Page 1

Operating instructions

Page 2

System

MICROTRON®

Type

MB 800

Issue

3.0 / 12.09.2018

Page

2

of

15

1.1 OPERATING INSTRUCTIONS ............................................................................................................................... 3

2.1 TARGET AUDIENCE ......................................................................................................................................... 4

2.2 ORGANISATIONAL MATTERS.............................................................................................................................. 5

2.3 LOCATION OF THE OPERATING INSTRUCTIONS ....................................................................................................... 5

2.4 MANUFACTURER AND CONTACT ADDRESS ............................................................................................... 5

2.5 WARNING NOTICES ........................................................................................................................................ 6

Page 3

System

MICROTRON®

Type

MB 800

Issue

3.0 / 12.09.2018

Page

3

of

15

This chapter gives information on the the structure of this document. It will assist you in making use of it and

show how to find the required information quickly.

Please read through these operating instructions before switching on or attempting to use the equipment.

They describe the use of the MICROTRON® MB 800, its installation and maintenance and the appropriate

replacement parts and accessories.

They will help you avoid erroneous use and consequent damage. Although MICROTRON® machines are

designed for ease of service, this does not release you from the obligation to inspect your equipment carefully

and to clean it thoroughly.

KINEMATICA AG is a specialist manufacturer of machines and equipment for dispersion and mixing technology.

An important objective of these operating instructions is to fully inform you, the user, about the correct and

safe use of our equipment.

In order to achieve this, it is essential that you should carefully study chapter, “Safety”, and follow the

instructions in this book.

Page 4

System

MICROTRON®

Type

MB 800

Issue

3.0 / 12.09.2018

Page

4

of

15

Manufacturer: KINEMATICA AG, CH-6014 Lucerne

Product name: MICROTRON®

Type designation: MICROTRON® MB 800

36010003

MB 800, Drive unit 230V

36010004

MB 800, Drive unit 110-120V

36050050

MBA 2000, Mixing attachment, 2000ml working volume

36050055

MBA 4000 Mixing attachment, 4000ml working volume

These operating instructions are intended for all authorised users of our

machines/equipment. We distinguish different user roles, taking account of the different demands placed on

the user by the activity to be carried out.

You will find the definitions of user roles with the demands on the user in chapter “Safety”.

You can fulfil one or more of these roles, provided that you meet the corresponding demands.

Page 5

System

MICROTRON®

Type

MB 800

Issue

3.0 / 12.09.2018

Page

5

of

15

If you are unable to find the answer to any question in the operating instructions, please contact the

equipment manufacturer directly.

The operating instructions can only be of use to you if you always have them to hand. They should, therefore,

always be kept at the place where the equipment is used.

Luzernerstrasse 147a

CH-6014 Lucerne

TEL.: +41 41 259 65 65

FAX: +41 41 259 65 75

E-Mail: info@kinematica.ch

Page 6

System

MICROTRON®

Type

MB 800

Issue

3.0 / 12.09.2018

Page

6

of

15

Please be aware of the meaning of the following warning signs:

Page 7

System

MICROTRON®

Type

MB 800

Issue

3.0 / 12.09.2018

Page

7

of

15

A six digit appliance number is printed on the rating plate located on

the bottom plate of the machine. The first two digits indicate theyear

of manufacture for that machine

So that your able to enjoy using your MICROTRON for a long time, please read these operating instructions

before starting operation. It will assist you in avoiding malfunctions and damage. MICROTRON units are

maintenance friendly – which, however does not release you from proper inspections and above all from good

cleaning.

• Connect the MICROTRON® MB800 to an earthed alternating current power supply only.

The voltage must correspond to the specifications on the rating plate.

• The appliance is tested in accordance with EN 60335-2-64.1993. (SEV CENELEC and CE). The MICROTRON®

MB800 is grounded, doubly insulated and electromagnetically shielded.

• Electrical appliances are not toys. The appliance must be used and stored away from children. Do not allow

the mains cable to hang down.

• Never leave the appliance unattended while it is plugged in.

• Keep your hands, hair and other objects away from the moving parts.

• The MICROTRON® MB800 can only be used when all the parts have been properly installed.

