Page 1

COIL ROOFING NAILER KIT

plusplus

performanceperformance

INSTRUCTION MANUAL

COPYRIGHT © 2005 ALL RIGHTS RESERVED BY KING CANADA TOOLS INC.

MODEL: 8245R

Page 2

IMPORTANT INFORMATION

2-YEAR

LIMITED WARRANTY

FOR THIS COIL ROOFING NAILER KIT

OFFERS A 2-YEAR LIMITED WARRANTY

KING CANADA TOOLS

FOR NON-COMMERCIAL USE.

PROOF OF PURCHASE

Please keep your dated proof of purchase for warranty and servicing purposes.

REPLACEMENT PARTS

Replacement parts for this tool are available at our authorized KING CANADA service centers across Canada. For servicing, contact

or return to the retailer where you purchased your product along with your proof of purchase.

LIMITED TOOL WARRANTY

KING CANADA makes every effort to ensure that this product meets high quality and durability standards. KING CANADA warrants to

the original retail consumer a 2-year limited warranty as of the date the product was purchased at retail and that each product is free

from defects in materials. Warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence or accidents,

repairs or alterations and lack of maintenance. KING CANADA shall in no event be liable for death, injuries to persons or property or

for incidental, special or consequential damages arising from the use of our products. To take advantage of this warranty, the product

or part must be returned for examination by the retailer. Shipping and handling charges may apply. If a defect is found, KING CANADA

will either repair or replace the product.

