Page 1

Limours

Balanced Flue Room Heater

MODEL NUMBER : KBFP00RN

INSTALLATION, USER AND SERVICING INSTRUCTIONS

THESE INSTRUCTIONS MUST REMAIN WITH THE USER

This appliance is suitable for use on Natural Gas (G20) at a supply pressure of

20mbar in G.B. / I.E. only.

0087

Page 2

2

THIS APPLIANCE MEETS THE REQUIREMENTS OF THE EUROPEAN GAS DIRECTIVE

Contents

Page No.

List of components 3

Appliance Data 3

GENERAL INSTALLATION REQUIREMENTS

Fitting the Appliance 3

Placing of Decorative Refractory Shapes 9

COMMISSIONING

USERS GUIDE

Useful tips & recommendations 11

Operation of the fire 11

Opening and Closing the Fascia Panel 11

Lighting the Appliance 12

Cleaning the fire 13

SERVICING & MAINTENANCE

Spares Parts list 16

3

10

11

14

Important Notes – Please read before undertaking the installation

1. This is not a “Do it yourself” product and it must be installed by a

competent person.

2. The Installation Instructions must be adhered to without exception.

3. The heat from this appliance will cause the wall directly above the

appliance to become quite hot. If there is any concern about the

integrity of the plaster or wall finish, we recommend that slips made

from heat resistant material are fitted to cover the wall for at least

100mm above the top of the inner fascia panel. Any remedial

plasterwork above the appliance should be allowed to thoroughly dry

before lighting the appliance. Premixed packet mortars should not be

used as the inhibitors incorporated in these products can cause

continual shrinkage after setting.

Page 3

3

LIST OF COMPONENTS

Before commencing the installation ensure that all the components listed below

are included in the appliance packaging.

a) Balanced Flue Convector

b) Ceramic components; i) 1 Packet Black Ceramic Granules

ii) 1 Packet of 12 ‘Cotswold Stone’ Pieces

iii) 1 Packet of 22 ‘Cotswold Stone’ Pieces

c) Flue and Terminal

d) Terminal guard

e) Aluminium Foil Tape, flue sealing rope gasket and fittings pack

f) Installation & Servicing and Instructions

g) Remote Control Handset & Receiver, 4 AA & 1PP3 size alkaline batteries.

h) 2 rolls of white foam tape

Before commencing the installation ensure that all the components listed below

are included in the fascia packaging.

a) Fascia Panel

b) Decorative trim and 4 magnets (if ordered)

Inset Installations only

a) Wall plate (must be used for Inset Installations)

APPLIANCE DATA:

GAS TYPE

SUPPLY PRESSURE

HEAT INPUT

GAS RATE

INJECTOR SIZE

GAS CONNECTION

WEIGHT

NOX Concentration

KBFP00RN

NATURAL GAS

20 mbar

4.5 kW Gross

0.43m3/h

Ø 1.6 mm

8mm

40Kg

Class 5

GENERAL INSTALLATION REQUIREMENTS

Fitting the Appliance

1 The law demands that all gas appliances are installed by a qualified installer in

accordance with the current GAS SAFETY (INSTALLATION AND USE)

REGULATIONS. The installation must comply with these installation

instructions and all relevant parts of Local and National Building Standards

(Scotland) (Consolidation) Regulations and those relevant recommendations of

the following British Standards. BS 5871: Part 1 BS 8303 BS 5440: Parts

1 & 2 BS 6891 BSEN1856 Parts 1 & 2 BS 5482 Part 1, as well as

IGE/UP/7.

