Page 1

PO Box 1200

305 Commerce Drive

Winfield, Alabama 35594

S-ATV-180-U

OPERATION AND PARTS

MANUAL

www.kingkutter.com

Page 2

Page 3

TO THE PURCHASER

This manual contains valuable information about your

new King Kutter ATV Spreader. It has been carefully prepared to give you helpful suggestions for operating, adjusting, servicing and ordering repair parts.

Keep this manual in a convenient place for quick and

easy reference. Study it carefully. You have purchased a

dependable and sturdy spreader, but only by proper care

and operation can you expect to receive the service and

long life designed and built into it.

Sometime in the future your spreader may need new

parts to replace those that are worn or broken. If so, go to

your dealer and provide him with the model and part number.

Customer Information

Name _______________________________________________

Purchased From ______________________________________

Date Purchased ______________________________________

Model No. ___________________________________________

Serial No. ___________________________________________

3

Page 4

It is the purchaser and/or operator ’s responsibility to….

zz

z Read and understand the information contained in

zz

this manual.

zz

z Operate, lubricate, assemble and maintain the equip-

zz

ment in accordance with all instructions and safety

procedures in this manual.

zz

z Inspect the equipment and replace or repair any parts

zz

that are damaged or worn which under continued operation would cause damage, wear to other parts, or

cause a safety hazard.

zz

z Return the equipment or parts to the authorized King

zz

Kutter dealer, from where it was purchased, for service or replacement of defective parts that are covered

by warranty. (The King Kutter Factory may inspect

equipment or parts before warranty claims are honored.)

zz

z Payment of all costs incurred by the dealer for travel-

zz

ing to or transporting the equipment for warranty

inspection and or claims.

4

Page 5

CONTENTS

ITEM PAGE

General Information.................................................6

Technical Data ..........................................................8

Safety Information....................................................9

Operating Instructions...........................................13

Safety Decal's And Locations ...............................14

Spreader Use & Adjustments ................................15

Hopper Loading .....................................................18

General Maintenance .............................................20

Lubrication .............................................................21

Replacement Parts .................................................22

Warranty..................................................................24

5

Page 6

INFORMATION ON THE MACHINE

The models in this manual have been designed and made exclusively allowing

the distribution of solid, granular fertilizers and seeds in the field. Their use is

particularly made for gardening and golf courses but can be used in many more

places. These machines are usually used in daylight. If you need to use the

spreader at night or poor visibility, you must use the lighting system of your tractor or some other source to operate safely.

A use different from described above is considered improper. Any modification

made to the machine relieves the manufacturer from any responsibility of damages or injury that can be caused to operators, third parties, objects or the

spreader.

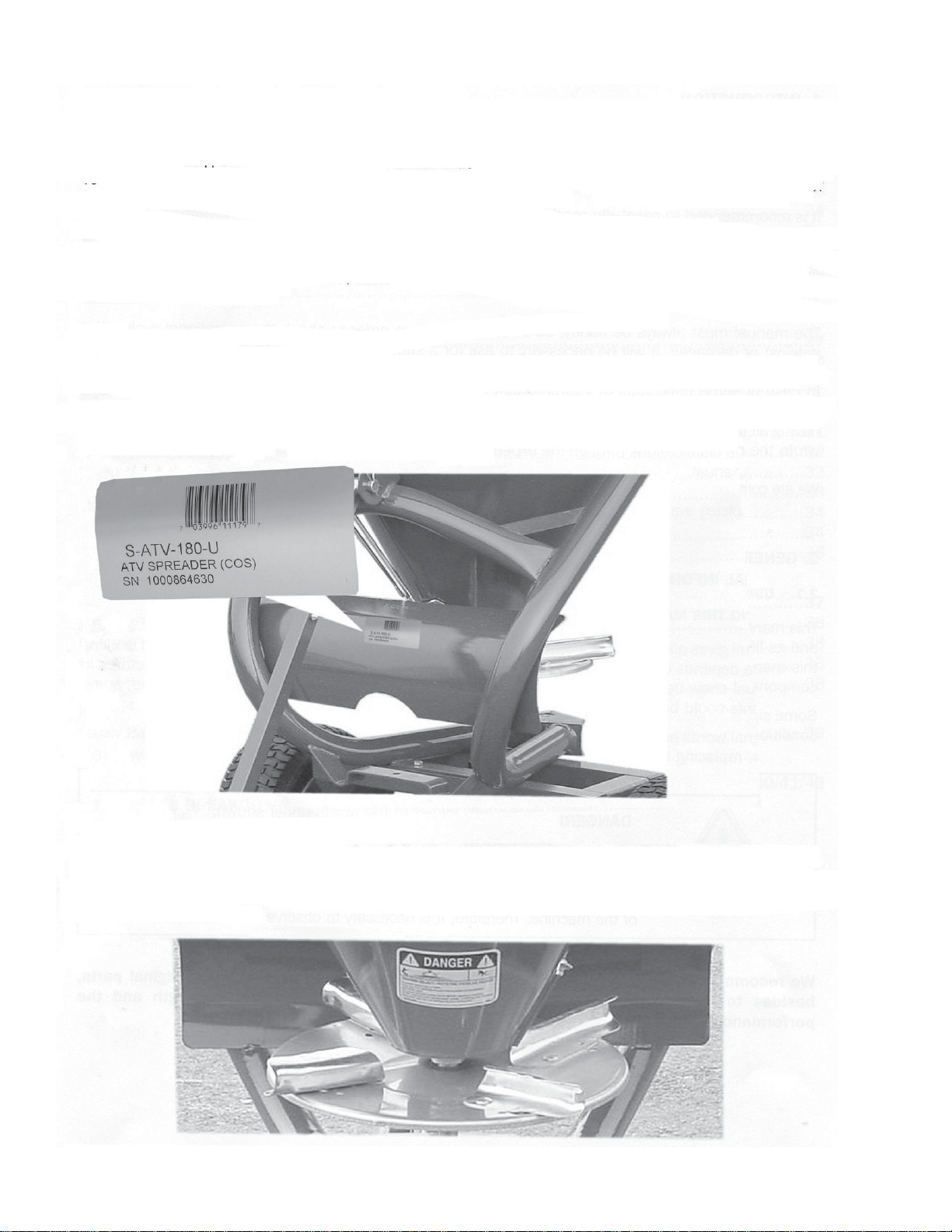

NAME PLATE

On the hopper of every spreader is a nameplate,which has the model number,

serial number and bar code of your machine. When parts are required, it is necessary to refer to the plate for the model of spreader.

