Page 1

..

<I

.LR 53550

Page 2

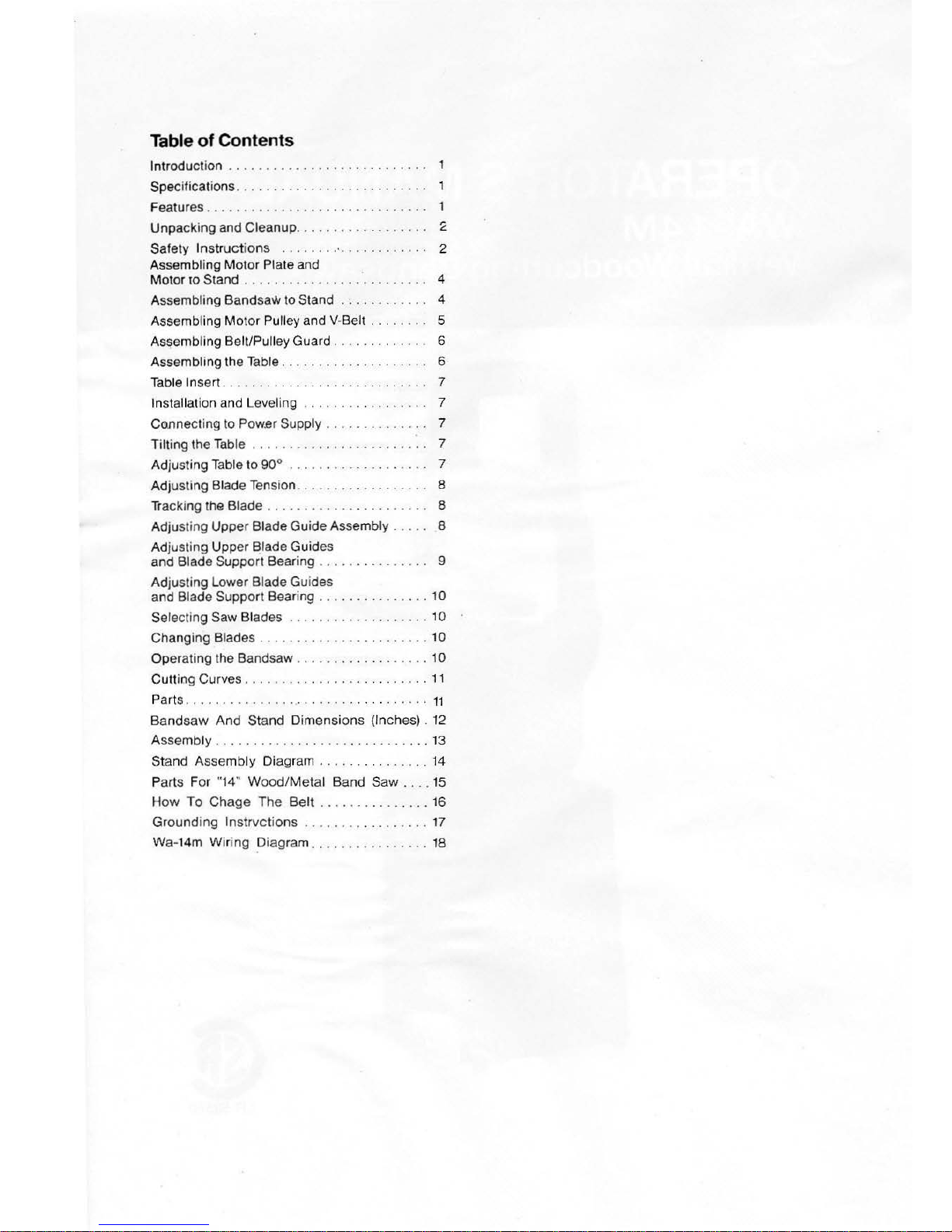

Table

of

Contents

Introduction

.............

.............

.

Specifications

......

. .

.................

.

Features

........................

..

...

.

Unpack

ing

and

Cleanup. . . . . . . . . . . . . . . . . . 2

Safety

Instructions

........

