Kinco FV100-2S-0007G, FV100-2S-0037G, FV100-2S-0015G, FV100-2S-0022G, FV100-2S-0075G User Manual

...

Preface

Any damage occurred during transportation;

Check whether the rated values on the nameplate of the drive are in accordance with your order.

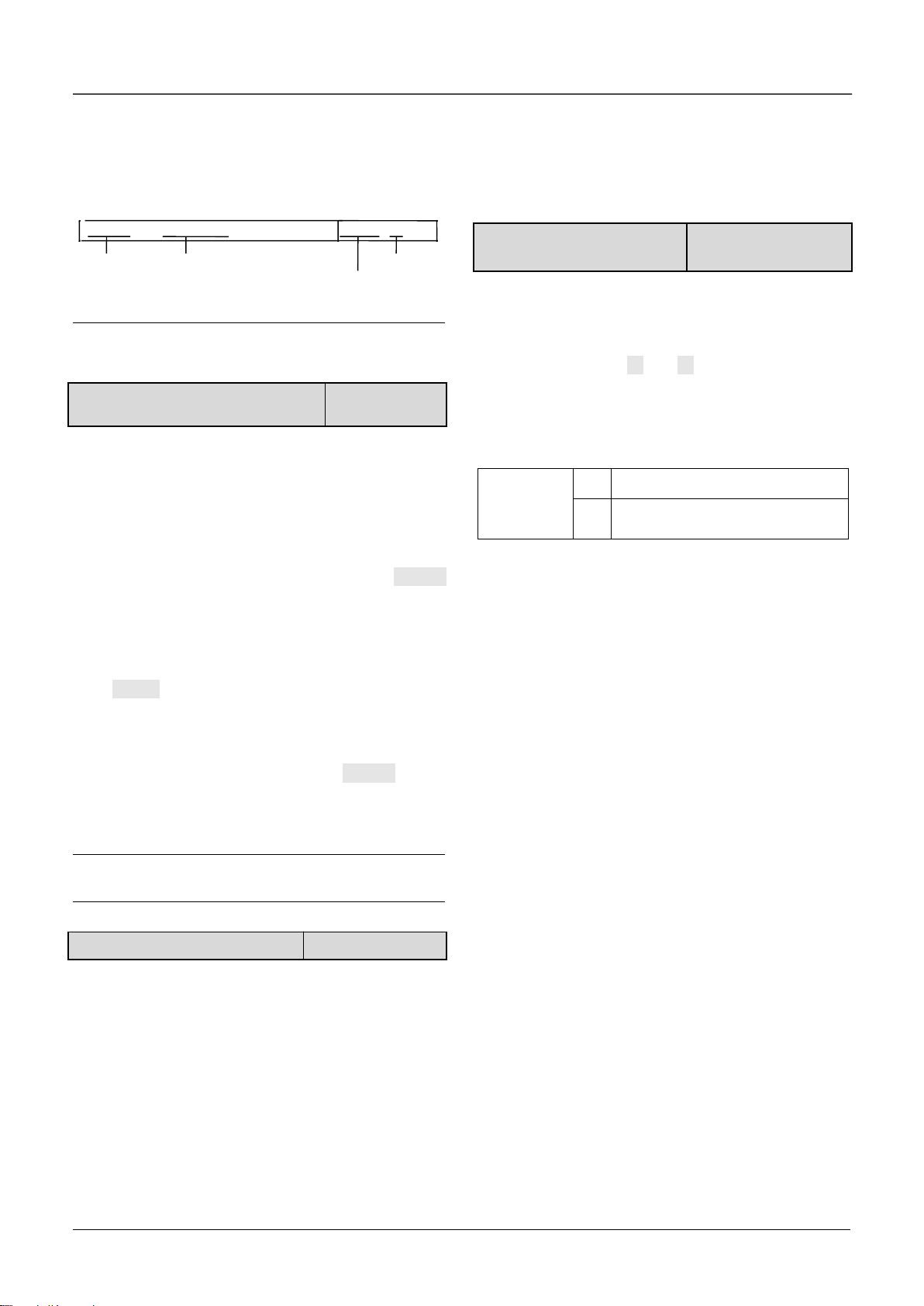

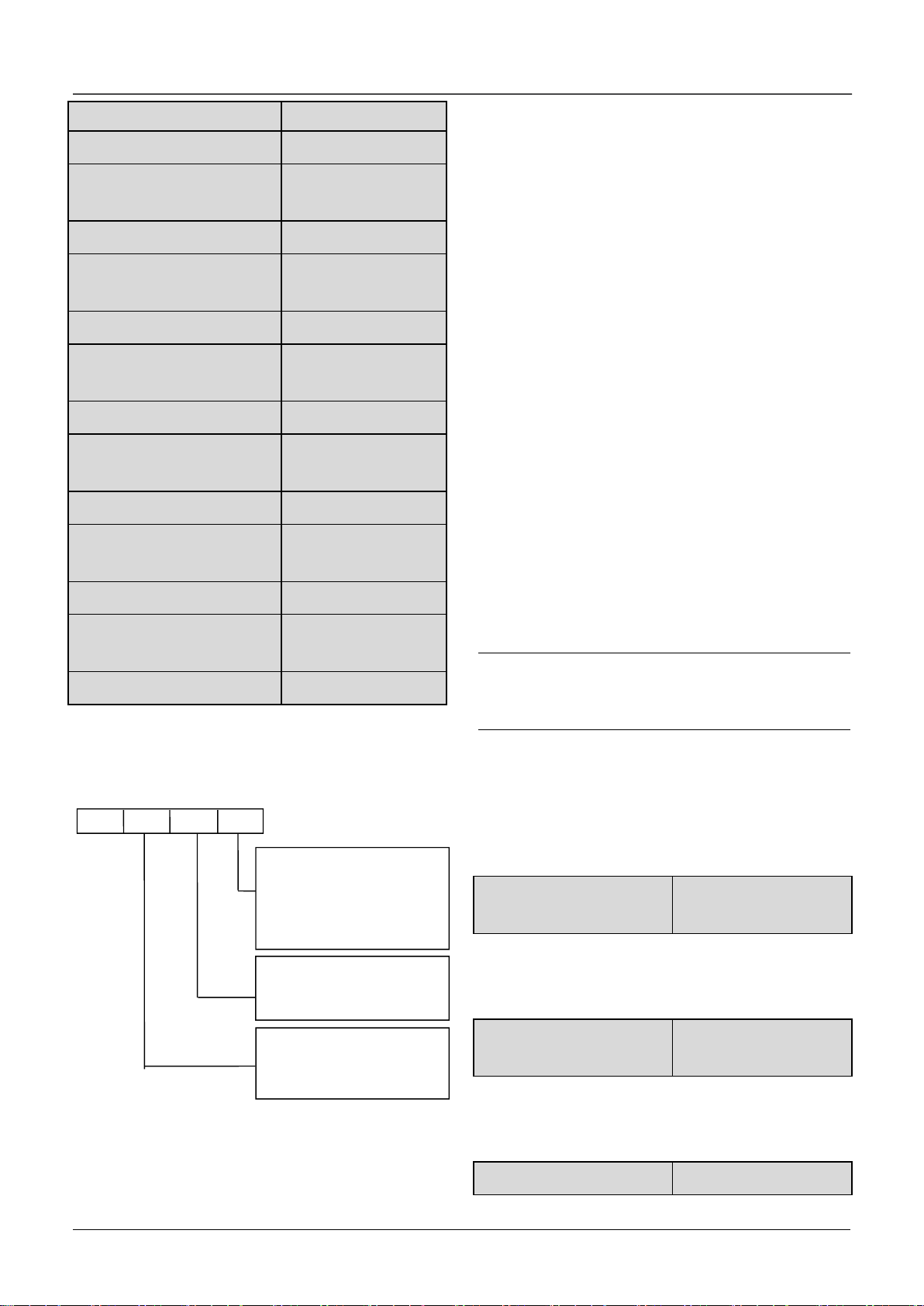

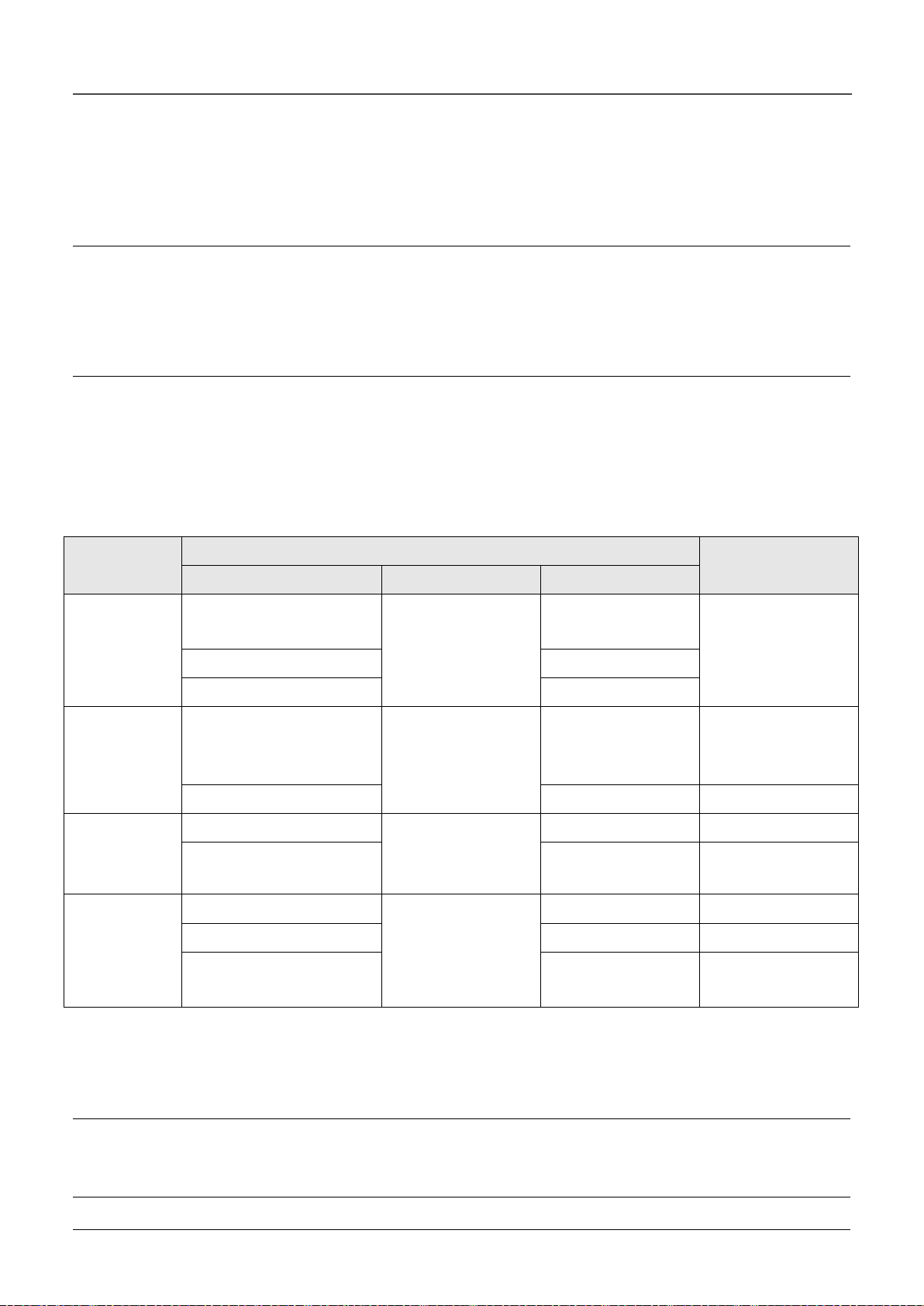

VFD code

FV:FV Series

CV:CV Series

The first generation

0075G:7.5KW

constant torque

0110L:11KW

constant power

Power supply

2:220V

4:380V

00:Standard model

S:Signal phase

T:Three-phase

Hardware custom code

Software custom code

Thank you for using FV100 series Variable Frequency Drive made by Kinco Automation.

FV100 satisfies the high performance requirements by using a unique control method to achieve high torque, high

accuracy and wide speed-adjusting range. Its anti-tripping function and capabilities of adapting to severe power

network, temperature, humidity and dusty environment exceed those of similar product made by other companies,

which improves the product’s reliability noticeably;

FV100 use modularization design, in the premise of satisfying the demand of customer, we also can satisfy

customer’s personalized and industrization demand by expansion design, and this fit the trend of VFD development.

