Page 1

SAVE THESE INSTRUCTIONS

KFUH Electric Unit Heater

Installation Instructions

“WARNING: RISK OF ELECTRIC SHOCK. CAN CAUSE

INJURY OR DEATH. DISCONNECT ALL REMOTE ELECTRIC POWER SUPPLIES BEFORE SERVICING.”

CAUTION: Turn off power source supplying the heater before attempting installation, maintenance or repairs. Lock or tag circuit breaker

or fuse panel door. Failure to do so could result in serious electrical shock, burns, or possible death.

It is extremely important you verify the electrical power supply is the same voltage as the heater being installed. 240 and 480 Volt heaters are not

interchangeable. Powering a 480 Volt unit with 240 Volt supply wires will reduce the heater output by approximately 75% and is never recommended.

Powering a 240 Volt unit with 480 Volt supply wires will destroy the heater and voids all warranties.

CHECK: Ensure blower wheel is free-turning and that element assemblies are in place. Be sure filter is in proper position and not torn or damaged.

Check that blower housing and motor have not separated from element compartment during shipment.

FIELD WIRING

208 and 240 Volt heaters are equipped with circuit breakers over 48 Amps to provide internal circuit protection and a field disconnect on the unit. A

terminal block provides a single strike for field wiring. 480 Volt units do not have circuit breakers but are fused when internal protection is required and

are also supplied with terminal blocks for field wiring. Consult the National Electric Code for proper wire size and service circuit breaker protection.

Ter m in a l B lo c k

1 Phase and 3 Phase

240VAC

L6

L5

240VAC

L4

L3

240VAC

L2

L1

60 Amp

Circuit Breaker

60 Amp

Circuit Breaker

60 Amp

Circuit Breaker

To L im i t C on t ro l s

and

Heater Elements

Low Voltage Thermostat

R

W

G

Y

Furnace Low Voltage

Ter m in a l B lo c k

C

R

W

G

Thermostat Control Wiring diagram

for use with electric furnaces and

showing cooling coil relay hook-up

Transformer

24VAC

Heat Relays

Fan Only Relays

Cooling Coil Relay*

(*provided by others)

Electronic Air Cleaner Wiring diagram

for use with electric furnaces and

utilizing an airflow interlock switch

D

I

M

E

N

S

I

O

N

AIR FLOW AIR FLOW

S

2007 KFUH.indd : 3/08

King Electrical Mfg. Company • 9131 10th Avenue South • Seattle WA 98108 • phone (206) 762-0400 • fax (206) 763-7738