·. . . . . . . . . . . . 2

Assembling Motor Plate and

Motor to Stand . . . . . . . . . . . . . . . . . . . . . . . . . 4

Assembling Bandsaw to Stand .

·. . . . . . . . . . . 4

Assembling Motor Pulley and V-Belt . . . . . . . . 5

A

s~embling

Belt/Pulley Guard . . . . . . . . . . . . . 6

Assembling the

Table

. . . . . . . . . . . . . . . . . . . . 6

Table

Insert. . . . . . . . . . . . . . . . . . • . . . . . . . . . 7

Installation and Leveli

ng

. . . . . . . . . . . . . . . . . 7

C0.11nectin!!J

to Powsr Supply . . . . . . . . . . . . . . 7

Tilting the

Tab

le . . . . . . . . . . . . . . . . . . . . . . . . 7

Adjusting

Table

to 90° . . . . . . . . . . . . . . . . . . . 7

Adjusting Blade

Tens

ion . . . . . . . . . . . . . . . . . . 8

Tr

acking the Blade . . . . . . . . . . . . . . . . . . . . . . 8

Adjusting Upper Blade Guide Assembly

.....

. 8

Adjusting Upper Blade Guides

and Blade Support Bearing . . . . . . . . . . . . . . . 9

Adjusting Lower Blade Guides

and Blade

Support Beari

ng

...............

10

Selecting Saw Blades

........

.

..........

1 o

Changing Blades

....

.....

.....

. .

...... .

10

Operating the Bandsaw

.......

..

.........

1 0

Cutting Curves

......

..........

.........

11

Parts

...

......

....

..........

....

......

11

Bandsaw And Stand Dimensions (Inches) .

12

Assemb

ly

.....

......... .

..............

13

Stand Assembly Diagram

.. ..

...

......

. .

14

Parts For "

14'' Wood/Me

tal Band S

aw ....

15

How

To

Chage

The

Belt

.....

. . .

......

. 16

Grounding lnstrvctions

.......

....

. . . . . .

17

Wa-14m

Wiring Diagram

................

18

Page 3

For

Your

Own Safety

Read Instruction

Manual Before Operating

Saw

1.

Wear eye protection.

2.

Do

not remove jammed cutoff pieces until blade

has.

stopped.

3.

Maintain proper adjustment of blade tension,

blade guides, and thrust bearings.

4. Adjust upper guide

to

just clear workpiece.

5. Hold workpiece firmly against table.

Page 4

OPERATOR'S

MANUAL

WA-14M

Vertical Woodcutting Bandsaw

Introduction

The Vertical Woodcutting Bandsaw is a highquality, precision-cutting tool. It will give you

years of superior service. Naturally, you

will get

maximum performance from your new woodcutting band saw if you

follow the instructions

in

this manual.

Before attempting to install or operate your new

bandsaw, we recommend you read this manual

and familiarize yourself with the details of operation. Understanding the contents of the manual

will help you obtain the best possible results and

achieve highest standards of accuracy.

It will also

resolve many of the problems you could encoun-

ter otherwise.

A serial number

is

stamped on the nameplate.

Please refer to this serial number

in

any communi-

cations regardi

ng

your machine, and refer to the

parts list accompanyi

ng this

manu

al

to order spe-

cific part numbered items.

Specifications

Cutting capacity

6"

Minimum saw blade

1/a"

Maximum saw blade

3/

4"

Saw blade length

92

1

/2

"

Table

size

14

" X 14''

Table

tilt

45°XR,

10°xl

Dimensions

65'

k"

H

(See Parts Section

for drawing

.)

(Overall)

24

1

/

2"

W,

19

1

/4

" D

Motor (1725 RPM)

single phase.

115/230V (prewir

ed

115V)

Net weight

201

lbs.

(approx.)

Ship weight

2081bs.

(approx.)

Features

The vertical banosaw

is

an

easy-to- use,

cost-effectiv e

tool for producing fixtures, fur-

niture or marine woodwork. It

is

an essential piece

of equipment for custom cabinet shops, boat

building shops, home workshops, and the

advanced hobbyist.

