Kinder Nevada Powerflue KCPC00MN Installation & Maintenance Instructions Manual

Nevada Powerflue

DECORATIVE FUEL EFFECT POWERFLUE GAS

FIRE

Installation & Maintenance Instructions

Hand these instructions to the user

Model No. KCPC00MN is for use on Natural Gas (G20) at a supply

pressure of 20 mbar in G.B. / I.E.

CONTENTS

Section 1

1.0 Appliance Information 3

1.1 Conditions of Installation 4

1.2 Flue Terminal Position 5

1.3 Fireplace / surround suitability 6

1.4 Fire place opening / catchment space 6

1.5 Shelf Position 6

1.6 Installation Types 7-9

1.7 Hearths 9

1.8 Spillage Monitoring System 9

Section 2 Installation of Fire

2.1 Unpacking the fire 10

2.2 Marking the Flue Pipe Opening 10

2.3 Marking the Fan Unit Recess on the Outer Wall 11-17

2.4 Making the Electrical Connections 18

2.5 Gas tightness and Inlet pressure 19

Section 3 Assembling Fuel Bed and Commissioning

3.1 Assembling the ceramics and fuel bed 20-24

3.2 Lighting the appliance 25

3.3 Checking for clearance of combustion 26

Information and Requirements

& Fitting the fire box

products

PAGE

Section 4 Maintenance

4.1 Removal of the Burner Assembly 27

4.2 Removal of the Piezo Igniter 27

4.3 Removal of the Control Tap 28

4.4 Removal of the Thermocouple 28

4.5 Removal of the Solenoid 28-29

Spare Parts Shortlist

This appliance is manufactured by :CFM Europe Ltd.

Trentham Lakes,

Stoke-on-Trent,

ST4 4TJ

2

29

SECTION 1

INFORMATION AND REQUIREMENTS

1.0 APPLIANCE INFORMATION

Model KCPC00MN

Gas Type G20

Main injectors (2 off) Size 235

Pilot Type S.I.T. Oxystop NG 9022

Max. Gross Heat Input : 6.5 kW

Min. Gross Heat Input : 4.2 kW

Cold Pressure : 20.0 +/-1.0 mbar

Ignition : Push-button Piezo

Supply Voltage : 230V a.c.

Supply Frequency : 50 Hz

Supply Fuse : 3Amp (Fixed Fused Spur) to BS 1362

IP Rating : IP 44

Electrode Spark Gap : 4.0mm

Packed Weight : 12 kg

Fan Unit Packed Weight : 15 kg

Fire box Dimensions (with trim’s fitted)

Nevada Models

Width : (with standard trim, no spacer) 470mm

Height : (with standard trim, no spacer) 586mm

Depth : (overall-without fender) 155mm

Depth : (overall-with spacer fitted) 105mm

Gas Connection :

8mm Compression

3

(Supplied with fire)

INSTALLATION REQUIREMENTS

1.1 CONDITIONS OF INSTALLATION

It is the law that all gas appliances are installed only by a CORGI Registered

Installer

(Installation and Use) Regulations 1998 as amended. Failure to install appliances

correctly could lead to prosecution. It is in your own interest and that of safety to

comply with the law.

The installation must also be in accordance with all relevant parts of the Local and

National Building Regulations where appropriate, the Building Regulations

(Scotland Consolidation) issued by the Scottish Development Department, and all

applicable requirements of the following British Standard Code of Practice.

1. B.S. 5871 Part 3 Installation of Decorative Fuel Effect Gas Fires

2. B.S. 6891 Installation of Gas Pipework

3. B.S. 5440 Parts 1 & 2 Installation of Flues and V

4. B.S. 1251 Open fire place components

5. B.S. 6461 Part 1 Installation of Chimneys and flues

6. I.S. 813 : 1996 Domestic Gas Installation (Republic of Ireland)

No purpose made additional ventilation is normally required for this

appliance, when installed in G.B. When Installing in I.E. please consult

document I.S. 813 : 1996 Domestic Gas Installation, which is issued by the

National Standards Authority of Ireland. If installing in Northern Ireland,

please consult local building regulations. Any purpose made ventilation

must be checked periodically to ensure that it is free from obstruction.

