Page 1

TH115 A/F/AF

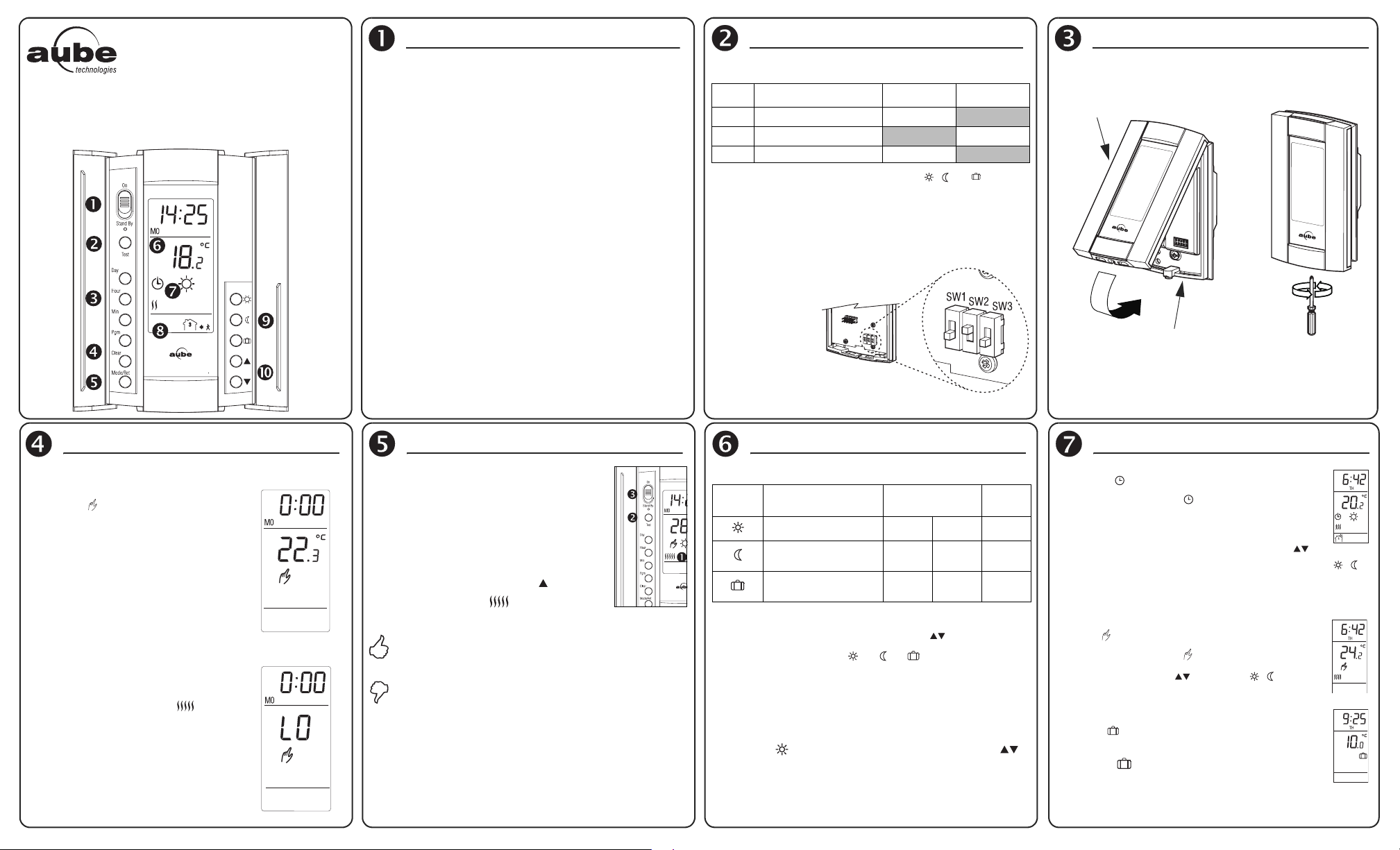

TH115 Description

Switch Selection

Control Module Installation

Owner’s Guide

Buttons and symbols

n On/Stand By Switch

Thank you for choosing the Aube TH115, a

programmable thermostat that provides both energy

savings and comfort.