It gives excellent results in

cutting plastic, aluminum and similar material s, or

wherever cutting curves and compound curves

is

required.

Page 5

The vertic

al

bandsaw is shown

in Figu

re 1.

WHEEL

COV

ER

FIGURE 1

UPPER

RO

LLER

BE ARING

2

Unpacking and Cleanup

To ensure maximum performance from your woo

dcuttin

g bandsaw, clean it properly; a

nd

install it accurately before use.

As soon as you receive

th

e bandsaw, we recom-

mend you follow these procedu

res

:

1.

In

spect packing crate for dama

ge

in transit.

Re

cord damage, a

nd

report it immediately to

shipper.

2. Carefully remove loose items, saw and

st

and,

and check that

all arrived in good condition. If

not, let your industrial distributor know immediately.

3. Machined surfaces of band saw are protected

by a heavy coating that

mu

st be remo

ved

before machi

ne

is used. Remove protective

coating

wi

th

kerosene

or diesel oil.

DO

NOT

USE CELLULOSE-BASED

SOLVENTS; they

damage pain

t.

Also

DO

NOT USE SOLVENTS on plastic parts; they dissolve or

damage plastic.

Safety

Instructions

1.

KEEP

GUARDS

IN PLACE and in

working

order

2.

REMO

VE

ADJUSTING

KEYS AND

WRENCHES.

Form

habit

of

checking

to

see that keys and

ad

just

ing

wrenche

s are

removed from

tool before

turning

it on.

3.

KEEP

WORK

AREA

CLEAN.

Cluttered

areas

and

benches

invite accidents.

4.

DON 'T USE IN

DANGEROUS

ENVI-

RONMENT. Don't use

power

tools in

damp

or

wet

locations,

or

expose

them

to

rain, Keep

work

area

well lighted.

5.

KEEP

CHILDREN

AWAY.

All visitors

should

be

kept safe

distance

from work

area.

6.

MAKE

WORKSHOP KID PROOF

with

padlocks, master switches,

or

by

removing

starter keys.

7.

DON 'T

FORCE

TOOL. It will

do

the

job

better

and

safer at the rate

for

which

it

was

designed.

8.

USE

RIGHT TOOL. Don't force tool or

attachment

to

do

a job for whi

ch

it w

as

not

designed

.

9.

'f'EAR

PROPER

APPAREL

Wear no

loose

clothing, gloves, neckties, rings,

bracelets,

or other

jewelry

which

may

get

caught

in

moving

parts.

Nonslip

footwear is recommended. Wear protective hair

covering to

conta

in long hai

r.

Page 6

10.

ALWAYS

USE

SAFETY

GLASSES.

Also

use face

or

dust

mask

if

cutting

operation

is dusty.

Everyday

eyeglasses

only

have

impact

resistant lenses,

they

are NOT

safety

glasses

11.

SECURE

WORK. Use·clamps

or a vise

to hold

work

when

practical. Jt's

safer

than

using

your

hand

and

it frees

both

hands

to

operate

tool.

12.

DON'T

OVERREACH.

Keep

proper

footing

and

balance

at all times.

13.

MAINTAIN

TOOLS

WITH

CARE.

Keep tools

sharp

and

clean

for best

and

safest

performance.

Follow

instructions

for lubricating

and

changing

accessor

ies.

14.

DISCONNECT

TOOLS

before

seryicing; when

changing

accessories,

such

as

blades,

bits,

cutters, and

the

like.

15.

REDUCE

THE

RISK

OF

UNINTENTIONAL

STARTING.

Make

sure

switch

is in

off

position

before

plugging

in.

16.

USE

RECOMMENDED

ACCESSORIES. Consult the owner 's manual for recommended

accessories.

The

use

of

improper

accessories

may

cause

risk

of

injury

to persons.

17 .

NEVER

STAND

ON

TOOL.

Serious injury

could

occur

if

the

tool is

tipped

or

if

the

cutting

tool

is

unintentionally

contacted.

18.

