Page 1

Operating Instructions

Page 2

REACTRON®

RT 1

3.0 / 01.07.2018

2

of

36

1.1 OPERATING INSTRUCTIONS ................................................................................................................................... 3

1.1.1 RANGE OF VALIDITY ............................................................................................................................................... 4

1.1.2 TARGET AUDIENCE ................................................................................................................................................. 5

1.2 ORGANISATIONAL MATTERS .................................................................................................................................. 5

1.2.1 LOCATION OF THE OPERATING INSTRUCTIONS...................................................................................................... 6

1.1.1 MANUFACTURER AND CONTACT ADDRESS ........................................................................................................... 6

1.3 CONTENTS .............................................................................................................................................................. 6

1.4 WARNING NOTICES ................................................................................................................................................ 7

2.1 SUMMARY .............................................................................................................................................................. 8

2.2 SAFETY CONCEPT ................................................................................................................................................... 8

2.2.1 INTENDED USE OF THE EQUIPMENT ...................................................................................................................... 8

2.2.2 IMPROPER USE ....................................................................................................................................................... 9

2.2.3 USER ROLES ............................................................................................................................................................ 9

2.2.4 DANGER AREA ...................................................................................................................................................... 10

2.2.5 AREAS OF RESPONSIBILITY ................................................................................................................................... 10

2.2.6 GENERAL SAFETY RULES ....................................................................................................................................... 11

2.3 RESIDUAL DANGERS ............................................................................................................................................. 11

2.4 WARNINGS ........................................................................................................................................................... 12

3.1 PROCESS CONDITIONS ......................................................................................................................................... 13

3.2 PROCESS VESSEL WITH DOUBLE JACKET .............................................................................................................. 14

3.3 POLYTRON® PT 2100 WITH DISPERSING UNIT PT-DA 2120/2G (OPTIONAL) .................................................................... 16

3.4 STIRRER ................................................................................................................................................................... 16

3.5 STAND RT 1 ........................................................................................................................................................... 16

4.1 INSTALLATION ...................................................................................................................................................... 17

4.2 START UP OF THE SYSTEM .................................................................................................................................... 21

4.3 SHUT-DOWN OF THE SYSTEM .............................................................................................................................. 21

4.4 CLEANING THE REACTRON® ................................................................................................................................. 22

5.1 MAINTENANCE OF THE POLYTRON DISPERSING DRIVE........................................................................................ 24

5.2 MAINTENANCE OF THE STIRRER .......................................................................................................................... 24

5.3 MAINTENANCE OF THE DISPERSING AGGREGATE PT-DA 3030/4G ...................................................................... 25

Page 3

REACTRON®

RT 1

3.0 / 01.07.2018

3

of

36

This chapter gives information on the the structure of this document. It will assist you in making

use of it and show how to find the required information quickly.

Please read through these operating instructions before switching on or attempting to use the

equipment. They describe the use of the REACTRON RT 1, its installation and maintenance and the

appropriate replacement parts and accessories.

They will help you avoid erroneous use and consequent damage. Although REACTRON machines

are designed for ease of service, this does not release you from the obligation to inspect your

equipment carefully and to clean it thoroughly.

KINEMATICA AG is a specialist manufacturer of machines and equipment for dispersing and mixing

technology.

An important objective of these operating instructions is to fully inform you, the user, about the

correct and safe use of our equipment.

In order to achieve this, it is essential that you should carefully study chapter 2, “Safety”, and follow

the instructions in this book.

