Page 1

TM

STOVES

USER’S INSTRUCTIONS

BSV-01SERIES,BSV-02SERIES,BSV-03,BSV-04,

BSV-05&15, BSV-06&16, BSV-07, BSV-08, BSV-09 SERIES,

BSV-17SERIES, BSV-21, BSV-22, BSV-23, BSV-24, BSV-25,

BSV-26,BSV-701,BSV-702,BSV-703,BSV-704,BSV-801,BSV-8

02,BSV-803,BSV-804,BSV-805

PLEASE READ THIS USER’S INSTRUCTIONS CAREFULLY WHEN YOU ASSEMBLE,

INSTALL, OPERATE, AND MAINTAIN YOUR STOVES! IF ANY MORE QUESTIONS,

PLEASE CONTACT OUR DEALERS IN YOUR LOCAL PLACE.

DEALER STAMP

EN13240:2001

Manufacturer:Xuzhou Best Art&Crafts Co.,Ltd.

Second floor,South building, No.390,Fuxing South Road,

Xuzhou City,Jiangsu,221000,P.R.China

Page 2

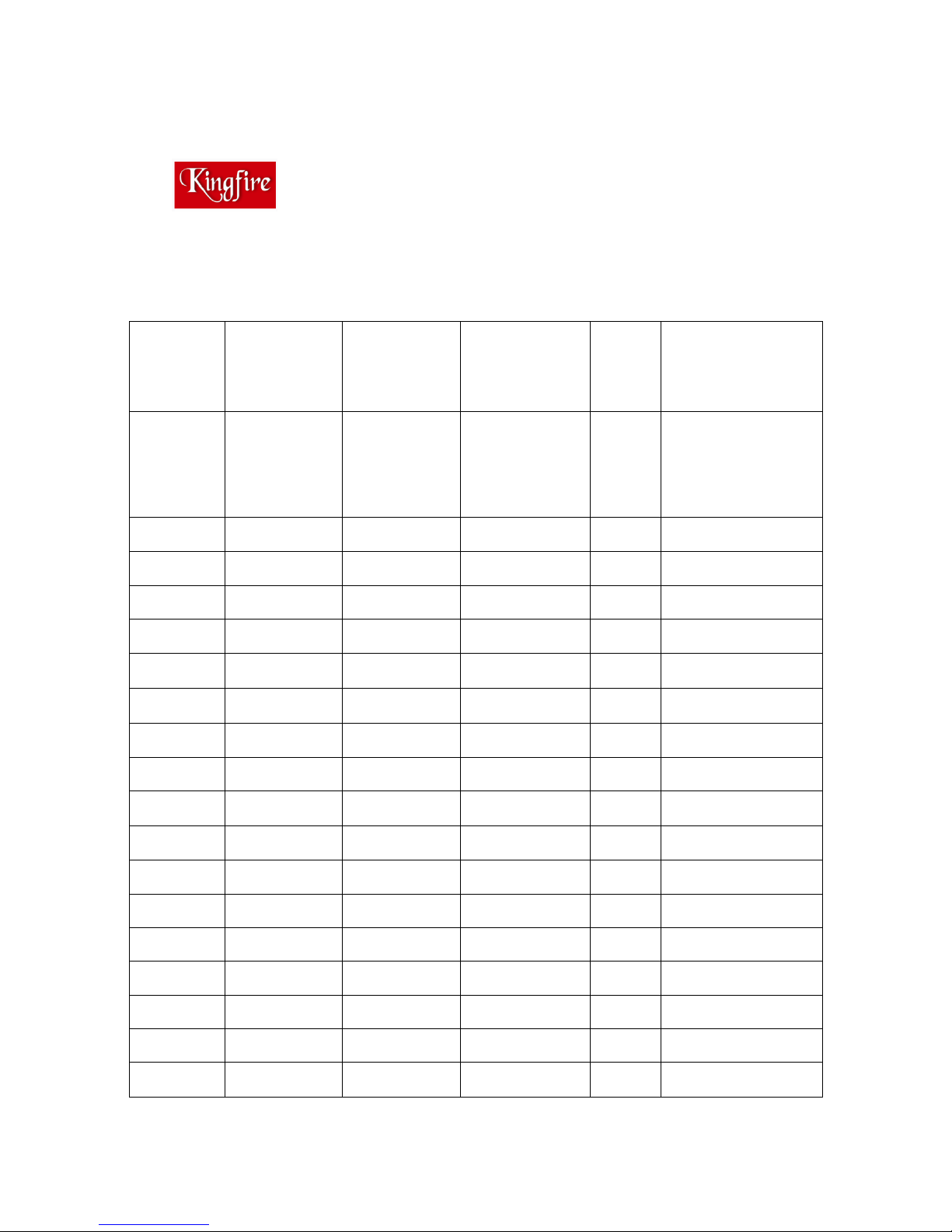

The user’s instructions are suitable for Kingfire models ranged from

BSV01 to BSV26, totally more than 30 models. Please see the

following chart information, and select your models:

