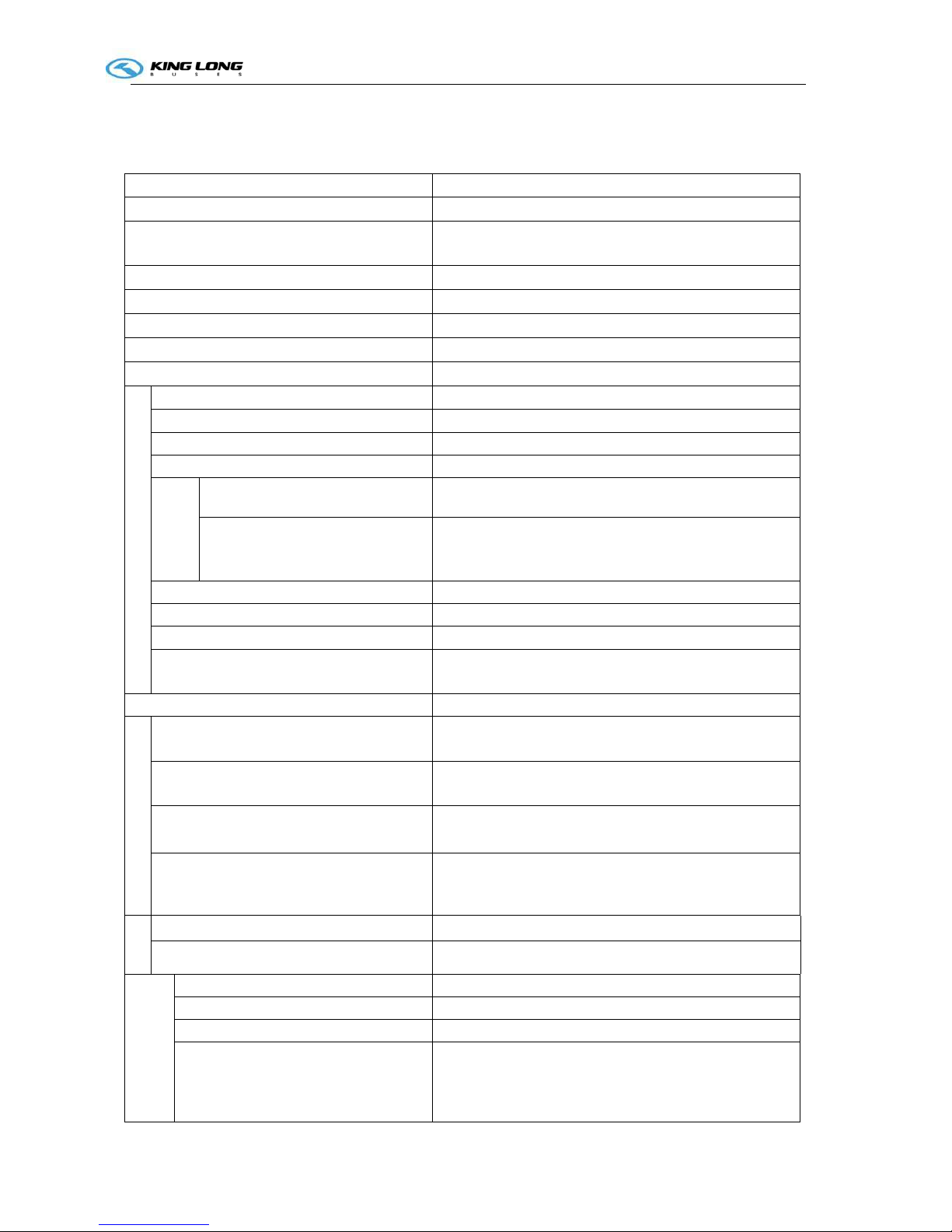

Technical parameter and complete vehicle description

2-1

Technical parameters of the complete vehicle

(Vehicle No:D2900633)

Product Model XMQ6900

Engine model

ISB6.7E5 250

Engine type In-line six-cylinder ,water-cooling four stroke direct-injection,

electronically controlling, diesel engine

Cylinder diameter × stroke (mm)

107×124

Displacement (mL)

6700

Compression ratio

17.3:1

Rated capacity / rotation speed Kw/r/min

184/2500

Max. torque / rotation speed N.m/r/min

950/1200

Dimensions

Overall length (mm) 8995

Overall width (mm) 2480

Overall height (mm) 3435

Wheelbase (mm) 4300

Wheel

track

Front mm) 2090

Rear (mm) 1860

Minimum lift-off clearance (mm) 230

Approach angle (°) 10

departure angle (°) 8

Front suspension / rear suspension

(mm)

1905/2790

Rated passenger (driver included) (person) ≤39

Mass parameter

Technically permissible maximum laden

mass(kg)

14000

Technically permissible maximum mass of

combination(kg)

17500

Technically permissible maximum laden

mass for front axle (kg)

4500

Technically permissible maximum laden

mass for rear axle (kg)

9500

wheel

Tire size (front, rear) 275/70 R22.5

Tire inflation pressure (kpa) 700

Performance

parameter

Max. speed (km/h) 115

Fuel consumption (L) --

Maximum gradeability (%) 30

Min. turning diameter (m) 17

Technical parameter and complete vehicle description

2-1

parking braking ability ( 20% gradient) parking for 5 minutes

Capacity data

Fuel tank(L) 200

Engine oil(L) 26.5

Transmission lubricant(L) 42(first oil fill);24(service oil change)

Main retarder lubricant(L) 11

Power steering hydraulic oil(L) 6~7

Clutch oil(L) 0

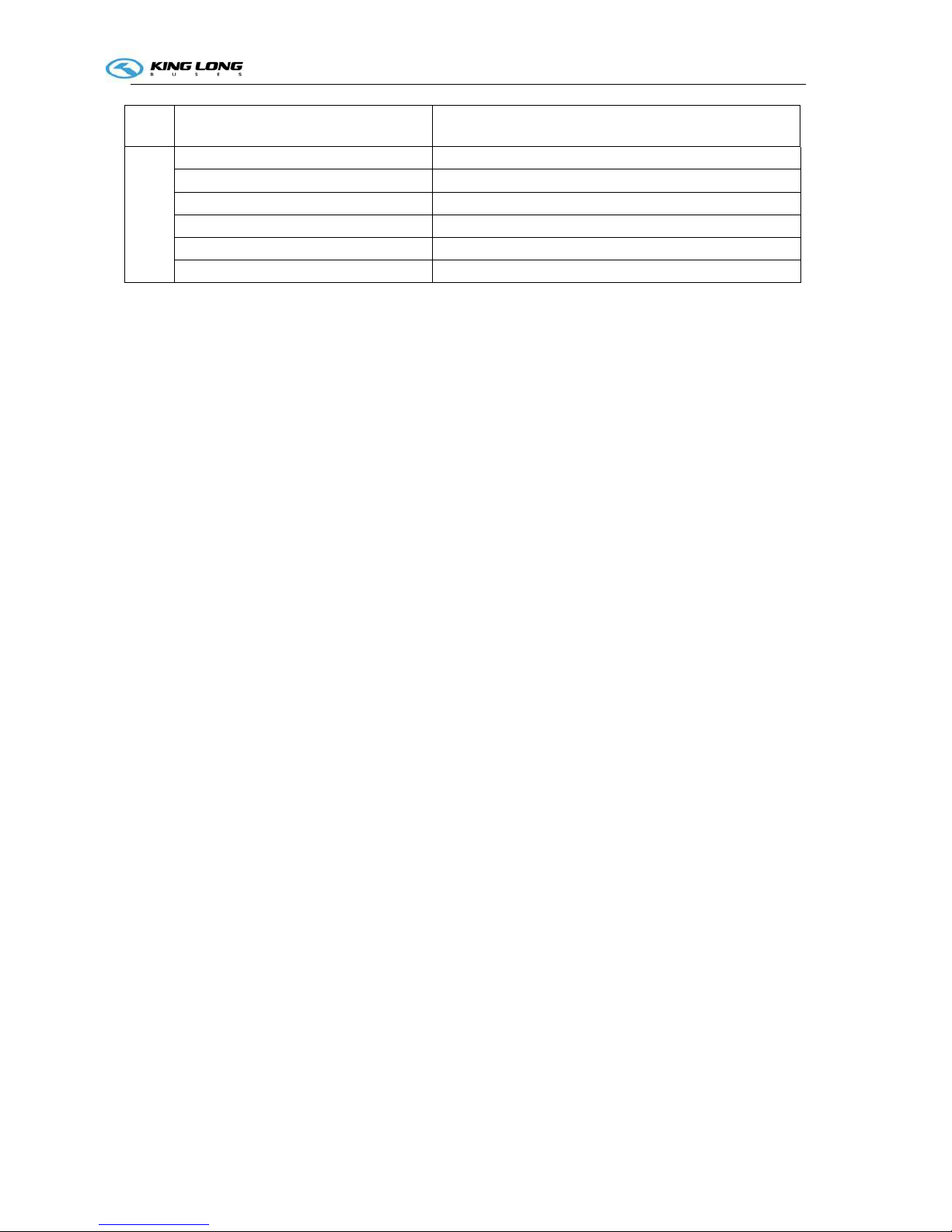

Technical parameter and complete vehicle description

2-2

Introduction to data plate

Bus data plate

The bus data plate may be affixed to either the upside of the front passenger door frame or to the side of the

front passenger door step (the position may vary with vehicle model). There are many parameters on the

plate, such as vehicle model, gross mass, vehicle serial number, vehicle capacity, VIN (short for vehicle

identification number), chassis serial number, engine serial number, engine model, rated power, production

data and etc..

Chassis data plate

The chassis data plate with vehicle identification number (VIN) is upon the front door.

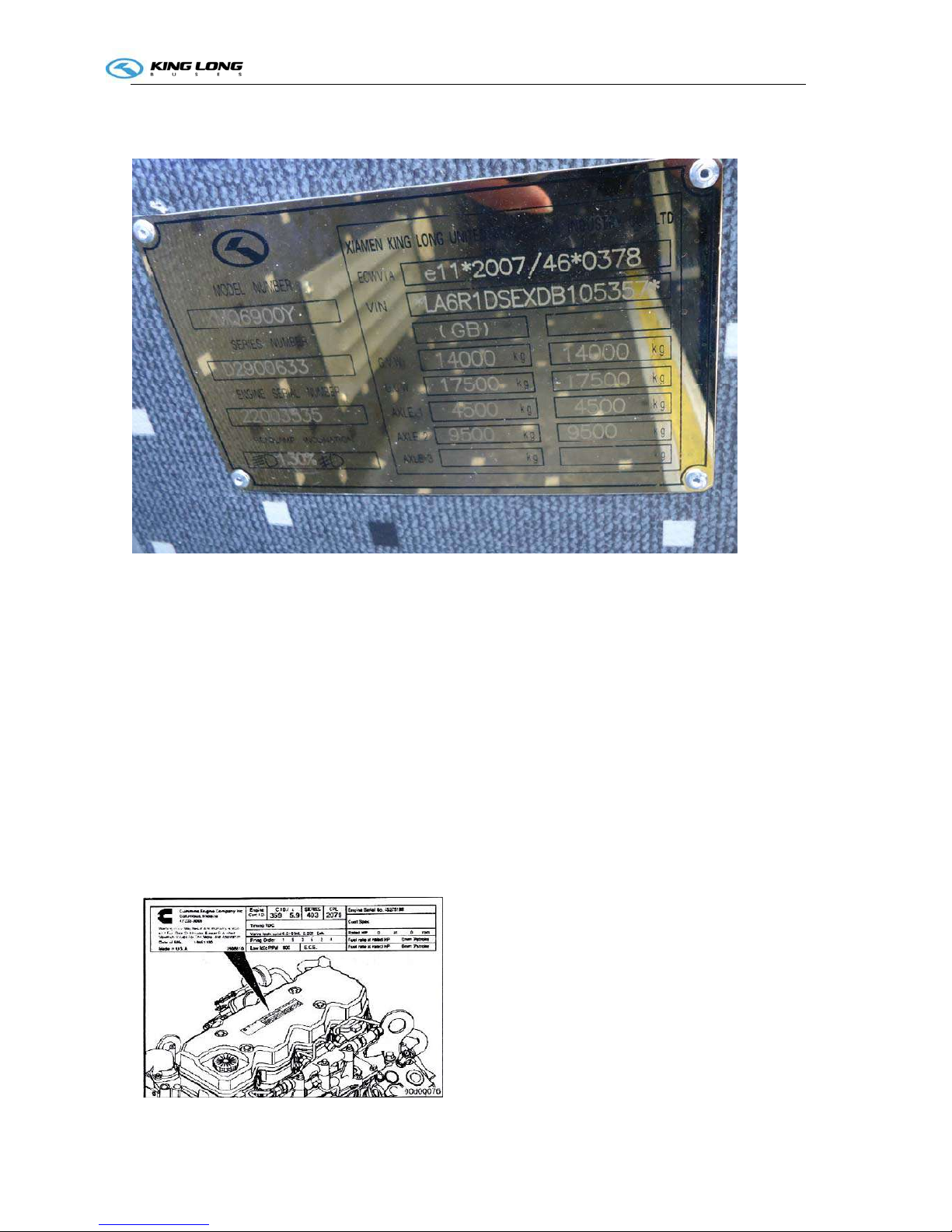

Engine data plate

The engine data plate is on top surface or salient top position of the engine, whose position may be

various according to different engine manufacturing plant.

The engine number is stamped on the left or right block of the engine, whose position may be various

according to different engine manufacturing plant.

Technical parameter and complete vehicle description

2-3

Product quality assurance

We insisted that the end user should make breaking-in maintenance of the rolling-out new vehicles in

their initial driving mileage of 5000 km. Users must make proper operation and maintenance strictly

according to relevant regulations in the instruction book. Please refer to “workshop manual” for product

quality assurance and abide by related specification.

Technical documents

The instruction book is used combined to the following specification:

Engine operation instruction or service manual

Note: the instruction book should be modified according to specific configuration of vehicle

Technical parameter and complete vehicle description

2-4

Body Structure

1. Structural style

Semi-integral body structure

2. Structure

The bodywork structure adopts closed girder construction of six major assembly parts, which are

combined welded by rectangle steel pipes with advantages of strong structural stiffness, torsion

resistance and bending resistance as well as relatively simple craftwork. Main components of skeleton

have been performed anticorrosion treatment to ensure steady adhesion of coating and strong capacity

of antirust and corrosion-proof.

3. Interior trim

The interior adopts flexible design and the floor adopts steel plate/wood block composite construction,

and covered with anti-slip and antifriction leather with favorable sound insulation value.

4. Windows

The front windshield is the hyperboloid triplex glass fixed by the gluing; the rear windshields is fixed

by harden glass, the side windows are sealing style, which are made of hollow glass. The driver’s

window is fixed with sliding window.

5. Baggage compartment

The baggage compartment adopts transverse run-through design, and they are all made of aluminum.

6. Seat

Driver’s seat: Q15-2 driver seat, adjustable seat with high backrest and three-point belt.

Passenger seats: KE-1 type seat, with foot pedal and transverse movement function, high backrest, the

all seats are equipped with three-points seat belt.