Built-in PG connector, strong speed control, flexible input/output terminal, pulse frequency setting, saving parameters

at power outage and stop, frequency setting channel, master and slave frequency control and so on, all these satisfy

various of high accuracy and complex drive command, at the same time we provide the OEM customer high

integration total solution, it values highly in system cost saving and system reliability improving.

FV100 can satisfy the customers’ requirements on low noise and EMI by using optimized PWM technology and

EMC design.

This manual provides information on installation, wiring, parameters setting, trouble-shooting, and daily

maintenance. To ensure the correct installation and operation of FV100, please read this manual carefully before

starting the drive and keep it in a proper place and to the right person.

Unpacking Inspection Note

Upon unpacking, please check for:

Our product is manufactured and packed at factory with great care. If there is any error, please contact us or

distributors.

The user manual is subject to change without notifying the customers due to the continuous process of product

improvements

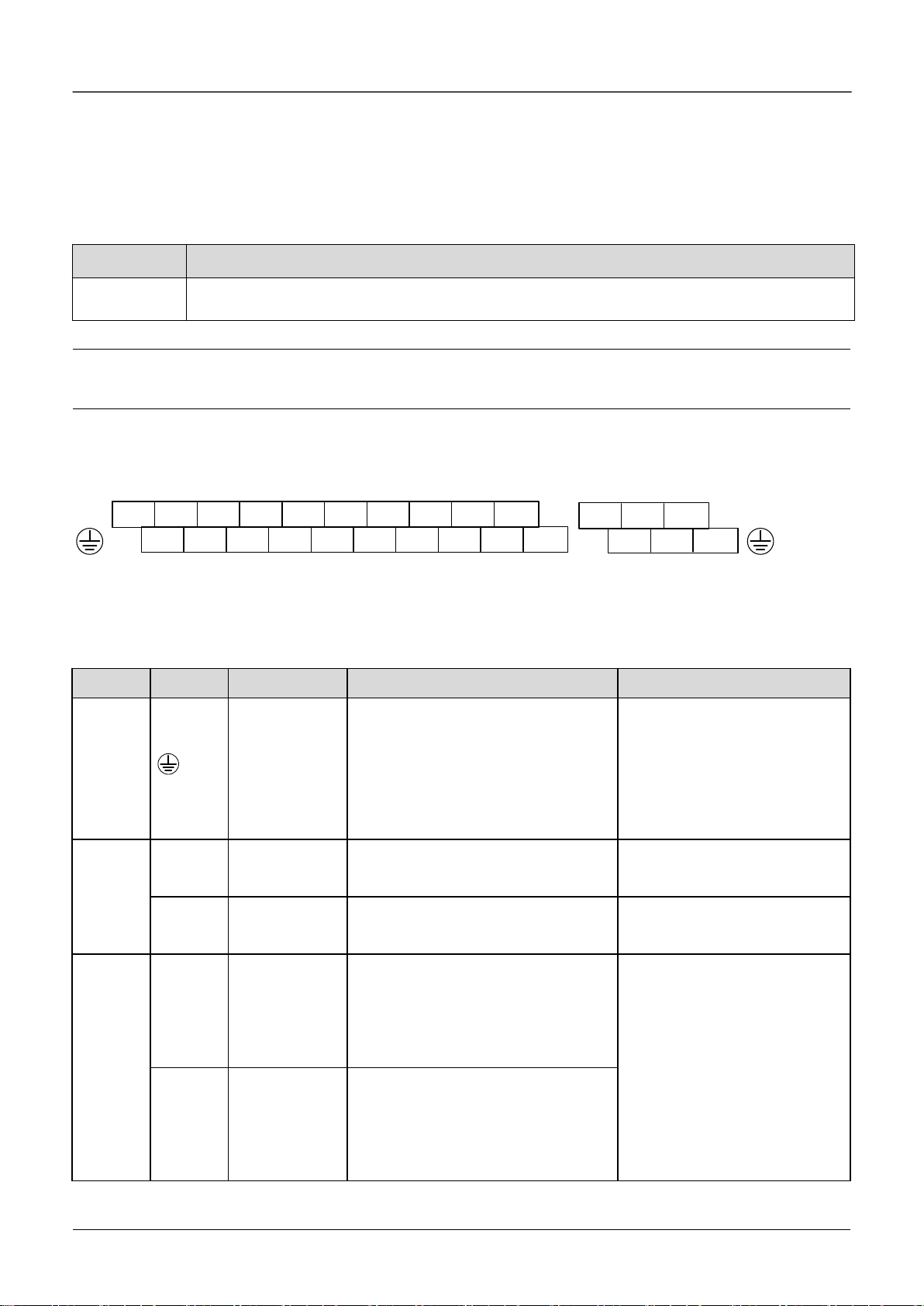

VFD model rule

FV 1 00 – 4 T– 0075G/0110L – U –000

Content

Chapter 1 Safety................................................................................................................................................................ 1

1.1 Safety......................................................................................................................................................................1

1.2 Notes for Installations............................................................................................................................................ 1

1.3 Notes for Using FV100.......................................................................................................................................... 1

1.3.1 About Motor and Load................................................................................................................................ 1

1.3.2 About Variable Frequency Drive.................................................................................................................2

1.4 Disposing Unwanted Driver...................................................................................................................................3

Chapter 2 Product introduction....................................................................................................................................... 4

2.1General specifications............................................................................................................................................. 4

2.2 Introduction of product series................................................................................................................................ 5

2.3 Structure of VFD....................................................................................................................................................7

2.4 External dimension and weight.............................................................................................................................8

2.4.1 External dimension and weight...................................................................................................................8

2.4.2 Operation panel and installation box.........................................................................................................11

2.4.3 Braking Resistor Selection........................................................................................................................12

Chapter 3 Installation Environment................................................................................................................................ 13

Chapter 4 Wiring Guide of VFD..................................................................................................................................... 14

4.1 Wiring and Configuration of Main circuit terminal.............................................................................................14

4.1.1 Terminal Type of Main Loop’s Input and Output.....................................................................................14

4.1.2 Wiring of VFD for Basic Operation..........................................................................................................16

4.2 Wiring and configuration of control circuit......................................................................................................... 17

4.2.1 Wiring of control circuit terminal............................................................................................................. 17

Chapter 5 Operation Instructions of Kinco VFD............................................................................................................ 24

5.1Using Operation Panel...........................................................................................................................................24

5.1.1 Operation panel appearance and keys’ function description.................................................................... 24

5.1.2 Function Descriptions of LED and Indicators.......................................................................................... 25

5.1.3 Display status of operation panel.............................................................................................................. 25

5.1.4 Panel Operation......................................................................................................................................... 26

5.2Operation mode of VFD........................................................................................................................................28

5.2.1 Control mode of VFD................................................................................................................................28

5.2.2 Operating Status........................................................................................................................................ 28

5.2.3 Control mode and operation mode of Kinco VFD....................................................................................28

5.2.4 The channels to set the VFD frequency.................................................................................................... 29

5.3Power on the Drive for the first time.................................................................................................................... 30

5.3.1 Checking before power on........................................................................................................................ 30

5.3.2 Operations when start up the first time.....................................................................................................30

Chapter 6 Parameter Introductions..................................................................................................................................31

6.1 Group A0.............................................................................................................................................................. 31

6.2 Group A1.............................................................................................................................................................. 33

6.3 Group A2.............................................................................................................................................................. 36

6.4 Group A3.............................................................................................................................................................. 37

6.5 Group A4.............................................................................................................................................................. 40

6.6 Group A5.............................................................................................................................................................. 41

6.7 Group A6.............................................................................................................................................................. 43

6.8 Group A7.............................................................................................................................................................. 53

6.9 Group A8.............................................................................................................................................................. 54

6.10 Group b0.............................................................................................................................................................55

6.11 Group b1.............................................................................................................................................................57

6.12 Group b2.............................................................................................................................................................59

6.13 Group b3.............................................................................................................................................................61

6.14 Group b4.............................................................................................................................................................61

6.15 Group C0............................................................................................................................................................ 62

6.16 Group C1............................................................................................................................................................ 62

6.17 Group C2............................................................................................................................................................ 66

6.18 Group d0.............................................................................................................................................................69

6.19 Group d1.............................................................................................................................................................72

6.20 Group d2.............................................................................................................................................................72

Chapter 7 Troubleshooting.............................................................................................................................................. 73

Chapter 8 Maintenance....................................................................................................................................................79

8.1 Daily Maintenance.............................................................................................................................................. 79

8.2 Periodical Maintenance........................................................................................................................................ 79

8.3 Replacing Wearing Parts...................................................................................................................................... 80

8.4 Storage..................................................................................................................................................................81

Chapter 9 List of Parameters...........................................................................................................................................82

Communication Protocol..................................................................................................................................................120

1. Networking Mode.................................................................................................................................................120

2. Interfaces.............................................................................................................................................................. 120

3. Communication Modes........................................................................................................................................ 120

4. Protocol Format....................................................................................................................................................121

1. RTU mode.................................................................................................................................................... 121

2.ASCII mode................................................................................................................................................121

5.Protocol Function.................................................................................................................................................. 122

6.Control parameters and status parameters of VFD...............................................................................................123

1

1

Chapter 1 Safety

1.1 Safety

Danger

Operations without following instructions

can cause personal injury or death.

!

Attention

Operations without following instructions

can cause moderate injury or damage the

products or other equipment

1.2 Notes for Installations

Danger

· Please install the drive on fire-retardant material like

metal, or it may cause fire.

· Keep the drive away from combustible material and

explosive gas, or it may cause fire.

· Only qualified personnel shall wire the drive, or it

may cause electric shock.

· Never wire the drive unless the input AC supply is

totally disconnected, or it may cause electric shock.

· The drive must be properly earthed to reduce

electrical accident

· Install the cover before switching on the drive, to

reduce the danger of electric shock and explosion.

· For drives that have been stored for longer than 2

years, increase its input voltage gradually before

supplying full rated input voltage to it, in order to

avoid electric shock and explosion

· Don't touch the live control terminals with bare

hands

· Don’t operate the drive with wet hands

· Perform the maintenance job after confirming that

the charging LED is off or the DC Bus voltage is

below 36V, or it may cause electric shock.,

· Only trained professionals can change the

components, it is prohibited to leave wires or metal

parts inside the drive so as to avoid the risk of fire.

· Parameter settings of the control panel that has been

changed must be revised, otherwise accidents may

occur.

· The bare portions of the power cables must be bound

with insulation tape

1.3 Notes for Using FV100

Pay attention to the following issues when using FV100.

1.3.1 About Motor and Load

Compared to the power frequency operation

!

Attention

· Don’t carry the drive by its cover. The cover can not

support the weight of the drive and may drop.

· Please install the drive on a strong support, or the

drive may fall off.

· Don’t install the drive in places where water pipes

may leak onto it.

· Don't allow screws, washers and other metal foreign

matters to fall inside the drive, otherwise there is a

danger of fire or damage;

· Don't operate the drive if parts are damaged or not

complete, otherwise there is a danger of a fire or

human injury;

· Don't install the drive under direct sunshine,

otherwise it may be damaged;

· Don’t short circuit +//B1 and terminal (-), otherwise

there is a danger of fire or the drive may be damaged.

· Cable lugs must be connected to main terminals

firmly

· Don’t apply supply voltage (AC 220V or higher) to

control terminals except terminals R1a, R1b and R1c.

·B1 and B2 are used to connect the brake resistor, do

not shortcut them, or the brake unit may be damaged

2

2

FV100 series drives are voltage type variable frequency

drive. The output voltage is in PWM wave with some

harmonics. Therefore, temperature rise, noise and

vibration of motor are higher compared to the power

frequency.

Low Speed operation with Constant Torque

Driving a common motor at low speed for a long time,

the drive’s rated output torque will be reduced

considering the deterioration of heat dissipation effect,

so a special variable frequency motor is needed if

operation at low speed with constant torque for a long

term.

Motor’s over-temperature protecting threshold

When the motor and driver are matched, the drive can

protect the motor from over-temperature. If the rated

capacity of the driven motor is not in compliance with

the drive, be sure to adjust the protective threshold or

take other protective measures so that the motor is

properly protected.

Operation above 50Hz

When running the motor above 50Hz, there will be

increase in vibration and noise. The rate at which the

torque is available from the motor is inversely

proportional to its increase in running speed. Ensure that

the motor can still provide sufficient torque to the load.

Lubrication of mechanical devices

Over time, the lubricants in mechanical devices, such as

gear box, geared motor, etc. when running at low speed,

will deteriorate. Frequent maintenance is recommended.