Models

Specification

of cast iron

Nominal

Heat output

Recommended

fuels

Weight

Dimension

(H*D*W)

BSV01

grey iron 18#

12 kW

Solid mineral

fuels,

peat briquettes,

wood, multifuel

130kg

710*470*570(mm)

BSV01-2

grey iron 18#

9 kW

Same above

100kg

670*425*510(mm)

BSV01-3

grey iron 18#

7 kW

Same above

81kg

605*320*460(mm)

BSV01-4

grey iron 18#

5kW

Same above

65kg

550*310*430(mm)

BSV02

grey iron 18#

14kW

Same above

175kg

715*460*720 (mm)

BSV03

grey iron 18#

12 kW

Same above

130kg

665*455*665 (mm)

BSV04

grey iron 18#

16kW

Same above

200kg

710*535*820(mm)

BSV05

grey iron 18#

8 kW

Same above

90kg

560*440*460 (mm)

BSV06

grey iron 18#

8kW

Same above

93kg

560*440*460(mm)

BSV07

grey iron 18#

6kW

Same above

76kg

590*360*470 (mm)

BSV08

grey iron 18#

7kW

Same above

83kg

610*410*470 (mm)

BSV09

grey iron 18#

8 kW

Same above

93kg

610*460*465(mm)

BSV09-2

grey iron 18#

6kW

Same above

71kg

600*380*430 (mm)

BSV09-3

grey iron 18#

4.5kW

Same above

62kg

535*320*400(mm)

BSV15

grey iron 18#

8 kW

Same above

90kg

560*440*460 (mm)

BSV16

grey iron 18#

8 kW

Same above

93kg

560*440*460(mm)

BSV17

grey iron 18#

11kW

Same above

130kg

625*570*640(mm)

BSV17-2

grey iron 18#

8kW

Same above

90kg

550*380*545 (mm)

TM

STOVES

Page 3

BSV701

grey iron 18#

8 kW

Same above

86kg

650*360*440 (mm)

BSV702

grey iron 18#

11kW

Same above

120kg

650*400*600(mm)

BSV703

grey iron 18#

14 kW

Same above

168kg

725*465*700(mm)

BSV704

grey iron 18#

10kW

Same above

115kg

682*422*476(mm)

BSV801

grey iron 18#

7kW

Same above

88kg

620*380*460 (mm)

BSV802

grey iron 18#

9kW

Same above

100kg

660*430*490 (mm)

BSV803

grey iron 18#

8 kW

Same above

95kg

635*360*480(mm)

BSV804

grey iron 18#

14kW

Same above

170kg

730*470*730 (mm)

BSV805

grey iron 18#

12Kw

Same above

130kg

680*420*580(mm)

BSV21

grey iron 18#

5kW

Same above

68 kg

630*340*440(mm)

BSV22

grey iron 18#

7 kW

Same above

80 kg

650*380*460(mm)

BSV23

grey iron 18#

7 kW

Same above

80 kg

670*380*460(mm)

BSV24

grey iron 18#

7 kW

Same above

80 kg

670*390*480(mm)

BSV25

grey iron 18#

6 kW

Same above

75 kg

680*350*480(mm)

BSV26

grey iron 18#

7 kW

Same above

80 kg

670*400*470(mm)

