Page 1

System POLYMIX® PX-MFC 90 D

Operating Instructions

Thi

s is a quality product made by

Luzernerstrasse 147a Tel.: +41-41-259 65 65

CH-6014 Littau-Luzern Fax: +41-41-259 65 75

Schweiz e-mail: laboratory@kinematica.ch

Voltage

100...120 V, 50/60 Hz

210...250 V, 50/60 Hz

Please check that the voltage is correct and corresponds with the

nameplate on the back of the machine.

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 2

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 2 of 36

CONTENT:

1 INTRODUCTION....................................................................................................................................... 3

1.1 OPERATING INSTRUCTIONS ........................................................................................................ 3

1.2 ORGANISATIONAL MATTERS ....................................................................................................... 5

1.3 WARNING NOTICES ....................................................................................................................... 6

2 SAFETY .................................................................................................................................................... 7

2.1 SUMMARY ....................................................................................................................................... 7

2.2 SAFETY CONCEPT......................................................................................................................... 7

2.3 RESIDUAL DANGERS................................................................................................................... 10

2.4 WARNINGS.................................................................................................................................... 11

3 DESCRIPTION OF THE MACHINE ....................................................................................................... 13

3.1 OVERVIEW .................................................................................................................................... 13

3.2 DRIVE UNIT ................................................................................................................................... 16

3.3 GRINDING ATTACHMENTS ......................................................................................................... 16

3.4 TOOLS AND ACCESSORIES ....................................................................................................... 17

3.5 TECHNICAL SPECIFICATIONS .................................................................................................... 18

4 INSTALLATION...................................................................................................................................... 19

4.1 UNPACK......................................................................................................................................... 19

4.2 START UP...................................................................................................................................... 19

4.3 EXCHANGE OF GRINDING ATTACHMENTS .............................................................................. 21

5 MAINTENANCE...................................................................................................................................... 25

5.1 DRIVE SYSTEM............................................................................................................................. 26

5.2 CLEANING & MAINTENANCE ...................................................................................................... 26

5.3 SPARE PARTS LIST...................................................................................................................... 30

6 TROUBLE SHOOTING .......................................................................................................................... 31

7 ACCESSORIES ...................................................................................................................................... 32

8 WARRANTY ........................................................................................................................................... 33

APPENDIX A. DIMENSIONAL DRAWINGS ............................................................................................ 34

APPENDIX B. PARTS LISTS ................................................................................................................... 35

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 3

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 3 of 36

1 INTRODUCTION

Thi

s chapter gives information on the the structure of this document. It will assist you in

making use of it and show how to find the required information quickly.

1.1 OPERATING INSTRUCTIONS

Please read through these operating instructions before switching on or attempting to

use the equipment. They describe the use of the POLYMIX

P

X-MFC 90 D, its installation

and maintenance and the appropriate replacement parts and accessories.

They will help you avoid erroneous use and consequent damage. Although POLYMIX

machines are designed for ease of service, this does not release you from the obligation

to inspect your equipment carefully and to clean it thoroughly.

KINEMATICA AG is a specialist manufacturer of machines and equipment for dispersion

and mixing technology.

An important objective of these operating instructions is to fully inform you, the user, about

the correct and safe use of our equipment.

In order to achieve this, it is essential that you should carefully study chapter 2, “Safety”,

and follow the instructions in this book.

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 4

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 4 of 36

1.1.1 RANGE OF VALIDITY

The information in these operating instructions relates to the POLYMIX® identified as

fol

lows:

Manufacturer: KINEMATICA AG, CH-6014 Littau / Luzern

Brand name: POLYMIX®

Pro

duct name: POLYMIX® PX-MFC 90 D

Artikelnummer Bezeichnung

35010020

Drive POLYMIX® PX-MFC 90 D, 115 V, with US-

power cable,

hammer-grinding attachment, tools

35010021

Drive POLYMIX® PX-MFC 90 D, 230 V, with EU-

power cable,

hammer-grinding attachment, tools

35010022

Drive POLYMIX® PX-MFC 90 D, 230 V, with CH-

power cable,

hammer-grinding attachment, tools

35010023

Drive POLYMIX® PX-MFC 90 D, 230 V, with GB-

power cable,

hammer-grinding attachment, tools

35010030

Drive POLYMIX® PX-MFC 90 D, 115 V, with US-

power cable,

blade-grinding attachment, tools

35010031

Drive POLYMIX® PX-MFC 90 D, 230 V, with EU-

power cable,

blade-grinding attachment, tools

35010032

Drive POLYMIX® PX-MFC 90 D, 230 V, with CH-

power cable,

blade-grinding attachment, tools

35010033

Drive POLYMIX® PX-MFC 90 D, 230 V, with GB-power cab

le,

blade-grinding attachment, tools

35031001

hammer-grinding attachment for PX-MFC 90 D

35031002

blade-grinding attachment for PX-MFC 90 D

35080001

Stodger tool for stringy materials

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 5

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 5 of 36

1.1.2 TARGET AUDIENCE

These operating instructions are intended for all authorised users of our

machines/equipment. We distinguish different user roles, taking account of the different

demands placed on the user by the activity to be carried out.