CHARACTERISTICS OF THE SPREADER

The pull type spreader has a fertilizer distributor made of stainless steel, a

spreader disc with (4) adjustable vanes with (4) different settings, in order to

obtain the maximum spreading precision and uniformity in the distribution, depending on the material to be spread.

6

Page 7

The feeding of the disc is by gravity through an opening located at the bottom of

the hopper, inside of which a mix/agitator is applied, in order to prevent formation of lumps in the fertilizer. A plate is put in front of the disc to prevent the

speading to the front side of the machine.

The fertilizer delivery is controled by properly opening the shutters in the hopper

bottom, through locking devices operated by levers. The fertilzer spreader and

the agitator are connected through a gearbox with the wheels, so the speed of

the disc is proportionate to the speed of the machine. The switching off and on

of the spreading disc is made by putting or removing the split pin on the axle.

The machine is connected with a ball hitch 1-7/8”.

There is an adjustable tongue so the height

can be adjusted to keep the spreader parallel

with the ground.

The hardness of the steel welded frame, together with the remarkable life of the

hopper, helps to obtain a highest quality level of the pull type spreaders. The

painting is made by an epoxy varnish with successive backing at 150 degrees

celsius with the application of the primer bath, assuring great protection and long

life of the machine.

7

Page 8

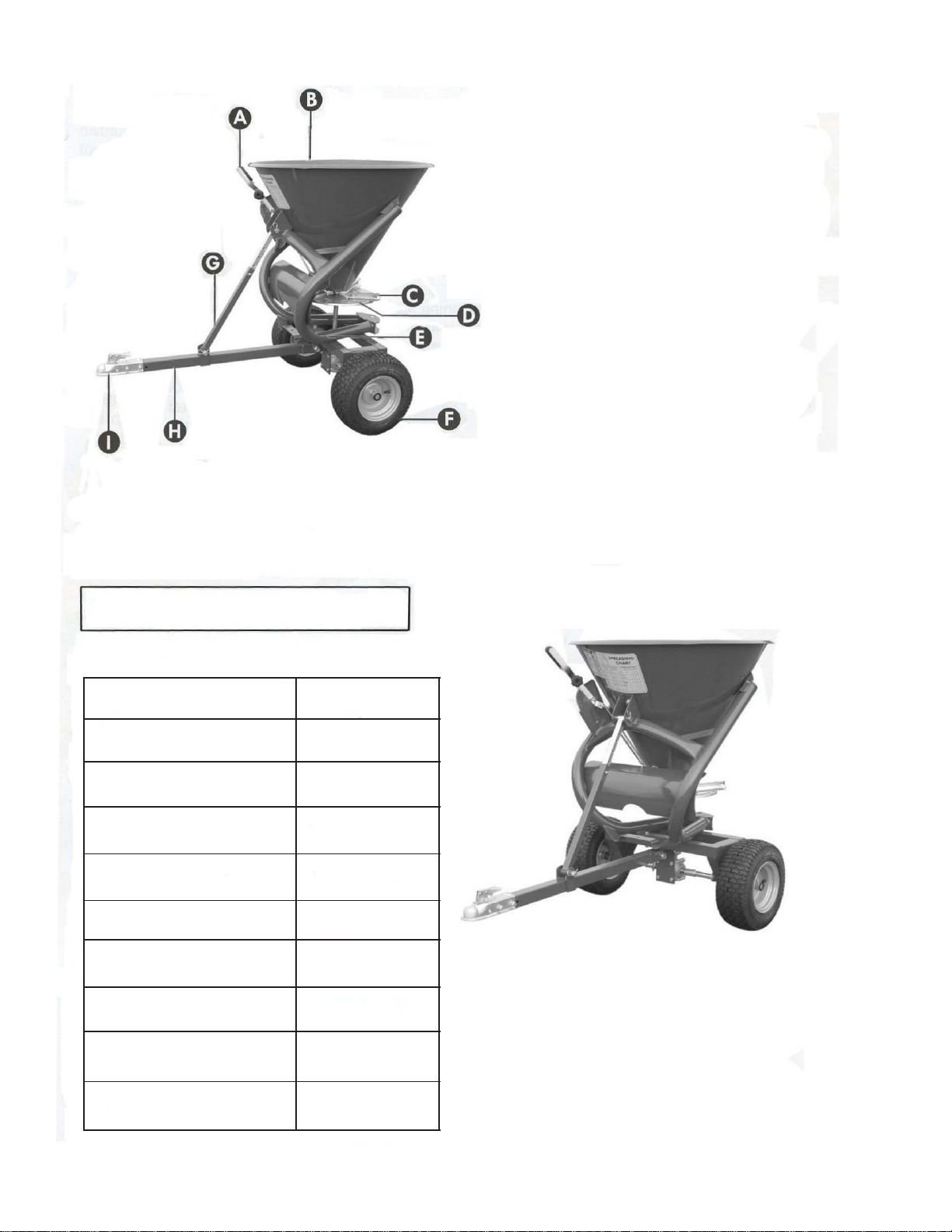

A. REGULATING LEVER

B. HOPPER

C. DISTRIBUTOR VANES

D. SPREADER DISC

E. STEEL FRAME

F. TIRES

G. ROD FOR TONGUE ADJUSTMENT

H. TONGUE

I. 1-7/8” BALL HITCH

TECHNICAL DATA

S-ATV-180

Hopper Capacity

(liters/gallons)

Weight of the Unit

(kgs/lbs)

Width (wheel-wheel, outside)

(meters/inches)

Loading Height

(meters/inches)

Length

(meters/inches)

Hopper Width

(meters/inches)

Ball Hitch Diameter

(cms/inches)

Tires

(type/bar)

Spreading Width

(meters/feet)

165 / 43,6

80 / 175

1,05 / 41”

1,30 / 51”

1,50 / 59”

0,90 / 35”

4,7625 / 1-7/8”

6,5 / 3,2

8 - 12 / 26’ - 40’

Ground Cover Per hour

8

from 27 to 55 ha/h

from 7 to 15 acres/h

Page 9

SAFETY

READ AND FOLLOW THE INSTRUCTIONS IN THIS MANUAL AND ESPECIALLY IN THE SAFETY SECTION.