Use this switch to put the thermostat in sleep mode

when its use is no longer required (e.g. summer).

This will not affect the clock or programming.

o GFCI Warning Light and Test Button

p Day & Clock Settings

q Programming Mode

r Mode Selection/Exit Programming

s Room OR Floor Temperature

t Current Mode and Setpoint

u Current Program Number

v Setpoint definition/Pre-defined Setpoints

w Increase/Decrease Temperature

Models

A Controls the Ambient temperature.

AF Controls the Ambient temperature and Floor temper-

ature limit.

F Controls the Floor temperature.

First Power ON GFCI Test (GA & GB power base only)

This thermostat is factory-set to the following values:

#Function UPDN

SW1

SW2

SW3 Time format 12-hour

a. If you switch from °F to °C or vice versa, the , and setpoints

b. When using AUTO mode, the thermostat calculates the optimum start

Switches are

located on the

rear of the control

module.

To mo d i f y a n y

setting, switch

UP or DN.

Temperature format

Early Start

may need to be redefined.

time to obtain the desired temperature by the set time. The heating

system could be started a few hours prior to set time when required.

a

b

°F °C

Disable Enable

24-hour

Temperature Setpoint

Align the bracket tabs on the control module with the

holes located on top of the power base.

Control module

Power base

NOTE: Keep the thermostat's air vents clean and free

from obstructions.

NOTE: The screw cannot be removed completely.

Operating Modes

When power is applied for the first

time, the LCD displays: 0:00, MO

(Monday), and temperature (room/

floor).

n Press HOUR - MIN to set the

current time.

o Press DAY to set current day.

For AF and F models: one of the two

following messages may be displayed

if the installation is incorrect:

LO: The floor temperature is below

32°F (0°C), or the temperature

sensor is defective, or not connected.

The heating indicator is displayed and the relay is closed

(energized).

HI: The floor temperature is above

140°F (60°C), or the temperature sensor is defective.

Correct

Incorrect

The GFCI monitors the electrical flow for

any loss of current; if there is one, the

thermostat will cut off power to the heating

system. We recommend you test the GFCI

immediately after installing the control

module, and once a month thereafter to

ensure it is operating properly. To test:

n Increase the temperature until the

heating indicator is displayed.

o Press TEST:

• Successful: the TEST warning light is ON and

power to heating system is cut off.

• Unsucessful: the TEST warning light is OFF. Cut

power to heating system from the main power

panel and call customer service.

p When successful, reset thermostat (Stand By/On) to

power the heating system.

NOTE: If the test warning light comes ON during normal

operation, cut power to heating system from the main

power panel and have an electrician verify the installation.

The following temperature setpoints are pre-programmed:

Symbol Description

Comfort (when at home) 70°F 82°F

Economy (

away from home

Vacation (

prolonged absence

To modify a setpoint:

when asleep/

)

during

)

Default

A/AF F

64°F 68°F

50°F 50°F

New

n Set the desired temperature using .

o Press and Hold the or or

button until symbol is displayed.

p Press RET to exit.

Floor temperature limit—The floor temperature limit is

82°F. To modify this limit:

n Press and hold

while switching from

ON to Stand By then

back to On.

o Set temperature

p Press RET to exit.

To avoid damaging your floor, we

recommend you follow the

supplier’s instructions.

Automatic —Executes the schedule.

n Press MODE until is displayed. The cur-

rent program number is displayed.

You can temporary bypass the current pro-

gram by setting a specific temperature or

by pressing on a pre-defined setpoint button ( ) .

The new setpoint will be maintained until the beginning of the next program.

Manual —Maintains a constant temperature.

n Press MODE until is displayed.

o Set temperature or press ( ) to use

pre-defined setpoint.

Vacation —Maintains the Vacation setpoint

during a prolonged absence.

