Page 1

Electric Floor Heating Mat Systems

mat

series

INSTALLATION

MANUAL

This installation manual includes factory guidelines for installing King Electric floor heating systems.

These guidelines must be followed to ensure warranty coverage. Contact King Electric for any questions

regarding proper installation of the heating cable.

IMPORTANT: Save these instructions!

800-603-5464king-electric.com

Page 2

King Electrical Floor Heating Mat Installation Manual 2

Electric Floor Heating Cable Systems

www.king-electric.com

1.

2.

3.

4.

5.

General Information ---------------------------------------------------------------

Typical Installations -----------------------------------------------------------------

3

3

4

5

6

Cable Test Log ---------------------------------------------------------------------

6.

STEP 2: Layout Planning and Product Selection ---------------------------------

7

7.

120 Volt Selection Table -----------------------------------------------------------

9

8.

240 Volt Selection Table --------------------------------------------------------------

9

9.

STEP 3: Thermostat Location --------------------------------------------------------

10

10.

Materials Required ------------------------------------------------------------------

11

11.

STEP 4: Electrical Rough-in New Construction -------------------------------

12

12.

STEP 4R: Electrical Rough-in for Remodel ------------------------------------

13

13.

STEP 5: Installing the Cold Lead ----------------------------------------------------

14

14.

STEP 6 : Installing the Mat -----------------------------------------------------------

16

15.

STEP 7: Install the Floor Sensor ------------------------------------------------------

18

16.

STEP 8: Apply Scratch Coat ---------------------------------------------------------

18

17.

STEP 9: Install the Thermostat ----------------------------------------------------

19

20

STEP 1: Inspect and Testing the Cable and Floor Sensor______________

Important Safeguards and Warnings ______________________________

Cable Test Log________________________________________________

18. Troubleshooting_______________________________________________

Table of Contents

Page 3

King Electrical Floor Heating Mat Installation Manual 3

Tiles, Stone

Scratch coat

(optional)

Thin-set

Plywood subfloor

Backerboard

(optional)

Tiles, Stone

Scratch coat

(optional)

Concrete slab

Thin-set

(optional)

Insulation

General information

Electric floor heating is a simple, economical way to warm any floor providing years of lasting comfort whether it is used as

supplemental or the primary heating source. This installation manual provides guidelines, safety warnings and describes the

elements of properly installing the King Electric floor heating system which are:

1. How to design the proper layout for the room.

2. How to select the right product for the application.

3. How to properly install the system.

This installation manual DOES NOT provide detailed information regarding thermostat installation. It is important to thoroughly review

the thermostat installation manual included with the thermostat. For additional information regarding any aspect of the King Electric

floor heating system, please contact us at:

King Electrical Manufacturing Co.

9131 10th Ave South

Seattle, WA 98108

1-800-603-5464

www.king-electric.com

Directly on plywood Directly on concrete

Typical Installations

Page 4

King Electrical Floor Heating Mat Installation Manual 4

WARNING: ELECTRIC SHOCK AND FIRE HAZARD!

Important Safeguards and Warnings

READ AND FOLLOW THE WARNINGS AND INSTALLATION INSTRUCTIONS PROVIDED IN THIS MANUAL.

FAILURE TO DO SO COULD RESULT IN ANY OF THE FOLLOWING: CABLE FAILURE, IMPROPER SYSTEM

OPERATION, PROPERTY DAMAGE, BODILY INJURY OR DEATH. THE WARRANTY IS INVALID IF THE

WARNINGS AND SPECIFIC INSTRUCTIONS ARE NOT FOLLOWED.

1. The instruction manual follows North American standard building construction conventions.

2. An electrical inspector may be required before, during and after the installation. It is recommended to

contact your local building department BEFORE beginning the installation.

3. DO NOT energize the mat before installation as it will cause overheating or damage to the cable.

4. Connect mats to rated voltage only. Be sure to size for conductors properly to carry the rated amperage.

5. This product is approved for indoor use only. Minimum installation temperature is 40 F .

6. Use only copper supply wires. Be sure to size for conductors properly to carry the rated amperage.

7. DO NOT cut the blue heating cable or attempt to alter the length in any way. The black cold lead can

be shortened, but only at the end of the cable where the power leads are exposed. DO NOT cut at the splice

between the cold lead (black wire) and the heating wire. (blue wire)

8. DO NOT install heating cable under any type of floor that requires nailing.

9. Ground fault protection (GFCI) is required when installed in wet environments such as a bathroom. Consult the

local electrical and building authority to determine and additional requirements in your area.