FAILURE TO DO SO CAN RESULT IN

SERIOUS INJURY OR DEATH.

TAKE NOTE! THIS SAFETY ALERT

SYMBOL FOUND THROUGHOUT

THIS MANUAL IS USED TO CALL

YOUR ATTENTION TO INSTRUCTIONS INVOLVING YOUR PERSONAL

SAFETY AND THE SAFETY OF OTHERS.

SIGNAL WORDS:

The signal words DANGER, WARNING and CAUTION are used with the

THIS SYMBOL MEANS

ATTENTION!

BECOME ALERT!

YOUR SAFTEY IS INVOLVED

safety messages in this manual and with each safety signs. They are

defined as follows:

DANGER: Indicates an immediate hazardous situation that, if not

avoided, could result in serious injury or death. This signal word is to be

limited to the most extreme situations typically for machine components

that, for functional purposes, cannot be guarded.

WARNING: Indicates a potentially hazardous situation that, if not

avoided, could result in serious injury or death, and includes hazards

that are exposed when guards are removed. It may also be used to alert

against unsafe practices.

CAUTION: Indicates a potentially hazardous situation that, if not avoided,

may result in minor or moderate injury. It may also be used to alert

against unsafe practice.

If you have any questions not answered in this manual or require additional

copies or the manual is damaged, please contact your dealer or King Kutter,

Inc. P.O. Box 1200 Winfield, AL 35594 (205) 487-3202 or www.kingkutter.com

9

Page 10

EQUIPMENT SAFETY GUIDELINES

z Safety of the operator and by standards is one of the main concerns in designing and

developing a spreader. However, every year accidents occur which could have been

avoided by a few seconds of thought and a more careful approach to handling equipment. You, the operator, can avoid many accidents by observing the following precautions and insist those working with you, or for you, follow them.

z In order to provide a better view , certain photographs or illustrations in this manual may

show an assembly with a safety shield removed. However , equipment should never be

operated in this condition. Keep all shields in place. If shield removal becomes necessary for repairs, replace the shield prior to use.

z Replace any safety sign that is not readable or is missing. Copies of such safety signs is

shown in this manual.

z Never use alcoholic beverages or drugs that can hinder alertness or coordination while

operating this equipment. Consult your doctor about operating this machine while taking

prescription medications.

zz

z Under no circumstances should children under the age of 18 be allowed to work

zz

with this equipment. Do not allow persons to operate or assemble this unit until

they have read this manual and have developed a thorough understanding of

the safety precautions and of how it works. Review the safety instructions with all

users annually .

z This equipment is dangerous to children and persons unfamiliar with its operation. The

operator should be a responsible, properly trained and physically able person familiar

with farm machinery and trained in this equipment’s operations. If the elderly are assisting with farm work, their physical limitations need to be recognized and accommodated.

z Use a tractor equipped with a Roll Over Protective System and seat belts. (ROPS)

z Never exceed the limits of a piece of machinery . If its ability to do a job, or to do so safely,

is in question- DON’T TRY IT.

z Do not modify the equipment in any way . Unauthorized modification could result in seri-

ous injury or death and may impair the function and life of the equipment.

z In addition to the design and the confirmation of this implement, including safety signs

and safety equipment, hazard control and accident prevention are dependent upon the

awareness, concern, prudence, and proper training of personnel involved in the operation, transport, maintenance, and storage of the machine. Refer also to safety messages

and operation instruction in each of the appropriate sections of the tractor and seeder/

spreader manuals. Pay close attention to the safety signs affixed to the tractor and the

seeder.

10

Page 11

IMPORTANT SAFETY INFORMATION

-----------------------------------------------------------------------------------------------------------THE FOLLOWING SAFETY RECOMENDATIONS ARE FOR YOUR SAFETY.

THEREFORE IT IS NECESSARY TO READ THEM CAREFULLY, MEMORIZING AND ALWAYS APPLYING THEM.

------------------------------------------------------------------------------------------------------------

The present warnings in this manual regard exclusively the allowed uses and

reasonably foreseeable dangers. All below instructions must be integrated by a

common sense, experience worker to prevent accidents.

The spreader must be used by a single operator . The use of the spreader is forbidden to

youngsters. All the listed instructions must be carefully respected. Changes to the spreader

are not authorized by the manufacturer and exclude his responsibility .

Check the correct operation of the machine prior to each use.

General Advices

Read carefully this manual before proceding to start, operate, or to perform maintenence on

the spreader.

Watch, in addition to the warnings to this manual, all the safety , accident prevention rules

and general rules.

The manual must always be handy , so as to consult it, in order to check the working cycle

and safety information.In case of loss or damage, it will be necessary to get another copy .

ATTENTION

Any work of maintenance, regulation and cleaning must be done with

the machine on the ground (in stable conditions), turning off pulling

vehicle engine and removing the key.

Read carefully the safety signal words applied on the spreader and follow the instructions. In case

of wear and tear or insufficient readability of the safety signal words, clean them up or replace

them, placing the signal words in the right position.

A TTENTION! - W ARNING!

The operator, during the period of use,

maintenance, repair , handling or

storage of the machine, must wear safety shoes and safety gloves. Moreover, if it

is necessary , that the operator must wear suitable hearing protection such as

ear muffs or earplugs, dust masks and protective glasses.

During loading phase, there is the danger of powders inhalation produced by fertilizer mixing. It is

suggested to use tractors with filters on the ventilation system of the cabin, to use suitable safety

systems of breathing, like powder masks or masks with a filter .

The spreader is designed to be used by one operator at a time, who during the use must always

stay in the pulling vehicle seat.

Never work with this machine if you are tired, sick, or after have taken drinks, drugs or medication.

11

Page 12

DANGER! It is forbidden to climb or to transport someone when the spreader is in motion. Do not let anyone

inside the hopper for any reason.