7. Interior accessory device

The vehicle is equipped with electronic clock, electric front windshield sunshade, driver side sunshade,

electric driver window, safety hammer, emergency escaping window, curtain and luxury bilateral H type

luggage rack,engine cabin fire extinguisher, electric mirrors, VDO travelling data recorder, reversal

monitor, middle door (located in front of the rear axle), icebox, front and middle flip LCD TV, DVD

player ,etc..

8. Air-conditioning system

Cooling system: WEBASTO top mounted dependent air-conditioning system..

Heating system: WEBASTO heating system. and NANFENG radiator system..

Defroster: NANFENG cooling /heating defrosting device

9. Door

The door adopts the full aluminum remote control out-swing pneumatic doors.

The out-swing door adopts the advanced electrically aerodynamic theory design, with the motion of

opening and closing placidly、agile、safe、lock credible and anti-clamp function.

A. Basic function

a. There are two electrically switches, the interior one is trigger touch-tone, which located on the

dashboard of the front right side of the driver, the outside one is a remote control switch. , both switches

can control the door.

b. When the circuit is in OFF position , the emergency switch can be used in the interior and

exterior ,the emergency switch of the door is located inwardly upon the entrance of the door and

outwardly behind the passenger door respectively, Please rotate the switch and throw open the door in

emergency.

c. Commonly the door is closed, when touch off any electrically switch, the door would move placidly

at a certain velocity, along with it, the step-lamp lights .when touch off the switch again , the door

would return placidly at a certain velocity, after the door returned , the step-lamp goes out.

Technical parameter and complete vehicle description

2-5

B. Hint:

a. The door remote control acts only when the parking brake is on the parking gear.

b. The door could only be opened when the external mechanical lock isn't locked up.

c. In order to avoid impact, make sure that the door is completed closed or opened, before you make the

next door switch operation.

Note: Deployment on the vehicle may be different with the above description because of different

deploying requirement of the clients.

Schematic illustration of the driver zone

1 DVD/MP3 player

2 Reversal monitor

3 Rocker switch

4 Light control handle

5 Combination instrument panel

6 Steering wheel

7 Wiper control handle

8 Gearbox operation panel

9 Fire extinguisher pushbutton switch

10 Electric mirrors pushbutton

11 WEBASTO heating panel

12 WEBASTO heater timing panel

13 Parking brake handle

14 Travelling data recorder

15 Radiator operation panel

1

2

3

4

5

8 9

10

11

6

7

12

13

14

15

Operation Instruction

3-1

Instruction of instrument (VITI EDITION)

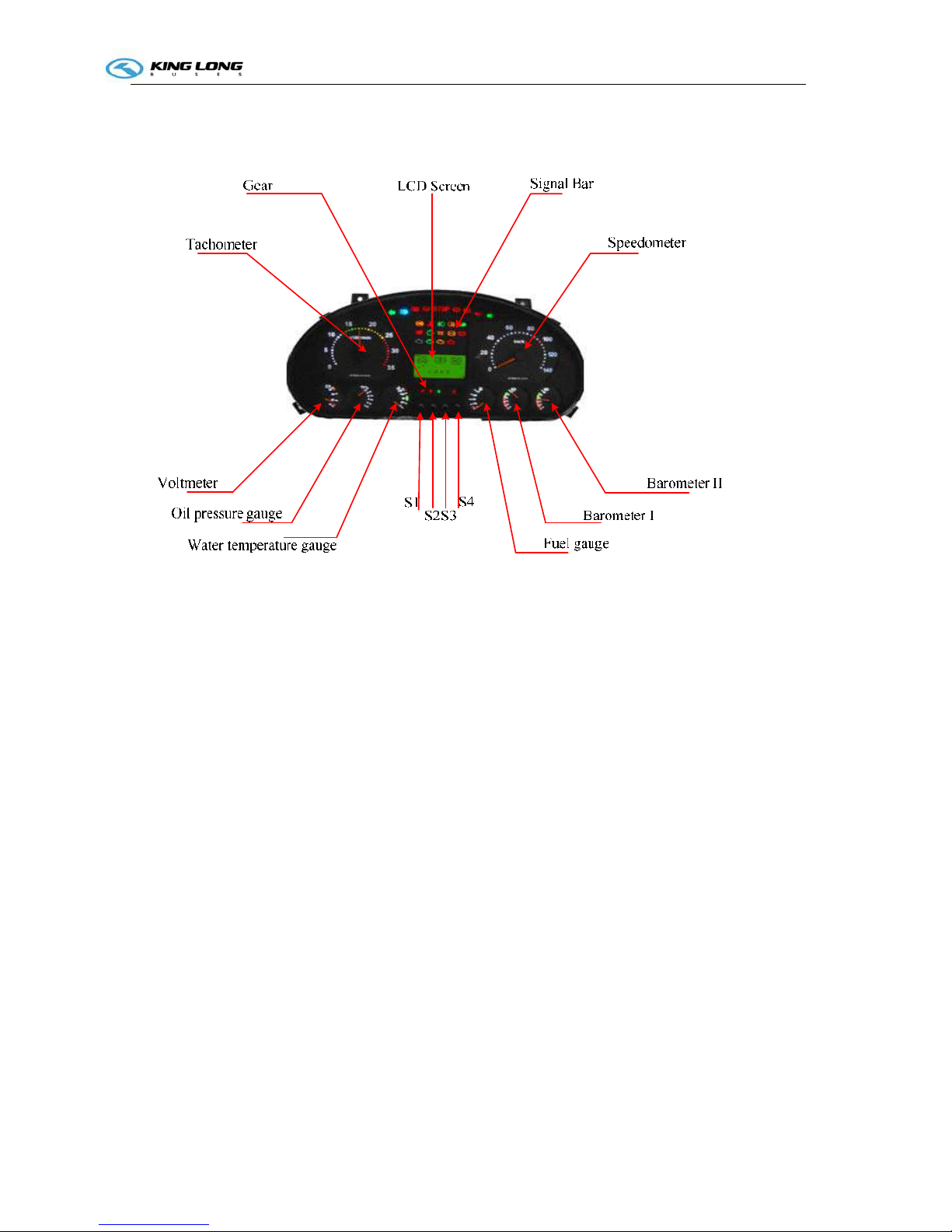

Figure-1 The Outline of ZB271M

The appearance of the ZB271M dashboard as shown in Figure-1 , it mainly contains eight indicator

type measuring instruments, 29 icons which were lighted by the light-emitting diodes, one LCD screen and

four buttons, dashboard pin definition go to Appendix A

2.1 Display Part.

1.Gear P—Brake gear, R—Reverse gear,N—Neutral gear,D—Drive gear,S—Safety belt.

2.Signal Bar. Go to Appendix B.

3.Speedometer .Display speed of car. Units :Km/h.

4.BarometerI and Barometer II. Display air pressure of car. Units: 0.1MPa .

5.Fuel gauge. Display amount of fuel. Units: Percentage.

6.Water temperature gauge .Display engine temperature of car. Units: ℃.

7.Oil pressure gauge. Display oil pressure gauge of car. Units : 0.1MPa.

8.Voltmeter .Display Voltage of car. Unit: V.

9.Tachometer .Display rotate speed of car. Units: r/min.

10.LCD Screen. Display interface information, engine information and so on. Go to Appendix C.

2.2 Button part

Operation Instruction

3-1

ZB271M dashboard has four buttons,S1、S2、S3、S4.

S1—Set Button. S2—Up Button. S3—Down Button. S4—Return Button.

S1 could set some information of dashboard, for example ,times, blacklight, VehPPK and so on.

S2 and S3 could flip the screen up or down.

S4 Return main interface.

Remarks: Do not press S1 when flip the screen up or down.

3 Instructions

3.1 LCD Display

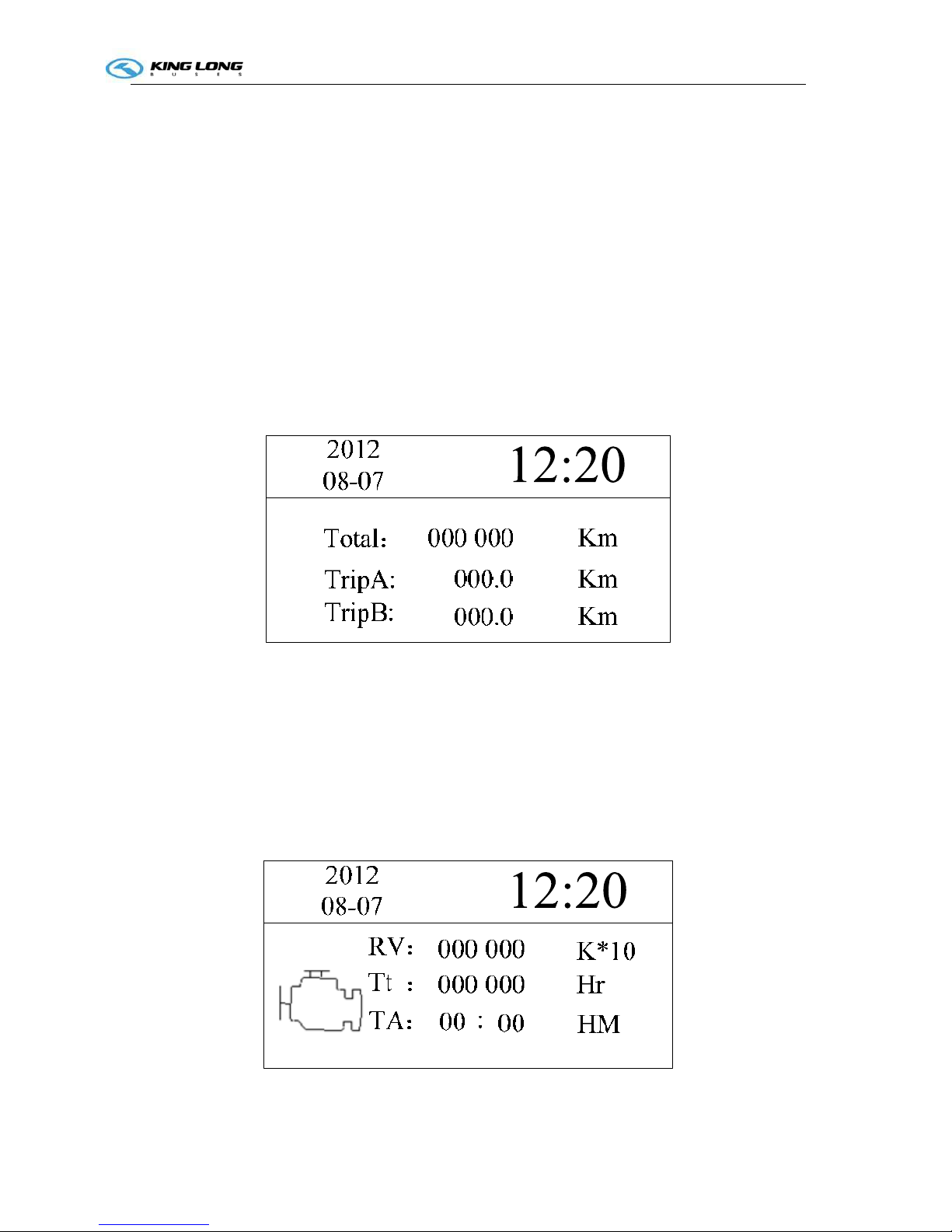

3.1.1 After power on as shown in Figure-2: Total Mileage, Trip Mileage A and Trip Mileage B

Figure-2 Main interface

3.1.2The second interface display engine information,as shown in Figure -3。

Accumulated rotates and Engine running time.

Figure-3 Engine information

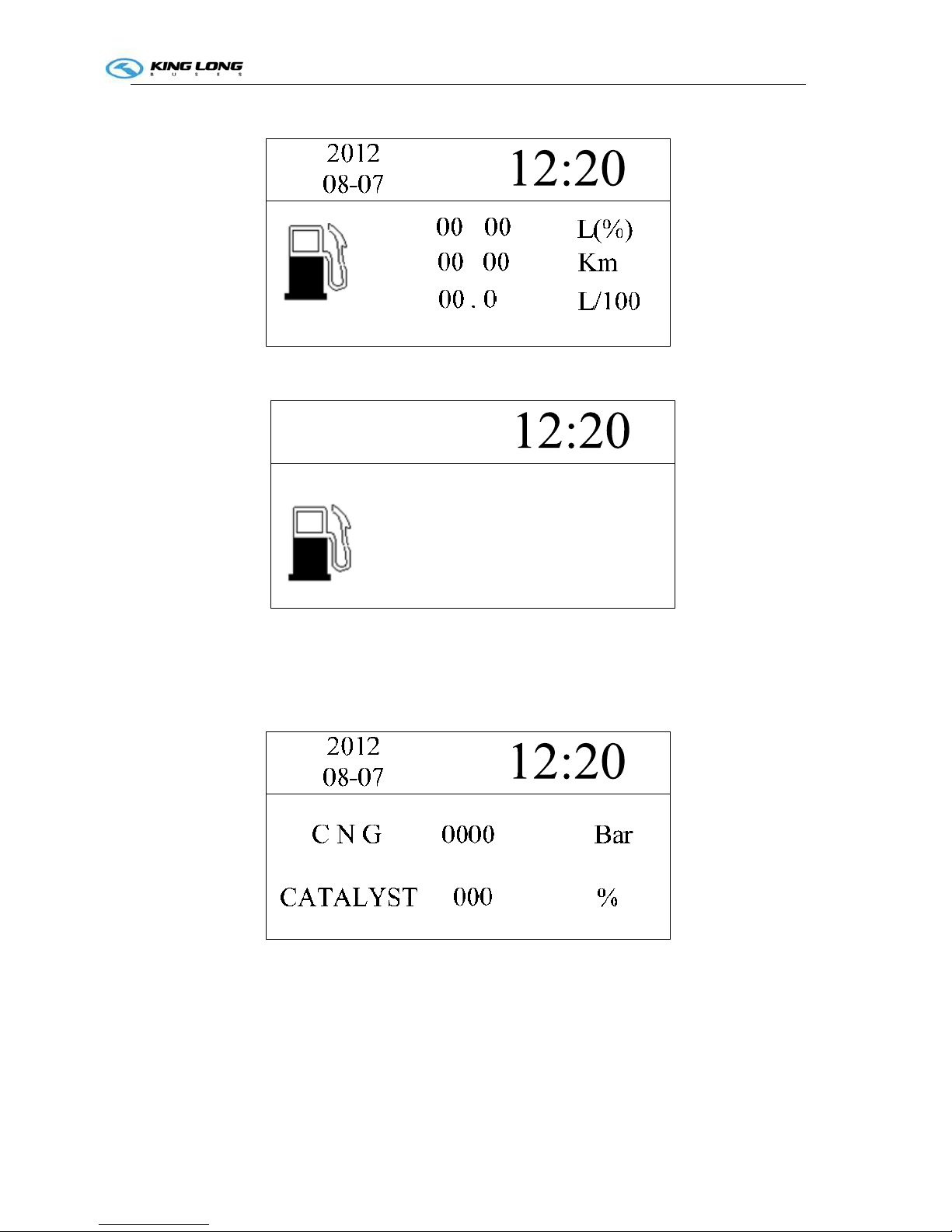

3.1.3 The third and the fourth interface display information of Fuel and Mileage as shown in Figure -4 and

Operation Instruction

3-1

Figure -5.

