King Long XMQ6900J series, XMQ6120C series Operating Manual

OPERATION MANUAL

User’s Guide

King-Long XMQ6900J series city bus

Xiamen King Long United Automotive Industry Co., Ltd.

Foreword

FOREWORD

King-Long XMQ6900J series city bus keeps features of superior economy,

security and comfort. It has stable performance, strong power, luxury interior

trimming and high speed, which could meet applications of passenger intra-city

transportation, touring affairs, etc.

As for the specifications introduced in relate to information of the driving

and operation, service and maintenance of the XMQ6900J series city bus, please

read them carefully and make proper operation, maintenance and repair so as to

ensure it in good condition. Special hint: without authorization of Xiamen King

Long United Automotive Industry Co., Ltd, never modify the electrical

deployment of the whole vehicle, and should not lap the power supply line in

disorder. Improper usage and repair may have a strong impact on service

performance of the complete vehicle, and thus the manufacturer , Xiamen King

Long United Automotive Industry Co., Ltd. will not takes the responsibility for

the damages caused by them.

Any problem in service, please contact our special maintenance network or

after-sales department. We will ensure timely and complete maintenance as well

as original parts supply.

In order to satisfy all kinds of different demand of the consumers, we strive

to improve the quality of the product continuously to optimize our products. We

should not give any further notice for any modification of the product in advance .

The contents on the instruction book can only be used as reference. If there are

facts not comply with the manual, will be subject to the actual state of the

products because for some device and items, the vehicle will be finally equipped

only if they have been taken as optional configurations.

Final interpretive right of the instruction book belongs to the technical

center of Xiamen King Long United Automotive Industry Co., Ltd.

Xiamen King Long United Automotive Industry Co., Ltd.

MAY. 2014

Contents

2

Contents

Foreword

Foreword---------------------------------------------------------------------------------------------------------------2

Contents

Contents----------------------------------------------------------------------------------------------------------------3

Main overall technical parameters

Technical parameters -------------------------------------------------------------------------------------------------7

Introduction to name plate--------------------------------------------------------------------------------------------8

Product quality assurance --------------------------------------------------------------------------------------------8

Technical document --------------------------------------------------------------------------------------------------8

Vehicle body structure------------------------------------------------------------------------------------------------9

Schematic illustration of the driver zone--------------------------------------------------------------------------10

Operation Instruction

Instrument instruction-----------------------------------------------------------------------------------------------I-1

Illustration of switch and indicator s----------------------------------------------------------------------------SI-1

Air conditioner control panel-----------------------------------------------------------------------------------P-A-1

Bus centre controller---------------------------------------------------------------------------------------------P-B-1

Open or close the passenger door-----------------------------------------------------------------------------O-K-1

Adjustment of the driver's seat----------------------------------------------------------------------------------OI-1

Horn button---------------------------------------------------------------------------------------------------------OI-2

Adjustment of the steering wheel-------------------------------------------------------------------------------OI-3

Ignition switch-----------------------------------------------------------------------------------------------------OI-4

Lamplight operating handles-------------------------------------------------------------------------------------OI-5

Wiper operating handle-------------------------------------------------------------------------------------------OI-6

Retarder operation-------------------------------------------------------------------------------------------------OI-7

Safety hatch--------------------------------------------------------------------------------------------------------OI-8

Safety hammer-----------------------------------------------------------------------------------------------------OI-9

Prompt stop switch for get off ---------------------------------------------------------------------------------OI-10

Contents

3

Switch control box----------------------------------------------------------------------------------------------O-E-1

Vehicle starting and driving

Check oil level of the engine--------------------------------------------------------------------------------------S-1

Check level of the coolant-----------------------------------------------------------------------------------------S-2

Check fuel pre-filter with water separator-----------------------------------------------------------------------S-3

Check fuel level-----------------------------------------------------------------------------------------------------S-4

Check vehicle lighting, intermittent lights and brake lights---------------------------------------------------S-5

Check the level of AdBlue and the daily maintenance of SCR system--------------------------------------S-7

Drain water in air tank---------------------------------------------------------------------------------------------S-8

Check engine oil pressure------------------------------------------------------------------------------------------S-9

Check Pneumatic pressure---------------------------------------------------------------------------------------S-10

Check Tachograph working order-------------------------------------------------------------------------------S-11

Steering wheel play-----------------------------------------------------------------------------------------------S-12

Check tire for abrasion and pressure and tire nut for fixture------------------------------------------------S-13

Air cleaner----------------------------------------------------------------------------------------------------------S-14

General leakages (water, oil, fluids and fuel) -----------------------------------------------------------------S-15

Fastening and state of seat belts---------------------------------------------------------------------------------S-16

Check emergency devices and driver’s tools(fire extinguisher) --------------------------------------------S-17

Windshield wipers and conditions of wiper blades and arms-----------------------------------------------S-18

Electrical rearview mirror----------------------------------------------------------------------------------------S-19

Power steering system--------------------------------------------------------------------------------------------S-20

Clutch actuation system fluid level-----------------------------------------------------------------------------S-21

General state and tension of drive belts------------------------------------------------------------------------S-22

Clutch actuation system fluid level-----------------------------------------------------------------------------S-21

General state and tension of drive belts------------------------------------------------------------------------S-22

Check level of battery electrolyte-------------------------------------------------------------------------------S-24

Procedures for engine start up-----------------------------------------------------------------------------------S-25

Engine shut down-------------------------------------------------------------------------------------------------S-26

Engine start up and shut down in the engine compartment--------------------------------------------------S-27

Contents

4

Starting the vehicle------------------------------------------------------------------------------------------------S-28

Parking the vehicle------------------------------------------------------------------------------------------------S-29

Vehicle maintenance and service

General knowledge------------------------------------------------------------------------------------------------M-1

Maintenance of engine and chassis subassembly--------------------------------------------------------------M-1

Body maintenance ------------------------------------------------------------------------------------------------M-1

ABS system maintenance and service --------------------------------------------------------------------------M-1

Electrical system maintenance and notices --------------------------------------------------------------------M-2

Tire transposition--------------------------------------------------------------------------------------------------M-2

Adjustment of the clutch pedal freeplay------------------------------------------------------------------------M-3

Adjustment of the brake pedal freeplay-------------------------------------------------------------------------M-3

Bus cleaning--------------------------------------------------------------------------------------------------------M-3

Cleaning air filter --------------------------------------------------------------------------------------------------M-4

Cleaning outside of radiator -------------------------------------------------------------------------------------M-5

Coolant specification ---------------------------------------------------------------------------------------------M-5

Oil specification recommendation of the fuel and the lubricant---------------------------------------------M-6

Breaking-in of a new vehicle-------------------------------------------------------------------------------------M-9

Daily or Refueling Maintenance Operation-------------------------------------------------------------------M-11

Maintenance first 2500km --------------------------------------------------------------------------------------M-12

Maintenance per 5000km---------------------------------------------------------------------------------------M-13

Maintenance per 10000km--------------------------------------------------------------------------------------M-16

Maintenance per 20000km--------------------------------------------------------------------------------------M-17

Maintenance per 40000km -----------------------------------------------------------------------------------M-20

Maintenance per 80000km ------------------------------------------------------------------------------M-20

Maintenance more than 80000km------------------------------------------------------------------------------M-21

Maintenance period chart---------------------------------------------------------------------------------------M-22

Common trouble and its eliminating method

Engine Common trouble and elimination ---------------------------------------------------------------C-1

Clutch---------------------------------------------------------------------------------------------------------------- C-6

Propeller shaft-------------------------------------------------------------------------------------------------------C-8

Contents

5

Transmission--------------------------------------------------------------------------------------------------------C-9

Rear axle-----------------------------------------------------------------------------------------------------------C-10

Front axle and steering system----------------------------------------------------------------------------------C-11

Braking system----------------------------------------------------------------------------------------------------C-14

Electrical equipment and the starting system ---------------------------------------------------------------C-16

Air conditioner system-------------------------------------------------------------------------------------------C-18

Appendix

Driver's tool table ---------------------------------------------------------------------------------------------- A-1

Tightening moment of the bolts and the nuts in major position ------------------------------------------A-2

Air braking schematic diagram -------------------------------------------------------------------------------- A-4

Electrical schematic diagram-------------------------------------------------------------------------------------A-4

Technical parameter and complete vehicle description

6

Technical parameters of the complete vehicle

(Vehicle No.EC600024-25)

Product model

XMQ6900

J

Engine model

ISBE6.7E5 250B

Engine type In-line six-cylinder water-cooling direct-injection diesel engine

Cylinder diameter ×stroke (mm)

107X124

Displacement (ml)

6700

Compression ratio

17.2:1

Rated capacity / rotation speed (kw/rpm)

184/2300

Max. torque / rotation speed (N·m/rpm)

1200 /1200-1600

Dimensions

Overall length (mm)

9175

Overall width (mm) 2450

Overall height(mm)

3050(3140)

Wheelbase (mm) 4250

Wheel

track

front (mm) 2094

rear (mm) 1860

Minimum lift-off clearance(mm) ≥158

Approach angle/ departure angle

(°)

7.8/8

Front overhang / rear overhang

(mm)

2175/2750

Rated passenger (driver included)

(person)

23+4+1

Mass parameter

Kerb weight(kg) 9000

Max. gross mass (kg) 12000

No

load

Front axle (kg) 2700

Rear axle (kg) 6300

Full

load

Front axle (kg) 4000

Rear axle (kg) 8000

Performance

parameter

Max. speed (km/h) ≥90

Fuel consumption (L) --

Maximum gradeability (%) ≥20

Min. turning diameter (m) ≤20

Parking slope (20%)

Parking for 5 minutes

Capacity data

Fuel tank(L) 165

Engine oil(L) 19.5

Transmission lubricant(L) 23

Main retarder lubricant(L) 5

Power steering hydraulic oil(L) 8

clutch lubricant(L) 1.3

Technical parameter and complete vehicle description

7

Introduction to data plate

Bus data plate

The bus data plate may be affixed to either the upside of the front passenger door frame or to the side of the

front passenger door step (the position may vary with vehicle model). There are many parameters on the

plate, such as vehicle model, gross mass, vehicle serial number, vehicle capacity, VIN (short for vehicle

identification number), chassis serial number, engine serial number, engine model, rated power, production

data and etc..

