Page 1

electrical mfg. company

9131 - 10th Avenue South Seattle Washington 98108

INSTALLATION & MAINTENANCE MANUAL

SAVE THESE INSTRUCTIONS

for KB SERIES UNIT HEATERS

WARNING

THIS UNIT IS MANUFACTURED TO OPERATE ON A SPECIFIC CONTROL VOLTAGE IN COMPLIANCE WITH YOUR

ORDER. STANDARD CONTROL VOLTAGES ARE 208/240/277 FOR 208/240/277 VOLT HEATERS. 24 VOLT

CONTROL IS STANDARD ON 4 80 VOLT HEATERS. 120 VOLT CONTACTOR COILS ARE AVAI LABL E FOR EXTERNAL

120 VOLT CONTROL SUPPLY. 208/240 OR 277 VOLT HEATERS MAY ALSO BE ORDERED WITH 24 VOLT

CONTROL - KBLV-1 (WHICH INCLUDES TRANSFORMER AND CONTACTOR) OR KBLV-2 (WHICH INCLUDES

TRANSFORMER AND WIRING FOR HEATERS THAT ALREADY HAVE CONTACTORS AS STANDARD EQUIPMENT). IT

IS IMPORTANT THAT YOU VERIFY YOUR POWER SUPPLY VOLTAGE WITH THE HEATER THAT YOU HAVE CHOSEN.

IMPROPER INSTALLATION OR FAILURE TO FOLLOW THE PROCEDURES AS OUTLINED IN THIS MANUAL CAN RESULT

IN SERIOUS ELECTRICAL SHOCK OR DEATH. DISCONNECT ALL POWER FROM THE HEATER AT THE MAIN SERVICE

PANEL BEFORE ATTEMPTING TO INSTALL OR SERVICE THIS UNIT. ALL ELECTRICAL WIRING MUST CONFORM TO

LOCAL ELECTRICAL CODES. HEATER CIRCUIT MUST BE PROTECTED WITH PROPER FUSES.