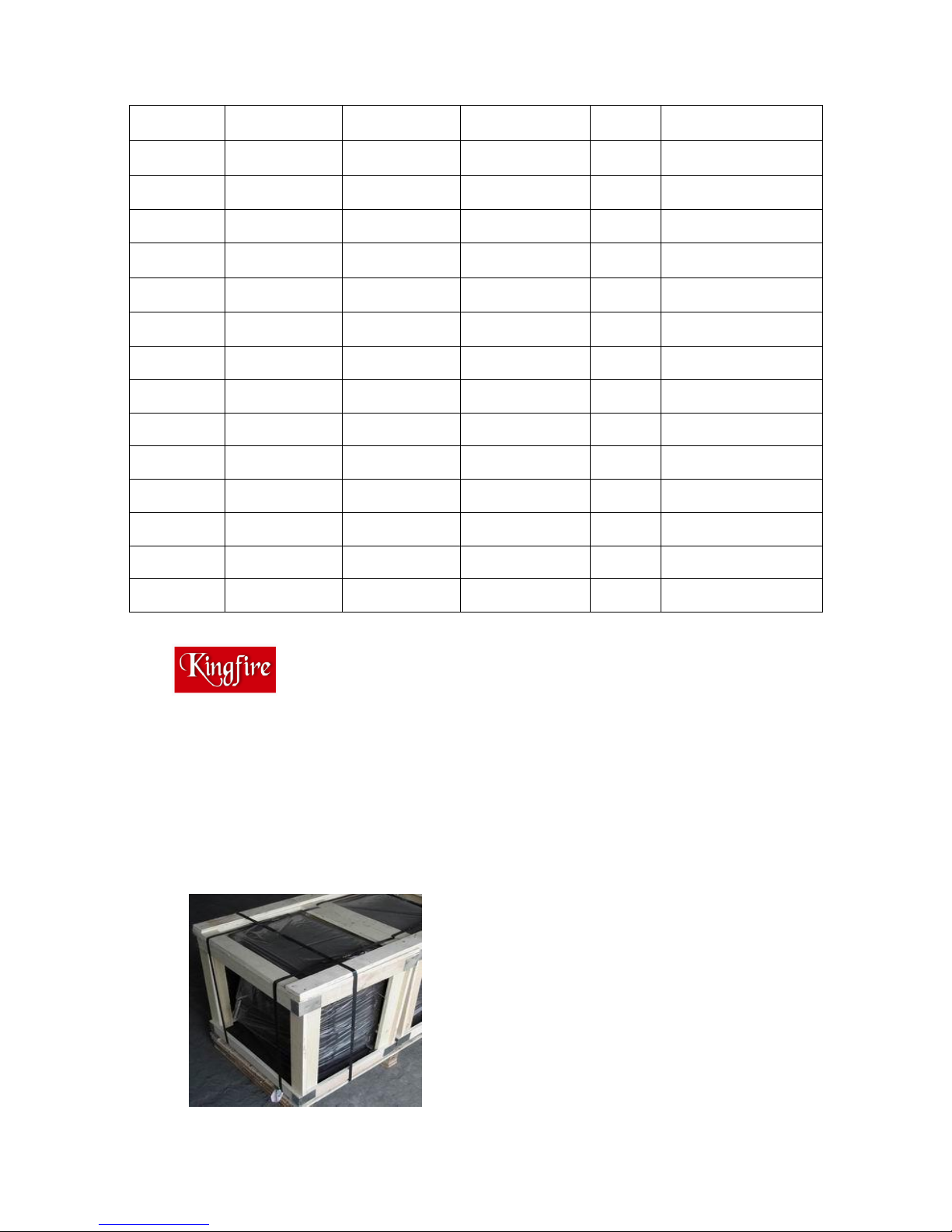

ASSEMBLY

Please assemble your Kingfyre stove according to the following

instructions:

→ Kingfyre stoves come to you packaged

In a plywood crate

TM

STOVES

Page 4

↓

↓

↓

↓

→ fix the legs with the set of bolts and

washers, do not over tighten. (Legs are

supplied packed inside the stove)

→ Remove the crate and take out all the

components

→ Remove the protective plywood panel

on the bottom of the stove.

TM

STOVES

Page 5

↓

Assembling your stove correctly is essential for ensuring a safe and efficient

burning control. If you have any doubts, please contact local dealer where your

stove was purchased.

Warning! When assembling the appliance, care should be taken to avoid the

possibility of personal injury.

Any unauthorized modification of the appliance is prohibited.

INSTALLATION

It is important that all local regulations, including those referring to national

and European Standards need to be complied with when installing the

appliance. We are not responsible for any fault arising through incorrect

installation. Always have the stove installed by a competent person and ensure

its installed with accordance to your local building regulations.

UK customers should consider using a HETAS installer.

Visit www.hetas.co.uk to find a registered installer near you.