Keep the spreader clean from foriegn bodies (debris, tools, miscellaneous), as they could

damage the operations or the operator . Generally the fertilizers are rather corrosive. For this

reason, it is important that no particle of fertilizer stay in the spreader for a long period of

time. Clean the hopper and distributor after each use.

If during cleaning operations you use air or water with pressure, it is necessary to wear

glasses and safety masks and keep animals and other people away during cleaning.

Before connecting machine to the pulling vehicle check that it is in good condition and that

the brakes work properly , especially if working on sloping ground.

Unhook the machine from pulling vehicle only on level, compact ground (with hopper empty),

checking that the spreader is stable.

W ARNING!

During transport, operating, loading and spreading of fertilizers, the operator must follow all the label indications and particularly to the content of the written risks and precautions.

ATTENTION!

The manufacturer does not cover damages caused by

improper use of the spreader.

The manufacturer is not responsible in case of:

- improper use of spreader, used by non trained person.

- serious deficiencies in the maintainance of spreader.

- changes or modifications that are not allowed.

- use of anything except original replacement parts.

- not observing partial or all of instructions.

- unusual cases.

12

Page 13

OPERATION OF THE MACHINE

Make a check of the spreader before switching it on. Start to work only if spreader is

in perfect condition.

Before using the spreader please be sure that all safety devices are correctly in place

and in good working condition; in case of breakdowns or damages to the guards,

please replace them immediately .

A TTENTION!

During work, please be sure there is no person or animals within 50 meters.

When you work close to roads or public places, it is ABSOLUTEL Y

NECESSARY to keep people away and to increase the precautions.

A TTENTION!

Anybody who comes up to the spreader while in use is in a danger

area, therefore they become “AN EXPOSED PERSON”. The operator

must prevent anyone from coming into the danger area and work with

maximum caution. If someone comes up, stop spreader immediately .

- Before every use of the spreader, please always check the wear of the vanes and

the spreader disc. Check that all screw and bolts are in and tight.

- The machine must never be unattended while moving.

- Always keep the machine in good operating condition and perform maintenance

regularly.

TRANSFER ON THE ROAD

A TTENTION!

Please follow the Highway Code carefully that is in force for the country

or state you are using spreader in. During transport on public roads it is

necessary to empty the hopper .

Remember that during moving on public roads, special attention must be taken.

refer to possible and special regulations noted on pulling vehicle manual,

choosing the proper speed especially when the street is crowded, winding or

sloping. If the spreader hides the back signal lights of pulling vehicle, it is necessary to put a light bar and/or some back

signaling signs.

During transport on the road, the gearbox must

not be engaged. Switch off the mechanical block

from the axle, as shown in the picture to the right.

13

Page 14

SAFETY SETTINGS

A TTENTION!

Be sure that the safety labels are readable. Clean them up using a

cloth, water and soap. Replace damaged labels placing them in

the right position.

The safety signs on the machine supply the most improtant indications: their observance helps your safeness.

1. ATTENTION!

Before doing any work or repair on the spreader, stop the

engine of the pulling vehicle, remove the key, put on the

parking brake and read the operator’s manual carefully.

2. A TTENTION! - DANGER!

Possibility of throwing of material and/or objects, please

do not come up to machine. Keep a safe distance of at

least 50 meters (165 Ft.) from the machine.

3. A TTENTION! - DANGER!

It is forbidden to get inside the hopper or to transport

someone with the machine.

4. ATTENTION!

Use the devices of individual protection

required.

14

Page 15

PULL TYPE SPREADER USE

ATTENTION! - Before use, please check that zerks

are adequately greased (see page 21).

A TTENTION! - During the use of the spreader , please be

sure there are not any persons or animals within 50 meters

(165 Ft.). If someone comes up please stop immediately .

Recommendations for correct distribution

- Please always test lbs/acre you want to spread before starting to work.

- Use a fertilizer or seeds in perfect condition: a humid fertilizer cannot be spread

uniformly and correctly .

- A void spreadiing fertilizer or seeds on windy days, in order to improve the uniformity of the distribution.