10. If the GFCI trips during normal conditions and cannot be reset, consult an electrician for service. NEVER

attempt to bypass or disable the GFCI system.

11. When installing cable in shower areas, the cable must be installed under the waterproofing membrane to

keep the cables dry.

12. DO NOT drill, nail of cut into any floors that have heating cable installed underneath. This could result in

contact with live electrical wires causing electrical shock.

13. DO NOT use staples, nails or similar fasteners directly on the cable. Use only factory the factory

recommended system to attach the mat. The use of any other fastening method will void the warranty.

14. Use a smooth plastic trowel only. NEVER bang or drop a tool on the cable. Care should be taken not to

nick or gouge cable.

15. DO NOT install the heating cable under a cabinet or other built-in. This will cause the cable to overheat.

16. DO NOT install the heating cable (blue wire) inside a wall. Only the cold lead can go into a wall stud.

17. DO NOT extend the heating cable beyond the room or area that it originates.

18. DO NOT attempt to repair damaged cable without a factory splice kit.

19. DO NOT overlap heating cables. Dangerous overheating will occur.

20. DO NOT allow the cold lead or thermostat sensor to cross or overlap the heating cable.

21. All cables must be completely embedded into a cement based mortar including the cold lead, cold lead

splice, heating cable, heating cable tail splice and thermostat sensor with the wire lead.

22. DO NOT bend the cable at sharp right angles. Always maintain a minimum 1” radius.

23. Maintain at least a minimum of 2” between heating cables.

24. Test and record the cable resistance at least 4 times during installation.

25. After installation of the cable, the installer must inspect and remove damaged or defective cables

before they are covered or concealed.

26. The installer should mark the appropriate circuit breaker reference label indicating which branch circuit

supplies the circuits to those electric space heating cables.

27. These products are to be installed in accordance with ANSI/NFPA 70, National Electrical Code (NEC) and

CAN/CSA-C22.1, Canadian Electrical Code, Part I (CEC).