Page 4

4

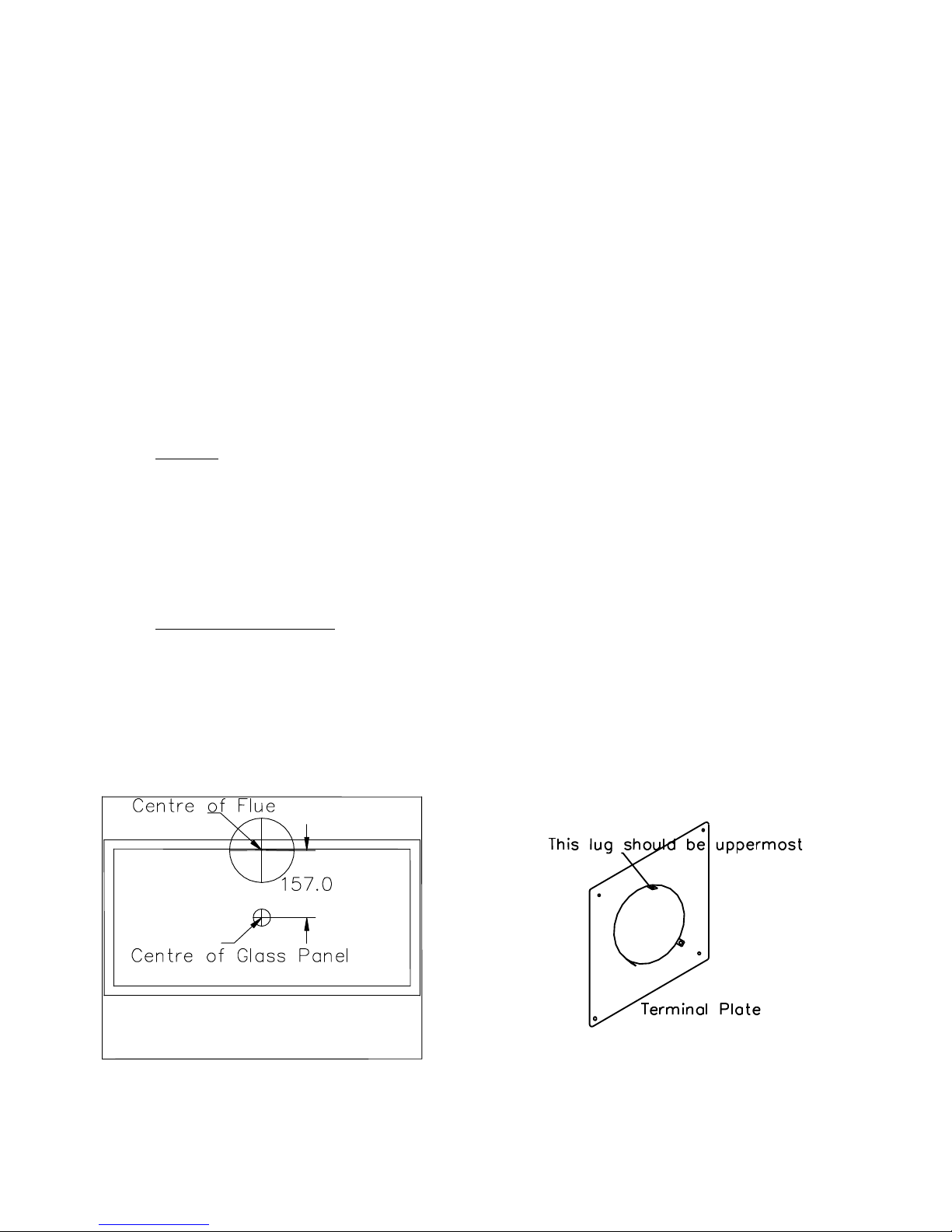

2 The appliance can be fitted onto and inset into outside walls where the terminal

does fall into any of the prohibited positions mentioned in the next section. The

centre of the glass window is 157mm below the centre of the flue terminal. The

centre of the terminal should be positioned at least 700mm above floor level to

allow space for the fascia to drop down on its runners. If the fireplace has to be

altered a lintel will be required to support masonry over the opening and if it is

to be surface mounted the maximum wall thickness allowed is 405mm. If the

appliance is to be inset into the wall this may be increased to 525mm. If

required, a longer flue duct is available which allows the maximum wall

thicknesses to be increased to 800mm for the surface mount installation and

920mm for the inset installation.