Page 4

REACTRON®

RT 1

3.0 / 01.07.2018

4

of

36

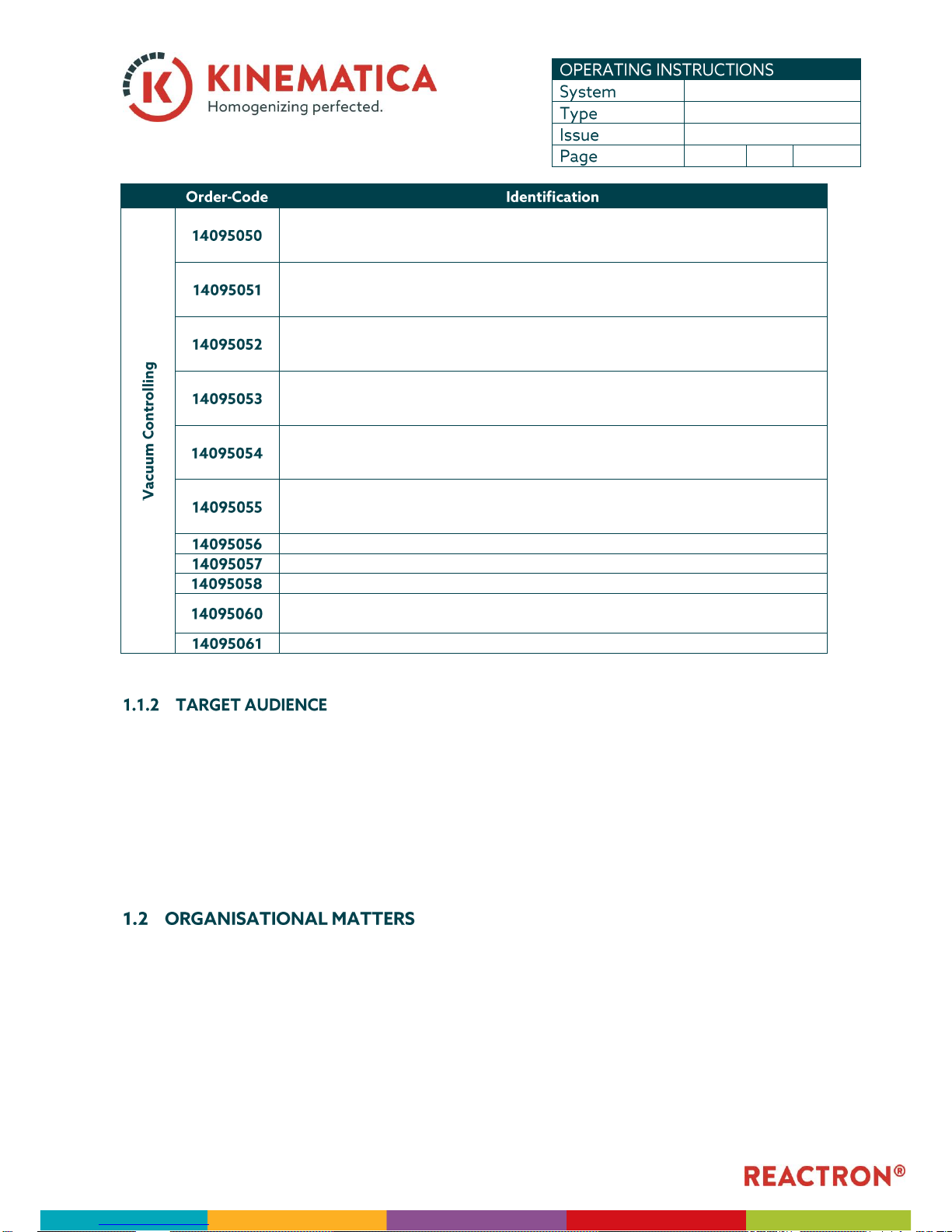

The data mentioned in this document refer to the machine(s)/ unit(s) with the following

identification:

Manufacturer: KINEMATICA AG, CH-6014 Luzern

Brand name: REACTRON®

Product name: REACTRON® System RT 1

Base

Syste

ms

14090010

REACTRON® RT 1 standard configuration, 230V (with EU-plug)

14090011

REACTRON® RT 1 standard configuration, 230V (with CH-plug)