You will find the definitions of user roles with the demands on the user in chapter 2,

“Safety”. You can fulfil one or more of these roles, provided that you meet the

corresponding demands.

1.2 ORGANISATIONAL MATTERS

If you are unable to find the answer to any question in the operating instructions, please

contact the equipment manufacturer directly.

1.2.1 LOCATION OF THE OPERATING INSTRUCTIONS

The operating instructions can only be of use to you if you always have them to hand.

They should, therefore, always be kept at the place where the equipment is used.

1.2.2 MANUFACTURER AND CONTACT ADDRESS

KINEMATICA AG

Luzernerstrasse 147a

CH-6

014 Littau / Lucerne

TEL: +41 41 259 65 65

FAX: +41 41 259 65 75

e-mail: laboratory@kinematica.ch

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 6

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 6 of 36

1.3 WARNING NOTICES

Please be aware of the meaning of the following warning signs:

ATTENTION DANGER / WARNING!

OBSERVE OPERATING INSTRUCTIONS.

ATTENTION!

DANGER OF ELECTRIC SHOCK.

ATTENTION!

WARNING OF HOT SURFACE.

ATTENTION!

MACHINE NOT SUITED FOR USE IN EX-AREAS

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 7

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 7 of 36

2 SAFETY

Thi

s chapter is directed at all users of KINEMATICA laboratory equipment. It includes

information on safe and optimum use.

2.1 SUMMARY

Any incorrect use of the installed equipment can be dangerous. Inadequately trained users

can cause material damage and personal injury. This chapter informs you of the safety

concept and the requirements for safe and optimum use of the equipment.

All those authorised to operate, service and repair the equipment are required to study

chapter 2, “Safety”.

2.2 SAFETY CONCEPT

The safety concept sets down the entitlement to use the equipment and the responsibilities

of the individual users.

The machines and equipment are designed and constructed according to the state of the

art and the recognised safety rules.

2.2.1 INTENDED USE OF THE EQUIPMENT

The equipment is designed and constructed for the following use:

Cutting and milling of dry products in accordance with

the technical specifications

(see point 3.5) and compatibility with the materials coming into contact with the

products.

If you use the equipment for any purpose other than those listed, the manufacturer cannot

be held liable for any resulting damage.

2.2.2 IMPROPER USE

Any use other than the “proper use” without the written approval of the manufacturer or

operation outside the technical limits of use is improper use.

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 8

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 8 of 36

2.2.3 USER ROLES

To guarantee safety, we place requirements on the users of the equipment that must be

met without fail. Only persons meeting the requirements are authorised to work with the

equipment.

We describe all those who work with the equipment as users. Since the requirements of

these users are very much dependent on their activity, we distinguish the following user

roles.

Contract partner:

The manufacturer can impose legal obligations on the contract partner when the

equipment is purchased. The contract partner is obliged to ensure that the equipment is

properly used.

Operating company:

The operating company ensures that the equipment is properly used and authorises

persons who are entitled to work with the equipment in any one of the defined user roles.

He is under the obligation to instruct the users.

Note:

Contract partner and operating company can be the same person.

Service technician:

The service technician is an employee of the operating company and looks after the

equipment in special operating mode(s). He is a specialist with mechanical, electrical and

electronic professional training. The service technician undertakes commissioning,

decommissioning service and repair of the equipment. He must be appropriately trained to

be able to carry out the service work required.

Operator:

The operator turns the equipment on and off. In the event of an alarm signal he informs the

service technician.

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 9

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 9 of 36

2.2.4 DANGER AREA

System/equipment

The system danger area includes the whole system/equipment including the connecting

lead and controls.

Proximity danger area

This refers to all areas within a defined distance of the equipment.

User danger area

This danger area includes all persons working with the equipment.

2.2.5 AREAS OF RESPONSIBILITY

In order that the system/equipment can be used safely and without risk, the users in

various roles bear the responsibility for particular danger areas.

Contract partner:

The contract partner bears the responsibility for the “proximity danger area”.

Operating co mpany:

The operating company bears the responsibility for the “user danger area”. Only those

users may be authorised to operate the system/equipment who fulfil all requirements of the

user roles concerned. In so doing, attention must be paid to the following points:

It is to be ensured that all users of the system/equipm

ent have fully read and

understood chapter 2, “Safety” and act accordingly in a safety-conscious manner.