• The MICROTRON® MB800 should only be used by instructed personnel.

• Before every cleaning unplug the appliance from the power supply.

• Never attempt to pull out the plug by the cable or with wet hands.

• Do not allow the mains cable to hang over the sharp edge of a table, do not allow it to lie on a work

surface and avoid having it come into contact with hot surfaces.

• Use only proper, approved extension cords.

• The MB 800 motor unit must never be submerged in water or any other liquid!

• Never attempt to clean it with a water jet!

Wipe clean with a damp cloth.

• Do not attempt to operate the MICROTRON® MB800 if:

- the appliance or the mains cable is damaged

- the appliance has been dropped or has fallen. In this case the appliance must be brought in for repairs or

inspection at the next KINEMATICA authorized service center.

• Repairs should only be done by professionally trained technicians.

Serious dangers to the user could result from improperly carried out repairs.

Page 8

System

MICROTRON®

Type

MB 800

Issue

3.0 / 12.09.2018

Page

8

of

15

The MICROTRON® MB 800 can be just used for chop, beat, stir, mix, puree and emulsify of cuttable chemical

materials/substances.

The chemical and temperature Resistance of the used material (Glass, stainless steel,

PP and rubber) has to be noticed in context with the blender.The process of explosive materials is strictly

prohibited. It is forbidden to mix 2 materials which to not correspond with each other, or to get the mixture

explosive because of overheating etc.

1. Motor base

2. Top part with safety rod to lid monitor

3. Rubber foot

4. Bottom plate

5. Rating plate

6. Mains cable

7. Container with cutter

8. Lid lock

9. Stopper

10. Speed control knob

Power supply: 230 V / 4,4 A or 120 V / 8,3 A, +/- 6%, 48...62 Hz,

sinusoidal, interference free

Power requirement: 800 W for continuous operation

Motor: High temperature resistant collector motor with fan

Motor control: - smooth, gradient starting

- infinitely variable speed adjustment between 1 000...15 000 r.p.m.

- electronically controlled speed stabilization (actual and

desired value comparison)

- the motor has a thermal protection switch and is electronically monitored

Electrical equipment: - safety control system for lid monitor - grounded with additional double

insulation according to standard EN-60335-1

- electromagnetically shielded accordance with

EMC-Directives 89 / 336 EEC.

Construction: - Motor base is constructed of chromium-plated casting

- Cutter blades of stainless steel

Weight: 5,5 kg (800 W) net, without container

Temperature range: operating: 10...40°C

storage: 20...70°C

Humidity: operating: 0...80% non condensing

storage 0...95% non condensing

Altitude: 0..2 000 m. (0...6 600 ft)

Page 9

System

MICROTRON®

Type

MB 800

Issue

3.0 / 12.09.2018

Page

9

of

15

The power supply voltage must correspond to the values on the rating plate on the appliance

(the voltage rating is given in volts (V))

The appliance should only be connected to a single phase grounded alternating current.

Make sure that the original mains cable and the wall outlet correspond.

The use of a faulty-energy-protection switch, (Fl) is suggested by all the works with electro-appliances.

If at all possible, avoid using an extension cord. If it is unavoidable, only proper, approved extension cords

should be used. Do not subject the mains cable to strong tension or pressure.

Before using the appliance for the first time it must be thoroughly cleaned. Follow the instructions in Chapter 9

under "Cleaning".

Place the MICROTRON

®

MB 800 on a firm, flat base and plug it into a nearby, appropriate electrical outlet.

The windings of the Rotor commutator motors are covered with high-quality insulating

lacquer. For this reason, the motor may, at first, exude an odour when it heats up.

This is normal and does not damage the motor; it disappears after the motor has been

used several times.

Insert the cutter head together with the gasket into the black threaded ring

Screw the bowl turning counter clockwise into the threaded ring.

Always ensure that it is inserted straight

- Insert the container into the retaining ring on the motor base, taking care to keep it vertical.

- Add ingredients to be mixed.

- Place the lid in such a way, that the hole in the tab at the lid sticks over the end of the rod, that the lid is firmly closed.

- Switch on motor and vary the speed according to the ingredients being mixed, turn the speed control knob clockwise until

the desired speed is reached. The maximum speed is reached at position 8.