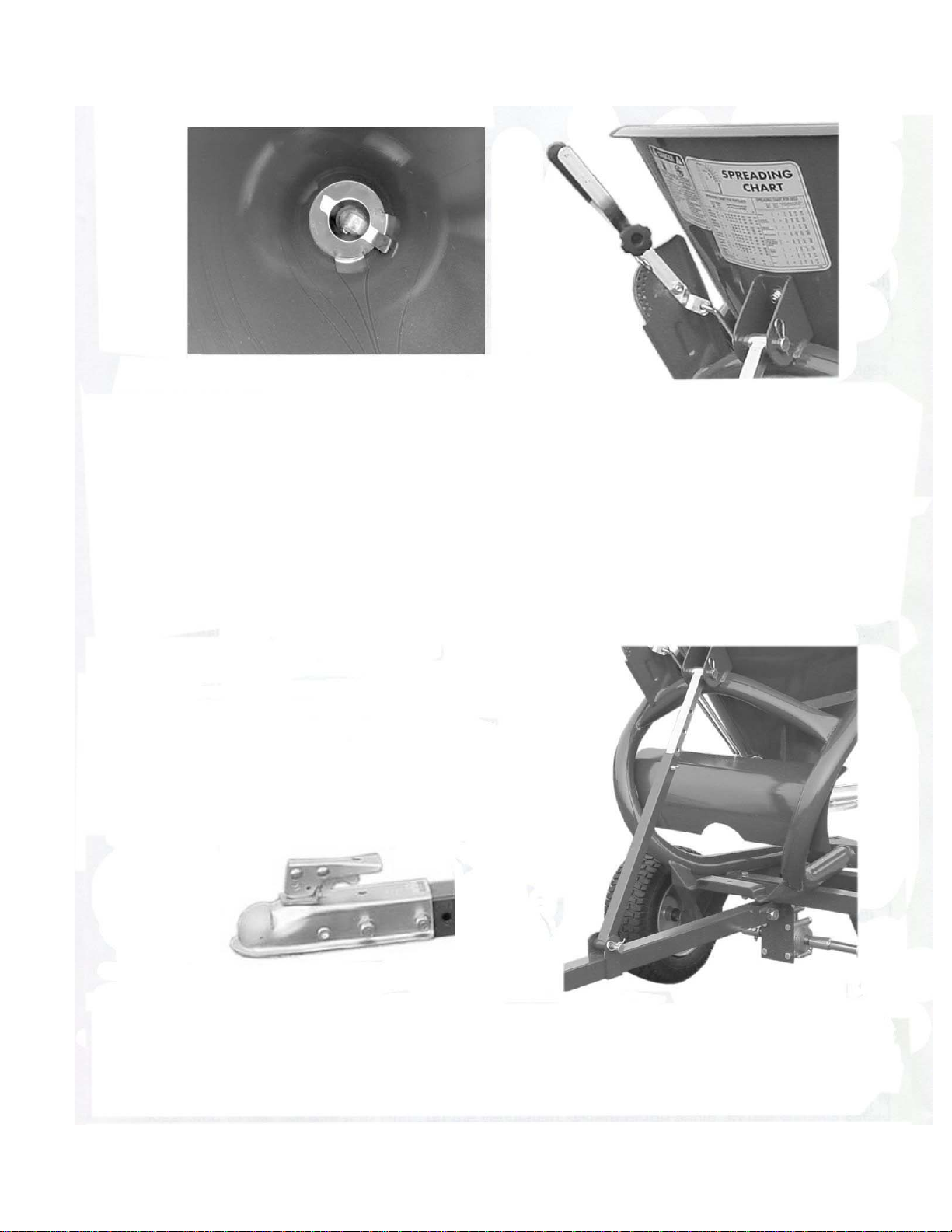

Connections

The pull type spreader can be hitched to every type of tractor or atv with 1-7/8” ball

hitch providing it has the horsepower to pull it . T o make the connection, it is necessary to put the ball hitch in the coupler on the pull type spreader, locking it pushing

the lock handle towards the bottom. Check and regulate the length of the regulation

tongue rod, so that the spreader disc is, as parallel as possible, to the ground in

order to get a uniform distribution of the fertilizer or seed. Unscrew the locking bolt,

as shown with the arrow in the picture below and move the rod to the position mak-

ing unit parallel and lock the bolt in the new position.

Locking Bolt

Shaft Regulation Bar

Correct position of the spreadiing disc.

15

Page 16

Adjustments

It is not possible to have an exact spreading chart for equipment that makes use of

the centrifugal force principle, the distributed quantity depends on the speed , on the

radius of distribution, on the quality and humidity of the fertilizer or seed and roughness of the land. The fertilizer must always be stored and conserved adequately , so

as to keep it’s physical characteristics unchanged. It is necessary to set the speed of

the pull spreader , before starting the operation of distribution, trying, in the possible

limits, to keep it constant for the total duration. The spreading chart contains the

information, in order to determine the quanity to spread in a field; these must be

completed by the experience and competant operator .

How T o Adjust The S preader Vanes

In order to assure an even distribution on both sides of the spreader , depending on

the different specific weight of the material used, the vanes on the disc can be set to

different positions.When all the vanes are put in hole 1 (Shown in picture), the distribution of the material is increased towards the left compared to the way the tractor is

moving. But if you put the vanes in hole 4, the distribution will be more towards right.

Moving vanes from position 1 to 4 on same speed there will be an increase in the

distibuting width. This regulation must be made compared to the type of material you

are spreading and from experience.

Spreading disc’ s vanes regulation

Such a regulation must be done in accordance with the material type that is

used and the operators experience.

16

Page 17

HOW TO ADJUST THE SPREADING

The material spreading is regulated through the regulation lever that moves the

opening section on the bottom of the hopper. In order to carry out the regulation,

after having consulted the spreading table, acording to the type of material to spread

and to the speed of pulling vehicle, it is necessary to move the lever “A” along the

graduated scale “E” and locking it in the chosen position with pin “D”.

In order to spread from both sides (ref. I), “A” and “B” levers must be in

the same position, connected through grip handle “C”. In order to carry

out the spreading only through the left side (ref. II), it is necessary to

disconnect the two levers removing the “C” grip handle, to set the lever

“B” in the chosen position, given by spreading chart, and to bring the

lever “A” towards the higher part (position1) in order to close the shutter

of the right side. In oreder to spread only to the right side (ref. III) you

have to move lever “B” up, ( in position 1) and regulate the quantity to

spread with lever “A”.

17

Page 18

HOPPER LOADING

It is advised not to load the hopper manually but by using a lift or suitable

mechanical means.

A TTENTION! The hopper must be loaded only af ter

having hitched the spreader to a pull vehicle.

Do not drive for very long distances with a full load and do not put full bags on the

material in the hopper during transport to the field or during working, in order not to

overload the capacity of the machine and compress the material.

WARNING! During the operations of transport, loading and use of

spreading materials, the operator must behave in compliance with the

instructions on the labels of the product and in particular with the

content of the sentences of risk and the precaution advices.

SPREADING OF THE MA TERIAL IN THE FIELD

ATTENTION! - WARNING! The operator

during the period of use, maintenance,

repair, transport or storing the machine

must wear accident prevention shoes and gloves. If it is necessary operator must wear headset, mask and glasses.

After having hitched spreader to pulling vehicle and carried out necessary precautions it is now possible to begin work.

ATTENTION! Before getting off of pulling vehicle and be-

fore every operation of maintenance, set the parking brake,

turn off the engine and remove ignition key and wait until

all moving parts have completely stopped.

Engage the axle with the pin, so so that the

spreader can be set in action by the turning

wheels, only when you are ready to start

spreading.

