Page 1

SRP Pre-assembled Self-regulating Cable

SRP126

SRP126

SRP126

SRP126

SRP126

SRP126

SRP126

Installation, Operation and Maintenance Instructions

IMPORTANT: Save These Instructions!

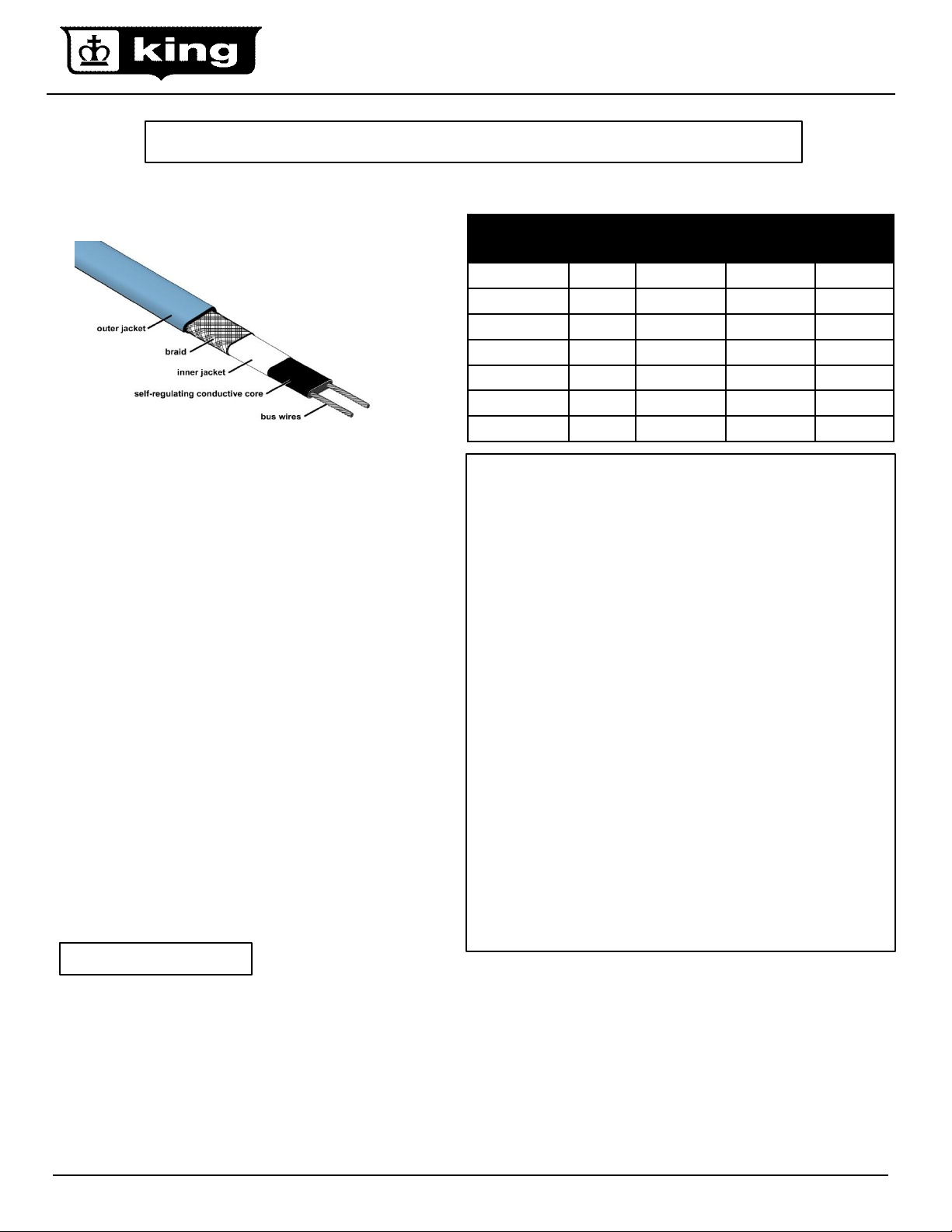

Cable Construction

DESCRIPTION:

SRP self-regulating pre-assembled heating cables are

designed for a variety of pipe freeze protection as well as roof

and gutter deicing applications. The heat output (wattage)

increases and decreases based on the temperature, so the

cable adjusts automatically to varying climate conditions. This

unique feature ensures maximum energy efficiency by

increasing the heat output only when it is needed. No

thermostat is required.