Safety Attentions

→ fit the baffle, retainer bar, and

ashpan as shown.

→ fix the flue collar with set bolts and washers

supplied; rear or top flue option.

TM

STOVES

Page 6

Handling

Necessary facilities must be available for loading, unloading and site handling.

Minimum of 2 persons is required for handling and a sack barrow is recommended,

always ensure you make the necessary precautions to avoid injury.

Fire Cement

Some types of fire cement are caustic and should not touch your skin. In case of

contact, wash immediately with plenty of water.

Metal Parts

Be careful of personal injury when installing or maintaining this appliance.

Other possible injuries

The stove contains no harmful materials, but if there is a possibility of using any

dangerous materials in the course of installation then please seek specialist

guidance and use appropriate protective equipment.

Important Warning!

This appliance must not be installed into a chimney shared with any other heating

appliance.

There must not be an extractor fan fitted in the same room as the stove as this can

cause the stove to emit fumes into the room.

INSTALLATION

Chimney

The chimney must be fitted in accordance with manufacturer’s instructions and

Building Regulations.

The chimney height and the position of the chimney terminal should conform to

Building Regulations and all local regulations, including those referring to national

and European Standards.

The chimney must be in good condition, and any cracks and obstructions are not

permitted. The diameter of the flue should not be less than 125mm and not more

than 200mm. If any of these requirements are not met, the chimney should be lined

by a suitable method.The chimney must be swept before connection to the any liner

or stove. We also recommend that the chimney be swept a second time within a

month of regular use after installation.Please consult your local dealer,if you have

any doubts about your chimney.

As a protective measure to ensure safer use of your stove, we always recommend

you use a Multifuel Liner within your chimney, if suitable.

Flue Draught

A flue draught ranged from 1.2mm to 2.5mm water gauge may keep the appliance

in good performance. If the flue draught exceeds 2.5mm, a draught stabilizer must

be installed in order to control the rate of burning and prevent overfire. You should

TM

STOVES

Page 7

check the flue draught when fire is on high output.

Chimney Connection

You should brick up or seal an existing fireplace opening with a register plate. A

short length of flue pipe of a minimum 125mm internal diameter may then be used

to connect the stove to the chimney. This flue pipe should be of 316 grade stainless

steel or vitreous enamelled, nominal thickness 1.2mm. Ensure that the pipe end is

no closer than 76mm to the side or rear chimney walls.

Ideally, the old fireplace should be filled in so that there is a smooth streamline

entry into the flueway.

The length of any horizontal run of flue pipe must not exceed 125mm.

It is essential that all connections between the stove and chimney-flue are sealed

and made airtight.

Both the chimney and flue pipe must be accessible for cleaning and if any parts of

the chimney cannot be reached through the stove(with baffle removed), a soot door

must be fitted in a suitable position to enable this to be done.

Water Connection (Boiler Model Only)

We recommend that the installation is carried out by a qualified heating engineer

who is fully experienced in solid fuel heating installations.

These must be provided

-an expansion tank open to the atmosphere,

-an indirect cylinder,

-a gravity circulation to one radiator to dissipate heat when the pump is off,

-the fitting of a low limit thermostat to the primary return to ensure the pump dose

not operate when return water temperatures are less than 50°C,

-a drainage tap in the return flow.

Air Supply

A permanent, unobstructed air opening is essential for the room or space containing

this appliance. The air opening should be at least 3625mm2 when a draught

stabilizer is equipped. Due care for air requirements will need to be taken if any

other appliances are permitted to work in the same room and space.

Safety Clearances

It is workable for the appliance to be recessed in a prepared fireplace, but a suitable

free air gap (minimum 150mm) must be left around the sides and top and at least

50mm at the back of the appliance to reach maximum heat output and for access to

the rear of the stove. All non-combustible walls closer than 300mm to the stove

should be at least 75mm thick.

In all circumstances the back wall of the fireplace recess and the hearth should be

made of non-combustible material,

Allow an apron of a least 300mm at the front of the stove and 150mm on either

side.

TM

STOVES

Page 8

The hearth on which the stove is to be placed should not be less than 125mm thick

and should be in accordance with the current building regulations.

Care should be taken to level the stove using the adjusting screws in the feet.

The appliance shall be installed on floors with an adequate load-bearing capacity. If

an existing construction doesn’t meet this prerequisite, suitable measures (e.g. load

distributing plate) shall be taken to achieve it.