28. Only UL Listed conduit, fittings, and/or other components are to be used.

29. Products are listed for installations with a maximum thermal resistance value of R-1 for floor covering that

can be placed on top of your product

Page 5

King Electrical Floor Heating Mat Installation Manual 5

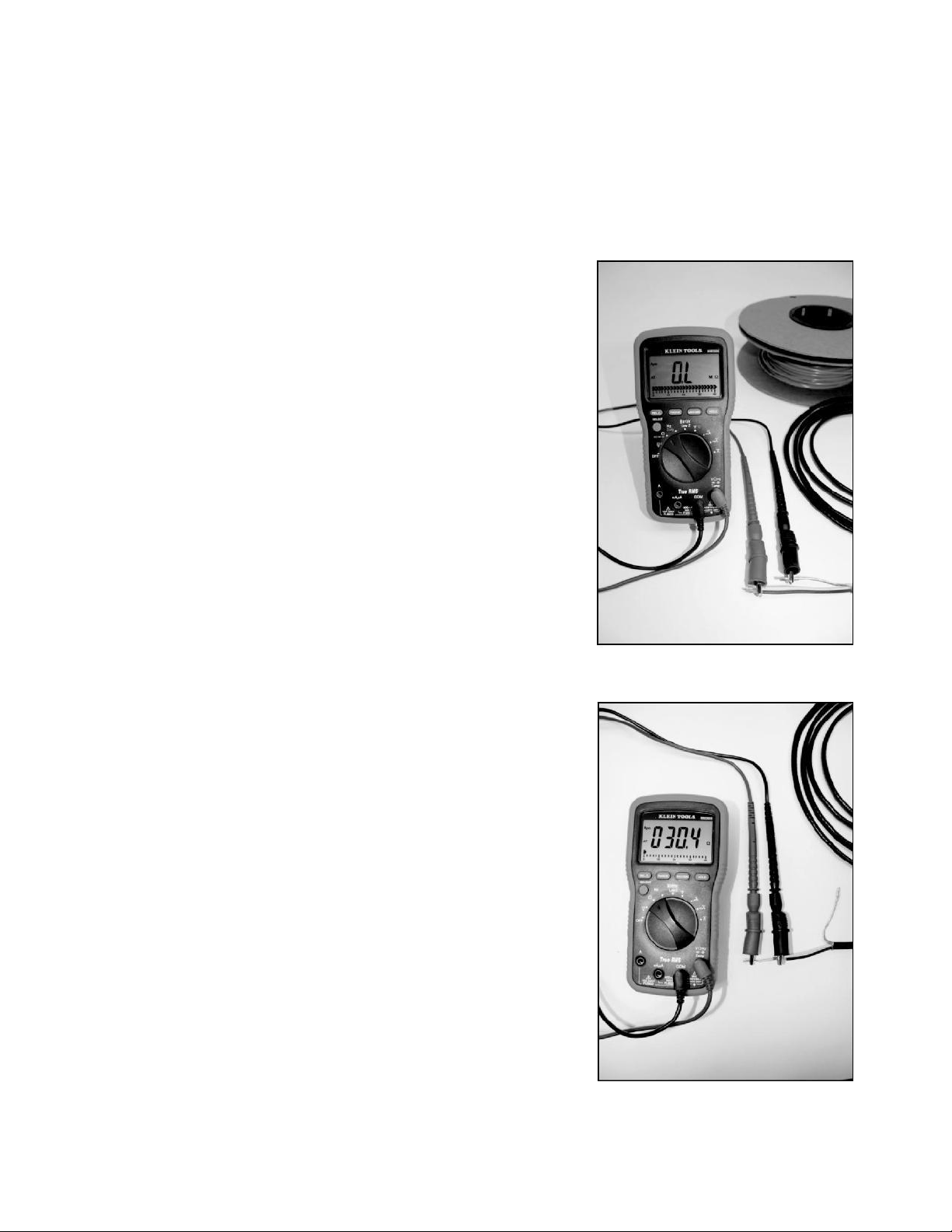

1.5 This test measures the resistance of the cable which verifies the

continuity (no breaks) and that the cable has the proper wattage rating.

A. Set the multi-meter to read ohms.

B. Connect the meter leads to the black and white old lead wires, DO NOT

connect the ground wire.

C. Compare the resistance reading to the value specified in the product

selection table, it should read 10%. If the reading

+

-

is different, contact King Electrical for support.

D. Record the readings on the cable tag and in the cable test log.

Resistance Test

Insulation Test

Resistance test:

STEP 1: Inspecting and testing the cable and floor sensor

1.1 Take the mat out of the box and inspect it for any physical damage.

1.2 Test the insulation and the resistance of the cable and record data in the CABLE TESTING LOG listed on page 6 of this

manual. This is test #1.

1.3 The cable and sensor must be tested and recorded a minimum of 4 times during the installation for the warranty to be

valid.

Insulation Test:

1.4 This test ensures that the insulation jacket of the cable is not damaged. A

low value on the meter indicates the cable

has been damaged and must be replaced. Follow the following steps:

A. Set the multi-meter to read ohms.

B. Connect the ground wire (braided un-insulated wire) to the black test lead of

the multi-meter and the red test lead to both the black and white wires of the

cold lead.

C. The meter should read “OPEN” or “OL”. If you get a different reading, the cable

is damaged, contact King Electric for support.

D. Record the readings on the cable tag and in the cable test log.

Page 6

King Electrical Floor Heating Mat Installation Manual 6

Tests must be recorded for warranty

Resistance

( + 10%)

Insulation

Test

Model:

Volts:

Factory QC Test

TEST 1. Before installation

TEST 2. After installation, but before

embedding

TEST 3. After embedding

TEST 4. After floor tile

STEP 1: Inspecting and testing the cable and floor sensor.

1.6 FLOOR SENSOR TEST:

This test measures the resistance of the

floor sensor to verify the integrity of the

component.

A. Set the multi-meter to read ohms.

B. Connect the multi-meter leads to the

floor sensor wires.

C. The meter should read between 8-25k ohms

depending on the ambient temperature

when taking the test. If test results are not

between 8-25k contact King Electrical for

support.

D. Record the readings on the cable tag and in

the cable test log.