Braking Torque

Braking torque is developed in the machine when the

drive is hoisting a load down. The drive will trip when it

can not cope with dissipating the regenerative energy of

the load. Therefore, a braking unit with proper

parameters setting in the drive is required.

The mechanical resonance point of load

The drive system may encounter mechanical resonance

with the load when operating within certain band of

output frequency. Skip frequencies have been set to

avoid it.

Start and stop frequently

The drive should be started and stopped via its control

terminals. It is prohibited to start and stop the drive

directly through input line contactors, which may

damage the drive with frequent operations.

Insulation of Motors

Before using the drive, the insulation of the motors must

be checked, especially, if it is used for the first time or if

it has been stored for a long time. This is to reduce the

risk of the Drive from being damaged by the poor

insulation of the motor. Wiring diagram is shown in Fig.

1-1. Please use 500V insulation tester to measure the

insulating resistance. It should not be less than 5MΩ.

Fig. 1-1 checking the insulation of motor

1.3.2 About Variable Frequency Drive

Varistors or Capacitors Used to Improve the Power

Factor

Considering the drive output PWM pulse wave, please

don't connect any varistor or capacitor to the output

terminals of the drive, otherwise tripping or damaging of

components may occur; as shown in fig 1.2

3

3

M

U

V

W

FV100

Fig. 1-2 Capacitors are prohibited to be used.

Circuit breakers connected to the output of VFD

If circuit breaker or contactor needs to be connected

between the drive and the motor, be sure to operate these

circuit breakers or contactor when the drive has no

output, to avoid damaging of the drive.

Using VFD beyond the range of rated voltage

The drive is not suitable to be used out of the

specified range of operation voltage. If needed, please

use suitable voltage regulation device.

Protection from lightning

There is lighting-strike over-current device inside

the Drive which protects it against lighting.

Derating due to altitude

Derating must be considered when the drive is

installed at high altitude, greater than 1000m. This is

because the cooling effect of drive is deteriorated due to

the thin air, as shown in Fig.1-3 that indicates the

relationship between the altitude and rated current of the

driver.

Fig. 1-3 Derating Drive's output current with altitude

1.4 Disposing Unwanted Driver

When disposing the VFD, pay attention to the following

issues:

The electrolytic capacitors in the driver may explode

when they are burnt.

Poisonous gas may be generated when the plastic parts

like front covers are burnt.

Please dispose the drive as industrial waste.

4

4

Chapter 2 Product introduction

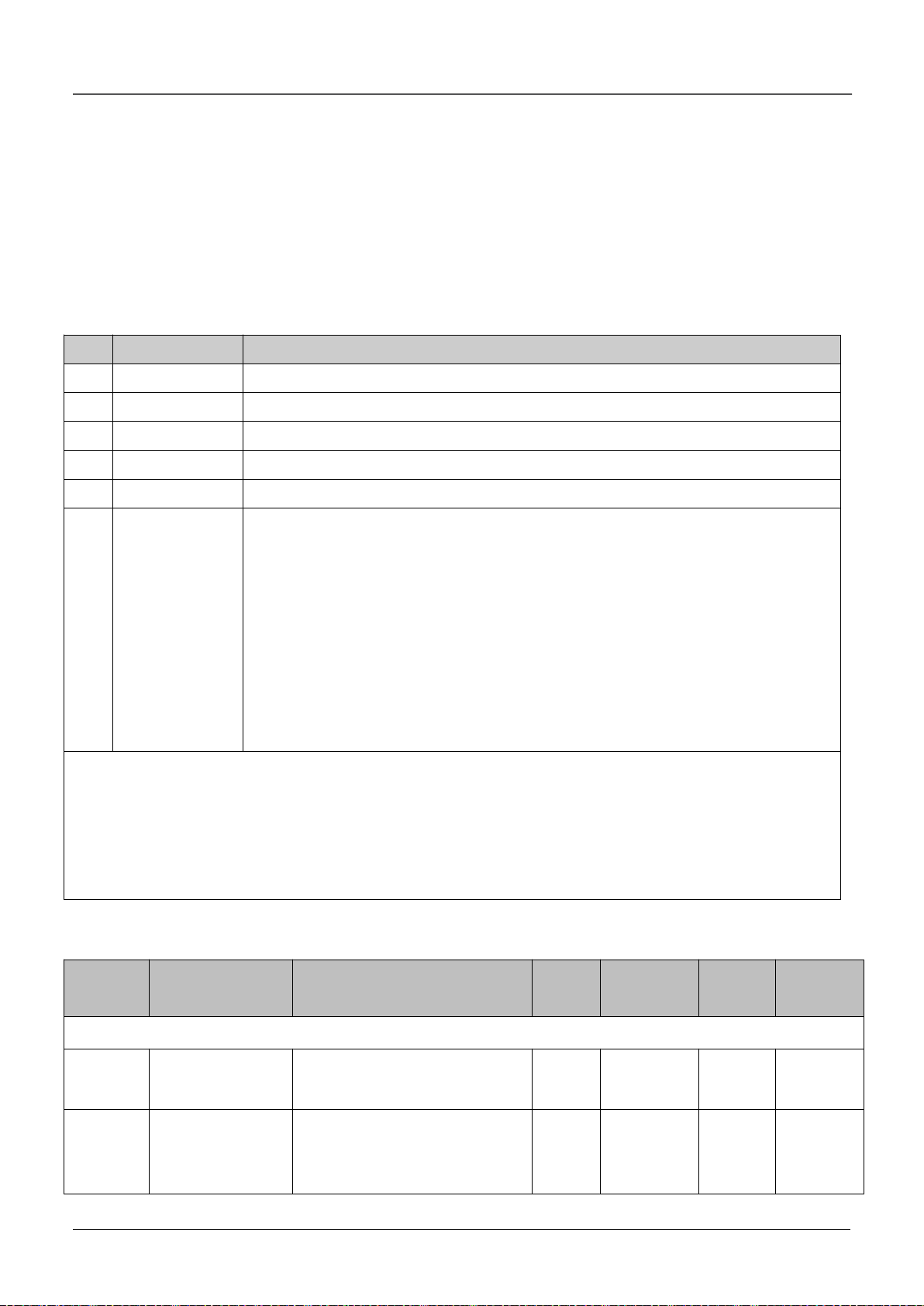

Item

Description

Input

Rated voltage and

frequency

4T:3-phase,380V ~ 440V AC; 50Hz/60Hz; 2T: 3-phase, 200V~240V;50Hz/60Hz

2S:Single-phase,200V~240V;50Hz/60Hz

Allowable voltage

range

4T: 320V~460V AC; 2T/2S:180V~260V;Voltage tolerance<3%; Frequency: ±5%

Output

Rated voltage

0~Rated input voltage

Frequency

0Hz~300Hz(Customized 0Hz~3000Hz)

Overload capacity

G type : 150% rated current for 1 minute, 180% rated current for 10 seconds;

L type :110% rated current for 1 minute, 150% rated current for 1 second

Control

Charact

eristics

Control mode

Vector control without PG, Vector control with PG; V/F control

Modulation mode

Space vector PWM modulation

Starting torque

0.5Hz 150%rated torque (Vector control without PG ) , 0Hz 200% rated torque

(Vector control with PG)

Frequency accuracy

Digital setting:Max frequency ×±0.01%;Analog setting:Max. frequency ×±0.2%

Frequency

resolution

Digital setting: 0.01Hz;Analog setting: Max frequency×0.05%

Torque boost

Manual torque boost :0%~30.0%

V/F pattern

4 patterns: 1 kind of V/F curve mode set by user and 3 kinds of torque-derating

modes (2.0 order, 1.7 order, and 1.2 order)

Acc/Dec curve

Linear acceleration/deceleration, Four kinds of acceleration/deceleration time are

optional

Auto current limit

Limit current during the operation automatically to prevent frequent over-current trip

Customi

zed

function

Jog

Range of jog frequency: 0.20Hz~50.00Hz; Acc/Dec time of Jog operation: 0.1~60.0s,

Interval of Jog operation is also settable.

Multiple speed

operation

Implement multiple speed operation by digital inputs

Operatio

n

function

Operation command

Keypad setting, terminal setting, communication setting

Frequency

command setting

Digital setting, Analog voltage setting, Analog current setting, Pulse setting

In this chapter we introduce the basic product information of specifications, model, and structure and so on.

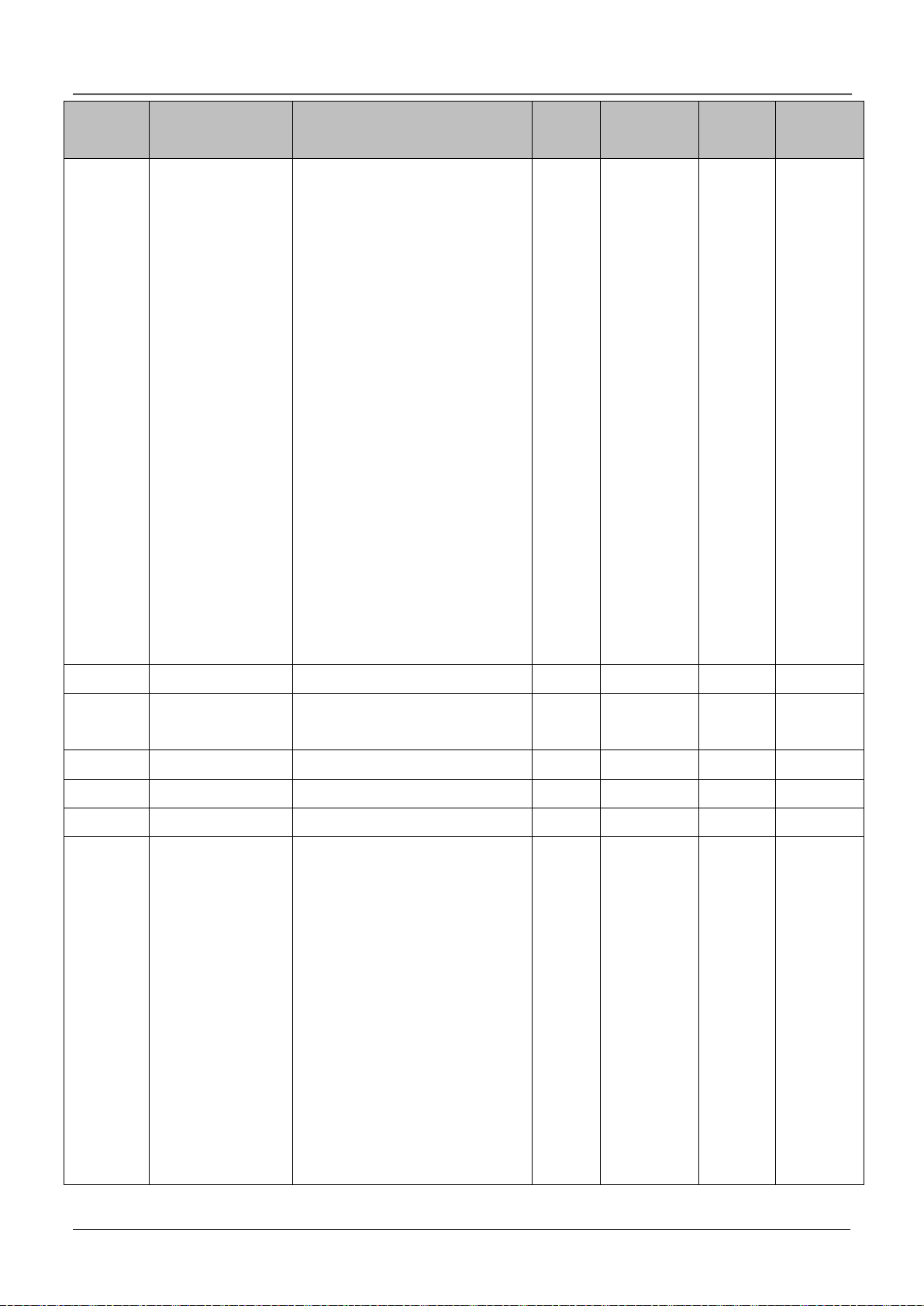

2.1 General specifications

Table 2-1 General specifications

5

5

Auxiliary frequency

setting

Implement flexible auxiliary frequency trim and frequency synthesis.

Pulse output

terminal

0.1~100kHz pulse output. For example setting frequency, output frequency etc.

Analog output

terminal

2 channels analog output (0/4~20mA or 0/2~10V). For example setting frequency,

output frequency etc.

Operatio

n panel

LED Display

Display frequency setting, frequency output, voltage output, current output and so on,

about 20 parameters.

Parameters copy

Copy parameters by operation panel.