Press until the icon is displayed.

920-115-007-00-1-A

Page 2

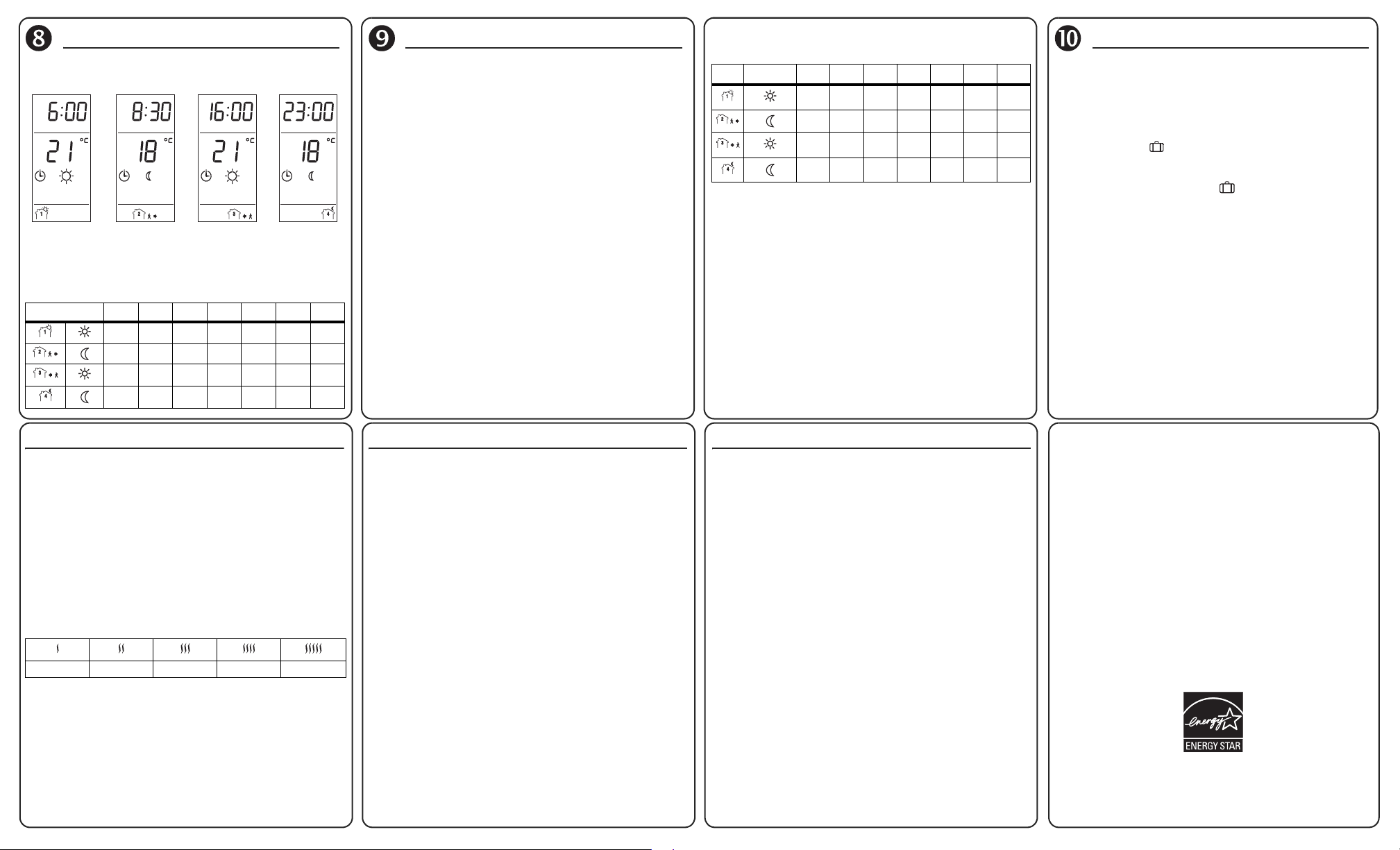

Pre-programmed Schedule

The TH115 programmable thermostat is pre-programmed

with the following schedule:

