OWNER’S MANUAL

3125 | 3425 gfx offshore

TABLE OF CONTENTS

SECTION 1 – WELCOME ABOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SECTION 2 – SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

PREPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SAFE BOATING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

IMPORTANT LABELS AND WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

WARNING LABELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

CAPACITY / CONFORMITY LABEL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

EXHAUST EMISSIONS HAZARD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SECTION 3 – OPERATOR AND PASSENGER SAFETY . . . . . . . . . . . . . . . . . . . . . . . .7

BOAT OPERATORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SAFE BOATING PRACTICES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

SECTION 4 – BOAT CHARACTERISTICS AND OPERATION . . . . . . . . . . . . . . . . . . . . .9

GETTING TO KNOW YOUR BOAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SAFE OPERATION, CARE AND ATTENTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

OPERATING TIPS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

POST OPERATION CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

TRAILERING YOUR BOAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

TRAILER CHECKLIST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SECTION 5 – MAINTENANCE AND CARE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

EXTERIOR MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

COMMON TYPES OF CORROSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

NEW COMPONENT INSTALLATION INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

INTERIOR MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

MAINTENANCE AND ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

STORAGE AND WINTERIZING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

RE-COMMISSIONING BOAT AFTER STORAGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3125

|

3425 OWNERS MANUAL KINGFISHER BOATS III

SECTION 6 – System and Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

THRU HULL LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

ELETRICAL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

BOAT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

ANCHOR ROPE AND CHAIN REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

OPTIONS AND FEATURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

BATTERIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

TRIM TAB OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

BOW THRUSTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

WATER AND PLUMBING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

FRESH WATER SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

SECTION 8 – TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SECTION 9 – NAUTICAL TERMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

SECTION 10 – MAINTENANCE LOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Iv KINGFISHER BOATS 3125 | 3425 OWNERS MANUAL

SECTION 1 – WELCOME ABOARD

Please read this manual completely before operating your

boat for the rst time. It is a valuable reference and should

help you answer most questions about caring for your boat,

how to operate it and your responsibilities as the boat’s

operator.

Take the time to complete and submit the Warranty

Registration. Failure to submit the registration or neglect

or improper care of your boat may void the warranty. The

best way to protect your new KingFisher is to carry out

regular maintenance and inspect your boat regularly as

recommended in this guide.

This manual refers to other manuals that come with your

boat’s equipment and accessories. It is essential you read

all manuals and become familiar with the care, maintenance

and safe operation of all the equipment aboard your boat.

KingFisher wants you to maximize your boating experience

and to be safe every time. If you are missing manuals, see

your KingFisher dealer for a replacement.

In Section 1 of this manual, you will nd a place to record

information such as your engine and boat serial number,

and your dealership contact information. Keep this

information with your boat for easy reference.

If you have any questions about your boat, consult your

KingFisher dealer. If you have any questions about boating

regulations, contact the local United States Coast Guard,

Transport Canada Ofce of Boating Safety or Canadian

Coast Guard, Fisheries and Oceans Ofce.

Before you go boating it is wise to read your boat Owner’s

Manual and go through the pre-trip safety checklist found

in Section 2. Ensuring that your boat is in perfect working

order before beginning a voyage will allow you to get the

most enjoyment out of your boat.

Important Identication Number Records

Record your serial numbers of your hull and motor(s).

The Hull Identication Number or H.I.N. is located on

the starboard side of the transom. Consult the engine

manufacturer’s owners manual for engine serial number

location.

HULL IDENTIFICATION NUMBER:

QBSY _____________________________________

MOTOR 1 SERIAL NUMBER:

___________________________________________

MOTOR 2 SERIAL NUMBER:

___________________________________________

KICKER SERIAL NUMBER:

____________________________________________

Note: It is also recommended to record the serial numbers

of other signicant items if your boat is so equipped.

____________________________________________

____________________________________________

____________________________________________

____________________________________________

3125

|

3425 OWNERS MANUAL KINGFISHER BOATS 1

2 KINGFISHER BOATS 3125 | 3425 OWNERS MANUAL

SECTION 2 – Safety INFORMATION

PREPARATION

Before starting your voyage, ensure that you are

familiar with applicable boating regulations for

the region. These can be obtained from Transport

Canada Ofce of Boating Safety or your local

United States Coast Guard ofce.

Below is a safety checklist that should be performed every

time you head out on the water.

❏ Ensure your boat insurance and vessel

license are complete and up to date

❏ Check your on-board safety equipment, including but

not limited to:

• Paddles

• Class 5BC Fire extinguisher

in good working condition

• Bailing container

• Watertight ashlight

• Type A, B, or C ares on board and that they are

not expired. (Vessels less than 6m must carry 3,

and vessels over 6m must carry 6)

• Buoyant heaving line at least 15m in length

❏ Check the horn

❏ Ensure you have a container to collect any garbage

❏ Check the weather report

❏ Always have someone along who can operate

the boat if you become incapacitated

❏ Make sure you and your guests are wearing

approved personal oatation devices

❏ Instruct your guests on safety procedures and

equipment on board

❏ Leave an itinerary of your trip or “Float Plan” with

someone on shore and have them contact local

Search and Rescue if you don’t return at the

appointed time

SAFE BOATING

It is strongly recommended to read either “The Safe

Boating Guide” (Fisheries and Oceans Canada, Coast

Guard), or “A Boater’s Guide to the Federal Requirements

for Recreational Boats” (US Coast Guard) prior to

operating your boat. Similar publications may be available

through other state or provincial bodies. Check with

your local governing body to see if an operator license

is required in your jurisdiction. Marine safety and boat

handling courses such as those offered through Power

Squadrons are also highly recommended.

❏ Check all lights

❏ Check your radio, cell phone and or signalling device

❏ Check your bilge pump

❏ Ensure every passenger has an approved, properly

tting personal oatation device

❏ Check all seats and ensure they are rmly attached

❏ Check battery and electrical system for damage or

corrosion and spare fuses

❏ Check the steering for smooth operation through the

full range of travel

❏ Ensure that all loose items are safely and securely

stowed

❏ Check for any damage to the boat

❏ Check that the hull drain plugs are in place

❏ Check engine uid levels

❏ Check your capacity rating and ensure your boat is not

overloaded or overpowered

❏ Check bilge for water, fuel and oil.

3125

|

3425 OWNERS MANUAL KINGFISHER BOATS 3

IMPORTANT LABELS AND WARNINGS

For your safety, please do not remove any decals.

GENERAL INFORMATION

Your boat is supplied with a number of identication and warning labels. These labels are intended

to inform and protect the boat operator and passengers. Any lost or damaged labels should be

immediately replaced. Failure to comply with the warnings can result in severe injury or death.

Should you need replacement warning labels, conformity/capacity labels, or instruction labels,

contact your dealership.