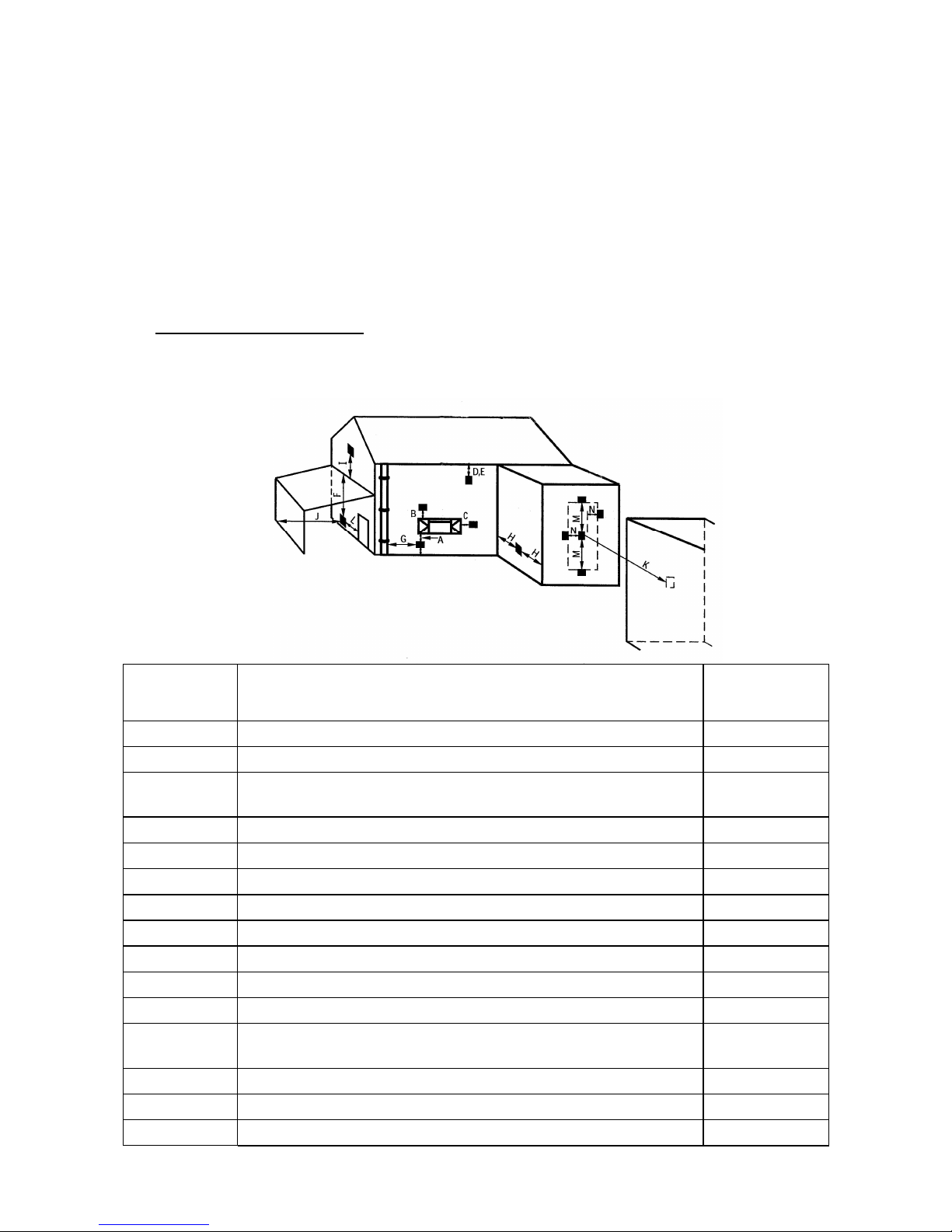

3 Flue Terminal Position

The minimum distances permissible from the flue terminal to obstructions and

ventilation openings are shown below.

DIMENSION

Not shown

Figure 1

TERMINAL POSITION MINIMUM

DISTANCE

A Directly below an opening, air brick or window, etc. 300mm

B Above an opening, air brick, opening windows, etc. 300mm

C

D Below plastic gutters, soil pipes or drain pipes 300mm

E Below eaves 300mm

F Below balconies or car port roof. 600mm

G From a vertical drainpipe or soil pipe. (Eire only 75) (GB) 300mm

H From an internal or external corner. 600mm

I Above ground, roof or balcony level. 300mm

J From a surface facing the terminal. 600mm

K From a terminal facing a terminal. 600mm

L

M Vertically from a terminal on the same wall. 1500mm

N Horizontally from a terminal on the same wall. 300mm

Horizontally to an opening, air brick, opening windows,

etc.

From an opening in a carport (e.g. door, window) into the

dwelling.

From an opening in a building directly opposite. 600mm

300mm

1200mm

Page 5

5

on diagram

Below horizontal hinged windows (Eire only) 1000mm

4 Decorative Fascia Panel

This appliance must be installed with the fascia panel set supplied. This panel

allow the passage of air for convection and for the cooling of the control system.

It must be installed as described in these instructions. The fire should never be

left running with this fascia panel dropped down. This will overheat both the

fascia and glass window.

5 Ventilation

This is a room-sealed appliance; therefore, there is no requirement for purpose

made ventilation into the room containing the fire.

6 The appliance is designed for use with natural gas only.

7 The appliance must not be installed in a room containing a bath or shower or in

a private garage.