Figure-4 Fuel and Mileage information

2012

08-07

0000000000 .0 L

0000000000 .0 L

Figure-5 Fuel and Mileage information

3.1.4 The fifth interface display CNG and Catalyst. as shown in Figure-6

Figure-6 CNG and CATALYST

3.1.5 The sixth display inside temperature,outside temperature and engine compartment temperature. as

shown in Figure-7

Operation Instruction

3-1

Figure-7 Car and Engine compartment temperature

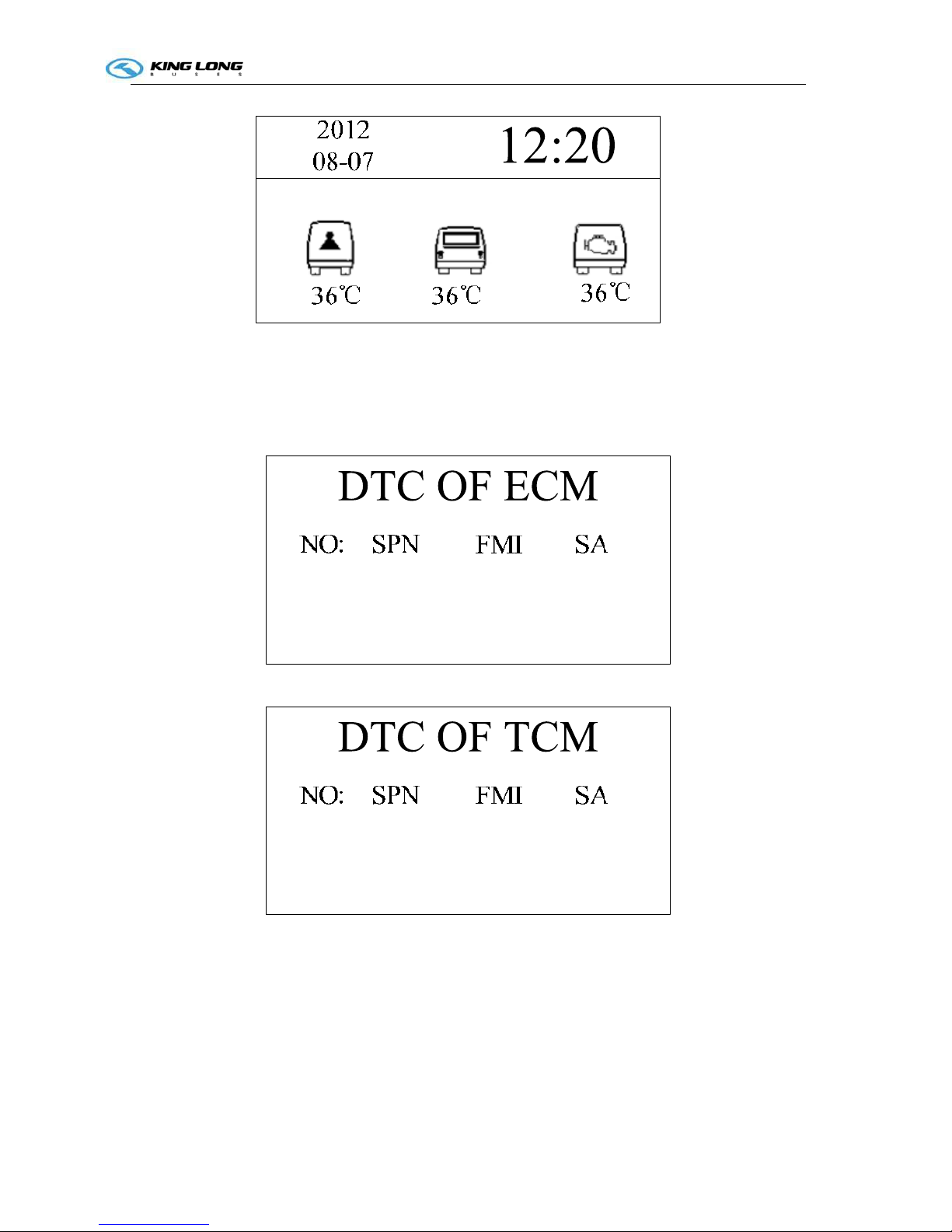

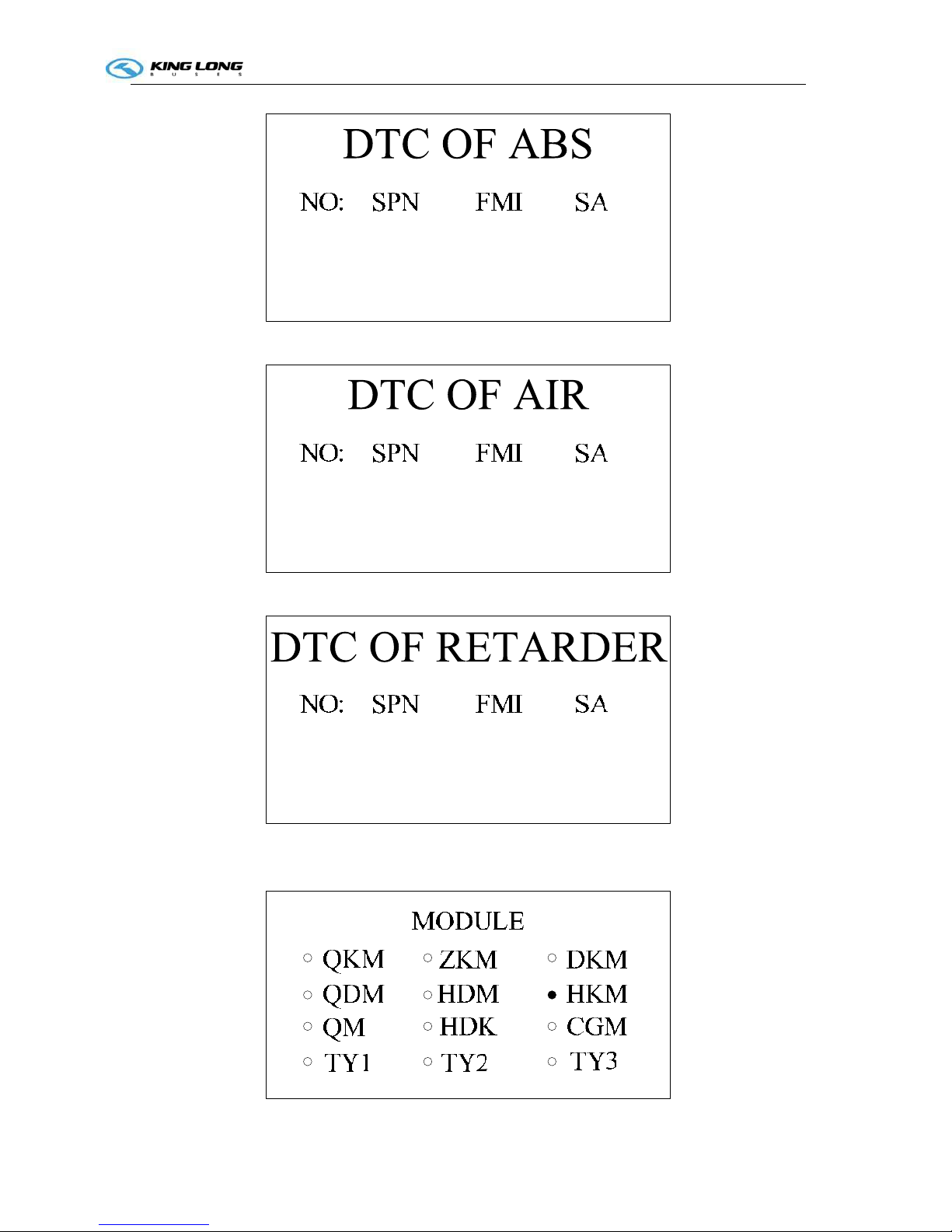

3.1.6 The seventh、eighth、ninth、tenth and eleventh interface display ECM、TCM、ABS、AIR、Retarded

information. as shown in Figure-8、9、10、11、12.

Figure-8 ECM Code

Figure-9 TCM Code

Operation Instruction

3-1

Figure-10 ABS Code

Figure-11 AIR Code

Figure-12 Retarded Code

3.1.7 The thirteenth interface display online module. as shown in Figure-13.

Operation Instruction

3-1

Figure-13 Online Module

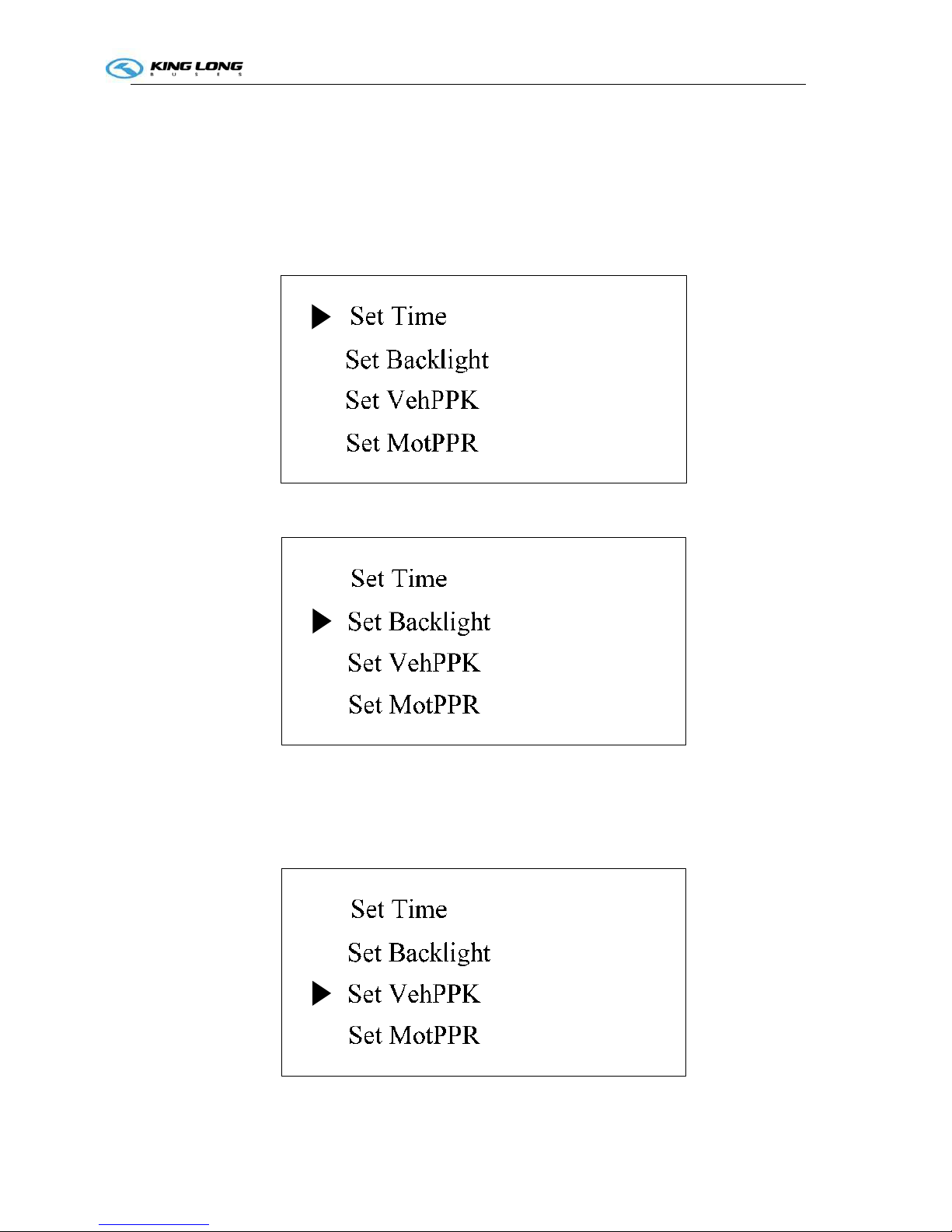

3.2 Dashboard Set

3.2.1 First,Press S1 go to set interface, Second, Press S2 and S3 flip the interface up or down.

Could Set Time、Set Backlight、Set VehPPK、Set MotPPR、Clear Trip A、Clear Trip B、ClearTA、