Keys lock and

function selection

Lock part of keys or all the keys. Define the function of part of keys, in case of

misoperation.

Protection function

Open phase protection (optional), overcurrent protection, overvoltage protection,

undervoltage protection, overheat protection, and overload protection and so on.

Environ

ment

Operating site

Indoor, installed in the environment free from direct sunlight, dust, corrosive gas,

combustible gas, oil mist, steam and drip.

Altitude

Derated above 1000m, the rated output shall be decreased by 10% for every rise of

1000m

Ambient

temperature

-10℃~40℃, derated at 40℃~ 50℃

Humidity

5%~95%RH, non-condensing

Vibration

Less than 5.9m/s² (0.6g)

Storage temperature

-40℃~+70℃

Structur

e

Protection class

IP20

Cooling method

Air cooling, with fan control.

Installation method

Wall-mounted

Efficiency

Power under 45kW≥93%;Power above 55kW≥95%

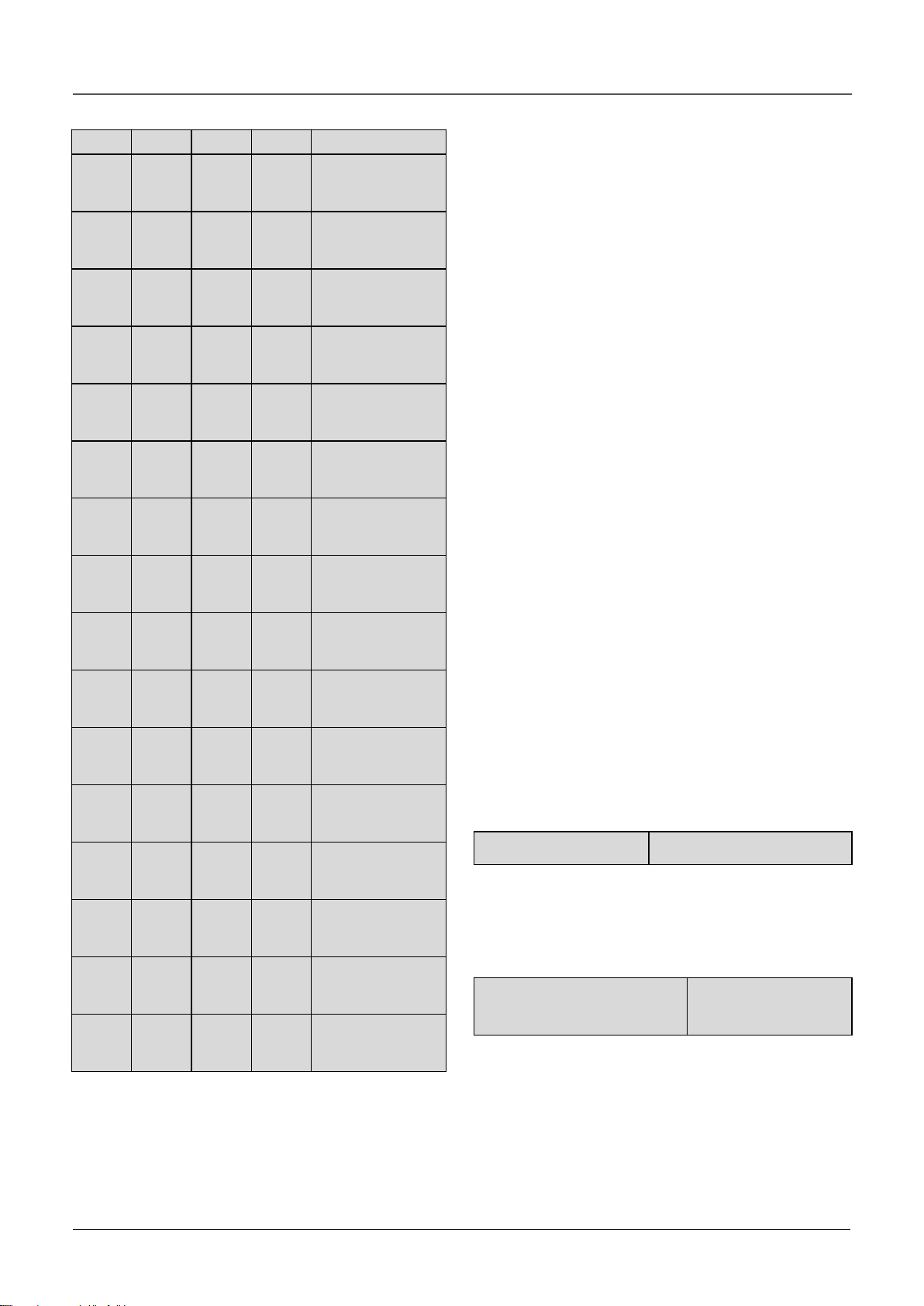

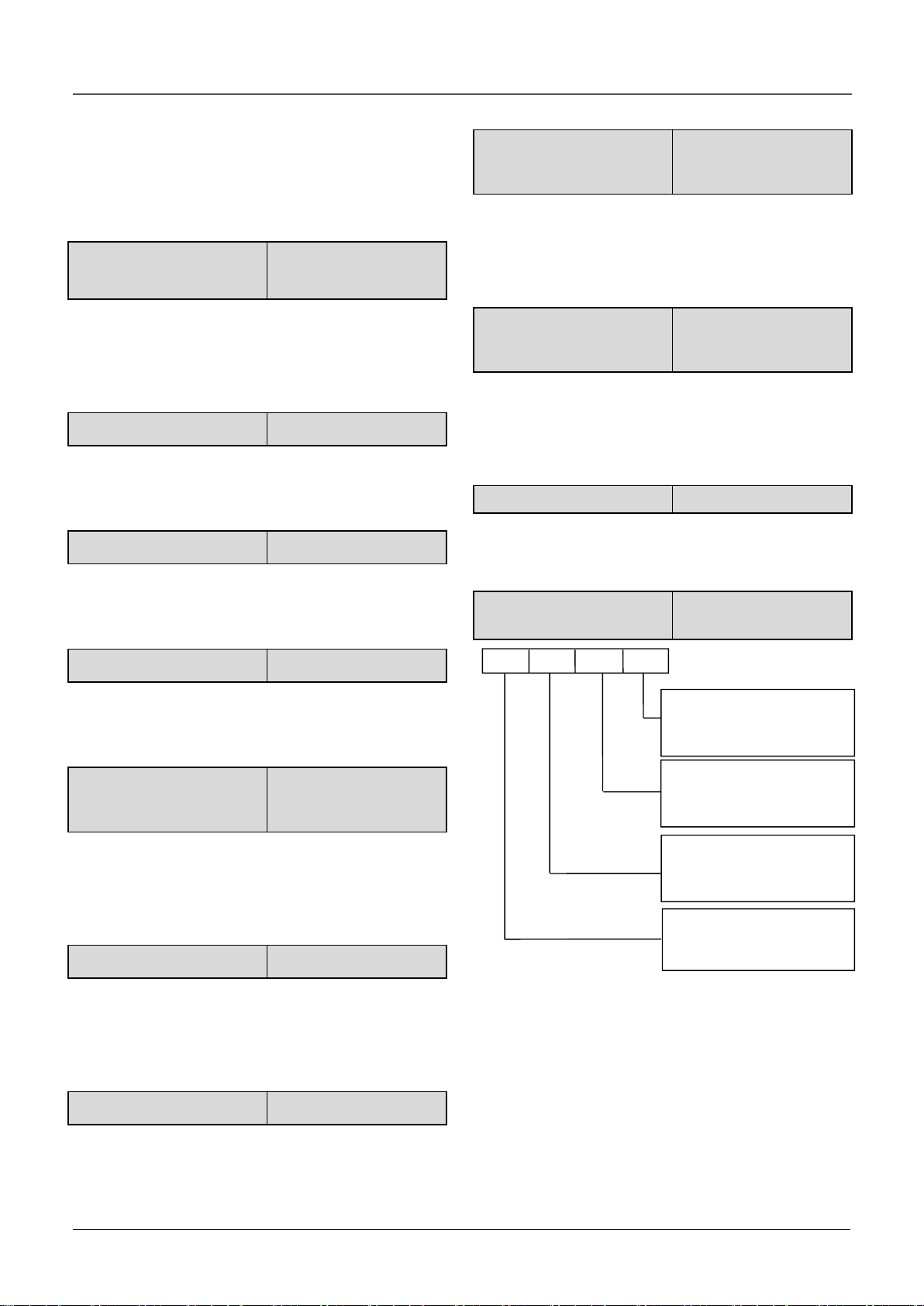

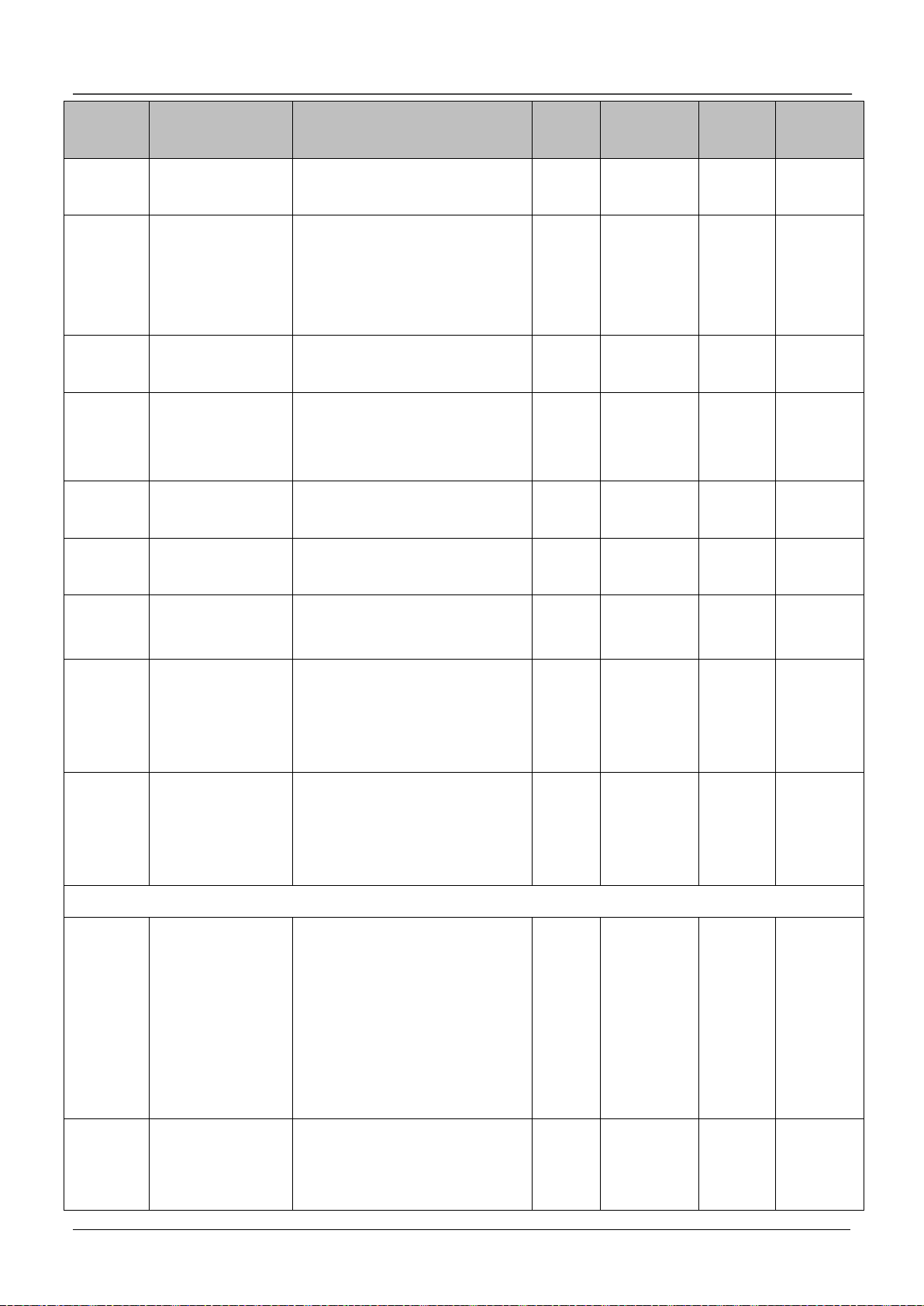

2.2 Introduction of product series

Model of VFD

Rated capacity

(kVA)

Rated input current

(A)

Rated output current

(A)

Motor power(kW)