It is to be ensured that no unauthorised person carries out work with the

system/equipment.

It is to be ensured that users are informed of the possible risks and dangers connected

with the system/equipment.

It is to be ensured that those being trained or engaged in general training are under the

permanent supervision of a trained and authorised person.

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 10

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 10 of 36

Service technician:

The service technician bears the responsibility for the “system/equipment danger area”. He

ensures that the system/equipment is at all times free from technical faults, safe and

functions correctly.

2.2.6 GENERAL SAFETY RULES

Observe the following general safety rules:

follow these operating instructions,

in addition, observe the legal obligations and requirem

ents for accident prevention and

environmental protection of the country in which you operate the equipment,

do not make any modifications to the equipment without the written authorisation of the

manufacturer,

only original replacement parts may be used for repairs,

before any service work on the equipment, it must be ensured that the electrical supply

is switched off,

after any service, maintenance or repair work has been carried out on the

system/equipment, it must be given a test run by the service technician.

depending on the place at which it is installed, circumstances may require that hearing

protection is worn when remaining in the vicinity of the equipment for long periods.

2.3 RESIDUAL DANGERS

When the system/equipment is used in accordance with rules and regulations, residual

dangers are minimal.

Residual danger Remedy

Tripping over connecting

cables

Adequate installation

Breaking of glass

containers

Product spurting out

Wear eye protection.

Close lid.

Damage to hearing by

continuous exposure to

noise

Wear ear protection according

to duration and nature of task.

Tilting of machine Use non-slip, sturdy and horizontal base pad.

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 11

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 11 of 36

AN EXPERT ELECTRICIAN MUST CARRY OUT ALL

ELECTRICAL INSTALLATIONS

2.4 WARNINGS

• Make sure that the voltage of electric power source corresponds with

machine.

•

Exchange grinding geometries only after electric power supply has been

disconnected..

•

The electric power supply system, to which the machine is connected,

must comply with the requirements stipulated on the nameplate in order

to ensure a flawless functioning.

•

If hazardous chemicals or harmful materials can impact the environment

or the usage of the equipment, adequate corrective action has to be

taken.

• During longer operation and high load the grinding chamber can warm

up significantly – risk of light burns..

• The machine must not be operated in explosion-

prone rooms (highly

flammable gases, fluids, solids or dust in the environment)

•

Make sure that during the grinding of certain products no explosive dust

atmosphere is generated. If stron

g formation of dust occurs during

grinding, work under extractor hood

WARNINGS: To be continued on next page

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 12

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 12 of 36

WARNINGS: continuation

• Only service specialists authorised by KINEMATICA AG may open the

mach

ine.

• The areas around the ventilation grille and the ventilation slots at the

back of the machine must always remain unobstructed in order to

ensure efficient cooling. If cooling is not sufficient, performance will

decrease.

• The machine has to be installed in a way that no dirt or liquid can enter

via

the ventilation slots.

• Only dry, preferably non-fatty products may be ground.

• Exchange grinding geometries only after electric power supply has

been disconnected.

• Make sure that the grinding geometries are thoroughly cleaned after

each usage.

• The grinding chamber must not be opened during operation.

• For the feeding of stringy materials only the optional tamper (order No.

35080001) may be used. Using other objects may cause destruction of

the grinding unit and/or injuries.

• Never manipulate with hands or tools in/around the open grinding

chamber while electric power cable is connected.

• Never grab down into the open hopper.

Products made by KINEMATICA AG comply with all established and

relevant CE-regulations; they carry the CE-label and are delivered with a

corresponding declaration of conformity.

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 13

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 13 of 36

3 DESCRIPTION OF THE MACHINE

The

PX-MFC 90 D complies with all established and relevant CE-regulations, it carries the

CE-label and is delivered with a corresponding declaration of conformity.

3.1 OVERVIEW

The POLYMIX® PX-MFC 90 D is a lab mill, suited for grinding batches of dry substances.

By

exchanging the grinding geometries the mill can be converted into a hammer mill or a

cutting mill.

The mill is not designed for continuous operation.

For a serviceable system you need to have:

• The drive unit PX-MFC 90 D with power cable

• A milling-set (hammer mill set or cutting mill set)

• A sieve

• Collecting basin

• Power supply according to nameplate

On the following page you find a picture of the complete system PX-MFC 90 D with legend

and explanation of components.

MAKE SURE THAT ONLY DRY SUBSTANCES WITH A FAT CONTENT

AS LOW AS POSSIBLE ARE GROUND. HIGHLY HUMID OR FATTY

SUBSTANCES CAN CAUSE PLUGGING AND ACCUMULATION OF

MATERIALS AT THE SIEVE AND THE GRINDING GEOMETRIES.