14090012

REACTRON® RT 1 standard configuration, 115V

14095010

POLYMIX® PX-SR 90 D with digital display, instead of PX-SR 50 E

14095070

Funnel 1 ½“ Tri-Clamp

Dispersing

-

Systems

14095020

PT-MR 2100, 230 V with dispersing aggregate

PT-DA 2120/2G (mechanical seal version) and clamp for the lead-in hole on the cover,

suitable for the RT 1

14095021

PT-MR 2100, 115 V with dispersing aggregate

PT-DA 2120/2G (mechanical seal version) and clamp for the lead-in hole on the cover,

suitable for the RT 1

Temperature Controlling

14095040

Heating thermostat 230V, temp. Range 35°C-300°C, heating power 3.5 kW, max. 0.7 bar,

max. 25 l/min

14095041

Heating thermostat 115V, temp. Range 35°C-300°C, heating power 3.5 kW, max. 0.7 bar,

max. 25 l/min

14095042

Bath fluid, 10 liters, destilled water for temperatures between 5 - 90°C

14095043

Complete tubings made from VITON

14095044

Temperature measuring device with Pt 100 sensor and LC display box, 230V/EU

14095045

Temperature measuring device with Pt 100 sensor and LC display box, 230V/CH

14095046

Temperature measuring device with Pt 100 sensor and LC display box, 115V

Page 5

REACTRON®

RT 1

3.0 / 01.07.2018

5

of

36

Single step vacuum system for vacuum down to 100 mbar with single-step chemical

diaphragm pump with tubings and digital vacuum controller with key pad and LED-display,

230V / EU

Single step vacuum system for vacuum down to 100 mbar with single-step chemical

diaphragm pump with tubings and digital vacuum controller with key pad and LED-display,

230V / CH

Single step vacuum system for vacuum down to 100 mbar with single-step chemical

diaphragm pump with tubings and digital vacuum controller with key pad and LED-display,

115V

Double step vacuum system for vacuum down to 25 mbar with double-step chemical

diaphragm pump with tubings and digital vacuum controller with key pad and LED-display,

230V / EU

Double step vacuum system for vacuum down to 25 mbar with double-step chemical

diaphragm pump with tubings and digital vacuum controller with key pad and LED-display,

230V / CH

Double step vacuum system for vacuum down to 25 mbar with double-step chemical

diaphragm pump with tubings and digital vacuum controller with key pad and LED-display,

115V

LVS Laboratory vacuum system 2-step, 230V (EU)

LVS Laboratory vacuum system 2-step, 230V (CH), details see above

LVS Laboratory vacuum system 2-step, 115V, details see above

Vacuum hose connection for Clamp 1 1/2" fittings

suitable for RT 1 / RT 1 E – Systems, made of stainless steel 316 L, electropolished

Steam trap with vessel 500 ml at suction side

These operating instructions are intended for all authorised users of our

machines/equipment. We distinguish different user roles, taking account of the different demands

placed on the user by the activity to be carried out.

You will find the definitions of user roles with the demands on the user in chapter 2, “Safety”. You

can fulfil one or more of these roles, provided that you meet the corresponding demands.

If you are unable to find the answer to any question in the operating instructions, please contact

the equipment manufacturer directly.

Page 6

REACTRON®

RT 1

3.0 / 01.07.2018

6

of

36

The operating instructions can only be of use to you if you always have them to hand. They should,

therefore, always be kept at the place where the equipment is used.

Luzernerstrasse 147a Tel.: +41-41-259 65 65

CH-6014 Luzern Fax: +41-41-259 65 75

Switzerland e-mail: info@kinematica.ch

If you are unable to find the answer to any question in the operating instructions, please contact

the equipment manufacturer directly.

This should act as part of a quick-reference. The information is classified according to its application

and topic and is divided into the following parts:

This chapter describes the structure of this document

This chapter describes the safe use and optimum gain of the machine

This chapter describes the components of the machine

This chapter presents all information important for a safe installation and start-up of

the machine.

This chapter informs about service and maintenance.

