Kinder Cameo BF, KBFLRN2, Proclaim BF Installation And Maintenance Instructions Manual

Cameo BF

LOG EFFECT BALANCED FLUE ROOM HEATER

Installation and Maintenance Instructions

Hand these instructions to the user

Model No. KHBL**RN is for use on Natural Gas (G20) at a supply pressure of

20 mbar in G.B. / I.E.

** Denotes trim & colour variant

CONTENTS

P

AGE

S

ection 1 Information and Requirements

1.0 Appliance information 3

1.1 Conditions of installation 4

1

.2 Fireplace surround & suitability 4

1.3 Flue terminal position 5

1.4 Shelf position 6

1.5 Hearths 6

1.6 Installation to plastered wall surfaces 6

Section 2 Installation of Fire

2.1 Unpacking the combustion chamber 7

2.2 Preparing the combustion chamber opening (In studded wall) 8

2.3 Preparing the combustion chamber opening (In chimney breast) 9-10

2.4 Installation of the gas supply 11

2.5 Specifying the flue system & components 12-13

2.6 Preparation of the wall 14

2.7 Preparation of the flue hole 15

2.8 Fitting the starter pipe 15-16

2.9 Fitting the flue pipes together 17

2.10 Fitting the flue terminal 18

2.11 Fitting the flue terminal guard 19

2.12 Removal & re-fitting of the glass frame 20

Section 3 Assembling Fuel Bed and Commissioning

3.1 Fitting the fuel bed logset 21-24

3.2 Making the gas conection & checking for gas tightness 24

3.3 Lighting the appliance 25-27

3.4 Removal & re-fitting the Cameo fascia 28

Section 4 Maintenance

4.1 Removal of the burner assembly 29

4.2 Removal of the control valve 29-30

4.3 Removal of the ultrasonic reciever 30

4.4 Removal of the pilot assembly 30-31

4.5 Removal / Replacement of batteries in the Ultrasonic Receiver 31

4.6 Removal / Replacement of the handset battery 31

Model number KHBL**RN manufactured by:-

BFM Europe Ltd, Trentham Lakes, Stoke-on-Trent, Staffordshire, ST4 4TJ

Appliance Efficiency Declaration

The efficiency of this appliance has been measured as specified in

BS EN 613 : 2001 and the result is 76%. The gross calorific value of the fuel has

been used for this efficiency calculation. The test data from which it has been

calculated has been certified by GL Industrial Services UK Ltd. The efficiency

value may be used in the UK Government’s Standard Assessment Procedure

(SAP) for energy rating of dwellings.

2

SECTION 1

INFORMATION AND REQUIREMENTS

1.0 APPLIANCE INFORMATION

Main injector : (1 off) Cat 82 – size 380 (NG)

Pilot Type : S.I.T. 140 Series NG – size 27

Max. Gross Heat Input : 5.5kW

Min. Gross Heat Input : 3.0kW

Gas Rate : 0.512 m3/hr (High)

0.280 m3/hr (Low)

Cold Pressure : G20 20.0+/-1.0 mbar (8.0 +/- 0.4 in w.g.)

Ignition : Integral to gas valve

Electrode Spark Gap : 4.0mm

Packed Weight Combustion Chamber : 32.0 kg (Pack 1 of 2)

Packed Weight Flue Terminal Pack : 16.0 kg (Pack 2 of 2)