Time you

wake up and

desired

temperature

Programs MO TU WE TH FR SA SU

Time you

leave and

temperature

during your

absence

6:00 6:00 6:00 6:00 6:00 6:00 6:00

8:30 8:30 8:30 8:30 8:30 --:-- --:--

16:00 16:00 16:00 16:00 16:00 --:-- --:--

23:00 23:00 23:00 23:00 23:00 23:00 23:00

Time you

return home

and desired

temperature

Time you go

to bed and

overnight

temperature

Modify the Schedule

Notes:

You can program up to 4 different programs per day.

Each day can have different programs.

It is sometimes faster to program the same schedule

for the entire week and then to modify the exception

days.

To modify:

n Press PGM to access the programming mode

o Press DAY to select the day to be programmed (hold

for 3 seconds to select all days of the week).

p Press PGM to select the program number.

q Press HOUR and MIN to set the time or press

CLEAR to clear the time (--:-- is disregarded).

r Repeat steps 2 to 4 for remaining programs.

s When completed, press RET to exit mode.

NOTE: After 60 seconds of inactivity, the thermostat will

automatically exit programming mode.

Custom Grid

Use this blank grid to record your new schedule.

Prog Setpoint MO TU WE TH FR SA SU

Model:

Temperature display: °F °C

Time display:

A F AF

12hrs 24hrs

Remote Input

The TH115 is equipped with a remote input which allows

connection of a telephone controller (accessory

Aube CT240) or any other remote control system.

When a signal is received through this input, the TH115

will automatically switch from normal operating mode to

Vacation mode ( ), and vice versa when the signal is

removed.

Activating the Vacation mode

There are two ways to activate the Vacation mode:

n From the thermostat, see “Operating Modes” above.

o From a telephone (remote location). For details on

how to activate using a telephone, refer to the CT240

Instruction Manual.

WARNING: When the Vacation mode is activated

remotely, it must be deactivated remotely.

Temperature Control

The TH115 thermostat works differently than conventional

electromechanical thermostats.

It is equipped with a proportional integral adaptive (P.I.A.)

controller which determines heating cycles by analyzing

the temperature behavior history within the room.

The P.I.A. controller reduces temperature variations

providing an accurate temperature control while

increasing user comfort.

The controller determines the amount of power required

by the heating system to maintain the setpoint

temperature.

1 to 20% 21 to 40% 41 to 60% 61 to 80% 81 to 100%

Technical Specifications

Model: TH115 A / AF / F

Display range: 32°F to 140°F (0°C to 60°C)

Setting range (ambient): 40°F to 86°F (5°C to 30°C)

Setting range (floor limit): 40°F to 104°F (5°C to 40°C)

Pre-programmed temperature setpoints:

Comfort: A/AF: 70°F (21°C) and F: 82°F (28°C)

Economy: A/AF: 64°F (18°C) and F: 68°F (20°C)

Vacation: A/F/AF: 50°F (10°C)

Floor limit:AF: 82°F (28°C)

Accuracy:± 0.9°F (0.5°C)

Storage:-4°F to 120°F (-20°C to 50°C)

Temperature control: Proportional integral adaptive,

15-minute or 15-second heating cycles according to the

application and power base.

Memory backup: In the event of a power failure, an

internal circuit will maintain the programming. Only the

time will have to be set if the power failure is more than

two (2) hours. The thermostat will return to the same

operating mode as set before the power failure.

Warranty

AUBE TECHNOLOGIES INC. ONE (1) YEAR LIMITED WARRANTY

This product is guaranteed against workmanship defects for a

one year period following the initial date of purchase. During this

period, AUBE Technologies Inc. will repair or replace, at our

option and without charge, any defective product which has been

used under normal conditions.

The warranty does not cover delivery costs and does not apply to

products poorly installed or randomly damaged following

installation.