8 Shelf

If a shelf made of combustible material is to be fixed to the wall above the

appliance a space of at least 150mm must be left between the top of the fascia

and the underside of the shelf.

9 THE HEARTH (Appliances in floor level fireplaces)

Where the appliance is fitted in a floor level builders opening, floor level fireplace

recess or floor level flue box, the hearth shall:

a, Extend through the whole base of the builders opening, fireplace recess or

beneath the flue box.

b, Project at least 275mm in front of the glass window panel.

c, Project at least 150mm beyond each side of the edge of the glass window

panel. or if there is a non-combustible wall within 150mm of glass panel,

up to that wall.

d, Have a thickness of not less than 12mm and a minimum height of 50mm

along its front and side edges.

Hole-in-the-wall installations

Where the appliance is installed in a hole-in-the-wall fireplace, a hearth as

previously detailed for floor level fireplaces shall be fitted on the floor beneath

the hole so as to protect combustible material from radiant heat.

a, If a hearth is not to be used, so as to maintain a minimal and

contemporary styling, the appliance must be installed so that the base of

the appliance is at least 200mm vertically above any carpet or floor

covering.

b, Where no hearth is to be fitted consideration should be given to fixing a

tactile separator to protect young children, the elderly and the infirm. A

tactile separator can be in the form of a fender, kerb, hearth, shelf or

horizontal bar all made from non combustible material and fixed not less

than 50mm & not more than 1000mm above the floor level. It should be

positioned not less than 275mm in front of and 150mm beyond the edge

of the window glass.

Page 6

6

10 Combustible Walls & Timber Framed Dwellings

The appliance may be fitted directly to wall made both from combustible and

non combustible material. If it is to inset into the wall, the inner wall plate

(supplied separately) must be used and a gap of 25mm should be maintained

between the top, rear and sides of the convector box and any combustible

material. These gaps should be filled with mineral wool insulation.

A gap of 50mm must be maintained between the outer flue and any combustible

material including the external wall. This gap must be filled with mineral wool

insulation.

Installations into timber framed dwellings must follow the recommendations of

IGEM/UP/7 ‘Gas Installation in Timber Framed Buildings’ available from The

Institute of Gas Engineers and Managers’. The appliance must not be inset

unless provision has been made by the builders with the approval of the

designers of the dwelling.

Fitting

This appliance can be installed either by being fixed directly on to the surface or

it can be inset into the inner leaf of a cavity wall. Before starting the installation

remove the glass door by unscrewing the eight nuts securing the door and place

in a safe place until required.

Undoing the nuts and bolts on the outer flanges of the appliance separate the

heat exchanger from the convector box.

Surface Installation

1 Select a position for the appliance and mark the centre of the flue. This should

be at least 700mm above finished floor level. (This is to give sufficient clearance

to allow the door to drop down). The centre of the glass panel will be 157mm

below this mark (See Figure 2). At this position drill a 152mm diameter hole in

the wall for the flue. Apply white foam tape (supplied) around the edges of the

back of the convector box to form a dust seal between the box and the wall.

Figure 2

2 Thread the outside Terminal plate onto the flue and push the flue into the wall

Figure 3

Page 7

7

from the outside. Apply mastic to the rear face of the Terminal plate and fix to

the wall using screws and wall plugs. Make sure the plate is fixed the correct

way up. (See Figure 3) Slide the flue further into the wall until the tabs on the

wall plate line up with the holes in the outer flue tube. Temporally fix the tube

to the wall plate with the self tapping screws provided. Use the inner holes as

shown in Figure 4.

Figure 4

3 On the inside wall centre and level the convector box over the protruding flue

pipe. Once level, fix the convector box to the wall with four screws and wall

plugs. The convector box has been designed to ensure an air gap remains

between the wall and the back of the convector box. Consideration should be

given to ensure this gap is achieved and not affected by uneven wall surfaces.

4 From the inside of the convector box measure inwards along the flue 6mm. At

this point draw a line completely around the outer pipe. Unscrew the self

tapping screws securing the outer flue tube to the wall plate and withdraw the

flue assembly. Move the polystyrene support ring inside the flue assembly to a

position near the marked line. Cut the excess flue of at the marked line. De-bur

the cut edges and remove the polystyrene ring.