KING CANADA

OOLS INC. DORVAL, QUEBEC, CANADA H9P 2Y4

T

Page 3

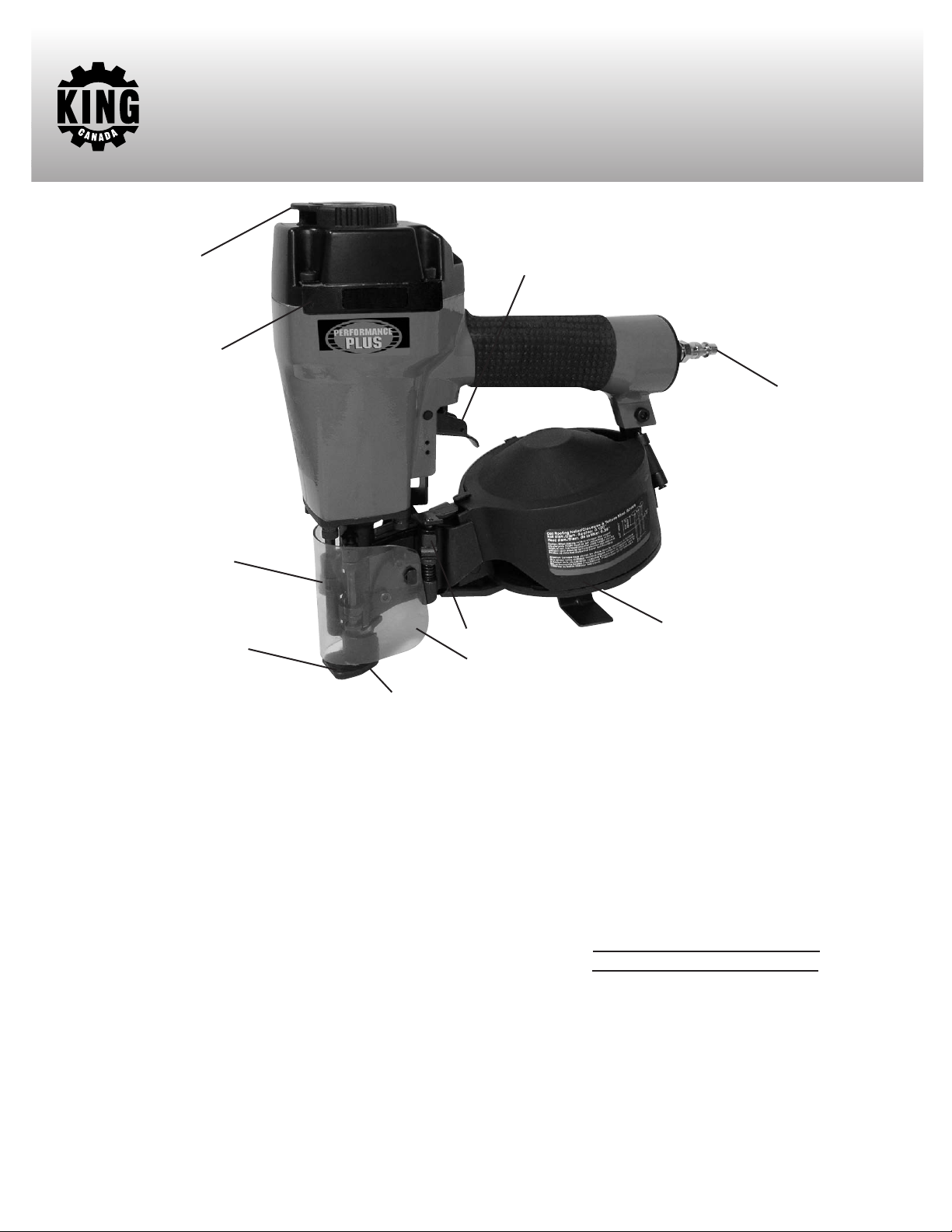

GETTING TO KNOW

YOUR COIL ROOFING NAILER

Air deflector

Wear protector

Depth adjustment

device

Safety release

Magazine latch

Debris protector

Nail discharge area

rigger

T

Air inlet

Magazine cover

SPECIFICATIONS

............................................................................................................................................................................................8245R

Model

Air inlet ......................................................................................................................................................................................1/4” NPT

Compressed air:

Maximum permissible operating pressure ................................................................................................................

Recommended operating pressure range ............................................................................................................................70-120 PSI

Nail range ......................................................................................................................................

Diameter

Head diameter ................................................................................................................................................................................0.39”

Nail capacity ..........................................................................................................................................................120 coil roofing nails

Features:

•Powerful coil roofing nailer drives standard .120˝ coil roofing nails

from 7/8˝ to 1-3/4˝

•Special one piece hardened driver for long, trouble-free performance

•Adjustable air deflector controls the direction of air exhaust

•Sequential and bump firing modes

•Depth adjustment device

•Side mounted wear protectors

•70-120 PSI operating pressure

•Comes with 1/4˝ air inlet, debris shield, safety glasses, oiler, hex. keys and

sturdy carrying case

........................................................................................................................................................................................0.120”

COIL

RN-12025 1’’ (25MM APPROX.)

RN-12032 1-1/4’’ (30MM APPROX.)

7/8” to 1-3/4” 11ga. coil roofing nails

AVAILABLE

KING INDUSTRIAL

ROOFING NAILS

120 PSIG (8.3 bar)

Page 4

SAFETY INSTRUCTIONS

• Read and understand this manual and all the safety instructions before operating this coil

oofing nailer. If you have any questions, please contact our authorized service centres or

r

retailers for help.

• Never allow the use of flammable gases as a power source for the coil roofing nailer. Use

filtered, lubricated and regulated compressed air only.

• Never use gasoline or other flammable liquids to clean this coil roofing nailer. Vapors in the coil

roofing nailer will ignite by a spark and cause the coil roofing nailer to explode.

• Do not exceed the maximum permissible operating pressure of this coil roofing nailer (120

PSIG).

• Disconnect the coil roofing nailer from its air supply before clearing jams, servicing, adjusting

and while the coil roofing nailer is not in use.

• Do not keep the trigger pulled on contact safety trip mechanism when carrying or holding the

coil roofing nailer. Never carry the coil roofing nailer by the air hose or pull on the air hose to

move the coil roofing nailer.

• At the workplace, always wear protective equipment such as Z87 safety glasses, hearing and

head protection.

• Do not use a check valve or any other fitting which allows air to remain in the coil roofing nailer.

• Do not place your hand or any part of your body in the nail discharge area of the coil roofing

nailer when connecting or disconnecting from the air supply.

• Never point any operational nail driving tool at yourself or at any other person.