Clear Oneway OC. as shown in Figure-14、15、16、17、18、19、20、21

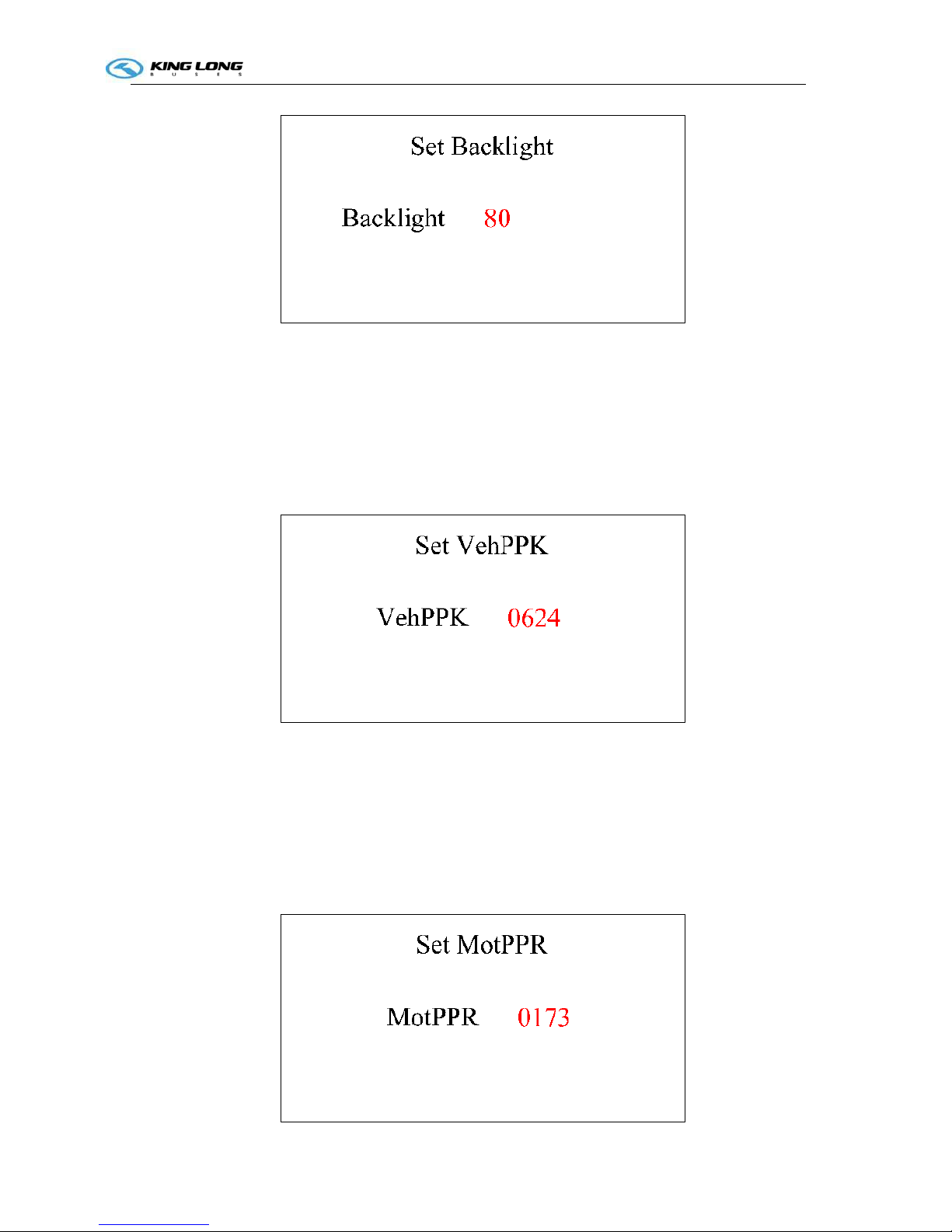

Figure-14 Set Time

Figure-15 Set Backlight

Figure-16 Set VehPPK

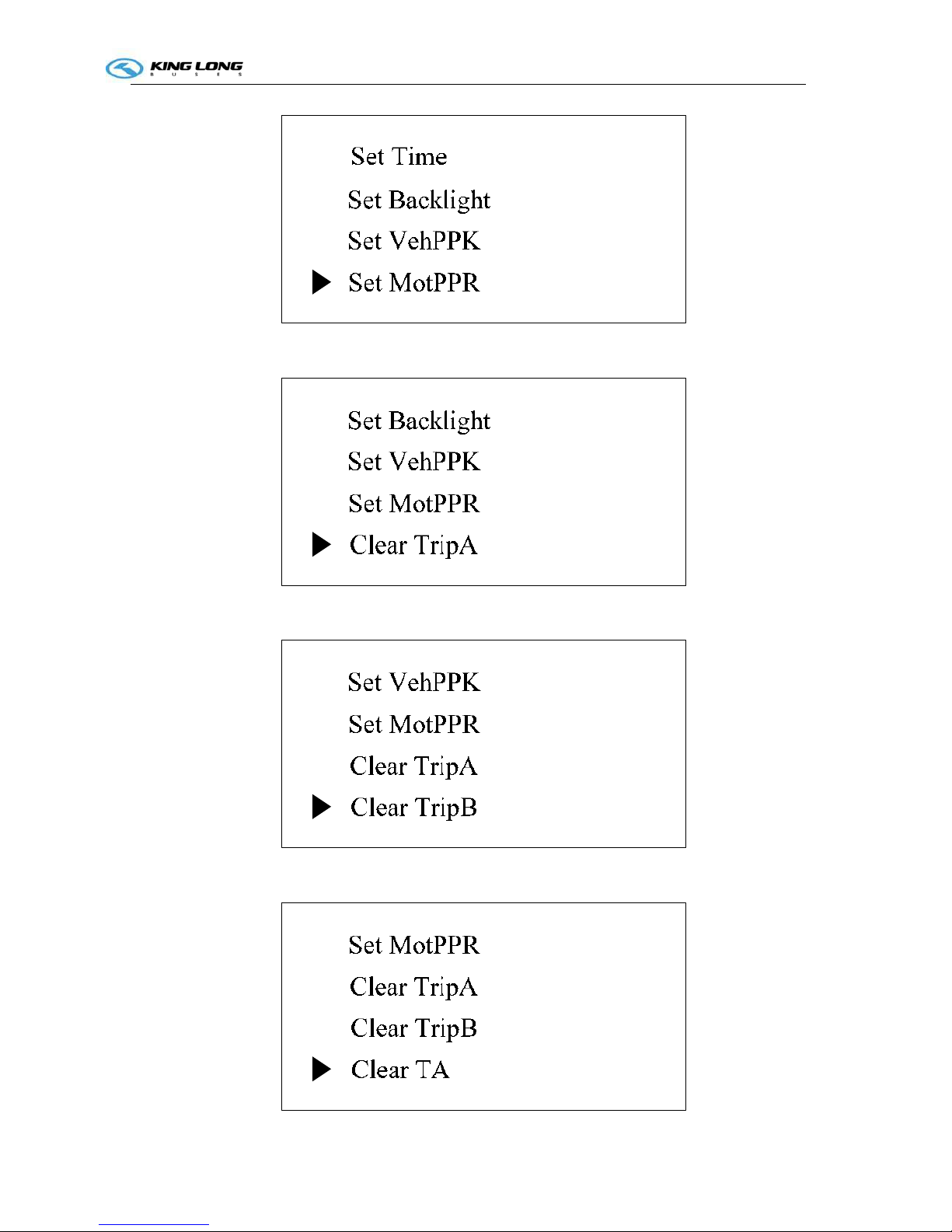

Operation Instruction

3-1

Figure-17 Set MotPPR

Figure-18 Clear Trip A

Figure-19 Clear Trip B

Operation Instruction

3-1

Figure-20 ClearTA

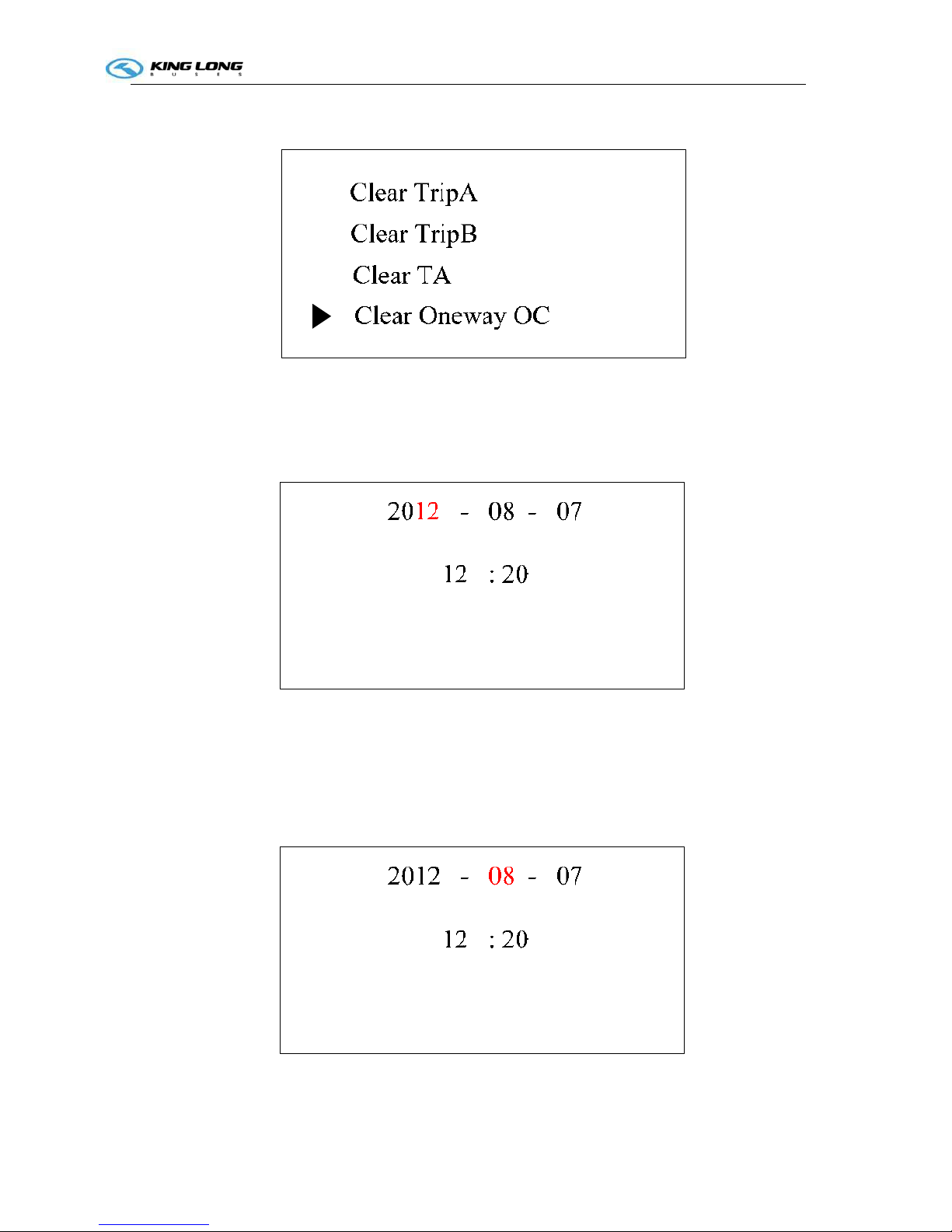

Figure-21 Clear Oneway OC

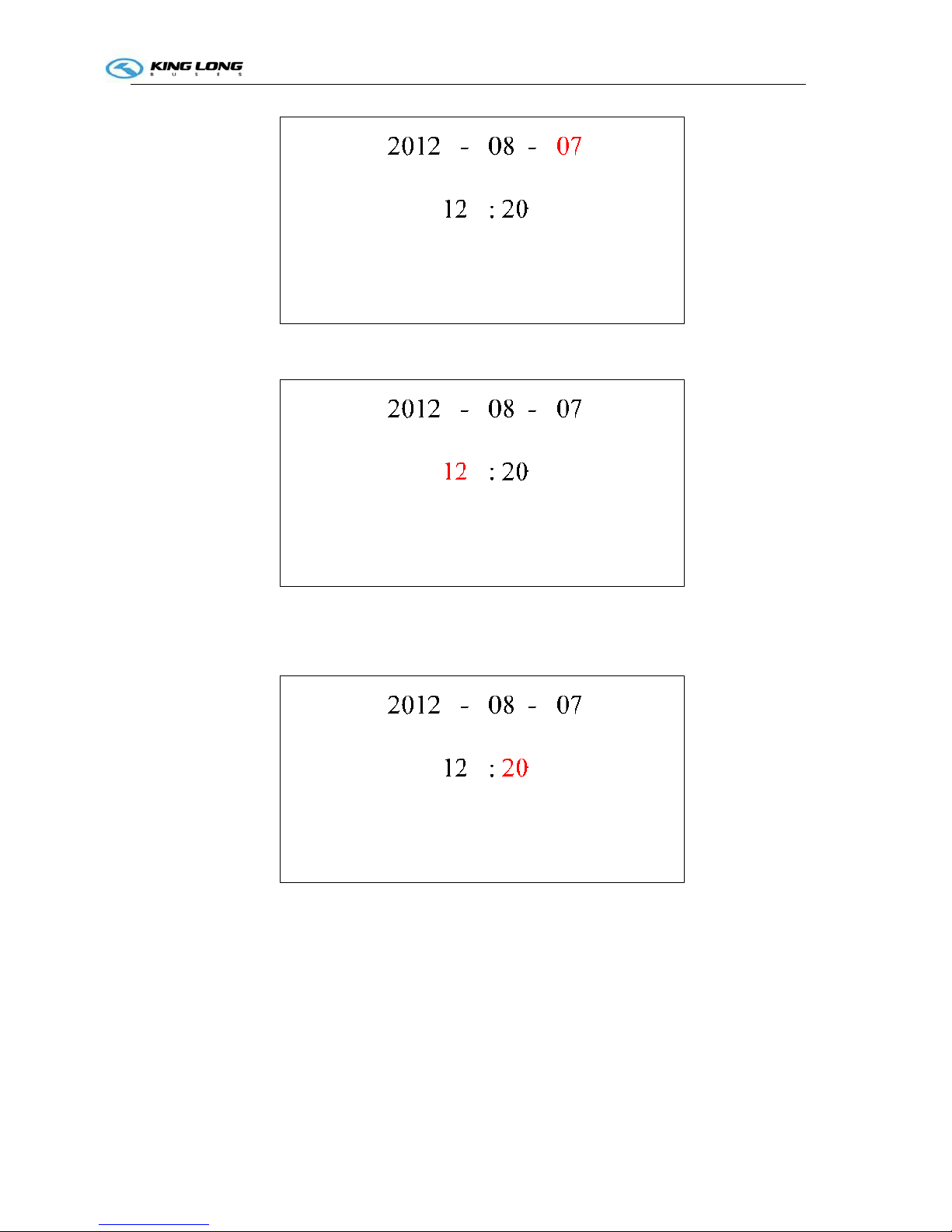

3.2.2 Set Time .First press S1 go to set interface, Second press S2 or S3 choose Set Time position as

shown in Figure-14, Third press S1 go to Figure-22.

Figure-22 Set Year

Finally press S2 and S3 could increase or decrease years. After set year, could press S1 choose Month、

Day、Hour、Minute as shown in Figure-23、24、25、26.And press S2 and S3 could set Month、Day、

Hour、Minute. After Set press S4 two times return main interface.

Figure-23 Set Month

Operation Instruction

3-1

Figure-24 Set Day

Figure-25 Set Hour

Figure-26 Set Minute

3.2.3 Set Backlight. First press S1 go to set interface, Second press S2 or S3 choose Set Backlight

position as shown in Figure-15, Third press S1 go to Figure-27.

Operation Instruction

3-1

Figure-27 Set Backlight

Finally press S2 and S3 could increase or decrease backlight. After set backlight, press S4 two times

return main interface.

3.2.4 Set VehPPK. First press S1 go to set interface, Second press S2 or S3 choose Set VehPPK position

as shown in Figure-16, Third press S1 go to Figure-28.

Figure-28 Set VehPPK

Finally press S2 and S3 could increase or decrease VehPPK. After set VehPPK, press S4 two times

return main interface.

3.2.5 Set MotPPR. First press S1 go to set interface, Second press S2 or S3 choose Set MotPPR

position as shown in Figure-17, Third press S1 go to Figure-29.

Operation Instruction

3-1

Figure-29 Set MotPPR

Finally press S2 and S3 could increase or decrease MotPPR. After set MotPPR, press S4 two times

return main interface.

3.2.6 Clear Trip A. First press S1 go to set interface, Second press S2 or S3 choose Clear Trip A

position as shown in Figure-18. Third press S1 clear Trip A and auto return main interface.

3.2.7 Clear Trip B. First press S1 go to set interface, Second press S2 or S3 choose Clear Trip B

position as shown in Figure-19. Third press S1 clear Trip B and auto return main interface.

3.2.8 Clear TA. First press S1 go to set interface, Second press S2 or S3 choose Clear TA position as

shown in Figure-20. Third press S1 clear TA and auto return main interface.

3.2.9 Clear One way OC. First press S1 go to set interface, Second press S2 or S3 choose Clear One

way OC position as shown in Figure-21. Third press S1 clear One way OC and auto return main interface.