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 14

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 14 of 36

.

Fig. 1

Fig. 2

Grab handle for

relocation

Display for rotation

speed indicator

and alarms

Main switch

Cooling air intake

Connector plug for

power cable

Turning knob for

speed

adjustment

Cooling air

outlet

Rubber foot (5x)

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 15

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 15 of 36

Hopper for

feeding product

Knurled screw

for opening/

losing the

chamber

Hopper lid

Metering

Knurled screw

for fixing/

loosening the

metering

Knurled screw

for fixing/

loosening the

Stators (6x)

Flange for

NS29/32 –

vessels

Product outlet

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 16

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 16 of 36

3.2 DRIVE UNIT

The drive unit PX-MFC 90 D is equipped with a strong 1000 W motor and is switched on

via the main switch on the front side of the machine. The machine disposes of an

integrated electronic control system. Rotating speeds between 0 – 6000 rpm can be set.

Maximum power is reached between 4500 and 5000 rpm.

The electronic control system disposes of safety functions, which induce an emergency

shutdown in case of overheating or jamming of the drive unit, along with a corresponding

alarm on the display. After an emergency shutdown the machine has to be restarted.

A detailed list of these error messages and remedies can be found in

chapter 6 ”TROUBLE SHOOTING“

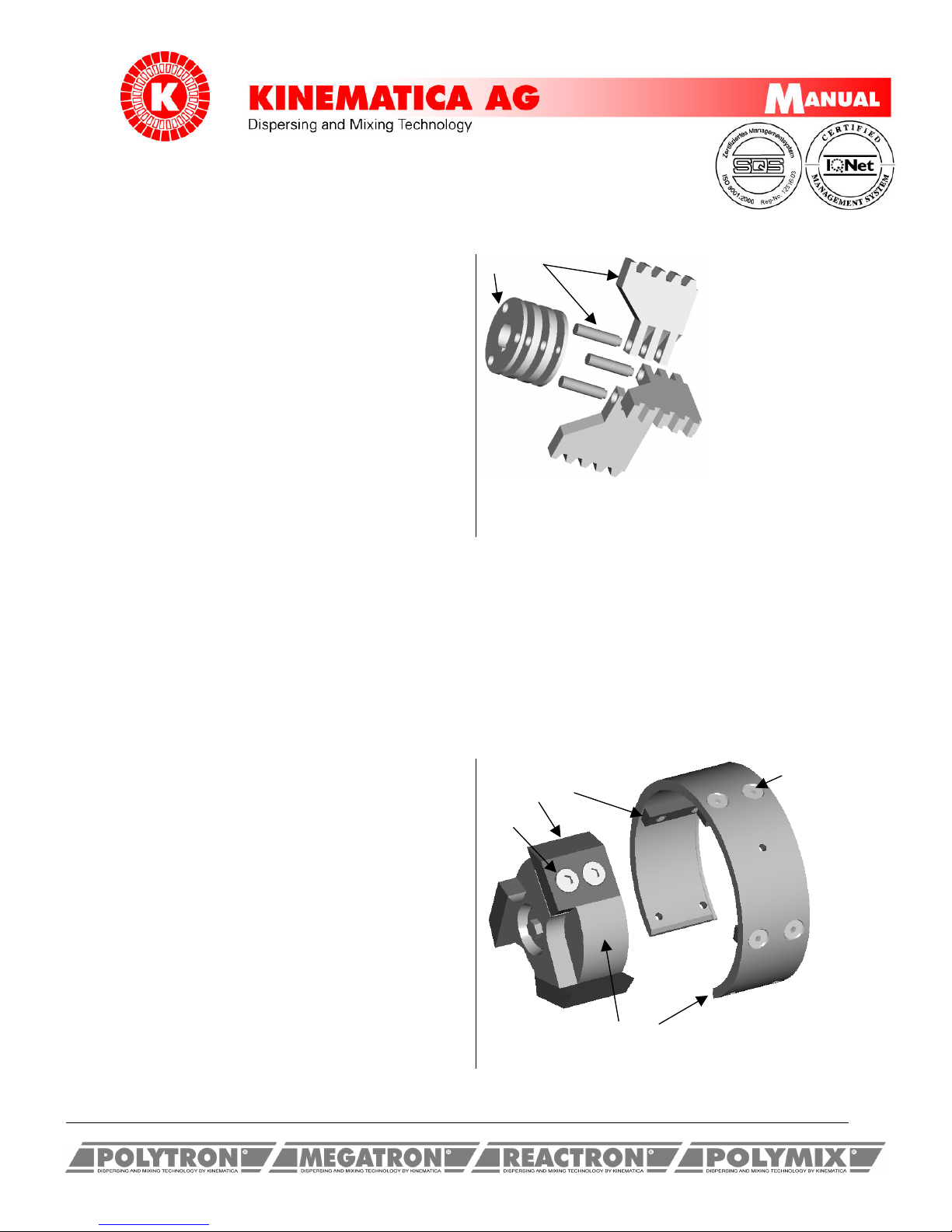

3.3 GRINDING ATTACHMENTS

For the grinding process there are 2 different grinding attachments as interchangeable kits.