5 Slide the remaining piece of flue, which should include the terminal, on to the

flue connection on the back of the heat exchanger. Note that the two flue tubes

are not concentric and that the inner tube is positioned towards the top of the

outer tube. Using a 3.5mm diameter drill, drill holes through the holes in the

flue outer ring and into the outer flue tube. Secure in place with self tapping

screws and then cover and seal the joint with the length of aluminium tape

supplied. Thread the fibreglass rope ring sealing gasket on to the flue.

6 The gas supply should be routed from the meter or cylinder to a point

underneath or behind the appliance. There are two grommeted apertures

provided for gas pipe entry in the convector box. From this point route the

supply in 8mm diameter tubing to the combined pressure test point and isolator

fitting. Any exposed pipe within the wall cavity should be wrapped, painted with

bituminous paint or factory sheathed. Prior to connecting the burner to the gas

supply it is advisable to blow out the pipe to clear any dirt that may be present

and which could cause a blockage in the control valve or pilot.

7 Lift the heat exchanger and flue assembly and slide the flue assembly through

the hole in the wall until the heat exchanger flange meets the convector box

flange. Fix the heat exchanger to the convector box using the M5 nuts and bolts

supplied. Replace the self tapping screws that secured the flue to the wall plate.

Seal the flue to the wall plate with mastic. Fit the terminal guard centrally over

the terminal using screws and wall plugs.

Page 8

8

8 If plasterwork requires to be made good, please pay attention to note no. 3 on

page 2 of these instructions

Inset Installation

1 To inset the Limours gas fire, a wall plate, supplied separately, must be used.

2 Select a position for the appliance and the height required from the centre of the

glass panel to the floor. Cut a hole in the inner leaf of the cavity wall to the

dimensions shown in Figure 5. A lintel may be required to support the masonry

over the opening .Any cavity wall insulation should be held back away from the

appliance. Drill a 152mm diameter hole in the outer leaf of the cavity wall for

the flue 157mm above the position of the centre of the glass panel. Ensure that

the centre of the flue is at least 700mm above finished floor level.

Figure 5

3 Thread the outside wall plate onto the flue and push the flue into the wall from

the outside. Apply mastic to the rear face of the wall plate and fix to the wall

using screws and wall plugs. Make sure the plate is fixed the correct way up.

(See Figure 3) Slide the flue further into the wall until the tabs on the wall plate

line up with the holes in the outer flue tube. Temporally fix the tube to the wall

plate with the self tapping screws provided. Use the inner holes as shown in

Figure 4.

4 Temporally screw the convector box to the inner wall plate with four M5 screws.

Place the convector box over the protruding flue pipe and push the box into the

hole already cut in the inner leaf of the cavity wall. Centre the convector box

over the flue pipe. Once level, fix the inner wall plate to the wall with six screws

and wall plugs. Cover the access holes to these screws with the six black plastic

plugs supplied. Once the convector box has been finally secured to the inner

fascia the arrangement can be considered to have sealed the cavity. Any gaps

around the inner fascia and any other gaps can be sealed with mastic.

5 From the inside of the convector box measure along the flue 6mm. At this point

draw a line completely around the outer pipe. Unscrew the self tapping screws

securing the outer flue tube to the wall plate and withdraw the flue assembly.

Move the polystyrene support ring inside the flue assembly to a position near

the marked line. Cut the excess flue of at the marked line. De-bur the cut edges

and remove the polystyrene ring.

6 Slide the remaining piece of flue, which should include the terminal, on to the

flue connection on the back of the heat exchanger. Note that the two flue tubes

are not concentric and that the inner tube is positioned towards the top of the

outer tube. Using a 3.5mm diameter drill, drill holes through the holes in the

Page 9

9

flue outer ring and into the outer flue tube. Secure in place with self tapping

Figure 7

screws and then cover and seal the joint with the length of aluminium tape

supplied. Thread the fibreglass rope ring sealing gasket on to the flue.

7 The gas supply should be routed from the meter or cylinder to a point

underneath or behind the appliance. There are two grommeted apertures

provided for gas pipe entry in the convector box. From this point route the

supply in 8mm diameter tubing to the combined pressure test point and isolator

fitting. Any exposed pipe within the wall cavity should be wrapped, painted with

bituminous paint or factory sheathed. Prior to connecting the burner to the gas

supply it is advisable to blow out the pipe to clear any dirt that may be present

and which could cause a blockage in the control valve or pilot.

8 Remove the four M5 screws holding the convector box to the inner fascia. Lift

the heat exchanger and flue assembly and slide the flue assembly through the

hole in the wall until the heat exchanger flange meets the convector box flange.