This warranty cancels and replaces any other manufacturer's

express or implied warranty as well as any other company

commitment. AUBE Technologies Inc. cannot be held liable for

related or random damages following the installation of this

product.

The defective product as well as the purchase invoice must be

returned to the place of purchase or mailed, prepaid and insured,

to the following address:

Aube Technologies Inc.

705 Montrichard

Saint-Jean-sur-Richelieu, Quebec, Canada J2X 5K8

If you have any questions concerning the

installation or programming of the TH115

programmable thermostat, call our technical

support team at:

Phone: Montreal area:(450) 358-4600

Canada / U.S.:1-800-831-AUBE

(2823)

Fax: (450) 358-4650

Email: service@aubetech.com

Monday to Friday from 8:30 AM to 5:00 PM EST

For more information on our products, visit us at:

www.aubetech.com

As an ENERGY STAR® partner, Aube Technologies has

determined that this product meets the E

guidelines for energy efficiency.

NERGY STAR

04/08/2003 920-115-007-00-1-A

Page 3

Installation Instructions

MASTER THERMOSTATS

TH113-A/F/AF (12VDC)

TH114-A/F/AF (12VDC)

TH115-A/F/AF (12VDC)

TH116-A/F/AF (12VDC)

SLAVE UNITS

CT230-120GA

CT230-120GB

CT230-240GA

CT230-240GB

1. Introduction

This master and slave unit system is specially

designed for large floor heating applications

exceeding 15 A.

The master thermostat controls a single or

multiple floor heating zones driven by slave units.

The master thermostat can control up to 10 slave

units.

Each slave unit drives its own zone and is

equipped with a GFCI test button and warning

light as well as an On/Standby switch to facilitate

maintenance on specific zones of the floor

installation.

2. Operation

Master Thermostat

The master unit controls the temperature and

sends a signal to slave units when heating is

required. The floor sensor is connected to the

master unit. The master unit is powered by the

slave units.

Slave Unit

The slave unit receives the signal sent by the

master unit and activates its load.

NOTE: There must be a minimum of one slave

unit ON to power the master unit.

3.2 Slave Units - Installation and Wiring

The slave units can operate on different voltages (e.g. 5 units @ 120 V and 5 @ 240 V).

• Required parts: CT230-120GA, -120GB, -240GA or -240GB

• Installation: On an electrical box

• Location: Installation near the master

thermostat is not required (i.e. can be

installed in a utility room).

• Wiring: The power bases are joined

through a daisy chain connection.

n Connect the 120 V or 240 V power

base wires to the power (line) and to

the load (floor) using solderless connectors for copper wires, and secure

the base to the electrical box.

o Affix the wiring sticker (in the CT230

box) to the base.

p Connect the slave power bases

together as per FIGURE 1.

q Once installation and wiring is com-

plete, mount the CT230 interface:

a) Align the bracket tabs of the

CT230 with the holes located on

top of the power base.

b) Secure the CT230 interface using the screw (captive).

3. Installation

Turn off power to the heating system at the

main power panel to avoid electrical shock.

Installation should be carried out by an

electrician.

3.1 Wiring Guidelines

• The wire distance between the master thermostat and slave unit should not exceed 500 ft.

(150 m).

• The floor sensor cable should not exceed

200 ft. (60 m).

• A 3-wire 20 AWG cable is recommended.

FIGURE 1

Connections

r Switch all slave power bases to STANDBY by sliding the protective door upwards

and positioning the switch to STANDBY.

Install and connect the master unit (see 3.3).

400-230-000-C 5/12/05 1/2

Page 4

3.3 Master Thermostat - Installation and Wiring

WARNING: Make sure all slave units are in STANDBY mode.

•Required parts: TH113-A/F/AF (12VDC),

TH114-A/F/AF (12VDC),

TH115-A/F/AF (12VDC) or

TH116-A/F/AF (12VDC)

• Location: anywhere easily accessible to users.

Temperature control: AF (ambient with floor limit) / A (ambient)

• Install the master thermostat in the controlled area.

• Choose a location about 5 ft. above the floor in an area where the temperature is stable.