Particularly in the case of thick, viscous materials, the highest possible speed should be selected so that the motor is not

heated up unnecessarily.

Liquids and fine grained materials can be added through the filler opening in the lid of the container during operation

(Remove the lid lock).

→ The motor only runs if the lid is in position!

By switching on and operating at high speed, it is recommended that the bowl should be held (lay hand on the lid).

Page 10

System

MICROTRON®

Type

MB 800

Issue

3.0 / 12.09.2018

Page

10

of

15

The safety control prevents the motor from being switched on when the protection cap/mixing lid is not in

position and stops it if the protection cap/lid is raised during operation.

When the protection cap/lid is replaced, the speed control knob must be turned back to

"0" (reset function), before the motor can be restarted.

→ Only the speed control knob can be used to turn the machine on and off

When the machine is overstressed or overheated, it switches off automatically.

If this occurs, after about 60 seconds, please press the black button

on the bottom plate of the motor base.

If you notice any irregularities or defects, please contact your

supplier. For more information see under "Repairs".

Never submerge or spray the engine block in water or other fluids! Do not clean with a water jet!

If necessary, only clean it with a damp cloth and be sure to unplug the machine first.

DANGER!

Thoroughly clean the machine after each use! Improper and careless cleaning can cause considerable health

risks from microorganisms.

The mixing attachments should not be cleaned while assembled in the dishwasher, they have to be

disassembled. The mixing attachments are to be thoroughly cleaned after each use or once a day.

Our mixing attachments are made from borosilicate glass and are therefore autoclavable. Borosilicate glass has

very good chemical and physical properties and is used for applications where in addition to the very good

chemical resistance, a very high heat resistance and thermal shock resistance and high mechanical strength are

required (e.g. round-bottomed flasks, beakers).

Upon heating of the flask no deformations are to be expected up to 400° C, however, they already occur at

lower temperatures due to the thermal expansion and the poor thermal conductivity of tensile and

compression stresses. If the permissible strength values are exceeded as a result to rapid heating or cooling

rates, fracturing occurs. Therefore - as with any glass - a maximum permissible temperature can not generally

be defined. If the flask is evenly and slowly heated up in the autoclave and then correspondingly cooled off,

then no problems should be expected for example at 135° C.

Never heat the flask on a hotplate and never expose it to abrupt temperature changes (e.g. don’t take it hot

out of the drying cabinet and put on a cold or wet lab table).

Just rinse and brush off if necessary. Never place in water or in the dishwasher, because otherwise the selflubricating bearings will wear out.

Page 11

System

MICROTRON®

Type

MB 800

Issue

3.0 / 12.09.2018

Page

11

of

15

The cutter head is made of stainless steel parts, which are actually very resistant. However, high temperatures

and detergents generally reduce the lubricating effect of the grease in the built-in stainless steel ball bearings

(with integrated NBR seals, heat resistant up to a maximum of 120° C). As a result, wear and tear-related failure

often occurs sooner if the cutter head is treated in a dishwasher or an autoclave. Normally bearing damage

initially only leads to a steady increase in noise of the mixer, so that the device is able to continue to work a

long time yet before it fails. It can often be worth it for the user to save time by cleaning the disassembled

mixing attachment mechanically and for that reason to more frequently replace the cutter head.

on the bottom of the cutter head are made of H-NBR (max. 140° C, cleaning with hot

water and steam also possible) and the hard-paper cover plates on both sides of the bearings are based on

phenolic resin and tolerate at most 120° C

(gray ring) is standard NBR (max. 90° C, FDA, ideal for the food industry, resistant to gasoline,

oils, weak acids, and bases). For special requirements (laboratory applications), the seals can be supplied in

special materials that have a higher chemical and thermal resistance:

▪ (can withstand approximately 200° C, ideal for chemical applications, excellent resistance to

aromatic solvents)

▪ (up to 150° C, industrial applications, especially for hot water and steam)

▪ (max. 200° C, FDA, for the food and pharmaceutical industries)

The black threaded ring (that mostly does not come into contact with the product) is resistant up to 115° C and

has a good resistance in the dishwasher. The inside of the threaded ring is best cleaned with a stiff brush.