, in accordance with these installation instructions and the Gas Safety

entilation

4

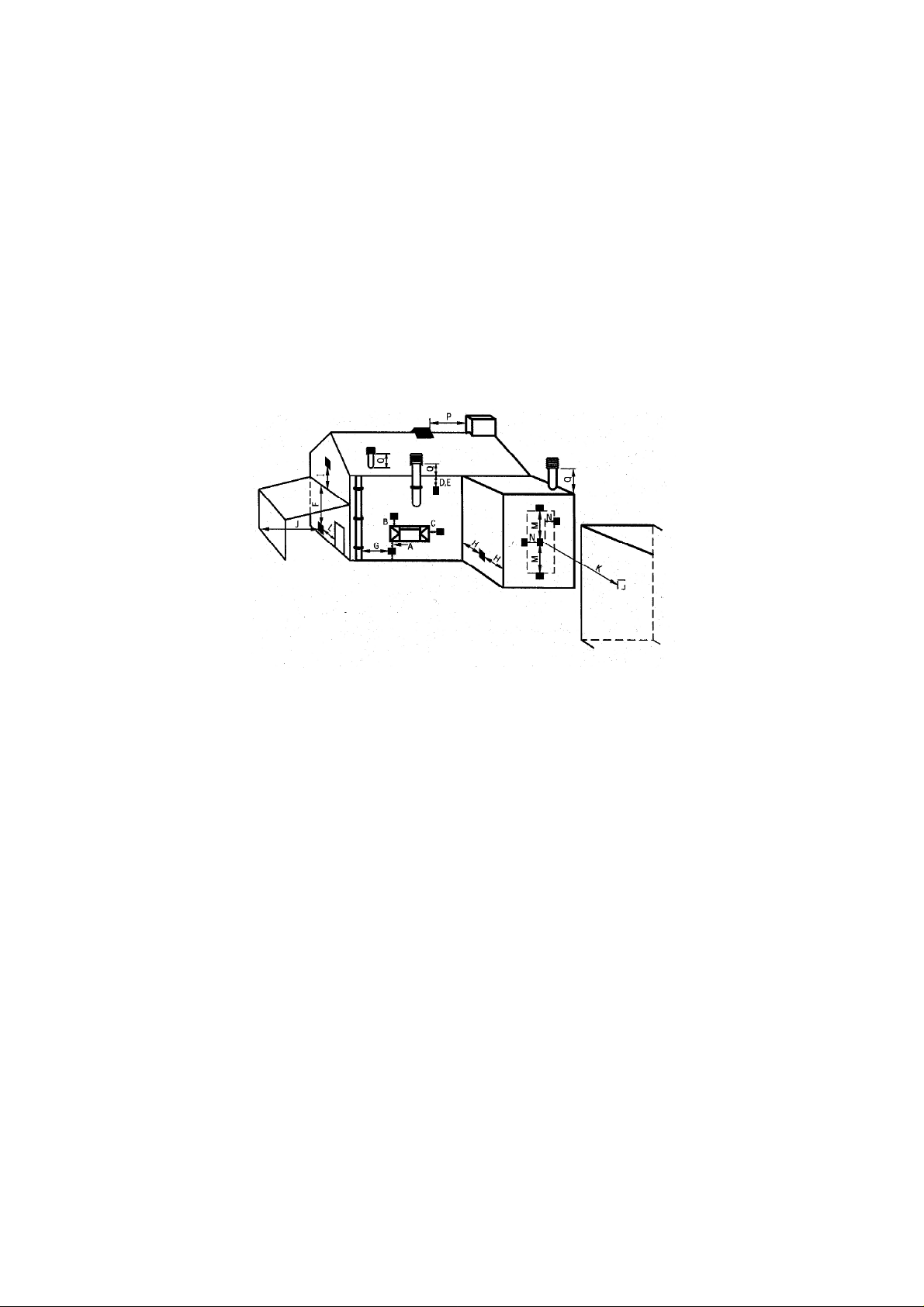

1.2 FLUE TERMINAL POSITION

The minimum acceptable dimensions from the flue terminal to obstructions and

ventilation openings are shown below in fig. 1 and listed in the table (fig. 2 below)

IT IS IMPORTANT THAT THE POSITION OF THE FLUE ALLOWS THE FREE

PASSAGE OF AIR ACROSS IT AT ALL TIMES.

Fig. 1

Fig. 2

DIMENSION TERMINAL POSITION MINIMUM DIMENSION

A Directly below an opening, air brick, 300mm (12 in.)

opening window

B Above an opening, air brick, 300mm (12 in.)

opening window

C Horizontally to an opening, air brick, 300mm (12 in.)

opening window etc.

D Below gutters, soil pipes or drain pipes 75mm (3 in.)

E Below eaves 200mm (8 in.)