(continued)

Typical sensor values:

55F (13C ) ________ 17,000 ohms

65F (18C ) ________ 13,000 ohms

75F (24C ) ________ 10,000 ohms

85F (20C ) _________ 8,000 ohms

CABLE TEST LOG

Floor Sensor Test

Page 7

King Electrical Floor Heating Mat Installation Manual 7

10ft

Shower=9ft2

Toilet=3ft2

10 ft

Vanity= 10ft2

2 2 2

STEP 2: Layout planning and product selection

King Electric heating mats are used to warm interior floors. It is not to be used for exterior applications such as snow

melting or roof and gutter applications. It is not to be used in walls or ceilings. Follow these steps in planning the

installation:

2.1 Draw the room dimensions on a piece of grid paper.

2.2 Draw in any fixed obstructions such as a shower, bath tub, vanity or counter. The cable is not to be installed under these

type of items. In addition, DO NOT run cables into closets or confined areas where heat could build-up.

2.3 Mark the locations of any toilets, heating vents or any other heating appliance. Note on the drawing that the heating

cable must be installed at a minimum distance of:

A. 6” from the center of the toilet drain.

B. 8” form heating vents or any other heating appliance.

2.4 Determine the heated area of the floor by subtracting the permanent fixtures. For example: Figure 1.5 the room is

10ft x 10ft equaling 100 square feet. (ft ). The area of each permanent fixture is as

follows:

A.

Vanity = 10ft2

B.

Toilet = 3ft2

C.

Shower = 9ft2

D. Total heated area: 100ft - 22ft =78 ft

Page 8

King Electrical Floor Heating Mat Installation Manual 8

Simple cut and roll installation

2.5

Border allowance: Heating cable should be installed between 1” and 6” from the perimeter walls, but not more than 1.5”

from a kick space vanity, shower, bathtub, counter or doorway. It is not necessary to heat the floor all the way to the wall as it is not

typical that people will stand that close to the walls. In addition, the heat will radiate out an additional 2” from where the cable is

embedded.

2.6

In most cases simply select the mat kit that is 5% but no more than 10% less that the total square footage of the area to

be heated as calculated in the previous step. For example: if the square footage after deduction the fixed obstacles equals 74 ft ,

then the closest cable kit is 70 ft which is 5.4% less allowing for an unheated border. The next size down is 60 ft which is too

small and would not be enough cable to properly heat the room.

2.7

Select either 120 or 240 volt cable depending on the power supply available. DO NOT mix voltages on the same system

when more than one cable is used to cover a room.

Page 9

STEP 3: Thermostat location and strapping layout

King Electrical Floor Heating Mat Installation Manual 9

120V

Heated Area

Mat Dimensions

Watts

(12W/sq.ft.)

Amps

ohms

Catalog

Number

sq.ft.

m2

in.*ft.

m*m

FCM1-10

10

0.93

30*4

0.76*1.2

120

1

120

FCM1-15

15

1.39

30*6

0.76*1.8

180

1.5

80

FCM1-20

20

1.86

30*8

0.76*2.4

240

2

60

FCM1-25

25

2.32

30*10

0.76*3.1

300

2.5

48

FCM1-30

30

2.79

30*12

0.76*3.7

360

3

40

FCM1-35

35

3.25

30*14

0.76*4.3

420

3.5

34.3

FCM1-40

40

3.72

30*16

0.76*4.9

480

4

30

FCM1-50

50

4.65

30*20

0.76*6.1

600

5

24

FCM1-60

60

5.57

30*24

0.76*7.3

720

6

20

FCM1-70

70

6.5

30*28

0.76*8.6

840

7

17.1

FCM1-80

80

7.43

30*32

0.76*9.8

960

8

15

FCM1-90

90

8.36

30*36

0.76*11.0

1080

9

13.3

FCM1-100

100

9.29

30*40

0.76*12.2

1200

10

12

240V

Heated Area

Mat Dimensions

Watts

(12W/sq.ft.)