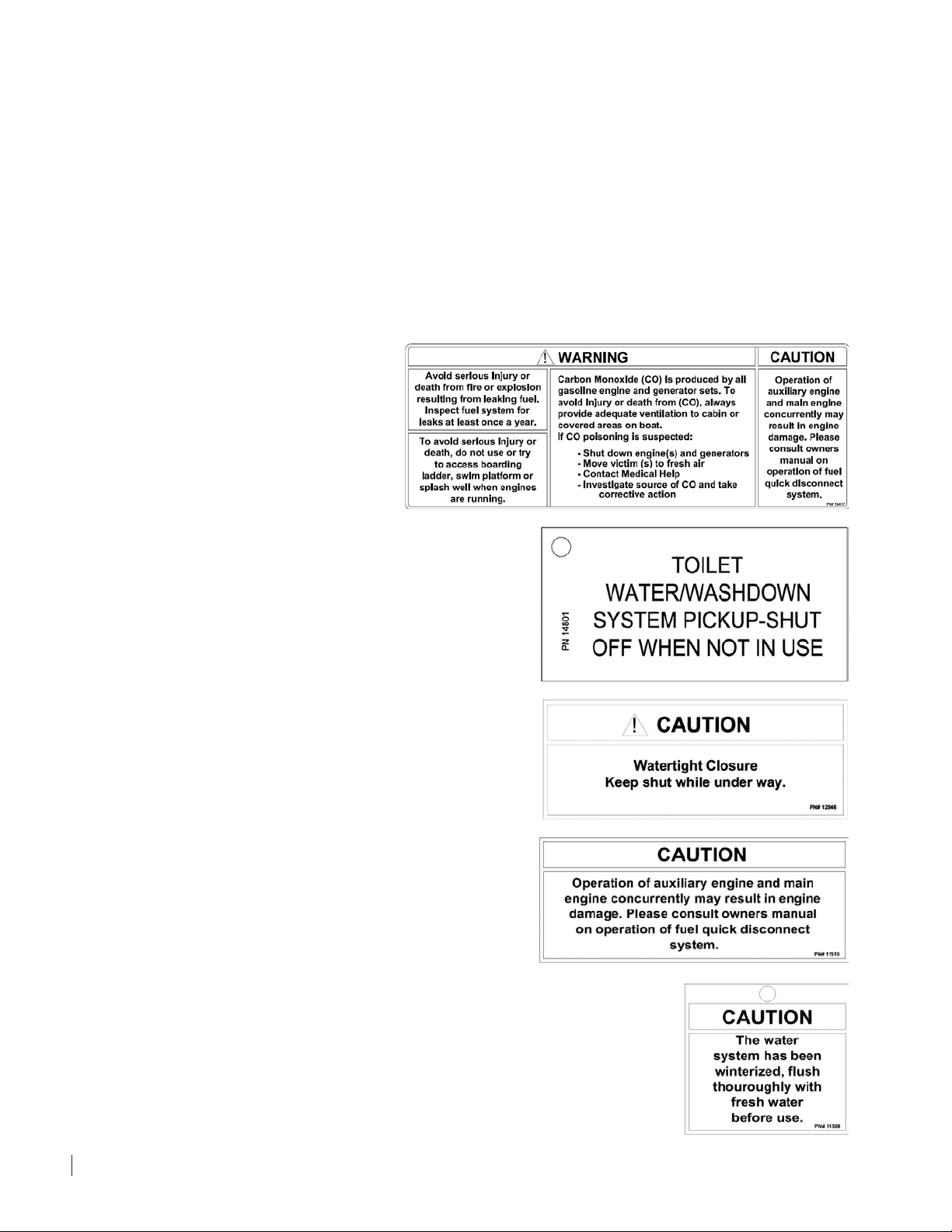

WARNING LABELS

Be sure to familiarize yourself with the following warning labels:

NOTE: Your boat only includes the warning label if applicable.

Decal 1

Located on the starboard side rear deck

tray and relates to the shore power system

Fuel system inspection decal

is located inside the bilge doors

Boarding ladder warning label

is located on the rear swim platform

Decal 2

Auxiliary and main engine operation warning

decal is located above the auxiliary steering station

Decal 3

Winterization warning decal is attached to the sink

faucet and should be removed after the system is ushed

Decal 4

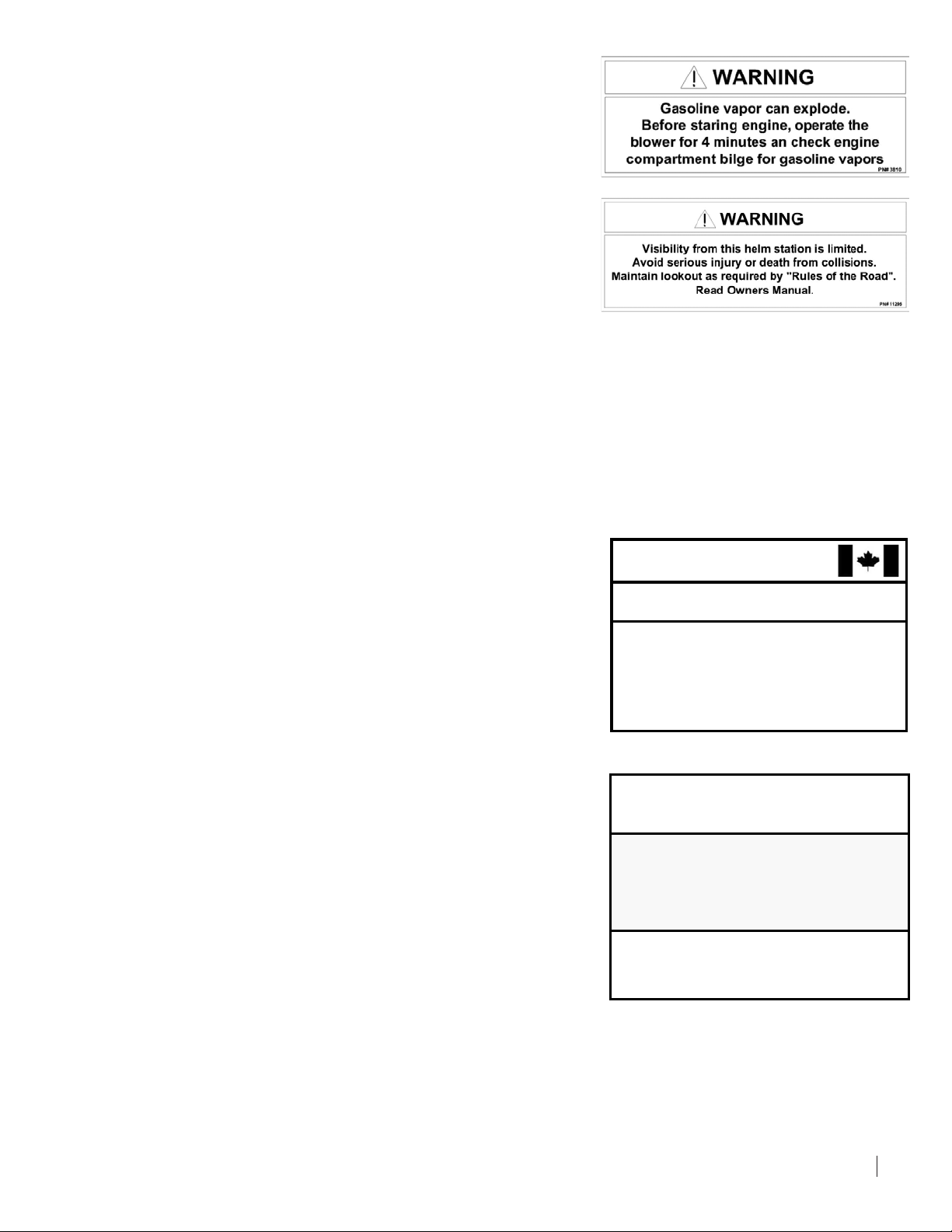

Decal 5

Auxiliary station visibility

warning label is located above

the rear helm station

4 KINGFISHER BOATS 3125 | 3425 OWNERS MANUAL

Decal 6

3125 / 3425

WESTWINN GROUP ENTERPRISES INC

P/N

THIS BOAT COMPLIES WITH U.S. COAST GUARD

SAFETY STANDARDS IN EFFECT ON

THE DATE OF CERTIFICATION

MANUFACTURER:

MODEL / MODELE:

CONFORMITY LABEL

WESTWINN GROUP ENTERPRISES INC (QBS)

VERNON B.C. CANADA

3125 / 3425

3125 / 3425

THE MANUFACTURER DECLARES THAT THIS VESSEL COMPLIES WITH THE

IMPORTED.

THIS BOAT COMPLIES WITH U.S. COAST GUARD

SAFETY STANDARDS IN EFFECT ON

THE DATE OF CERTIFICATION

Water pickup shutoff label is located by the thru-hull

petcock in the headstall, beside the toilet

Decal 7

The watertight closure decal is located near all doors or hatches,

which should be kept closed while underway

CAPACITY / CONFORMITY LABEL INFORMATION

Every vessel is supplied with a label indicating it conforms to related federal requirements as of the date of manufacture.

Vessels over 6 m (19’ 8”) in length are required to display a USSG or Transport Canada Conformity Label (Decal 8 or 9).

If your Conformity label is missing, please contact your KingFisher dealer with your Hull Identication Number (HIN) for a

replacement.

Decal 8

The Transport Canada Conformity label

is located on the baitwell at the stern

Decal 9

The US Coast Guard Conformity label

is located on the baitwell at the stern

CANADIAN COMPLIANCE NOTICE

AVIS DE CONFORMITE CANADIEN

PLEASURE CRAFT CONSTRUCTION REQUIREMENTS OF THE SMALL VESSEL

REGULATIONS, AS THEY READ ON THE DAY ON W HICH THE CONSTRUCTION OF

THE VESSEL WAS STARTED OR ON THE DAY ON WHICH IT THE VESSEL WAS

LE FABRICANT ATTESTE QUE CE BÂTIMENT EST CONFORME AUX EXIGENCES DE

CONSTRUCTION DES EMBARCATIONS DE PLAISANCE DU RÈ GLEMENT SUR LES

PETITS BÂTIMENTS, EN VIGUEUR À LA DATE DU DÉBUT DE SA CONSTRUCTION

OU À LA DATE DE SON IMPORTATION.