F Below balconies or car port roof 200mm (8 in.)

G From a vertical drain pipe or soil pipe 150mm (6 in.)

H From an internal or external corner 200mm (8 in.)

I Above ground roof or balcony level 300mm (12 in.)

J From a surface facing the terminal 600mm (24 in.)

K From a terminal facing the terminal 1200m (48 in.)

L From an opening in the car port 1200m (48 in.)

M Vertically from a terminal on the same wall 1500mm (59 in.)

N Horizontally from a terminal on the 300mm (12 in.)

same Wall

O From the wall on which the terminal is mounted 50mm (2 in.)

P From a vertical structure on the roof N/A

Q Above intersection with roof 150mm

5

1.3 FIREPLACE / SURROUND SUITABILITY

The fire must only be installed on a hearth it must not be installed directly onto

carpet or other combustible floor materials.

The fire is suitable for fitting to

non-combustible fire place surrounds and proprietary fire place surrounds with a

temperature rating of at least 150oc. If a heating appliance is fitted directly against

a wall without the use of a fire surround or fire place all combustible material must

be removed from behind the trim. Soft wall coverings such as blown vinyl, wall

paper etc. could be affected by the rising hot air and scorching and/or discoloration

may result. Due consideration should be made to this when installing or

decorating.

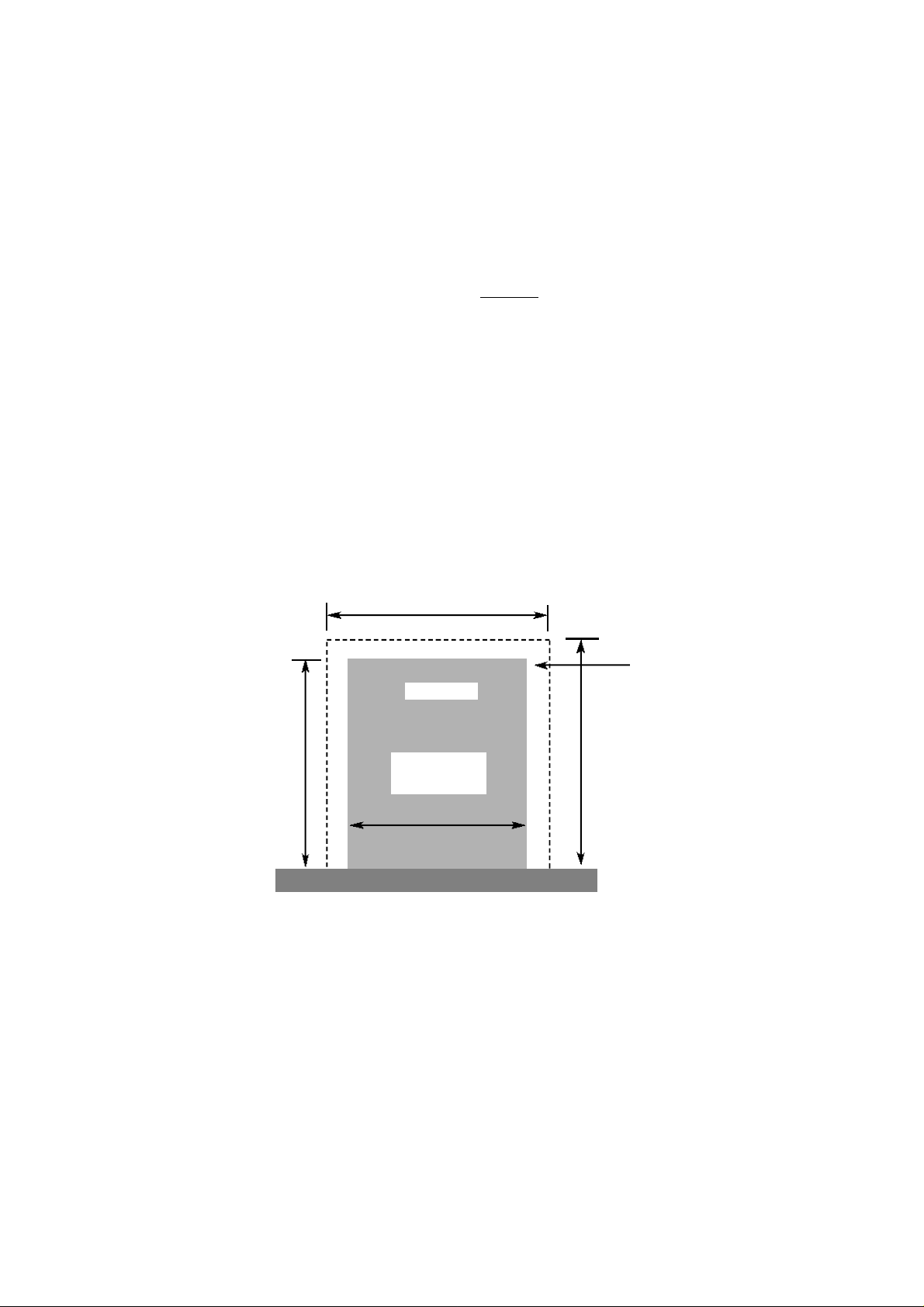

1.4 FIRE PLACE OPENING

The front opening of the fire place must be between 330 and 430 mm wide, and

between 550 and 565mm high. If the opening exceeds these dimensions then a

surround must be constructed from suitable non-combustible material to produce a

correct size opening. Any surround must be suitably sealed to the fire place to

prevent leakage. See below in fig.3

520mm Minimum

Fig. 3

Minimum Flat

Sealing Area

Fire Opening

550mm Minimum

565mm Maximum

330mm Minimum

430mm Maximum

610mm Minimum

1.5 SHELF POSITION

The fire may be fitted below a combustible shelf providing there is a minimum

distance of 200mm above the top of the fire and the shelf does not project more

than 150mm. If the shelf overhangs more than 150mm the distance between the

fire and the shelf must be increased by 15mm for every 25mm of additional

overhang over 150mm.

