Page 1

MEGATRON® MT 5100 S²

General Operating Instructions

General Installation Instructions

General Maintenance Instructions

Page 2

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

2

of

38

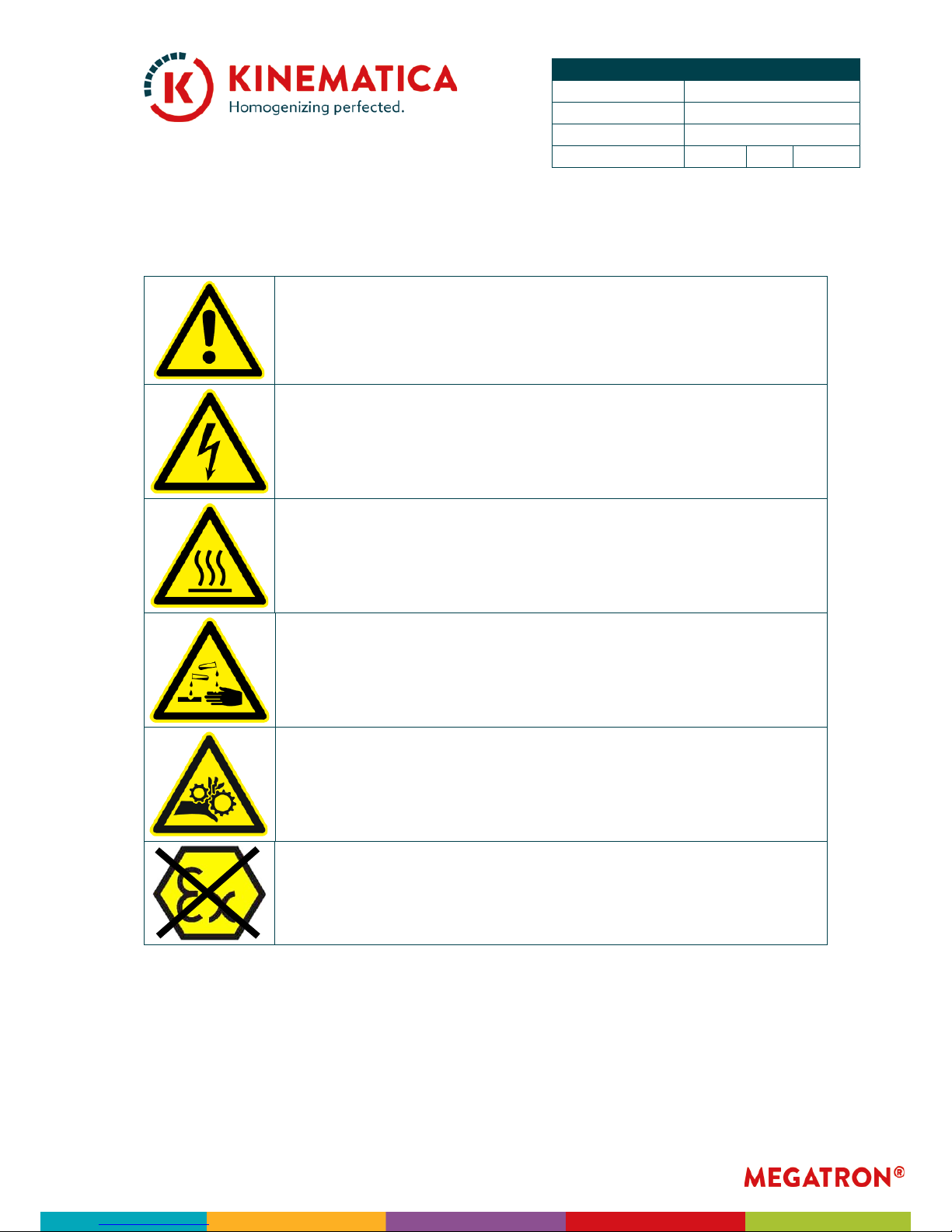

SAFETY INDICATIONS

Please pay attention to the meaning of the following warning signs:

SAFETY INSTRUCTIONS MUST BE OBSERVED TO ENSURE SAFE

OPERATION

THIS SYMBOL INDICATES HIGH VOLTAGE, WITH RISK TO

HEALTH AND ENVIRONMENT

CAUTION!

BEWARE OF HOT SURFACE

CAUTION!

BEWARE OF HAZARDOUS CHEMICALS OR MATERIALS THAT

ENDANGER HEALTH

CAUTION!

BEWARE OF ROTATING MECHANICAL PARTS

CAUTION!