There should be no combustible material within a distance of 500mm from any

surface of the stove

Commissioning and Handover

You should leave an appropriate period of time for fire cement and mortar to dry

out upon completion of the installation. In order to ensure the smoke and fumes are

taken from the stove up the chimney and emitted safely to atmosphere, a small fire

should be lit first. Do not run the stove at full output for at least 24hours.

Finishing installation and commissioning, the operating instructions and tools for

your stoves should be kept in hand. It is also important to know how to use the

stove properly and use only the recommended fuels for this appliance. The user

should know how to have smoke or fumes emitted properly from the stove and be

warned to prevent injuries in case of the presence of children, aged or infirm

persons.

Operating Instructions

WARNINGS AND IMPORTANT!

All local regulations, including those referring to national and European

Standards need to be complied with when installing the appliance.

This appliance is not suitable for installation in a shared flue system.

The firebox and ashpit cover shall be kept closed except during ignition,

refueling and removal of residue material to prevent fume spillage.

It is important to use this appliance correctly so as to achieve best results.

WARNING!(Boiler Model Only)

Ensure that there is enough water in the heating system.

Do not light the fire if it is suspected that any part of the water system is

frozen.

Air Controls

Warning! Parts of the appliance, especially the external surfaces, will be hot to

touch when in operation and due care need to be taken, e.g. protective gloves

should be given in operation.

It is essential for the appliance to have a sufficient air supply for combustion and

ventilation.