Fix the heat exchanger through the convector box flanges to the inner fascia

using the M5 bolts supplied. Replace the self tapping screws that secure the flue

to the wall plate. Seal the flue to the wall plate with mastic. Fit the terminal

guard centrally over the terminal using screws and wall plugs.

9 If plasterwork requires to be made good, please pay attention to note no. 3 on

page 2 of these instructions

Placing of Decorative Refractory Shapes

1 Pour enough black ceramic granules to fill the space between the front air guide

and the window opening. The granules should finish level with the top of the

window ledge.

2 Two packets of ‘Cotswold Stone’ pieces are supplied with the fire. Open the

smaller packet containing twelve wedge shaped pieces.

3 Place ten of these pieces behind the rear air guide with the longer wedge

pointing downwards. These pieces should be supported by the rear air guide

and by the board at the rear of the fire. See Figure 6.

Figure 6

4 Place the two remaining pieces on top of the brackets at either end of the air

guides.

5 Two pieces from the second packet should be placed at each end of the air

guides. They should rest partly on the front air guide and partly on the black

ceramic granules. See Figure 6.

Page 10

10

6 Place ten ‘Cotswold Stone’ pieces from the second packet on top of the black

ceramic granules in front of the front air guide as shown in Figure 6.

7 Place the remaining ten ‘Cotswold Stone’ pieces from the second packet across

the air guides pushing each piece down on a location spike formed in the front

air guide. See Figure 7 on previous page.

8 It is important that decorative ‘Cotswold Stone’ pieces are placed as per these

instructions.

Closing the Glass Door

1 Place the glass door in position over the studs on the heat exchanger making

sure the joint in the rope seal lies along the lower edge. Secure in position with

the eight nuts. Tighten evenly.

Installing the Fascia Panel

1 Check that the fascia panel is mounted the correct way up. A TEE is punched in

the top of the inner flanges.

2 Ensure the four M4 screws are mounted in their bushes on the inner flanges.

3 Offer the fascia up to the appliance and slide the heads of the M4 screws

through the cut – outs and into the slots formed in the sides of the convector

box.

4 Make sure that the fascia panel slides up and down freely and locks in the top

position.

COMMISSIONING:

1 Before attempting to light the appliance the gas supply must be turned on by

removing the cap from the isolator fitting and unscrewing the plug all the way

out. Replace the cap making sure that the tab engages with the slot in the top of

the plug. Tighten the cap securely. Check all joints with leak detection fluid.

Light the appliance in accordance with the instructions in the lighting section.

2. a. Slide back the battery compartment cover and insert the four AA size

alkaline batteries observing the correct polarities. Replace the cover and place

the battery box on the floor of the convector box.

b. Fit the battery into the handset by removing the access cover in the rear

of the handset and inserting a 9 volt PP3 size battery. Connect the battery by

pushing the connector on to the terminals. Make sure the battery is connected

correctly. Replace the access cover.

Briefing the User

1 Demonstrate the full operation of the appliance to the customer.

2 Inform the customer that all cleaning procedures should be carried out only

when the appliance is cold.

3 Leave these instructions with the customer.

4 Advise the importance of having the appliance serviced on an annual basis.

Page 11

11

USERS GUIDE:

Useful tips & recommendations

Once your fire has been fitted, the following recommendations are made to

ensure you enjoy the best results from your purchase;

1 The installation of this appliance must have been carried out by a qualified

installer and in accordance with the requirements of the Gas Safety

(Installation & Use) Regulations

2 The glass door and the upper part of the fascia panel are considered to be

working surfaces and as such will become hot when in use. Care should be

exercised when using the controls of the appliance when it is hot. We also

recommend that a fireguard, conforming to BS 8423, be fitted for the protection

of young children, the elderly or infirm.

3 When new, any painted surfaces or ceramic components may produce a slight

odour, but this will completely vanish after a few hours of use.

5 The appliance MUST NOT be used with the front fascia panel in the dropped

down position or with the glass panel removed. If there is any suspicion of

damage to the glass the appliance must not be used.

6 To obtain the best results from your fire we recommend that it be serviced

annually.

7 These instructions are provided to assist you to operate the fire correctly and

should be kept in a safe place.

8 If you have any reason to suspect a gas leak, turn off the appliance at the

isolating point and contact your installer.