FV100-2S-0004G

1.0

5.3

2.5

0.4

FV100-2S-0007G

1.5

8.2

4.0

0.75

FV100-2S-0015G

3.0

14.0

7.5

1.5

FV100-2S-0022G

4.0

23.0

10.0

2.2

FV100-2S-0037G

6.4

32.0

16.0

3.7

FV100-2S-0055G

9.8

40.0

24.5

5.5

Table 2-1 Series of Kinco VFD

6

6

FV100-2S-0075G

12.5

45.0

30.0

7.5

FV100-2S-0110G

19.0

70.0

46.0

11

FV100-2S-0150G

25.0

90.0

60.0

15

FV100-2S-0185G

31.0

110.0

75.0

18.5

FV100-2S-0220G

35.6

125.0

85.0

22

FV100-2T-0004G

1.0

3.2

2.5

0.4

FV100-2T-0007G

1.5

6.3

4.0

0.7

FV100-2T-0015G

3.097.5

1.5

FV100-2T-0022G

4.01510

2.2

FV100-2T-0037G

6.12216

3.7

FV100-2T-0055G

9.43024.5

5.5

FV100-2T-0075G

123530

7.5

FV100-2T-0110G

165046

11

FV100-2T-0150G

216360

15

FV100-2T-0185G

278075

18.5

FV100-2T-0220G

318785

22

FV100-4T-0007G/0015L

1.5/3.0

3.4/5.0

2.3/3.7

0.75/1.5

FV100-4T-0015G/0022L

3.0/4.0

5.0/5.8

3.7/5.5

1.5/2.2

FV100-4T-0022G/0037L

4.0/5.9

5.8/10.5

5.5/8.8

2.2/3.7

FV100-4T-0037G/0055L

5.9/8.5

10.5/14.5

8.8/13.0

3.7/5.5

FV100-4T-0055G/0075L

8.5/11.0

14.5/20.5

13.0/17.0

5.5/7.5

FV100-4T-0075G/0110L

11.0/17.0

20.5/26.0

17.0/25.0

7.5/11

FV100-4T-0110G/0150L

17.0/21.0

26.0/35.0

25.0/32.0

11/15

FV100-4T-0150G/0185L

21.0/24.0

35.0/38.5

32.0/37.0

15/18.5

FV100-4T-0185G/0220L

24.0/30.0

38.5/46.5

37.0/45.0

18.5/22

FV100-4T-0220G/0300L

30.0/40.0

46.5/62.0

45.0/60.0

22/30

FV100-4T-0300G/0370L

40.0/50.0

62.0/76.0

60.0/75.0

30/37

FV100-4T-0370G/0450L

50.0/60.0

76.0/92.0

75.0/90.0

37/45

FV100-4T-0450G/0550L

60.0/72.0

92.0/113.0

90.0/110.0

45/55

FV100-4T-0550G/0750L

72.0/100.0

113.0/157.0

110.0/152.0

55/75

FV100-4T-0750G/0900L

100.0/116.0

157.0/180.0

152.0/176.0

75/90

FV100-4T-0900G/1100L

116.0/138.0

180.0/214.0

176.0/210.0

90/110

FV100-4T-1100G/1320L

138.0/167.0

214.0/256.0

210.0/253.0

110/132

FV100-4T-1320G/1600L

167.0/200.0

256.0*/282.0

253.0/304.0

132/160

7

7

FV100-4T-1600G/1850L

200.0/230.0

282.0*/326.0

304.0/355.0

160/185

FV100-4T-1850G/2000L

230.0/250.0

326.0*/352.0

355.0/380.0

185/200

FV100-4T-2000G/2200L

250.0/280.0

352.0*/385.0

380.0/426.0

200/220

FV100-4T-2200G/2500L

280.0/355.0

385.0*/437.0

426.0/500.0

220/250

FV100-4T-2500G/2800L

355.0/396.0

437.0*/491.0

500.0/540.0

250/280

FV100-4T-2800G/3150L

396.0/445.0

491.0*/580.0

540.0/600.0

280/315

FV100-4T-3150G/3550L

445.0/500.0

580.0*/624.0

600.0/700.0

315/355

FV100-4T-3550G/4000L

500.0/565.0

624.0*/670.0

700.0/780.0

355/400

FV100-4T-4000G/4500L

565.0/630.0

670.0*/792.0

780.0/830.0

400/450

*FV100-4T-1850G/2000L and above standardly integrated with external DC reactor.

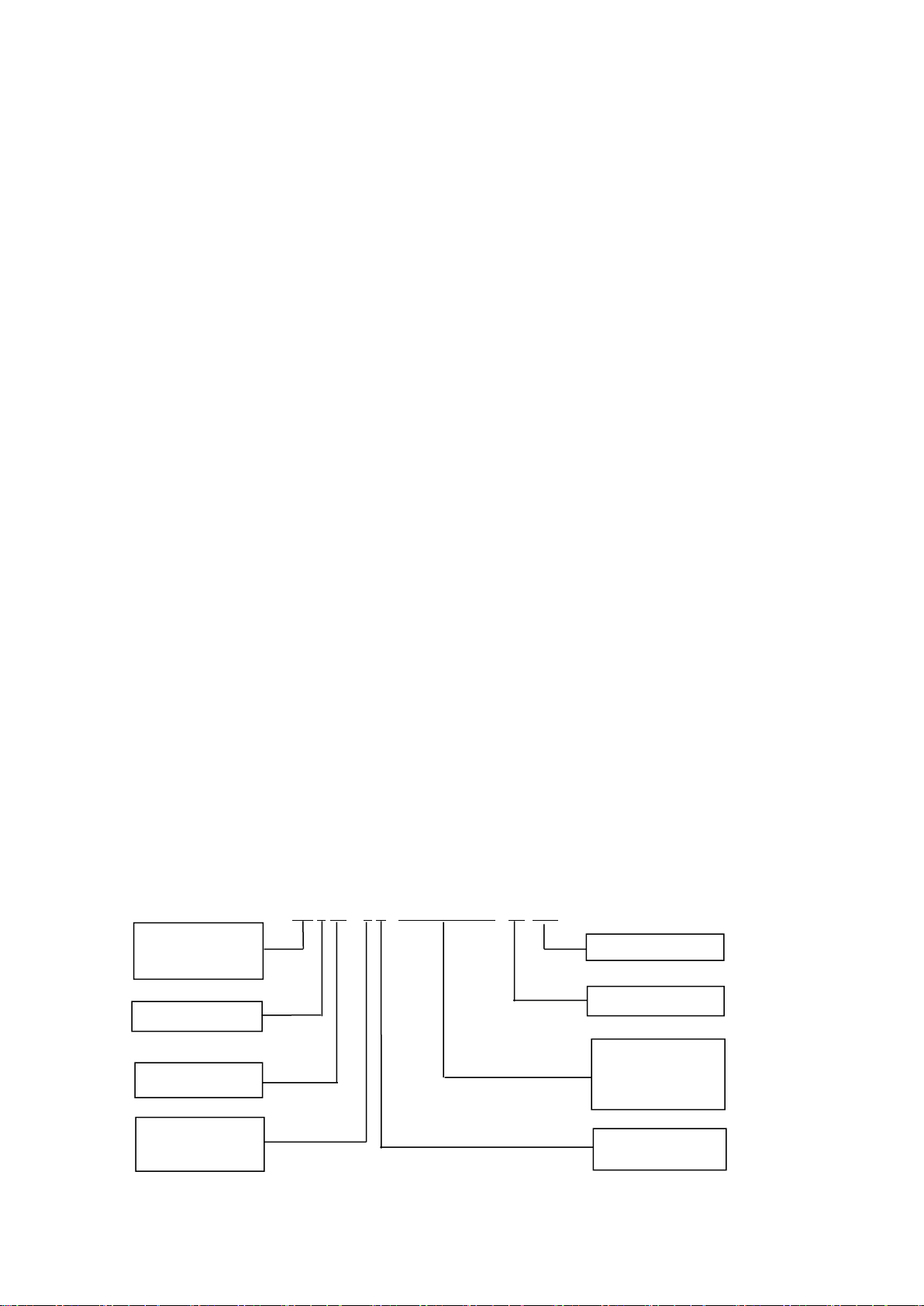

2.3 Structure of VFD

The structure of VFD is as following figure.

FV100-4T-0037G/0055L and below power FV100-4T-0055G/0075L and above power

Fig 2-1 Structure chart of VFD

8

8

2.4 External dimension and weight

2.4.1 External dimension and weight

External dimension and weight is as following figure.