TM

STOVES

Page 9

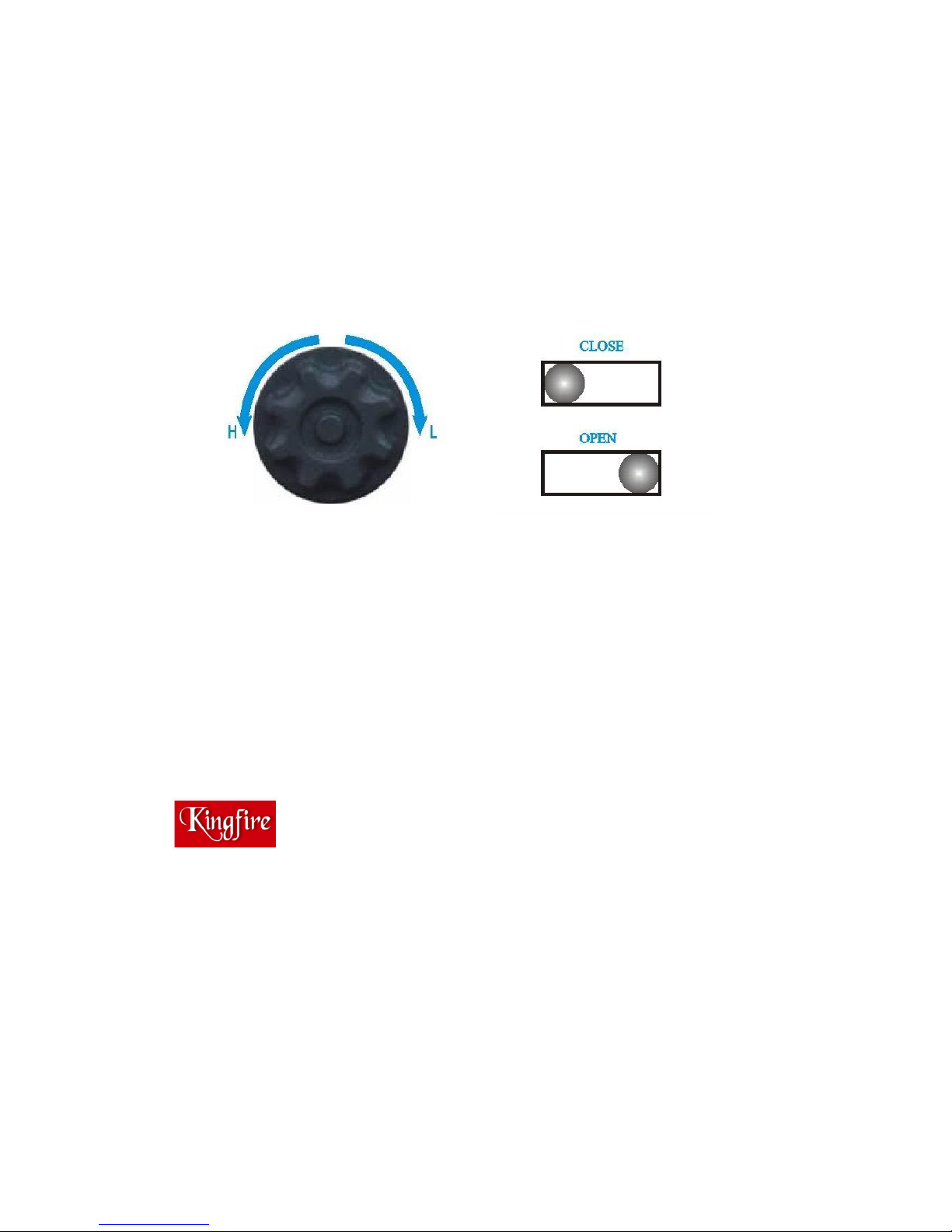

Primary Air

Primary air is controlled through the assembly on the bottom of the door. This

provides a conventional air draught which passes through the fuel bed. The primary

air intakes can be adjusted to control the fire in combustion chamber.

Secondary Air

This appliance is fitted with an air wash system which can keep heat-resistant glass

of firedoor clean. This secondary air is controlled through the fittings on the top of

the stove.

The air controls have two types: one is rotary air controls; the other is sliding air

controls. They are operated as follows:

Bottomgrate

Two types of bottomgrate are equipped with your Kingfire stoves for your option:

rotary style and grid style. For rotary style grate, you can operate it by dragging

stainless steel rod forward and backward to de-ash. For grid style grate, a special

hook is supplied to de-ash. It is highly recommended to de-ash regularly in case any

build-up of ash will damage the cast iron fuelbed. You should be careful of hot parts

of the appliance in operation.

Ashpan

You should clean up the ashpan regularly. Use the supplied appropriative tool to

pull the ashpan out of the stove.

on solid mineral fuels

Please keep no more than a 30℃ incline of the fuel bed from front to back, when

you put solid mineral fuels on the fuelbed. The height of loading fuels must not

exceed the rear cast iron lining.

The refueling intervals at nominal heat output will approximately 4 hours. We

suggest you refuel in time so as to get the best possible results. When using solid

mineral fuels, we suggest you keep the secondary air control in the closed position,

which can burn in maximum efficiency. At this time the primary air controls can

adjust the burn rate of the appliance.

TM

STOVES

Page 10

In order to prevent the ash from being stacked to the underside of the bottomgrate,

please always de-ash before refueling. Once the ash builds up, it possibly stifles the

airflow and causes the fire to die.

Important!- It is very important to empty the ashpan regularly. In case the ash

build up the underside of the grate, burnout or distortion of the grate may be

caused;

on wood fuels

The refueling intervals at nominal heat output will approximately 1.5 hours. You

may load wood higher in the stove than solid mineral fuel but wood or logs are not

permitted to touch the baffle plate.

When using solid mineral fuels, we suggest you keep the primary air control in the

closed position, which can burn in maximum efficiency. At this time the secondary

air controls can adjust the burn rate of the appliance.

Wood burns best with a layer of ash on fuelbed, and care should be taken to only

remove surplus residue from the stove timely.

We recommend you only use dry, seasoned wood as fuels; the wood should have

been cut, split and stacked for at least one year in circulating air surround to dry out.

Otherwise, wet or unseasoned wood will cause tar deposits in the stove and

unsatisfactory heat output will occur.

Ignition

It is better for you to have 2 or 3 small fires before operating your stove to its

maximum heat output. This can help the paint to cure steadily and to give a long

service life of the paint finish. During the period, there will be an unpleasant smell,

you may keep all doors and windows open for your comfort, though the smell is

non-toxic.

First, load with starting fuel, i.e. paper, dry sticks or firelighters etc. Second, Light

the fire at the base keeping all air controls open. Wait until the fuel reach a steady

glow, then build the fire up step by step, more fuel should be added when you have

a nice fire settled across the grate bed.

Warning! You need to check for blockage prior to re-lighting after a prolonged shut

down period.

Shutting Down

Firstly, close the primary air controls;

Secondly, close the secondary air controls;

At last the fire will go out owing to lack of air.

If reviving the fire, the primary air controls are recommended to open first, then

open the secondary air controls.

TM

STOVES

Page 11

Warning! The stove is still hot in the following time after the fire has been

extinguished.