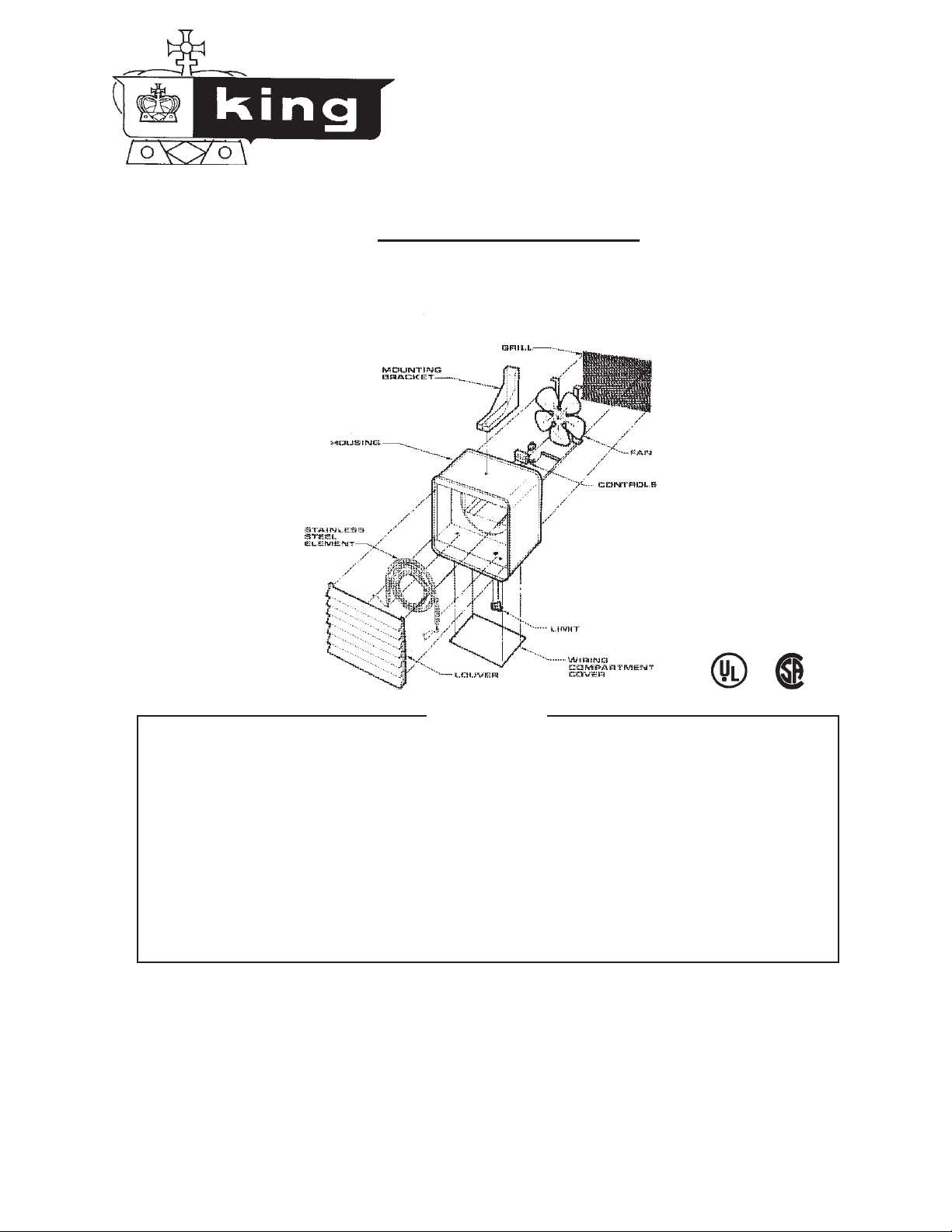

Congratulations on the purchase of your new KING ELECTRICAL UNIT HEATER. Your

new heater is made with the highest standards in electrical design and quality components

to ensure your satisfaction in durability and performance. The steel fin tube element which

has a 5 year warranty is backed by a heavyduty fan directing a strong flow of warm air to any

desired area through adjustable louvers. The rugged, totally enclosed, service-free motor

is combined with our fan design to maintain the correct relationship of air volume to final air

temperature. The quick access panel allows easy connections in the wiring compartment.

The universal bracket will allow ceiling or wall installation to fit your particular application.

KB.indd : 10/08

Page 2

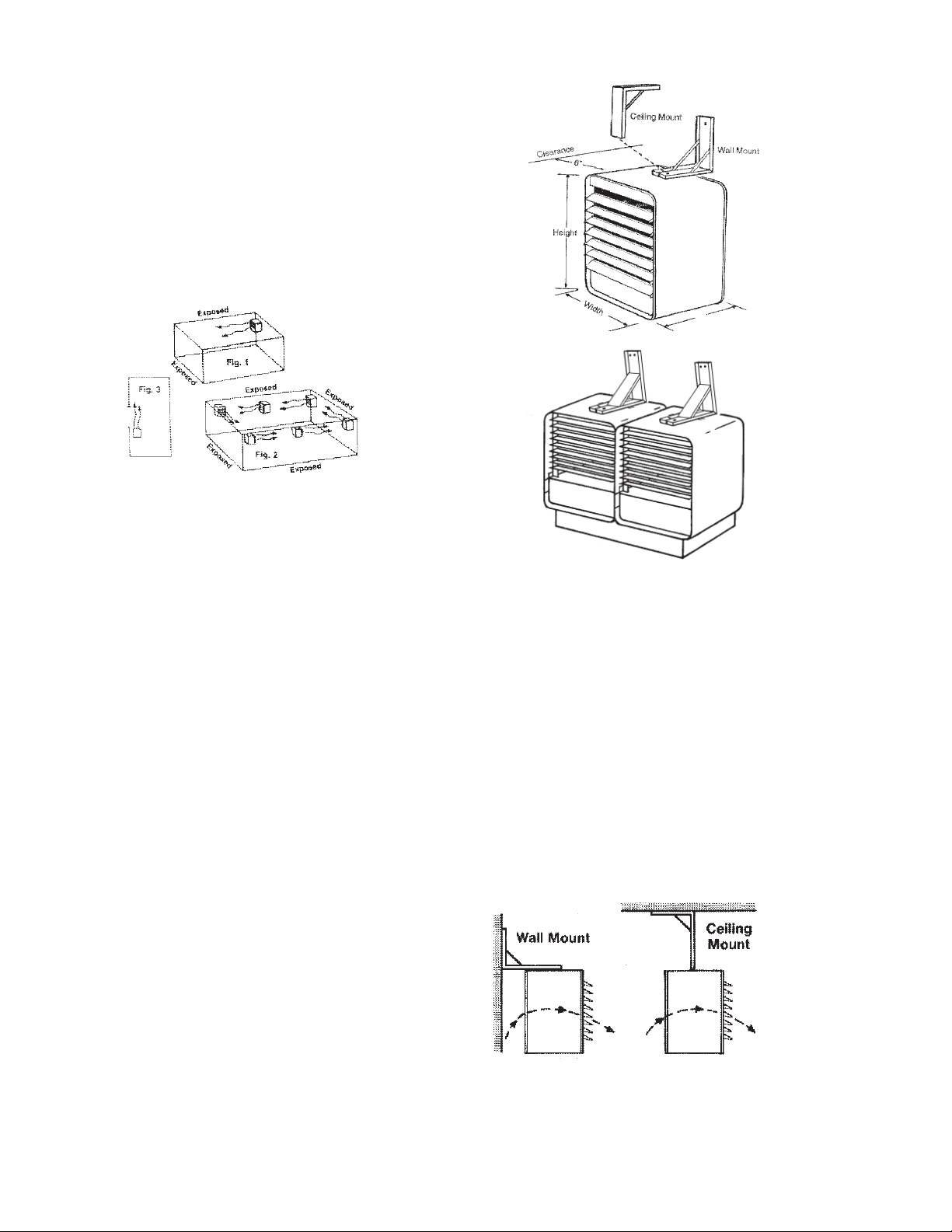

Location of Heater

The heater should be installed out of the reach of

persons. The direction of air flow should not be

restricted by machinery, beams, etc., and the air

flow should wipe exposed walls rather than blowing

directly at them. When more than one heater is used

in an area the heaters should be arranged so that

the air discharge of each heater supports the air flow

of the others to provide best circulation of warm air.