18

Page 19

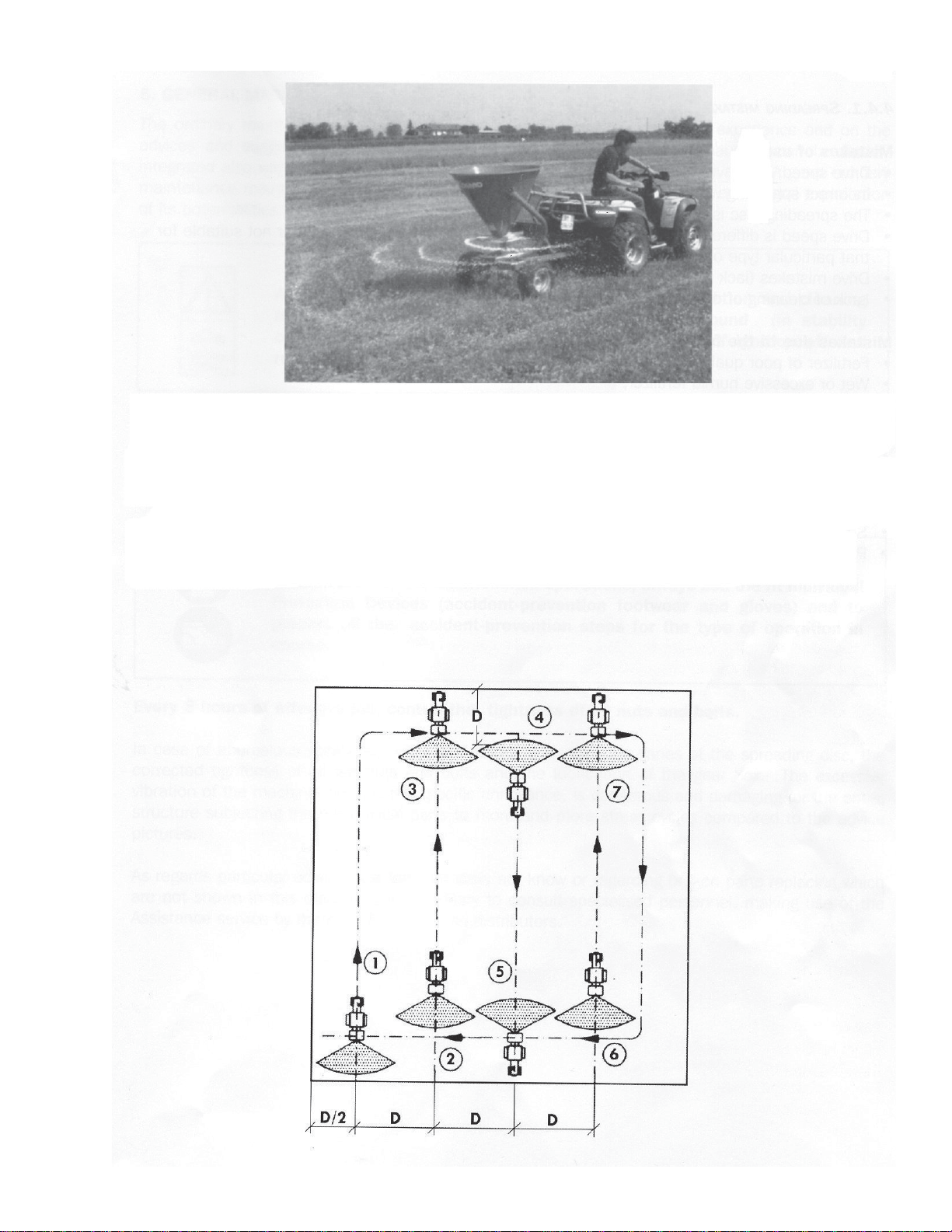

Various ways exist to spread the material in the field. One of the simplest

methods is, as follows:

Position spreader at the beginng of the field you intend to fertilize or seed, to a

distance (D/2) that is the half of the working width that is used (point 1);

Driving in the field distributing the fertilizer or seed on all the perimeter;

Stop at one distance (D) from the point 1, equivalent to the set working width

(point 2);

Beginning the spreading proceeding in line, straight to point 3.

Turn and drive a D distance, equal to the working width (point 4);

Repeat such procedure until all the field is covered.

19

Page 20

SPREADING MISTAKES

Mistakes of use

- Drive speed;

- incorrect spreading width;

- The spreading disc is not in a horizontal position compared to the land;

- Drive speed is different to those suggested by the spreading tables, or speed is not suitable

for that particular type of material;

- Drive mistakes, (lack of overlap of the spreading surfaces);

- Lack of cleaning of distributing vanes and disc.

Mistakes due to fertilizer

- Fertilizer of poor quality.

- Wet or excessively humid fertilizer;

- Incorrect fertilizer composition or it doesn’t correspond to what is declared from the vendor.

- Presence of excessive lumps in fertilizer or with dimensions to large to go through exit.

- Foriegn body in the fertilizer.

Mistakes due to the spreader

- Spreading exits clogged;

- Parts of the spreading disc worn or damaged.

GENERAL MAINTENANCE

The ordinary maintenance criteria we suggest are based on the company experience and on

the advice and suggestions from customers. A good maintenance schedule keeps the operating costs of the spreader low and allows for a long spreader life.

ATTENTION! Whichever work of maintenance, regula-

tion and cleaning must be carried out on the spreader on

the ground ( in stable conditions), engine turned off, brake

on, ignition key off and removed.

In case of damage, the operator must stop the machine immediately, assess the problem and

proceed only after problems are repaired. If pressured water or compressed air is used for the

cleaning of the machine, it is necessary to protect yourself with proper glasses and/or protection masks and to remove people and/or animals from near machine. Do not use flammable

liquids.

ATTENTION! For maintenance operations, always use the

proper Individual Protection Devices(safety shoes and

gloves) and to take all the accident protection steps for the

type of operation to be performed.

Every 8 hours of operation, check the tightness of all nuts and bolts.

In case of unusual vibrations, check the wear of the vanes and spreading disc, the tightness of

all nuts and bolts and lubrication of gearbox. The excessive vibration of the spreader, besides

being annoying is dangerous and damaging for the entire structure, subjecting the mechanical

parts to more and more stress. It may be necessary to seek the help of specialized personnel

regarding some broke parts replacement that are not shown in this manual.

20

Page 21

LUBRICA TION

Before every use and after every 8 hours of use, grease the spreader. Be sure that the

grease zerks are clean from dirt and debris before injecting with grease. Lubricate with

(with a grade II type tube grease) at the points shown in the picture, both sides of axle.

The unit comes with grease in the gearbox, there is a plug (see picture on left) on the

bottom of the gearbox that a flathead

screwdriver will fit if you ever need to

add grease. When adding grease to

gearbox remove plug and pump full of

grease.