SRP CABLE FEATURES:

- Rated 6 watts/foot at 40º F, (4º C) for pipe freeze protection.

- Rated 8 watts/foot at 32º F, (0º C) for roof and gutter deicing.

- 30 inch power lead with grounded plug.

- Pre-terminated with 30 inch 120V cord with plug and end

splice.

- Suitable for use on metal and plastic pipes.

- Suitable for metallic and nonmetallic gutters and downspouts.

- Cable will not overheat or burnout when overlapped.

- 16 gauge heating cable bus wire.

- 2 year warranty.

SRP CABLE KIT CONTAINS:

• SRP pre-assembled electric heating cable

• Roof and gutter caution labels

• Pipe trace caution labels

Model Volts

-6 120V

-12 120V

-18 120V

-24 120V

-50 120V

-75 120V

-100 120V

Pipe

Rating

36 watts

72 watts

108 watts

144 watts

300 watts

450 watts

600 watts

Deicing

Rating

48 watts

96 watts

144 watts

192 watts

400 watts

600 watts

800 watts

Length

6 ft.

12 ft.

18 ft.

24 ft.

50 ft.

75 ft.

100 ft.

CAUTION:

1.Heating cables must be installed in compliance with the

national electric code (NEC) in addition to state, provincial and

local codes. Check with your local inspector for specific code

requirements (or regulations or standards) in your area.

2.Save these instructions and transfer them to future owner(s).

3.Never install on pipes that could potentially exceed 150º F,

(65º C).

4.Not for use with an extension cord.

5. Cable should not run through the building walls,

ceilings or floors.

6.For safety, King recommends that all heating cables are placed

on a Ground Fault Equipment Protection (GFEP) circuit.

Consult your local electrical inspector to determine the specific

requirements in your area.

7.Do not cut or alter the length of the cable in any way. Any

alteration may result in electrical shock or fire.

8.Post warning labels supplied with the cable at the power supply

and along the pipe on the outside of the insulation.

9.Do not bend the cable to less than a 1/2” radius.

10.Do not Install cable on shingle roofs in freezing temperatures;

as this may cause damage to the shingles.

11.Cables are intended for freeze protection of water pipes only.

Not intended for use with other liquids or hazardous materials.

12. For installation in accessible areas only.

Warranty Information:

King Electrical Mfg. Company will repair or replace, without charge to the original owner, any heating cable found to be defective or malfunctioning within the 2 year warranty.

In Case of Product Failure: Contact King Electrical Mfg. Co. at 800.603.5464. The owner will be required to provide, within the designated warranty period, the following

information: model number, date of purchase, and a complete description of the problem encountered with product. Upon receipt of the aforementioned, the company will

reply to the owner within a period not to exceed fifteen (15) working days, and will provide the action to be taken by owner. Terms: This warranty requires the owner or his

agent install the equipment in accordance with the National Electrical Code, any other applicable heating or electrical codes and the manufacturer's installation instructions. It

further requires that reasonable and necessary maintenance be performed on the unit. Failure of proper maintenance by owner will void the warranty in its entirety. The

company is not liable for any actions it deems to be abuse or misuse of the product. The customer shall be responsible for all costs incurred in the removal or reinstallation of

products, including, but not limited to, labor costs, and shipping costs incurred to return products to King Manufacturing. At their discretion, King Manufacturing will decide to

either repair or replace the product, with no charge to the owner, with return freight paid by King. The Company shall not be liable for consequential damages arising with

respect to the product, whether based upon negligence, tort, strict liability or contract. No other written or oral warranty applies, nor any warranties by Representatives,

