HIGH BRIGHTNESS LED LIGHT BAR

PRELIMINARY SPEC

Part Number: KASL-4805QBFS/3 Blue

ATTENTION

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

DISCHARGE

SENSITIVE

DEVICES

Features

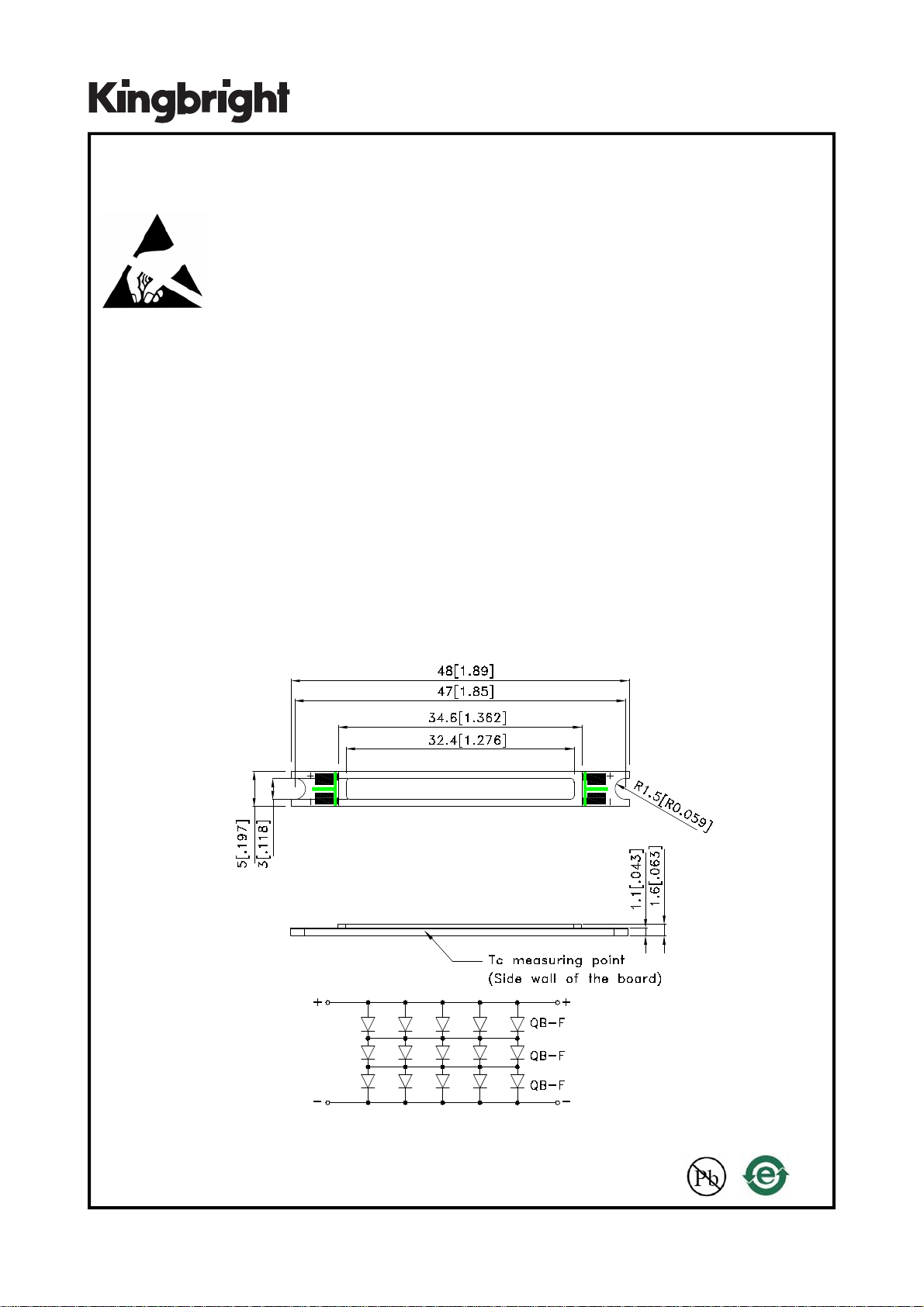

z Dimension: 48mm X 5mm X 1.6mm.

z Instant light.

z Linear type.

z High efficiency.

z Long operating life.

z Low power consumption.

z More energy efficient than incandescent,most halogen lamps, and fluorescent lamp.

z RoHS compliant.

Package Dimensions

Notes:

1. All dimensions are in millimeters (inches).

2. Tolerance is ±0.25(0.01") unless otherwise noted.

3.Specifications are subject to change without notice.