Chassis data plate

The chassis data plate is on right (or left) lateral surface

of the front wheel position of the main sill with vehicle

identification number (VIN) on the frame.

Engine data plate

The engine data plate is on top surface or salient top

position of the engine, whose position may be various

according to different engine manufacturing plant.

The engine number is stamped on the left or right

block of the engine, whose position may be various

according to different engine manufacturing plant.

Technical parameter and complete vehicle description

7

Product quality assurance

We make breaking-in maintenance of the rolling-out new vehicles in their initial driving mileage of

5000 km. Users should make proper operation and maintenance strictly according to relevant

regulations in the instruction book. Please refer to “workshop manual” for product quality assurance

and abide by related specification.

Technical document

The instruction book is used combined to the following specification:

Engine operation instruction or service manual

Transmission operation manual

CAN BUS Instrument system instruction book

ABS anti-braking system instruction book

Air conditioner instruction book

Heater instruction book

Monitor instruction book

VCD/DVD instruction book

Note: the instruction book should be modified according to specific configuration of vehicle.

Technical parameter and complete vehicle description

7

Body Structure

1. Structural style

Semi-integral body structure

2. Structure

The bodywork structure adopts closed girder construction of five major assembly parts, which are

combined welded by rectangle steel pipes with advantages of strong structural stiffness, torsion

resistance and bending resistance as well as relatively simple craftwork. Main components of skeleton

have been performed anticorrosion treatment to ensure steady adhesion of coating and strong capacity

of antirust and corrosion-proof.

3. Interior trim

The interior adopts flexible design and the floor adopts steel plate/wood block composite construction,

and covered with anti-slip and antifriction leather with favorable sound insulation value.

4. Windows

The front windshield is the hyperboloid triplex glass fixed by the gluing; the rear windshields are the

hardened glass fixed by the gluing; the side windows are close cycle window which are made of

hardened glass. The driver’s window is fixed with sliding window.

5. Baggage compartment

The baggage compartment without installing

6. Seat

Driver’s seat: adjustable seat with high backrest and three-point belt(E-MARK).

Passenger seats: FANSA city bus seat, the all seats are equipped with two-point safety belt.

7. Interior accessory device

The vehicle is equipped with electronic clock, sunshade, safety hammer, emergency escaping window,

curtain,destination board, inner display screen, reversal monitor, Vehicle traveling data recorder ,

reading lamp, disabilities ramp ,guide mike .etc.

8. Air-conditioning system

Cooling system: WEBASTO top mounted dependent air-conditioning system.

Defroster: cooling /heating defrosting device

9. Door

The door adopts the full aluminum remote control inner-swing pneumatic doors.

The inner-swing door adopts the advanced electrically aerodynamic theory design, with the motion of

opening and closing placidly、agile、safe、lock credible and anti-clamp function.

A. Basic function

a. There are two electrically switches, the interior one is trigger touch-tone, which located on the

dashboard of the front right side of the driver, the outside one is a remote control switch. , both switches

can control the door.

b. When the circuit is in OFF position , the emergency switch can be used in the interior, the emergency

switch of the door is located on the lower right side of the entrance of the door , Please rotate the switch

and throw open the door in emergency.

c. Commonly the door is closed, when touch off any electrically switch, the door would move placidly

at a certain velocity, along with it, the step-lamp lights .when touch off the switch again , the door

would return placidly at a certain velocity, after the door returned , the step-lamp goes out.

Technical parameter and complete vehicle description

8

B. Hint:

a. The door remote control acts only when the parking brake is on the parking gear.

b. The door could only be opened when the external mechanical lock isn't locked up.

c. In order to avoid impact, make sure that the door is completed closed or opened, before you make the

next door switch operation.

Note: Deployment on the vehicle may be different with the above description because of different

deploying requirement of the clients.

Technical parameter and complete vehicle description

9

Schematic illustration of the driver zone

1 Rearview mirror heating

2 Rearview mirror control switch

3 Station reporter

4 Rocker switch

5 Light operation handle

6 Combination instrument

7 Steering wheel

8 Horn

9 MP3 player

10 Emergency electric power cut off switch

11 Wiper operation handle

12 A/C operation rotation button

13 Cigar lighter/USB charging socket

14 Door air valve switch

15 Transmission control panel

16 Parking brake shift

1

4

12

6 7 8 9 10

13

14

11

2

3

15

16

5

Operation Instruction

I-1

Instruction of instrument (Siemens Edition)

No. Function Description

1 ABS indicator ABS work/warning

2 High beam indicator When Highbeam is switched on

3 Left turning indicator When Left turning/hazard switch is turned on

4 Severe Error When the electrical system has severe error. (see1.1 )

5 General Error When the electrical system has general warning. (see1.2)

6 Right turning indicator When Right turning/hazard switch is turned on

7 Retarder indicator Retarder work/warning

8 Parking brake

9 DTCO warning communication error or without drivers card

10 Engine Revolution speed too

high

Need to change the gear or slow down the bus

11 Trip distance reset button Set trip distance to 0

12 LCD illumination adjust button Press the button to adjust the illumination of LCD

13 Fuel level gauge The fuel remain

14 Coolant temperature gauge Temperature of engine coolant

15 LCD display

16 Speedometer Current vehicle speed

17 Odometer Current engine speed

Operation Instruction

I-2

1.1 Severe error conditions

EDC red lamp; ECAS red lamp; EBS red lamp; coolant level low; battery not charging (after engine

starts); worn brake shoes; brake circuit 1/2 pressure low; coolant temperature high; catalyst level low;

engine cabin temperature high; oil pressure low (after engine starts).

1.2 General error conditions

Hammer not at right position; ASR error; air filter block; ECAS amber lamp; EBS amber lamp; rear flap

open; toilet water level low; steering oil level low; steering oil pressure low; fuel level low; DM1 error; light

error; communication error.

2 LCD Display

Press the page switch button, the pages will be displayed by the following sequence. Detailed

description is listed as below:

2.3 Driving Information

When the bus is running, this page will show (Figure-1 ):

Figure-1 driving information

pictogram comments pictogram comments

Gear info (see 2.1.1)

Acceleration pedal position

Current time (see 2.1.2)

System voltage (see 2.1.3)

Front door status (see2.1.7)

Preheating indicator

Mid door status (see 2.1.7)

Passenger service/request from

cabin(see 2.1.9)

Fluid fan error

Engine red lamp error

Operation Instruction

I-3

pictogram comments pictogram comments

Low beam working

Engine amber lamp error

Front fog light working

Engine Malfunction

Rear fog light working

Engine wait to start (do not start

the engine until this symbol

disappear)

Brake light wroking

EBS red lamp warning

Lift-axle lock

EBS amber lamp warning

Steering oil level low

ECAS status (see2.1.8)

Steering oil pressure low

Battery not charging (indicate

charging error if this symbol still

exist after engine starts)

Coolant temperature high

(>=98°C)

The bar shows brake circuit 1

pressure

Coolant level low

The bar shows brake circuit 2

pressure

Rear flap open (can not start the

engine)

The bar shows engine oil pressure

Worn brake shoes

The bar shows SCR remain

Hammer not at right position

Function description

2.3.1 Transmission gear Display:

:current gear is "neutral";

:current gear is "forward";

:current gear is "reverse";

2.3.2 Time:

This information comes from DTCO.

2.3.3 System voltage:

This value shows the battery voltage when generator is not working; and shows the voltage by

generator after engine starts.

Operation Instruction

I-4

2.3.4 Acceleration pedal position:

Range: 0 – 100 %。

2.3.5 Oil pressure:

This information comes from engine ECU. Before engine starts, the value is 0.

2.3.6 Brake system pressure:

Brake circuits 1 refers to the front brake system pressure.

Brake circuits 2 refers to the rear brake system pressure.

The symbol becomes red if the pressure is too low or if sensor is open-load.