This chapter points out how to order spare parts and what kind of spares you should

have in stock.

In this chapter you will find indications about break down, possible cause and repair.

In this chapter the warranty limit is defined

Page 7

REACTRON®

RT 1

3.0 / 01.07.2018

7

of

36

Please be aware of the meaning of the following warning signs:

Page 8

REACTRON®

RT 1

3.0 / 01.07.2018

8

of

36

This chapter is directed at all users of KINEMATICA laboratory equipment. It includes information

on safe and optimum use.

Any incorrect use of the installed equipment can be dangerous. Inadequately trained users can

cause material damage and personal injury. This chapter informs you of the safety concept and the

requirements for safe and optimum use of the equipment.

All those authorised to operate, service and repair the equipment are required to study chapter 2,

“Safety”.

The safety concept sets down the entitlement to use the equipment and the responsibilities of the

individual users.

The machines and equipment are designed and constructed according to the state of the art and

the recognised safety rules.

The equipment is designed and constructed for the following use:

▪ Dispersion and homogenisation of pumpable fluid products in accordance with the

technical specifications (see point 3.5) and compatibility with the materials coming into

contact with the products.

If you use the equipment for any purpose other than those listed, the manufacturer cannot be held

liable for any resulting damage.

Page 9

REACTRON®

RT 1

3.0 / 01.07.2018

9

of

36

Any use other than the “proper use” without the written approval of the manufacturer or operation

outside the technical limits of use is improper use.

To guarantee safety, we place requirements on the users of the equipment that must be met

without fail. Only persons meeting the requirements are authorised to work with the equipment.

We describe all those who work with the equipment as users. Since the requirements of these users

are very much dependent on their activity, we distinguish the following user roles.

The manufacturer can impose legal obligations on the contract partner when the equipment is

purchased. The contract partner is obliged to ensure that the equipment is properly used.

The operating company ensures that the equipment is properly used and authorises persons who

are entitled to work with the equipment in any one of the defined user roles. He is under the

obligation to instruct the users.

Contract partner and operating company can be the same person.

The service technician is an employee of the operating company and looks after the equipment in

special operating mode(s). He is a specialist with mechanical, electrical and electronic professional

training. The service technician undertakes commissioning, decommissioning service and repair of

the equipment. He must be appropriately trained to be able to carry out the service work required.

The operator turns the equipment on and off. In the event of an alarm signal he informs the service

technician.

Page 10

REACTRON®

RT 1

3.0 / 01.07.2018

10

of

36

The system danger area includes the whole system/equipment including the connecting lead and

controls.

This refers to all areas within a defined distance of the equipment.

This danger area includes all persons working with the equipment.

In order that the system/equipment can be used safely and without risk, the users in various roles

bear the responsibility for particular danger areas.

The contract partner bears the responsibility for the “proximity danger area”.

The operating company bears the responsibility for the “user danger area”. Only those users may

be authorised to operate the system/equipment who fulfil all requirements of the user roles

concerned. In so doing, attention must be paid to the following points:

◼ It is to be ensured that all users of the system/equipment have fully read and understood chapter

2, “Safety” and act accordingly in a safety-conscious manner.

◼ It is to be ensured that no unauthorised person carries out work with the system/equipment.

◼ It is to be ensured that users are informed of the possible risks and dangers connected with the

system/equipment.

◼ It is to be ensured that those being trained or engaged in general training are under the

permanent supervision of a trained and authorised person.

The service technician bears the responsibility for the “system/equipment danger area”. He ensures

that the system/equipment is at all times free from technical faults, safe and functions correctly.

Page 11

REACTRON®

RT 1

3.0 / 01.07.2018

11

of

36

Observe the following general safety rules:

◼ follow these operating instructions,

◼ in addition, observe the legal obligations and requirements for accident prevention and

environmental protection of the country in which you operate the equipment,

◼ do not make any modifications to the equipment without the written authorisation of the

manufacturer,

◼ only original replacement parts may be used for repairs,

◼ before any service work on the equipment, it must be ensured that the electrical supply is

switched off,

◼ after any service, maintenance or repair work has been carried out on the system/equipment, it

must be given a test run by the service technician.