6

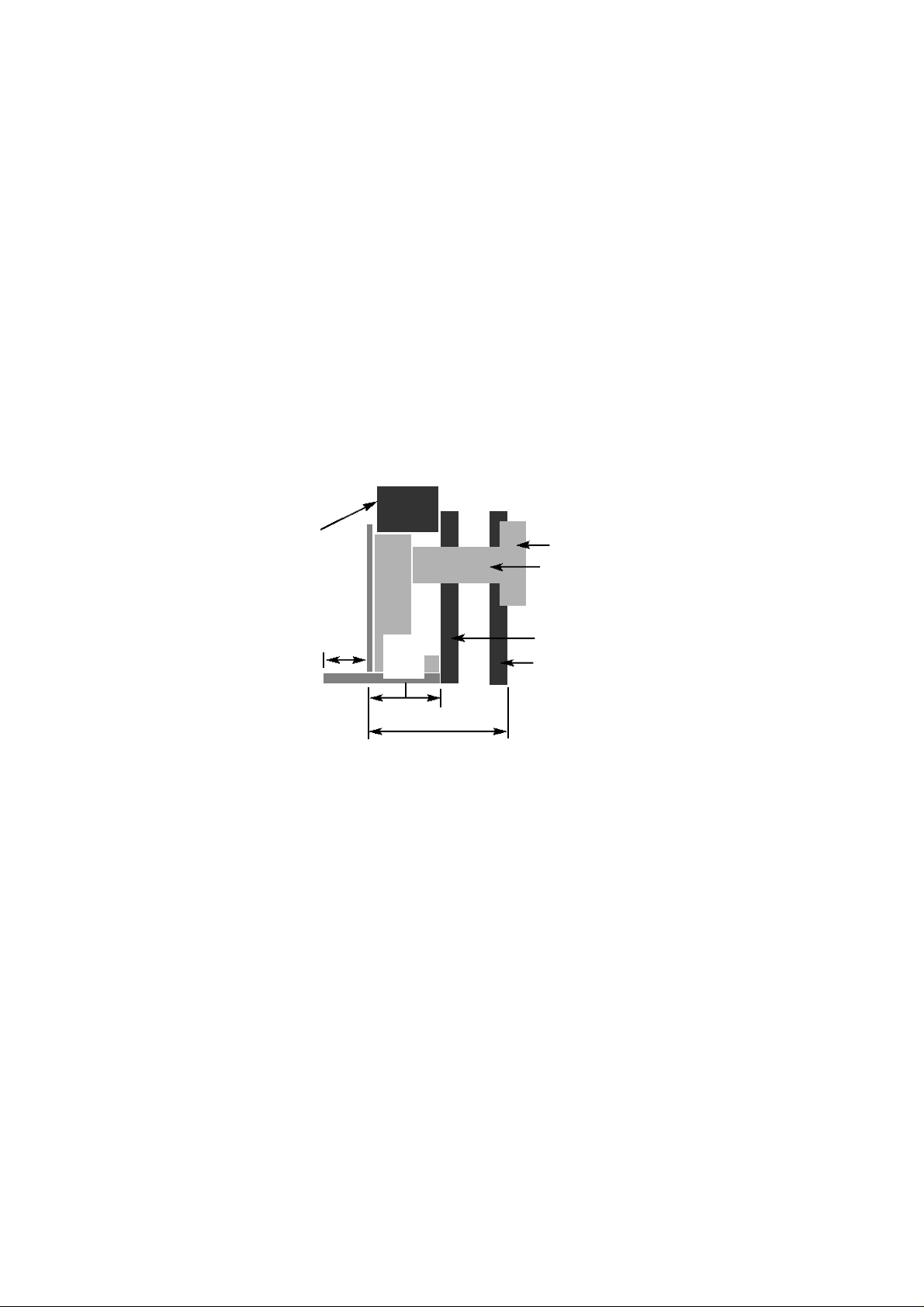

1.6 INSTALLATION TYPES

This fire can be fitted against an outside facing facing flat wall surface or into a

fireplace opening cut into the wall.

When fitting the fire in front of the inner cavity wall

, the distance between the

mounting face of the fire and the rear face of the firebox must be a minimum of

170mm, a false chimney breast or fireplace surround should be constructed.

The

firebox must then be secured into the fireplace using the method described in

section 2. Any combustible material must be removed from the the area around

the firebox flange. In all installations, ensure that there is no structural damage to

the property or the damp course. See fig. 4 below

Fig. 4

False Chimney

Breast / Fireplace

Minimum Hearth

Forward Projection

300mm

155mm

All

Models

550mm Maximum

Fan Unit

Flue Pipe

Inner Cavity Wall

Outer Cavity Wall

When fitting the fire into a cavity wall, this requires the opening of the inner leaf

of brickwork, to recess the firebox into. The opening needs to be sufficient to

accomodate the firebox. T

o support the wall above the hole, a suitable lintel must

be inserted across the top of the opening. If fitting the appliance into a cavity wall,

a lintel 750mm long having a thickness of 75mm with a height of the inner wall

should be used.

The lintel could be either pre-cast concrete or steel - Catnic

CN52 or CN 46 could be used, depending upon the inner wall thickness. Before

proceeding with the installation of the fire, an assessment of the area immediately

above the fire is required, see Fig. 5 overpage. If there is no existing openings

within either triangle, proceed with forming the opening. However, if opening or

beams occur within either triangle, then you should seek specialist advice from a

structural engineer or consider relocating the proposed position of the firebox.

7

Fig. 5

400mm interactive

area

600mm load

triangle

The Interactive Zone Openings, beams or joists within

this area need to be assessed.