Hammer-grinding attachment

(Order-no. 35031001)

Blade-grinding attachment

(Order-no. 35031002)

Fig. 3

Fig. 4

Hammer-grinding stator

Hammer-rotor

Sealing centre

Hexagon-head screw M4

Blade-grinding stator

Blade-grinding rotor

Sealing centre

Hexagon-head screw M4

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 17

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 17 of 36

ATTENTION!

DURING DETACHING, EXCHANGING

OF UNITS THE DRIVE MUST BE

DISCONNECTED FROM POWER

SUPPLY.

DURING LONGER OPERATION AND HIGH LOAD

BOTH

THE COUPLING AND THE DISPERSION UNIT CAN

HEAT UP SIGNIFICANTLY - RISK OF BURNS.

3.4 TOOLS AND ACCESSORIES

The mill is shipped with complete set of tools for dismounting, maintaining and cleaning.

For dismantling of the blade-grinding rotor a special extractor tool is provided. Please see

tables below.

General tool set

Identifier Item-no. Purpose

dimension

[mm]

Picture

Socket key 9341185

Dismantling

of the rotor

110 x Ø6/7

Rotating pin 9341186

Dismantling

of the rotor

Ø6 x 160

Extractor hook 9754564

Dismantling

of the stator

80 x 140

Hex wrench 9300112

Dismantling

of the

rotorblades

110 x 18 / 3

Hex wrench 9341441

Dismantling

of the rotor

insert plate

56 x 16 / 2

Brush 9341435 Cleaning -

Scratcher 9341436 Cleaning -

Pull out hook 9341437

Dismantling

of the sieve

-

Needle 9341438

Cleaning of

sticking

products

-

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 18

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 18 of 36

Tool for blade-grinding attachment

Identifier Item-no. Purpose

dimension

[mm]

Picture

Inboard-

extractor

9754548

Dismantling

of the blade

grinding

rotor

146 x Ø50

Provided accessories

Identifier Item-no. Purpose

dimension

[mm]

Picture

Rack with

drawer for 12

tubes & tools

9609114

Support for

tubes

245 x 135 x 84

Set of tubes

(12 pc.)

9341439

Collecting the

milled

material

Ø22 x 125

3.5 TECHNICAL SPECIFICATIONS

Drive unit PX-MFC 90 D

Motor Three-phase a.c. motor

Power supply 210...250 V, 50/60 Hz 100...120 V, 50/60 Hz

Max. speed 6’000 rpm

Max. input power 1’000 W

Max. output power 600 W

Noise emission at max. speed approx. 72 dB(A) (no load)

Ambient temperature

0 – 40°C

Relative humidity 95% max.

Ingress Protection IP 20

Standards

EMV acc. to IEC/EN 61000-6-2 / EN 61000-6-

3

safety acc. to IEC/EN 61010-2-51

International Protection Class

IP 20

Duration of service 60%(S3): 10 min operation / 6 min idle

Dimensions see appendix

Weight 12 kg

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 19

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 19 of 36

4 INSTALLATION

4.1

UNPACK

Open the transport box and check whether contents are consistent with bill of delivery.

CHECK ALL PARTS FO

R POSSIBLE TRANSPORT

DAMAGES.

IMMEDIATELY REPORT ANY INCONSISTENCY OR

ERROR DIRECTLY TO US OR YOUR SPECIALIST

DEALER.

4.2 START UP

The drive unit is delivered ready-to-use with mounted grinding geometry. Only the supplied

power cable needs to be plugged into the connector plug on the backside of the machine.

• Insert the desired sieve into the process chamber. Proceed as shown in the

following images.

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 20

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 20 of 36

ASSURE THAT THE SIEVE IS PLACED INTO GROVE OF

THE STATOR CORRECTLY AND NOT JUST PLACED ON

THE STATOR.

SEE IMAGE BELOW.

WRONG !

• Check voltage on the basis of nameplate

• Plug in power cable

• Switch on main switch

• Shut feeding channel with metering.

• Fill hopper with product.

• Place collecting basin under outlet.

• Set desired rotating speed.

• Start dosing product.

The following table offers a guideline regarding which milling set is best suited for which

product.