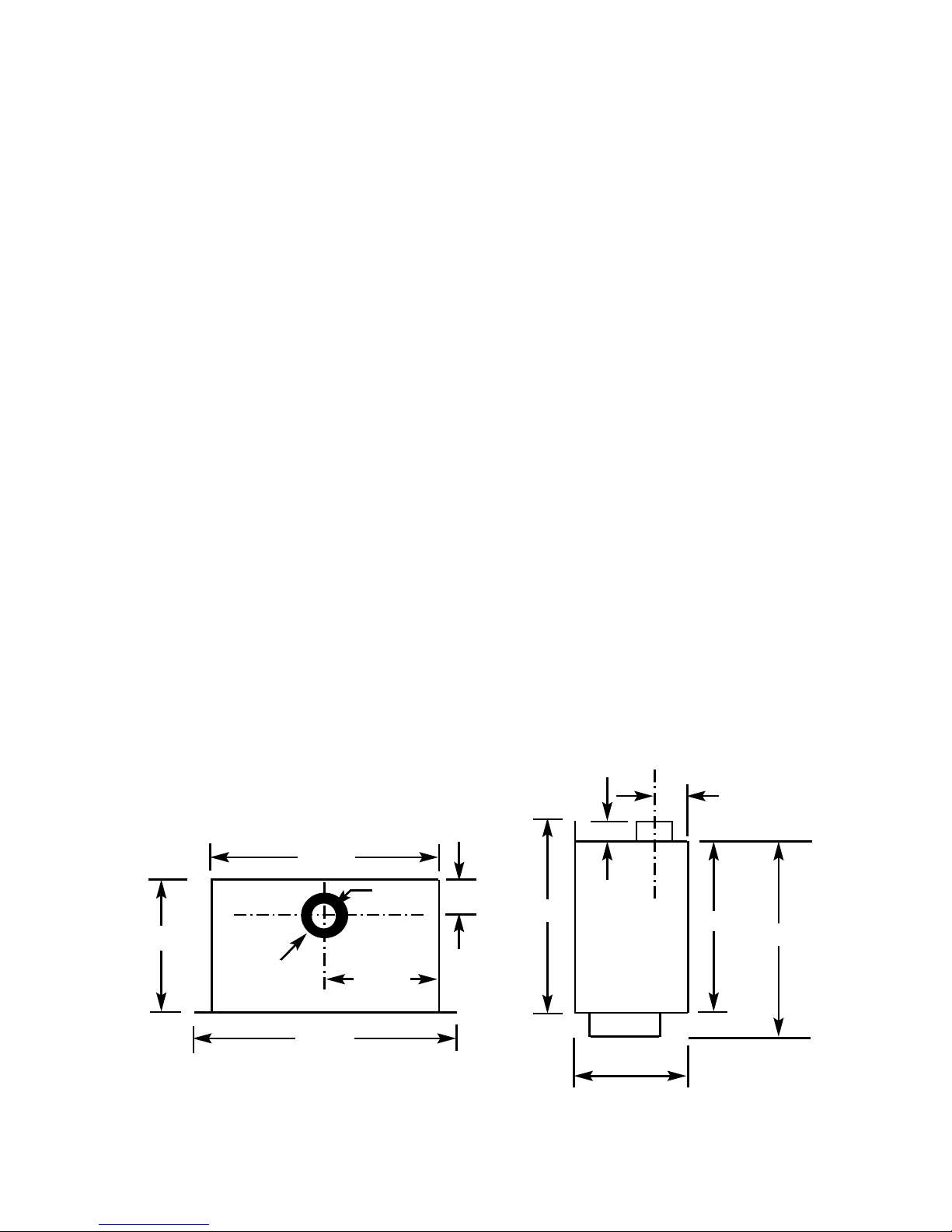

Fig 1

Top View of Combustion Side View of Combustion

Chamber Chamber

3

729 mm

631 mm

316 mm

315mm

150mm

Diameter

128mm

100mm

460mm

420mm

128mm CRS

316mm

375mm

26mm

INSTALLATION REQUIREMENTS

1.1 CONDITIONS OF INSTALLATION

It is the law that all gas appliances are installed only by a GAS SAFE Registered

Installer, in accordance with these installation instructions and the Gas Safety

(Installation and Use) Regulations 1998 as amended. Failure to install appliances

correctly could lead to prosecution. It is in your own interest and that of safety to

comply with the law.

The installation must also be in accordance with all relevant parts of the Local and

National Building Regulations where appropriate, the Building Regulations

(Scotland Consolidation) issued by the Scottish Development Department, and all

applicable requirements of the following British Standard Code of Practice.

1. B.S. 5871 Part 1 Installation of Gas Fires

2. B.S. 6891 Installation of Gas Pipework

3. B.S. 5440 Parts 1 & 2 Installation of Flues and Ventilation

4. I.S 813 : 1996 Domestic Gas Installation, issued by the National Standards

Authority of Ireland.

1.2 FIREPLACE / SURROUND SUITABILITY

The fire must only be installed on a hearth it must not be installed directly onto

carpet or other combustible floor materials.

The fire is suitable for fitting to non-combustible fire place surrounds and

proprietary fire place surrounds with a temperature rating of at least 150oc.

If a heating appliance is fitted directly against a wall without the use of a fire

surround or fire place all combustible material must be removed from behind

the trim. Soft wall coverings such as blown vinyl, wall paper etc. could be

affected by the rising hot air and scorching and/or discoloration may result.

Due consideration should be made to this when installing or decorating.