DEVICE NOT DESIGNED FOR USE IN EXPLOSION DANGER

ENVIRONMENTS

Page 3

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

3

of

38

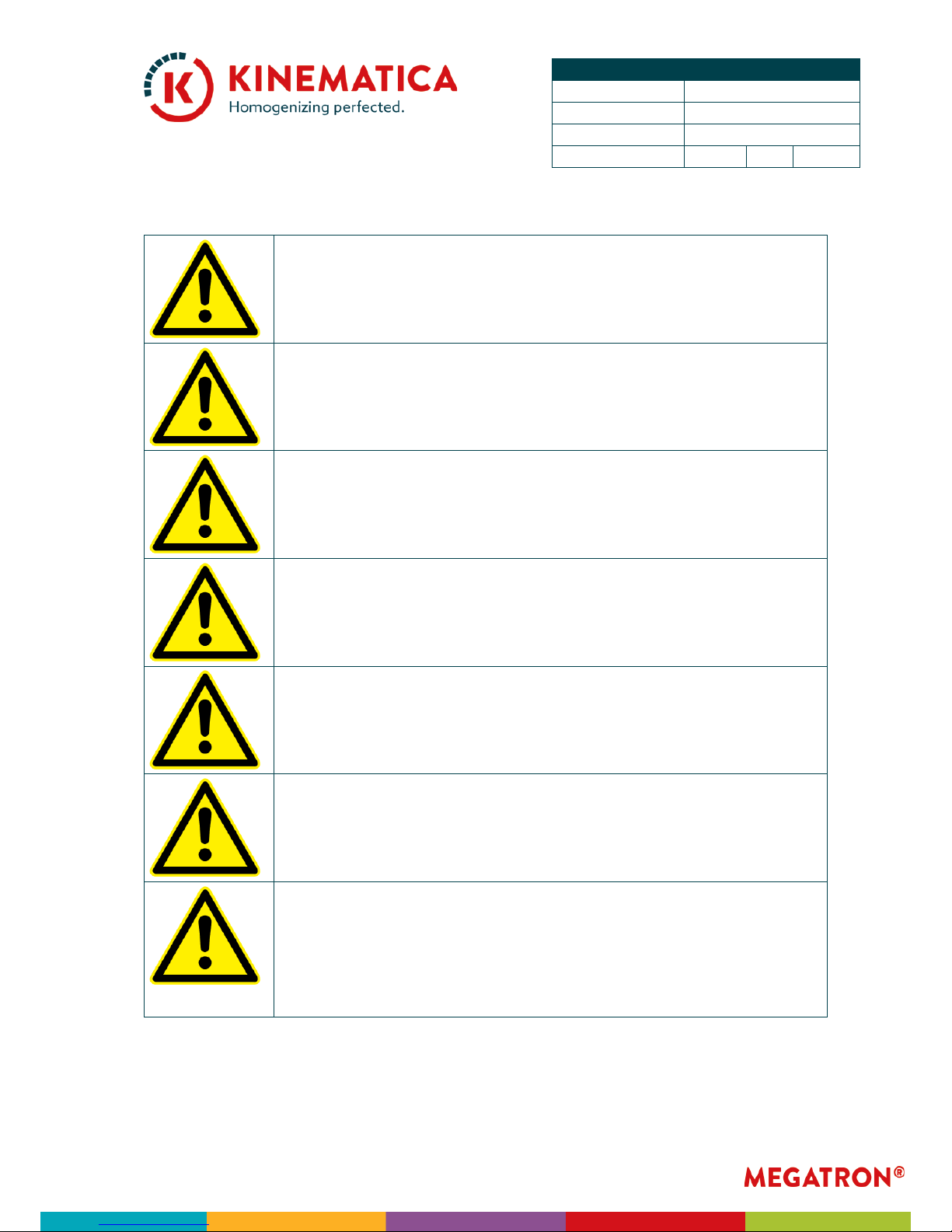

GENERAL SAFETY INSTRUCTIONS

RESPECT THE INSTRUCTIONS GIVEN IN THIS DOCUMENT

READ THESE OPERATING INSTRUCTIONS BEFORE SWITCHING

ON OR OPERATING THE EQUIPMENT

IF YOU HAVE ANY QUESTIONS OR DOUBTS REGARDING

OPERATING THE UNIT, DO NOT START OR OPERATE THE UNIT

AND CONTACT YOUR DEALER OR NEAREST KINEMATICA

SERVICE CENTER

IMPROPER USE OF THE MACHINE / UNIT DUE TO

UNAUTHORIZED PERSONNEL CAN LEAD TO DAMAGE ON THE

MACHINE / UNIT AND / OR ENDANGER LIFE, CAUSE PERSONAL

INJURY AND HARM THE ENVIRONMENT

ALL AUTHORIZED PERSONNEL INVOLVED IN THE OPERATION,

THE SERVICE OR THE REPAIR OF THE MACHINE / UNIT HAVE TO

READ AND TO UNDERSTAND THIS MANUAL

ONLY AUTHORIZED PERSONNEL / INTENDED USERS ARE

ALLOWED TO USE THE MACHINE

THE INTENDED USER ASSURES THAT THE MACHINE / UNIT

WILL BE INSTALLED CORRECTLY IN ORDER TO FULFILL THE

INTENDED APPLICATION AND AUTHORIZES OTHER QUALIFIED

USERS TO WORK WITH THE MACHINE / UNIT. HE IS ALSO

RESPONSIBLE TO INSTRUCT THE USERS OF THE MACHINE /

UNIT

Page 4

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

4

of

38

THE SERVICE ENGINEER IS EMPLOYED BY THE INTENDED USER

AND MAINTAINS THE MACHINE / UNIT DURING OPERATION.