Amps

ohms

Catalog

Number

sq.ft.

m2

in.*ft.

m*m

FCM2-20

20

1.86

30*8

0.76*2.4

240

1

240

FCM2-30

30

2.79

30*12

0.76*3.7

360

1.5

160

FCM2-35

35

3.25

30*14

0.76*4.3

420

1.8

137.1

FCM2-40

40

3.72

30*16

0.76*4.9

480

2

120

FCM2-50

50

4.65

30*20

0.76*6.1

600

2.5

96

FCM2-60

60

5.57

30*24

0.76*7.3

720

3

80

FCM2-70

70

6.5

30*28

0.76*8.6

840

3.5

68.6

FCM2-80

80

7.43

30*32

0.76*9.8

960

4

60

FCM2-90

90

8.36

30*36

0.76*11.0

1080

4.5

53.3

FCM2-100

100

9.29

30*40

0.76*12.2

1200

5

48

FCM2-110

110

10.22

30*44

0.76*13.4

1320

5.5

43.6

FCM2-120

120

11.15

30*48

0.76*14.7

1440

6

40

FCM2-145

145

13.47

30*58

0.76*17.7

1740

7.3

33.1

FCM2-160

160

14.86

30*64

0.76*19.6

1920

8

30

* 240 volt cables are approved for 208 volt, but will produce 25% less wattage.

120V Models

240V Models

Product Selection Chart

(continued)

Page 10

King Electrical Floor Heating Mat Installation Manual 10

Leng

Heated area spacing

Fast

STEP 3: Thermostat location

3.1

Mark the location of the thermostat on the drawing. This is where the cold lead will drop from the wall box and

become the starting point for the heating cable as well as where the floor sensor will be installed.

End Splice

2

2

Cold Lead

T Thermostat

3.2 Determine the direction of the cable runs. It is recommended that the cable run parallel to the wall that the

thermostat is mounted. 48 inches. Center straps should be 3 to 4 feet apart.

3.3 On average, a 5 to 10% deduction in heated area will create a 2-4” border. To determine the exact distance to mount the mat

from the wall, take the actual room square footage less the selected mat kit less to

determine the unheated border. Then take the unheated border and divide it by the perimeter. Now multiply by 12 for the number

of inches to mount the mat away from the wall.

A. 10ft x 10ft room = 100 ft 2

B. 4ft x 10ft = 40 ft perimeter

C. Mat kit selected 90 ft

D. 100ft - 90 ft = 10ft unheated border

E. 10ft / 40ft = .25ft

F. .25ft x 12in/ft = 3” from the wall

3.4 It is difficult to predict exactly where the heating cable will end, thus it is important to have a buffer zone.

A buffer zone is an area where heating in not essential and if unheated will go unnoticed. This area is also used for any excess

cable where a higher heated density will also be un-noticed.

Page 11

STEP 3: Thermostat location and strapping layout

King Electrical Floor Heating Mat Installation Manual 11

1. King floor heating mat

2. King GFCI thermostat

3. King temperature sensor (included with thermostat)

4. King instant alert monitor, model FCS11

5. Electrical box and cable clamps

6. Wood chisel or router

7. Multimeter or megometer

8. Electrical wire connectors and cable fasteners

9. Nail plate (included with cable kit)

10. Duct tape

11. Stapler

12. Protective glasses

12. Tape measure

13. Broom

14. Felt tip marker

15. Electrician tools

16. Electric drill

17. Plastic trowel

18. Hammer

19. Hot glue gun

For installation on concrete slab add:

20. Double backed tape

Simple roll-out installation

Materials required

(continued)

Page 12

King Electrical Floor Heating Mat Installation Manual 12

STEP 4: Electrical rough-in (New construction)

Mount Electrical Box Drill Horizontal Hole

4.1 Determine the proper location and

height (typically 60”) for the

junction box. The cold lead and the floor

sensor lead wires should be in the same stud

cavity as the electrical junction box. Install the

junction box for the thermostat and

run the power supply wires into the box.

4.2 Drill a 3/4” hole 1-1/2” deep horizontally into

the sill plate for the cable routing. Drill the hole

as close to the bottom of sill plate as possible. Chisel

out the bottom of the

sill so that the cold lead wire will not create a

high spot in the floor when the thin-set is

applied.

Drill Vertical Hole

4.3 Drill a 3/4” hole vertically into the sill plate

1-1/2” deep. If installing a floor sensor, drill a

second set of holes 4”away in the same stud

cavity.

4.4 Clear the cable routing holes of debris

and install in the same stud cavity.