SPEC NO: DSAI8690 REV NO: V.1 DATE: NOV/14/2008 PAGE: 1 OF 8

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: D.M.Su ERP:1209000081

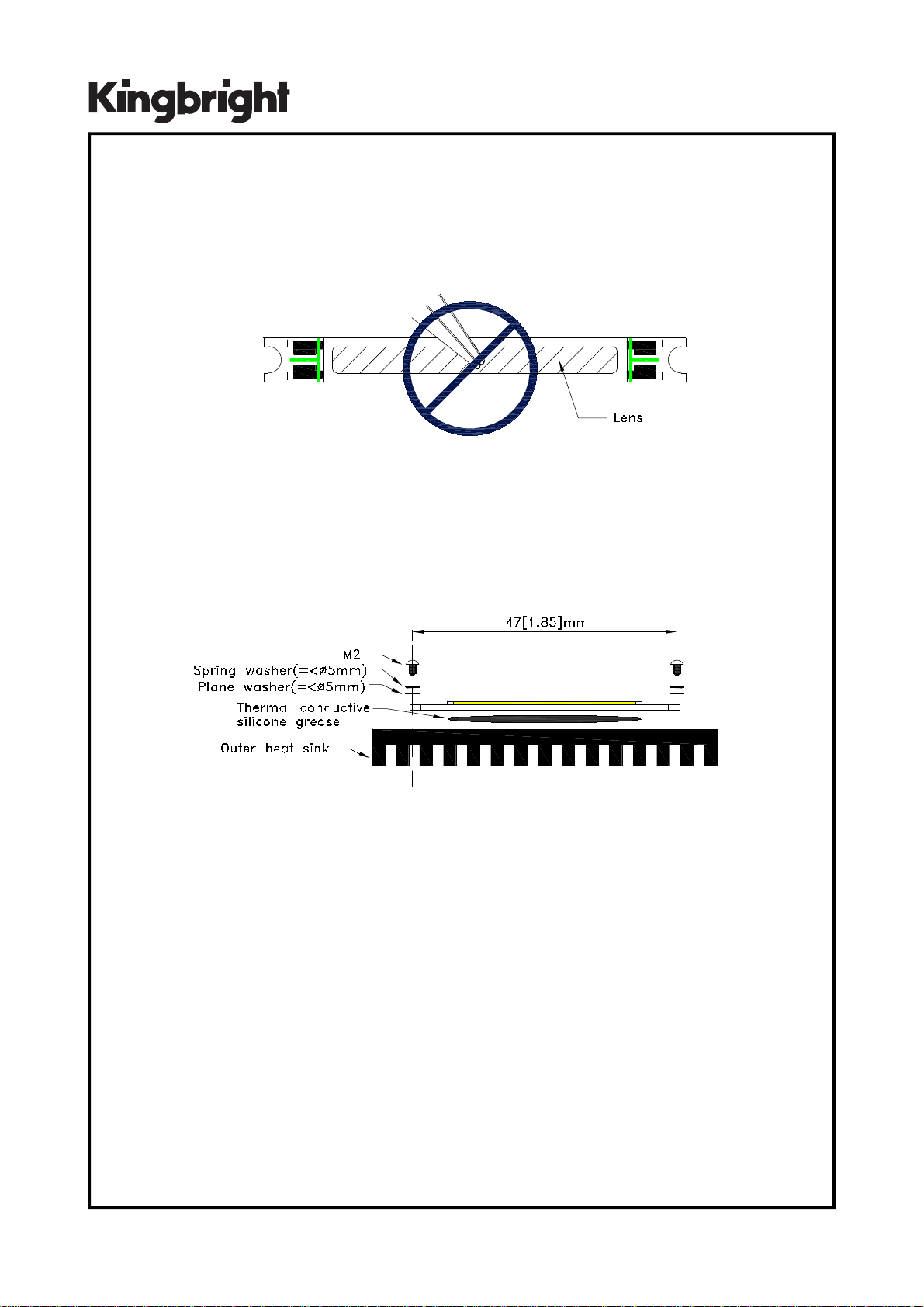

Precautions

1. Do not touch the lens with any sharp object.

2. No stress should be applied on the lens.

3. Thermal grease between the light bar and heat sink is recommended to fill air gaps for better thermal conductivity.

4. For securing the LED light bar, M2 screws are recommended. The light bar should not be bent or stressed in any way

which could damage the internal circuit.

5. To prevent damages caused by electrostatic discharge (ESD), it is recommended to wear proper gear such as

wristband or anti-static gloves when handling the product.

6. Constant current source is recommended to power the light bar. When more than one light bar are used, they should

be connected in series if possible.