HE IS A SKILLED CRAFTSMAN WITH MECHANICAL, ELECTRICAL

AND ELECTRONIC EDUCATION. THE SERVICE ENGINEER IS

RESPONSIBLE FOR THE INSTALLATION AND START-UP OF THE

MACHINE / UNIT AS WELL AS FOR THE MAINTENANCE AND

REPAIR OF THE MACHINE / UNIT. HE MUST BE TRAINED

ACCORDINGLY TO CARRY OUT ALL NECESSARY

MAINTENANCE WORK

ENSURE THAT ALL LEGAL AND ENVIRONMENTAL

REGULATIONS OF THE COUNTRY WHERE THE MACHINE / UNIT

WILL BE INSTALLED ARE FOLLOWED

DO NOT MODIFY THE MACHINE / UNIT WITHOUT A WRITTEN

CONFIRMATION BY KINEMATICA

IT IS STRICTLY FORBIDDEN TO RUN THE MACHINE / UNIT WITH

DISASSEMBLED OR BRIDGED SAFEGUARDS, FOR EXAMPLE

SAFETY LIMIT SWITCH, EMERGENCY SWITCH OR COVER

FOR REPAIRS, ONLY ORIGINAL SPARE PARTS SHOULD BE USED

BEFORE STARTING INSPECTION AND MAINTENANCE WORK

ON THE MACHINE / UNIT (SERVICE, REPAIR ETC.), ALL POWER

SUPPLIES MUST BE DISCONNECTED

THE DRIVE UNIT MAY ONLY BE OPENED BY AUTHORIZED

KINEMATICA SERVICE STATIONS

SERVICE AND MAINTENANCE SHALL ONLY BE PERFORMED BY

AUTHORIZED AND SKILLED SERVICE ENGINEERS

Page 5

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

5

of

38

AFTER EVERY INSPECTION AND MAINTENANCE WORK ON THE

MACHINE / UNIT (SERVICE, REPAIR ETC.), THE SERVICE

ENGINEER HAS TO DO A TEST-RUN

EAR PROTECTION SHOULD ALWAYS BE USED WHEN WORKING

IN THE ENVIRONMENT OF THE MACHINE

KEEP THIS OPERATING MANUAL NEARBY THE EQUIPMENT FOR

FUTURE REFERENCE

THIS DOCUMENT IS PART OF THE MACHINE / UNIT AND

SHOULD NOT BE REMOVED OR STORED ELSEWHERE

EASY ACCESS TO THE OPERATING AND MAINTENANCE CREW

MUST BE GRANTED AT ALL TIMES

ALTHOUGH MEGATRON UNITS ARE DESIGNED FOR EASY USE,

THIS DOES NOT RELEASE YOU FROM THE OBLIGATION TO

INSPECT YOUR EQUIPMENT CAREFULLY AND TO CLEAN IT

THOROUGHLY

Page 6

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

6

of

38

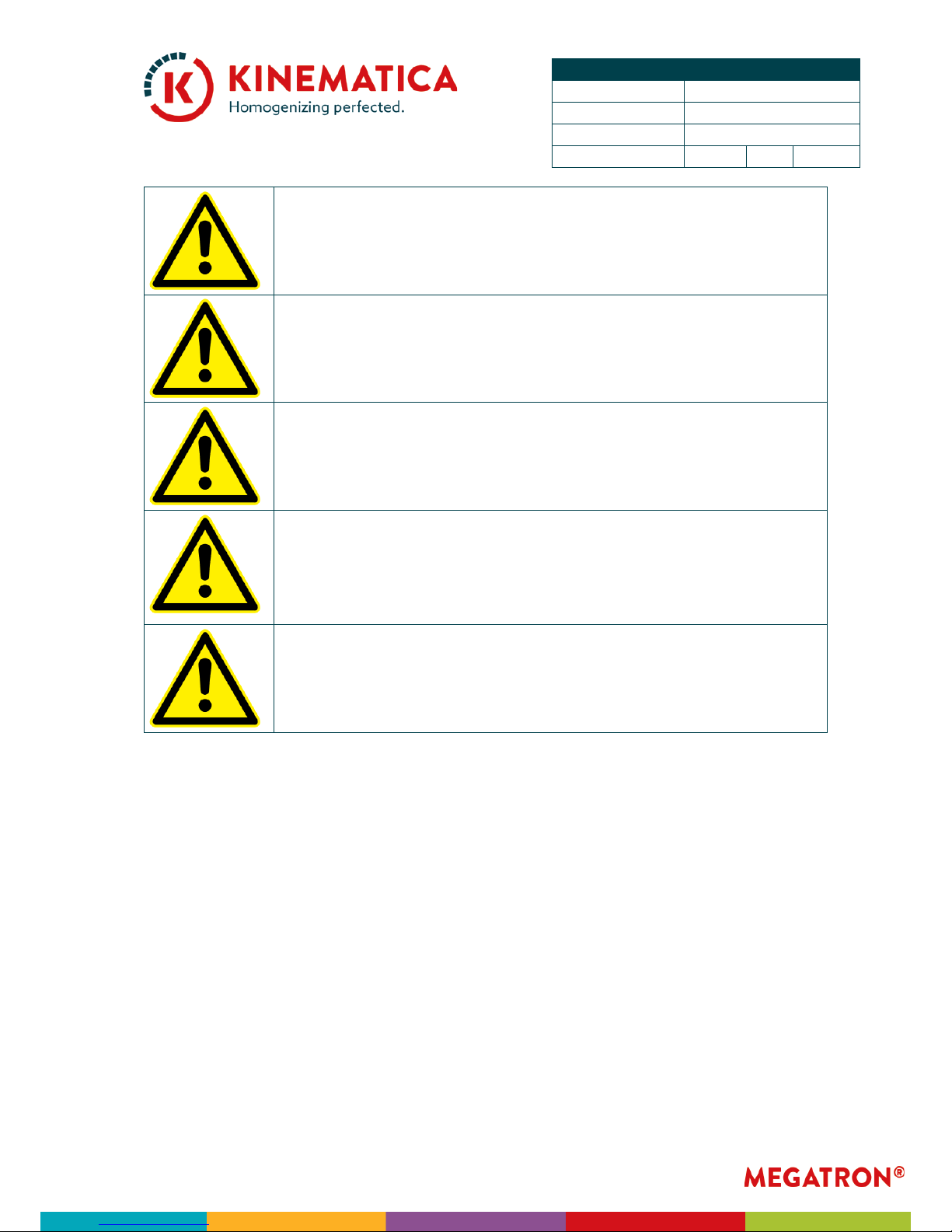

WARNINGS

ALL WARNINGS AND RECOMMENDATIONS IN THE FOLLOWING

CHAPTERS MUST BE RESPECTED

THE EQUIPMENT MAY NOT BE OPERATED IN EXPLOSIVE AREAS

IT IS NOT ALLOWED TO WORK WITH FLUIDS WHICH ARE

HIGHLY INFLAMMABLE

IT IS NOT ALLOWED TO MIX MATERIALS WHICH CAN CAUSE

STRONG EXOTHERMAL REACTIONS

THE ELECTRICAL INSTALLATION MUST BE DONE BY A

QUALIFIED ELECTRICIAN!

ENSURE THAT THE RATED VOLTAGE OF THE EQUIPMENT

MATCHES THE SUPPLY

IT IS IMPORTANT THAT THE MAINS SUPPLY WHERE THE DEVICE

IS PLUGGED IN COMPLIES WITH THE INFORMATION ON THE

TYPE LABEL AND THE INTERNATIONAL STANDARDS FOR

POWER SUPPLIES. IF NOT, SUCCESSFUL OPERATION CANNOT

BE GUARANTEED

ENSURE THAT ENOUGH FREE SPACE IS AVAILABLE AT THE

BACKSIDE OF DEVICE, SO THAT EFFECTIVE AIR FLOW AND

COOLING IS ASSURED – INSUFFICIENT COOLING MAY LEAD TO A

DECREASE OF POWER OUTPUT

THE DEVICE HAS TO BE PLACED IN A MANNER THAT DIRT OR

FLUIDS CANNOT PENETRATE THROUGH THE VENTILATION

SLOTS AT BACK SIDE OF THE DRIVE

Page 7

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

7

of

38

DIRECTION OF ROTATION IS COUNTER-CLOCKWISE SEEN FROM

FRONT ONTO THE COUPLING!

DRY-RUN OF MECHANICAL SEALS AND/OR SLIDE BEARINGS

MUST BE AVOIDED!