CHECK

DAMAGED

PARTS. Before

further

use

of

the

tool, a

guard

or

other

part

that

is

damaged

should

be

carefully

checked

to

detenmine

that

it

will

ope

rate

properly

and

perform

its

intended

function -check

for al i

gnment

of

moving

parts, binding

of

moving

parts,

breakage

of

parts,

mounting,

and

any

other

conditions

that

may

affect

its

operation. A guard

or

other

part

that

is

damaged

should

be

properly

repaired

or

replaced.

19.

DIRECTION

OF

FEED. Feed

work

into a blade

or

cutter

against

the

direction

of

rotation

of

the

blade

or

cutter

only.

20.

NEVER

LEAVE

TOOL

RUNNING

UNATTENDED.

TURN

POWER

OFF.

Don't

leave

tool

until it

comes

to a

comp

lete stop.

3

Page 7

Assembling Motor Plate and Motor

to

Stand

1. Position motor on mounting plate. Secure

with four hex head

bolts, eight washers. and

four

he

x

~ uts

at slots in mounti

ng

plate (Fig-

ure 2}.

MOUNTiNG

PLATE

HEX HEAD

BOLT

WASHER.

HEX

NUT

FIGURE2

2.

With motor shaft pointing away from switch

and

smaller wing of mounting pla

te

up, slide

motor and plate onto cross brace (Figure 3).

MOUNTING

PLATE

MO

TOR

SHAFT

CROSS

SLIDE

FIGURE3

4

3.

Secu

re

top of mounting

plate to top of stand

at matching

holes. Use two h

ex

head bolts,

four washers, and two hex nuts. Leave bolts

loose

for later belt adjustment.

4. Secure bottom of mounting

plate to cross

brace at matchi

ng

holes. Use two hex head

bolts, four washers, and two hex nuts. Leave

bolts loose for later belt adjustment.

5.

Attach motor to switch as follows:

Match

red

motor wire

with up per right

terminal on switch at interior of stand. See

Figure 4.

Match

black motor wire

at

lower right

of

switch.

Green motor wire goes to ground

clamp

below

switch.

Refer

to

wiring diagram at end

of

manual.

FIGURE 4

Assembling Bandsaw to Stand

To

assemble bandsaw to stand:

~

·

-:.

..

•'

1.

Set bandsaw on top of sta

nd

at

matching

holes. Be sure that wheel covers are

on same

side

as

switch.

2.

Secure bandsaw

to

stand with four long bolts.

eight washers, and four hex nu

ts (Figure

5).

Page 8

MOUNTI NG

HOLES

FIGURES

Assembling Motor Pulley and V-Belt

1.

Assemble motor pulley to motor shaft (Figure

6)

, engaging motor pulley setscrew with key

in moto r shaft.

FIGURES

2.

Align motor pulley and drive pulley, using

straightedge.

(Position

of

pulleys and motor

mounting plate can be change

d.

)

3.

Loop the V-belt onto each pulley.

4.

Adjust

V-belt for tension.

To

do

so,

raise or

lower motor

on

motor plate whi

le

keep ing

pulleys aligned. When belt deflects about one

inch with li

ght

firrger pressure,

midway

betwee11

pulleys, belt tension is correct.

5.

Tighten all stand and motor mounti

ng

screws.

5

Page 9

Assembling Belt/Pulley Guard

1.

Position belt/pulley guard over belt opening

at top of stand (Figure 7

).

FIGURE 7

2.

Match holes

in

guard flanges to holes in cabi-

net top.

3.

Attach guard flanges to cabinet, using round

head screws.

Secure with split washer and

wing nut under stand top.

Assembling the Table

1.

Position table swivel bracke

t'

onto main

frame ,

mr,tching two locating pins to holes

(Figure 8

).

·

6

TABLE

SWIVEL

BRACKET

FIGURE 8

2. Insert and secure two hexhead bolts with

washers into bracket

holes and main frame

(F

igure 9 ).

HEXHEAD

BOLT

AND

WASHER

\

FIGURE 9

3.

Set table on bracket, lining up degree marking with

0°

mark on front

of

bracket.