2.3.7 Door status:

: green; means door is open

: yellow; means the cap on the emergency switch is open (either inside or outside)

: brown; means the knob in the emergency switch is moving

2.3.8 ECAS status

:ECAS lift :kneeling

:ECAS general error :ECAS severe error

2.3.9 Service request

:Passenger service request :Request from cabin

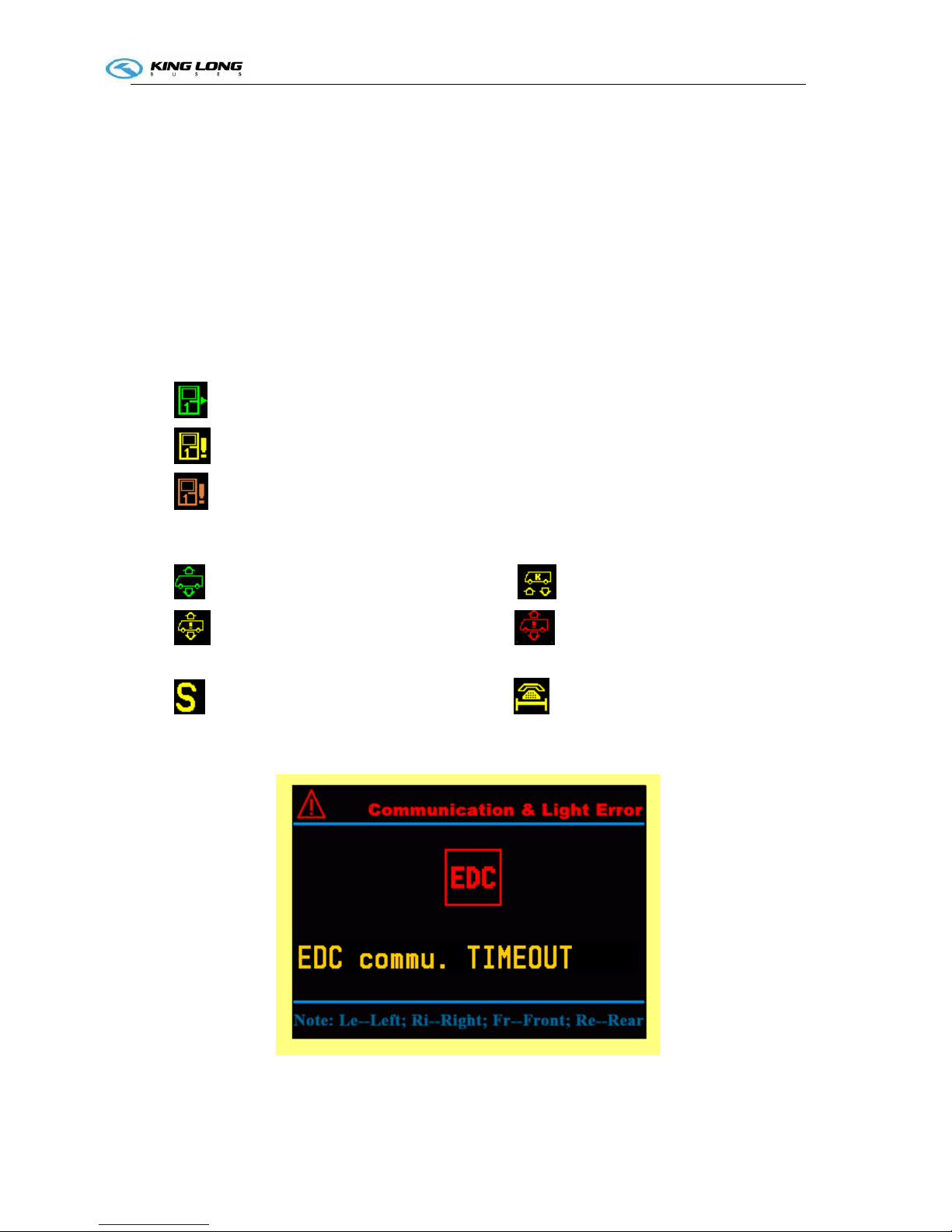

2.2 Error display Page:

Figure -2 text error information

Operation Instruction

I-5

If there is error exists, this page will show after driving information page when you press the page

change button.

Description:

Pictogram

:object name;

Text: detailed description of the error;

Errors can be displayed in this page:

Communication Error: EDC, EBS, TCO, AC, Front node, Top node, Cabin node, Rear node;

Light Error: high-beam, low-beam, reverse light, front fog light, rear fog light, brake light, turning

light

Other Error: brake circuit pressure open-load, fuel-sensor open-load, Engine cabin too hot, worn

brake shoes (1-6), fuel level low, water in toilet level low, air filter block,

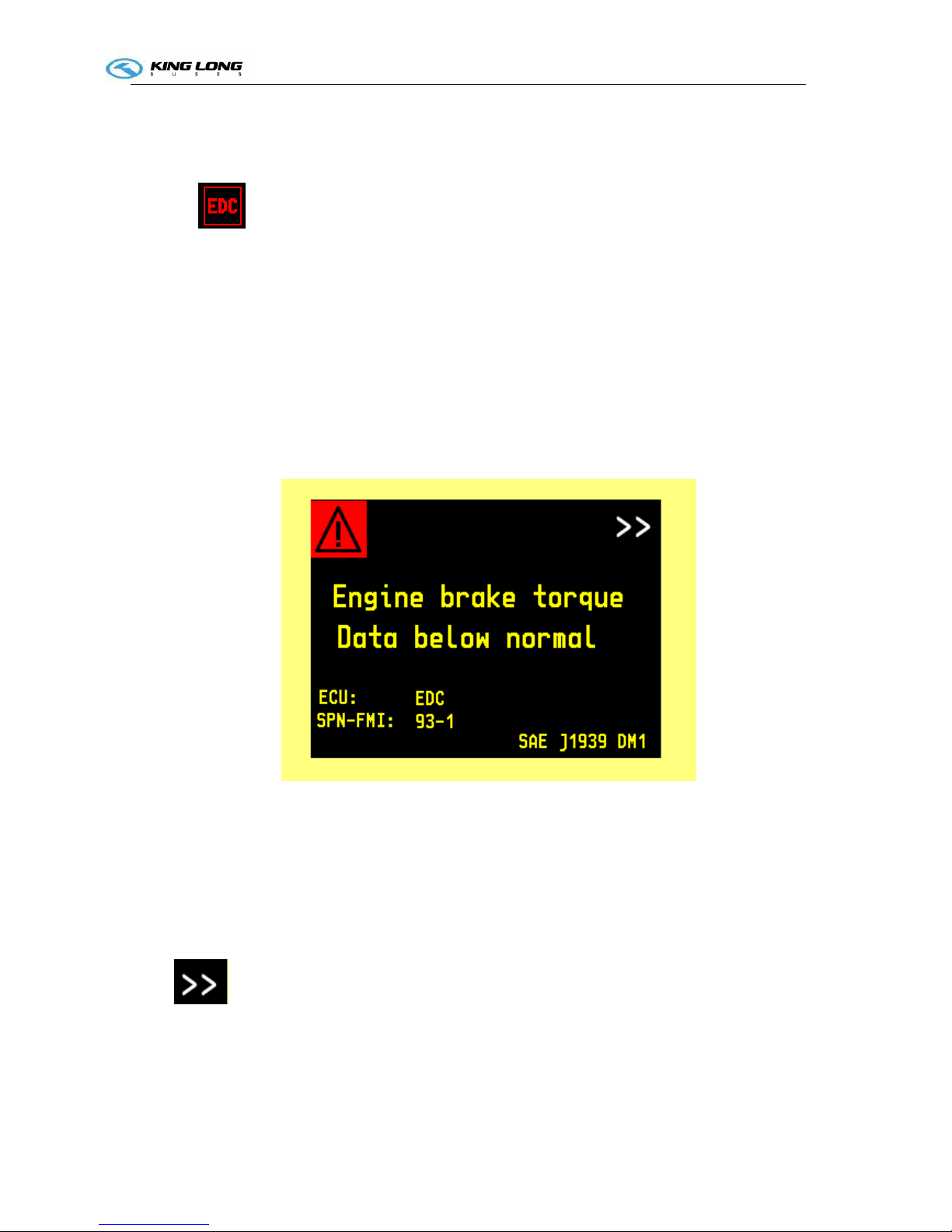

2.3 DM1 Diagnosis Information

Figure -3 DM1 display page

This page will show when some ECU sends out DM1 message. The diagnosed ECU must support

CAN diagnosis, and provides SPN-FMI code.

Line1: the object that has error (from SPN).

Line2: Error status (from FMI)

Line ECU: name of the ECU that sends the message (i.e. EDC, EBS, AC)