THE MECHANICAL SEAL MUST BE OPERATED WITH A SUITABLE

SEALANT LIQUID

THE QUENCH SYSTEM FOR THE MECHANICAL SEAL MUST BE

MONITORED BY THE INTENDED USER

THE INTENDED USER MUST ENSURE FLOW OF PRODUCT

THROUGH THE UNIT AT ALL TIMES

MEGATRON DISPERSION WORKING CHAMBERS MAY NOT BE

OPERATED DRY – THE MECHANICAL SEAL IS COOLED AND

LUBRICATED BY THE MEDIUM BEING PROCESSED AND THE

QUENCH MEDIUM. RUNNING DRY WILL DESTROY THE

MECHANICAL SEAL

Page 8

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

8

of

38

THE MAX. OPERATIONAL SPEED IS INDICATED ON THE DATA

PLATE

THE INTENDED USER HAS TO ENSURE THAT NO FOREIGN

PARTICLES WHICH MIGHT LEAD TO A DAMAGE CAN PASS

THROUGH THE UNIT

THE ASSEMBLY AND DISASSEMBLY PROCEDURE IS DESCRIBED IN

THIS MANUAL

THE UNIT IS ONLY ALLOWED TO BE OPERATED WHEN

ASSEMBLED COMPLETELY

NEVER PULL THE COUPLING DURING OPERATION – THE

WORKING CHAMBER COULD FALL OUT OF THE COUPLING

THE WORKING CHAMBERS SHOULD BE CLEANED AFTER EVERY

OPERATION

THE INTENDED USER HAS TO ENSURE THAT USED SOLVENTS

AND CLEANING MATERIALS ARE COMPATIBLE WITH THE

MATERIAL OF THE SEALS AND COMPONENTS OF THE UNIT

THE RESPONSIBILITY OF KEEPING THE OPERATING

PARAMATERS SUCH AS PRESSURE, TEMPERATURE AND

PRODUCT FLOW WITHIN THE SPECIFIED LIMITS LIES WITH THE

INTENDED USER

SHAFT SEALS ARE NOT ALLOWED TO BE SUBJECT TO PRESSURE

Page 9

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

9

of

38

IN THE EVENT THAT HAZARDOUS CHEMICALS OR MATERIALS

THAT ENDANGER HEALTH CAN INFLUENCE THE

SURROUNDINGS OR USE OF THE EQUIPMENT, APPROPRIATE

COUNTERMEASURES MUST BE TAKEN

WHEN HANDLING DANGEROUS PRODUCTS, TAKE CARE THAT

THE LOCAL SAFETY REGULATIONS ARE RESPECTED

AT LONG TERM USE, THE WORKING CHAMBER AND THE

BEARING HOUSING / COUPLING MAY GET HOT – DANGER OF

SKIN BURN

WHEN THE LINE CORD IS PLUGGED, NEVER TOUCH THE

COUPLING IN THE DRIVE – DANGER OF INJURIES DUE TO

ROTATING EDGES

IF THE MACHINE / UNIT IS USED FOR ANY OTHER PURPOSE

THAN THE INTENDED APPLICATION OR IF THE MACHINE / UNIT

WILL BE OPERATED BEYOND THE TECHNICAL DATA RANGE

WITHOUT THE WRITTEN APPROVAL BY KINEMATICA,

IMPROPER USE IS DECLARED AND KINEMATICA WILL TAKE NO

RESPONSIBILITY, NOR WILL GRANT ANY GUARANTEE

IMPROPER USE OF THE MACHINE / UNIT CAN RESULT IN

PERSONAL INJURY OR IN DAMAGE OF THE EQUIPMENT

KINEMATICA WILL NOT BE LIABLE AND WILL TAKE NO

RESPONSIBILITY IN SUCH AN EVENT

IF THE PROCESSED MEDIA TENDS TO HARDEN OR STICK IN

THE WORKING CHAMBER, THE PRODUCT HAS TO BE

REMOVED COMPLETELY FROM THE WORKING CHAMBER

PAY ATTENTION THAT THE TEMPERATURE DIFFERENCE

BETWEEN ACTUAL TEMPERATURE OF THE WORKING

CHAMBER AND CLEANING TEMPERATURE IS KEPT TO A

MINIMUM

Page 10

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

10

of

38

A TEMPERATURE SHOCK CAN DAMAGE STRUCTURAL

COMPONENTS

THE CLEANING LIQUID SHOULD BE COMPATIBLE WITH THE

PARTS WETTED BY THE PRODUCT

BEFORE CLEANING WITH SOLVENTS, CHECK THE

COMPATIBILITY BETWEEN THE SOLVENT AND THE MATERIAL

OF THE O-RINGS

ALL MAINTENANCE WORK HAS TO BE DONE BY

SPECIALISTS OR ENGINEERS

BEFORE STARTING THE DISASSEMBLY, ALL ELECTRICAL

PARTS HAVE TO BE DISCONNECTED

BE SURE THAT THE MOTOR CANNOT BE STARTED FROM

ANOTHER PERSON, WHILE YOU ARE WORKING

CRANES AND/OR LIFTING EQUIPMENT MUST BE USED TO

MOVE AND TRANSPORT HEAVY MACHINERY

Page 11

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

11

of

38

ALL PARTS HAVE TO BE INSPECTED FOR SIGNS OF WEAR AND

DAMAGE AND, IF NECESSARY, THEY HAVE TO BE REPLACED

BEFORE REASSEMBLY, ALL SCREWS HAVE TO BE GREASED

NEVER GREASE THE SEALING FACES OF THE MECHANICAL

SEALS

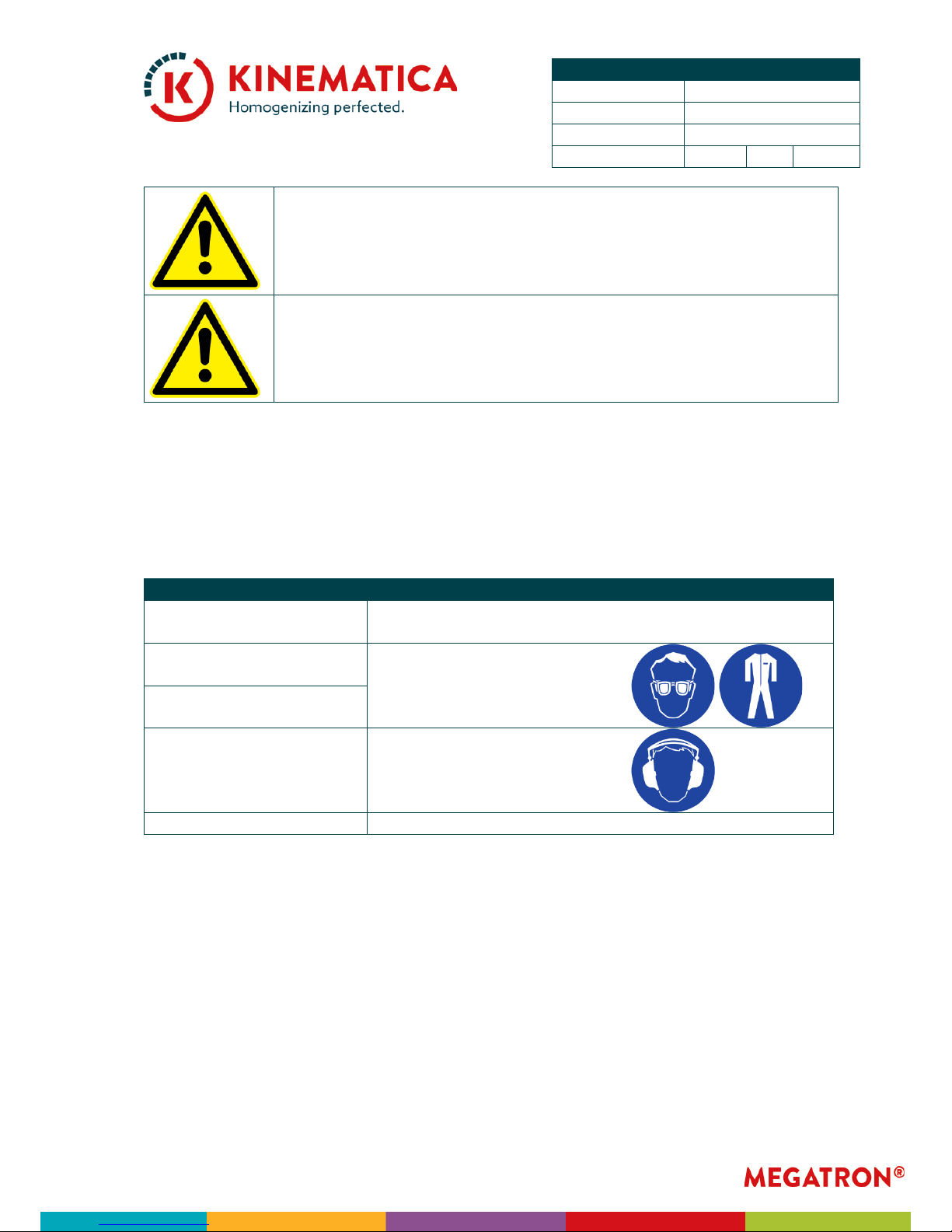

RESIDUAL DANGERS

When the system/equipment is used in accordance with rules and regulations, residual dangers are minimal.

Residual danger

Countermeasures

Tripping over feed or re-

turn lines

This should be laid appropriately

Breakage of glass contain-

ers

Wear protective clothing (gog-

gles etc.)

Splashing of the product

Hearing loss due to loud

noise

According to the application,

ear protection must be used

Tilting of the device

Use stable, non-slip base

Page 12

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

12

of

38

List of Content

1 INTRODUCTION ................................................................................................ 13

2 DESCRIPTION OF THE EQUIPMENT ................................................................... 14

2.1 DRIVE UNIT ........................................................................................................................ 15

2.2 WORKING

CHAMBER ......................................................................................................... 16

2.2.1

DISPERSING GENERATORS ................................................................................................ 17

2.2.2 MECHANICAL SEAL ............................................................................................................ 18

2.2.3 FITTINGS FOR PRODUCT INLET & OUTLET ......................................................................... 19