• Avoid locations where there are air drafts (top of staircase, air outlet), dead air

spots (behind a door), direct sunlight or concealed chimneys or stove pipes.

Temperature control: F (floor)

• Can be installed anywhere.

s Wire the 12 VDC base to the nearest slave unit.

The floor sensor must be installed in an area where average temperature can be

read. The cable must follow the wall down to the floor and must not cross any

heater wires or be directly on or adjacent to a heating wire.

For maximum performance, the sensor probe should be centered between the

wires in the mat (max. 80°C).

t Push the excess wire into the wall, secure the base using the provided screws

and wall anchors, and install the TH11x thermostat onto the base.

u Once the thermostat is installed, return power to heating system and switch all

slave units and the master thermostat to ON.

Technical Specifications

Temperature:

- Operation: 32°F to 122°F (0°C to 50°C)

- Storage: -4°F to 122°F (-20°C to 50°C)

TH113/TH114/TH115/TH116 (A/F/AF-12VDC)

Power supply 12 V from remote unit

Maximum

slave units

Wire gauge 20 AWG

Size (H • W • D)

BASE

NOTE: Refer to the TH11x user guide for techni-

cal specifications.

CT230-120GA/120GB/240GA/240GB

Supply

- PB112-120

- PB112-240

GFCI GA=5 mA / GB=30 mA

Certification c CSA us

Size (H • W • D)

BASE

up to 10 slave units per

master thermostat

4.63 x 2.7 x 0.61 in.

(117.5 x 68.3 x 15 mm)

1800 W @ 120 VAC

60 Hz, 15 A resistive

3600 W @ 240 VAC

60 Hz, 15 A resistive

4.63 x 2.7 x 1.45 in.

(117.5 x 68.3 x 37 mm)

3.4 Slave Units - GFCI Test

We recommend you test the GFCI immediately after installing the thermostat, and

once a month thereafter to ensure it is operating properly.

If the test warning light comes ON during normal operation, cut power to heating

system from the main power panel and verify the installation.

n Slide the protective door upwards and make sure the switch is ON.

o Press TEST.

• The test is successful if the TEST warning light is ON and power is cut off.

• If the test fails (first installation test):

a. Verify installation

b. Check the load wires

c. Once you've identified the problem, run the GFCI test again

• If the test fails (monthly maintenance):

a. Cut power to heating system from the main power panel and call customer

service

p When the test is successful, reset the slave unit by switching from ON to

STANDBY then back to ON.

q Repeat steps 1 to 3 for all slave units.

Size (H • W • D)

INTERFACE

4.67 x 2.74 x 0.67 in.

(118.6 x 69.6 x 17 mm)

Service

If you have any questions concerning the

installation of the master thermostat or slave

units, contact our technical support team at:

Montreal area: (450) 358-4600

Canada / U.S.: 1-800-831-AUBE (2823)

Fax: (450) 358-4650

Email: service@aubetech.com

Monday to Friday from 8:30 AM to 5:00 PM EST.

For more information on our products, visit us at

www.aubetech.com

Warranty

AUBE TECHNOLOGIES INC.

ONE (1) YEAR LIMITED WARRANTY

This product is guaranteed against workmanship

defects for a one year period following the initial

date of purchase. During this period, AUBE

Technologies Inc. will repair or replace, at our

option and without charge, any defective product

which has been used under normal conditions.

The warranty does not cover delivery costs and

does not apply to products poorly installed or

randomly damaged following installation. This

warranty cancels and replaces any other

manufacturer's express or implied warranty as

well as any other company commitment.

AUBE Technologies Inc. cannot be held liable for

related or random damages following the

installation of this product. The defective product

as well as the purchase invoice must be returned

to the place of purchase or mailed, prepaid and

insured, to the following address:

Aube Technologies Inc.

705 Montrichard

Saint-Jean-sur-Richelieu, Quebec,

Canada J2X 5K8

400-230-000-C 5/12/05 2/2

Loading...

Loading...