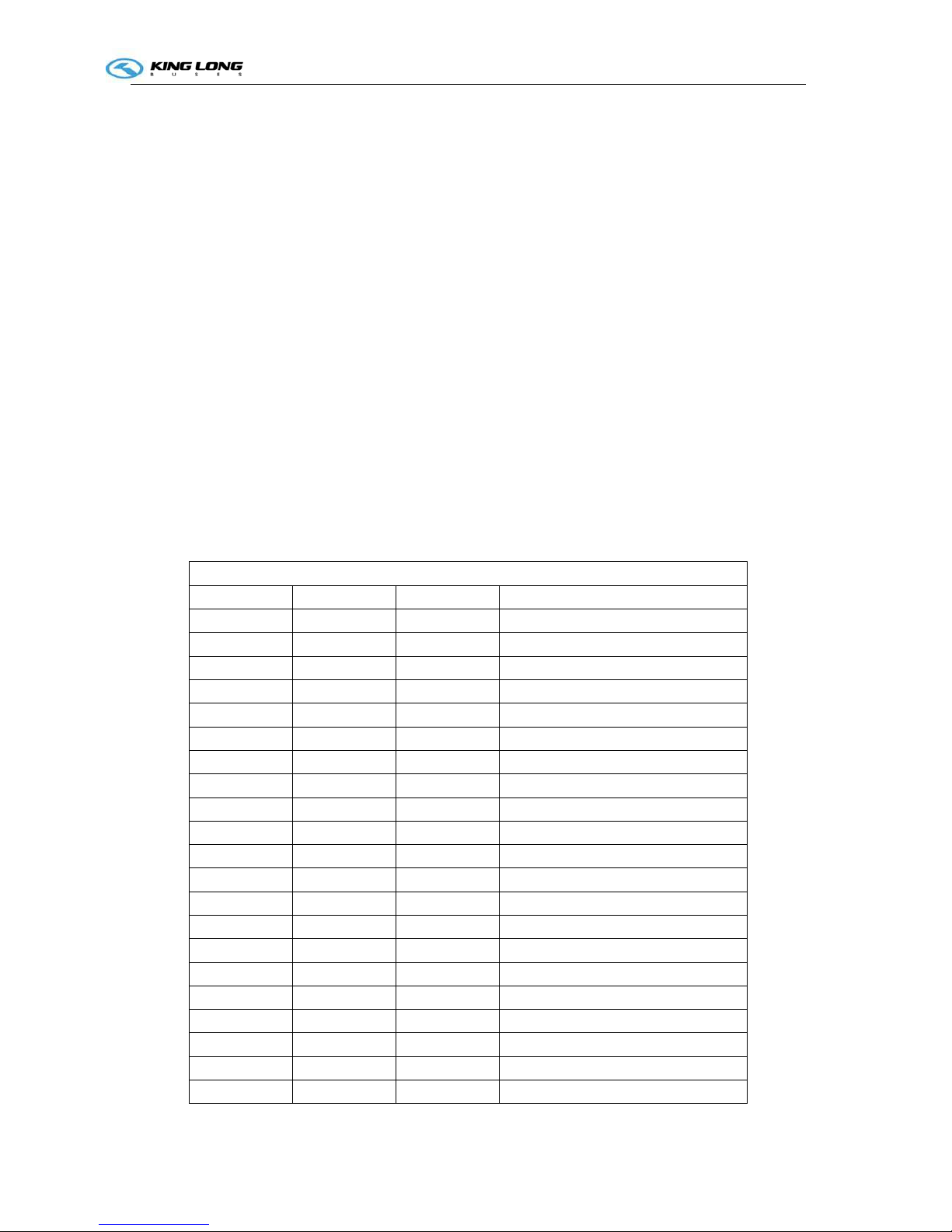

Appendix A ZB271M Dashboard Pin Definition

Table A Pin Definition

Pin Name Color Remark

1 VPP Red

2 GND Black

3 WAKE_UP1 Red Connected to WAKE_UP2 inside

4 CANH1 Yellow Connected to CANH2 inside

5 CANH2 Yellow

6 CANL1 Green Connected to CANL2 inside

7 CANL2 Green

8 Empty

9 Empty

10 Empty

11 WAKE_UP2 Red

12 Empty

13 Empty

14 Empty

15 Empty

16 Empty

17 Empty

18 Empty

19 Empty

20 Empty

21 Empty

Operation Instruction

3-1

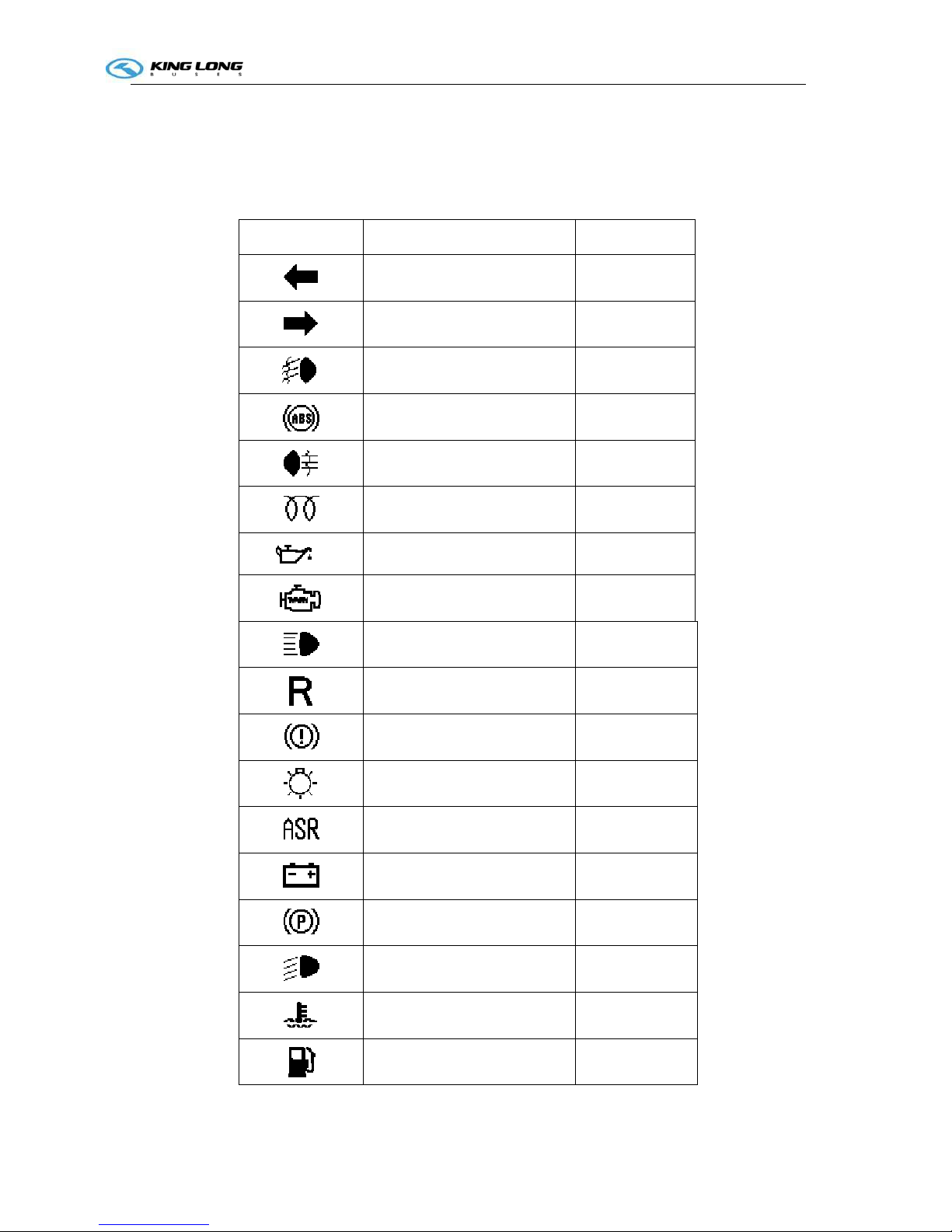

Appendix B ZB271M Signal Bar instructions

Icon Name Color

Left turn light Green

Right turn light Green

Front fog light Green

ABS Yellow

Rear fog light Yellow

Preheater Yellow

Alarm of oil pressure Red

Engine fault Yellow

High beam Blue

Return Red

Alarm of gas pressure Red

Clearance Lamp Green

Avoid side slide Red

Charge Red

Parking light Red

Low beam Green

Alarm of water temperature Red

Alarm of Fuel Low Red

Operation Instruction

3-1

Appendix C ZB271M LCD Alarm instructions

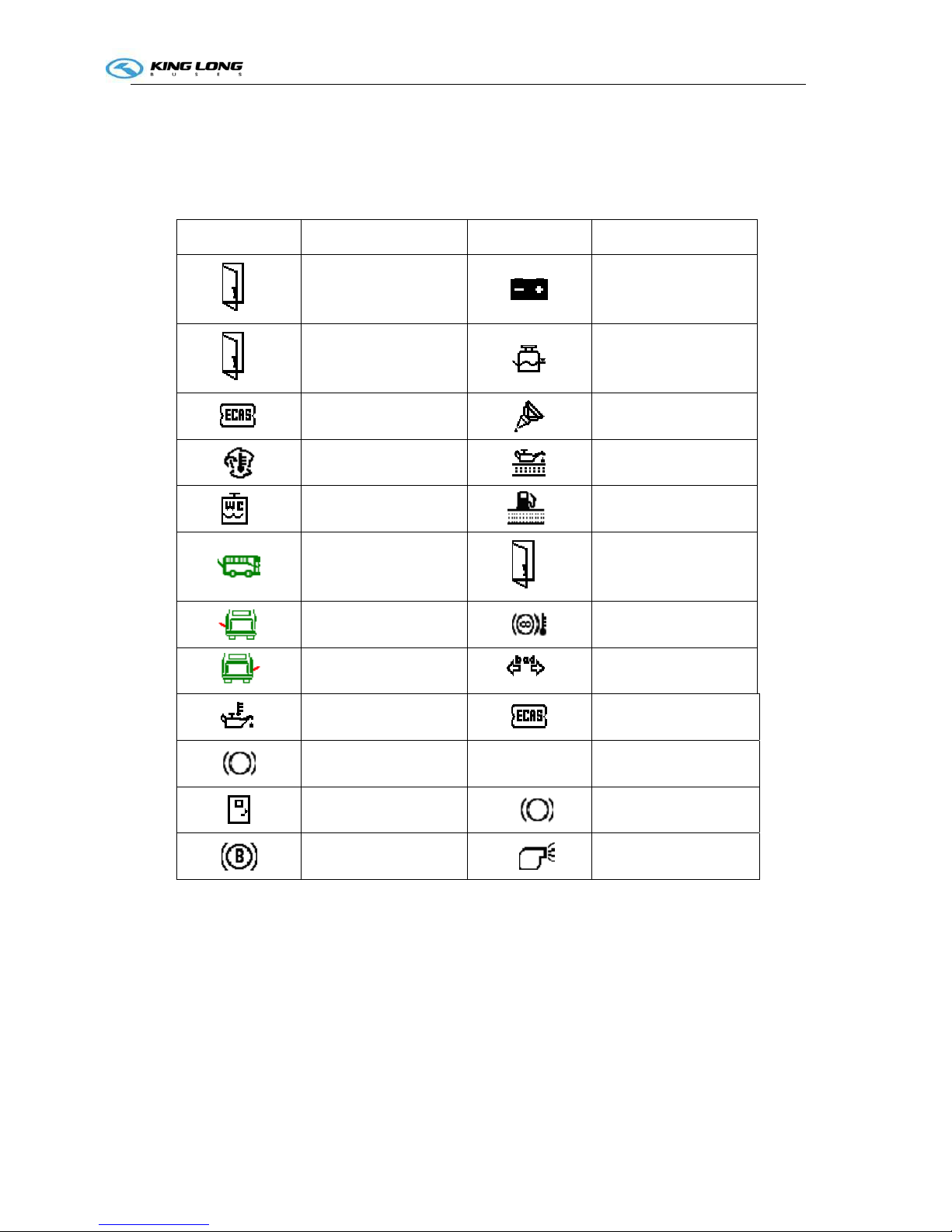

Icon Icon Name Icon Icon Name

Front Door

Low Power

Middle Door

Alarm of water level

ECAS Fault

Concentrate lubrication

Engine cabin

temperature too high

Alarm of oil filter

Lack water alarm of

W. C

Alarm of oil filter

Rear cabin door

Rear Door

Left cabin door

Alarm of Retarded

temperature

Right cabin door

Fault of turn light

Alarm of Oil

Temperature

Alarm of ECAS

Brake Light Fault CRUISE Cruise

Safety Door

Brake Light

Break Wear

Antifreeze controller

Operation Instruction

3-2

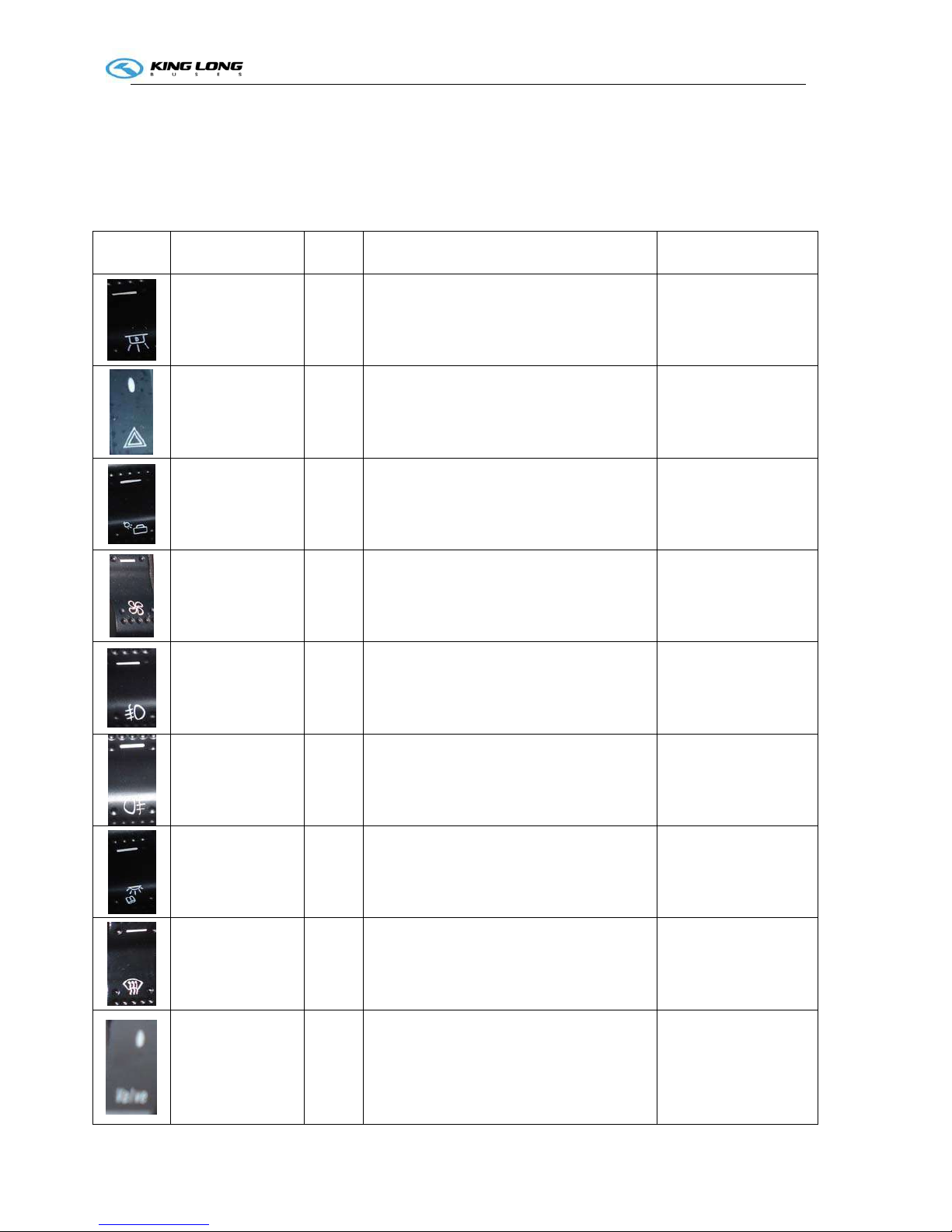

Illustration of switch and indicator

Number of switches , indicators and each own position may vary with the vehicle model and configuration

state, please refer to the flowing sheet :