P/N

CONFORMITY LABEL

VERNON, BC, CANADA

3125

|

3425 OWNERS MANUAL KINGFISHER BOATS 5

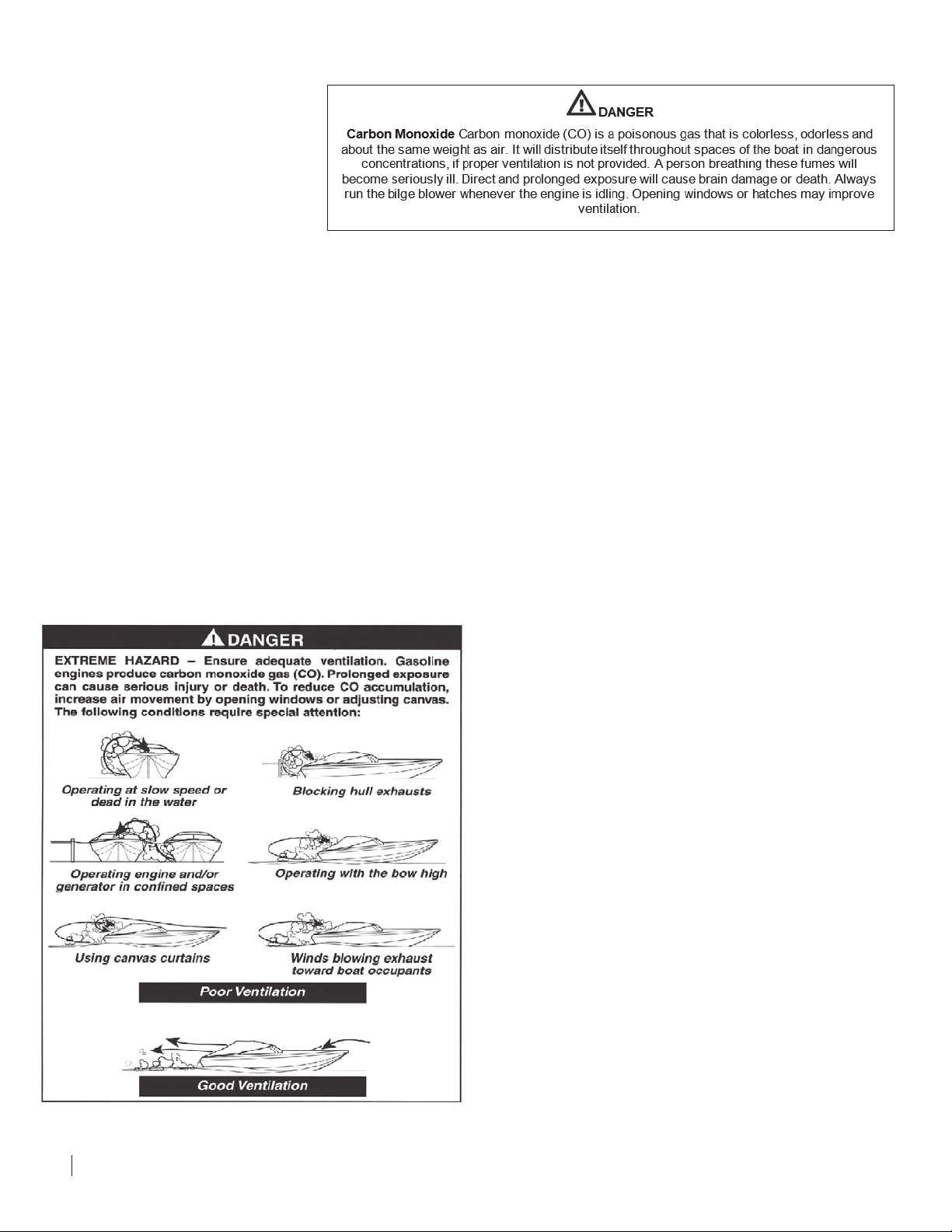

EXHAUST EMISSIONS HAZARD

Decal 10

The Carbon Monoxide (CO) warning

decal is located on the rear bait well

Enclosed cabins or cockpits may accumulate Carbon

Monoxide (CO). This can be a result of fumes from your

own engine or from neighboring boats. To prevent CO

Poisoning ensure continuous movement of fresh air and do

not run the boat fully enclosed. You may wish to install one

or more carbon monoxide detectors in the boat’s enclosed

cabin or cockpit.

CO diffuses in the air much more rapidly than easily

detectable gases; you cannot rely on smell to recognize

its presence. CO will be produced anytime materials

containing carbon are burned. Common sources of CO are

internal combustion engines and open ame devices such

as cooking ranges, space heaters, and charcoal grills.

Ventilation Graphic

Symptoms of CO poisoning include,

but are not limited to, the following:

1. Watering and itchy eyes

2. Flushed appearance

3. Inattentiveness and the inability to think clearly

4. Ringing in the ears

5. Tightness in the chest

6. Headache and/or throbbing temples

7. Drowsiness and fatigue

8. Incoherence

9. Nausea and/or vomiting

10. Dizziness

11. Collapse

12. Convulsions

6 KINGFISHER BOATS 3125 | 3425 OWNERS MANUAL

IMPORTANT: If someone is suffering from CO poisoning

move the person to fresh air, administer oxygen, if available,

and contact medical help. If the victim is not breathing,

perform approved CPR procedures until medical help

arrives and takes over.

SECTION 3 – OPERATOR AND PASSENGER SAFETY

BOAT OPERATORS

The safe use and operation of this boat requires proper

operating techniques, common sense, good judgment,

and expertise. Operators must know the basics of marine

navigation and boat handling. It is vital that operators are

capable of safely navigating their vessel while upholding

respect for others on the waterway.

It is the operators responsibility to operate the boat safely

in accordance with the law, common sense and good

judgment. Check with your local governing body to see

if an operator license is required in your jurisdiction. The

boat operator bears responsibility for the safety of the

boat’s passengers and others that may be in the immediate

vicinity affected by the operation of the boat.

As the boat operator, one of your legal responsibilities is to

come to the aid of other boaters or persons in the water that

are in danger, provided it does not put you or your vessel

in danger. Consult the manuals that come with your life

saving equipment. When approaching persons in the water

approach as slowly as possible. When in the vicinity of

persons in the water, turn off your engine and use paddles

to maneuver. Your boat is not designed to tow other boats.

In an emergency, use your bow or transom eyes for towing

purposes. Your deck cleats are not designed for towing

and can fracture suddenly or pull out of the deck. Towing

another vessel at speeds above 5 mph will put an unusually

heavy load on your motor, possibly resulting in mechanical

damage not covered under engine warranty.

The operator also has a responsibility to operate and

maintain the boat and its equipment in accordance with

the manufacturer’s instructions. Failure to do so may

result in damage to the boat or its equipment or void the

warranty. Your KingFisher requires standard cleaning and

maintenance to ensure many years of enjoyment. See

Section 5 for detailed maintenance requirements and

instructions.

The operator is responsible for the safety of all passengers.

All passengers must be wearing an approved personal

oatation device suitable for their weight. All passengers

should be familiar with the location and use of all emergency

equipment on board.

Everyone who operates the boat must read this manual

to gain a better understanding of KingFisher Boats

components, best handling practices and to understand

their responsibilities.

3125

|

3425 OWNERS MANUAL KINGFISHER BOATS 7

SAFE BOATING PRACTICES

Marine safety is of the utmost importance to keep yourself, your passengers and other boaters safe.

The below tips are common sense and must be followed. Negligence can result in severe injury or death.

• Approved personal oatation devices of the correct

size must be worn at all times by persons aboard the

boat while it is in the water.

• Turn off the engines while any passengers are

entering or leaving the water, or anyone is swimming

in the vicinity of the boat.

• Always operate your boat at a safe speed for weather

conditions. Slow down during periods of restricted

visibility, choppy water and high winds.

• Do not operate the boat if any object is obstructing the

line of sight forward of the steering station.

• Gasoline vapors are explosive. Be careful when

fueling to avoid spillage in the boat or water.

Extinguish all smoking material and open ame while

refueling or while within 15m of a refueling site. Avoid

static electricity discharges and do not operate a cell

phone while fueling.

• Never consume alcohol and/or recreational drugs

during or prior to operating any vessel.

• Never attempt to modify your vessel’s hull or structure

without explicit instructions from the manufacturer or

your dealership. Doing so may result in catastrophic

structural failure that could cause severe injury or

death. Modifying your hull will void the warranty.

• Your boat will always turn more aggressively the

faster that you are going. Always be aware of your

surroundings and give yourself lots of room to

maneuver safely.

• In the event of engine failure, check all electrical,

mechanical and plumbing connections to the engine.

Ensure that there is sufcient fuel in the tank, and that

there has been no fuel or oil leakage. Attempt to restart the engine in accordance with the manufacturer’s

instructions. If the motor will not start wait for it to cool

down and try again. If the motor will not start after

several attempts, summon assistance.

• Check for water or gasoline in the bilge. If there is

gasoline in the bilge, evacuate everyone from the

immediate area and contact your local re department.

Never use the bilge pump to pump out even a tiny

amount of gasoline or oil from the bilge.

• Never sit on seat backs, gunnels or arm rest, and

never stand on seats.

WARNING:

• DELIBERATE MISUSE OF YOUR BOAT AND EQUIPMENT CAN VOID YOUR WARRANTIES

AND POTENTIALLY RESULT IN SERIOUS INJURY OR DEATH

• FAILURE TO COMPLY WITH NAVIGATIONAL REGULATIONS AND RESTRICTIONS

COULD RESULT IN FINES, SEVERE INJURY OR DEATH

• In the event of re, use your re extinguisher in

accordance with its instructions. All other persons

should abandon the boat immediately in the event of

re if it is safe to do so. In the event of loss of steering,

throttle or shift control system failure, turn off the

engine and summon assistance. Use the paddles to

make your way back to shore.