9 Curtains should not be hung above the appliance.

Operation of the fire

1 The pilot flame heats the thermocouple probe and allows gas to flow to the

burners. If due to pilot failure, the thermocouple cools, no gas will flow to the

main burner. If the fire is turned off or the flames go out, wait for AT LEAST 3

MINUTES before attempting to relight the fire.

2 For convenience you will find with the appliance a card giving concise lighting

instructions, please keep this in a safe place.

Opening and Closing the Fascia Panel

CAUTION: ONLY DO THIS WHEN THE FIRE IS COLD

1 To open the fascia panel grip it at each side, lift slightly, pull outwards and

lower.

2 This will allow access to the gas control and to the battery pack-signal receiver

to light the appliance and change the batteries.

3 To close the fascia grip it at each side, lift fully, push forwards and release.

Always grip the fascia at each side where it will be cool and not at the top where

it may be very hot.

Page 12

12

Figure 8

Lighting the Appliance

1 Lighting: See Figure 8.

a Push in and turn control knob ‘A’ anti-clockwise to the PILOT position.

b Hold knob ‘A’ in for several seconds to purge any air from the system.

c With knob ‘A’ still depressed turn it from the "OFF" position to the "PILOT”

position until the pilot light ignites. Continue to depress the control knob

for a further 10-15 seconds. Release the control knob, the pilot should

stay alight. If the pilot flame goes out, repeat the process, holding down

the control knob for a slightly longer period.

d Depress control knob ‘A’ slightly and turn anti-clockwise to the ON

position. The main burner will not operate until this is done. The main

burner may light depending on the position of Control Knob ‘B’.

e Manual override for remote control

Turn Control Knob ‘B’ anti-clockwise to increase the flame height and

clockwise to decrease the flame height.

2 Extinguishing

a Manual override for remote control

Turn Control Knob ‘B’ fully clockwise. This will turn off the main burner

leaving the pilot burner alight.

b Turn Control Knob ‘B’ to the pilot position. This will also turn off the main

burner leaving the pilot burner alight.

c To extinguish the pilot burner, turn Control Knob ‘B’ to the off position.

Figure 9

Page 13

13

3 Adjusting the Flame Height using the Remote Control Handset

(Figure 9)

The remote control system fitted to the fire uses ultrasound to transmit

signals between the handset and the fire. It will work best if the grill at the

front of the handset is pointed in the direction of the fire. To prevent

inadvertent ignition of the fire the UP button on the handset will not

function unless the SMALL button is held down at the same time. A loud

clicking noise indicates that control knob ‘B’ has reached the end of its

travel.

a Make sure that the pilot burner has been lit and Control Knob ‘A’ has

been turned to the ON position. Also ensure that batteries have been

fitted to the handset and to the battery pack-signal receiver.

b To light the main burner or increase the flame height press and hold the

UP button and the SMALL button on the handset. Release when the flame

is at the desired height. The electric motor should be heard moving

Control Knob ‘B’.

c To extinguish the main burner or reduce the flame height press and hold

the DOWN button on the handset. Release when the flame is at the

desired height or has gone out. Once again the electric motor should be

heard moving Control Knob ‘B’.

Cleaning the fire

Ensure that the appliance is cool. Regular dusting with a dry cloth is usually all

that is necessary to keep your appliance looking at its best. From time to time it

may be necessary to clean the steel surface with a slightly damp cloth - do this

while the fire is cool and ensure that no water remains on the appliance surface.

Glass

Let the fire and glass cool completely. Only the outside of the glass can be

cleaned by the user. Wash the glass with warm water, using a soft paper towel

or cloth, rinse and dry thoroughly. Never use abrasive or harsh chemicals to

clean the glass.

For stubborn deposits use a cleaner available from your dealer. Do not allow the

cleaner to touch any brass or stainless steel ornamentation. Ensure that the fire

is cold before undertaking any cleaning. Remember that heat is retained for

some time after the fire is switched off. In normal use your fire requires only

minimal cleaning. Some soot may form on any ceramic pieces placed in the

flames but this is generally harmless unless an excessive amount is deposited.

Page 14

14

SERVICE AND MAINTENANCE

BEFORE ANY SERVICING IS CARRIED OUT ISOLATE THE APPLIANCE

FROM THE GAS SUPPLY. AFTER REFITTING THE APPLIANCE, CHECK

FOR GAS SOUNDNESS AT ALL GAS JOINTS AND TEST FOR SPILLAGE.