Page 10

4. Screw on handknob at back and front of

machine under swivel bracket.

5. I

ns

tall bla

de

(see "Changing Blades" in this

manual

).

Table Insert

Sl

ip table insert (Figure 1 0) into hole on saw table,

engaging

table pin with one of indents in inser

t.

Insert table spreader into slit on right-hand side of

table.

FIGURE 10

Installation and Leveling

For best cutting performance, locate bandsaw on

solid,

level foundation. Place metal shims under

low corners. Check that

all four corners are sup-

ported. Retest

level of stand top in both direc-

tions; and adjust if necessary.

Connecting

to

Power

Supply

The vertical bandsaw is prewired for 115

volts and comes fitted with a power cord. Simply

plug in you r electric cord when ready to connect to

power source.

Tilting the Table

The bandsaw table tilts up to 45° to the right or up

to

10° to the left.

To

tilt the table:

1.

Loos

en

both star wheels (Figure 11) under

table.

7

I

..

FIGURE 11

2. Tilt table to desired ang le on degree gauge

under table.

Adjusting Table to 90 °

An adjustable stop (bolt) is provided

to

set t

he

table

90

° to the blade.

To

adjust:

1. Tilt table slightly to rig ht.

2. Screw in adjustable stop (bolt) and nut (Fig-

. ure 12

).

FIGURE 12

Page 11

3. Set table

at 90° to the blade, usi

ng a square

on

table

and

against

blade.

4.

The

adjustable bolt

should

touch

the

table. If

it

doesn

't, loosen

nut

on

bolt; and turn bolt

until

it

touches

table.

NOTE: When tilting table to left, bolt must be

removed.

5. Ti

ghten

nut.

Adjusting Blade Tension

The

slide

bracket

(at rear beh i

nd

upper

wheel)

allows

proper

tension

for

various

widths

of

blades.

With

blade

on

wheels, turn

star

wheel (Figure 13),

raising

or

lowering

blade

wheel

unt

il desired blade

2. If blade slides toward front edge, slightly turn

tracking

hand

knob

(Figure 1 4) clockwise.

This tilts top of wheel toward back of

machine

and

draws

blade toward center

of

tire.

tension is obtained.

BLADE

NOTE:

Too

much tension

or

strain could break

blade.

FIGURE 13

Tracking

the

Blade

I WARNING

NEVER track blade when machine is

running.

Manually

turn wheels.

Remove motor drive

belt.

1.

When

blade

tension

is

properly

Sf;lt,

slowly

rotate

wheels

clockwise,

checking

that blade

travels

in

center

of

upper

tire.

8

FIGURE14

3.

If

blade

slides toward

back

edge, slightly turn

handknob

counterclockwise.

Adjusting Upper Blade Guide

Assembly

1.

Set

upper

blade

guide

assembly

as

closely as

possible to

top

of

stock

~

To

do

so, swivel lock

hand,le

(Figure 15 ), moving

guide

assembly

into position.

Page 12

FIGURE 15

2.

Adjust blade guides flat with blade (Figure

16).

FIGURE

16

9

Adjusting Upper

Blade

Guides

and

Blade Support Bearing

After blade is tensioned and tracking, adjust

upper

blade guides and blade support bearing.

To

adjust:

1 . Loosen

Allen setscrews (Figure 1

7})

with Allen

wrench.

FIGURE 17

2.

Move both guid

es

within .002 inch to blade

using feeler gauge.

DO

NOT pinch blade.

3. Tig hten setscrews.

4. Loosen u

pper triangle knobscrew:

5. Move

blade support bearing shaft in

or

out

until bearing

is~~

inch behind back

of

blade.

NOTE:

The

upper blade support bearing pre-

vents blade from moving

back

too far and

damaging

saw

teeth setting.

6.

Tighten upper triang le knobscrew.

7. Adjust blade support bearing so that blade

stands vertically

1/,s inch to left of rig

ht

edge

of

bearing.

Page 13

Adjusting Lower Blade Guides and

Blade Support Bearing

Adjust lower blade guides and blade support

bearing at same time as upper ones.

To

do

so:

1.