Line SPN-FMI: the SPN and FMI combination

: means this error is not the last one

Other contents are fixed

Operation Instruction

I-6

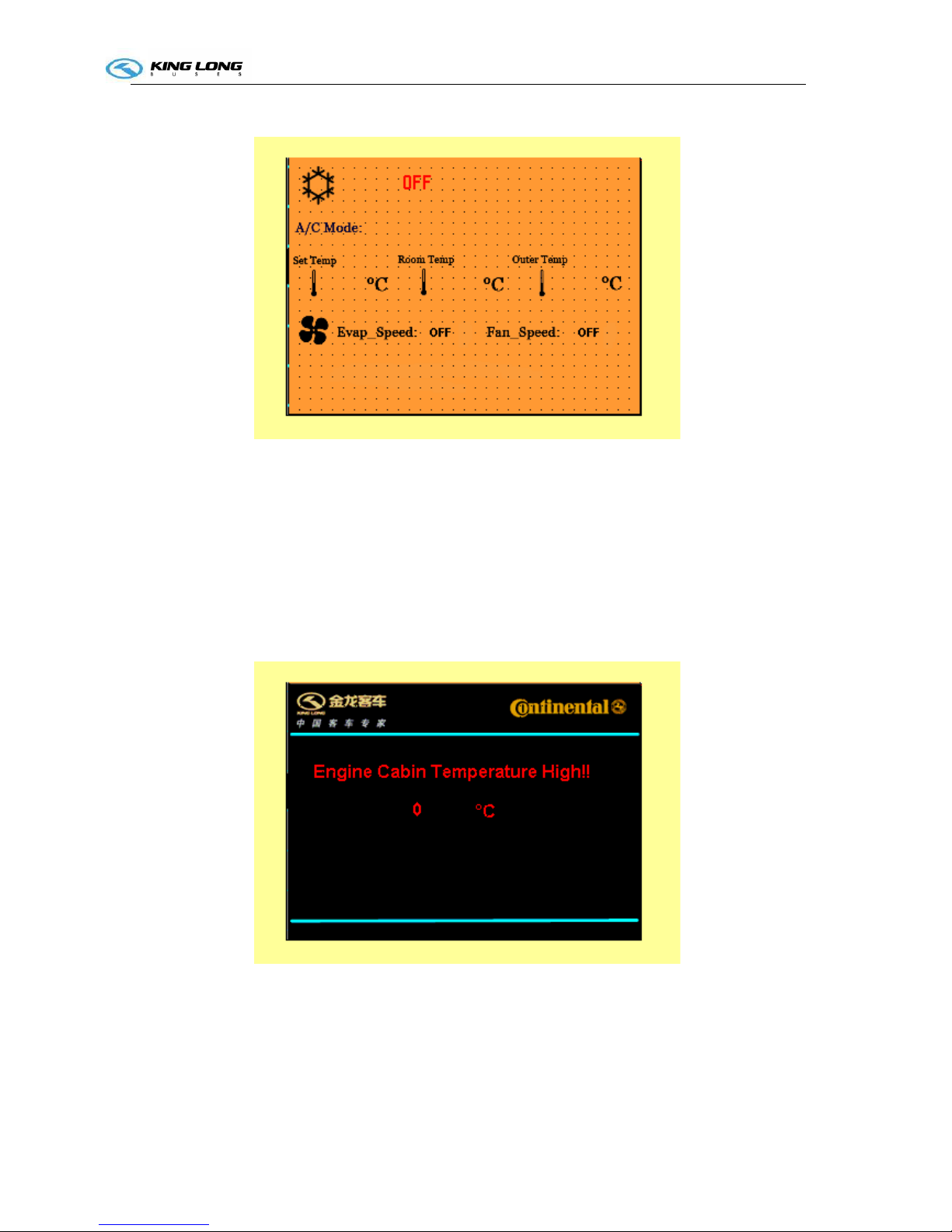

2.4 Air conditioner status

This page will appear is air conditioner is working and the communication is right.

A/C mode include: ventilation; heating; cooling; demist/defrost; auto mode; off

Set temp: the temperature currently set to be;

Room temp: the real ambient temperature in the bus;

Outer temp: outside temperature;

Evap_speed: OFF; High; Mid; Low

Fan_speed: OFF; High; Low

2.5 Engine Cabin Temperature high warning page

If engine cabin temperature is higher than 85°C, this page will appear automatically. The temperature

will show on the page. The driver need to press the page change button to switch to the driving page

Operation Instruction

I-7

2.6 Beeper warning conditions

Brake circuit 1 pressure low

Brake circuit 2 pressure low

Coolant level low

Hammer not at right position

Engine cabin temperature high

Oil pressure low (after engine running)

Service request

Left turning

Right turning.

Operation Instruction

SI-1

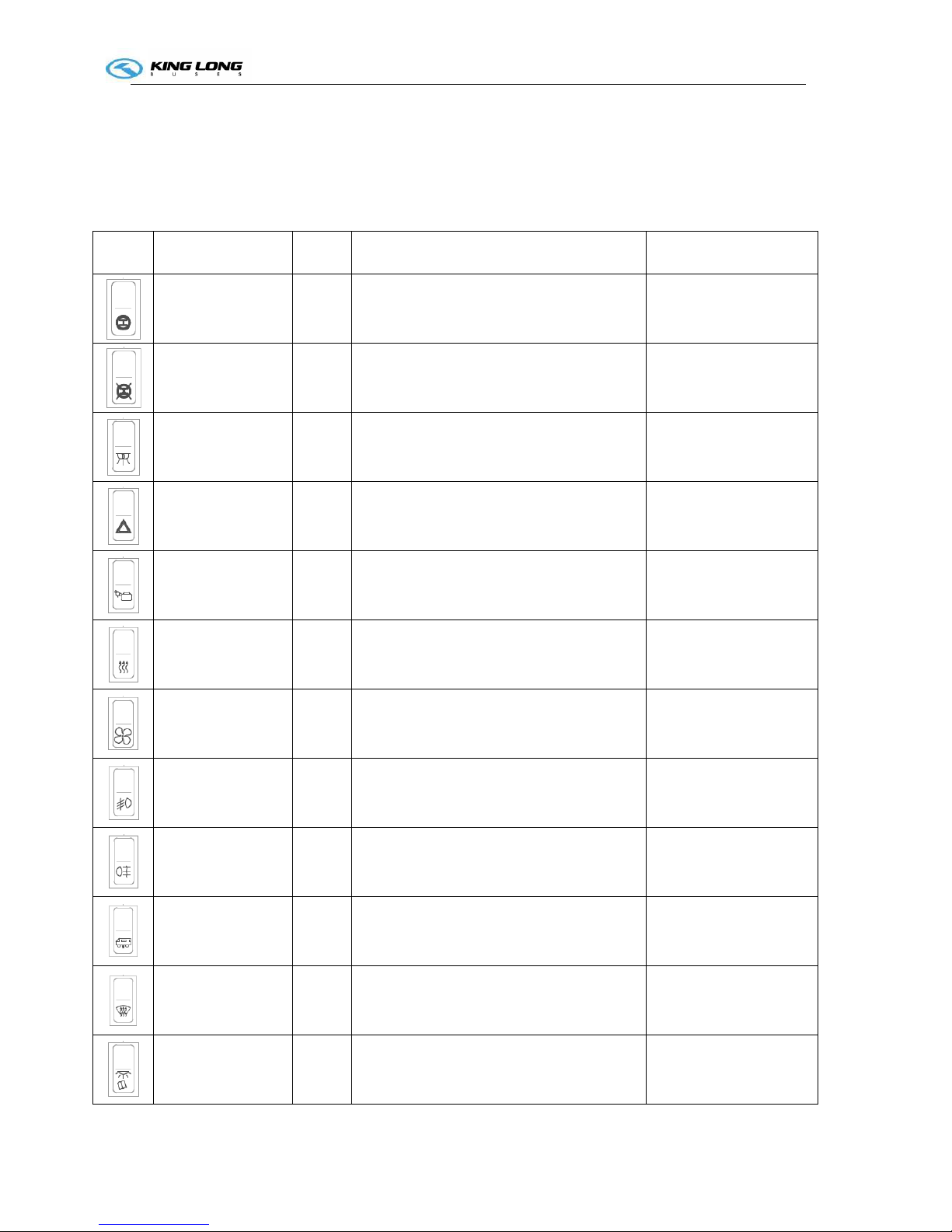

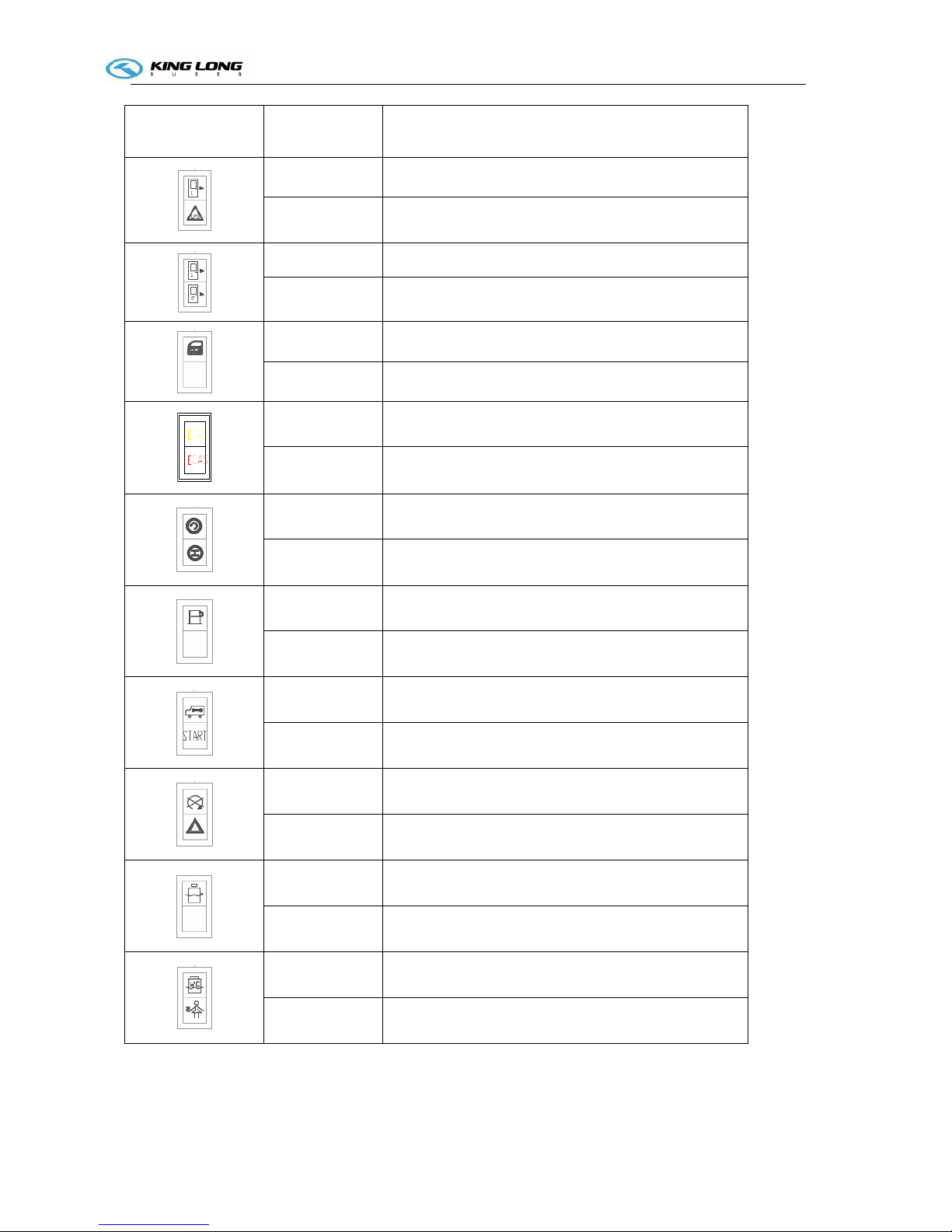

Illustration of switch and indicator

Number of switches and indicators and position may vary with vehicle model, please consult the flowing

sheet and use correctly according to actual condition of vehicle.