Page 5

LUBRICATION

AIR SUPPLY AND CONNECTIONS

LUBRICATION AND MAINTENANCE

• Your coil roofing nailer needs to be lubicated before and after the first time you use it.

• Disconnect the air supply from the coil roofing nailer before lubricating.

• Turn the coil roofing nailer so that the inlet is facing up and put

or oil without detergent into the air inlet. Never use detergent oil or additives. Operate the nailer briefly

after adding oil.

• Wipe off excessive oil at the exhaust. Excessive oil will damage O-rings of the coil roofing nailer. If a

in-line oiler is used, manual lubrication through the air inlet is not required on a daily basis.

AIR SUPPLY AND CONNECTIONS

WARNING!

THE FOLLOWING ILLUSTRATION SHOWS THE CORRECT MODE OF CONNECTION TO THE AIR

SUPPLY SYSTEM WHICH WILL INCREASE THE EFFICIENCY AND USEFUL LIFE OF THE NAILER.

Air hose

Quick couplers

Quick connector

Quick

connector

Oiler

Regulator

Filter

ONE DROP of high speed spindle oil

Compressor

• Many air tool users find it convenient to use an oiler to help provide oil circulation through the tool and

it increases the efficiency and useful life of the tool. Check oil level in the oiler daily.

• Many air tool users find it convenient to use a filter to remove moisture and impurities which can rust

or wear internal parts of the tool. A filter also increases the efficiency and useful life of the tool. The

filter must be checked on a daily basis and, if necessary

• For better performance, install a 3/8” quick connector (1/4” NPT

.315” on your tool and a 3/8” quick coupler on the air hose.

, drained.

threads) with an inside diameter of

Page 6

CONTACT SAFETY TRIP MECHANISM

OPERATING A CONTACT SAFETY TRIP TOOL:

• The operator is required to have the finger off the trigger and the nose of the coil roofing nailer to be

placed on the workpiece.

• The contact safety trip mechanism is then depressed against the workpiece and the trigger is pulled to

drive the nail.

• The trigger is released after each nail is driven.

• Move the coil roofing nailer to the next location and repeat the above procedure.

VERIFICATION

• Disconnect the air supply from the air inlet.

• Empty all nails from the magazine.

• Make sure the trigger and the contact safety trip mechanism moves up and down without sticking.

• Connect the air supply to the nailer air inlet.

• Depress the contact safety trip mechanism against the workpiece without pulling the trigger. The coil

roofing nailer must not cycle.

Never use the tool if a cycle occurs.

• Hold the coil roofing nailer clear of the workpiece. The contact safety trip mechanism should return to

its original down position. Pull the trigger. The tool must not cycle.

if a cycle occurs.

• Depress the contact safety trip mechanism against the workpiece and pull the trigger, the coil roofing

nailer must cycle.

Never use the coil roofing nailer

Page 7

LOADING NAILER & CLEARING JAMS

LOADING NAILER MAGAZINE

• Disconnect the air hose from the coil roofing nailer air inlet.

• Pull down latch and swing open the magazine cover.

• The tool must be set for the length of the nail to be used. Nails will not feed smoothly if the magazine

is not correctly adjusted. The magazine contains an adjustable nail platform called an adjuster plate

on which the nail coil rests. The adjuster plate height can be adjusted up or down by turning the

adjuster nut above it. Adjust the adjuster plate height to suit the nail length you are about to load.

• Place the coil of nails over the magazine post. Uncoil enough nails to reach the feed pawl. Place the

first nail in front of the front tooth on the feed pawl in the driver channel. The nail heads must be in the

slot in the nose.

• Swing the latch door and magazine cover closed. Check to make sure that the latch pin engages when

released and that the magazine cover is locked behind the latch.

CLEARING JAMS

Disconnect the coil roofing nailer from the air compressor before adjusting, clearing jams,

servicing, relocating and during non-operation.

• Disconnect the air hose from the coil roofing nailer air inlet.

• Pull down latch and swing open the feeder cover, then open the magazine cover

• Pull nails away from the nose.

.

• Grab the jammed nail with pliers and remove.