This product uses fuel effect pieces containing Refractory Ceramic Fibre

(RCF). This material contains man-made vitreous silicate fibres. Excessive

exposure to these materials may cause temporary irritation to eyes, skin

and respiratory tract; consequently, it makes sense to take care when

handling these articles to ensure that the release of dust is kept to a

minimum.

To ensure that the release of fibres from these RCF articles is kept to a

minimum, during installation and servicing we recommend that a HEPA

filtered vacuum cleaner is used to remove any dust accumulated in and

around the appliance before and after working on the appliance. We

recommend that any replaced items are not broken up, but are sealed

within heavy duty polythene bags and clearly labelled as RCF waste. RCF

waste is classed as a stable, non-reactive hazardous waste and may be

disposed of at landfill sites licensed to accept such waste. Protective

clothing is not required when handling these articles but we recommend

that the normal hygiene rules are followed of not smoking, eating or

drinking in the work area and that hands are washed before eating or

drinking.

The appliance should be serviced at least once a year by a registered

engineer and must include changing the oxypilot as a condition of the

guarantee. This is the basic procedure.

1 Remove the fascia panel. See section above headed ‘Installing the Fascia Panel’.

2 Unscrew the eight nuts and remove the glass door.

3 The ‘Cotswold Stones’ should be taken off the fire. The centre row should be

carefully lifted off the locating spikes and kept in order so that they can be

returned to their original positions. All the pieces should be shaken to remove

any debris but should only be cleaned if absolutely necessary. This should be

done by gently brushing with a soft brush in a direction away from the person

and any persons nearby. This operation should be performed outside facing

downwind.

4 Remove all the black ceramic granules.

5 Undo the two screws holding the air guide assembly in position a lift it gently

out of the firebox making sure the black ceramic granules remain in their

locating tray. Remove the two screws holding the burner and lift it out of the

appliance.

6 Thoroughly clean the burner ports.

7 The injector can be inspected without removing the control mount platform by

unscrewing it with a small box spanner or pliers.

8 To remove the control mount platform;

a Disconnect the isolator fitting from the gas control.

Page 15

15

b Remove the 2 screws holding the left hand board bracket. Remove the

bracket and left hand lining board.

c Remove the screw holding the pilot draught shield to the pilot bracket and

lift the shield away.

d Remove the six screws securing the control mount platform to the firebox.

Take care not to damage the gasket.

9 Replace the control mount platform (if it has been removed) and secure with the

six screws previously removed. Replace the pilot shield and the lining board and

bracket. Re-connect the gas supply. Place the burner and air guide assembly in

position ensuring that the mixing tube locates in its hole in the burner mount

over the injector and fix in place with the four screws removed in paragraph 5.

Replace the refractory shapes that were in place on the burner.

10 Replace the black ceramic granules in the tray attached to the air guide. Replace

the ‘Cotswold Stones’ exactly as they were removed making sure that the centre

row are replaced on the spikes using the original piecing in the stones.

11 After cleaning the glass door inside and out replace it and secure with the eight

nuts. Tighten the nuts evenly. Stubborn marks can be removed with steel wool

and detergent.

AFTER REFITTING THE APPLIANCE CHECK FOR GAS SOUNDNESS AT ALL GAS JOINTS.

12 Replace the fascia panel.

13 The service record sheet enclosed with these instructions should be complete to

maintain the validity of the warranty.

Battery Replacement

14 HANDSET; The handset is powered by one Alkaline 9volt PP3 size battery. If the

fire fails to respond to the handset control check that the red LED on the

handset lights whilst pressing either of the two buttons. If the LED does not

light, the battery in the handset requires renewing. To change the battery in the

handset, remove the battery cover on the underside of the handset, unclip the

battery from its connector and put a new one put in its place. Replace the

cover.

15 BURNER; Open the fascia panel. Lift out the gas control battery pack – signal

receiver from its position on the bottom tray of the convector box. Slide back the

battery compartment cover and replace the four AA size alkaline batteries

observing the correct polarities. Replace the cover and then replace the battery

box in its clip.

Page 16

16

Spare Parts List

In the event of a part requiring replacement the parts list is as follows

Part Description Part Number

Motorised valve CV-104103

Remote hand control &

CV-104413

Receiver

Pilot Burner NG Model CV-104506

Injector NG Model CV-104608

Page 17

17

B-124830

Issue 2

BFM Europe Limited

Trentham Lakes

Stoke on Trent, Staffordshire ST4 4TJ

Tel: (01782) 339000 Fax: (01782) 339009

Email: info@bfm-europe.com

www.bfm-europe.com

Loading...

Loading...