Switch

Name Color Function Notes

Retarder Green

Pressed on top: retarder is turned ON

Pressed on bottom: retarder is turned OFF

Retarder turn off

switch

Pressed on top: retarder is turned OFF

Pressed on bottom: retarder is turned ON

Daylight lamp

Green

Pressed on top: interior lighting ON,

Pressed on bottom: interior lighting OFF

Hazard lamp Red

when the vehicle have a screw loose, switch

it on, the whole vehicle lamps light

Luggage

compartment lamp

Green

Pressed on top: lamp lights ,

Pressed on bottom: lamp goes out

Compulsory

radiator

Green

Pressed on top: radiator working ;

Pressed on bottom: to turn it off

only use this button

when vehicle is stopping

Ventilator

Green

Pressed on top: ventilator is active,

Pressed on bottom: ventilator is turned off

Front fog lamp

Green

Pressed on top: front fog lamps ON,

Pressed on bottom: front fog lamps OFF

Rear fog lamp

Yellow

Pressed on top: rear fog lamps ON,

Pressed on bottom: rear fog lamps OFF

Vehicle raise/lower

Green

Pressed on top: vehicle raise,

Pressed on bottom: vehicle lower

only use this button

when vehicle is stopping

Defroster

Yellow

Pressed on top: windscreen heater ON,

windscreen heater OFF

Reading lamp

Green

Pressed on top: reading lamp ON, Pressed on

bottom: reading lamp OFF

Operation Instruction

SI-2

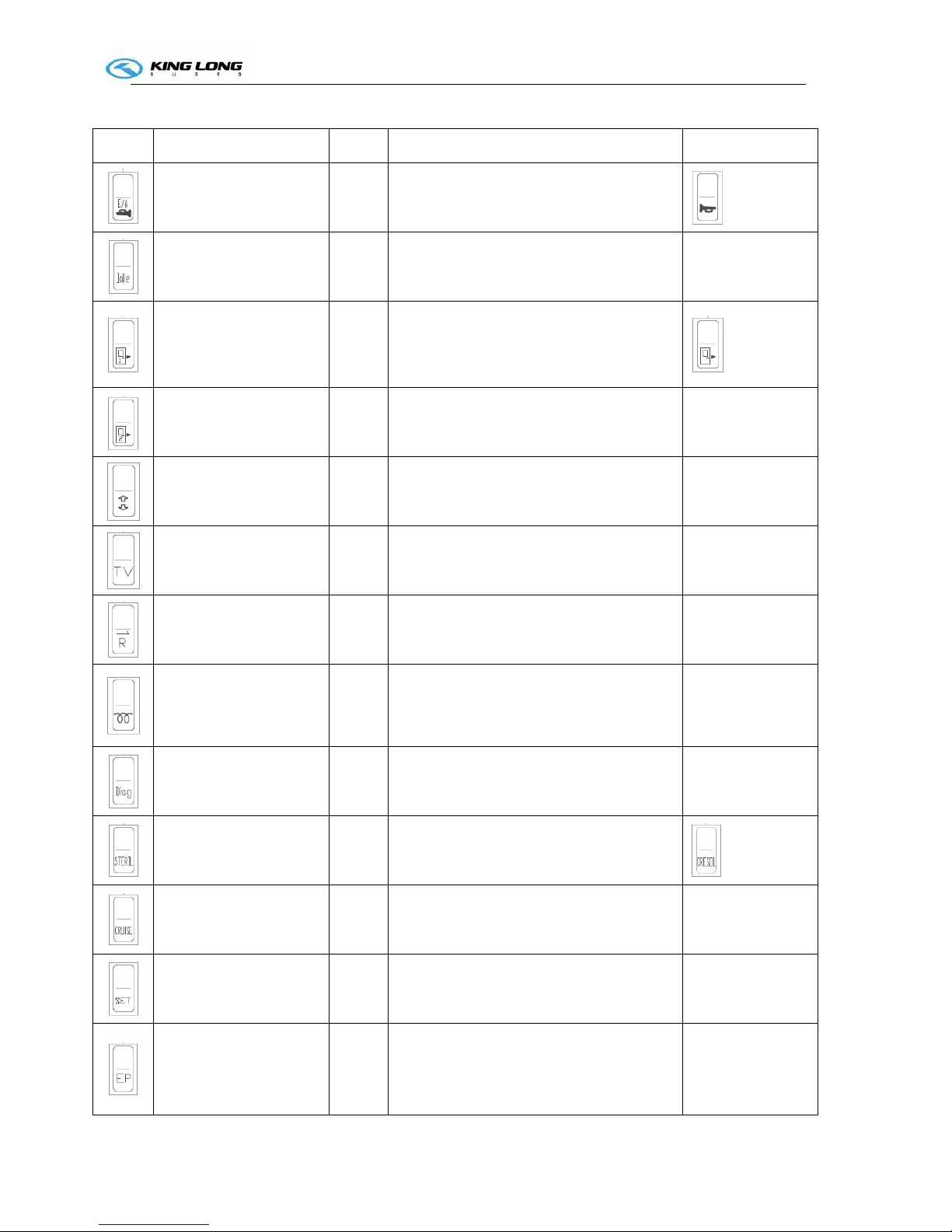

Switch Name Color Function Notes

horn Green

Pressed on top: air horn is active, Pressed on

bottom: electric horn is active

Engine idle Green

Pressed on top: engine idle speed raise,

Pressed on bottom: engine idle speed lower

adjust engine

speed

Front passenger door Green

press button once to open front passenger

door;

press button again to close

Rear passenger door

Green

press button once to open passenger door;

press button again to close

Electric curtain Green

Pressed on top: to raise curtain;

Pressed on bottom: to lower curtain

TV

green

Pressed on top: TV is turned ON,

Pressed on bottom: TV is turned OFF

Reversal monitor

Green

Pressed on top: reversal monitor turned ON,

Pressed on bottom: reversal monitories

turned OFF

Rearview mirror

defrost(preheating)