Dealers, Employees of King or any other person. King Manufacturing can be contacted by phone at 206.762.0400, fax 206.763.7738 or website www.king‐electric.com.The

company's minimum liability shall not in any case exceed the list price for the product claimed to be defective.

www.king-electric.com 1

Rev 8.28.12

Page 2

Heating Cable Selection Table for Pipe Freeze Protection

Pipe Type* 5 ‘

½”

1”

1 ½”

2”

2 ½”

M A B C D E E E E E E F F F F F G G G G G

P A B C D E E E E E F F F F F G G G G G G

M A B C D E E E E E E F F F F F G G G G G

P B B C D E E E E E F F F F F G G G G G G

M A B C D E E E E E E F F F F F G G G G G

P B C D E E E E F F G G G G G - - - - - M A B C D E E E E E F F F F F F G G G G G

P B C E E E F F G G G G - - - - - - - - M A C C D E E E E E F F F F F G G G G - P B D E E F F F G G - - - - - - - - - - -

A

SRP12-6

10’ 15’ 20’ 25’ 30’ 35’ 40’ 45’ 50’ 55’ 60’ 65’ 70’ 75’ 80’ 85’ 90’ 95’ 100’

B C D E F G

SRP12-18 SRP12-24 SRP12-50 SRP12-75 SRP12-100 SRP12-12

* Type: M = Metal Pipe, P = Plastic Pipe

- Add 1 foot to the cable length for each valve or spigot.

- Chart is based on the lowest outside temperature of 0º F (-18º C) with a minimum of

½” thick insulation. Use 1” insulation for protection in temperatures down to -20º F (-29º C).

Heating Cable Installation

GENERAL NOTES

1. Verify that the heating cable is the correct length, wattage and

voltage prior to installation.

2. All welding, hydrostatic testing, and painting of the pipe

should be completed before the heating cable installation.

3. The piping system must be inspected to ensure that it is clean,

dry and has no sharp or jagged edges that could potentially

damage the heating cable.

4. Do not install the heat tracing before completion of the entire

piping system.

5. The cables must be installed a minimum of 10 inches away

from wood or any other combustible materials.

6. The minimum cable bending radius is 1/2 inch.

PREPARE FOR INSTALLATION

1. Store the heating cable in a clean, dry place.

2. Perform a pressure test on the pipe prior to cable installation.

3. Remove any sharp surfaces on the pipe that could potentially

damage the outer jacket of the heating cable.

4. Walk the pipe system and plan the routing of the heating cable

on the pipe.