Loosen both setscrews (Figure 18), moving

both guides as closely to sides

of

blade as

possible.

DO NOT pinch blade.

I

BLADE • TRIANGLE

SUPPORT . KNOB

BEARING

--.......

~

SCREW

BLADE

~~

_;:;,__

~

GU

IDE

~-

"

..

FIGURE

18

2.

Tighten setscrews.

3.

To

adjust lower

blad~

support bearing, loosen

bearing setscrew.

4.

Move blade support bearing shaft in or out

until support bearing is about

1

/6"

inch behind

blade.

5.

Tighten setscrew.

6. Adjust blade support bearing so that blade

stands vertically

1

11s

inch to left

of right edge

of

bearing.

Selecting Saw Blades

For longest blade wear and best cutting results,

use correct blade thickness, width and temper for

type

of

material cut. When sawing small curves

and delicate work, use narrow blades. Otherwise,

use widest blade possible.

Saw blades may be purchased at any saw shop ,

welded, set and shar.pened ready for use. For

cutting wood and similar materials, purchase blades

in widths

up

to

3/4

inch.

For longest blade wear, avoid these most common

causes

of

blade breakage:

• Poor guide alignment and adjustment

• Forcing or twisting a wide blade around a

short radius

• Feeding too fast

• Dull teeth or not enough set

•

Too

much blade tension

• Setting top guide assembly too high

above workpiece

• Lumpy or improperly finished braze or

weld

on

blade

• Continuous running

of

blade when not

cutting

The saw blade when new is

931/z

inches long.

Adjustments can be made on blades from

91

1

/2

to

94 inches.

Changing Blades

To

change blades:

1. Remove upper and lower wheel guards.

2.

Release blade tens ion. See "Adjusting Blade

Tension" in this manual.

3.

Remove table insert and table spreader pin at

right edge of table.

4.

Slip blade off wheel, guiding it through table

slot.

5.

To

install blade, reverse procedur

e.

Operating the Bandsaw

Operation

of

power tools involves a certain

amount of hazard. Before attempting regular

work, we recommend

you

get the feel of ooera-

tions, us i

ng

scrap lumber to check settings. Read

entire ins tructions

·before cutting a workpiece.

Always pay attention to safety precautions to

avoid inj

ury.

Before turning on power, make all adjustments.

check th

at

guard is

in

place. and turn pulley by

hand to make sure

all parts work properly. ·

Always keep top guide assembly down close to

your work.

Do

not force material against blade:

light contact permits easier cutti

ng

and prevents

unwanted friction, heating and work-hardening

on

back edge

of

blade.

If you keep saw blade sharp. little pressu

re

is

needed for cutting. Steadily move stock against

blade without forci

ng

it.

To avoid twisting the

blade, do not turn sharp corners;

sa

w arou

nd

cor-

ners.

10

Page 14

Cutting Curves

When

cutting curves, carefully turn stock so blade

follows without twisting.

If curve is so sharp that

you must repeatedly back

up

and cut new kerf,

use narrow blade

or

blade wit h more set. When

blade has more set, stock turns easier but cut is

rougher.

When changing a cut, avoid withdrawing workpiece, as with

dra

wing may draw blade off wheels.

Rath

er,

turn stock; and saw

out

through waste

material.

PARTS

WA-14M

Vertical Woodcutting Bandsaw

Table

of

Contents

Bandsaw and Stand dimensions ......................

12

Assembly Diagram ...........................................

13

Stand Assembly Diagram ...... ...........................

14

Parts for 14" Wood/Metal Band Saw ................

15

How to Change The Belt.. ............................... 16

Gr

ounding Instruction ..................

.......

............. 17

Wi

ri

ng Diag

ram ......... ...... .............................

....

iS

11

Page 15

BANDSAW AND STAND DIMENSIONS (inches)

r---

14

_.,

~

183/4

-

~r

..

5114

~

---+---------~

13

65114

I

24

()

I I

I I

I I

I I

~

f- ':: =

-:...-.....

-,..-------=-=--=

=-

-...r;l

0

0

'-

(

J*l

0

0

L--

19

___j

,.....,

______________

.