REPLACEMENT OF SPREADER V ANES

In case the spreader vanes brake or get damaged, it is

necessary to replace them with new ones. Unscrew the

nut and replace the damaged vane. The nuts and bolts

must be of the same type of those prescribed from the

manufacturer.

STORAGE

Don’t wait until you are ready to use the spreader to

do the repairs and maintenance. It is best to repair and

replace the damaged and broken parts before storing

after last use. So it will be ready for next use.

Store the spreader in a sheltered place away from atmospheric agents and protect it in

order to avoid deteriorations. The fertilizers are generally corrosive. For this reason it is

important that no particles of fertilizer remains on any part of the spreader for long periods of time.

Before storing for long periods,

- thoroughly wash the spreader and especially inside the hopper and spreading disc;

- look over the spreader thoroughly and check for structural damages, looking for deep

abrasions in the paint;

- verify that the safety signs are on the spreader and readable, In case they are torn and

unreadable, replace with new ones.

- grease all mechanical parts.

- store spreader in a sheltered, dry place if possible.

SP ARE P ARTS

For the replacement of parts the customer must use original parts, ordering them from

the manufacturer or an authorized dealer .

When ordering parts it is necessary to have your model number.

21

Page 22

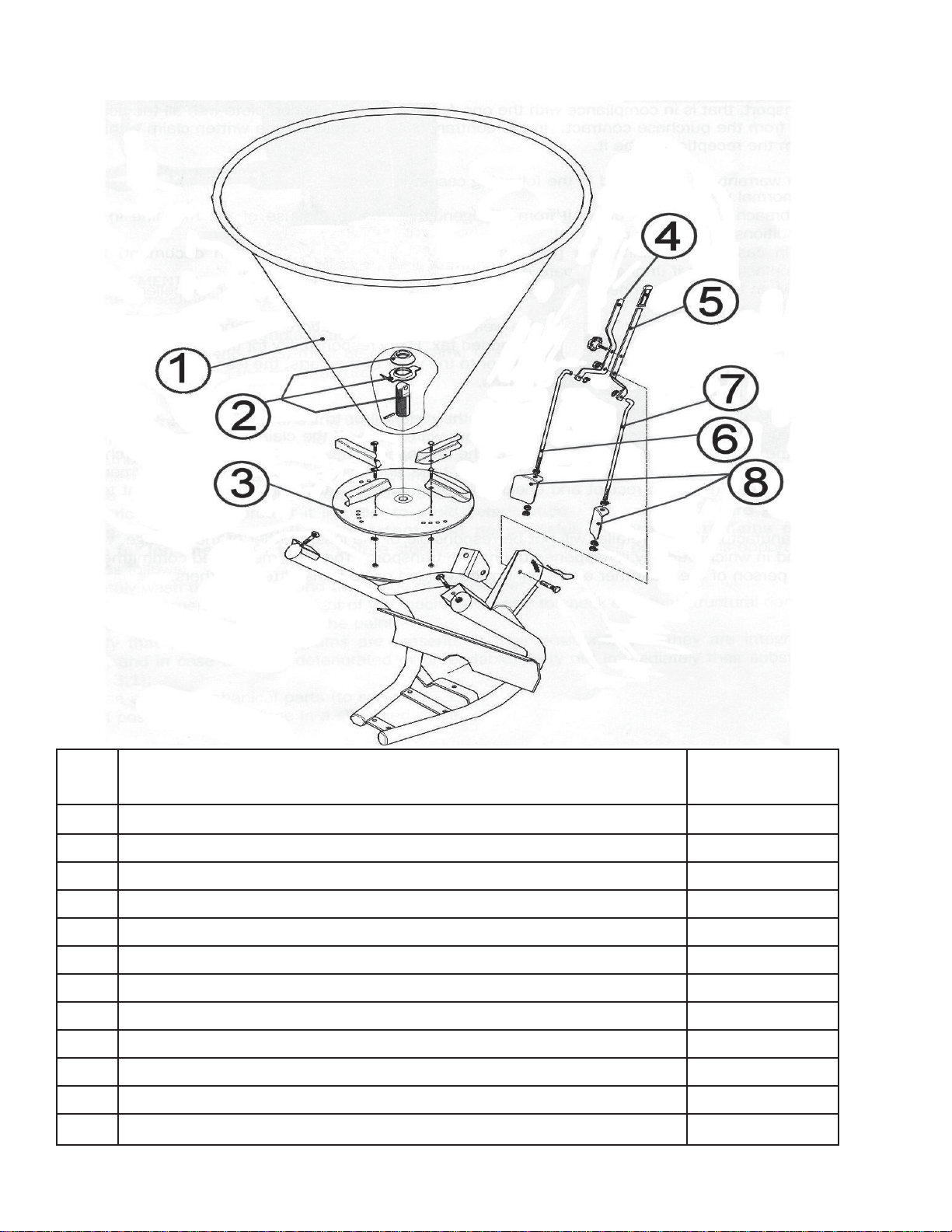

S-ATV-180 PARTS

Ref.

No.