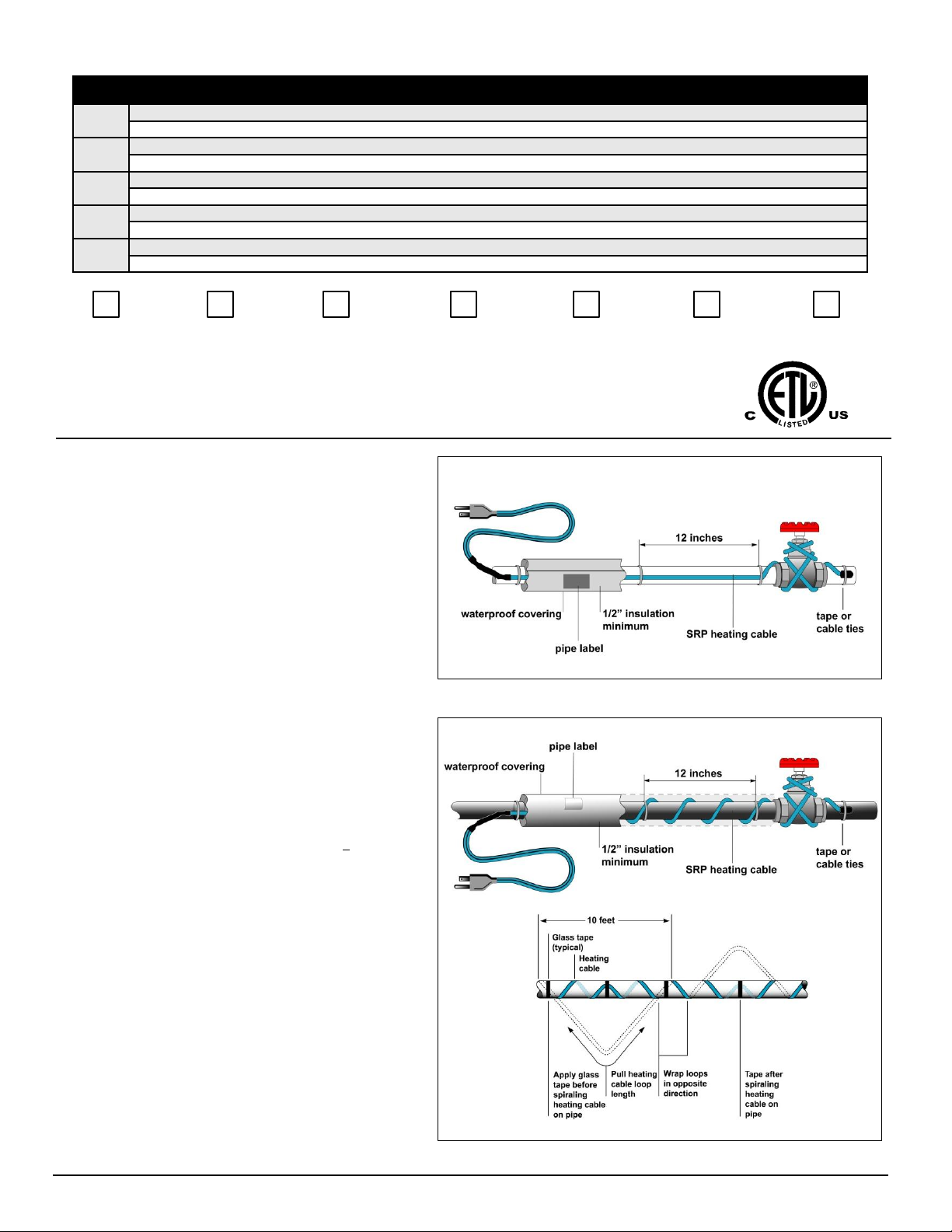

ATTACH THE HEATING CABLE TO THE PIPE

1. Verify pipe to be traced is completely dry.

2. For straight tracing, install the heating cable on a the lower

half of the pipe; for example, in the 4 o’clock or 8 o’clock

position as shown in Figure 1.

3. For spiral tracing, install the cable as shown in Figure 2.

4. Install the extra heating cable required for valves, flanges,

etc.

5. When applying spiral tracing, begin by suspending a loop of

cable every 10 feet as shown in Figure 2. To determine the

loop length, divide the length of pipe length and multiply by

10.

6. For example, if you are using a 50 ft heating cable on a 40

foot pipe, leave a 12 foot loop of heating cable at every 10-foot

section of pipe. Grasp the loop in its center and wrap it around

the pipe. Even out the distance between spirals by sliding the

wraps along the pipe. Use glass tape (SRK03) to secure the

center of the loop to the pipe.

7. Fasten the heating cable to the pipe at 1 foot intervals using

SRK03 fiberglass tape or nylon cable ties. Do not use vinyl

electrical tape, duct tape, metal bands or wire.

8. If there is excess cable at the end of the pipe, double

remaining cable back along the pipe.

www.king-electric.com 2

Rev 8.19.12

Figure 1: Straight Tracing

Figure 2: Spiral Tracing

Page 3

Heating Cable Installation (Cont.)

CHECK FOR PROPER INSTALLATION

1. Before installing the thermal insulation, inspect the

heating cable to verify damage did not incur during

installation including any thermal damage or other

disturbance which may have occurred if exposed to

a excessive heat.

INSTALL THE THERMAL INSULATION

1. The heat trace system requires weatherproofed

thermal insulation installed as shown in Figure 3.