8 KINGFISHER BOATS 3125 | 3425 OWNERS MANUAL

SECTION 4 – BOAT CHARACTERISTICS AND OPERATION

GETTING TO KNOW YOUR BOAT

Read the owners manual for all of your installed components

completely. Locate your circuit breakers, switches and

the location of in-line fuses for the bilge pumps and other

accessories. Use the various component owner’s manuals

provided with your boat to learn where your check points

are located, and what acceptable levels and conditions

are at each point. Get to know where your shut-offs are for

power, seawater, and fuel.

Once you are familiar with the components of your boat, it’s

time to head to the water. Take it easy for the rst little while

until you know how your boat responds to the throttle, turning

and encountering waves. The transition zone between

plaining and displacement speeds can be abrupt at times.

Also, a boat’s sensitivity to steering, wave impact and even

wind at high speed can be unpredictable, because there

is very little of the boat in contact with the water’s surface

to provide stability and control. Practice docking your boat

carefully a few times to get the feel of your boat.

Fuel and Oil

Consult your engine manufacturer’s owner’s manual for the

proper type of fuel to use and any appropriate additives.

Understand the difference between 2-stroke and 4-stroke

and know what engines your boat is equipped with. Your

4-stroke engine may either have a wet-sump oil system

which means that it has an oil lled crank case, or a dry-

sump oil system which means it has an oil tank. If equipped,

your 2-stroke will have an oil tank on board under the deck

with a deck ll, or directly on the engine itself. Never ignore

low oil warnings and always ensure you have sufcient

oil on board. In either case always check your oil before

starting the motor. Consult your engine owner’s manual for

the location of your dipstick, the procedure for checking the

oil level, and the correct type of oil to use.

Avoid lling your boat’s fuel tank to its full capacity and never

park your boat with a completely full fuel tank. Fuel expands

when the surrounding air temperature increases. This can

cause your fuel system to overow. Spilled fuel creates a re

and explosion hazard, can cause severe irritation to skin and

can damage the paint on your boat. Paint damage due to

spilled fuel is not covered by your warranty.

Steering and Controls

Your boat is equipped with hydraulic or powered hydraulic

steering. The uid level must be checked frequently to

ensure that the hydraulic system is intact and that there

is sufcient uid in the lines for your steering system

to function correctly. It is very important to use the

manufacturer’s recommended steering oil type. The oil

type can be found in the applicable steering manufactures

owner’s manual. The steering should only be adjusted by

a qualied technician.

Consult your engine and control owner’s manuals for

instructions on operating your boats throttle and shift

controls. Marine engines can only be started with the

controls in the “Neutral” position. Always shift your controls

to “Neutral” before starting the motor. If you are able to start

your engine with the shifter in gear have your Kingsher

dealer service the boat immediately to correct the problem.

Your vessel will also be equipped with a safety lanyard. The

lanyard consists of a clip attached to your boat’s engine

controls and a snap-hook that attaches to the operator’s

clothing. If the operator is ejected from the boat or collapses,

the lanyard pulls the clip from the controls and shuts off the

engine. Before starting the engine ensure that this lanyard

is in place and the clip ts snugly into its receptacle. For

other engine starting instructions consult your owner’s

manuals.

Instruments and Gauges

Your boat will likely be equipped with an engine

manufactures multi-function display. These gauges are

capable of providing the operator with a comprehensive list

of engine data and operating information such as: voltage,

trim status, boat speed, steering angle, fuel level, oil, water,

engine RPM and engine diagnostic alerts. Always be aware

of your gauge reading. Low RPM’s can mean a fouled prop.

For full break down of capabilities related to your gauge,

see the manufacturer’s owner’s manual. Stay current with

corresponding software updates for your display. Contact

your Kingsher Dealer for more information.

Engine Trim

You can change the angle of the propeller shaft by adjusting

the trim switch. Start from idle with the outboard tucked in/

down all the way. While accelerating and planing, start to

trim the outboard out/up. By trimming the outboard out/up,

you will raise the bow of the boat. By doing this, it reduces

drag and bow steering and increases speed and fuel

economy. Find where your boat has optimal performance.

Over trimming will reduce performance and could potentially

damage your engine by cavitation.

3125

|

3425 OWNERS MANUAL KINGFISHER BOATS 9

SAFE OPERATION, CARE AND ATTENTION

Operating your boat with due care and attention requires

the operator be aware of the surrounding environment at

all times.

• Sudden stop or change of direction can cause

loss of control of the boat resulting in injury or death.

• Operate the boat defensively at all speeds and

keep a safe distance from people, objects and other

watercraft.

• Following directly behind other boats or operating the

boat in an erratic manner can lead to collision, injury

and death.

• Operators should reduce speed and exercise extreme

caution when operating the boat in shallow areas or

where there might be submerged objects.

• Be aware of the weather conditions at all times. If

wind and waves begin to rise or visibility begins to

deteriorate, return to the dock or boat ramp.

• Placing heavy objects over to one side of the boat or

very far forward in your boat can result in poor boat

performance, or in an extreme situation result in loss

of control or capsizing of the boat. Always distribute

any cargo evenly around the center of the passenger

carrying area of your boat.

OPERATING TIPS

Launching

When you arrive at the boat ramp remove the rear tie-

downs from your boat and perform all pre-operation checks.

Ensure the drain plug is in place. When safe to do so, back

your trailer slowly down the ramp until the underside of the

boat is touching the water. Stop your vehicle and set the

parking brake. Disconnect the trailer safety chain from your

boat and let out a few feet of winch line. Ensure you do not

let out enough winch line to become tangled on your vehicle

or the trailer. Back your trailer down the ramp until the boat

is ready to oat free. Set your parking brake. Disconnect

your winch line from the boat and attach a long mooring

line to the bow. Guide your boat off of the trailer and secure

it to the shore using the mooring line or have someone on

shore hold the line. Park your trailer and vehicle. Board

your boat. Ensure that there is enough water under your

boat before lowering the motor.

Loading

Tilt your outboard motor into the traveling position. Moor

your boat on shore or have someone on shore hold the

mooring line. Carefully back your trailer down the ramp

when safe to do so until the trailer bunks are just underwater.

Set your parking brake. Guide your boat onto the trailer as

squarely between the trailer fenders as possible. Attach the

trailer winch line to the bow eye of the boat, detach the

mooring line and winch the boat the remainder of the way

onto the trailer. Attach the safety chain to the bow eye of

the boat. Remove your boat from the water and perform

all post operation checks prior to leaving the parking lot.

Attach the tie downs to the transom, stow all loose items

securely and store the boats fabric top in the down position.

Perform all trailer checks.

10 KINGFISHER BOATS 3125 | 3425 OWNERS MANUAL

Starting your Engine

Consult your engine and control owner’s manuals for proper

engine starting, break-in, and shut-down procedures.

Boarding the Boat

Never attempt to board a boat while the engine is running,

whether from the water or from the shore or dock. When

boarding from a dock or the shore, ensure that the boat is

secured so that it cannot move away from you while you

are boarding. Use a step if necessary to board comfortably.

When boarding from the water, use the transom platform

and ladder if so equipped.

Stopping

We recommend that operators avoid stopping the boat

abruptly because the boats wake can catch up with the

boat and lift the rear of the boat suddenly. Slow the boat

down gradually prior to stopping, and never use reverse

gear as a brake.

Docking

Always enter marinas and dock areas at low speed ~ 5mph

(8km/h) or as posted. Approach the dock head-on, turning

the steering wheel sharply as you come closer to the dock,

bringing the side of the boat you wish to dock on around

to face the dock. Put the boat into reverse gear and turn

the wheel or tiller in the opposite direction to pull the stern

towards the dock, and then put the boat in “Neutral”. The

boat should drift sideways, gently towards the dock. Practice

this often, carefully and at low speeds. Take advantage of

any assistance you may be offered when docking.

POST OPERATION CHECKLIST

❏ After you are nished enjoying your boat for the day

return to the dock or boat ramp and turn your motor off

❏ Check propeller or impellor for nicks

and tangled debris

❏ Check the bilge for gasoline and water

❏ Remove garbage from the boat

Leaving a Dock

When leaving a dock, check for trafc and start the engine

in neutral. Then have a passenger or someone on shore

untie the boat and push the boat away from the dock. Once

the boat is clear of the dock by approximately 1m (3 ft) and

is clear of any obstructions or other boats, put the boat in

gear and proceed with caution at the slowest throttle setting

until the boat is into open water.

Beaching

When beaching the boat, it is critical that the motor

be turned off and the motor or leg tilted up so that the

propeller does not strike sand or rocks on the beach. When

approaching the shore for beaching, slow the boat down so

that a sudden stop will not cause jarring to the passengers

or damage to the boat. As you approach the beach and the

water becomes shallower turn the motor off, tilt the drive up

fully, and drift onto the beach. Once on the beach secure

the boat to a xed object on shore.

Take care in tidal waters that the boat is not beached long

enough for the tide to come in and carry your boat away, or

for the tide to go out and leave your boat stranded.

When you’re ready to leave the beach, have your

passengers board the boat, untie your boat from shore, and

push it into the water. Do not lower the outboard until there

is sufcient water to avoid engine damage. Hull damage as

a result of beaching is not covered under warranty.