1 Hopper 900124

2

3

4

5

6

7

8

22

Spreader Disc with Blades

Right Hand Shutter Lever - Long

Left Hand Shutter Lever - Long

Right Hand Lever Tie Rod

Left Hand Lever Tie Rod

Shutters- (1) Left & (1) Right

Part Name

Lower Agitator Kit

Part Number

509000

900004

900132

900131

900123

900121

509001

Page 23

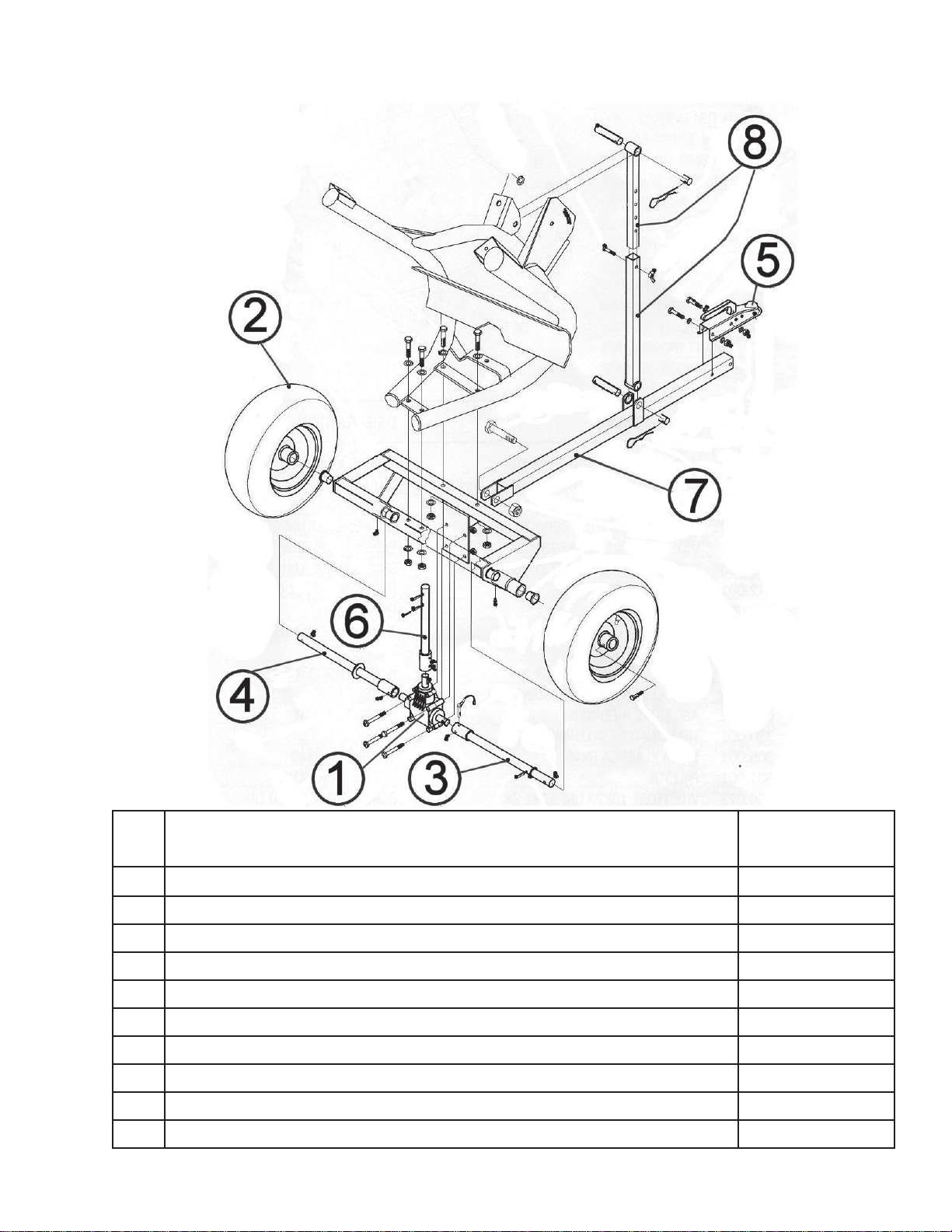

S-ATV -180 PARTS

Ref.

No.

1 Gear Box 900125

2

3

4

5

6

7

8

Output Shaft with Bushing

Tow Bar for 1-7/8” Hitch

Part Name

Tire 16 x 6.50-8

Left Axle

Right Axle

1-7/8” Ball Hitch

Tongue Rod

Part Number

900126

900127

900128

195169

900129

900118

900119

23

Page 24

1. Limited Warranty .

King Kutter, Inc. (“King Kutter”), P.O. Box 1200, W infield, Alabama 35594, warrants to the original retail

purchaser (“Purchaser”) that the product that is the subject of this sale is free from defects in material and

workmanship at the time of sale.

Under this warranty , King Kutter will repair the defective product free of charge to the Purchaser , with either

new or used and reconditioned replacement parts. All warranty service will be performed at service centers designated by King Kutter. If King Kutter is unable to rep air the product to conform to the warranty after

a reasonable number of attempts, King Kutter will provide, at its option, one of the following: (a) a replacement for the product or, (b) a full refund of the purchase price. Repair, replacement, or refunds are the

Purchaser’s EXCLUSIVE remedies against King Kutter under this limited warranty. King Kutter will not be

liable for any special, incidental or consequential damages based upon breach or warranty, breach of

contract, negligence, strict tort liability , or any other legal theory . Such damages include, but are not limited

to, loss of profits, loss of savings or revenue, loss of use of the product or any associated equipment, cost

of capital, cost of any substitute equipment, facilities or services, down time, the claims of third parties

including customers, and injury to property. These limitations also apply, to the extent allowed by law, to

personal injury .

The purchaser must notify the Seller in writing of any defect in material or workmanship within one (1) year

following the date of purchase. If the equipment is used for commercial purposes, the Purchaser must

notify the Seller in writing of any defect in material or workmanship within ninety (90) days following the date

of purchase. In no event will King Kutter be liable under this warranty unless written notice is received by

the Seller within one (1) year from the date of original retail sale.

2. Warranty of Title.

King Kutter warrants that it transfers a good title to the product free of any encumbrances, and free of the

rightful claim of any third party for infringement of patent or copyright.

3. What is Not Covered by This Limited Warranty.

King Kutter will not be responsible for damage to or failure in the product which results from accident,

misuse, abuse, neglect, installation of attachments not provided by King Kutter, modifications to the product, or damage caused by use of the product for purposes other than those for which it was designed.

4. No Other Warranties.

Unless modified in writing and signed by both parties, this agreement is understood to be the complete and

exclusive agreement and warranty between King Kutter and Purchaser, superseding all prior agreement s,

oral and written, and all other communication between King Kutter and Purchaser related to the subject

matter of this agreement.

THIS LIMITED WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY AND THE IMPLIED

WARRANTY OF FITNESS FOR A P ARTICULAR PURPOSE. No employee of King Kutter nor anyone else

is authorized to make any warranty or representation in addition to or different from those made in this

agreement.

5. Allocation of Risk.

This agreement allocates the risk of product failure between King Kutter and the Purchaser. This Allocation is recognized by both parties as reflected in the price of the goods. The Purchaser acknowledges that

he or she has read this agreement, understands it, and is bound by its terms.

Loading...

Loading...