2. A minimum of at least 1/2" of preformed foam or

equivalent thermal insulation must be used on all

piping, including valves, joints, and wall

penetrations.

3. For protection to -20° F (-29° C), use 1" thick

insulation.

4. Install the insulation on the piping as soon as

possible to minimize the potential for mechanical

damage after installation.

5. Place caution labels so they are visible on the

outside of the thermal insulation.

CREATE STRAIN RELIEF AND FASTEN LABELS.

1. Secure the power cord (cold lead) with a plastic

cable tie, glass cloth tape, or duct tape as shown in

Figure 4.

2. The SRP cable kit includes caution labels to

identify the presence of electric pipe heating

system. Attach the labels on the outer surface of

the pipe insulation at suitable intervals.

Figure 3

Figure 3: Thermal Insulation

STARTING THE HEATING CABLE SYSTEM.

1. Test per the “cable testing and maintenance”

section.

2. Plug the heating cable into a 120 V ground-fault

protected outlet.

3. Check the circuit breaker to verify there is power to

the cable.

4. Check standing water in the pipe after one hour, it

should feel warm.

CABLE TESTING AND MAINTENANCE

1. Using a 2500-volts DC megohmmeter, check the

resistance between both of the power prongs on the

plug and the ground prong after installing the heating

cable. Minimum reading should be 1000 megohms.

2. Record the original values for each circuit, and

compare subsequent readings taken during regular

maintenance to the original values.

3. If the readings fall below 1000 megohms, replace

the cable with a new unit. Do not attempt to repair

the cable.

Figure 4: Strain Relief

WARNING

Fire and shock hazard. Damaged heating cable can cause

electrical shock, arcing, and fire. Do not attempt to repair

or energize damaged heating cable. If damaged,

immediately remove it and replace with a new cable.

www.king-electric.com 3

Rev 8.19.12

Page 4

GENERAL INFORMATION FOR ROOF AND GUTTER DEICING

1. SRP cable is designed to remove ice, not accumulated snow.

2. SRP cable will not keep snow or ice from falling off of the roof.

Snow fences or snow guards should be used to eliminate snow

movement.

3. SRP heating cables may be used on:

- Roofs made from all types of roofing materials, such as

shake, shingle, rubber, tar, wood, metal, and plastic.

- Gutters made from standard materials, such as metal

and plastic.

- Downspouts made from standard materials, such as metal

and plastic.

4.Do not use an extension cord.

5. Do not install the heating cable underneath any roof

covering.

6. Install only in accessible locations; do not install behind

walls or where the cable would be hidden.

7. Do not run the heating cable through walls, ceilings, or floors.

8. Connect only to ground-fault protected outlets that have

been installed in accordance with all national and local codes

and standards and that are protected from rain and other water

sources such as melting ice water.

9. SRP cable is factory preassembled and cannot be altered.

Use of any in-line splices or tee-splices will void the warranty.

Cut to length cable is available from King, contact your local

distributor or visit the King website for information.

10. Do not exceed the amp rating of the over current

protection device.

Figure 5: Roof and Gutter Application

ELECTRICAL CODES

Article 426 of the National Electrical Code (NEC), and Part 1, Section

62 of the Canadian Electrical Code (CEC), govern the installation of

SRP heating cables for roof and gutter deicing and must be followed.

IMPORTANT: For the warranty to be valid, the installer, customer and

user must comply with all the requirements outlined in these guidelines.

All design information provided in these instructions are based on a

“standard” shake or shingle and metal roof applications. For any other

application or method of installation, consult a design specialist.