Switch

Name Color Function Notes

Daylight lamp

White

Pressed on top: interior lighting OFF

Pressed on bottom: interior lighting ON

Hazard alarm lamp

White

Pressed on bottom: all turning indication

lamps will turn on and flash

Luggage

compartment lamp

White

Pressed on top: the luggage cabin lamp OFF

Pressed on bottom: the luggage cabin lamp

ON

Ventilator

White

Pressed on top: the ventilator is turned off

Pressed on bottom: the ventilator is turned

on

Front fog lamp

White

Pressed on top: the front fog lamp OFF

Pressed on bottom: the front fog lamp ON

Rear fog lamp

White

Pressed on top: the rear fog lamp OFF

Pressed on bottom: the rear fog lamp ON

Reading lamp

White

Pressed on top: the reading lamp OFF

Pressed on bottom: the reading lamp ON

Front windshield

defrosting switch

White

Pressed on top: turn off defrosting function

Pressed on bottom: turn on defrosting

function

Heating water

valve switch

White

Pressed on top: the valve is switched off

Pressed on bottom: the valve is switched on

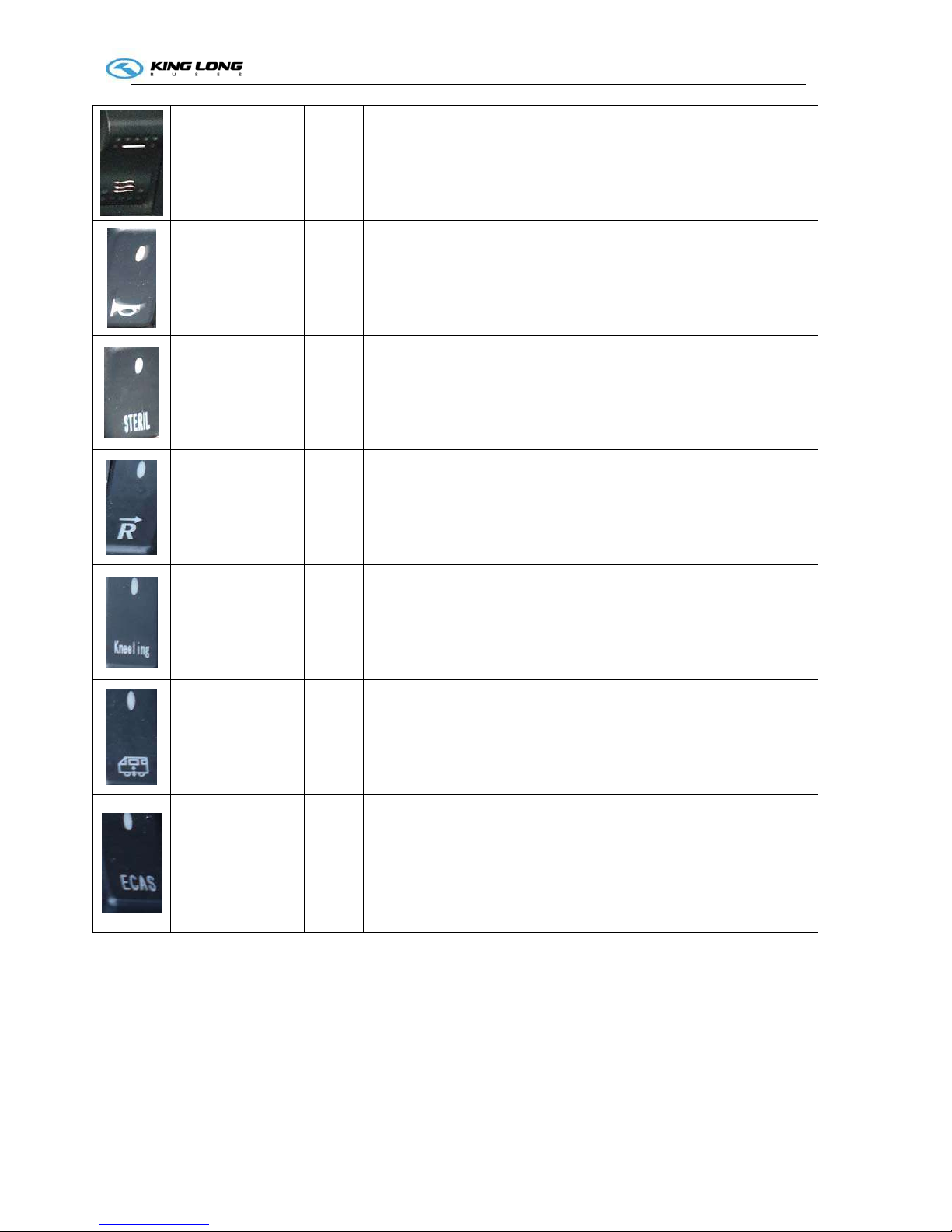

Operation Instruction

3-2

Fresh air

ventilating switch

White

Pressed on top: the ventilation function is

switched off

Pressed on bottom: the ventilation function

is switched on

Horn

White

Pressed on top: the electric horn is turned off

Pressed on bottom: the electric horn is

turned on

Disinfection

function switch

White

Pressed on top: the function is switched off

Pressed on bottom: the function is switched

on

Reversal monitor

power switch

White

Pressed on top: turned off the monitor

power

Pressed on bottom: turned on the monitor

power

Body Kneeling

function switch

White

Pressed on top: turned on body restoration

function, the body start restoring action.

Pressed on bottom: turned on the body

kneeling function, the body start kneeling

action

Body

raise/descend

switch

White

Pressed on top: turned on the body

height adjust function, the body start raising

Pressed on bottom: turned on the

b

ody

height adjust function, the body start

descending

Body 2th height

adjusting switch

White

Pressed on top: the body height restore to

the normal height state from 2th height

location.

Pressed on bottom: turned on the

b

ody

height raise function, the body start raising

the 2th height location.

When driving in

rugged road, raise the

vehicle body height for

safe.

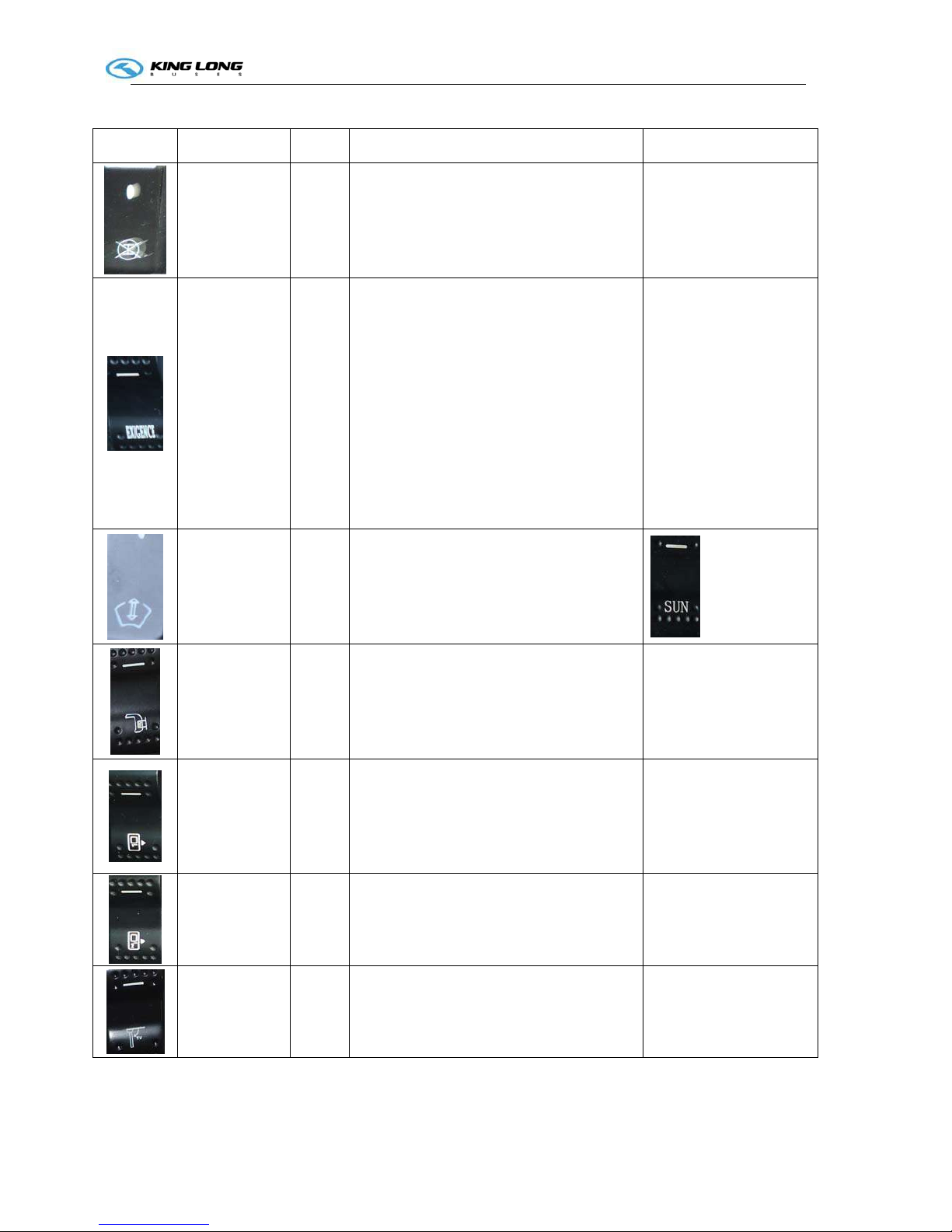

Operation Instruction

3-2

Switch Name Color Function Notes

Retarder

foot-control

function

release switch

White

Pressed on top: the retarder foot-control

function is turned on ;

Pressed on bottom: the retarder foot-control

function is turned off

Emergency

power switch

White

Pressed on top: turn off the vehicle

power

Pressed on bottom: turn on the vehicle

power

1) While only turn on

the switch, could

supply power only

for 2 minutes;

2) Meanwhile, if also

rotate the ignition

key to ACC or ON

shift, thus could

supply power for

long.

Front

windshield

sunshade

switch

White

Pressed on top: the sunshade will be raised

Pressed on bottom: the sunshade will be

descended down

Rearview

mirror

defrosting

switch

White

Pressed on top: turn off defrosting function;

Pressed on bottom: turn on the defrosting

function.

Front

passenger door

switch

White

Pressed on top: close the door

Pressed on bottom: open the door

Rear passenger

door switch

White

Pressed on top: close the door

Pressed on bottom: open the door

Flip TV switch

White

Pressed on top: turned off the power, folded

the TV

Pressed on bottom: turned on the power,

unfolded the TV

Operation Instruction

3-2

High/low shift

switch

White

Pressed on top: turned on the high shift

function

Pressed on bottom: turned on the low shift

function

Engine cabin

fire

extinguisher

switch

Red

Pressed down : extinguisher will be activated

The powder will be burst

out and coated on engine

cylinder block so as to

block up flame and

combustion. Don't test to

press this button down at

normal condition

Driver window

raise/descend

switch

White

Pressed on top: turned on the raise function

Pressed on bottom: turned on the descend

function

Driver window

pre-heating &

defrosting

switch

White

Pressed on top: turned off the defrosting

function

Pressed on bottom: turned on the defrosting

function

Engine

Diagnose

function switch

White

Pressed on top: turned off the engine

diagnose function

Pressed on bottom: turned on the engine

diagnose function

Engine cruise

function switch

White

Pressed on top: turned off the engine cruise

function

Pressed on bottom: turned on the engine

cruise function

we advise clients not to

use this switch

Cruise set

switch

White

Pressed on top: turned off the engine cruise

set

Pressed on bottom: turned on the engine

cruise set

we advise clients not to

use this switch

Operation Instruction

3-2

Indicator lamp

Color

Function

Red Engine fault alarm

Yellow Exceeding emission standard indication

Red Gearbox oil temperature over-heat alarm

Red Gearbox fault alarm

Yellow Kneeling function work indication

Green Body keep 2th height state indication

Yellow ECAS alarm indication

Red ECAS function fault alarm

Yellow Vehicle require maintenance indication

White Engine wait starting indication

Operation Instruction

3-3

CC350-355 series A/C Operation

Operation Instruction

3-3

Operation Instruction

3-3

Operation Instruction

3-3

Operation Instruction

3-3

Operation Instruction

3-3

Pre-heater Operation (Webasto)

1. General

The standard digital timer enables you to preset the

start of the heater operation up to 7 days in

advance.

It is possible to program 3 different starting times,

only one of which can be activated.

The standard digital timer features a wakeup alarm

function.

When the ignition switched on, the timer displays

the current time and the day of the week.

When the heater is switched on, the display and

the buttons are illuminated.

After the power supply has been connected,

all symbols on the display will flash.

The current time and weekday must be set.

2. Operation

The timer can be operated in that all flashing symbols

can be adjusted by means of the 10 and 9 buttons.

If the buttons are not pressed within 5 seconds,

the time displayed will be stored.

If the 10 and 9 buttons are pressed for more than

2 seconds, the fast time-setting mode is activated.

If the ignition is switched off while the heater is operating in the continuous mode, the

remaining operating time of 15 minutes is displayed and the heater continues to operate for this

period of time.

3. Switch the heater on

Manually: by pressing the button 8 (continuous heating mode)

Automatically: by programming the heater starting time

4. Switch the heater off

Manually: by pressing the button 8

Automatically: after the programmed operating time has elapsed.

With the heater running: by programming the remaining operating time

5. Setting time/day of the week

Press the 6 button for more than 2 seconds-time of the day if flashing-and set the clock using

the 9 and 10 buttons. Day of the week is flashing – adjust the day of the week.

6. Viewing the time

With the ignition switched off: press the 6 button.