Hammer-grinding attachment Blade-grinding attachment

• Hard, dry cereal grains like corn

• Rock substance

• Pebbles

• Dry beans

• Salt

• Coffee

• Dry grass, hay

• Paper scraps

• Fish bones

• Fish fins

• Plastic pellets with portions of glass

fib

res

• Wood chips

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 21

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 21 of 36

4.3 EXCHANGE OF GRINDING ATTACHMENTS

Dismounting/Mounting of the hammer-grinding attachment

Make sure that the mill is switched off and the power cable disconnected before you start

dismounting/mounting.

First, pull out a possibly inserted

sieve.

Lock the hammer-

rotor from below

with the supplied rotating pin (1).

With the mandrel (3) inserted into the

socket wrench (2), loosen the screw

Fig. 5

Loosen the remaining screws

according to the picture and remove

first the rotor and then the grinding

ring (stator).

If the grinding ring is stuck, use the

supplied extractor hook in order to

grip the grinding ring at the inside

thr

ead and pull it out. Please see Fig.

12, 13 & 14 for proper proceeding)

For mounting proceed in reverse

order.

Fig. 6

(1)

(3)

(2)

(1) (2)

(3)

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 22

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 22 of 36

Dismounting/Mounting of the blade-grinding attachment

Make sure that the mill is switched off and the power cable disconnected before you start

dismounting/mounting

First, pull out a possibly inserted

sieve.

Lock the rotor from below with the

supplied rotating pin (1).

With the mandrel (3) inserted into

the socket wrench (2), loosen the

screw.

Fig. 7

Loosen the remaining screws

according to Fig 8 and remove

first the rotor and then the stator.

Use the supplied extractor tool in

order to grip the rotor at the inside

groove and pull it out. As shown

in Fig. 9 on the next page.

Use the supplied extractor hook

tool in order to grip the stator at

the inside threads to pull it out.

As shown in Fig. xx on the next

page.

Fig. 8

(3)

(1)

(2)

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 23

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 23 of 36

Place the extractor (1) in the

groove. Afterwards use the

rotating knob (2) so that the lips

of the extractor grab the rotor.

Fig. 9

When the rotor is grabbed, pull

out the extractor with rotor, as

shown in Fig. 10 and 11.

Fig. 10

Always use the extractor in your

hands to dis/mount the bladegrinding rotor.

For mounting proceed in reverse

order.

Fig. 11

(1)

(2)

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 24

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 24 of 36

Both blade- and hammergrinding stator should be

removed using the

extractor hook.

Place the extractor hook

(1) in the inside threads,

as shown in Fig. 12 & 13

Fig. 12 Fig. 13

When both hooks are

inside the threads, pull

out the stator using both

hands, as shown in Fig.

14.

Fig. 14

(1)

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 25

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 25 of 36

ATTENTION!

DURING DETACHING, EXCHANGING OF

GRINDING GEOMETRIES THE DRIVE

MUST BE DISCONNECTED FROM

POWER SUPPLY.

DURING LONGER OPERATION AND HIGH LOAD THE

GRINDING CHAMBER CAN HEAT UP SIGNIFICANTLY RISK OF BURNS.

MAKE SURE THAT GRINDING GEOMETRY GETS CLEANED

THOROUGHLY AFTER EACH USAGE.

NEVER TOUCH A ROTATING ROTOR OF THE GRINDING

GEOMETRY. HIGH RISK OF INJURY.

5 MAINTENANCE

You

r POLYMIX® machine is easy to maintain; nevertheless a sound inspection and a

thorough cleaning are indispensable.

THE MACHINE MUST BE DISCONNECTED

FROM THE ELECTRICAL POWER SOURCE

DURING THE FOLLOWING ACTIVITIES IN

ORDER TO PREVENT INJURIES TO

PERSONAL AND/OR DAMAGES TO THE

MACHINE:

•

EXCHANGE/REMOVAL OF GRINDING

ATTACHMENTS

•

CLEANING OR MAINTAINING THE

MACHINE

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 26

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 26 of 36

5.1 DRIVE SYSTEM

The drive unit PX-MFC 90 D is maintenance-free under normal working conditions. Parts

as bearings are subjected to normal wear.

We strongly recommend to let service or repairs of the drive unit be performed only at

authorised KINEMATICA service locations or directly at KINEMATICA, where original

spare parts are available.

Any changes that are not authorised or any manipulation will result in immediate

cancellation of the warranty.

5.2 CLEANING & MAINTENANCE

Dafür vorgesehene Werkzeuge: siehe Kapitel 3.4

ATTENTION!

DURING MOUNTING/DISMOUNTING PLEASE

MIND SHARP EDGES AND TEETH AT GRINDING

GEOMETRIES - RISK OF CUTTING.

5.2.1 Hammer-grinding attachment

Stator: • Dirty grooves can be cleaned with supplied scratch-out tool.