(see air flow chart)

Unpack & Inspect Your New Heater

Remove heater from the box and inspect it for any

damage. Verify you have received the mounting

bracket or thermostat if needed. (optional)

Mounting Height

Tools Needed

You will need the following tools to install your unit

heater:

• Screwdriver - (Phillips head & slotted)

• Pliers

• Electric Drill

• Wire Cutters

• Adjustable Wrench

Hardware Needed

You will also need the following hardware, which

can be purchased from your local hardware store or

electrical supply house:

• adequate gauge and length of wire for your applica tion

• proper size fuses or breakers to handle amperage

• proper wire connectors for your application

• fasteners appropriate for application that are strong

enough to hold unit

For certain applications conduit may be required.

Check local electrical codes. Also, if you run the wiring in conduit and wish to be able to turn the heater,

be sure to purchase enough flexible conduit to allow

the heater to be turned.

When the airflow of the heater is directed vertically or

horizontally the minimum mounting height is 6 feet.

Mounting heights depend upon building utilization and

heater kW capacity.

Distance From Walls

Be sure to maintain 6" minimum clearance to walls

and ceilings.

Mounting Bracket & Heater

Locate a stud in ceiling or wall and securely fasten

bracket to supporting surface with 3 1-1/4" screws.

Attach heater to bracket with 3/8" x 1" bolt & lock washer

supplied with bracket. After desired air discharge position has been determined, tighten bolt so the heater

will not pivot.

KB.indd : 10/08

Page 3

Wiring

WARNING

Before proceeding further with the installation of this heater, turn off the power and

lock to the supply line for the heater at the

main service box.

Remove wiring compartment cover. Remove one of

the knockouts from back of unit.

Select power supply wire to comply with local and

national electric codes using heater rating given in

table. Connect wire to heater as shown in wiring diagram attached to cover. Secure power supply cable

with clamps.

Connect grounding conductor to green screw. Reinstall wiring compartment cover.

Adjust the louvers to the desired position. NOTE: The

lovers are designed so they can not be completely

closed. Do not attempt to defeat this feature - damage to the unit can result.

capillary tube will exit knockout.

Adhere nameplate and attach thermostat with two

#6 screws as shown. Carefully bend capillary tube

through hole and attach bulb clamps with screws to

lip of chassis as shown in figure.

Connect wires as shown in wiring diagram. Reinstall

wiring compartment cover. Attach knob to thermostat.

Nameplate

6/32 Screws

Bulb Clamps

Knob

Capilary Tube

Thermostat Installation - Inbuilt

Remove wiring compartment cover. Remove plug

from back of chassis. Insert thermostat (model KBT

on standard units - for stainless steel see below) into

holes punched in chassis. Position thermostat so

Maintenance

Because of its rugged design, superior engineering and

high quality craftsmanship and manufacturing, the King

KB Unit Heater requires little maintenance. With proper

care your electric heater should last a lifetime, however,

seasonal cleaning is recommended to maintain the

efficiency of the heater.

To c le a n t he h ea ti n g el e me n t l oo s en t h e 4 Ph il l ip s h ea d

screws located behind the louvers in the corners of

the louver housing. Grasp the louver housing on both

sides, lift up and pull out. This provides access to the

heating element. Remove dust or lint with a soft brush

or a vacuum cleaner. Replace the louver housing and

tighten the Phillips head screws.

To clean the fan and motor remove the safety grill from

the rear of the heater. This provides access to the fan

and motor. Wipe the fan and motor with a soft cloth or

brush. The fan motor does not require lubrication.

WARNING - All Power must be shu t

off at the main service panel before

inspecting or cleaning the heater.

Stainless Steel Models require a special thermostat

model (TF115) that will be mounted to the outside

of the heater. This must be sealed properly and is

recommended to be done at the manufacturing plant.

For additional information please consult the factory.

Warranty

All products covered by this instruction sheet are warranted against defects in workmanship and materials for

one year from date of installation, except heating elements which are warranted against defects in workmanship and materials for five years from date of installation.

This warranty does not apply to damage from accident,

misuse, or alteration; nor where the connected voltage

is more than 5% above the nameplate voltage; nor to

equipment improperly installed or wired or maintained

in violation of this instruction sheet. All claims for warranty work must be accompanied by proof of the date

of installation. The customer shall be responsible for all

cost incurred in the removal or reinstallation or products,

including labor costs, and shipping costs incurred to

return products to King Manufacturing. King Mfg., will

repair or replace, at our option, at no charge to you with

return freight paid by King. King Electrical Mfg., shall

not be liable for consequential damages arising with

respect to the product, whether based upon negligence,

tort, strict liability or contract. King Manufacturing can

be contacted in Seattle Washington by phone at 206

762-0400 or by fax at 206-763-7738.

KB.indd : 10/08

Loading...

Loading...