Yellow

Pressed on top: preheating ON,

Pressed on bottom: preheating OFF

Diagnose

Green

press this button to make a diagnosis of

engine, when engine indicate trouble

Disinfect Green

Pressed on top: disinfection turned ON,

Pressed on bottom: disinfection

turned OFF

Cruise

Green

Pressed on top: cruise function is active,

Pressed on bottom: cruise function isn't

active

we advise clients

not to use this

switch

Cruise setting

Green cruise setting

we advise clients

not to use this

switch

Emergency time-delay

parking

Red

Pressed on top: Emergency time-delay

parking function is active,

Pressed on bottom: Emergency time-delay

parking function isn't active

only used when

engine failure

Operation Instruction

SI-3

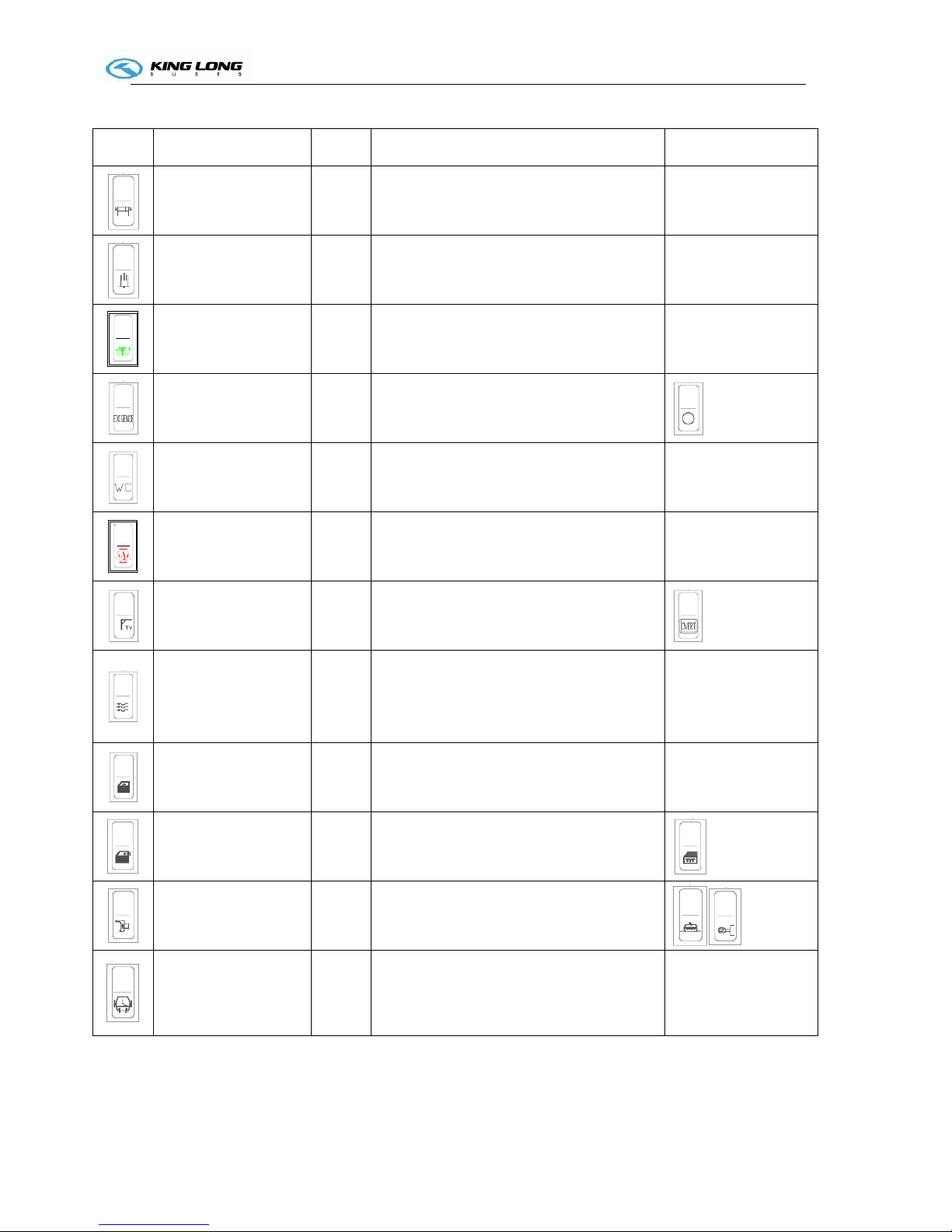

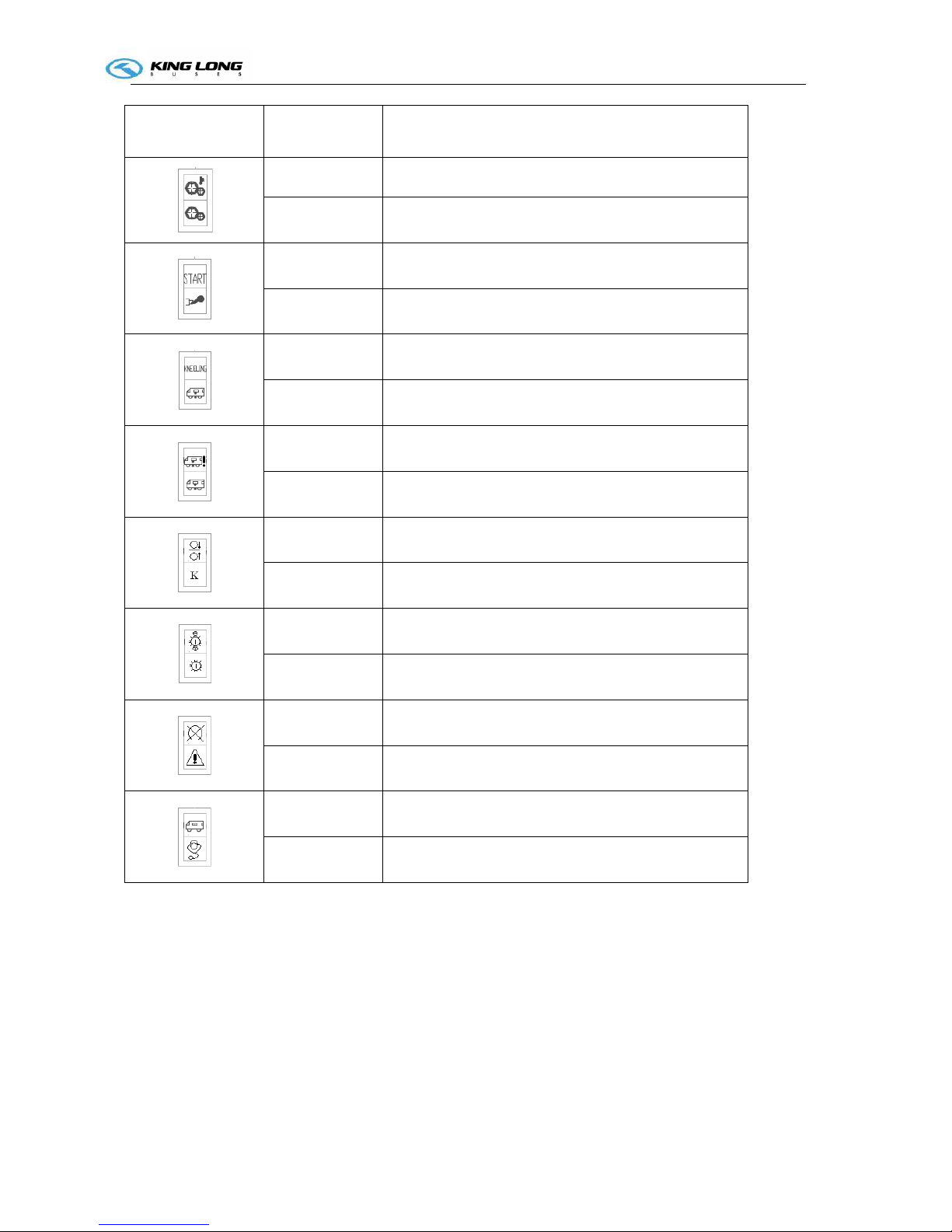

Switch Name Color Function Notes

Exterior guidepost

Red

Pressed on top: turn on guidepost lamp;

Pressed on bottom: turn off guidepost lamp

Assistant brake

Yellow

Pressed on top: turn on assistant brake;

Pressed on bottom: to turn it off

only switch on when

vehicle need park

Vehicle level reset Green Pressed on top: vehicle level reset

Emergency power

Red

Pressed on top: emergency power turned ON

Pressed on bottom: emergency power is

turned OFF

Toilet power switch

Green

Pressed on top: Toilet power is turned ON,

Pressed on bottom: Toilet power is turned

OFF

Heater switch

Red

Pressed on top: to turn on heater ;

Pressed on bottom: to turn it off

TV overturn switch Green

Pressed on top: expand the TV,

Pressed on bottom: collapse the TV

Fresh air switch Green

Pressed on top: turn on the changing fresh

air function;

Pressed on bottom: turn off the changing

fresh air function.

Electric driver window

switch

Green

Pressed on top: the glass getting up;

Pressed on bottom: the glass getting down.

Electric driver window

defrosting switch

Yellow

Pressed on top: turn on defrosting function;

Pressed on bottom: turn off defrosting

function.

Rearview mirror

defrosting switch

Pressed on top: turn on defrosting function;

Pressed on bottom: turn off the defrosting

function.

Left side bin gate Green

Pressed on top: open the left side bin gate;

Pressed on bottom: close the left side bin

gate.

Operation Instruction

SI-4

Switch Name Color Function Notes

Right side bin gate Green

Pressed on top: open the right side bin gate;

Pressed on bottom: close the right side bin

gate.

Powerful/abstemious

transfer switch

Pressed on top: turn on powerful function;

Pressed on bottom: turn off abstemious

function.

Electric sun blind Green

Pressed on top: the sun blind getting down;

Pressed on bottom: the sun blind getting up.

Driver seat lamp switch Green

Pressed on top: turn on the driver seat lamp;

Pressed on bottom: turn off the driver seat

lamp.

Kneeling switch Green

Pressed on top: turn on kneeling function;

Pressed on bottom: turn off kneeling

function.

Coin box switch Green

Pressed on top: open the coin box;

Pressed on bottom: turn off the coin box.

Turning lamp switch Green

Pressed on top: turn on the turning lamps;

Pressed on bottom: turn off the turning

lamps.

ACU unlock switch Green

Pressed on top: ACU unlock;

Pressed on bottom: ACU lock.

For articulate plate

only

Inner guidepost switch Green

Pressed on top: turn on the inner guidepost;

Pressed on bottom: turn off the inner

guidepost.