7. Thermal management should be taken into consideration when using the product. Maximum driving current

should be reduced accordingly at higher ambient temperature to prevent overheating.

8. Soldering recommendations:

z Soldering iron power should not exceed 40W, and should not be in contact with the joint for more than 3.5 secs.

z The maximum soldering temperature should be less than 350°C.

z Do not touch the product immediately after soldering.

z Not reflow compatible.

SPEC NO: DSAI8690 REV NO: V.1 DATE: NOV/14/2008 PAGE: 2 OF 8

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: D.M.Su ERP:1209000081

Absolute Maximum Ratings

Parameter Symbol Rating Units

Forward Current I

Forward Pulse Current [1] I

Power Dissipation P

LED Junction Temperature T

F 350 mA

FP 500 mA

d 4.2 W

j 110 °C

Operating Temperature Topr -30~+100 °C

Storage Temperature Tstg -40~+110 °C

Case Temperature T

Note:

1. 1/10 Duty Cycle, 0.1ms Pulse Width.

c 100 °C

Electrical / Optical Characteristics

Part Name Device Parameter Symbol Min. Typ. Max. Units Conditions

Forward Voltage [2] V

Luminous Flux [3] Φv 18 25 - lm I

Wavelength at peak emission[4] λpeak - 461 - nm I

F 9.0 10.4 12.0 V IF=350mA

F=350mA

F=350mA

Dominant Wavelength λdom - 465 - nm I

Spectral bandwidth at 50%Φ

REL MAX Δλ1/2 - 25 - nm IF=350mA

Temperature coefficient of λpeak TCλpeak - 0.12 - nm/°C I

KASL-4805QBFS/3 Blue

Temperature coefficient of λdom TCλdom - 0.10 - nm/°C I

Temperature coefficient of Forward

Voltage

Thermal Resistance R

F/ΔT - -2.9 - mV/°C IF=350mA

ΔλV

th j-c - 3.5 - °C/W IF=350mA

2 θ 1/2

X direction

- 130 -

Emission Angle

Notes:

2. Forward Voltage is measured with an accuracy of +/-0.1V.

3. Flux is measured with an accuracy of +/-15%.

4.

Wavelength :+/-0.1nm.

Test Item

2 θ 1/2

Y direction

Test Condition

- 130 -

Moisture-proof Test 85°C , 85%RH for 1000 hours

°

°

F=350mA

F=350mA

F=350mA

I

F=350mA

I

F=350mA

SPEC NO: DSAI8690 REV NO: V.1 DATE: NOV/14/2008 PAGE: 3 OF 8

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: D.M.Su ERP:1209000081

SPEC NO: DSAI8690 REV NO: V.1 DATE: NOV/14/2008 PAGE: 4 OF 8

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: D.M.Su ERP:1209000081

SPEC NO: DSAI8690 REV NO: V.1 DATE: NOV/14/2008 PAGE: 5 OF 8

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: D.M.Su ERP:1209000081

SPEC NO: DSAI8690 REV NO: V.1 DATE: NOV/14/2008 PAGE: 6 OF 8

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: D.M.Su ERP:1209000081

PACKING & LABEL SPECIFICATIONS KASL-4805QBFS/3

SPEC NO: DSAI8690 REV NO: V.1 DATE: NOV/14/2008 PAGE: 7 OF 8

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: D.M.Su ERP:1209000081

KASL-4805 Application Note

Introduction

The KASL-4805 LED light bar provide very high light output, and can be configured to suit a wide rage of applications. However the

heat generated during operation, if not handled properly, could shorten the product life significantly. Therefore for optimal per-

formance, proper thermal management should be incorporated to keep it below the rated temperature. This document describes

the heat sink attachment procedure.

Attachment to Heat sink

1. Apply a thin layer (0.1 ~ 0.2 mm) of thermal grease on the bottom of the KASL-4805 LED light bar .

Rear surface Thermal glue on rear surface

2. Press the KASL-4805 LED light bar firmly on the heat sink to ensure good contact between the heat sink and the LED light

bar . A guide for heat sink size selection at various driving currents is listed in the table below.

3. A specifically designed electronic circuit is required to power the LED light bar . Do not connect the product directly to the main

power.

Current (mA) 350 500 600 700

Heat sink

surface area (mm

SPEC NO: DSAI8690 REV NO: V.1 DATE: NOV/14/2008 PAGE: 8 OF 8

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: D.M.Su ERP:1209000081

2

)

10,000 15,000 17,000 21,000

It is strongly recommended

that temperature of pad be

not highter than 75°C when

you use the product.

Loading...

Loading...