3 INSTALLATION AND START-UP ........................................................................ 20

3.1 INSTALLATION .................................................................................................................. 21

3.1.1

MECHANICAL INSTALLATION ............................................................................................ 21

3.1.2 ELECTRICAL INSTALLATION .............................................................................................. 22

3.2 START-UP ......................................................................................................................... 22

3.3 SHUT-DOWN .................................................................................................................... 25

3.4 CLEANING ......................................................................................................................... 26

4 MAINTENANCE WORK ...................................................................................... 27

4.1 MAINTENANCE AND INSPECTION PLAN ............................................................................ 27

4.2 DISASSEMBLY

AND ASSEMBLY OF STANDARD WORKING CHAMBER ................................. 28

4.2.1

REPLACEMENT OF THE MECHANICAL SEAL ....................................................................... 29

4.2.2 REPLACEMENT OF THE BALL BEARINGS ............................................................................ 30

4.2.3 REPLACEMENT OF THE SHAFT SEALING RING .................................................................... 30

4.2.4 RESTART OF THE SYSTEM AFTER MAINTENANCE .............................................................. 30

5 SPARE PARTS ..................................................................................................... 31

5.1 ORDERING OF SPARE PARTS ............................................................................................. 31

5.2 RECOMMENDED

SPARE PARTS .......................................................................................... 31

6 FAULTS AND REMEDIES ..................................................................................... 32

7 TECHNICAL DATA ............................................................................................. 33

7.1 DRIVE UNITS ...................................................................................................................... 33

7.2 WORKING

CHAMBERS ....................................................................................................... 34

7.3 QUENCH

SYSTEMS ............................................................................................................ 35

7.5 DISPERSING

GENERATORS ................................................................................................ 36

7.6 FITTINGS

FOR PRODUCT INLET & OUTLET ......................................................................... 37

8 WARRANTY ....................................................................................................... 38

Page 13

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

13

of

38

1 INTRODUCTION

KINEMATICA is a specialist for design and manufacturing of dispersing and mixing

machines. The aim of this document is to instruct new users in the effective and safe

utilization of our equipment.

The KINEMATICA Inline homogenizing system MEGATRON® MT 5100 S² has been

designed and manufactured according the CE guidelines, the actual technical

standards and applicable safety rules and is marked with the CE mark.

This document is valid for the KINEMATICA Inline homogenizing system

MEGATRON® MT 5100 S².

The system is designed and manufactured for the intended application consisting of:

• In-Line processing of flowable and pumpable products under the considera-

tions and limitations given in the “Technical Data”.

• The processed media must be compatible with all constructional parts wetted

by the product.

• If suitable precautions to personnel are taken to prevent any harm due to

noise emission.

• The use of the system with no structural, mechanical or electrical changes dif-

ferent from the original scope of supply.

Typical applications:

• Preparing emulsions

• Pharmaceutical or cosmetics products

• Suspending solids in liquids (such as liquid polymers)

• Dispersing fine solids in liquids or molten phases

• Suspending additives and solid polymers in mineral oils

• Extracting enzymes from biomass

• Extracting active ingredients and substances from plants, for example (when

used with REACTRON®)

• Grinding and shredding of solids and fibers in liquids or polymers

If the system is used for purposes different than or over and above the capabilities

specified herein, KINEMATICA does not guarantee proper function and assumes no

obligation or liability.

Should you have any questions which are not answered in this document, please

contact KINEMATICA.

Check on www.kinematica.ch for your closest contact address.