4

1.3 FLUE TERMINAL POSITION

The minimum acceptable dimensions from the flue terminal to obstructions

and ventilation openings are shown below and listed in the table

It is important that the position of the flue allows the free passage of air

across it at all times. The minimum acceptable space from the flue terminal

to obstructions and ventilation openings are specified below (Fig. 2)

Fig. 2

DIMENSION TERMINAL POSITION MINIMUM DIMENSION

A Directly below an opening, air brick, 300mm (12in)

opening window

B Above an opening, air brick, 300mm (12in)

opening window

C Horizontally to an opening, air brick,

opening window etc.

D Below gutters, soil pipes or drain pipes 300mm (12in)

E Below eaves 300mm (12in)

F Below balconies or car port roof 600mm (12in)

G From a vertical drain pipe or soil pipe 300mm (12in)

H From an internal or external corner 600mm (24in)

I Above ground roof or balcony level 300mm (12in)

J From a surface facing the terminal 600mm (24in)

K From a terminal facing the terminal 600mm (24in)

L From an opening in the car port 1200m (48in)

M Vertically from a terminal on the same wall 1500mm(59in)

N Horizontally from a terminal on the 300mm (12in)

same Wall

O NOT APPLICABLE N/A

P NOT APPLICABLE N/A

Q NOT APPLICABLE N/A

5

1.4 SHELF POSITION

The fire may be fitted below a combustible shelf providing there is a minimum

distance of 300mm above the top of the fire and the shelf does not project more

than 150mm. If the shelf overhangs more than 150mm the distance between the

fire and the shelf must be increased by 15mm for every 25mm of additional

overhang over 150mm.

1.5 HEARTHS

This appliance does not require the fitting of a hearth that projects in front of it

when installed into a recess in either an existing chimney breast or a studded wall.

The appliance must however stand on a non-combustible base that is a minimum

thickness of 12mm.

1.6 INSTALLATION TO PLASTERED WALL SURFACES

If installing to a plastered wall, all material must be removed from the 50mm area