Selecting the Required Heating Cable Length for Roof and Gutter Deicing

CALCULATION FOR HEATING CABLE LENGTH:

Use the formula below to determine the amount of heating

cable required. Total heating cable length = A+B+C+D

A (Roof edge) × (heating cable multiplier)

B (Roof edge x 0.5)

C ( Total gutter length)

D (Total downspout length + 1 ft)

= Total heating cable length required

Example:

1. Roof edge = 14 ft

2. Eave overhang = 1 ft (Refer to cable multiplier table)

3. Gutter = 14 ft

4. Downspout = 12 ft

Heating Cable Required:

A Roof edge: 14 ft × 2.8 (Multiplier from table) = 39.2 ft

B Roof extension:14 ft x 0.5 = 7.0 ft

C Roof gutter: 14 ft = 14.0 ft

D Downspout: 12 ft + 1 ft = 13.0 ft

Total heating cable length required: = 73.2 ft

Example Solution = SRP126-75

*Roof extension is the length of cable required to prevent ice

dams between the roof edge and the gutter. When there are

no gutters present it forms a drip loop to prevent ice dams at

the roof edge.

Heating Cable Multiplier Table

Eave

Overhang

None 2.0 2.5 2.0

12” 2.8 2.8 2.4

24” 3.8 3.6 2.9

36” 4.8 4.3 3.6

Use the number in the table and multiply it by the length of the roof edge.

CALCULATIONS FOR GUTTERS, DOWNSPOUT AND VALLEYS:

1. For standard non-metal roofs, add 1 foot of heating cable for

each foot of gutter.

2. Add 1 foot of heating cable per foot of downspout.

3. If the downspout is in the middle of the run, loop the cable

down and back up. Double the length of the downspout for

determining the length of cable to install.

4. For valleys, run the heating cable two thirds of the way up and

down the valley. Add this additional length to the overall cable

needed.

5. For gutters 6 inches wide use two cable runs.

Standard

Roof

Metal Roof

18” Seam

Metal Roof

24” Seam

www.king-electric.com 4

Rev 8.19.12

Page 5

HEATING CABLE INSTALLATION

Tracing Heights for Shake and Shingle Roof

Eave

overhang

Tracing

width

None 24” 18” 2.0 ft

12” 24” 18” 2.8 ft

24” 24” 30” 3.8 ft

36” 24” 42” 4.8 ft

Tracing Heights for Metal Seam Roof Table

Table

Tracing

height

Cable/roof

edge

Eave

overhang

Tracing

width

Tracing

height

Cable/roof

edge

None 18” 18” 2.5 ft

12” 18” 24” 2.8 ft

24” 18” 36” 3.6 ft

36” 18” 48” 4.3 ft

None 24” 18” 2.0 ft

12” 24” 24” 2.4 ft

24” 24” 36” 2.9 ft

36” 24” 48” 3.6 ft

The tracing heights for standard shake and shingle roof or a

metal seam roof are listed in the two tables above. The last

column gives the amount of cable required per foot of roof edge.

PREPARE FOR INSTALLATION

1. Store the heating cable in a clean, dry place.

2. Inspect for any mechanical damage prior to installation.

3. Warranty is void if non-King accessories are used. King approved

accessories include:

- SR1K5 Downspout hanger bracket

- SRK13 Roof clips

4. Gutters and downspouts must be free of leaves and other debris.

5. Plan the routing of the heating cable for roof and gutter deicing.

ATTACH THE HEATING CABLE ON ROOFS

1. Loosely loop the heating cable on the roof at the overhang area. Pull

the bottom of each heating cable loop over the roof edge and, using a

UV-resistant cable tie. Connect the bottom of each loop to the cable

running in the gutter. This will ensure a drainage channel for the

melting ice to drain off the roof and into the gutter and downspout. The

cable in the gutter should remain against the bottom of the gutter as

shown in Figure 6 (Standard Roof) and Figure 7 (Metal Roof).

2. Extend the top of each heating cable loop beyond where the wall joins

the roof.

3. Trace two-thirds of the way up each valley with a double run of heating

cable as shown in Figure 8.

4. Use SRK13 roof clips to route heating cable up and down the edge of

the roof according to the tracing height noted in the tables above and

shown in Figures 11 and 12. Route the heating cable in such a way as

to prevent abrasion to the cable jacket.