7. Programming heater starting time:

Standard Timer

1. heater “on” indicator

2. day of the week

3.

time display

4.

memory location

5.

alarm indicator

6.

time

7.

program selection

8.

instant heating

9.

reverse

10.

forward

11. panel

Operation Instruction

3-3

Press the 7 button – the memory location is flashing – using the 9 and 10 buttons set start of the

heater operating time. Day of the week is flashing- set the day of the week. By repeatedly

pressing the 6 button, memory locations 2 and 3 can be programmed or the time display mode

can be reached.

8. Recalling/erasing preset times

Repeatedly press the 6 button until the desired memory location is displayed. To erase the

preset time, press the 7 button several times until the time of the day is displayed instead of the

memory.

9. Programming duration of operating time The heater must be switched off. Press the 9

button for 3 seconds – operating time is flashing – and set the desired operating time (10 to 120

minutes) using the 9 and 10 buttons.

10. Setting the remaining operating time

Set the desired remaining operating time (1 to 120 minutes) using the 9 and 10 buttons. The

remaining operating time refers to the time the heater still continues to remain in operation and

the ignition switched off.

11. Setting the wakeup time

A wakeup time can only be programmed on the standard digital timer. The wakeup time is not

bound to a specific day of the week.

Repeatedly press the 7 button until the bell symbol appears on the display. Set the

desired wakeup time using the 9 and 10 buttons. The alarm clock turns off after 5 minutes or

when one of the buttons is pressed.

12. Recalling/erasing the wakeup time

Repeatedly press the 7 button until the bell symbol appears on the display – read off

wakeup time. To erase the wakeup time: press the 7 button until the bell symbol is no

longer visible on the display.

13. remote control

Possible by means of an optional external “instant heating” button

14. Vehicles with ADR equipment

On ADR vehicles it is not possible to program a preset starting time. The remaining time is

shown on the display while the heater is in operation. The clock can be set. The alarm clock

function can be programmed on the standard digital timer.

Operation Instruction

3-3

NANFENG Panel Operation Description:

1. Heating panel power switch: while pressing the button 1, the panel lamps are turning on

or turning off, meanwhile, the heating opened or closed.

2. MANUAL/AUTO mode setting : while pressing on the button 2, may change over different

mode state, once in AUTO mode, the water valve would open automatically and keep

heating for room as far as the room temperature is below the temperature value which the

system was already pre-established in advance; once in MANUAL mode, the WATER

VALVE lamp lit on, the water valve keep opening all the time..

3. Temperature setting : In MANUAL mode state, if intend to adjust the room temperature,

may press button 4 or button 5 until your desirable temperature value, but your operation

should be pressed on the button 3 simultaneously.

1 2 3 4 5

Operation Instruction

3-4

Gearbox Operation

Transmission model (Automatic gearbox ZF 6AP1200B)

Variant with 3 push buttons, horizontally arranged(details may be different from illustration)

Fig.1

Fig.2

Operation Instruction ( as per Fig.1 or Fig.2 panels)

1.1 Push-button control with diagnostics connector

1.1.1 Variants

1.2

1.1.2 Push-button illumination

Operation Instruction

3-4

control unit(for potential cases see Section 1.3and 1.4)

1.1.3 Push-button selector position

1.2 Driving range

(see Section 1.1),consult the vehicle operation instructions

Operation Instruction

3-4

1.3 Starting the engine

Starts(see Section 1.1.2)and the transmission will remain

Have to be depressed and subsequently(see Section.1.4)

1.4 Engaging a gear

1.4.1 Standard

Operation Instruction

3-4

cases, the pushbutton depressed will flash (see Section 1.1.2)

1.4.2 Transmission with additional functions

1.4.2.1 Additional function “ Gear Release”

Procedure as described under 1.4.1. In addition to the

cases mentioned under 1.4.1, engagement of a starting

will flash (see Section 1.1.2)

1.4.2.2 Additional function“ Additional pushbutton reverse gear”

1.4.1

1.4.1

(see Section 1.1.2)

1.5 Starting

Operation Instruction

3-4

1.6 Downhill driving

1.7 Change in direction of travel

. Continue as described under Section 1.4

1.8 Kickdown (forced downshift)

Operation Instruction

3-4

1.9 Retarder operation

Operation Instruction

3-4

Section 1.1.2

1.10 Stopping, parking

Operation Instruction

3-4

1.11 Towing

1.11.1 Towing vehicle with coaxial transmission

1.11.1.1 Transmission is functioning

Operation Instruction

3-4

1.11.1.2 Transmission damage suspected

1.11.2 Towing vehicle with angle drive transmission

1.12 Temperature monitoring

Operation Instruction

3-4

1.13 Status monitoring/warning lamps

selector will flash (see Section 1.1.2)

1.14 Transmission response to a malfunction

(see Section 1.14.1)

Operation Instruction

3-4

1.14.1 Emergency operation

Operation Instruction

3-5

WABCO ABS BASIC INTRODUCTION

Operation Instruction

3-5

Operation Instruction

3-5

Operation Instruction

3-5

Operation Instruction

3-5

Operation Instruction

3-6

ECAS System Introduction (for tourist bus use)

1. System introduction

Operation Instruction

3-6

3. System function

Operation Instruction

3-6

Operation Instruction

3-7

Open/close the passenger door.

1. Before leaving the vehicle, press the button 1 of the door remote controller

to close the door.

2. Use the key to lock the door. First insert key into

the hole 3 and clockwise rotate key about 90°,

then anticlockwise rotate handle 4, after that the

door would be locked.

3. If need open the passage door, insert key into the

hole 3 and clockwise rotate it about 90°, then

clockwise rotate handle 4, follow press the button

2, after that the door would be opened.

Appendix:

The following are all type of door lock and door remote controller of King-Long.

1

3

4

2

Lock1

Lock 2

Lock 3

1

2

Operation Instruction

3-8

Door emergency switch

The model 1 door emergency switch is located on right upside

of the ingress.

The model 2 door emergency switch is located on right

underside of the ingress

The model 3 door emergency switch is located inside the door

pump cover which is on the top of the door.

Please rotate the switch and throw open the door in

emergency.

Special attention: The door emergency switch is only used

in the emergency mode. Please don't rotate the door

emergency switch in driving for fear of danger.

Door remote controller 2

Door remote controller 1

Model 1

Model 2

Model 3

Operation Instruction

3-9

Adjustment of the driver's seat

The driver's seat may be made proper adjustment for the

back and forth as well as the backrest angle according to

requirement of the driver.

Handle 1 and Handle 2: cushion height adjustment

Handle 4: back and forth adjustment

Handle 3: adjustment of the driver’s weight

Left handle: backrest angle adjustment

Note: Number of handles varies with vehicle model

Attention!

The seat should not be adjusted during driving

to ensure driving safety.

Adjust the driver seat only when the vehicle is stopped

and the parking brake is on.

1

2

3

4

Operation Instruction

3-10

Horn button

It is on the steering wheel. The horn is hooting when

pressing the button 1.

The type of steering wheel may vary with vehicle model.

Please use the horn only when strictly necessary to warn

other drivers and pedestrians.

Model 1

Model 2

1

1

Operation Instruction

3-11

Adjustment of the steering wheel

Pull-up the loosening handle 1 or rotate the loosening button

2. Adjust the height and the inclination of the steering wheel

to the desired position. After adjusting, press the regulating

handle or button down to lock the steering column.

Note: Number of handles varies with vehicle model

Attention!

Adjust the steering wheel only when the vehicle is stopped

and the parking brake is on.

After adjusting, press the regulating handle or button down

in order to lock the steering column.

1

2

Operation Instruction

3-12

Ignition switch

Position of the ignition key is shown in fig.1.

1."L" LOCK: Insert or remove the key in this position.

2."A" ACC: Power supply of the instrument is switched on

3."O" ON: Normal driving position

4."S" START: Initiating position of the engine, and the key

may rebound to the "ON" position automatically after the

startup

.

Before starting the engine, turn the key to the “ACC”

position and then to the “ON” position. At this point, three

lights (red, yellow and green) on the dashboard will come on.

Wait for the lights to go out completely before you start the

engine. However, make sure that all of the self-check lights

have gone out completely before starting the engine. Allow

the engine to run at idle speed for three to five minutes after

it has been started; but never let it run for more than 10

minutes at idle speed. If the vehicle does not move, increase

the fuel to the accelerator modestly to increase the rotational

speed of the engine a little; this will also prevent the early

wear and tear of the engine.

Note:

1. Turn the ignition key to the OFF position after the engine has been turned off and has stopped

running.

2. If the first attempt to start the engine is not successful, please wait two minutes before trying again.

3. If the engine fails to start after three attempts, check the fuel supply system. If the vehicle runs on

natural gas, check the gas supply system.

Attention!

1. Do not remove the ignition key while the vehicle is in movement. And the ignition key should be

turned to the LOCK position only after the engine shut down.

2. When leaving the vehicle, even for a short period, take the key out to avoid operation of the vehicle

by children or unauthorized persons.

1

Operation Instruction

3-13

Lamplight operating handles

The lamplight operating handle is located on left

underside of the steering wheel, which control the front

small light, headlamp, headlamp dimming, etc

OFF Indicating that the headlamp and the small

lamp are all off.

Is the small lamp indication. The small lamp,

the instrument light and the side indicator lamp will all

be turned on when anti-clockwise rotating the handle to

position of this identification.

Is the Is the headlamp indication. The headlamp,

small lamp, meter lamp and width lamp will all be

turned on when continuously anti-clockwise rotating the handle to position of this identification.

Is the turning indication. By up and down motions of the operating handle may control the

left and right turning lamp and that on the dashboard.

Is dimming indication. Back and forth the operating handle gently may actuate the headlamp

dimming.

Note:

It’s important to dip the lights promptly when approaching an upcoming vehicle in order to avoid

dazzling its driver with the high beam of the headlight.

Model 1

Model 2

Operation Instruction

3-14

Wiper operating handle

The wiper operating handle is located on right underside

of the steering wheel. (model 1~2)

OFF Out of work

INT interval wiper operation step

LO Slow wiping

HI Quick wiping

The wiper may spray water by pressing the end of the

handle.

The shifts of the retarder may be converted by up and

down motion of the handle.

Note: do not actuate the wiper without water; press the

washer button as needed, then actuate the wiper.

Model 1 (with retarder)

Model 2 (with exhaust brake)

Operation Instruction

3-16

Passenger control panel instruction

1. air outlet

2. service button

3. reading lamp button

4. lamp

5. loudhailer

6. stop button

Model 1

6 1 2 5 4

1 2 3 4

Model 2

5 4 2 1 3

Model 3

Operation Instruction

3-17

Safety hatch

The safety hatch is located on scaffold of the vehicle.

Please open the safety hatch according to the above

diagrammatic representation and illustration for

escaping in case of danger.

When in emergency and dangerous condition, should

1) push upward with hands and make the hatch open

2) pull down the plastic cover and rotate red handle

3) push dome open

4) exit through hatch

Model 1

Model 3

Model 4

Model 2

Operation Instruction

3-18

Safety hammer

The safety hammer is located on the side window.

Please take down the safety hammer and break open

the safety window for escaping in case of danger.

Model 1

Model 2

Model 3

Operation Instruction

3-19

Relays & Fuses

The Relays & Fuses Box always installed in the

compartment of the instrument desk or a tool cabin belong

to front right side panel.

The box integrates 50 chip-type fuses, 20 general and

special relays, and has 8 standby chip type fuses, one fuse

clip, which makes its construction more compact and

function more powerful. It improves design of the past

Relays & Fuses Box , therefore it avoids weakness such as

unreliability and short service life, it applies integrated

circuit and designs 5 special relays: intermittent wiper

relay, turning flasher relay, lower water level warning

controller relay, monitor power relay, brake light failure

warning relay (when power supply voltage is lower than

23V, power supply of acoustic set and monitor is cut off

and will be begin to work again after power supply voltage resumes to normal)

.

The vehicle installed the Relays & Fuses Box in the compartment of instrument desk.

Installation Position

The position of Management Module,

CAN Processor Module, and the

Relays & Fuses Box

They are located in the compartment of

instrument desk. When servicing, may open the

desk cabin gate

Operation Instruction

3-20

Switch control box (Model: CQ2025)

CQ2025 A wiring diagram (Printed on opposite cover of the switch control box)

Vehicle Starting and Driving

4-1

Preparative for vehicle operation start up:

Check daily, before turning engine on:

1. Check oil level of the engine

The warning “Engine oil pressure” is displayed as a signal

item on the combination instrument when the oil pressure

is too low, the alarm buzzer sounds, the warning light

STOP comes on, stop the engine and check engine oil level

at the dipstick. Provide immediately for the oil

replenishment to its correct level.

The oil level should always be checked with the vehicle

parked on level ground, before starting the engine up, or at

least 5 minutes after having shut it down.

Open the engine compartment hood.

Take out the oil dipstick, and clean it with a clean cloth

without loose threads, and put it back into its place fitting it

in completely.

Once again pull out the dipstick and check the oil level.

a. The oil should not exceed the maximum level.. drain

the excess.

b. If the oil is at operational level, do not add more oil to

the crankcase.

c. If the oil is at or below the minimum level, add the

same type and brand of oil to the crankcase as that

already there, until reaching the maximum level..

After the checking, replace and fit the dipstick completely

back into its place.

If the oil level is checked after the engine has been run for

a period of time, then it should take at least five minutes

before the measure to ensure the oil back flow to the oil

sump in full.

Oil level dipstick

Oil inlet

Vehicle Starting and Driving

4-2

2 Check level of the coolant

The coolant level is automatically monitored.

If coolant level gets too low,the digital indicator

displays a driver information on the combination

instrument. In this case, park vehicle in a safe place as

traffic conditions permit, stop engine and visually

check the coolant level.

Check the coolant level only when the engine doesn’t

work and its temperature is below 50℃.

The anti-freezing rust-inhibiting engine coolant level

can be observed from the observe pipe.

The coolant level should be between the maximum

level (MAX.) and minimum (MIN.) level indicators in

the compensation tank.

If it is necessary to add coolant to the system:

a. Place the heating system command in the position

of maximum heating potency.

b. Add the coolant to the system up until the

maximum level indication. Only use coolant

which is recommended.

c. The compensation tank cover should not be

opened when temperature of the coolant is still

high to avoid being scalded Place the lid on the

system and turn it to the limit.

d. Pressure valve of the compensation tank should be

opened when adding the coolant to eliminate air in

coolant pipeline of the diesel engine.

e. Run the engine for a short time at varied rotations.

f. Stop the engine and check the coolant level.

If necessary add more coolant to the system

Anti-freeze and antirust solution (mixture of glycol and water) should be added to cooling system from

time to time to avoid sediment, frost, oxidation and increase boiling point.

Note: When adding coolant, please choose the same model to avoid sediment. If coolant is degenerative,

replace it immediately.

Coolant specification as shown below: users should choose products produced by normal factories

according to requirement

Observe pipe

Observe pipe

Vehicle Starting and Driving

4-3

3 Fuel pre-filter with water separator (drain accumulated water)

Draining accumulated water

On a daily basis, check the lower cup of the water separator. If there is water in the cup, unscrew the

draining plug one or two turns, to drain the accumulated water.

After draining the water, tighten the draining plug correctly.

When the accumulation of impurities in the lower cup is noticed, take the vehicle to a workshop to carry

out its cleaning.