Fig 2-2 FV100-4T-0037G/0055L and lower power VFD

Fig 2-3 FV100-4T-0055G/0075L~FV100-4T-4000G/4500L

9

9

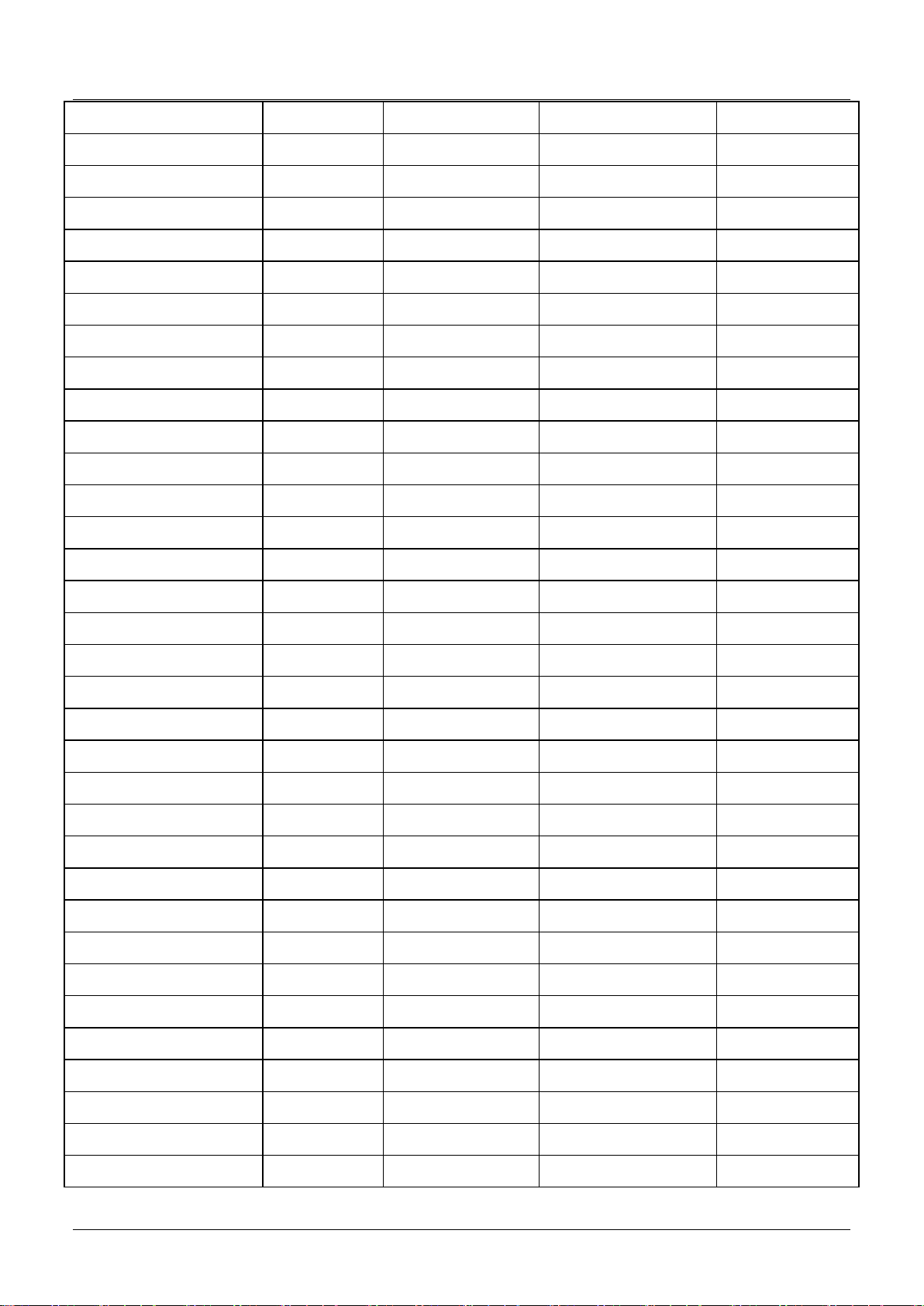

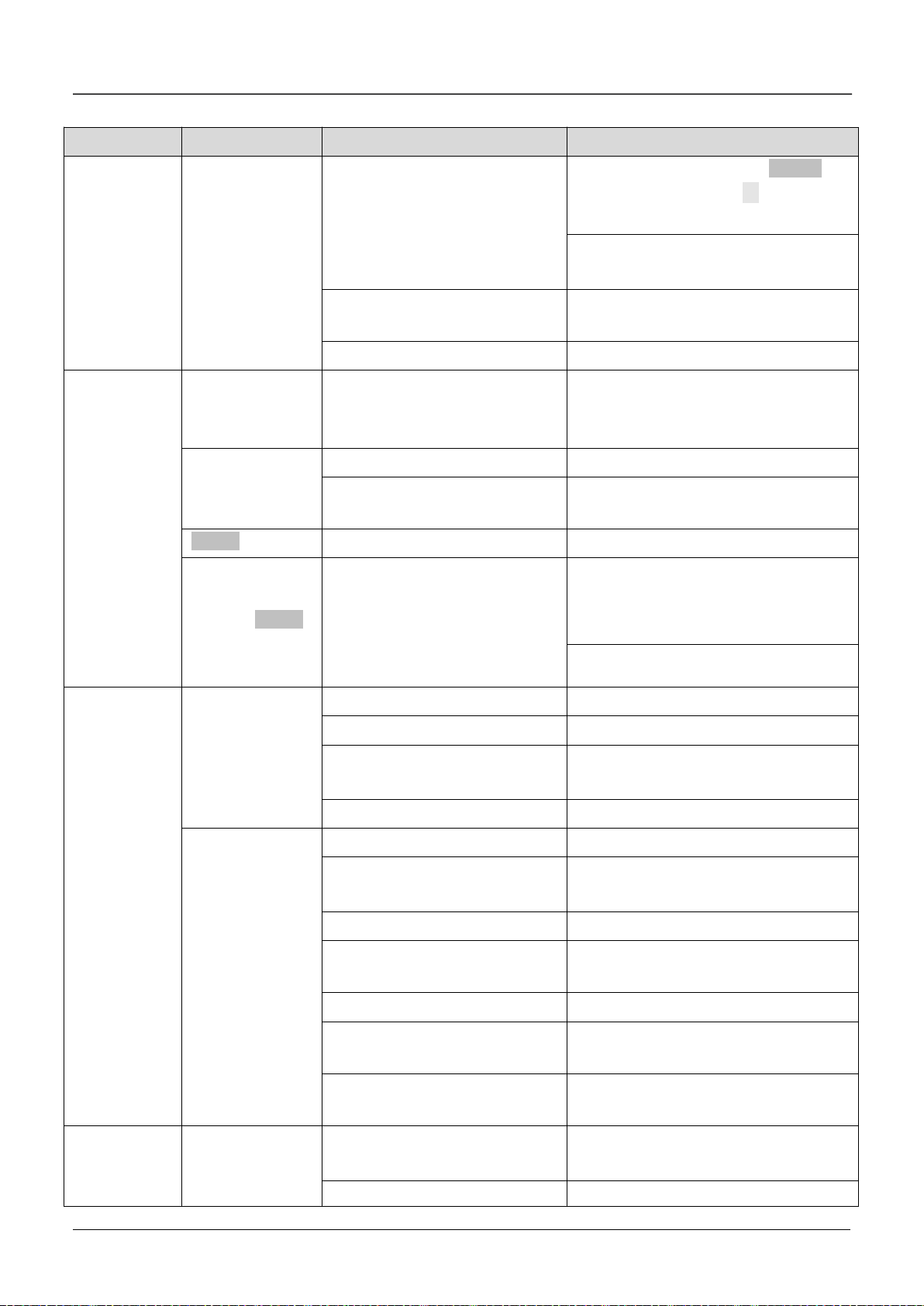

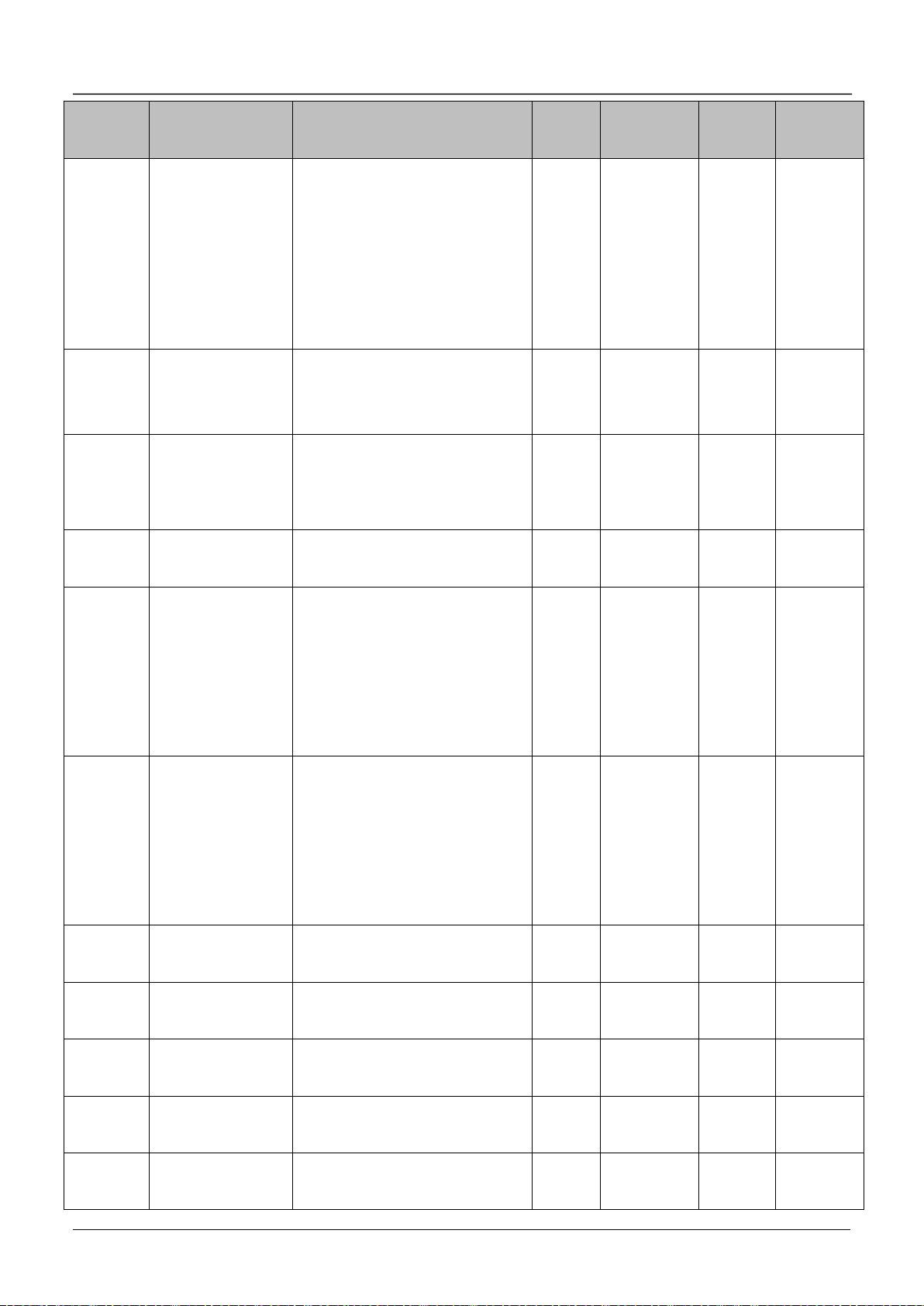

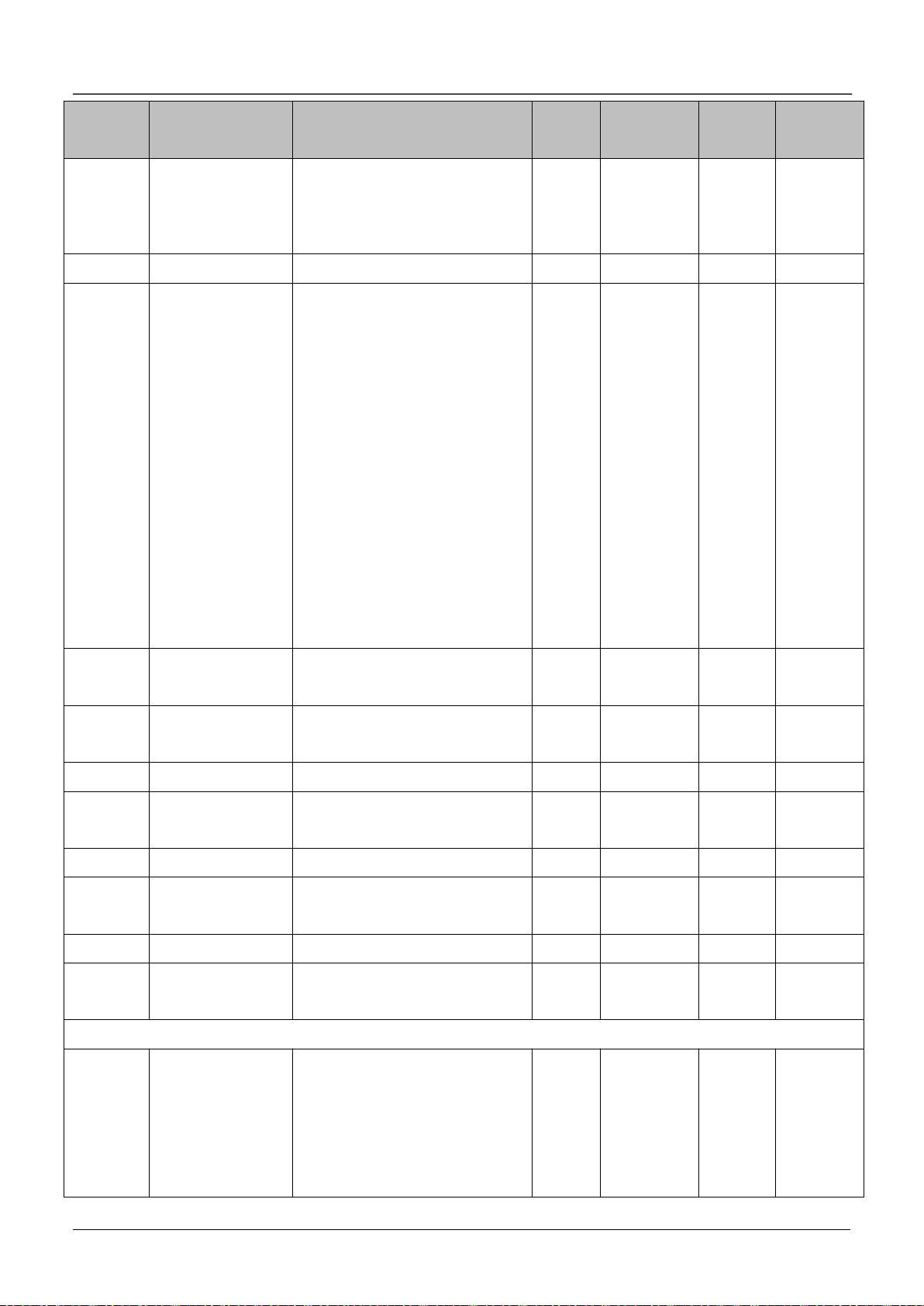

Table 2-2 Mechanical parameters

VFD model

(G:Constant torque load;

L: Draught fan and

water pump load)

External dimension and (mm)

Weight

(kg)

WHDW1H1D1T1

Installation

hole(d)