concerning

chemical resistance when they come into contact with chlorides (e.g. hydrochloric acid). The initial drying of

chloride-containing disinfectants or the evaporation of hydrochloric acid-containing floor cleaner or similar can

lead to chloride-induced pitting on the surface of the stainless steel. Such disinfectants should be sufficiently

rinsed off after the prescribed contact time. Alternatively, chloride-free disinfectants can be used. Hydrochloric

acid-containing cleaners should be avoided. Improper use (e.g. inadequate rinsing) of active chlorinecontaining cleaning agents, leads to pitting. Any stainless steel can corrode under adverse conditions. Outside

rust is caused by iron particles that attach themselves to the steel surface.

The source of the particles can be:

▪ The water supply

▪ Steel wool sponges, with which the dishes were pre-cleaned

▪ Paper clips, drill cuttings, screws, etc., just to name a few.

Since all of these parts are introduced from the outside, it is called outside rust. If the rust spots and whose

source can not be directly resolved, corrosion damage can become increasingly common.

Chemically-speaking, Plexiglas® (brand name) is a product made from polymethylmethacrylate, abbreviation

PMMA, which is also known as acrylic glass.

Plastics can generally become electrostatically charged. This can cause the parts to then attract dust. Outdoors,

this phenomenon is normally prevented by the rain and humidity. The phenomenon can also be promoted by

mechanical rubbing of the plastic surfaces, air movement, and dry air with plastic parts indoors.

To clean the protect caps, which do not often come into contact with the product, use only a microfiber cloth

lightly dampened with water.

Page 12

System

MICROTRON®

Type

MB 800

Issue

3.0 / 12.09.2018

Page

12

of

15

A chemical resistance chart for PMMA can be downloaded here: https://adobe.ly/2lXBgrP

(Document only available in German).

In it you can see which chemicals are compatible with PMMA and which are not.

Page 13

System

MICROTRON®

Type

MB 800

Issue

3.0 / 12.09.2018

Page

13

of

15

Maintenance

The motor bearings are permanently lubricated and therefore require no maintenance.