❏ Tilt the outboard and trolling motor to the secure

traveling position

❏ Secure all loose items prior to trailering

❏ Wash the boat down with fresh water and pull the

hull’s drain plugs to remove any water from the boat,

securely replacing them afterwards

❏ Consult your engine owner’s manual for special

instructions on purging water from your boat’s exhaust

system and ushing your boat’s cooling system

❏ Perform any post operation maintenance specied in

your engine owner’s manual

Night Operation and Anchoring

Your boat is equipped with navigation lights which must

be turned on from dusk till dawn. The anchor or “all-round”

light must be displayed while at anchor during the night

in any area that experiences marine trafc. Never operate

your boat after dusk if the navigation and anchor lights are

not functioning properly.

Auxiliary Engine Operation

When operating the vessel under the main engine power,

always have the auxiliary motor tilted out of the water.

Engine damage may occur if the auxiliary engine is in the

water while in planning speeds.

3125

|

3425 OWNERS MANUAL KINGFISHER BOATS 11

TRAILERING YOUR BOAT

Please defer to your state or provincial regulations for

towing and licensing requirements.

Gross Vehicle Weight Rating (GVWR)

Take careful consideration of the GVWR. Locate the decal

with the GVWR information. It is usually found on the frame

near the tongue of the trailer. The boat, engine(s), fuel,

water and your boats accessories and gear should never

exceed this rating.

TRAILER CHECKLIST

Before towing your boat complete the below checklist:

❏ Refer to local and regional laws to ensure that

your trailer complies with regulations

❏ Read the trailer manufacturer’s owner’s manual

❏ Check the trailer hitch on your vehicle and make

sure that it is the correct size and load rating

for the trailer you are towing

Trailer Setup

Setting up the correct trailer t for your boat and vehicle is

very important. An improper trailer setup can do cosmetic

as well as visible and unseen structural damage to your

boat. KingFisher strongly recommends having a technician

from an authorized Kingsher dealership ensure your trailer

is properly set up. Damage due to trailering is not covered

under warranty.

Before trailering your boat, become familiar with how your

vehicle handles while towing a trailer. Practice making

turns and get to know the turning clearance that you will

require while towing. Practice backing up with your trailer

and get to know how quickly your trailer will respond to

small movements of your steering wheel. An empty parking

lot is an excellent place to practice.

Handling of the boat on and off the trailer as well as towing a

trailer should never be attempted on a trial and error basis. If

you are a novice boater or have not been boating in a while,

please ask your dealer to show you the proper handling of

the boat on and off the trailer. Use special care for boats

equipped with bow pulpits and anchor systems.

❏ Check for correct function of the trailer braking system

❏ Secure the bow of the boat to the trailer with

the winch line and safety chain

❏ Tie down straps should be attached from the

eyehooks in the transom to the rear of the trailer

❏ Attach the trailer’s break-away chains to your vehicle.

Properly secured chains cross over each other

❏ Secure the trailer tongue over the hitch on your

vehicle using the release handle and locking pin on

the trailer

❏ Tongue jack is in the full upright position

❏ Trailer electrical harness is plugged in and brake

lights, turning indicators, side markers and

parking lights are functional

❏ The boat should be level and sit squarely on the trailer

❏ When trailered correctly, the aft end of the bottom

of the hull should line up as close as possible with

the end of the trailer bunks

❏ Check the trailer for any loose fasteners,

corrosion or damage

CAUTION

Improper trailering may cause irreparable

damage to your boat. If you are unsure

about how to properly secure your boat, please

contact your authorized Kingsher dealer.

12 KINGFISHER BOATS 3125 | 3425 OWNERS MANUAL

❏ Check the tires for proper ination and wear

❏ Check your trailer wheel hubs periodically during

your trip to ensure that they are not overheating

For trailer maintenance parts and warranty information,

please refer to the trailer manufacturer’s owner’s manual.

SECTION 5 – MAINTENANCE AND CARE

EXTERIOR MAINTENANCE

KIngFisher uses marine grade products and takes extra

caution during installation to ensure the longevity of

your boat. However, after each voyage there is a need

to thoroughly clean your vessel to minimize electrolytic

action (galvanic corrosion). In addition to instructions

found elsewhere in this manual and in literature specic to

certain components, the following information is provided

for general maintenance and repair. Because conditions

vary widely in different areas and the frequency and type

of use can differ greatly between owners, intervals for

maintenance are not listed here.

Sacricial Anodes

Sacricial anodes are a highly active alloy material used to

prevent less active alloys from corroding. Your Kingsher

hull is tted with four 2.5lbs aluminium sacricial bar anodes

bolted to the stern of the boat. The boat’s motor(s) will also

be tted with several sacricial anodes. Careful inspection

and replacement of worn anodes are essential to keep

the hull in the best condition possible. Good practice is to

change the anodes if they deteriorate by 40-50%. Failure

to replace a worn anode will result in hull damage and will

void your warranty. See your authorized Kingsher dealer

for sacricial anode replacement information.

Cleaning

Wash your boat with soap and fresh water the way you

would wash a car. Power washing at more than 1000psi

may cause paint to delaminate. Pull the hull drains if

practical and allow the boat to dry thoroughly. Clean all

surfaces and apply a coat of automotive or marine grade

wax protectant two to three times annually to protect your

painted nish from the elements, and to seal the metal

where any paint scratches may have occurred. Rinse with

fresh water after every salt water use. Always spot test new

cleaners and waxes before using. Marine growth, barnacles

and other debris deposits should be removed from the hull

prior to storage. Never use a metal brush of any kind on

the exterior surface of your boat. Do not use abrasive or

non-biodegradable solvents. Do not discharge chemicals

overboard. Regular periodic maintenance will maintain the

overall appearance of your boat.

Oxidization and Corrosion

The high electrically conductive nature of salt water

intensies corrosive action on aluminum. The hostility of

the marine environment affects most materials - metals,

wood, plastic, breglass, etc.

KingFisher hulls are manufactured with marine grade

aluminum alloys such as 5086 - H32 and 5052 - H32. Marine

grade aluminum alloys produce a natural protective lm -

either a whitish or darker surface layer - when exposed to

oxygen or water. Although extremely thin, (approx. 5 to 10

millionths of a millimeter), this oxide lm forms a corrosive-

resistant barrier. Experience shows that large and small

vessels constructed of these alloys can stay in constant

saltwater service for decades as long as proper care is

taken.

Avoid dissimilar metals coming in contact with aluminum

surfaces (e.g. all ferrous metals including steel, brass, or

copper ttings). If there is a need to attach ttings made

of a dissimilar metal make sure that a non-wicking gasket

or sealant is placed between the tting and the boat hull.

If the hull is drilled for any reason, a sealant such as a

marine grade silicone should be used as a barrier between

the hull and components. See the corrosion manual for

more information.

Warranty does not apply to:

Corrosion or damage resulting from fuel overlling, the

use or storage of harmful solvents or cleaners, electrolysis

caused by reversed polarity connections or inadequate

galvanic isolation, improper use of anti-fouling paint, or

dissimilar metals and saltwater exposure. Salt water

corrosion damage resulting from absence of zinc anodes,

cathodic protection devices, improper or unattended

storage or moorage.

Paint Touch Ups

For small scratches that need repainting, clean the area to

be painted of wax, grease and dirt. Apply the touch up paint.

When the paint is dry, (at least 24 hours) polish the area

with an automotive cutting wax compound.

For larger scratches that need repainting, please see your

authorized Kingsher dealer or an automotive body shop.

3125

|

3425 OWNERS MANUAL KINGFISHER BOATS 13

COMMON TYPES OF CORROSION

Galvanic Corrosion

Common type of corrosion caused by dissimilar metals. This can occur for a

variety of reasons including dissimilar ttings and fasteners in direct contact

with bare aluminum; or even loose items like sinkers and old hooks that nd

their way into the bilge or an inconspicuous area. These dissimilar metals cause

galvanic corrosion when immersed together or while in contact with saltwater,

brackish or even contaminated freshwater.

Crevice Corrosion

Lack of oxygen can be another reason why aluminum corrodes. Standing

saltwater, brackish, and even contaminated freshwater sitting in the hull of your

boat over a long period of time can cause tiny areas where the oxide layer

slowly gets deteriorated. Not having that natural hard protective coating of oxide

will cause the aluminum to become pitted over time and could potentially evolve

into microscopic pinholes through the hull.

Electrolysis Corrosion

When an electrical component in either the AC or DC system is incorrectly

installed or has an electrical fault which leads to ground. This fault doesn’t

necessarily need to be on your vessel to cause an issue. It could be located on

a neighboring vessel or a boat on the other side of the marina connected to the

same AC grounding bus on the marina supplied shore power connection. These

faults will turn your boat and every other boat in the marina into a battery, with

the saltwater as the conducting electrolyte.

Poultice Corrosion

Accumulation of debris can create a highly corrosive condition. Combined with

aluminum, this debris creates an acidic solution called aluminum hydroxide that

can corrode through the parent metal. These areas tend to seriously aggravate

aluminum when there is wet-dry cycling.