4.5 It is recommended to thread a pull string

as the cable installation will be done after the

drywall is in place. Run a second pull string if a

floor sensor is being installed.

Otherwise the wires can be fished through

the wall with an electrician’s fish tape after the drywall is

installed.

Install Nail Plate

Page 13

King Electrical Floor Heating Mat Installation Manual 13

STEP 4R: Electrical rough-in (For Remodel)

Cut Hole for remodel J-box Install remodel J-box

4.1R

Determine the proper location and height

(typically 60”) for the

junction box. The cold lead and the floor sensor

lead wires should be in the same stud cavity as the

electrical junction box.

4.3R

Remove base moldings as needed where the

cable routing holes need to be drilled.

4.2R

Install a remodel type electrical junction box

for the thermostat and run the supply power into the

box.

4.5R

Install Nail Plate

Install a nail plate to protect the wires.

4.4R

Chisel out a 1-1/2” by 1-1/2” channel into

the sill plate 1-1/2” deep. If installing a floor sensor, chisel a

second relief 4” away in the same stud cavity.

Page 14

King Electrical Floor Heating Mat Installation Manual 14

Hot Glue Spice

5.3 Secure the cold lead splice into the chiseled channel with hot

glue. DO NOT USE SCREWS OR STAPLES TO SECURE THE COLD

LEAD.

5.4 Secure any loose (blue) heating cable between the start of the

run and the location where the cable is first laced through the

strapping. Use the single hole straps provided.

IMPORTANT:

THE COLD LEAD SPLICE MUST BE FULLY

EMBEDDED IN THE MORTAR. In addition, the cold

lead splice Must not be bent. No portion of the cold lead

should Enter into a wall or drop through a subpolar.

IMPORTANT: Do NOT skip this step.

Install Alert Monitor

5.5 Install the cable monitor and leave it connected throughout the entire

installation process until the tile has set. If the cable monitor sounds an alarm, stop

and check the cable for damage. The cable is only to be repaired with a factory

splice kit.

Line2 (L)

Black

Line1

(N)

White

Ground

Wire

STEP 5: Installing the cold lead

Chisel .25” Grove

5.1 Unroll the power leads of the mat up to the factory splice and

feed it up the wall into the thermostat junction box. The factory splice

MUST BE mounted on the floor and MUST NOT be installed in the

wall.

5.2 Due to the large diameter of the cold lead splice, a .25”

deep channel must be cut into the floor to avoid interference with

the finished floor. For a wood floor Use a router or wood chisel.

For a concrete floor, use An appropriate masonry chisel or power

hammer.

Remove any debris to avoid damage to the cable.

Page 15

King Electrical Floor Heating Mat Installation Manu al 15

STEP 6: Installation of Mat

Clean floor before starting Installation

6.1 The floor should be swept of all debris including dirt, saw dust, nails

and other construction materials.

Plan routing of mat.

6.2 Use tape to mark the fixed objects in the room the cable needs to

avoid, such as a vanity, shower or bathtub. These areas will remain

unheated.

6.3 Plan the cable routing around the fixed objects. It is best to plan

the cable runs parallel to the longest wall in the room. Be sure to have a

plan for the end of the cable, including an overflow area to place any

excess cable. The cable MUST NOT be cut.

Test Fit the Mat.

6.4 Roll out the mat, cutting the mesh and flipping it as needed to

cover the area that you intend to heat. It is critical that you ensure

proper fitting of the mat before securing to the floor. If the mat is too

large for the area, it can not be cut shorter and the cable cannot be

installed inside a wall, or under baseboards or cabinets. All cable must

be embedded in floor mortar.

6.5 Border allowance: Heating cable should be installed between

1” and 6” from the perimeter walls, but not more

than 1.5” from a kick space vanity, shower, bathtub, counter or

doorway. It is not necessary to heat the floor all the way to the

wall as it is not typical that people will stand that close to the

walls.

Page 16

King Electrical Floor Heating Cable Installation Manual 16

6.6 DO NOT leave gaps between mats. Heat will only radiate

out approximately 2” from the cable.

6.5 To ensure maximum coverage of the floor, it will likely be

necessary to cut the mesh of the mats to fit odd-shaped areas,

such as corners or working around various angles or cabinets.