FV100-2S-0004G

115

185

171

106

17665752

FV100-2S-0007G

FV100-2S-0015G

FV100-2S-0022G

FV100-2S-0037G

FV100-2T-0004G

FV100-2T-0007G

FV100-2T-0015G

FV100-2T-0022G

FV100-2T-0037G

FV100-4T-0007G/0015L

FV100-4T-0015G/0022L

FV100-4T-0022G/0037L

FV100-4T-0037G/0055L

FV100-2S-0055G

165

274

193

110

264-266

FV100-2S-0075G

FV100-2T-0055G

FV100-2T-0075G

FV100-4T-0055G/0075L

FV100-4T-0075G/0110L

FV100-2S-0110G

194

324

197

120

312-268

FV100-2T-0110G

FV100-4T-0110G/0150L

FV100-4T-0150G/0185L

FV100-4T-0185G/0220L

FV100-2S-0150G

297

451

224

200

433

-37

18

FV100-2S-0185G

FV100-2S-0220G

FV100-2T-0150G

FV100-2T-0185G

10

10

FV100-2T-0220G

FV100-4T-0220G/0300L

FV100-4T-0300G/0370L

FV100-4T-0370G/0450L

320

535

224

220

512

88.5310

31

FV100-4T-0450G/0550L

FV100-4T-0550G/0750L

373

649

262

240

628

102.5310

42

FV100-4T-0750G/0900L

FV100-4T-0900G/1100L

440

758

285

340

737

102

2.51173

FV100-4T-1100G/1320L

430

780

330

280

755

168311

76

FV100-4T-1320G/1600L

FV100-4T-1600G/1850L

530

940

380

340

910

206414

114

FV100-4T-1850G/2000L

FV100-4T-2000G/2200L

FV100-4T-2200G/2500L

690

1006

380

500

974

207414

156

FV100-4T-2500G/2800L

FV100-4T-2800G/3150L

FV100-4T-3150G/3550L

810

1228

400

520

1196

209414

225

FV100-4T-3550G/4000L

FV100-4T-4000G/4500L

11

11

2.4.2 Operation panel and installation box

Fig 2-4 Operation panel dimension

Fig 2-5 Installation box dimension

12

12

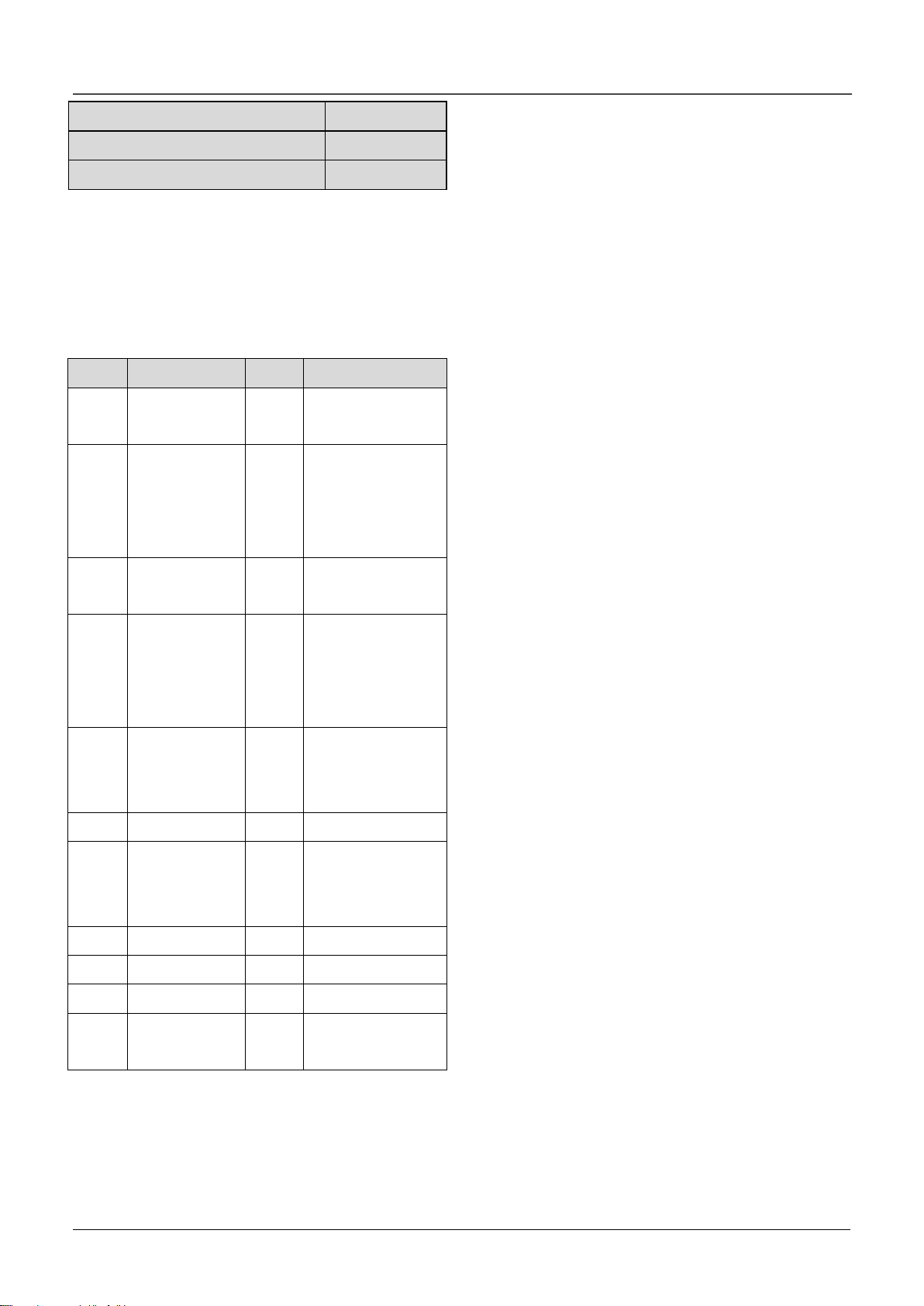

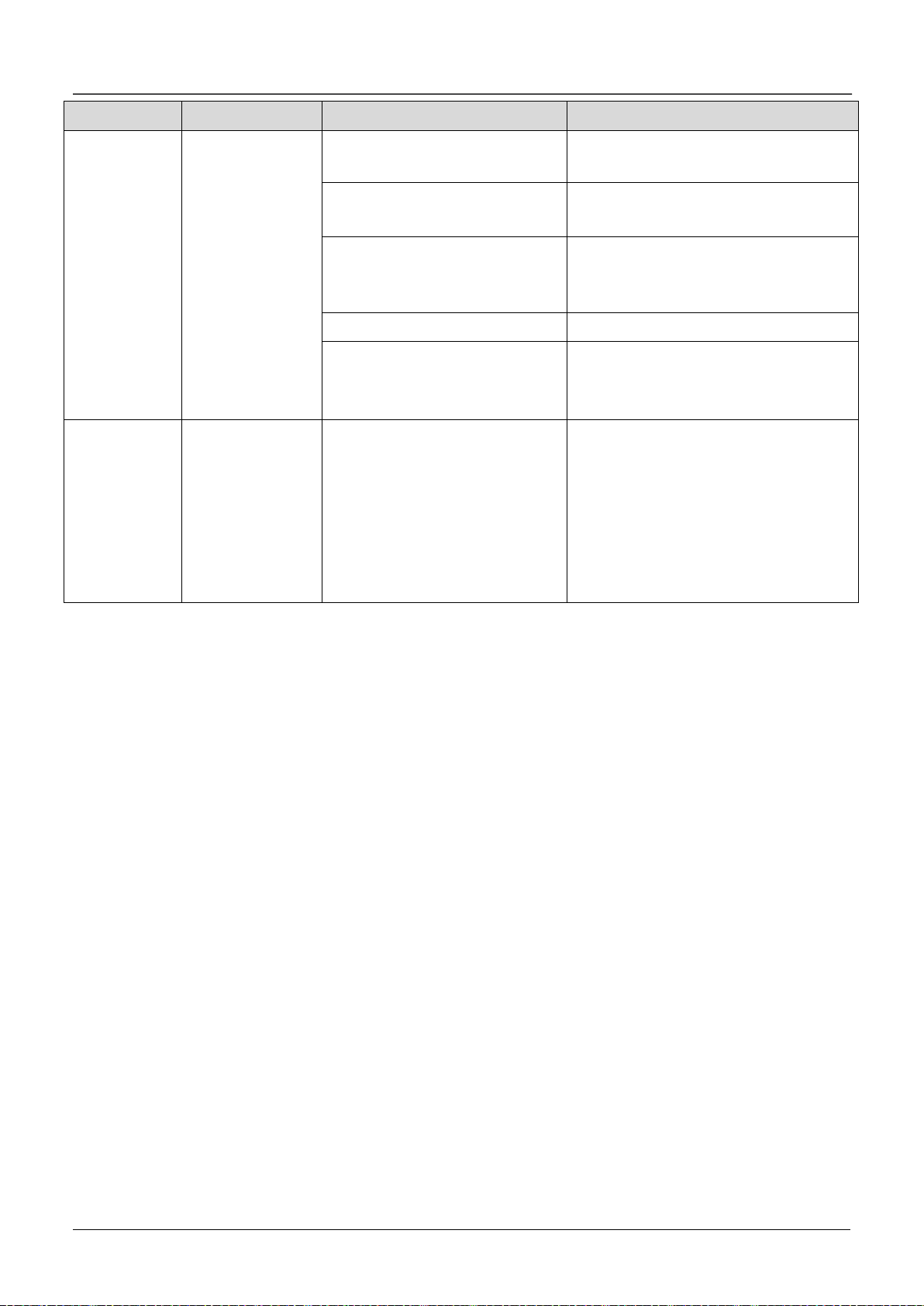

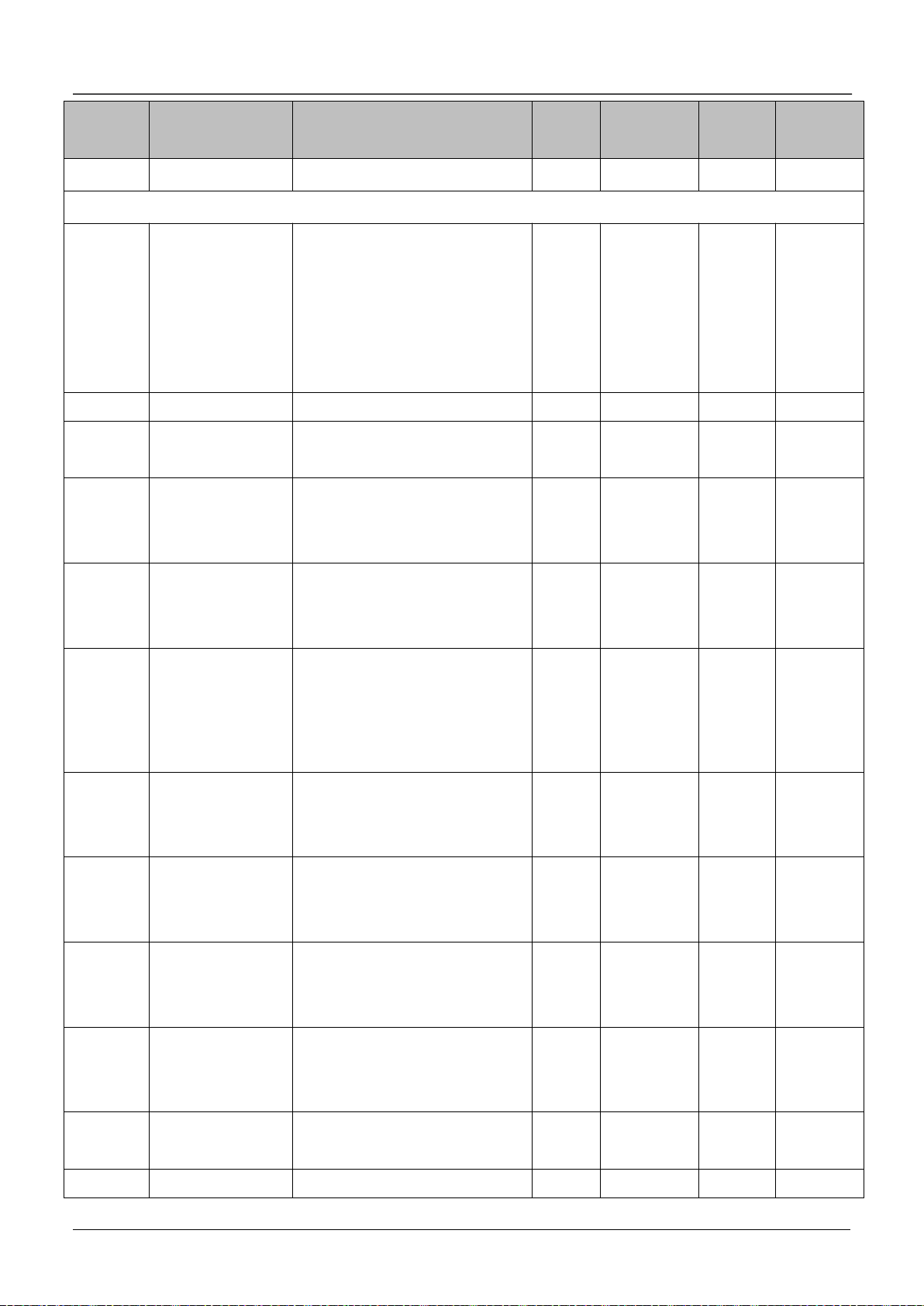

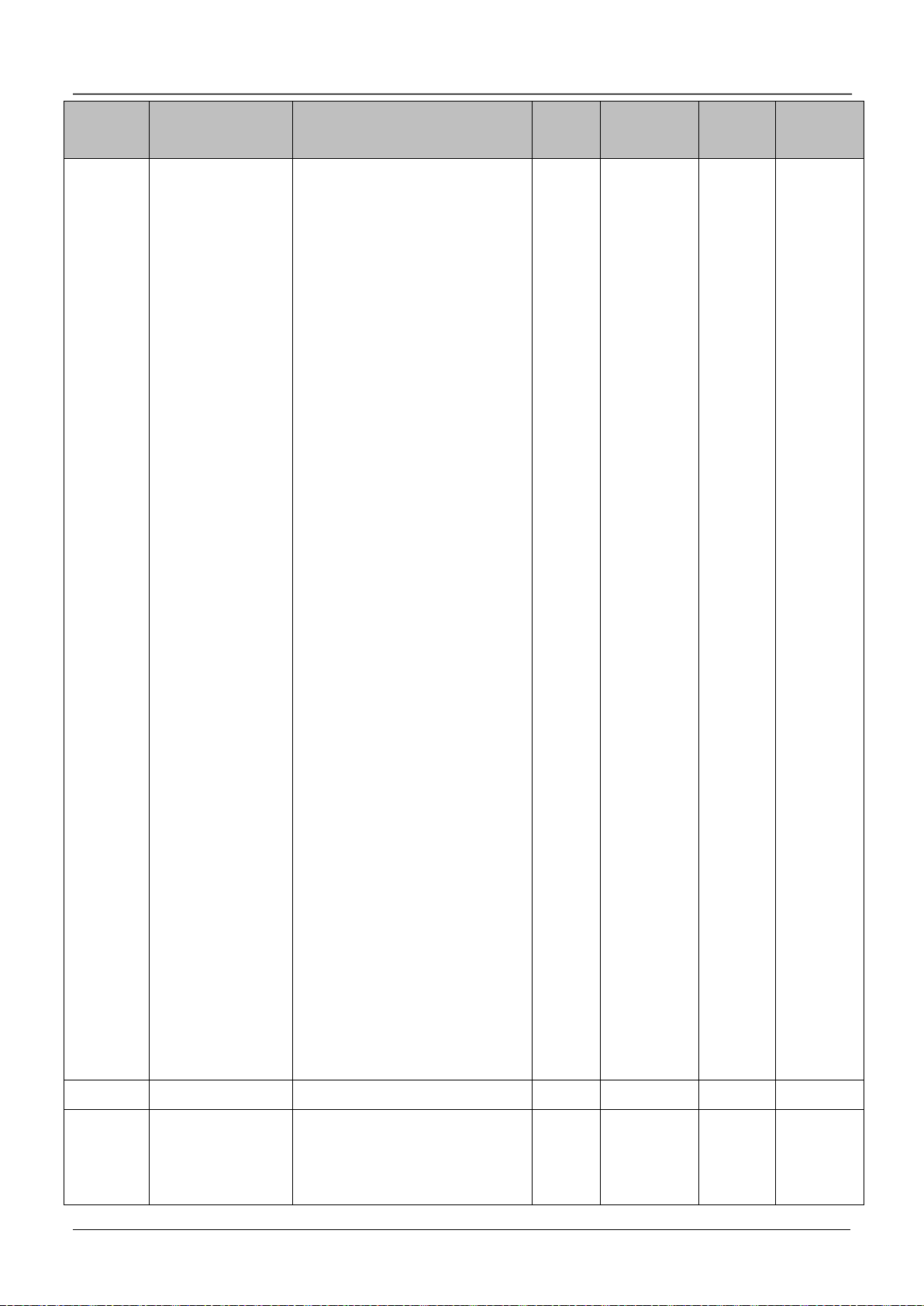

2.4.3 Braking Resistor Selection

VFD Model

Braking Unit

Braking resistor

Standard

resistance

Qty.

Min. resistance

Standard power

FV100-2S/2T-0004G

Built-in

200Ω1100Ω

100W

FV100-2S/2T -0007G

150Ω1100Ω

150W

FV100-2S/2T -0015G

150Ω1100Ω

150W

FV100-2S/2T -0022G

50Ω135Ω

400W

FV100-2S/2T -0037G

45Ω135Ω

450W

FV100-2S/2T-0055G

50Ω125Ω

1600W

FV100-2S/2T-0075G

40Ω125Ω

2000W

FV100-2S/2T-0110G

27.2Ω120Ω

2000W

FV100-4T-0007G/0015L

750Ω1125Ω

110W

FV100-4T-0015G/0022L

400Ω1100Ω

260W

FV100-4T-0022G/0037L

250Ω1100Ω

320W

FV100-4T-0037G/0055L

150Ω166.7Ω

550W

FV100-4T-0055G/0075L

100Ω166.7Ω

800W

FV100-4T-0075G/0110L

75Ω166.7Ω

1070W

FV100-4T-0110G/0150L

50Ω125Ω

1600W

FV100-4T-0150G/0185L

40Ω125Ω

2000W

FV100-4T-0185G/0220L

32Ω120Ω

4800W

FV100-2S/2T-0150G

Built-in

(optional)

20Ω114Ω

2000W

FV100-2S/2T-0185G

16Ω114Ω

4800W

FV100-2S/2T-0220G

13.6Ω110Ω

4800W

FV100-4T-0220G/0300L

27.2Ω120Ω

4800W

FV100-4T-0300G/0370L

20Ω114Ω

6000W

FV100-4T-0370G/0450L

16Ω114Ω

9600W

FV100-4T-0450G/0550L

External

15Ω113.6Ω

9600W

FV100-4T-0550G/0750L

20Ω213.6Ω

6000W*2

FV100-4T-0750G/0900L

20Ω213.6Ω

9600W*2

FV100-4T-0900G/1100L

18Ω313.6Ω

9600W*3

FV100-4T-1100G/1320L

18Ω313.6Ω

6000 W*3

FV100-4T-1320G/1600L

10Ω14Ω

30KW

FV100-4T-1600G/1850L

8Ω14Ω

30KW

FV100-4T-1850G/2000L

6Ω14Ω

30KW

FV100-4T-2000G/2200L

5Ω14Ω

30KW

13