Changing monitor

video switch

Green

Pressed on bottom: changing the monitor

video from cameras

Spare switch

Pre-heater solenoid

valve switch

Green

Pressed on top: turning on the pre-heater

solenoid valve for water way

Pressed on bottom: turning off

Press the switch while

turning on the

pre-heater ignition

switch

Pre-heater water pump

switch

Green

Pressed on top: turning on the pre-heater

water pump

Pressed on bottom: turning off

Press the switch while

turning on the

pre-heater ignition

switch

Handicapped footplate

switch

Red

Pressed on top: switching on the

handicapped footplate

Pressed on bottom: turning off

Power switch on

dashboard , control

switch in disable area

Operation Instruction

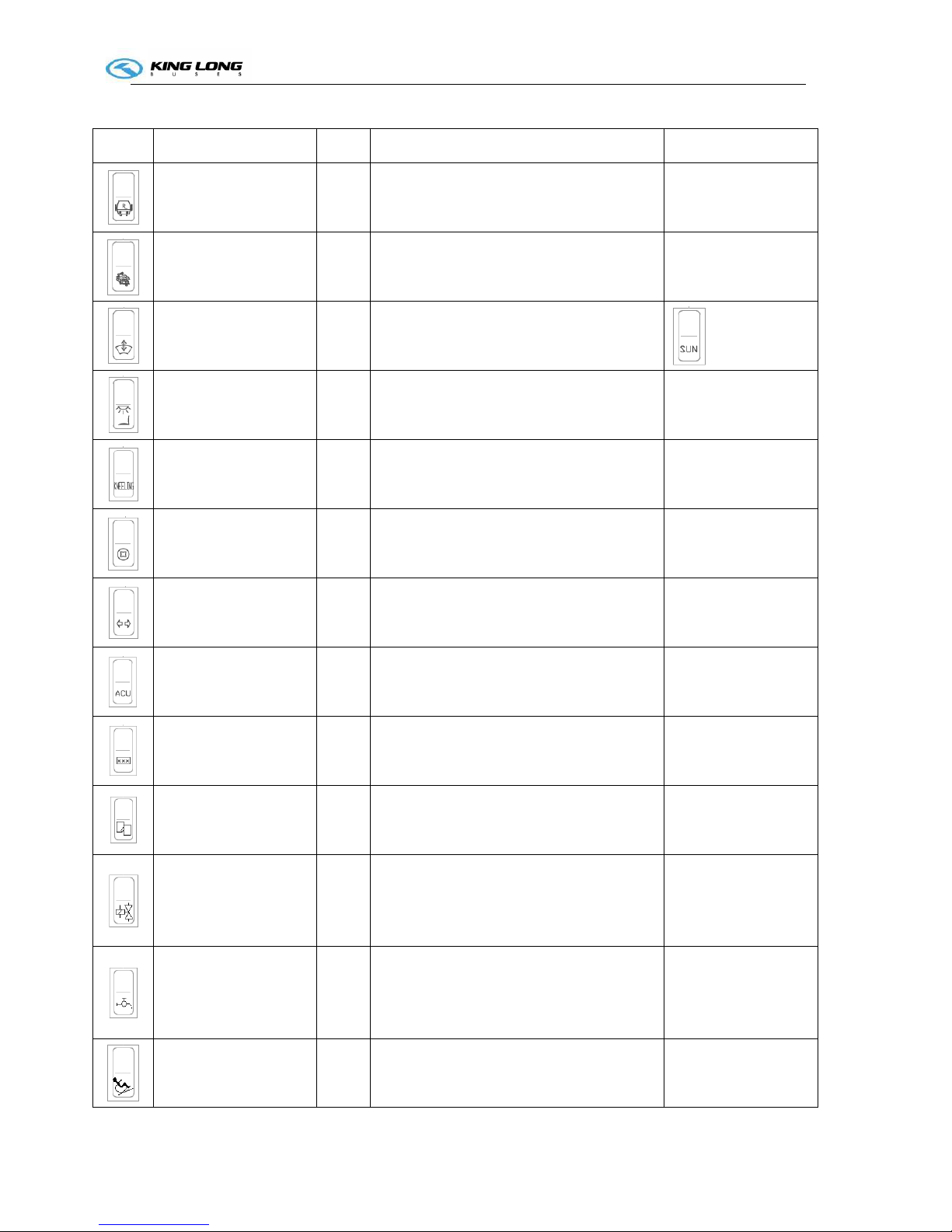

SI-5

Switch Name Color Function Notes

Height adjusting

switch

Green

Pressed on top: switching on the height

adjusting function;

Pressed on bottom: turning off

Side kneeling

setting switch

Green

Pressed on top: switching on the side

kneeling function;

Pressed on bottom: turning off

Engine

diagnostic

switch

Yellow

Pressed on top: switching on the engine

self-diagnostic;

Pressed on bottom: turning off

The engine diagnostic

indicator flashing 3 times

for each code

Operation Instruction

SI-6

Indicator lamp

Color

Function

Red passenger door open indicating

Red natural gas leakage indicating

Red front passenger door open indicate

Red rear passenger door open indicating

Red exit has been open indicating

hollow plate

Yellow ECAS alarm indicating

Red ECAS fault indicating

Red gearbox fault warning indicating

Green retarder indicating

yellow Fuel filter seeper

Hollow plate

Yellow Maintain waiting

yellow Start

Red Stop

Yellow Alarm

Red Water level

hollow plate

Green WC

Red Service

Operation Instruction

SI-7

Indicator lamp

Color

Function

Red Transmission oil temperature too high

Red Transmission fault

White Start-up waiting

Yellow Over emission

Yellow Kneeling lamp

Green Normal height

Red Vehicle in abnormality height

Red Air chamber trouble warning indicator

Red 2

nd

height indicator

Yellow Side kneeling indicator

Red Transmission oil temperature warning indicator

Red Transmission trouble warning indicator

Red Engine major trouble

Red Engine small trouble

Yellow Engine maintenance indicator

Yellow Engine diagnostic indicator

Operation Instruction

P-H-1

Spheros A/C Controller Instruction

1. Display

It indicates the internal temperature and the regulated

temperature.

PS: the display will always show the vehicle internal

temperature even when the motor is off.

2. Key

- On/Off

1st touch – turns on the equipment

- the equipment operates in refrigeration at high velocity

PS: If the led light is blinking, it indicates the compressor still has not started operating. If the light is on,

it indicates the compressor has started operating.

2

nd

touch – the equipment starts operating in refrigeration at low velocity.

3

rd

touch – turns off the equipment.

PS: It is always recommended to turn off the equipment before turning off the vehicle motor.

PS: When the air conditioner is activated for the first time, the compressor will be activated at

approximately 10 seconds. After the air conditioner turning off and its subsequent turning on (without

turning off the vehicle motor) the compressor will be activated at about 30 seconds.

HA – When the command panel shows HA, the compressor and the ventilators of the condenser will be

off for 3 minutes, after that, they will restart working again.

3. Key:

- turn down or up the desired temperature.

When you press any of these keys, the (blinking) display will show the selected temperature. For

turning it down or turning it up, keep pressing one of the keys until you get the desired temperature

value (minimum 16 e maximum 32 ). After 5 seconds without pressing one of the keys, the℃℃

temperature will be recorded and the display will once again show the temperature inside the vehicle.

4. Failure code

When the display shows one of the indications related below, it is an indicator of failures in the system.

HA – Indicates low or high pressure in the system. It may be a condenser obstruction or lack of gas.

OP – Sensor of temperature is open. Select one temperature below 24 so that the equipment may ℃

operate in refrigeration and above 24 so that the equipment may operate in ventilation.℃

SC – Sensor of temperature in short circuit. On such a case, the equipment will operate at an internal

refrigeration temperature of 24 .℃

AL – Indicates the alternator is not charging current.

Operation Instruction

P-H-1

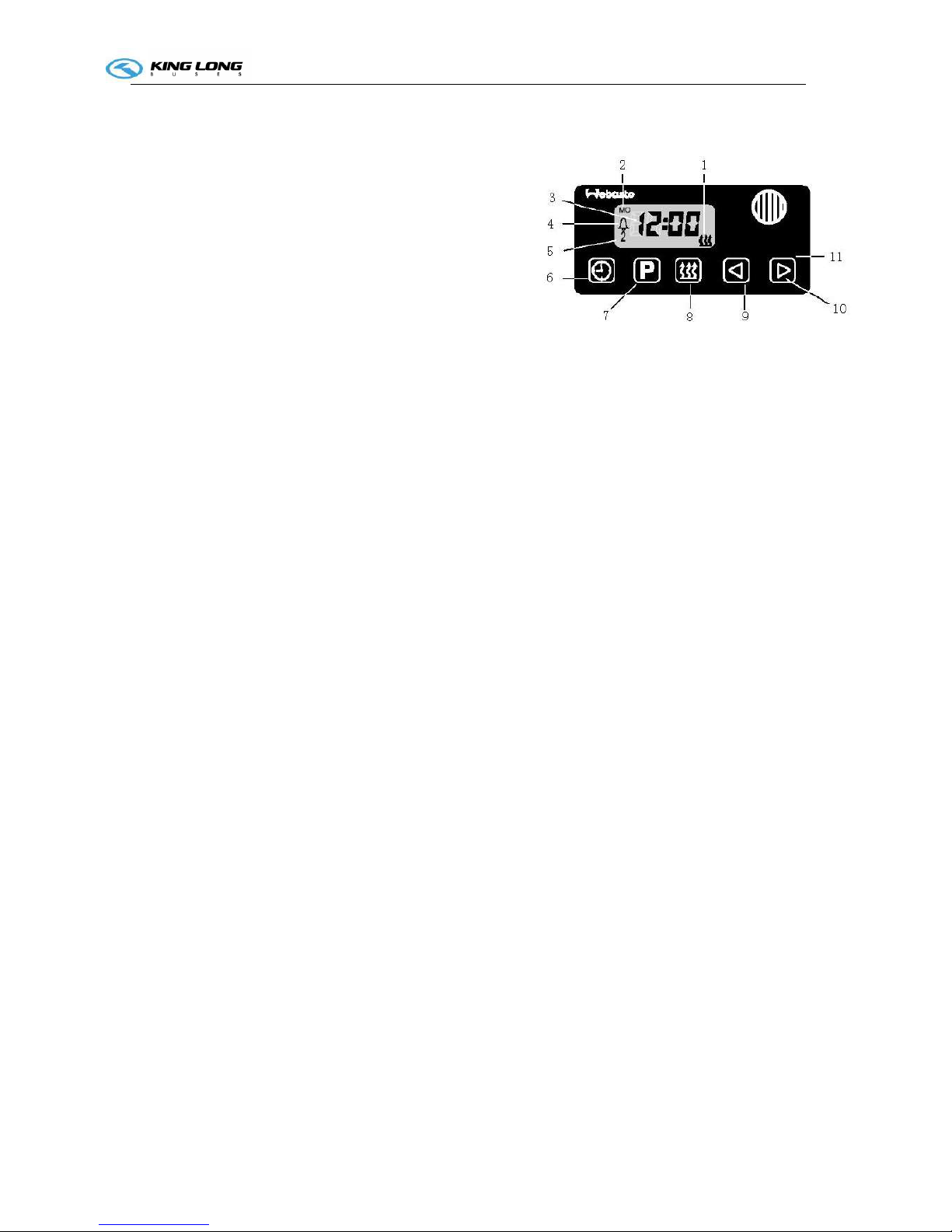

Pre-heater Operation (Webasto)

1. General

The standard digital timer enables you to preset the

start of the heater operation up to 7 days in advance.