21

~

12

~-I

.....

-------

163/4-----~·~1

Page 16

ASSEMBLY

DlAGRAM

13

Page 17

STAND

ASSEMBLY

DIAGRAM

14

Page 18

PARTS

FOR

14"

WOOD/

METAL BAN

D SAW

WA-14M

Pan

Pans

.:'-Jo.

f---1.

Up

per

frame ann

2.

Lock Handle

1-·- -

Guide post

bracket

3.

4.

Guide post

- -

5.

Support

bracket

for

upper

gui

de

6.

Knob

screw

7.

Cpper

spacing

sleeve

8. C-clip

9.

Bear~

(6200)

10.

Screw

-

11.

Blade

guid

e

12.

Star

wheel

~

-

- 13.

Pin

14.

Blade

adjust

er

screw

--rs.

-

Coil

spring

16.

Upper

wheel

sliding

b_:acker

!-

1

7.

Square

nut

-

18

. .

Upper

wheel

adjuster knob

,_

19.

Upper

wheel

shaft

hinge

20.

Set

screw

21.

Steel

pin

22.

Upper

wheel

shaft

23

. Wheel

bearing

(6202)

~4.

Op

per

wheel

25.

vVheel

protector

-

£6.

1\ut

27.

Stud

.......

28.

Upper

wheel

guard

(inner)

29.

Upper

wheel

guard {outter)

30.

Knob

31.

Set

pin

-

32.

Bolt

33

.

Flat

\Vasher

34

. Base

1--

3.

S_

quare

nut

-

:>.

36.

Saw

blade

37.

Table

insert

-

38.

Table

pin

r--s

9.

Table

- - -

-

-!0.

Base

table

stoe

-!1.

Trunnion

clamp

shoe

-1-2

.

Trunnion

~1.

- -

Steel

washer

f-

·--

Hex.

screw

-

--

-

-

44.

-!5.

T:·unnion

supporr

bracket

--

-

-

--

-

46

.

Star

wheel

knob

47.

Hex.

screw

-

-t8.

Steel

washer

- -

-!9.

Bolt

50.

:\

tl

t

51.

Ti

at

washer

r-

52.

:\

ll

{

- -

53

.

Hex.

screvv

-

5-1-.

Stee

l \·vash

er

55.

Support

bracket

for lower

guide

-

56.

Set

screw

f-

57.

Flat

\\·ash

er

Part

No

.

1-

58

::-:---

59

.

-

~

-

60.

61.

1-

G2

.

63.

6-1-.

65.

66.

t-

Gf

1--·68:-

69.

-

70:

1--

"7

J

I •

72.

73.

- 74.

75.

'-

76.

77.

82.

83.

84

.

85.

86.

87.

88.

89.

90.

91.

1--

92.

1-

93.

94

.

-

---

95.

~)6.

1-97.

98

.

99.

_

107~

'J

08.

-

I 09.

-

110.

111.

-

112.

113.

114.

115.

- 116.

- 117.

-ns.

1-.

119.

120.

-

121.

122.

123.

12-l.

125.

15

Parts

Bot tom

1-

- -

--

- - - - -

Pl

astic

cover

r-s

el

screw

·- -

Key

Set

screw

-

Pulley

-

C-clip

Shaft

Bearing

(6204)

L

<)Wer

wheel

I-;.

-

l\'u t

-

Lower

wheel

guard

Cycola

c guarc_l

__

_

Bo

lt

flat

washer

-

Stand

1\'"ut

Carriage

bolt

·

~

Flat

,.,·asher

Flat

washer

Hex.

screw

Flat

washer

Motor

Flat

wash

er

Nut

Set scr

ew

~'l

otor

pulley

Switch

screw

Switch

Electric cord

--'-

V-belt

A-36

Screw

·-

Lo\

·ver wheel

shoe

-·

-

Case

- -

-

Scr<':w

·-

Spring

washer

-

Hex.

nut

--

-

Hex.

nut

_!)egrec

plate

45

°

Turn

to

zero

-

Pin

--

- -

- -

- -

Key

Kev

~

lle

y,

bracket

-

Set

screw

Pulley

Key

-

3

Speed

shaft

-

Ball

bearing

G202

V

belt

A-2-l

--

-

---

Cpper

fram

~n

cover

--

Screv.,

CoY

er

for

~ide

post

Teeth

washer.