• Cleaning in ultrasonic bath is recommendable

•

The stator can also be cleaned with water. Important is a

sound drying directly afterwards in order to prevent possible

formation of rust..

Rotor: • The same recommendations apply.

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 27

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 27 of 36

Dismounting/Mounting of the hammer-grinding rotor

Push out the pins (2) of the center (1)

Mounting in reverse order

Fig. 15

5.2.2 Blade-grinding attachment

Stator: • Dirty grooves can be cleaned with supplied scratch-

out tool

and a needle.

• The 6-edge-

depressions of the screws can also be cleaned

with the needle.

• Cleaning in ultrasonic bath is recommendable.

Rot

or: • The same recommendations apply.

•

Unscrew (5,6). the rotor- and stator-blades

(1,2) very carefully.

When mounting the stator-

blades again,

assure that the cutting edges are directed

clockwise.

Fig. 16

(1) (2)

(1) (2)

(3) (4)

(5)

(6)

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 28

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 28 of 36

5.2.3 Grinding chamber

The grinding chamber can be dismounted for cleaning purposes. Mounting/dismounting is

described below:

First remove the grinding rotor as

described under 4.3.

Loosen the 3 screws (1). The chamber

can be removed.

Subsequently the insert plate (2) and

the felt seal (3) can be removed.

For remounting proceed in reverse

order.

Fig. 17

The grinding chamber can be cleaned with water and in the ultrasonic bath. Make sure

that chamber is completely dry before it is remounted in order to prevent the formation of

fit corrosion.

(1)

(3)

(2)

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 29

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 29 of 36

5.2.4 Gate with hopper

The gate with integrated hopper can be dismounted for cleaning purposes.

Mounting/dismounting is described below:

Dis/mounting of the rotary slide

Dismantle the screw (1) using the supplied

hex wrench and pull out the rotary slide (2).

Remove the O-ring (3).

Rotary slide and o-

ring can now be cleaned

/replaced.

For the mounting please proceed in reverse

order.

When mounting the rotary slide, assure that

the groove in the slide is adjusted like in Fig.

15.

Fig. 18

Dis/mounting of the guard plate in the

gate

Dismantle the screws (1) using the supplied

hex wrench. Remove the plate (3) and the

O-ring (2)

O-Ring and plate now be cleaned/ replaced.

For the mounting please proceed in reverse

order.

Fig. 19

(1)

(3)

(2)

groove

(3) (2) (1)

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 30

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 30 of 36

5.3 SPARE PARTS LIST

The spare parts list is separated according to the assemblies: drive, hammer-grinding

attachment and blade-grinding attachment. For ordering spare parts please advise

assembly, identifier and article-no.

Assembly Identifier Article-no. Position

Figure no.

rear guard plate 9753847 2 17

guard plate for gate 9753849 3 19

felt sealing 9754157 3 17

o-ring for gate

9341828 2 19

o-ring for rotary slide 9320067 3 18

rotary slide 9753974 2 18

Drive

PX-MFC 90 D

rubber foot 9323028 - 2

hammer-grinding stator 9753848 - 3

center 9754186 1 15

sealing center 9753834 - 3

Hammer-

grinding

attachment

set of 3 hammers with pins 9754185 2 15

blade rotor 9753898 3

blade stator 9753901

4

countersink screw M5x16 9940516

5

countersink screw M4x8 9900048

6

stator blade 9753900

2

Blade-grinding

attachment

rotor blade 9753899

1

16

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 31

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 31 of 36

6 TR

OUBLE SHOOTING

PROBLEM CAUSE REMEDY

unusual noise

Bearing at drive motor

damaged

Change ball bearings, find and

replace defective parts

Heating up Insufficient cooling

Damaged bearing

Overload

Check ventilation slots

Change ball bearings

Check application

Vibrations Twisted shaft

Worn bearings

Replace shaft

Replace bearings. Find and replace

defective parts

Drive not running

Display shows O-I

Drive overloaded

Unit jammed

Motor or wiring defective

Check drive for overload

and jamming

Check wiring. Reset and restart.

Drive running out

Display shows O-Uolt

Too high voltage in

frequency converter

Braking time too short

Check power supply voltage

Set potentiometer back more slowly

Drive not running

Display shows U-Uolt

Too low voltage in

frequency converter

Check power supply voltage

Drive not running

anymore

Display shows I.t-trP

Drive overloaded

150% current for more than

a minute

Check load

Reset and restart.

Drive not running

anymore

Display shows E-triP

Motor overheated

Wiring of control unit to

drive defective

Check ventilation slots

Check wiring

Product leaking from

gap between chamber

and gate.

O-ring in gate defective Replace O-ring.

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 32

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 32 of 36

7 ACCESSORIES

Stodger

Order-No. Dimensions Material

Is used for the active

feeding of stringy materials

via the hopper, which

cannot be fed by its own

weight.