Page 14

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

14

of

38

2 DESCRIPTION OF THE EQUIPMENT

For a ready-to-use system you need:

• Drive unit MEGATRON® MT 5100 S²

• A working chamber MTO/MTK 5100 Q

• A recirculation system (can also be supplied by the customer)

Drive Unit

Working

Chamber

Example of a customized and

extended recirculation system

Page 15

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

15

of

38

2.1 DRIVE UNIT

The drive unit contains the powerful three-phase high frequency motor (with quick

coupling for the working chamber) controlled by the integrated VFD installed in a

stainless steel housing.

Main Switch

On/Off

Control panel

with Display

Quick coupling

for the working

chamber

Stop button

Start button

Speed Down

Speed Up

Enter Programming

Mode VFD

Speed

Display

Page 16

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

16

of

38

2.2 WORKING CHAMBER

The working chamber is a flow through in line chamber.

The working chamber consists of the following general parts:

• Bearing

• Mechanical sealing

• Inner chamber with dispersing generator and product inlet/outlet connections

• Cooling/Heating jacket if applicable

Product

Inlet

Product

Outlet

Cooling/Heating Jacket

(optional)

Dispersing

Generator

Coupling /

Bearing

Mechanical

Seal

Page 17

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

17

of

38

2.2.1 DISPERSING GENERATORS

A dispersing generator consists of a rotor and a stator. Rotor and stator consists of

one or more teeth rows each for different levels of fineness.

Turning with high speed, the rotor creates inside the stator high mechanical shear

forces and shear stress resulting in size reduction and turbulent mixing of the processed media.

The generators are exchangeable with different types for different particle sizes.

Please bear in mind due to operation the dispersing generator(s) belong to the wear

and tear parts.

Rotor

Stator

Teeth / Teeth

row(s)

Page 18

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

18

of

38

2.2.2 MECHANICAL SEAL

The product side of the working chamber (inner chamber with dispersing generator)

has to be separated from the non-product or atmospheric side of the working chamber. For that purpose, a single mechanical seal is installed inside the working chamber.

The type and material combination of the mechanical seal have been chosen for the

application described in the contract and should therefore not be used for other purposes without the permission of the manufacturer.

A mechanical seal is not allowed to run dry. Moreover, it has always to be lubricated,

flushed and cooled by a suitable sealing lubricant. The lubricant must also be compatible with the product and the materials of construction. The lubricant temperature has always to be 40°C below the boiling point to prevent any damages to the

sealing system.

In the case of a single mechanical seal, a pressureless quench liquid system (flow

through or pressureless tank) is used.

The standard working chambers for the MEGATRON® MT 5100 S² can be equipped

with a KINEMATICA quench system TS1 (also available with vessel made of PTFE)

Vessel Cover

Quench vessel

Standpipe

Quench outlet

Quench inlet

Page 19

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

19

of

38

IF YOU DO NOT USE A QUENCH SYSTEM TS1, YOU HAVE TO

CONNECT A FLOW-THROUGH, UNPRESSURIZED COOLING

LIQUID PIPING (E.G. TAP WATER) AND A FLOW RATE ≤ 1 L/MIN

2.2.3 FITTINGS FOR PRODUCT INLET & OUTLET

The standard inlet and outlet connections at the working chamber are inside thread

G1/2”.

Different standard fittings are available and can be screwed into the connections:

• Tri-Clamp ¾”

• Milk thread DN15

• Hose nipples DN15

G1/2”

G1/2”

Page 20

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

20

of

38

3 INSTALLATION AND START-UP

The drive unit MEGATRON® MT 5100 S² will be delivered completely assembled and

the package will include:

• Drive unit

• Mains cable

• Manual

The working chamber will be delivered completely assembled and the package will

include:

• Working Chamber (as ordered, optional)

• Dispersing Generator (as ordered, optional)

• Quench System (as ordered, optional)

• Product inlet & outlet fittings (as ordered, optional)

• Cooling/heating jacket (as ordered, optional)

Other accessories or equipment will be packed separately and delivered as ordered.

Always check the delivery note and check immediately when unpacking the unit. Always report immediately any irregularities.

Page 21

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

21

of

38

3.1 INSTALLATION

3.1.1 MECHANICAL INSTALLATION

• The MEGATRON

®

has to be positioned on an even surface or foundation. Ensure that no vibrations can be transmitted onto the MEGATRON®. Please

check if there is a sufficient air circulation.

• The working chamber has to be connected to the drive unit by using the quick

coupling. Simply push back the slide ring of the quick coupling, fit the working

chamber into the coupling and release the slide ring again.

Page 22

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

22

of

38

• Check that the quick coupling has secured the working chamber against turn-

ing and/or removing.

• To remove the working chamber from the drive unit, simply push back the

slide ring of the quick coupling and carefully remove the working chamber

from the coupling.

• Connect product inlet and outlet lines and necessary supply lines (e.g. cooling

water, sealing liquid…). A seal should always be used to avoid leakages. The

piping should not generate any forces (stresses, vibrations) on the working

chamber nozzles.

3.1.2 ELECTRICAL INSTALLATION

• Before connecting the electrical power supply using the mains cable, check

the “Technical Data” as well as the data on the drive tag plate.

3.2 START-UP

• Check if all connections, piping and supply lines are tight and mounted cor-

rectly.

• Remove the cover of the quench vessel and fill up the quench system with

the sealing liquid.

• The sealing liquid has to be compatible with the product, the seals and the

mechanical seal. The sealing liquid is not within the scope of supply of

KINEMATICA.

• Use enough sealing liquid so that the standpipe is always covered. Otherwise

the mechanical seal will be damaged.

• Check that the filling level remains constant.

Covered

height

Page 23

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

23

of

38

• Open the inlet and outlet product circuits.

• Check all connections, piping and supply lines for signs of leakage.

• The piping containing the product to be processed must be free of air pockets

and air enclosures.

• For starting the MEGATRON

®

, push the On/Off button.

• In ON position, the main switch will light up and the speed display will show

“Stop”. The system is ready to start.

Page 24

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

24

of

38

• Then push the green RUN “I” button in order to start the unit. The unit will in-

crease the speed to the last set speed.

• Use the Up/Down buttons to increase or decrease the speed.

• The unit will increase/decrease the speed to the new set speed.

INFO: It is also possible to set first the desired speed level with the Up/Down buttons and then starting the unit with the green RUN “I” button.

Speed indication

Page 25

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

25

of

38

3.3 SHUT-DOWN

• Use the Down buttons to decrease the speed to “0”.

• Push the red STOP “O” button to stop the unit.