Recommended Fuels

Fuels vary greatly in quality and performance. Anthracite is an approved natural

smokeless fuel( not processed). Sufficient air supply and above average fuelbed

temperatures are required to maintain best performance for this fuel, therefore, we

suggest the fuel is used in combination with other approved manufactured

smokeless fuels as per the HETAS approved list.

The following fuels are approved in closed appliance by HETAS Ltd.: Coalite

Cosycoke

Coalite Nuts Pureheat

Blazebrite Supercoke

Homefire Maxibrite

Homefire Ovals Newflame

Phurnacite Supacite

Mixed Nuts Fireglo Ovoids

Ancit Dragonbrite

Taybrite Anthracite Small Nuts

Sunbrite Doubles Wood Logs

You should only use authorized smokeless fuels in smoke control areas .

Warning! The use of the appliance as an incinerator and the uses of liquid,

unsuitable and non recommended fuels are prohibited.

If any difficulties and problems on fuel, consult your local approved fuel merchant.

HETAS Ltd.- Telephone 01242 673257- www.hetas.co.uk

Solid Fuel Association-Telephone 0800 600 000- www.solidfuel.co.uk

Safety guidance

FIRES CAN BE DANGEROUS-Do use a fireguard in the presence of children,

the elderly or the infirm. The fireguard should be consistent with

BS6539-Fireguards for use with solid fuel appliances.

DO NOT OVERFIRE- overfire can be dangerous. If any part of the stove grow

red, it shows overfire do occur. It means the use beyond its design capacity is not

allowed, and you should keep an eye on how it is burning and adjust the control

accordingly;

FUME EMISSION

Emit fumes can be avoided if it is installed and operated properly, fumes usually

appear from operations of de-ashing and refueling. Constant fume must be boring.

If fume emission does persist, then the following measures can be helpful:

TM

STOVES

Page 12

1) Open doors and windows

2) Let the fire out, or take out of fuel form the stove safely.

3) Check flue chimney to prevent blockage and clean if required.

4)Do not try to re-light the fire before the cause has been identified and corrected.

5) If needed, please seek professional assistance.

Warnings! –an extractor fan is prohibited to fit in the same room as this appliance.

IN THE EVENT OF CHIMNEY FIRE

a. Let others in the house know.

b. Call the Fire Brigade.

c. Close all the air controls

d. Move furniture and rugs away from the fireplace and remove any nearby

ornaments.

e. Place fireguard or spark guard in front of the stove.

f. Feel the chimney for signs of excessive heat.

If the wall is becoming hot, move the furniture away. Ensure that the Fire Brigade

can have a command of your roof space in order to check the area for signs of

spread.

MAINTENANCE

Stove body

Use a soft brush to clean the stove, cleaning must be given after it has cooled down.

The finish can be renewed with proprietary stove paint

Baffle plate

Remove and clean the baffle plate once a month to avoid soot or fly ash

blocking the flue ways and producing dangerous fume emission

Fireproof glass

use a proprietary glass cleaner to clean the glass when cool. You can not use any

materials which may bring glass damage to clean the panel. Wet logs on heated

glass, a badly aimed poker or heavy slamming of the doors could crack the glass

panels and you must be very careful.

Ceramic rope

We have extra ceramic rope along with the stove. Inspect the rope around the door

and glass. If rope is becoming detached, use a proprietary rope glue to reattach it.

Please replace the rope in case of poor condition.

Flueway and Chimney

Keep the chimney, flueway and any connecting flue pipe swept regularly. For users

TM

STOVES

Page 13

of smokeless fuels, sweep at east once a year; for wood and other fuels, at least

twice a year. If the stove is fitted in place of an open fire, then the chimney should

be swept one month after installation to clear any soot falls which may have

occurred due to the difference in combustion between the stove and the open fire.

We suggest users buy replacement and spare parts only from our dealers in

your local place.

Trouble clearing

No Fire can be burnt

Please check the following measures:

A proper fuel is being used.

The air inlet is unobstructed.

Chimneys and flueways are clear

Sufficient air supply is into the room.

No extractor fan is working in the same room as the stove.

Fire blazing out of control

Please Check:

A suitable fuel is being used.

The doors are tightly closed.

The air controls are all in the closed position.

The primary air control flap is not wedged in the open position.

The glass retaining clips are not loose.

The door rope seals are in good condition

TM

STOVES

Loading...

Loading...