5. One SRK13 kit contains 25 roof clips for approximately 17 linear feet

of the roof edge.

6. Roof clips may be attached to a shake or shingle roof using nails or

screws. Roof clips may be attached to a metal roof using nails, screws,

or adhesive. Reseal the nail or screw holes if necessary before

installing heating cable in the clips.

7. A barrier (snow fence) can be placed on the roof above the heating

cable. This prevents damage to the cable and keeps the roof brackets

from tearing loose during ice slides. The heating cable can be

attached to the barrier with UV-resistant cable ties, instead of using

roof clips. The use of other materials, such as wire, may cause

damage to the heating cable and will void the warranty.

Figure 6: Shake and Shingle Roof Attachment

Figure 7: Metal Roof Attachment

Figure 8: Roof Valleys

www.king-electric.com 5

Rev 8.19.12

Page 6

INSTALLING THE CABLE IN GUTTERS AND DOWNSPOUTS

1. Run the heating cable in the gutters and into downspouts, end the

cable in a loop at the bottom of the downspout and then run the cable

back up the downspout using a tie wrap to fasten it as shown in Figure

9. Permanent attachment of the cable to the gutter bottom is not

necessary. Do not leave the end of the heating cable pointing down at

the end of the downspout, double back as shown.

2.Use King SRK15 downspout brackets at the transition of the gutter

and downspout to protect the cable from fraying, to prevent damage

due to sharp edges and to provide a strain relief as shown in Figure

10. Refer to the SRK15 kit instructions for more installation details.

3. Route and secure cable with care to avoid mechanical damage during

installation or maintenance from such things as ladders, etc.

ATTACH THE WARNING LABLES

1. Two warning labels are provided with the SRP cable kit to indicate the

presence of electric deicing and snow-melting equipment on the

premises. One label should be attached at the electrical outlet cover

and the other label must be posted at the fuse or circuit breaker panel

feeding the outlet circuit. Labels must be clearly visible.

CHECK AND INSPECT THE INSTALLATION

1. Prior to plugging the deicing cable into the outlet, check the entire

length of the cable for mechanical damage such as nicks and cuts in

the outer insulation and any potential thermal damaged which may

have occurred if cable was exposed to excessive heat.

2. Use a megohmmeter to test each circuit according to the instructions

in the “Heating Cable Testing and Maintenance” section of these

instructions.

3. Junction boxes should be inspected for water and for evidence of

previous water damage. If moisture is present, the box should be

restored to a dry condition and the cause of the water intrusion should

be investigated and eliminated.

4. Test the ground fault circuit to be sure it is functioning properly. If

malfunctioning, replace prior to energizing the system. Functionality of

over-current protection devices such as circuit breakers or fuses

should be checked as well.

STARTING THE SYSTEM

1. King recommends that the heating cable system be tested per the

“Cable Testing and Maintenance” section below.

2. Plug the heating cable into a 120 volt ground-fault protected outlet.

3. Check the circuit breaker to the outlet to verify there is power to the

cable.

HEATING CABLE TESTING AND MAINTENANCE

1.Make sure that gutter and downspouts are free of leaves and other

debris annually prior to the winter season.

2. Using a 2500-Vdc megohmmeter, check the resistance between both

of the power prongs on the plug and the ground prong after installing

the heating cable. Minimum reading should be 1000 megohms.

3. Record the original values for each circuit, and compare subsequent

readings taken during regular maintenance to the original values.

4. If the readings fall below 1000 megohms, replace the cable with a new

unit. Do not attempt to repair the cable.

Figure 9: Downspout Termination

Figure 10: SRK15 Downspout Bracket

Figure 11: Roof Clip, Standard Shake Roof

WARNING

Fire and shock hazard. Damaged heating cable can cause

electrical shock, arcing, and fire. Do not attempt to repair or

energize damaged heating cable. If damaged, immediately

remove it and replace with a new cable.

Figure 12: Roof Clip, Metal Roof

www.king-electric.com 6

Rev 8.19.12

Loading...

Loading...