surrounding the combustion chamber opening, and replaced with non-combustible

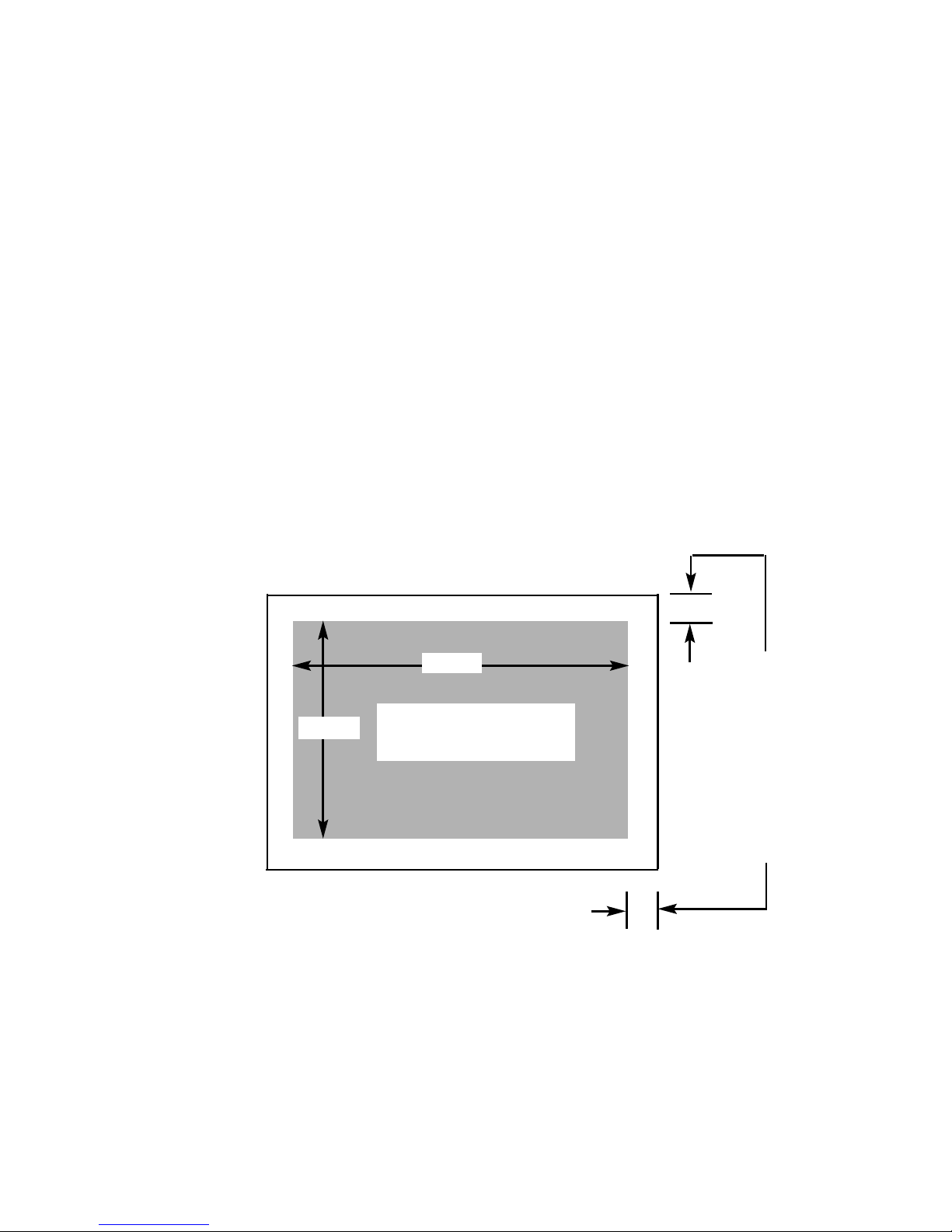

material, such as marble or granite, to prevent plaster cracking. See Fig. 3 below

Fig. 3

6

Combustion Chamber

Opening in Studded Wall or

Existing Chimney Breast

635mm

465mm

Minimum 50mm

of material to be

removed all

round perimeter

of combustion

chamber and

replaced with

marble, granite

or other noncombustible

material

SECTION 2

INSTALLATION OF FIRE

2.1 UNPACKING THE COMBUSTION CHAMBER

Carefully lift the combustion chamber out of the carton. Remove the loose item

packaging carefully from the pack. Check the contents as listed :-

DO NOT UNDER ANY CIRCUMSTANCES USE THIS APPLIANCE IF THE

GLASS PANEL IS BROKEN OR NOT SECURELY FIXED TO THE FIREBOX.

Packing Check List

Pack 1 of 2 - Combustion Chamber Pack

1 off Combustion Chamber & Glass Frame Assembly

1 off Trim (packed in front section of combustion chamber pack)

1 off Boxed ceramic fuel-bed set (packed inside combustion chamber)

1 off Installation Instruction Manual

1 off User Instruction Manual

1 off Flue Terminal Guard

1 off Loose Items pack – containing :- 6 off M6 wingnuts

4 off No. 12 x 40mm Screws

4 off Rawlplugs

Carefully lift the flue kit components out of the carton. Remove the loose item

packaging carefully from the pack. Check the contents as listed :-

Pack 2 of 2 - Flue System Pack

1 off Flue Terminal

1 off 150mm Starter Pipe

1 off *Telescopic Flue Pipe - supplied in two seperate sections

1 off 90 degree elbow

3 off Pipe Clips

*These two sections of the telescopic need to be assembled by the

installer to form the 250mm to 410mm telescopic piece.

7

2.2 PREPARATION OF THE COMBUSTION CHAMBER OPENING

(INTO STUDDED WALL)

All combustible parts of the studwork must be set at the distances as shown below

in Fig. 4 & 5.

Refer to Fig. 1 on page three for dimensions of the flue outlet.

8

M

inimum 50mm at sides

Minimum 50mm at rear

Combustion Chamber

Dimension “A”

Minimum Width

635mm

Maximum Width

645mm

Dim “A”

Dim “B”

Dimension “B”

Minimum Height

465mm

Dim “C”

Dimension “C”

Minimum Depth

366mm

Fig. 4

Fig. 5

A minimum clearance of

100mm is required above

the top of the flue pipe to

combustible surfaces

2.3 PREPARATION OF THE COMBUSTION CHAMBER OPENING

(INTO EXISTING CHIMNEY BREAST)

An opening should be constructed to the following dimensions in the existing

chimney breast.