1

Page 2

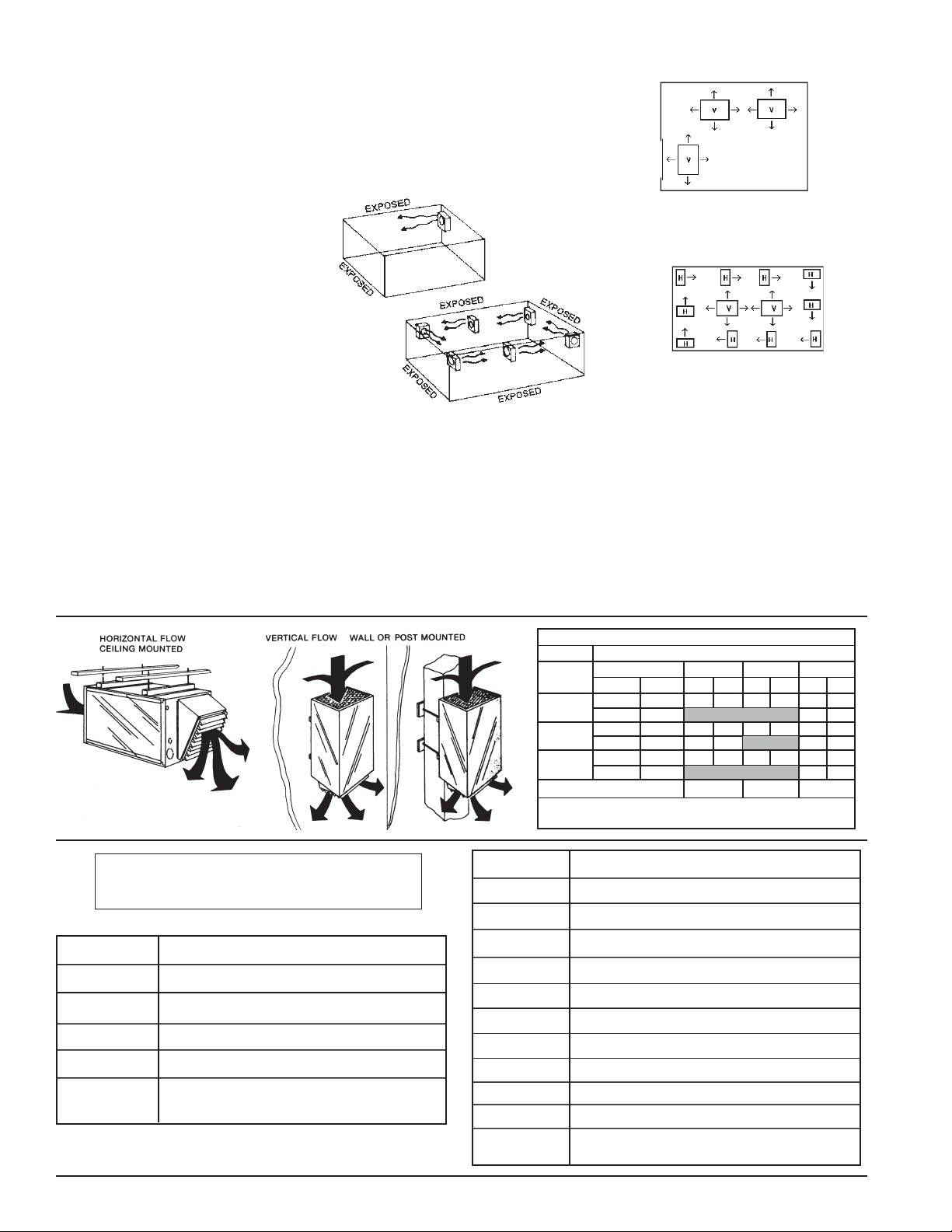

Mounting

KFUH heaters can be mounted vertically or

horizontally as shown. 3/8" weldnuts are welded into brackets and will accept 3/8 threaded

rod. A minimum of 6 inches clearance to

vertical and horizontal surfaces and 6 feet

minimum above floor are required. Louvers

can be adjusted for desired airflow.

Application Tips

First, calculate the heating loads in the conventional way using the N.E.M.A. handbook or

ASHRAE guide. Next, determine quantity and

size of heaters to be used. In instances where

large groups of people are normally settled

in the same location, use a large number of

smaller kW unit heaters. (Example: people on

a production line or skilled machine operations.) By utilizing heaters in this manner one

can best distribute uniform heat, prevent hot

drafts, reduce potential noise levels and balance the electrical operating demand.

When considering warehouse areas or

storage rooms (where heat distribution and

constant temperatures are less important) use

fewer heaters of higher capacity.

To maintain uniform heat and reduce stratified air it is recommended that the total CFM

of the units turn the air over approximately 3

times per hour.

Horizontal Mount

Smaller rooms can be heated by one unit

heater. Where two walls are exposed heaters

should be mounted as shown.

In larger rooms, units should be located so

their air streams wipe exposed walls without

Ceilings under 12 feet

6" Minimum

Clearance

Adustable

Louvers

blowing at them. Units should be located so

that the air stream of one supports that of

another thus setting up a circulatory air movement. (Distance between units to be approximately 1½ times published air throw).

Units should not be mounted horizontally in

areas having ceiling heights in excess of 10

to 12 feet.

Vertical Mount

Units should be mounted vertically where

they may otherwise interfere with assorted

material, handling equipment and in high bay

areas. Heaters should be situated to provide

free air circulation. Size and selection of units

should be based on recommended mounting

height.

Unit heaters are frequently used to combat

cold air inrush when loading dock doors are

opened. For such applications, one or more

units should be arranged to blow warm air

vertically in front of opening.

Ceilings over 12 feet

Motor HP

Dual Mounting

Where square footage is large and comfort

essential, both horizontal and vertical installations may best serve your requirements.