C

-dip

Flat

washer

- - - -

--

- -

--

--

-

- -

-

Screw

Page 19

a

---------...

I

HOW TO

CHANGE

THE BELT

There are three

speeds

of

saw

blade, 700, 1230, 2420 FPM .

First,

fix

the short belt in A

pulley

and a

of

B pulley then

c

1. Put long belt in d

of B pulley

and d

of

C pulley, the Run-

ning

speed

of

saw

blade

is

700 FPM.

2. Put long belt in c

of B pulley

and c

of

C pulley, Running

speed

of

saw

blade

is

1230 FPM.

3.

Put long

belt

in b

of B pulley

and b

of

C pulley, the Run-

ning

speed

of

saw

blade

is

2420

FPM.

16

BLADE SPEED

700 F.P.M.

1230 F.P.M.

L.._

____

. 2420 F.P.M.

Page 20

GROUNDING INSTRUCTIONS

In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

electric current to reduce the risk of electric

shock. This tool is equipped with an electric

cord having an equipmentgrounding conductor and a grounding plug. The plug must be

plugged into a matching outlet that is properly

installed and grounded in accordance with all

local codes and ordmances.

Do not modify the plug provided -

if

it will not

fit the outlet, have the proper outlet installed by

a qualified electrician.

Improper

connection

of

the

equipmentgrounding conductor can result in a risk of

electric shock. The conductor with insulation

having an outer surface that is green with or

without yellow stripes is the equipmentgrounding conductor. If repair or replacement

of

the electric cord or plug is necessary, do not

COJ1nect

the equipment grounding conductor to

a live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if

in

doubt as to

whether the tool is properly grounded.

Use only 3-wire extension cbrds that have

3-prong grounding plugs and 3-pole receptacles

that accept the tool's plug.

Repair or replace damage or worn cord

immediately.

Grounded, cord-connected tools intended for

use on a supply circuit having a nominal rating

less than 150 volts: ·

17

This tool is intended for use on a ci

rcu

it that has

an outlet that looks like the one illustrated in

Sketch A in Figure

1.

The tool has a ground-

ing plug that looks like the plug illustrated

in

Sketch A in Figure 1. A temporary adapter,

which looks like the adapter illustrated in

Sketches 8 and

C,

may be used to connect this

plug

to

a 2-pole receptacle as shown in Sketch

8

if

a properly grounded outl

et

is not available.

The temporary adapter should be used only

until a properly grounded outlet can be installed

by a qualified electrician. The green-colored

rigid

ear,

lug, and the like, extending from the

adapter must be connected

to

a permanent

ground such as a properly grounded outlet box.

Grounded, cord-connected tools intended for

use on a supply circuit having a nominal rating

between

150-250

volts, inclusive:

This tool is intended for

use

on a circuit that has

an outlet that looks like the one illustrated in

Sketch D

in

Figure 1. The tool has a ground-

ing plug that looks like the plug illustrated in

Sketch 0 i:l Figure 1. Make sure the tool

is connected to an outlet having the same

configuration as the plug. No adapter is available or should be used with this tool. If the tool

must

be

reconnected for use on a different type

of

electric circuit, the reconnection should be

made by qualified service personnel; and after

reconnection, the tool should comply with all

local codes and ordinances.

ADAPTER

NOT

APPLICABLE

IN

CANADA!

FIGURE 1

GHOUNOING ME rHODS

•

~

Page 21

I .

WA-14M

WIRING DIAGRAM

BACK

OF

SWITCH

WH

IT

E ·

TO

POWER SOURCE

BLACK

/

l'

t

GREEN

GROUND SCREW GREEN

18

MOTOR JUNCTION BOX

WIRED FOR 110V

CAPACITOR

Page 22

Loading...

Loading...