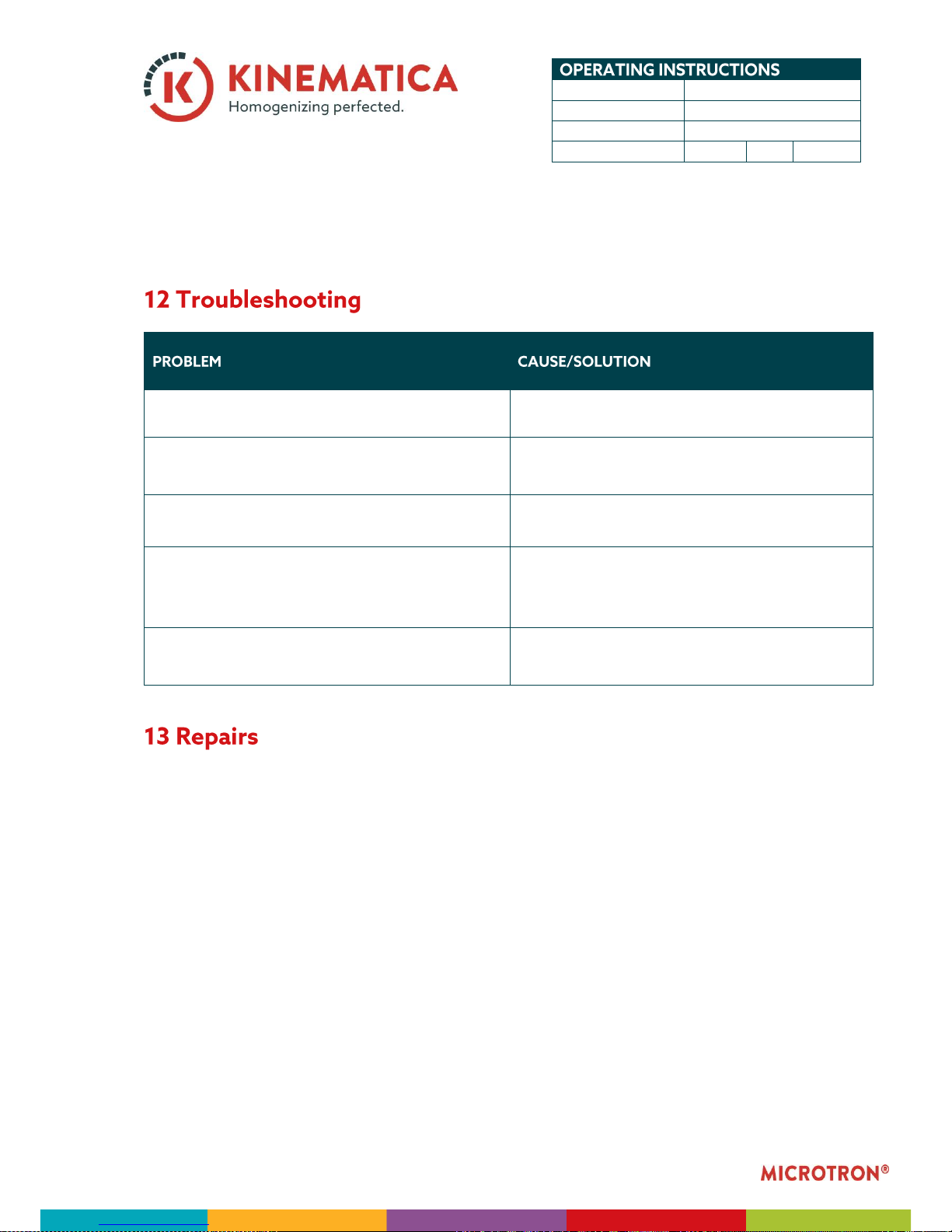

The appliance doesn't run.

- Make sure the mains cable is plugged into a wall socket.

The motor runs at the highest speed when the appliance is

switched on.

- Defective electronics

The motor speed is difficult or impossible to adjust.

- Defective potentiometer or electronics

The motor stops under load

- The overload switch has been activated

- Brushes worm

- Defective electronics

The motor continues to run even after the protection

cap/lid has been lifted.

- Defective safety switch or electronics

Obtain the address of your nearest KINEMATICA authorized service center from the store where you purchased

your appliance.

Bring your appliance to the service center or send it as a postage paid, registered package.

Page 14

System

MICROTRON®

Type

MB 800

Issue

3.0 / 12.09.2018

Page

14

of

15

A Circuit board holder

B Motor safety switch

C Potentiometer with On/Off-Switch

D Motor brushes connection

E Stator connection

F Safety switch for cap surveillance

G Electronic

H

K Potentiometer connection for control device

L

M Suppressor screen filter

0 EF-Choke

PE Ground

N Neutral wire Mains supply

P Phase

Page 15

System

MICROTRON®

Type

MB 800

Issue

3.0 / 12.09.2018

Page

15

of

15

KINEMATICA AG guarantees that the equipment that it produces will run free of any fault related to

materials or manufacturing faults for 24 months.

ADDITIONAL WARRANTY FOLLOWING REGISTRATION

Consumers who complete a warranty registration within 20 days of receiving their device will benefit

from a free warranty extension of a further 12 months. This means that the total warranty period

after registration is 36 months.

If thorough testing shows a fault to be due to either of the above causes, KINEMATICA AG guarantees

that the equipment will be repaired or replaced free of charge.The guarantee does not cover parts

that are subject to normal wear. It is void if any person other than an employee of KINEMATICA AG

or their appointed representative has made modifications to the equipment or if the damage is due

to failure to comply with the operating instructions, to carelessness, accident, incorrect use or

incorrect supply voltage.

KINEMATICA AG reserves the right to make technical changes to the equipment without modifying

equipment delivered earlier in the same way. In the event of technical problems, for spare parts

requirements or for advice, contact our regional appointed agent, your prefered dealer or us directly

at:

Luzernerstr. 147a Tel. +41-41-259 65 65

CH-6014 Luzern Fax +41-41-259 65 75

Switzerland Email

MICROTRON

®

is a registered trademark of KINEMATICA AG Lucerne

Loading...

Loading...