◼ depending on the place at which it is installed, circumstances may require that hearing

protection is worn when remaining in the vicinity of the equipment for long periods.

When the system/equipment is used in accordance with rules and regulations, residual dangers are

minimal.

Tripping over feed or return

lines

These should be laid appropriately.

Breakage of glass containers

Wear protective clothing (goggles

etc.).

Spitting of the product

Hearing loss due to loud

noise.

According to the application

ear protection must be used.

Tilting of the device

Use stable, non-slip base and the safety stands from

KINEMATICA

Page 12

REACTRON®

RT 1

3.0 / 01.07.2018

12

of

36

Page 13

REACTRON®

RT 1

3.0 / 01.07.2018

13

of

36

◼ The POLYTRON

®

PT 2100 (optional) is a batch mixing dispersion and homogenizing machine.

◼ The REACTRON

®

RT 1 needs a surface area of approx.. 440 x 400 mm and a height of approx.

1'200 mm

◼ The REACTRON

®

RT 1 has a weight of approx 37 kg

◼ The product to be processed must be flowable and pumpable.

◼ The dispersing generator has been selected for the contracted process, product and procedure

and shall therefore not be used for a different application without the permission of the

manufacturer.

◼ The steel parts in contact with the product are made of high-grade steel 1.4435 (ANSI 316 L)

◼ max. working pressure Process vessel : pressureless

Double jacket : max. 0.5 bar (g) (19 PSIA)

◼ working temperature max. 100°C (212°F)

◼ Speed max. PT 2100 : 30’000 RPM

Stirrer PX-SR 90 D : 400 RPM

Stirrer PX-SR 50 E : 300 RPM

Page 14

REACTRON®

RT 1

3.0 / 01.07.2018

14

of

36

The REACTRON RT 1 - System consists of:

◼ Process vessel with double jacket (3.2)

◼ POLYTRON

®

PT 2100 (3.3)

◼ Stirrer (3.4)

◼ Stand with pneumatic spring (3.5)

Description:

◼ Process vessel DN 120 with useable capacity of 1000 ml

◼ With Heating- / Cooling Jacket

◼ Mounted on a socket with vessel-holder and fixed with two hexagon socket set screws.

Page 15

REACTRON®

RT 1

3.0 / 01.07.2018

15

of

36

Process vessel

◼ Total Volume 1400 ml

◼ Working volume 1000 ml

◼ Operating pressure pressureless

◼ Working temperature max. 212 °F (100°C)

Dimensions

◼ Inside diameter 120 mm

◼ Outside diameter 155 mm

◼ Cyl. height 175 mm

Heating- / Cooling Jacket

◼ Heating/cooling volume approx. 1.1 liters

◼ Operating pressure max. 19 PSIA (0.5 bar)

◼ Working temperature max. 212 °F (100 °C)

Material

◼ Process vessel Borosilicate glass

◼ Heating- / Cooling Jacket Borosilicate glass

◼ Cover stainless steel 1.4435

◼ The cover is flanged to the vessel and tighten by a VITON-O-Ring

◼ The cover is equipped with two lifting lugs

Connections on the cover:

◼ Through-bore for anchor-stirrer (pre-mounted) with sealing

◼ 4 pc. NS29/32 conical connections

Connections in the Heating- / Cooling Jacket:

◼ Hose nipple DN 8 inlet of heating / cooling liquid

◼ Hose nipple DN 8 outlet of heating / cooling liquid

◼ none

Page 16

REACTRON®

RT 1

3.0 / 01.07.2018

16

of

36

See referring manual for drive

See referring manual for “PX-SR 50 E” or “PX-SR 90 D”

STAND:

◼ H-shape base

◼ Two columns

◼ The maximum height is approx 1100 mm.