14 KINGFISHER BOATS 3125 | 3425 OWNERS MANUAL

Identifying and Managing Corrosion

After every voyage you must pay special attention to

the overall cleanliness of your vessel. No different than

storing your gear and hanging items to dry, there is a

need to clean off the saltwater that has come into contact

with your vessel during your outing. A thorough freshwater

wash down is an effective way to reduce the risk of

corrosion, which could require extra maintenance in the

future. Places like under your cutting board, aft helm,

and nylon downrigger mounts are examples of points

of contact that aren’t meant to be watertight and should

always be well rinsed with fresh clean water after every

use. For best results, an initial quick heavy mist well help

loosen the dried salt crystals. Follow this up with a heavy

rinse working from the top down, putting extra spray into

areas with tight contact points that have little chance of

drying up quickly on their own.

Bilge compartments must also be kept as clean as

possible by ushing with fresh water every time you return

to dock. Make sure all internal drain-ways are free from

scum build-up and loose debris. If you notice a white

powder forming in crevasses it’s a sign this area has

been overlooked in previous cleaning attempts. Clean this

powder with a stainless tooth brush so the aluminum can

once again form a new oxide layer. This type of corrosion

will require immediate attention to stop further growth and

should not be delayed.

Chipped paint from stones while trailering, or a scratch

from a loose deck board, will also have a negative effect

when in contact with saltwater. Exposed aluminum in your

paint nish will allow moisture in between the paint and

hull. This will cause paint to blister and peel. It is important

to seal any exposed areas to prevent corrosion forming

and spreading.

Sacricial Anodes and Galvanic Protection

Depending on which model and options you have selected

your boat may be equipped with sacricial anodes and a

galvanic protection device.

A galvanic isolator is present on all models equipped

with a minimum 30A shore power system and is installed

just after the vessel’s shore power connection. Signals

can pass through this galvanically isolated circuit, but

stray currents such as differences in ground potential or

currents induced by AC and DC power are blocked.

Sacricial anodes on your vessel are part of your cathodic

protection system. The anode is made from a metal alloy

with a more “active” voltage than the surrounding metal

it is protecting. The difference in potential between these

two metals means that the sacricial anode material

corrodes in preference to the surrounding area it is

protecting.

Anodes do require maintenance to keep them at their

peak effectiveness. Repeated cleanings throughout the

season with a wire brush may be required to remove any

buildup that may form.

The anodes on your vessel should be inspected and

cleaned every two months. You should change your

anodes after it has corroded to half its original size or

when you’ve accumulated twelve months of immersion in

saltwater. When anodes are cleaned or replaced, it must

also be veried that they have good continuity with the

hull. This is an easy step by using a multi-meter set to the

ohms scale.

Blistering and peeling paint around fasteners and

ttings or chalky white powder is a sign that galvanic

corrosion may be taking place. These are areas not

properly rinsed from previous trips or areas where

movement of a loosened fastener has allowed water to

enter and make contact between the stainless fastener

and bare aluminum. This component must be removed

and the corrosion must be eliminated by light sanding

at a minimum. The affected area will then need to be

recoated with matching paint. The component should

then be reinstalled using the “New Component Installation

Instruction” sheet.

3125

New Sacricial Anode Anode Needing Replacement

|

3425 OWNERS MANUAL KINGFISHER BOATS 15

NEW COMPONENT INSTALLATION INSTRUCTION

If a xture or addition to your boat becomes loose, it increases the risk of exposure.

Check your xtures regularly. To safely and effectively install or replace components, follow the below instructions.

1. Place component

and hole the

markings with a pen

2. Ensure there are

no obstructions

on the back side

of your mounting

location before

drilling.

3. Drill and deburr

holes. Clean up

all metal chips

and shavings so

that none will get

trapped in your

newly installed

component

5. Center the

component over

pre-drilled holes

6. Heavily coat all

fasteners that will

be used to hold the

component in place.

7. There should be

no visible gaps in

the sealant when

the component is

tightened down.

4. Apply a generous

amount of sealant

such as Sikaux

291, Loctite UR 3370

or 3M 5200

16 KINGFISHER BOATS 3125 | 3425 OWNERS MANUAL

8. A soapy water

solution can be

used to clean up the

remaining excess

sealant.

INTERIOR MAINTENANCE

Cabinets and Countertops

Laminate countertops are offered on all Kingsher

models. To keep the sapelli wood cabinets and laminate

countertops in optimum condition, clean the cabinet as with

a lint-free cloth slightly dampened with water and soap. Dry

immediately with a lint-free cloth. Avoid using abrasive pads

or powdered cleansers as these products may scratch and

penetrate the surface, allowing moisture to enter and cause

deterioration of the nish. Keep the surface dry by wiping

up spills and water marks as they occur.

Vinyl Floor Coverings

Remove ordinary dirt and smudges with a mild soap and

water solution and a clean soft cloth or towel. Dry with a

soft lint-free cloth or towel. Do not use abrasive powder,

steel wool, or industrial strength or solvent cleaners. The

use of upholstery “conditioners” or “protectants” is not

recommended and should be avoided on all vinyl coated

fabrics. For tough stains, Formula 409 All-Purpose Spray

Cleaner or Fantastik Spray Cleaner is recommended by

the vinyl manufacturer.

Kingleather Upholstery

The vinyl seats can be routinely washed with a soapy water

solution. For tough stains, use Spray Nine. Protect the seat

coverings with a 303 protectant.

3125

|

3425 OWNERS MANUAL KINGFISHER BOATS 17

MAINTENANCE AND ADJUSTMENTS

Periodic Inspection Checklist

❏ Check entire fuel system for leaks

❏ Check all engine mount fasteners for tightness

❏ Check all deck fasteners for tightness

❏ Inspect hull and motor mounts for cracks and

other signs of fatigue such as deep scufng

❏ Check drain plug

❏ Check bilge for oil, water and gasoline

❏ Check steering lines for wear and ease of function

❏ Check oil level in engine and power steering pump

❏ Test battery and check for damage or corrosio.

❏ Test all switches, lights, horn, and accessories

❏ Check for burnt out lights

Inspecting the Steering

Your boat will come with an owner’s manual for the type

of steering system that your boat is equipped with. Refer

to this manual for information on proper maintenance.

Never operate your boat with a damaged or improperly

functioning steering system. Conrm that the hydraulic

reservoir is full, and check all hoses and connections are

leak-free and that the uid isn’t contaminated.

Inspecting the Circuit-Breakers and Fuses

Your boat is equipped mainly with resettable circuit

breakers. These will pop out if overloaded and can be

pushed back in with a ngertip to reset them. There is an

in-line grey 50A circuit breaker coming off the main battery

lead to your distribution panel. Inspect the fuses and the

electrical system of your boat monthly. You can also nd

a panel of fuses under the main helm. Shut off the main

electrical switch by your battery (or disconnect the battery)

and inspect the accessories. Trace the circuits and inspect

them for chang and for broken or damaged wires, plugs,

switches or connectors. Never bypass a fuse or circuit

breaker. If you are unable to nd the cause of the blown

circuit, have your boat serviced by your Kingsher dealer.

❏ Check seat fasteners and swivels

for tightness and wear

❏ Inspect zinc hull anode and replace if required

❏ Conrm proper operation of galvanic isolator.

See page 30 of this manual

Inspecting the Fuel System

The fuel system can be accessed through removable

panels in the transom and in the deck. Remove the

panels and check the ll tting, the tank ttings and

the vent lines at the ller cap and at the tank for signs

of leakage. Also check the hoses and primer bulb

(if equipped) for signs of wear, chang and other

deterioration. Replace any damaged fuel hoses

immediately. Check the fuel lters. Change the lters

once a season or after every 100hrs of operation.

Servicing Under the Deck

Access to the bilge and fuel tank is gained by removing

all the sidewalk screws and lifting the rear deck off.

Transducer Mounting Plates

Transducer brackets are a standard design feature. They

are intended to reduce the need to drill holes directly into

the hull below the water line. The plates are located at

the base of the transom, where the hull meets the rear of

the boat. Simply attach your transducer(s) directly to this

plate on the transom. Do not drill holes for routing cables

below the water line. Extreme caution must be used when

installing this type of transducer to avoid leakage and

potential injury or death.

WARNING:

GASOLINE VAPORS CAN EXPLODE IF IGNITED, CAUSING SERIOUS INJURY OR DEATH.

INSPECT FUEL SYSTEM FOR LEAKS REGULARLY.

18 KINGFISHER BOATS 3125 | 3425 OWNERS MANUAL

STORAGE AND WINTERIZING

KingFisher recommends your boat be winterized by an

authorized dealer. Your boat should be stored in a covered,

well ventilated area to prevent fungus, mold and mildew. It

is best to store it with a breathable cover over it to prevent

corrosion and staining promoted by leaves, tree sap and

other debris, and to prevent rainwater from accumulating

inside the boat.

Engine

Refer to engine manufacturer’s owner’s manual for

information and instructions on preparing your engine(s) for

winter storage.

Drain Plug

Always remove the drain plug from the boat when storing it

for long periods of time. This will ensure that any water that

has collected in the bilge will drain. When storing the boat

the bow should be slightly higher than the stern, this will

help excess bilge water to drain fully. Inspect the drain plug

when re installing it and replace it if necessary.