Examples of the different techniques you may need are described

below.

Page 17

King Electrical Floor Heating Mat Installation Manu al 17

Test cable before embedding

7.3 Use a fish tape or pull string to pull the sensor

wire to the electrical box, but not in the box.

IMPORTANT TEST 1: Test the cable resistance, cable

insulation and floor sensor now that the cable is installed

on the floor. Record the readings on the cable label and

the data table on page 6.

8.1 Apply a scratch coat of thin-set or self-leveling mortar

uniformly over the entire floor area. Make sure the heating

cables are completely embedded. Follow the compound

manufacturer’s instructions.

8.2 Use a plastic straight edge trowel and cover the entire

areas that don’t have cable to maintain uniform height.

8.3 Apply the mortar in the same direction of the cable runs

to minimize lateral movement.

IMPORTANT TEST 2: TEST THE CABLE

RESISTANCE, CABLE INSULATION AND FLOOR

SENSOR RESISTANCE TO BE SURE NO DAMAGE

OCCURRED DURING THE THIN-SET

APPLICATION. RECORD THE READINGS ON THE

CABLE LABEL AND IN THE DATA

LOG ON PAGE 6.

Scratch coat application

STEP 7: Install the floor sensor

Position floor sensor halfway

between the heating cables

7.1 The floor sensor must be positioned exactly halfway between two

heating cables to accurately read the floor temperature. Place the

sensor bulb at least 12” into the heated area. Mark the spot on the floor

where the sensor bulb will be located.

7.2 To make sure the sensor bulb will not create a high spot in the

floor, chisel a .25” channel into the floor and lay the sensor bulb into the

channel. Apply hot glue to secure the bulb into place.

STEP 8: Apply scratch coat

Page 18

King Electrical Floor Heating Mat Installation Manual 18

Follow the thermostat manufacturer’s instructions.

9.3 Connect the floor sensor wires to the thermostat. These are low voltage wires

and should not enter the line voltage junction box. These low voltage wires typically

run through the wall and connect into the face of the thermostat away from the line

voltage wires.

CAUTION: Allow mortar compound to completely cure before

energizing cable. This will ensure that the setting of the mortar mix will not

be compromised by the heat of the cables. Refer to compound manufacturer’s

instructions for curing times.

Line1 (L)

Black

Line2

(N)

White

Load1

Black

Load2

White

Ground

Wire

Small

Screwdriv

Floor Sensor

Example of Floor Sensor Wiring

Example of Thermostat wiring diagram

STEP 9: Install the wall thermostat

Follow the thermostat manufacturer’s instructions.

9.1 Before starting any wiring, verify that the power supply is turned off.

9.2 Connect the power supply wires and the load side heating wires.

Page 19

King Electrical Floor Heating Cable Installation Manual 20

King Electrical Mfg. Company will repair or replace, without charge to the original owner, any heating cable found to be defective or malfunctioning within the 20 year warranty.

In Case of Product Failure: Contact King Electrical Mfg. Co. at 800.603.5464. The owner will be required to provide, within the designated warranty period, the following information:

model number, date of purchase, and a complete description of the problem encountered with product. Upon receipt of the aforementioned, the company will reply to the owner

within a period not to exceed fifteen (15) working days, and will provide the action to be taken by owner. Terms: This warranty requires the owner or his agent install the

equipment in accordance with the National Electrical Code, any other applicable heating or electrical codes and the manufacturer's installation instructions. It further requires that

reasonable

and necessary maintenance be performed on the unit. Failure of proper maintenance by owner will void the warranty in its entirety. The company is not liable for any actions it

deems to be abuse or misuse of the product. The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including, but not limited to, labor

costs, and shipping costs incurred to return products to King Manufacturing. At their discretion, King Manufacturing will decide to either repair or replace the product, with no

charge to the owner, with return freight paid by King. The Company shall not be liable for consequential damages arising with respect to the product, whether based upon

negligence, tort, strict liability or contract. No other written or oral warranty applies, nor any warranties by Representatives, Dealers, Employees of King or any other person. King

Manufacturing can be contacted by phone at 206.762.0400, fax 206.763.7738 or website www.king-electric.com. The company's minimum liability shall not in any case exceed

the list price for the product claimed to be defective.

Loading...

Loading...