35080001 300 x 26 x 23

mm

POM black

Sieves

Order-No. Diameter-Ø Material

9609088

0.2 mm

9609089

0.5 mm

9609090

0.8 mm

9609092

1.0 mm

9609093

1.5 mm

9609094

2.0 mm

9609091

3.0 mm

9609105

4.0 mm

9609106

5.0 mm

Insert sieves can be

ordered with hole

diameters from 0.2 to 6.0

(*) mm and are made from

stainless steel.

(*) Special mesh sizes are

available on request.

9609107

6.0 mm

steel

1.4034

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 33

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 33 of 36

8 WARRANTY

KIN

EMATICA AG guarantees the flawless function of this machine manufactured by it for

a period of 12 months with reference to material and manufacturing defects.

.

KINEMATICA AG assures free repair of the machine or free replacement of delivered

defective parts, respectively, when close examination proves that it is a matter of a

material and/or manufacturing defect,

Exempt from the warranty are parts, which are subject to normal wear, or if someone other

than KINEMATICA AG employees or their designated representatives have made changes

to the equipment or the damage can be traced back to non-observance of the operating

instructions, imprudence, accident, wrong utilisation or incorrect electrical voltage.

.

KINEMATICA AG reserves the right of technical changes to the machines, without

implementing these retroactively in machines delivered earlier.

In case of technical problems, need of spare parts or for advice, please contact our

regional designated agent, your preferred special dealer or us directly.

KINEMATICA AG

Luzernerstr. 147a Tel. +41-41-259 65 65

CH-6014 Littau-Luzern Fax +41-41-259 65 75

Schweiz eMail laboratory@kinematica.ch

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 34

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 34 of 36

Appendix A. Dimensional drawings

Dri

ve PX-MFC 90 D

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 35

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 35 of 36

Appendix B. Parts lists

Assembly Main Identification Order-No. Production-No. Products Identification

9158043

Drive 230V with hammer-

gri

nding attachment

9835419 Power cable CH

9609114 Wooden rack

9851003 Tubes

POLYMIX® PX-MFC 90 D

230V / CH / H

35010020

9754504 Tools

9158043

Drive 230V with hammer-

grinding attachment

9835418 Power cable EU

9609114 Wooden rack

9851003 Tubes

POLYMIX® PX-MFC 90 D

230V / EU / H

35010021

9754504 Tools

9158043

Drive 230V with hammer-

grinding attachment

9835426 Power cable GB

9609114 Wooden rack

9851003 Tubes

POLYMIX® PX-MFC 90 D

230V / GB / H

35010022

9754504 Tools

9158044

Drive 100..120V with

hammer-grinding

attachment

9835416 Power cable US/JP

9609114 Wooden rack

9851003 Tubes

Mill with hammer-grinding attachment

POLYMIX® PX-MFC 90 D,

100..120V / H

35010023

9754504 Tools

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Page 36

Manual PX-MFC 90 D english / Release 2.0 / 29.12.2006 page 36 of 36

Parts lists continued

Assembly Main Identification Order-No. Production-No. Products Identification

9158067

Drive 230V with blade-

grinding attachment

9835419 Power cable CH

9609114 Wooden rack

9851003 Tubes

9754504 Tools

POLYMIX® PX-MFC 90 D 230V /

CH / B

35010030

9754548 Inboard extractor

9158067

Drive 230V with blade-

grinding attachment

9835419 Power cable EU

9609114 Wooden rack

9851003 Tubes

9754504 Tools

POLYMIX® PX-MFC 90 D

230V / EU / B

35010031

9754548 Inboard extractor

9158067

Drive 230V with blade-

grinding attachment

9835419 Power cable GB

9609114 Wooden rack

9851003 Tubes

9754504 Tools

POLYMIX® PX-MFC 90 D

230V / GB / B

35010032

9754548 Inboard extractor

9158068

Drive 100..120V with blade-

grinding attachment

9835419 Power cable US/JP

9609114 Wooden rack

9851003 Tubes

9754504 Tools

Mill with blade-grinding attachment

POLYMIX® PX-MFC 90 D,

100..120V / B

35010033

9754548 Inboard extractor

9753834 Sealing centre

9753848 Hammer-grinding stator

9341587 Hammer-grinding rotor

hammer-grinding attachment 35031001

9951135 Hexagon screw M4x16 A2

9115343 Blade-grinding rotor

9115344 Blade-grinding stator

9951135 Hexagon screw M4x16 A2

9753902 Sealing centre

Grinding

attachments

blade-grinding attachment 35031002

9754548 Inboard extractor

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (866) 244-1578 www.qclabequipment.com

Loading...

Loading...