Fresh Water System

Drain fresh water and grey water holding tanks. Once tanks

have been drained, add RV anti-freeze and ensure that it

is circulate throughout complete water system. Ensure that

all fresh water has been ushed from all faucets and pumps

and that antifreeze is present in all of the water lines.

Fuel System

Top off the fuel tank with fresh fuel to approximately 7/8

full, adding a fuel conditioner and stabilizer. Consult

your Kingsher dealer for fuel conditioner and stabilizer

purchase information). A 7/8 full fuel tank is less likely to

develop condensation, reducing the risk of contaminating

the fuel. This will also prevent the fuel from expanding and

running out of the fuel vent hose. Running treated fuel

through the engine during the engine winterization process

will also help protect the fuel system.

NOTE: The use of fuel conditioner and stabilizer eliminates

the need to drain the fuel system. Consult your dealer if you

prefer to drain the fuel system.

Always store your boat in a well ventilated area. Unlike a

car, your boat is not equipped with a vapour-tight fuel tank.

Batteries

The battery(s) should be removed for winter storage.

Batteries can suffer permanent damage as a result of

excessive or prolonged periods of discharge. Use terminal

paste to prevent corrosion on the battery terminals and

clamps.

1. Turn off the battery switch(es) and remove the

battery(s).

Ensure that hot water system is drained, ushed and

winterized with R.V. anti-freeze.

Trailer

We recommend your trailer be winterized by an authorized

Kingsher dealer or by a qualied technician. The trailer

frame should be washed and internally ushed if used in

salt water. Wheel bearings and breaking system can be

permanently damaged if not properly winterized and free

of all water.

2. Inspect each battery for cracks or leakage and ensure

the battery terminals are free from corrosion and dirt.

Clean the battery’s casing and terminals with a mixture

of baking soda and water (one tbsp of baking soda to

one-cup water). Apply dielectric grease or petroleum

jelly to the battery terminals and to all exposed

connectors.

3. If the battery is to be stored for a long period of

time, store the battery in a cool, dark place. Check

the specic gravity of the battery uid at least once

a month and recharge if the battery gets too low.

Specic Gravity: 1.28 at 68 degrees F. Sparks,

cigarettes and open ame can lead to a hydrogen

explosion. Your battery should be kept fully charged at

all times.

3125

WARNING:

BATTERIES CAN PRODUCE EXPLOSIVE

HYDROGEN GAS. BATTERY EXPLOSION CAN

LEAD TO BURNS, INJURY AND DEATH ALWAYS

SERVICE BATTERIES IN A WELL VENTILATED AREA

KEEP AWAY FROM SPARK AND OPEN FLAME

|

3425 OWNERS MANUAL KINGFISHER BOATS 19

RE-COMMISSIONING BOAT AFTER STORAGE

Engine

Refer to the engine operator’s manual for detailed

information on re-starting after winter storage.

Batteries Checklist

❏ Terminal posts – clean with wire brush or steel wool

❏ Cable clamps – attach positive (+) cable rst, then

negative (-) cable

❏ Wiring – inspect for deterioration and service or

replace as required

Steering System

Have steering system checked by and an authorized

Kingsher dealer.

Fuel System

Inspect for fuel in the bilge, loose connections, worn

hoses, and leaks.

Miscellaneous Items Checklist:

❏ Through hull ttings – Check to ensure water passage

is unobstructed and hoses and ttings are serviceable

❏ Navigation lights – Check for proper operation

❏ Bilge pumps – Check all pumps and oat

switches for correct operation

❏ Wiring – Check for loose connections

❏ Switches – Check for proper operation

of all equipment and components

❏ Bilge blowers – Check for proper operation;

turn blowers on and place hand over hull blower

vent to make sure air is exiting from vent

❏ Anchor lines and gear – Inspect and

replace if necessary

❏ Hull drain plugs – Installed

❏ Bilge – Clean thoroughly

❏ Engine uids – Check for proper levels as

described in the manufacturer’s owner’s manual

Trailer:

Refer to the trailer manufacturer’s owner’s manual

for re-commissioning of the trailer after storage.

20 KINGFISHER BOATS 3125 | 3425 OWNERS MANUAL

SECTION 6 – SYSTEM AND OPTIONS

THRU HULL LOCATION

1. Baitwell drain

2. Fish box macerator discharge

3. Main bilge pump discharge

4. Secondary bilge pump discharge

5. Livewell drain

6. Fresh water deckll

7. Cabin bilge pump discharge

8. Sink drain

9. Grey water tank vent

10. Grey water pump out

11. Fuel ll

12. Starboard side sh box macerator

13. Grey water overboard discharge

Note: Thru hull location may vary due to individual options selected.

3125

|

3425 OWNERS MANUAL KINGFISHER BOATS 21

IMPORTANT

Check with the Coast Guard and local authorities prior to

discharging grey water overboard.

SYSTEMS

Before operating your boat, become familiar with all

controls. Consult your authorized KingFisher dealer about

any controls or functions that you do not understand.

Bilge Drain

The bilge drain is located at the lowest part of the bilge at

the stern of the boat. When draining the bilge or storing the

boat for longer periods of time, the drain plug should be

removed. When replacing the drain plug it is advised that a

small amount of marine sealant be applied to the threads

before the plug is installed.

Steering System

The steering system requires checking each time that the

boat is taken out on the water.

• Check to ensure that the steering system operates

correctly and smoothly prior to each trip out on the

water.

Fuel Sending Unit

The fuel sending unit is a mechanical device that is

located in the fuel tank. It sends a signal to the fuel gauge

monitoring the amount of fuel that is present in the tank.

NOTE: The fuel sending unit will only give an accurate

reading when the boat’s fuel tank is level. Do not depend on

the fuel gauge as your only means of determining fuel levels.

• Poor or erratic steering may be a sign that the oil level

is low, or that uid or air is leaking out of or into the

system. Leaks can occur in the steering hoses, the

cylinder, or at connection points. Do not attempt to

operate your boat if you suspect a steering system

problem.

• Consult an authorized KingFisher dealer if the steering

system is not functioning correctly. Only a qualied

technician should adjust steering systems. Ensure that

the steering system is lubricated at the beginning of

the boating season and properly winterized at the end

of the season.

FUEL SYSTEM

When lling the gas tank care should be taken not to

spill fuel onto the paint of your boat. Any fuel that may

be spilled on the paint should be immediately wiped off.

Keep tanks approximately 7/8” full during boating season

to avoid condensation and fuel expansion. You may wish

to have a fuel separator installed to prevent water from

entering the engine(s).

If the fuel tank needs to be cleaned or water is found in

the fuel system, refer the boat to an authorized Kingsher

dealer

For recommended fuel please refer to your Engine

Manufacturer’s owner’s handbook.

Fuel Leak Check

Before operating the boat, check the fuel system for leaks.

Open the bilge doors and visually check all fuel hoses, vent

hoses, ttings, and the tank for leaks. If no leaks are found,

carry on with your pre-operation inspection.

If a leak is found or strong gasoline odor is detected,

DO NOT START THE ENGINE. Consult an authorized

Kingsher dealer.

Kicker Motor Fuel Quick Disconnect

A quick disconnect option is offered for the kicker fuel supply

line. The quick disconnect is located on the starboard side

of the transom.

The quick disconnect allows the fuel supply line to the

kicker to be easily detached from the transom bulkhead. To

do this, grasp the tting located at the transom end of the

kicker fuel supply hose and pull back rmly on the ttings

collar.

22 KINGFISHER BOATS 3125 | 3425 OWNERS MANUAL

The safety fuel shut off valve is clearly labeled and located

behind the rear bilge doors around where the fuel lters reside.

When the kicker is not in use, always turn off the fuel supply

shut off valve and tilt the engine up and out of the water.

Re-fueling the Boat

• Do not smoke when refueling.

Keep away from all other ignition sources.

Engine Oil and Fluid Levels

Engine oil and fuel levels specic to your engine model

can be found in the engine manufacturers owner’s manual.

• Stop engine and turn off ignition.

• Refuel in a well-ventilated area. If the boat is in the

water, be sure it is securely moored prior to refueling.

Avoid overlling the tank as fuel expansion may result

in a fuel spill. Gasoline spilled directly on the hull paint

of your boat may result in paint damage that will not

be covered by warranty.

• All passengers must be out of the boat during

refueling.

• Open the gas cap and begin refueling.

Refer to hull plan for location of gas cap.

• When tank is lled to the appropriate level,

replace the gas cap.

For engine oil and other engine uid levels, consult the

engine manufacturer’s owner’s manual.

For easy reference please mark down the engine

manufacturer’s recommended oil specications here:

Main Engine(s) Crankcase Oil: _____________________

Main Engine(s) Gearcase Oil: ______________________

Main Engine(s) Power Trim Oil: ____________________

Kicker Motor Crankcase Oil: _______________________

Kicker Motor Gearcase Oil: ________________________

Kicker Motor Power Trim Oil: _______________________

CAUTION

IF GASOLINE SPILLS ONTO YOUR SKIN, IMMEDIATELY WASH WITH SOAP AND WATER. CHANGE

CLOTHING IF SATURATED WITH GASOLINE. IF GASOLINE GETS INTO YOUR EYES OR FUMES

ARE INHALED, SEEK MEDICAL ATTENTION. IF GASOLINE IS SWALLOWED, CONTACT A POISON

CONTROL CENTER AND SEEK IMMEDIATE MEDICAL ATTENTION.