Changing the fuel pre-filtering element

The fuel filtering element should be changed periodically,

at the intervals recommended in the maintenance manual.

If however, the filtering element is easily saturated

needing substitution at very short intervals, this is an

indication of the accumulation of impurities in the

interior of the fuel tank, and the cleaning of the latter

should be carried out.

In order to change the fuel filter element, take the

vehicle to a Dealer or a King-Long Workshop.

Fuel system discharge

Activate the manual pump until feeling resistance on

pumping.

Start up the engine without accelerating. If the engine

does not start running in 20 seconds, interrupt the startup

and wait at least one minute before trying again.

If the engine insists on not working, repeat the discharge

operation.

Leave the engine running for about a minute to

completely eliminate the air from the system by way of

the auto-discharge system.

In order to reduce environment pollution problems, do

not drain the residues accumulated in the water separator

directly into Nature (rivers, lakes or soil). The drained

residues should be collected in appropriate containers

and taken to receiving centers to have proper final

destination (see local legislation).

Model for Euro III IV

Manual pump

Release valve

Vehicle Starting and Driving

4-4

4. Fuel level

Turn the ignition key to drive position (on).

Check the fuel level on the indicator. If necessary, fill up

the fuel tank.

(But direct viewing by open the tank cover is

preferred).

Eliminate deposite water in diesel filter in time and check

fuel pipe for no leakage. Ensure sealing performance of fuel

tank , and wipe up dirt before opening fuel tank.

Before filling up, shut down engine.

Do not drive vehicle in empty fuel tank. When the fuel

level indicator is on the red bar, refuel the vehicle to avoid

air entering the fuel system.

Fill the fuel tank only with good quality fuel free of

contaminants.

The fuel might as well be filled up when

running in the humid area to avoid inner rustiness.

Vehicle Starting and Driving

4-5

5. Vehicle lighting, intermittent lights and brake lights

Check all instruments and indicator lamps for normal, especially the head lamp, the turning lamp, the brake

lamp, the reversing lamp and the danger alarm lamp.

Check the bulb and the switch for their damage. To carry out the lamp substitution, hands should be very

clean. If possible handle new lamps with tissue paper.

Clean the external of all instruments and indicator lamps to ensure clear indication.

Attention!

The traffic laws regulate the location, lighting intensity, and color of the lenses and the quantity of

lanterns for each type of vehicle. The King-Long vehicles leave the factory in strict obeyance of these

specifications. Traffic safety depends on these factors; therefore do not change the place of the lanterns.

Substitute the damaged lanterns only for other original ones. Remember that a change of lantern colors

can confuse other motorists and result in serious accidents. Avoid unnecessary lantern adaptations.

When substituting lamps, use the same type and potency as the original lamps. Do not carry out any

lamp adaptation in the headlights, as this will affect their adjustment and performance, putting the

vehicle traffic safety at risk.

On a regular basis revise the illumination system, keeping it always in perfect working conditions

Vehicle Starting and Driving

4-6

6. Check the level of AdBlue and the daily maintenance of SCR system

(1) Check the level of AdBlue.

When the vehicle key rotate the ON position, the LED

screen of combination instrument will display the

remain volume of the AdBlue, please see the right

diagram.

The AdBlue consumption is 5 percent of the fuel

consumption. If the remain volume of AdBlue is less

than 12%, the lamp 1 will flash and you need add

AdBlue. If the remain volume of AdBlue is less than 6%,

this lamp will light and the power of engine will be

declined forcibly. This will cause the emission

substandard and it is not good to engine.

(2) The daily maintenance of SCR system

Please add the AdBlue when it is insufficiency. Ensure the AdBlue meet the requirement. Check the SCR

system is well enough and has no leaking before driving. There is obvious add mark in AdBlue tank. If

add substandard AdBlue, must stop the vehicle right now and clean the AdBlue tank, re-filling the

qualified AdBlue. The air filter should be clean and replace regularly.

Special attention:

1

The volume of AdBlue

Vehicle Starting and Driving

4-6

If the AdBlue spill in skin, mild irritation may occur. Wash off with soap and water. If the AdBlue spill in

eye, irrigate eyes with large amount of water. The AdBlue is Non-combustible, if heated water evaporates

and ammonia will be released.

Vehicle Starting and Driving

4-7

7. Drain water in air tank

Open the water drain valve of air tank to drain oily water fully. If too much oily water is bled, check to

see if desiccant needs to be replaced in air drier. (This may be avoided when adopting the automatic drain

valve but it should be checked every two weeks)

Vehicle Starting and Driving

4-8

Check daily after turning engine on:

1. engine oil pressure

Run the engine.

The information on engine oil pressure can be requested through the driver information digital display.

If the oil pressure is too low, the oil pressure is automatically shown on the combination instrument.

Indication of the oil gauge will show a high value after the cold start of the engine and then it should be

kept within the range of 0.07-0.52Mpa (0.7-5.2kg/cm

2

) along with the increment of the oil temperature as

well as the normal engine speed.

Vehicle Starting and Driving

4-9

2. Pneumatic pressure

The air pressure gauge indicates the reserve pressure individually for the front and rear service brake

circuits.

The reserve air pressure in each brake circuit must be sufficient for the correct operation of the brake

system.

The STOP warning light comes on in case of low brake pressure in the service brake circuits.

Attention!

If the driver information indicator displays the warning “brake pressure” and the STOP warning light

comes on with the engine running, it will be an indication that the air pressure is excessively low. Do not

drive the vehicle if the air pressure gauge displays low air pressure in one or both brake circuits, as the

service brake could fail to result in serious accident.

Vehicle Starting and Driving

4-10

3. Tachometer working order

Indications on tachometer scale:

a. Green zone – operating range of maximum

performance

b. Yellow zone – a little high speed range (warning of

engine overspeed )

c. Red zone – engine overspeed range (risk of

immediate engine damage)

Always observe tachometer while driving the vehicle.

Whenever possible keep engine running within the

economical range.(green zone)

On downgrade, select an adequate gearbox speed and monitor vehicle speed to avoid engine operating in

the danger range (red zone).

When the exhaust-brake is operating on down grades, select an adequate gearbox speed to keep engine

speed within efficient exhaust-brake operation (yellow zone).

Always avoid engine over revving (red zone), as engine operation in this speed range can give rise to a

immediate engine damage or seriously jeopardize its durability.

The yellow range with red reticle can be used occasionally when the exhaust-brake needs to be used at its

efficiency limit, however, at risk of engine durability. Therefore, do not operate in this range in a normal

or usual way.

Vehicle Starting and Driving

4-11

4. Steering play

Steering wheel play

Run the engine at idle gear and straighten the front

wheels forwards.

Turn the steering wheel alternatively to the right and to

the left.

The steering play (free movement of the steering wheel)

is measured on the perimeter of the steering wheel and

should be between 20 and 30 mm.

A

Vehicle Starting and Driving

4-12

Control periodically, at least once a week:

1. Check tire for abrasion and pressure and tire nut for fixture

The vehicle’s safety and performance depend considerably on the state of the tires, reason why they

should be checked daily.

Before driving a vehicle, check charging pressure of tire for normal, tire for damage, tire nut for fixture.

Note: At initial 50km, please tighten tire nuts of new vehicle to specified torque in appendix.

Tire pressure

Keep the tires always correctly calibrated. The inflation pressure should be checked with the tires cold at

least once a week.

After driving the vehicle for some time, the tires heat and in consequence of the heat, the inflation

pressure increases. Never, under any circumstance, empty heated tires to reestablish the recommended

inflation pressure.

The pressure difference between the assemble tires on the same axle should not be superior to 0.1 bar.

Wheel hubs

Keep them always clean, eliminating eventual mud or other dirt adherence. Substitute the damaged and/or

deformed hubs. The utilization of refurbished hubs is not recommended.

Wheel nut

Without fail re-tighten the wheel fastening nuts of new vehicles after running 50km.

The wheel fastening nuts should be retightened, crosswise, in turns, observing the recommended

tightening torque according to the type of fastening nut. If a torque meter is not available, tighten the nuts

strongly, using the vehicle tools without additional levers.

Vehicle Starting and Driving

4-13

2. Air cleaner (activate the dust discharge valve to loosen accumulated dust)

The maintenance of the air cleaner is made up of the

substitution of the filtering elements and should be

done only when the maintenance indicator indicates

the saturation of the element.

The cleaning of the main and safety filtering elements

is not recommended. The re-utilization of the filtering

elements can result in deficient filtering of the air and

cause serious damage to the engine.

When washing the engine, conveniently protect the air

inlet with a plastic or similar material to avoid the

infiltration of water to the air filtering element. After

washing the engine, remove the protection from the air

inlet.

Periodically press the dust discharge valve with your

hand, in order to incomplete the dust which possibly

be caught in the internal part maintaining them clear.

At the same time, check clip connecting rubber hose

of air intake system with steel tube in case of dust

entering air intake system due to looseness and

decrease in engine life.

The air cleaner restriction is electronically controlled.

If the indication of saturated air cleaner appears in the

display of digital indicator in combination instrument,

send the vehicle to a King-Long Dealer or authorized

workshop to inspect and clean the air intake system

and substitute the main filtering element.

Indication

The main filtering element of the air filter should be substitutes after maximum 2 years use.

The safety filtering element (optional) should be changed at every third main filtering element

substitution, or after maximum 2 years of use.

Model 1

Model II

1 automatic dust discharge valve

Vehicle Starting and Driving

4-14

3. General leakages (water, oil, fluids and fuel)

Check the engine, the transmission, the driving axle, the steering system, the cooling system and the oil

pipeline, the air pipeline of the complete vehicle for their leakage.

Vehicle Starting and Driving

4-15

4. Fastening and state of seat belts

Check buckle of the safety belt of the driver seat for normal and ensure for its lockup under the following

situations when fastening the safety belt.

● The body dashes forward all of a sudden;

● The vehicle makes an emergency braking or an abrupt acceleration;

Vehicle Starting and Driving

4-16

5. Check emergency devices and driver’s tools

Such as extinguisher, crosstie for blocking vehicle, emergency hammer, jack and etc..

Fire extinguisher:

The pulse super-micro powder fire extinguisher is fixed

in the engine compartment, when the compartment is on

fire, the fire extinguisher activate automatically or is

active by manual work to eradicate the fire

The fire button is usually located at auxiliary instrument

desk in the driver compartment where people could

operate it easily.

Operation:1. When the engine compartment caught fire,

the driver should stop vehicle and switch off engine

immediately, open the fire button cover, and press the

fire button, start-up fire extinguisher

2.Fire extinguisher may start-up automatically when

it catches fire or its temperature arrives at 170℃.

Important hint:

1. Fire extinguisher can be used for one time only,

DO NOT press the fire button except for

emergency condition.

2. The fire extinguisher can not start–up by press the

fire button manually if the vehicle battery is dead or

power turn off.

3. If the vehicle needs to be repaired, you could take

away the anode and the cathode. And put them back

after the reparation completed.

Inner fire extinguisher is fixed under the passenger’s

chair, when vehicle caught fire, stop vehicle and use the

fire extinguisher.

Fire extinguisher

Fire button

Vehicle Starting and Driving

4-17

6. Working order of windshield wipers and conditions of wiper blades and arms

Regularly check the windshield wiper blades for dirt or damage.

Press the lever to activate the windshield washer

Caution: Do not use the windshield wipers when the windshield

is dry. Before activating the wipers, push the head of the wiper

lever inward to spray detergent onto the windshield.

Check surplus of detergent

Stop vehicle on a flat road, open side cover of instrument desk.

Container of detergent is located inside instrument desk. If

detergent is insufficient, add.

Add the clean water into the tank for windshield washer.

There are 2 kinds of water tank.

Model 1

Model 2

Vehicle Starting and Driving

4-18

7. Electrical rearview mirror

Check, adjust and clean the rearview mirror.

Rearview mirror control button

Model 1

L: adjusting left rearview mirror.

R: adjusting right rearview mirror.

Mirror button: push down the arrow headed button to

adjust the mirror for 4 directions.

Model 2

L: adjusting left rearview mirror.

R: adjusting right rearview mirror.

Mirror button: rotate the handle to adjust the mirror for

4 directions.

Model 2

Model 1

Model 3

Vehicle Starting and Driving

4-19

Inspection every two weeks before and after driving

Power steering

Ensure that all the maintenance service jobs on the steering

system be carried out at the intervals recommended in the

maintenance manual to guaranty total efficiency and safety.

If any working abnormality in the steering is noticed,

immediately supply the necessary repairs.

The habits of forcing the steering too far against wheel

obstacles and of activating the steering while the vehicle is

stopped are harmful to the steering system and should be

avoided.

In emergencies, in the case of damage to the power steering

system, the steering may be used without hydraulic help,

however, in this condition there will be more steering wheel

play and the steering will become noticeably “heavier”. Drive

the vehicle very carefully and take it to an authorized

King-Long Dealer or Workshop to re-establish the correct

working order of the steering system.

Important: In the case of damage to the hydraulic steering

pump or of the total loss of fluid from the hydraulic system,

we recommend that the vehicle is not driven further than

50KM in order to avoid further damage to the steering system

components.

Power steering fluid level

The power steering fluid level should be checked while the

engine is running at idle and the fluid is hot. Run the engine at

idle gear and turn the steering from side to side various times

to heat the steering system fluid.

Check the level through the inspect window of the container.

Model 1

Model 2

Model 3

Vehicle Starting and Driving

4-21

General state and tension of drive belts

Check the tension of engine belt, fan belt and compressor belt, if loose, tension it; if damaged, replace it.

Do not start up the engine without the drive belts. In the case of one of the belts breaking, immediately

stop the engine and have a new belt put in.

The checking, adjustment or substitution of the drive belts should be carried out with the engine shut

down.

Check cross plane of the belt for no cracks. Crackle in the transverse direction (along the belt width

direction) is acceptable while that in longitudinal direction and transverse crack cross is unacceptable.

Please replace the strap in case of abrasion or chip dropping off.

Too tight or too loose belt would make against proper operation of engine. Press belt to check tension.

Please refer to the manual book of engine assembly for detailed adjusting method and tension of belt.

The poli-V belts demand technical knowledge, therefore we recommend that this job, when necessary, be

carried out at a King-Long authorized Dealer or Workshop.

Fan drive belts

If it is necessary to replace the fan drive belts in emergency situations, adjust their tension in such a way

that upon pressing them with one’s thumb in the middle of the distance between the pulleys, a defection

of approximately 20mm is observed. Loosen fastening nut of intermediary pulley before turning the

adjusting bolt. After adjusting fan belt tension, tighten the fastening nut of intermediary pulley firmly.

Model 1:

Adjusting method of the single belt driving fan belt is

shown in the figure

1. Check tension of belt

Apply force of 98N by the finger.

Strap sinkage between the crank pulley 1 and the fan

pulley 2 should be 15 ~ 20mm.

2. Adjust tension of cone belt

Adjust bolt 3 until the tension is proper.

The max offset angle of the fan pully shaft should not

exceed 5°, or else please replace it.

Model 2:

Adjusting method of the fan belt is shown in the figure

1. Check tension of belt

Apply force of 98N by the finger.