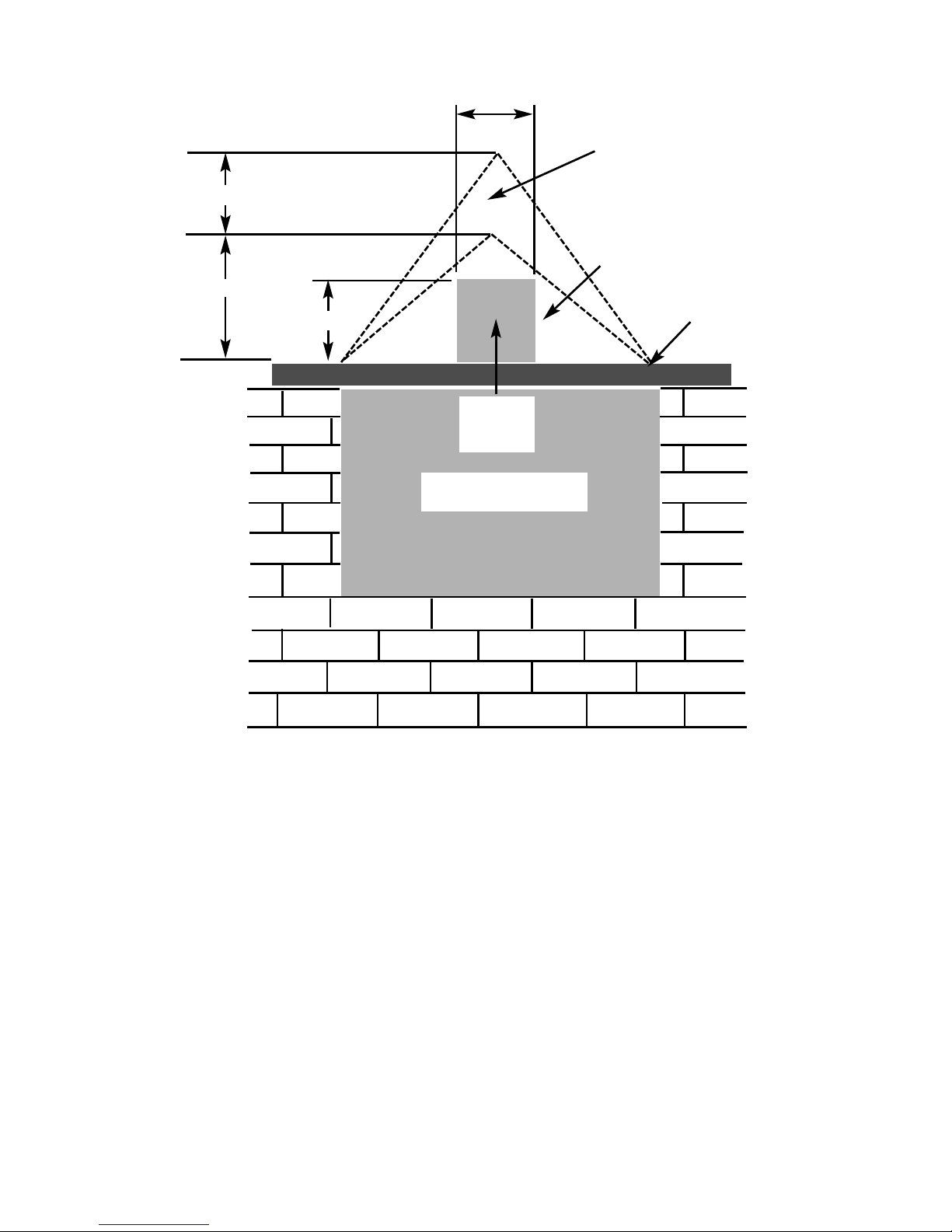

Fig. 6

The opening needs to be sufficient to accomodate the combustion chamber. To

support the wall above the opening, a suitable lintel must be inserted across the

top of the opening. The lintel could be either pre-cast concrete or steel - Catnic

CN52 or CN 46 could be used, depending upon the inner wall thickness. Before

proceeding with the installation of the fire, an assessment of the area immediately

above the fire is required, see Fig. 7 overpage. If there is no existing openings

within either triangle, proceed with forming the opening. However, if opening or

beams occur within either triangle, then you should seek specialist advice from a

structural engineer or consider relocating the proposed position of the firebox.

NOTE

: Please ensure that suitable cut outs in the sides and front face of the

chimney breast are implemented for fixing of the flue pipe, and for future

servicing.

9

Minimum Width 635mm

Maximum Width 645mm

Minimum Height 465mm

Minimum Depth 316mm

L

intle must

p

roject 150mm

either side of the

opening if

cutting into an

existing chimney

breast

Fig. 7

10

400mm interactive area

6

00mm load triangle

T

he Interactive Zone -

O

penings, beams or joists within

this area need to be assessed.

L

oad triangle - No beam or

opening permissible within this

area

Lintel

e.g. 750mm x 75mm

Proposed Opening in

Chimney Breast

Minimum 200mm

Flue Pipe

Installation

Access

1

50mm

Loading...

Loading...