3125

|

3425 OWNERS MANUAL KINGFISHER BOATS 23

ELECTRICAL SYSTEM

KingFisher Wiring Harness

Weather proof female plug

KingFisher’s standard main wiring harness has been spliced and tted with female weather proof plugs for each option offered.

If a boat has not been factory installed with a specic KingFisher option, the wiring harness may still have been spliced

and plugged to provide a connecter to accommodate the installation of that option after the boat has left the factory.

3425 Diagram

The following diagrams shows general wiring harness routings and plug locations for standard and optional features:

1. Fuse panel and ground block

2. AC panel (option)

3. DC fridge switch

4. Galvanic isolator (in wall)

5. Carbon monoxide (CO) detector

6. Faucet

7. Fridge

8. Toilet macerator switch

9. Washdown switch & shbox switch

10. Fishbox macerator switch (28/30 only),

livewell switch (option)

11. Remote battery controller

24 KINGFISHER BOATS 3125 | 3425 OWNERS MANUAL

12. Remote battery switches

13. Main fuse and bilge fuse(s)

14. Bilge pumps

15. Head stall light

16. Deck lights

17. Shower sump (under deck) (option)

18. Invertor Controller (option)

19. Power invertor (under deck) (option)

20. Cook top (option)

21. Fishbox macerator pumps

Fuse Panel

A fuse panel label is located underneath the dash console.

This label shows the location of the fuses for each option.

Dash Panel

A. Anchor/Nav light

B. Forward bilge

C. Aft bilge

D. Forward heat fan

E. Aft heat fan

F. Interior lights

G. Aft deck lights

H. Starboard and center wiper

I. Port wiper

J. Horn

NOTE: The dash layout may change depending on the

boat model or options chosen.

Example of a fuse panel layout

When a fuse is suspected to be blown, the following

procedure should be followed:

❏ Turn off the component or appliance

❏ Turn the battery switch to the off position

❏ Locate and remove the blown fuse

❏ Replace the blown fuse

❏ Turn on the battery switch to the desired location

❏ Turn on the component or appliance

IMPORTANT: If a fuse burns out continually, consult your

authorized KingFisher dealer.

NOTE: As part of the pre-trip safety check list, it is a good

idea to make sure that there is a selection of spare fuses

on board that can be used in case of emergency.

Breakers

The breakers are located next to each of the dashboard

switches and the 12v accessory plug in. When the breaker

is tripped, the button will pop out. Simply press the

breaker button back in to re-set. If the same breaker pops

continually, consult an authorized Kingsher dealer.

Navigation Lights & Horn

The correct function of the navigation lights and horn are

critical to safe operation of the boat.

Cabin lights

The cabin lights are controlled by the cabin light switch.

Deck lights

The deck light illuminates the cockpit area of the boat and

is operated by the deck light switch.

Wipers

The wipers are controlled by operating their corresponding

dash mounted switches.

3125

|

3425 OWNERS MANUAL KINGFISHER BOATS 25

Troubleshooting

If the navigation, anchor lights or horn are not

operating correctly:

❏ Conrm that the battery system is fully charged and

functioning and that all wires leading to the batteries

are secured rmly to the battery posts

❏ Check that the main 30 amp fuse and the fuse under

the dash have not blown

❏ Check that the bulbs in the lights are not blown

❏ Once the above has been checked, if the lights

or horn are not functioning correctly consult an

authorized KingFisher dealer

Note: If the boat is going to be operated at night or in poor

visibility, the navigation light and the anchor light must be

turned on. If the boat is being anchored at night or in poor

visibility, the anchor light must be turned on. Check the local

State or Provincial guidelines or with the U.S. or Canadian

Coast Guard for this and further safety regulations.

Accessory Wire Harness (Optional)

An optional wiring upgrade is available on all

KingFisher models.

❏ Check that the 30 amp inline fuse has not blown

❏ Check that the component fuse has not blown,

and that the component is not faulty

❏ Once that all the above has been checked, if the

component is still not operating, consult an authorized

Kingsher dealer

If a component or appliance trips the breaker:

❏ Turn off the appliance or component

❏ Move the breaker switch back into the on position

❏ Turn on the component or appliance

Note: If an appliance or component trips its breaker

continually, do not use the appliance or component and

refer to an authorized KingFisher dealer.

This consists of a direct power feed from the battery

switch to a fuse block and bus bar located underneath

the dash.

The positive feed is fused with a 30 amp inline fuse located

close to the battery switch, behind the bilge doors.

If components that are wired into the upgrade wiring

system fail to operate:

❏ Conrm that the battery switch is turned on.

❏ Conrm that the battery system is fully charged and

functioning and that all wires leading to the batteries

are secured rmly to the battery posts.

26 KINGFISHER BOATS 3125 | 3425 OWNERS MANUAL

ANCHOR ROPE AND CHAIN REQUIREMENTS

Anchoring:

(a) Anchoring (manually controlled freefall):

1. Release any anchor locks.

2. When safe, insert the Lewmar wrench in to the capstan drive cap. Rotate clockwise to grip the gypsy and

anticlockwise to free the gypsy controlling the rate of descent of the anchor. Lock the clutch by turning the drive cap

clockwise and engage the anchor locks.

3. To return the windlass back to powered operation lock the clutch by rotating the capstan drive cap clockwise until

tight and remove the wrench handle.

4. Engage the circuit breaker/isolator and press the up button.

5. NOTE: If the clutch nut is not tight the internal clutch mechanism will rotate freely and not engage the drive

to the capstan.

a. Anchoring (powered UP/DOWN):

To release anchor:

1. Check clutch nut is tight. If the clutch nut is not tight the internal clutch will rotate freely and not engage

the drive to the capstan.

2. Release any anchor locks.

3. Engage the circuit breaker/isolator. Press DOWN button.

To retrieve anchor:

1. Press the UP button continuously to retrieve the anchor.

Note: If the clutch nut is not tight the internal clutch will rotate freely and not engage the drive to the capstan.

3125

|

3425 OWNERS MANUAL KINGFISHER BOATS 27

TruePower Combi 2000 Pure Sine Wave Series

Your new ProMariner TruePower Combi unit is current limiting with built in “smart”

features to monitor vital functions and preclude damage to the charger and the

installed system. The unit incorporates alarms, indicators and an auto shutdown feature for peace of mind and trouble free operation. This section contains

descriptions of the LED indications and functions of controls. Turning the unit OFF

and ON again will restart the unit after a fault, however, if the fault is still present,

the unit will again shut down.

Inverter – The TruePower Combi serves as a Pure Sine wave or a Quasi

(modied) Sine wave inverter, converting DC power to clean, reliable AC power.

Charger – The TruePower Combi also serves as a high efciency automatic

battery charger suitable for all commonly available battery types.

Transfer Switch – The TruePower Combi includes an internal, automatic 30 amp AC Transfer switch that senses the

presence of AC shore/station power. Upon connection to a shore power/shore station source, the Combi will switch

from INVERTER mode (providing AC power via DC battery source) to CHARGE mode, automatically. This switch, in

compliance with ABYC E-11, disconnects the neutral AC lead from the AC ground when in shore/station power mode.

28 KINGFISHER BOATS 3125 | 3425 OWNERS MANUAL

OPTIONS AND FEATURES

Airtronic D2 Heater (Optional)

The Airtronic D2 is a compact diesel burning 7,500 BTU/

hr air heater. These heaters provide hot air to the interior

of the boat for passenger comfort and window defrosting.

Various control options are available to operate the heater.

It cycles through four heat outputs modes, (boost, high,

med, low) in order to maintain a desirable temperature. In

the event that the heat output required is less then what

the “low” power mode is distributing the heater switches to

“stand-by” mode.

Espar Hydronic Heater (Optional)

The Espar Hydronic heater not only provides hot water but

also cabin heat by ducting hot air via fan heaters into the

cabin, cuddy and dashboard vents. The Espar Hydronic

heater works by circulating heated water in a closed

loop through a heat exchanger in the hot water tank and

then in turn through two different radiator blower units

located below the rear counter top and underneath the

dash footrest. The blowers for these units are operated by

switches on the dash.

Hot Water Tank

The hot water tank works in conjunction with the Espar D5

hydronic heater and the shore power. When the boat is

plugged into shore power, the hot water tank runs off 120

AC voltage with the main breaker switched on and the

hot water tank breaker switched on. When the boat is not

plugged into shore power, the water gets heated by the

coolant being circulated by the D5 Espar heater.

Shore Power System

The shore power breaker panel is located to the starboard

side of the helm seat.The shore power option enables the

boat user to run the boats electrical components without

the use of the internal battery system.

These lights are located adjacent to the panel’s breakers.

If reverse polarity is indicated immediately disconnect the

shore power cord, and consult an authorized KingFisher

dealer.

A green light on the shore power breaker panel will be