◼ The base space required is 425 x 400mm.

Page 17

REACTRON®

RT 1

3.0 / 01.07.2018

17

of

36

The REACTRON® RT 1 system arrives completely assembled for 230V or 115V outlets. Plug the

power cable from the PT 2100 (optional) and plug the power cable from the stirrer in a suitable

outlet.

Page 18

REACTRON®

RT 1

3.0 / 01.07.2018

18

of

36

◼ Place the process-vessel into the vessel-holder using the two half-rings(red). Place the O-Ring

on the vessel-flange.

◼ Pull down the cover-unit using the knob. When the cover is touching the O-Ring-SEAL use the

fixing-knob to fix the cover-unit, then use the four fixing-screws of the vessel-holder to fix the

cover to the vessel.

fixing screws

2 half-ríngs

process-vessel

O-Ring

fixing-screws (4x)

fixing knob

knob

Page 19

REACTRON®

RT 1

3.0 / 01.07.2018

19

of

36

◼ The POLYTRON

®

can now be positioned in one of the four NS29/32-bores on the cover using

the NS29/32-Adapter. Same procedure for the funnel. Any other NS29/32-bore can be

equipped with any suitable NS29/32-device, such as Thermometer, vacuum-pumps, buckler

etc.)

NS29/32-adapter

with screws

POLYTRON

PT 10-35

funnel

Page 20

REACTRON®

RT 1

3.0 / 01.07.2018

20

of

36

◼ Pull the vacuum tube over the vacuum connection on the vessel and link it with the provided

vacuum system. For mounting the vacuum system, please see the referring manuals.

◼ The generator should be immersed in the product. This guarantees the proper cooling and

lubrication of the slide bearing.

◼ The force of suction of material into the generator is best between 1/3 and 2/3 of the vessel

height.

◼ Before connecting the electrical power supply, check the data sheet of the POLYTRON and the

stirring-unit

◼ To raise the cover-unit, first detach any vacuum-tubes on the cover, unfast the six fixing-screws

and then the fixing-knob at the cover-socket and the cover will raise automatically.

Page 21

REACTRON®

RT 1

3.0 / 01.07.2018

21

of

36

BEFORE STARTING THE UNIT MAKE SURE THE PROCESS VESSEL IS FILLED WITH THE PRODUCT TO BE

PROCESSED

◼ Check that the vessel cover and the POLYTRON

®

are mounted tight and correct

◼ Check that the anchor-stirrer does not interfere with the dispersing-unit.

Page 22

REACTRON®

RT 1

3.0 / 01.07.2018

22

of

36

◼ If the processed media tends to harden or stick, the product has to be removed completely from

process vessel after every use .The dispersing-unit, the anchor-stirrer and the cover have to be

cleaned.

◼ If the machine was not operated for a longer time, the POLYTRON

®

-aggregate has to be cleaned

(see Manual “PT 2100”)

◼ Before any maintenance work is carried out, the POLYTRON

®

-aggregate has to be cleaned

Page 23

REACTRON®

RT 1

3.0 / 01.07.2018

23

of

36

◼ The POLYTRON

®

has to be taken out of the process vessel

Page 24

REACTRON®

RT 1

3.0 / 01.07.2018

24

of

36

If one of the following irregularities is found during inspection, the machine / unit has to be

stopped immediately and repaired:

◼ Leakage of the whole system

◼ noise level too high or unusual noises from drives or dispersing aggregates

We strongly recommend that service work and repairs should be carried out only by authorised

KINEMATICA service centres or by KINEMATICA directly, where original replacement parts are available.

Any unauthorised modification or manipulation of the unit or its equipment leads to immediate

annulment of the warranty.

See corresponding manual

See corresponding manual

Page 25

REACTRON®

RT 1

3.0 / 01.07.2018

25

of

36

▪ For easy cleaning you can run the aggregate in any suitable cleaning fluid.