Load triangle - No beam or

opening permissible within this

area

Lintel

e.g. 750mm x 75mm

Opening Height

550mm Minimum

565mm Maximum

50mm Minimum Hearth Thickness

Firebox recess in

wall

Opening Width

330mm Minimum

430mm Maximum

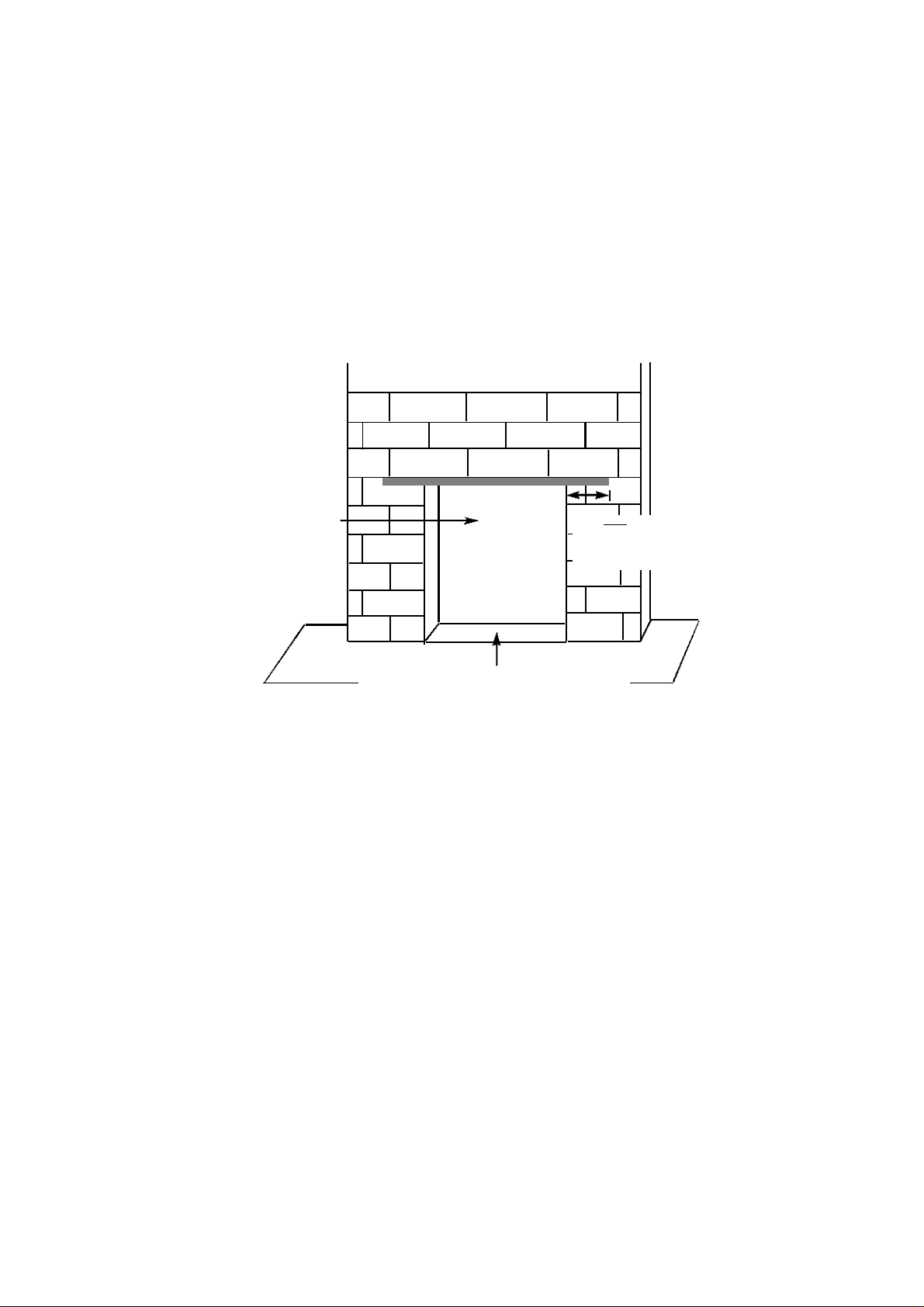

To proceed with the installation when the above stated criteria have been

satisfied :-

Mark out where possible, centrally beneath a block joint where the lintel is to be

fitted. Unless lime mortar has been used it will be necessary to drill four holes

with a masonary drill, then use a mechanical cutter such as a “shark saw” to cut

out the correct size of slot in the inner leaf of brickwork for the lintel you have

chosen to install. See fig. 6 below.

Fig. 6

Fit the lintel, ensure that it is bedded on mortar. Do not bed on a dry bed.

Then remove all debris from the cavity and construct the opening to the minimum /

maximum opening sizes as shown overpage (fig. 7) and in section 1.4, (fig. 3)

8

Remove any combustible material from within the area of the opening. No

combustible material can be allowed to come into contact with any area of the

appliance.

Fig. 7

Opening Sizes Width :330mm Minimum

430mm Maximum

Opening sizes Height :550mm Minimum

565mm Maximum

Ensure that the recess that is cut is to the required

dimensions and is screed level so that the firebox will

sit level within the recess.

Lintel must project

Minimum of 150mm

each side of the

opening

1.7 HEARTHS

This appliance must only be installed on to a concrete or non-combustible hearth.

The hearth material must be a minimum thickness of 12mm with the top surface at

least 50mm above the floor.

The hearth must be fitted symmetrically about the fire

opening and have a minimum width of 760mm and a minimum projection of

300mm forwards from the fire opening.

1.8 SPILLAGE MONITORING SYSTEM

This appliance is fitted with an atmosphere sensing spillage monitoring system in

the form of an oxygen sensing burner. This is designed to shut the fire off in the

event of a partial or complete blockage of the flue causing a build up of

combustion products in the room in which the fire is operated. The following are

important warnings relating to this spillage monitoring system

1)

The spillage monitoring system must not be adjusted by the installer

:-

.

2) The spillage monitoring system must not be put out of operation.

3) When the spillage monitoring system is exchanged only a complete original

manufacturers part may be fitted.

9

Loading...

Loading...