Mounting Limitations

KFUH unit heaters should not be used in

potentially explosive atmospheres. The finish

is not intended for direct salt spray exposure

in marine applications or the highly corrosive

atmospheres of swimming pools, chemical

storage bins, etc. Please refer to the factory

for explosion proof or marine application

heater information.

Do not install unit heaters above recommended maximum mounting height. Obstructions must not block unit heater air inlet or

discharge. To prevent possible injury heaters

must be mounted at least 6 feet above the floor

to prevent accidental contact with the heating

element or fan blade.

AIR DELIVERY CHART @ .2 static

MOTOR SPEED

Motor Load

230

230

230

Amps

3.4

1.7

3.2

1.7

3.8

1.9

Voltage

1/5

380/460

1/3

380/460

1/2

380/460

Wire Color

Air Volume = Cubic Feet per Minute (CFM)

Air Velocity = Feet per Minute (FPM)

Low Med

CFM FPM

775 570 860 630

1100 810 1250 920

1100 810

1250 920 1540 1130

Red

CFM

Blue

FPM

CFM

1000

1000

1540

1540

1750

1750

High

FPM

735

735

1130

1130

1285

1285

Black

The following accessories and/or options

may have been ordered with your unit.

Model

1E30-910

KFUH-90D

KFUH-RD

KFUH-90RD

KFUH-PTBL

2

Description

24V Wall Thermostat, range 50°- 90°

90 Degree Elbow w/ adjustable louver diffuser

Radial Diffuser

90 Degree Elbow w/ radial diffuser

Kit includes casters and mounting bracket to

create a Portable KFUH (no power cord)

Add Suffi x

-T

-2TS

-SF

-BR

-2S1

-2S3

-DS40

-DS60

-DS80

-DS100

-ND

Description

1-Pole thermostat - factory installed

2-Stage thermostat - factory installed

Summer fan switch - factory installed

Blower relay for remote fan only operation

2-Stage control, 1-Phase models

2-Stage control, 3-Phase models

40 Amp 3-Pole non-fused disconnect switch

60 Amp 3-Pole non-fused disconnect switch

80 Amp 3-Pole non-fused disconnect switch

100 Amp 3-Pole non-fused disconnect switch

No diffuser - 1" duct collar provided on discharge

side for connection to 14" x 14" duct

2007 KFUH.indd : 3/08

Page 3

CONTROL WIRING

Connect thermostat to terminals R and W for heating, R and G for air only. This can be done with a single stage heatcool thermostat or a single stage heat-only thermostat and a separate fan-only switch to control the fan-relay (optional)

installed on furnaces. Some models of furnace have two stage operation (optional) and are provided with terminals W1

and W2. If a single stage thermostat is used it should be connected to terminals R and W1 and a jumper wire installed

form terminals W1 to W2 (see enclosed control circuit wiring diagram). Some models of furnace have the 24 VAC power

available between terminal C and R for use with external air conditioning relay option. Never short or cross these two

terminals! The transformer will fail.

OPERATION

When control thermostat is turned up to demand heat the blower and heating elements should be energized. Furnaces

with sequences installed will have up to 30 seconds delay in start-up. When turned to cool position heat-cool thermostats

should bring on the blower only for air only.

MAINTENANCE

"CAUTION" Disconnect power at the main service panel before inspecting or cleaning this heater.

Lock or Tag breaker to prevent accidental shock.

Because of its rugged design, superior engineering and quality craftsmanship the King KFUH Unit Heater requires

little maintenance. With minimum care your electric heater should last a lifetime. King recommends changing the air

intake filter at least twice a year and checking the motor and blower for excessive dust / lint accumulation to maintain

the efficiency of the heater. While King recommends the filter be changed twice a year, your environment may require

more frequent changes.

WARRANTY

The King KFUH unit heater is warrantied against defects in workmanship and materials for five years from date of

installation. Extended warranty applies to heating element only; all other components are covered for two years. This

warranty does not apply to damage from accident, misuse or alteration; nor where the connected voltage is more than

5% above the nameplate voltage; nor to equipment improperly installed, wired or maintained in violation of this instruction

sheet. All claims for warranty work must be accompanied by proof of the date of installation. The customer shall be

responsible for all costs incurred in the removal or reinstallation or products, including labor costs, and shipping costs

incurred to return products to King Manufacturing. King, will repair or replace, at our option, at no charge to you with

return freight paid by King. King shall not be liable for consequential damages arising with respect to the product, whether

based upon negligence, tort, strict liability or contract. No other written or oral warranty applies, nor any warranties by

Representatives, Dealers, Employees of King or any other person. King Manufacturing can be contacted in Seattle,

Washington U.S.A. by phone at (206) 762-0400, fax (206) 763-7738 or website www.king-electric.com.