If further cleaning of the generator is needed, the dispersing aggregate and its components it has to be

disassembled as follows:

▪ Unfasten the rotor (5) by blocking the coupling. Assure that the spring does not hop away.

▪ Remove the mechanical seal (10)

▪ Remove the Stator (4) (left-hand thread) and the o-ring (8)

▪ Clean the removed components separately.

▪ Proceed in reverse order for reassembling.

▪ Ball Bearing

o To replace the ball bearing (3) do the de-assembling as shown above and remove

the retaining ring (7) at the shaft. Push out the shaft (1) and demount the ball

bearing (3). Replace the ball bearing and reassemble the aggregate.

▪ O-rings: as shown above

▪ Mechanical Seal: as shown above

Page 26

REACTRON®

RT 1

3.0 / 01.07.2018

26

of

36

Only original KINEMATICA spare parts will guarantee a trouble free operation of the machine

when ordering spare parts, please indicate:

Please refer to the bill of material in the APPENDIX to identify the required spare part.

When troubles with the POLYTRON and the dispersing-unit or the Stirrer occur, see corresponding

manuals.

The cover-unit does not raise

automatically.

The pneumatic-spring may be

damaged.

Change the pneumatic-spring

of the stand

Leakage of liquid between

cover and vessel.

O-Ring is damaged.

Replace the O-Ring

O-Ring, vessel and cover are not

centered well

Recenter these components (ORing has to be in the flute of

the bottom side of the cover)

Rattle noise

Foreign body in the vessel

touching anchor-stirrer and

dispersing-unit

Remove foreign body

Page 27

REACTRON®

RT 1

3.0 / 01.07.2018

27

of

36

KINEMATICA AG guarantees that the equipment that it produces will run free of any fault related to

materials or manufacturing faults for 12 months.

If thorough testing shows a fault to be due to either of the above causes, KINEMATICA AG

guarantees that the equipment will be repaired or replaced free of charge.

The guarantee does not cover parts that are subject to normal wear. It is void if any person other

than an employee of KINEMATICA AG or their appointed representative has made modifications to

the equipment or if the damage is due to failure to comply with the operating instructions, to

carelessness, accident, incorrect use or incorrect supply voltage.

KINEMATICA AG reserves the right to make technical changes to the equipment without modifying

equipment delivered earlier in the same way.

In the event of technical problems, for spare parts requirements or for advice, contact our regional

appointed agent, your preferred dealer or us directly at:

Luzernerstr. 147a Tel. +41-41-259 65 65

CH-6014 Lucerne Fax +41-41-259 65 75

Switzerland e-mail laboratory@kinematica.ch

Page 28

REACTRON®

RT 1

3.0 / 01.07.2018

28

of

36

REACTRON RT 1: drawing-no. 8.020-0008-2

Page 29

REACTRON®

RT 1

3.0 / 01.07.2018

29

of

36

bill of materials to drawing-no. 8.020-0008-3

Stirrer POLYMIX PX-SR 50 E

9158024

1

1

Extension tube RT 1

9753182

2

2

316 L

Gear i=5:1

9340962

3

1

Stand RT 1

9754097

4

1

Reactor RT 1 complete

9753207

5

1

Cardan joint DN8/10

9340971

6

1

Stainless steel

Zyl.-Schr. M8x110 A2

9918110

7

2

Stainless steel

Clamp sealing Tri-Clamp 1 1/2"

9324042

8 4 VITON

Clamp Tri-Clamp 1 1/2 "