It is possible to program 3 different starting times,

only one of which can be activated.

The standard digital timer features a wakeup alarm

function.

When the ignition switched on, the timer displays

the current time and the day of the week.

When the heater is switched on, the display and

the buttons are illuminated.

After the power supply has been connected,

all symbols on the display will flash.

The current time and weekday must be set.

2. Operation

The timer can be operated in that all flashing symbols

can be adjusted by means of the 10 and 9 buttons.

If the buttons are not pressed within 5 seconds,

the time displayed will be stored.

If the 10 and 9 buttons are pressed for more than

2 seconds, the fast time-setting mode is activated.

If the ignition is switched off while the heater is operating in the continuous mode, the

remaining operating time of 15 minutes is displayed and the heater continues to operate for this

period of time.

3. Switch the heater on

Manually: by pressing the button 8 (continuous heating mode)

Automatically: by programming the heater starting time

4. Switch the heater off

Manually: by pressing the button 8

Automatically: after the programmed operating time has elapsed.

With the heater running: by programming the remaining operating time

5. Setting time/day of the week

Press the 6 button for more than 2 seconds-time of the day if flashing-and set the clock using

the 9 and 10 buttons. Day of the week is flashing – adjust the day of the week.

6. Viewing the time

With the ignition switched off: press the 6 button.

7. Programming heater starting time:

1. heater “on” indicator

2. day of the week

3.

time display

4.

memory location

5.

alarm indicator

6.

time

7.

program selection

8.

instant heating

9.

reverse

10.

forward

11. panel

Operation Instruction

P-A-5

Press the 7 button – the memory location is flashing – using the 9 and 10 buttons set start of the

heater operating time. Day of the week is flashing- set the day of the week. By repeatedly

pressing the 6 button, memory locations 2 and 3 can be programmed or the time display mode

can be reached.

8. Recalling/erasing preset times

Repeatedly press the 6 button until the desired memory location is displayed. To erase the

preset time, press the 7 button several times until the time of the day is displayed instead of the

memory.

9. Programming duration of operating time The heater must be switched off. Press the 9

button for 3 seconds – operating time is flashing – and set the desired operating time (10 to 120

minutes) using the 9 and 10 buttons.

10. Setting the remaining operating time

Set the desired remaining operating time (1 to 120 minutes) using the 9 and 10 buttons. The

remaining operating time refers to the time the heater still continues to remain in operation and

the ignition switched off.

11. Setting the wakeup time

A wakeup time can only be programmed on the standard digital timer. The wakeup time is not

bound to a specific day of the week.

Repeatedly press the 7 button until the bell symbol appears on the display. Set the

desired wakeup time using the 9 and 10 buttons. The alarm clock turns off after 5 minutes or

when one of the buttons is pressed.

12. Recalling/erasing the wakeup time

Repeatedly press the 7 button until the bell symbol appears on the display – read off

wakeup time. To erase the wakeup time: press the 7 button until the bell symbol is no

longer visible on the display.

13. remote control

Possible by means of an optional external “instant heating” button

14. Vehicles with ADR equipment

On ADR vehicles it is not possible to program a preset starting time. The remaining time is

shown on the display while the heater is in operation. The clock can be set. The alarm clock

function can be programmed on the standard digital timer.

Operation Instruction

P-A-5

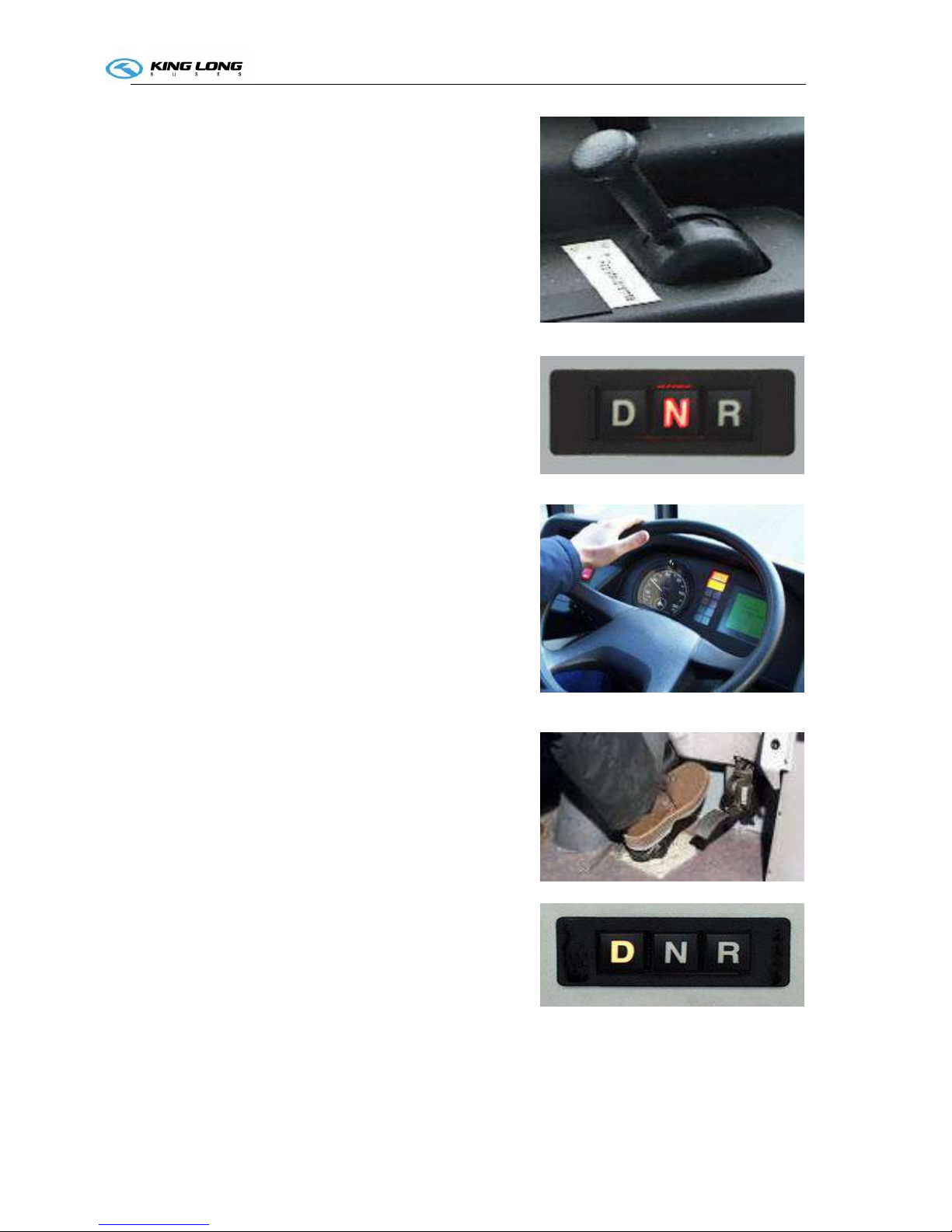

Transmission application (Voith)

Starting the engine

First apply the parking brake.

No button of the push-button switch may be depressed

during starting. Bring all buttons into neutral position by

depressing the button marked ’N’: all but-tons are released,

the ’N’-button

is illuminated.

Under certain conditions it may be possible to start the

engine after pressing any button other than the ’N’-button. In

that case, however, no gear will be engaged even if the

push-button switch indicates this. Make sure you only start

the engine after having pressed the ’N’-button.

Driving forward

If your vehicle is equipped with a safeguard against

inadvertent gear engagement this facility must be operated

first. For that purpose step onto the brake pedal.

Press button ’D’ while the vehicle is at standstill and the

engine idling.

When the brake is released now, the bus will start moving.

Note: If the vehicle fails to move off possible reasons may

be:

– the accelerator was actuated while selecting a gear,

– the safeguard against inadvertent gear engagement was not

released.

Please also consult the operating instructions of the vehicle.

When moving off on a gradient, step on the accelerator

before releasing the brake in order to prevent the vehicle

rolling back.

Note: Driving in the partial load range rather than at ful

throttle or kickdown mode will have a positive

effect on fuel consumption.

Loading...

Loading...