TROUBLE

Unit will not start

Motor will not stop

Unit goes off on high limit

Vibration noise

Unit has a buzzing sound

when not in use

Unit continues to heat after

room is up to set temperature

- does not shut off

TROUBLESHOOTER

POSSIBLE CAUSE

• Thermostat wire is not connected

• Circuit breaker is off

• 24 Volt transformer burned out

• Wire connection off or there are

broken wires

• Reset button tripped

• Wrong voltage

• Defective sequencer or contactor

• Dirty air filter

• Defective sequencer

• Defective limit control

• Power failure

• Blower assembly loose • Secure blower and motor cage

• Low voltage transformer

defective or loose

• Defective sequencer

• Defective thermostat

• Thermostat wires to ground

• Motor wires to ground

• Thermostat accidentally shorted

& contacts are welded

REMEDY

• Repair

• Reset

• Replace

• Repair or replace

• Reset

• Check the power source

• Replace

• Replace

• Replace

• Replace

• Reset manual limit push

button 20-35 kW units

• Replace or tighten

• Replace

• Replace

• Repair

• Repair

• Replace

- Make sure all connections are tight

2007 KFUH.indd : 3/08

3

Page 4

ITEM PART NUMBER DESCRIPTION

1

2

3

4

4000-09-E07K999

5

4000-03-E07J999

21-2405-00

21-2405-07

21-2405-9

21-2405-2

21-2405-12

21-2405-1

21-2405-6

21-3413-00

21-3413-01

60T11-201936

QOU260

QOU360

EB-200

ED-2

ERB-201

ED-3

4000-04-E07K999

Heating Element 5 kW / 240V

Heating Element 5 kW / 208V

Heating Element 5 kW / 480V

Heating Element 5.75 kW / 240V

Heating Element 5.75 kW / 240V

Heating Element 4 kW / 240V

Heating Element 4 kW / 480V

Heating Element - 3 Ph 5 kW / 240V

Heating Element - 3 Ph 5 kW / 480V

Auto. Limit Control - 60T11

Circuit Breaker 60 Amp - 1 Ph Square D

Circuit Breaker 60 Amp - 1 Ph Square D

Input Terminal Block - 1 Ph, 2P, 240V

Input Terminal Block - 1 Ph, 2P, 480V

Input Terminal Block - 3 Ph, 3P, 240V

Input Terminal Block - 3 Ph, 3P, 480V

Low Volt Transformer 240 / 208

Low Volt Transformer 277 / 24

Low Volt Transformer 480 / 24

4

R8330

15SH22-30956

6

R8229A

R8246A

60T25-330976

7

8

9

10

10935H3

9100233Q999

ELD-5-034

CA4SP

5KSP39FGW057AS

5KSP39FGW244AS

5KCP39MGE250AS

11

5KSP39FGG136S

4M207G

5KCP39M6J185S

DAO-3GJ005

DAO-3GJ007.5

12

DAO-3GJ010

FURNACE BLOWER SMALL

FURNACE BLOWER LARGE

13

Sequencer (used prior to 1981)

Sequencer (used after 1981)

Relay 28 Amp

Relay 46 Amp

Manual Reset Limit

Manual Reset Button

Dual Speed Fan Relay

Low Voltage Terminal Block

Ground Lug

1/5 HP 240V Motor

1/5 HP 480V Motor

1/3 HP 240V Motor

1/3 HP 480V Motor

1/2 HP 240V Motor

1/2 HP 480V Motor

Capacitor 3MP 370V

Capacitor 7.5MF 370V

Capacitor 10MF 370V

Blower Small for 1/5 HP Motors

Blower Large for 1/3, 1/2 HP Motors

120-8T-DD-.50PP Blower X-Large for 1/2 HP Motors

14

Air Filter 1" x 16" x 20"

2007 KFUH.indd : 3/08

Loading...

Loading...