9324043

9

4

316 L

Bellows Ø20&22

9340552

10

2

Rubber

Setcrew M4x5 DIN 916

9951059

11

2

Stainless steel

Momentunsupport RT

9753996

12

1

Stainless steel

Screw. M4x10 A2 I

9951107

13

4

Stainless steel

Page 30

REACTRON®

RT 1

3.0 / 01.07.2018

30

of

36

Stand RT 1: drawing-no. 6.030-0067-3

Page 31

REACTRON®

RT 1

3.0 / 01.07.2018

31

of

36

Bill of materials to drawing-no 6.020-0017-2 B

Socket

9753157

1 1 AlMgSi1

Boss head ST 2103

9750875

2 1 AlMgSi1

Cover socket

9754098

3 1 AlMgSi1

Cross beam

9753173

4 1 AlMgSi1

Pillar for stirrer

9754088

5

2

Stainless steel

Base right

9805052

6 1 AlMgSi1

Adjusting foot

9750856

7 1

Bolt

9751410

8 1 AlMgSi1

Pillar to stand

9751859

9

2

Stainless steel

Base left

9805053

10 1 AlMgSi1

Parallel pin Ø10h8x30

9991030

11 4 1.4305

U-shim M5

9960005

12 1 A2

Cylinder head screw M12x50

9911250

13 2 A4

Cylinder head screw M8x50

9900691

14 2 A2

Hexagon socket set screw M6x6

9951058

15 5 A2

Hexagon socket set screw M8x8

9900729

16 2 A2

Counter sunk screw M5x10R

9910510

17 4 A2

Knurled head screw M8x16 Ø50

9341076

18 1 Duroplast

Linear roll bearing

9340048

19

4

Stainless steel

Pneumatic spring

9340338

20 1

Decal WARNING

9340499

21 2

Decal REACTRON white

9340514

22 1

Rubber foot Ø21x6

9800070

23 4 Rubber

Knob EL 539-23-M10

9340328

24 1 Duroplast

Page 32

REACTRON®

RT 1

3.0 / 01.07.2018

32

of

36

Reactor complete RT 1: drawing-no. 6.020-0019-2 A

Page 33

REACTRON®

RT 1

3.0 / 01.07.2018

33

of

36

Bill of materials to drawing-no. 6.020-0019-2 A

Anchor stirrer

9753176

1 1 VITON

Cover RT 1

9753146

2 1 VITON

Vessel 1000ml DN120

9340528

3

1

Borosilicateglass

Distant piece

9753160

4 1 1.4305

Hollow shaft

9753159

5 1 316 L

Shim

9753162

6

2

Stainless steel

Sealing disc

9753163

7 1 POM black

Compensation spring

9340323

8

1

spring steel C75

Ball bearing Ø17/35x10

9322001

9

2

Stainless steel

Retaining ring A17

9990077

10

1

Stainless steel

Retaining ring I35

9990106

11

1

Stainless steel

Hexagon socket set screw M4x5

9951059

12 1 A2

O-ring DN 120 VITON

9342056

14 1 VITON

Vessel holder DN 120

9340308

15 1 PA

Shaft sealing ring

9340324

16 2 Gylon W

Decal "K" Ø50

9340515

17 1

O-ring Ø9.52x1.78

9341189

18 1 VITON

O-ring 20.24x2.62

9320066

19 1 VITON

Page 34

REACTRON®

RT 1

3.0 / 01.07.2018

34

of

36

Dispersing Aggregate PT-DA 2120/2 G: drawing-no. 1.020-0106-2 A

Page 35

REACTRON®

RT 1

3.0 / 01.07.2018

35

of

36

Bill of materials to drawing-no. 1.020-0106-2 A

Shaft complete 2120/2G

9752050

1 1 316 L

Shaft tube PT-DA 2120/2G

9752038

2 1 316 L

Ball bearing 688-ZZ

9322227

3 1 Stainless steel

Stator PTG 20/2 G

9752621

4 1 316 L

Rotor PTG 20/2

9752040

5 1 316 L

Counter ring retainer

9752041

6 1 316 L

Retaining ring A 8

9900808

7 1

O-ring 16x1

9320327

8 1 Viton

O-ring 4x1 Viton

9320326

9 1 Viton

Mecanical Seal

9735611

10 1 SBV

Spring retainer

9752604

11 1 316 L

Page 36

REACTRON®

RT 1

3.0 / 01.07.2018

36

of

36

Loading...

Loading...