• Close magazine cover and close latch securely

.

Page 8

OPERATING YOUR NAILER

OPERATING YOUR COIL ROOFING NAILER

WARNING! protect your eyes and ears. Wear Z87 safety glasses with side shields. Wear hearing

rotection. Employers are responsible for ensuring the user or anyone near the nailer wears the

p

above mentioned safety protection.

WARNING! Check and replace any damaged or worn components.

Add one/two drops of 30W oil for air tools into the air inlet.

•

• Install a quick connect fitting to the coil roofing nailer.

• Connect the coil roofing nailer to an air compressor using a 3/8” I.D. hose. Make sure the magazine

does not contain any nails and that the air hose has a rated working pressure exceeding 200 psi and

a female quick coupler.

• Regulate the air pressure to obtain 70 psi. Check the operation of the contact safety trip mechanism

following the instructions in this manual.

• Disconnect the coil roofing nailer, then load magazine with nails following loading instructions.

• Reconnect the air hose to the coil roofing nailer air inlet.

• Test for proper nail penetration by driving nails into appropriate scrap material. If the nails do not

achieve the desired penetration, regulate the air pressure to a higher setting until the desired

penetration is achieved. Do not exceed 120 psi.

Page 9

MAINTENANCE & TROUBLESHOOTING

CLEANING YOUR NAILER

• Never use gasoline or other flammable liquids to clean this coil roofing nailer. Vapors in the

nailer will ignite by a spark and cause the tool to explode and result in death or serious

personal injury.

• Disconnect the air supply from the coil roofing nailer.

Remove tar buildup with #2 kerosene fuel oil or diesel fuel. Do not allow solvent to get into the

•

TROUBLESHOOTING CHART

WARNING: Stop using this tool immediately if any of the following problems occur. Serious personal injury could occur. Any

repairs or replacements must be done by a qualified person or an authorized service centre only.

Problem Cause Solution

cylinder or dammage may occur. Dry off the tool completely before use.

• Air leaking at trigger valve

area.

• Air leaking between

housing and nose.

• Air leaking bewteen

housing and cap assembly.

• Nailer skips a nail.

• Nailer runs too slowly or

has loos of power.

• Jammed nails.

• O-rings in trigger valve are damaged.

• Loose screws in housing.

• Damaged O-rings.

• Bumper damage.

• Loose screws.

• Damaged seal.

• Worn bumper.

• Dirt in nailer nose.

• Dirt or damage prevents nails from

moving freely in the magazine.

• Inadequate air flow to nailer.

• Worn O-ring on piston or lack of

lubrication.

• Damaged O-rings on trigger valve.

• Air leaks.

• Cap seal is leaking.

• Nailer is not sufficiently lubricated.

• Broken spring in cap assembly.

• Exhaust port in cap is blocked.

• Driver guide worn or damaged.

• Nails are bent.

• Magazine or nose screws are loose.

• Damaged driver.

• O-rings must be replaced and safety trip

mechanism must be verified.

• Screws need to be tightened.

• O-rings must be replaced.

• Bumper needs to be replaced.

• Screws need to be tightened.

• Seal must be replaced.

• Bumper needs to be replaced.

• Clean.

• Magazine must be cleaned.

• Fitting hose and air compressor need

to be checked.

• O-rings must be replaced, lubricate.

• O-rings must be replaced.

• Screws and fittings need to be tightened.

• Seal needs to be replaced.

• Lubricate.

• Spring needs to be replaced.

• Damaged internal parts must be replaced.

• Replace driver guide.

• Replace with undamaged nails.

• Screws need to be tightened.

• Replace driver.

REPLACEMENT DRIVER, BUMPER & O-RING REPAIR KITS

After prolonged use of your Nailer, the internal O-rings, Bumper & Driver may have to be replaced

caused by wear & tear. To repair, a complete Driver, Bumper & O-ring Replacement Accessory

Kit is available for your Nailer (model: KW-083). Contact your local King Canada distributor for

more information.

PARTS DIAGRAM & PARTS LISTS

Refer to the Parts section of the King Canada web site for the most updated parts diagram and

parts list.

KW-083