INFO: It is also possible to push the red STOP “O” button to stop the unit without

decreasing the speed first. When pushing the green RUN “I” button again, the unit

will increase again to the last set speed.

Page 26

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

26

of

38

• Push the On/Off button. In OFF position, the light of the main switch and

speed display will vanish and the system will shut down.

• Finally, close the inlet and outlet circuits if applicable

3.4 CLEANING

• If the processed media tends to harden or stick, the product has to be re-

moved completely from the working chamber after every use.

• If the machine is not operated for a longer time or before any maintenance

work is carried out, the working chamber has to be cleaned.

• There are different methods to clean the working chamber, depending on the

customer’s facilities:

o The product can be pushed out under pressure; do not use higher pres-

sure than the normal working pressure to avoid damage to the mechanical seal and preventing product from entering the bearing area;

o Or the working chamber can be disassembled.

Page 27

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

27

of

38

4 MAINTENANCE WORK

• The MEGATRON

®

MT 5100 S² drive unit is designed to be almost maintenance-free. Nevertheless to guarantee a long lifetime the unit should always

be used with care.

• The attached working chamber contains several wear parts which have to be

checked and/or exchanged regularly depending on the use of the unit, mainly:

o Ball bearings

o Mechanical Seal, Shaft Seal

o O-Rings

o Dispersing Generator

• Keeping these wear parts as spare parts on site is mandatory to avoid longer

interruptions during maintenance and service – see also chapter “spare parts”.

• Before any maintenance work the working chamber of the MEGATRON

®

has

to be rinsed out, emptied completely and cleaned.

4.1 MAINTENANCE AND INSPECTION PLAN

The MEGATRON® has to be inspected regularly in order to assure an optimum and

safe operation.

DAILY INSPECTION WORK

If one of the following irregularities is found during inspection, the machine has to be

stopped immediately and repaired:

• Leakage of the sealant fluid out of the opening in the mechanical seal housing

• Leakage of the whole piping system

• Overheated bearing housing

• Noise level too high or unusual noises

• Foreign body in the working chamber

YEARLY INSPECTION WORK OR EVERY 3000 RUNNING HOURS

• Signs of wear of the generator, deformation of the generator,

• Phenomena of wear and damages on the mechanical seal

• Replacing the ball bearings

Page 28

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

28

of

38

4.2 DISASSEMBLY AND ASSEMBLY OF STANDARD WORKING CHAMBER

This procedure is valid for the working chamber MTO 5100 Q (23005017).

Before demounting, please drain the working chamber completely and remove the

quench connections.

• Remove the inlet and outlet connections.

• Unfasten the screws (24) and remove cover (4).

• Remove stator (9) carefully out of the working chamber.

• Fix the shaft (7) using a bolt (max. Ø5mm) and unfasten the rotor (10) using the

disassembly tool. The rotating ring of the mechanical seal (26) will come off

with the rotor.

• Unfasten the screws (25) and remove the chamber (6). The static ring of the

mechanical seal (26) will come off with the chamber.

• Unfasten the screws (23) and remove the seal housing (2). Take care of the

shaft seal (31) and the spring of the mechanical seal (26).

• Fix the shaft (7) and unfasten the crown coupling (8).

Page 29

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

29

of

38

• Push the shaft (7) with ball bearings (19, 18) out of the bearing housing (1) into

direction of the generator.

• If necessary, remove the locking ring (21) and the compensation disc (22) from

the bearing housing (1).

• Remove the locking ring (20) and pull off the ball bearings (18, 19) from the

shaft.

• Mount the new ball bearings on the shaft and dispose the used ones (do not re-

install pulled off ball bearings).

4.2.1 REPLACEMENT OF THE MECHANICAL SEAL

When mounting the mechanical seal (26), assure that the spring is in the correct position. Assure that the slide areas of the mechanical seal are clean and do not contain

any hard solid particles – solid particles in the slide areas may cause break down of

the mechanical seal.

Mechanical seals always have to be replaced as a complete set. Replacing just the

static or the rotating face of the mechanical seal leads to strong and fast wear of the

sliding faces.

Static Ring of the

mechanical seal

Rotating Ring of the

mechanical seal

Page 30

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

30

of

38

PROTECT THE MECHANICAL SEAL AGAINST STROKES AND

POKES, IT CAN BE DAMAGED EASILY

NEVER GREASE THE SLIDE SURFACES AND ROTATING RINGS.

WHEN REPLACING THE MECHANICAL SEAL, DO NOT REPLACE

SINGLE PARTS. WE RECOMMEND TO TAKE A WHOLE NEW

SPARE MECHANICAL SEAL AND SEND THE DAMAGED ONE

BACK TO THE NEAREST KINEMATICA REPRESENTATIVE

4.2.2 REPLACEMENT OF THE BALL BEARINGS

To put on new ball bearings (18,19) on the shaft, they must be heat up to 120 °C (not

more than 130°C). Heated ball bearings can then be mounted on the shaft without

strong effort.

4.2.3 REPLACEMENT OF THE SHAFT SEALING RING

Grease the shaft sealing ring (31) before mounting it. Assure that the grease is in

compliance with your application and product. When using EPDM sealings, never

use grease based on mineral oil.

4.2.4 RESTART OF THE SYSTEM AFTER MAINTENANCE

The assembly of the working chamber has to be done in reverse order. Before starting up with real product, please assure the correct function of the system using water.

Page 31

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

31

of

38

5 SPARE PARTS

Only original KINEMATICA spare parts will guarantee a trouble free operation of the

machine.

See also the “Technical Data Sheet” and the referenced documentation, drawings

and parts lists.

5.1 ORDERING OF SPARE PARTS

when ordering spare parts, please indicate:

1. Type of machine (e.g. MEGATRON® MT 5100 S²)

2. Serial-No. indicated on the machine data plate (e.g. 823-0017-01-02)

3. Position, description and ident number according to the Parts List (e.g. Pos. 1,

Shaft, 9750001)

5.2 RECOMMENDED SPARE PARTS

To avoid any inconvenience or time delays when handling service or repair cases, it is

strongly recommended to hold on stock some main and/or critical components like:

• Mechanical seal

• Ball bearings

• O-Rings

• Shaft

• Dispersing Generator(s)

Please bear in mind that some components have lead times of several weeks.

Do not hesitate to contact KINEMATICA for a corresponding quotation or advise.

Page 32

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

32

of

38

6 FAULTS AND REMEDIES

Fault

Possible causes

Remedy

Noise in the bearing

housing

Dusty, dirty or damaged

bearings

Replace the bearings

Rattle noise

Foreign body in working

chamber

Remove foreign body

Vibrations

Twisted shaft Replace the shaft

Faulty bearings Replace the bearings

Foreign body in working

chamber

Remove foreign body

Rotational speed exceeded Reduce the speed

Bearing housing hot

Faulty bearing housing Replace bearing housing

Damaged bearings Replace bearings

Wrong grease Use specified grease

Rotational speed exceeded Reduce the speed

Leakage of sealing liquid Mechanical seal damaged Replace mechanical seal

No throughput of product

Air in working chamber

Remove air out of product line

Viscosity of product too

high

Install a feed pump in

front of the

MEGATRON

®

Display shows “CL”

Current Limit reached, Motor overload

Verify drive/motor are

proper size for application

Display shows “FCL”

Fast Current Limit, Overload

Verify drive/motor are

proper size for application

Page 33

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

33

of

38

7 TECHNICAL DATA

7.1 DRIVE UNITS

Description

Drive Unit MEGATRON® MT 5100 S²

Order Code

23005060

23005061

23005062

23005063

Plug type

CH

EU

UK

US

motor type

AC motor 3-phase, gearfree direct drive

supply voltage

1-phase, 230 V ~

supply frequency

50/60 Hz

max. speed 21’000 rpm

input power

Max. 2’000 W

output power

Max. 1’500 W

soft-start

Yes

noise emission (drive

only)

Lower than 62 dB(A)

direction of rotation

Counter clockwise, seen from front

ambient temperature

0 – 40°C

relative humidity

80% max. non-condensing

standards

Manufactured according to EN / IEC regulations for

EMC & SAFETY

protection type

IP 20

max. period of continuous

operation

100 %

Coupling type

F

weight (drive only)

Approx. 21.2 kg

324 mm

322 mm

255 mm

Page 34

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

34

of

38

7.2 WORKING CHAMBERS

Description

MTO 5100 Q

MTK 5100 Q

Order Code

23005017

23005010

Stages

1 (for one dispersing generator)

Cooling / Heating

jacket

No Yes, connections 2xG1/8”

Max. speed

21’000 rpm

Working

Temperature

max. 90°C

Working pressure

max. 6 bar(g)

Differential pres-

sure

max. 2 bar(g) between product inlet-outlet

Working pressure

jacket

N/A Max. 4 bar (g)

Mechanical Seal

Type 2031-012 QBV-G

Q=Silicon-Carbide / B=Carbon / V=Viton /G=Stainless Steel

Quench connec-

tions

Yes, G1/8”

Quench pressure

Pressureless (continuous or with quench vessel)

Materials wetted

by the product

Stainless steel 316 L

O-Rings/Gaskets made from Viton

Surface finish

Electropolished

Surface roughness

Product wetted parts Ra ≤ 1.6 µm

Product requirements

The product must be pumpable and must not contain solid particles

that may destroy the mechanical seal

Product

Viscosity

Depending on the temperature, pressure and products properties,

the dynamic viscosity should not exceed:

Approx. 500 mPas

CIP

No

SIP

No

Autoclavable

No

Weight

Approx. 3.0 kg

Other versions incl. autoclavable design available on request.

Page 35

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

35

of

38

7.3 QUENCH SYSTEMS

Description

TS1 (Standard)

TS1 PTFE

Order Code

23005020

23005021

Volume

Approx. 350 ml

Materials

Acryl, PU, SS, Viton

PTFE, Teflon, SS, EPDM

Autoclavable

No

Yes

Page 36

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

36

of

38

7.5 DISPERSING GENERATORS

Dispersing generators MTG ../. X

Order code

23005011

23005012 23005013

2300501

4

23005015

23005016

2300501

8

2300502

5

Type

MTG

30/2 M

MTG

30/4 F

MTG

40/2 G

MTG

40/4 M

MTG

40/6 F

MTG

40/6 FV

MTG

40/6 FF

MTG

40/6 FFV

Rotor Ø

29 mm

31 mm

37 mm

39 mm

41 mm

41 mm

41 mm

41 mm

Stator Ø

37 mm

37 mm

46 mm

46 mm

46 mm

46 mm

46 mm

46 mm

Max. speed

21’000

rpm

21’000

rpm

18’000

rpm

18’000

rpm

17’000

rpm

16’000

rpm

16’000

rpm

16’000 rpm

Max. flow

[l/min]

50 40 60 50 45 45 45 45

Materials

Stainless steel 316 L

Surface fin-

ish

Electropolished

Surface

roughness

Ra 1.6 µm

Cleaning

Sterilizable and autoclavable at all common methods

Page 37

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

37

of

38

7.6 FITTINGS FOR PRODUCT INLET & OUTLET

Description

Order no.

Hose nipple DN15

(set of 2)

23005022

Milk thread DN 15

according to DIN

11851

(set of 2)

23005023

Tri-Clamp ¾”

(set of 2)

23005024

Page 38

INSTRUCTION MANUAL

System

MEGATRON®

Type

MT 5100 S

2

Issue

3.0 / 01.07.2018

Page

38

of

38

8 WARRANTY

This KINEMATICA unit is warranted to be free from defects in material and workmanship without wear and tear parts for a period of 24 months.

KINEMATICA will repair or replace and return free of charge any part which is returned to its factory within said period, transportation prepaid by the user and which

is found upon inspection to have been defective in materials or workmanship. The

warranty includes both, parts and service, without charge.

This warranty does not include normal wear from use; it does not apply to any instrument or part which has been altered by anyone other than an employee, which

has been damaged through accident, negligence, failure to follow operating instructions, the use of electric currents or circuits other than those specified in this manual, misuse or abuse.

KINEMATICA reserves the right to change, alter, modify or improve any of its instruments without obligation to make corresponding changes to any instrument previously sold or shipped.

The foregoing obligations are in lieu of all other obligations and liabilities including

negligence and all warranties, of merchantability or otherwise, expressed or implied

in fact or by law and state our entire and exclusive liability and buyer's exclusive remedy for any claim of damages in connection with the sale or furnishing of goods or

parts.

KINEMATICA will in no event be liable for any special or consequential damages

whatsoever and their liability under no circumstances will exceed the contract price

for the goods for which liability is claimed.

Made in Switzerland by

KINEMATICA AG

Luzernerstrasse 147a

CH-6014 Littau / Lucerne

Tel.: +41-41-259 65 65

Fax: +41-41-259 65 75

e-Mail: info@kinematica.ch

Loading...

Loading...