12

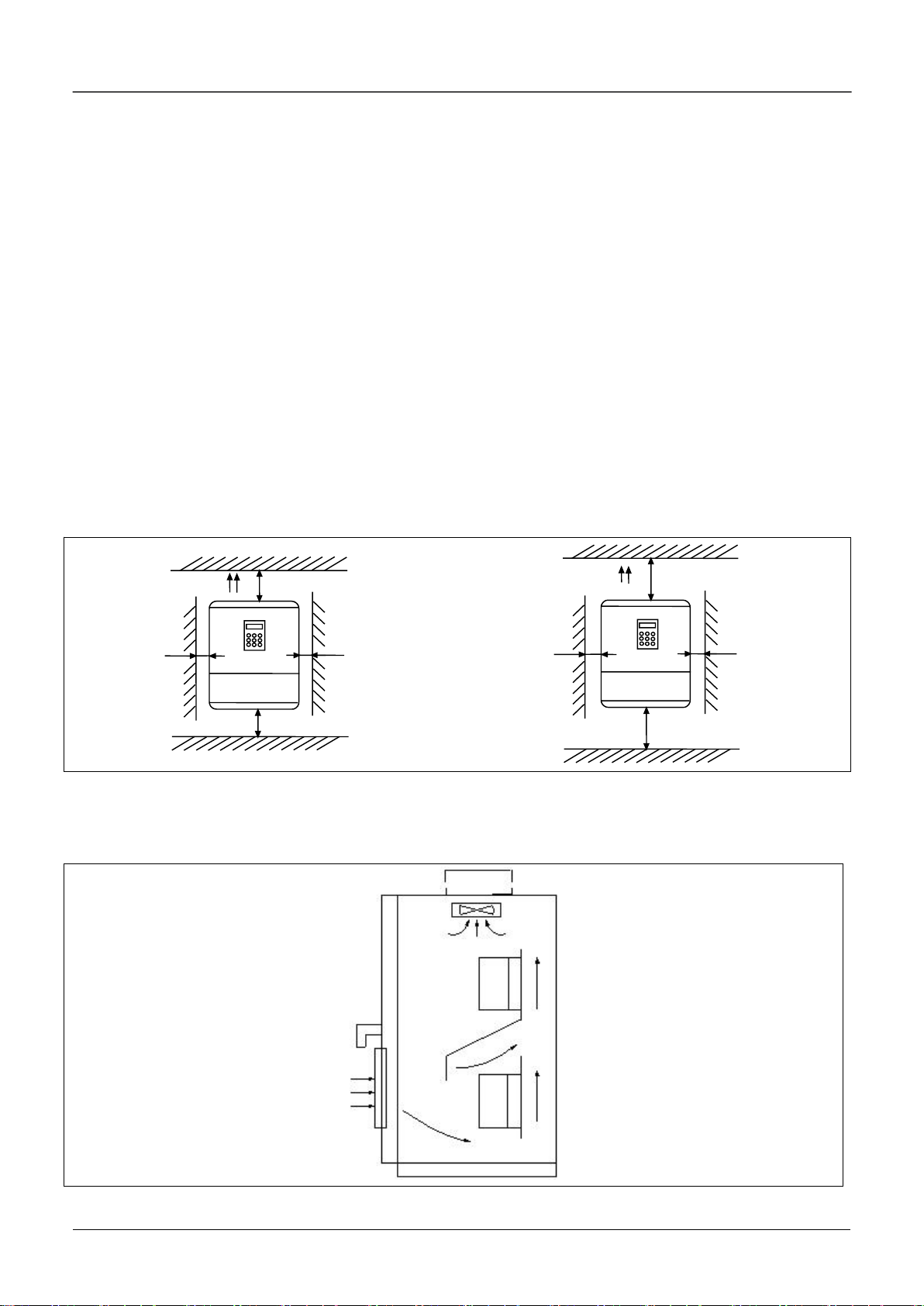

Chapter 3 Installation Environment

Ambient temperature should be within the range of-10℃~40℃. If the temperature is higher than 40 ℃, the drive

Humidity should be lower than 95%,non-condensing

Install in the location where vibration is less than 5.9m/s² (0.6g);

Install in the location free of direct sunlight.

Install in the location free of dust, metal powder.

Install in the location free of corrosive gas or combustible gas.

>

5cm

>10cm

Fan airflow

>5c

m

>10cm

>35cm

>15cm

Fan ariflow

>15cm

>35cm

Fig 3-1 Installation interval (Power below 45kW)

Fig 3-2 Installation interval(Power above 55kW)

In this chapter we introduce the installation environment of VFD

Please mount the drive vertically inside a well-ventilated location.

When considering mounting environment, the following issues should be taken into account:

should be derated and forced ventilation is required;

If there are any special requirements for installation, please contact us for clarifications.

The requirements on mounting space and clearance are shown in Fig. 3-1 and Fig. 3-2.

When two VFD are mounted and one is on the top of another, an air flow diverting plate should be fixed in between

them as shown in Fig. 3-3.

Fig 3-3 Installation of several VFD

14

12

Chapter 4 Wiring Guide of VFD

Danger

·Wiring can only be done after the drive’s AC power is disconnected, all the LEDs on the operation panel are off

and waiting for at least 10 minutes. Then, you can remove the panel.

·Wiring job can only be done after confirming the charge indicator on the right bottom is off and the voltage

between main circuit power terminals + and - is below DC36V.

·Wire connections can only be done by trained and authorized person

·Check the wiring carefully before connecting emergency stop or safety circuits.

·Check the drive’s voltage level before supplying power to it, otherwise human injuries or equipment damage

may happen.

!

Attention

·Check whether the Variable Speed Drive’s rated input voltage is in compliant with the AC supply voltage

before using.

·Dielectric strength test of the drive has been done in factory, so you need not do it again.

·Refer to chapter 2 on connected braking resistor or braking kit.

·It is prohibited to connect the AC supply cables to the drive’s terminals U, V and W.

·Grounding cables should be copper cables with section area bigger than 3.5mm², and the grounding resistance

should be less than 10Ω.

·There is leakage current inside the drive. The total leakage current is greater than 3.5mA, depending on the

usage conditions. To ensure safety, both the drive and the motor should be grounded, and a leakage current

protector (RCD) should be installed. It is recommended to choose B type RCD and set the leakage current at

300mA.

·The drive should be connected to the AC supply via a circuit breaker or fuse to provide convenience to input

over-current protection and maintainance.

In this chapter we introduce the wiring of VFD

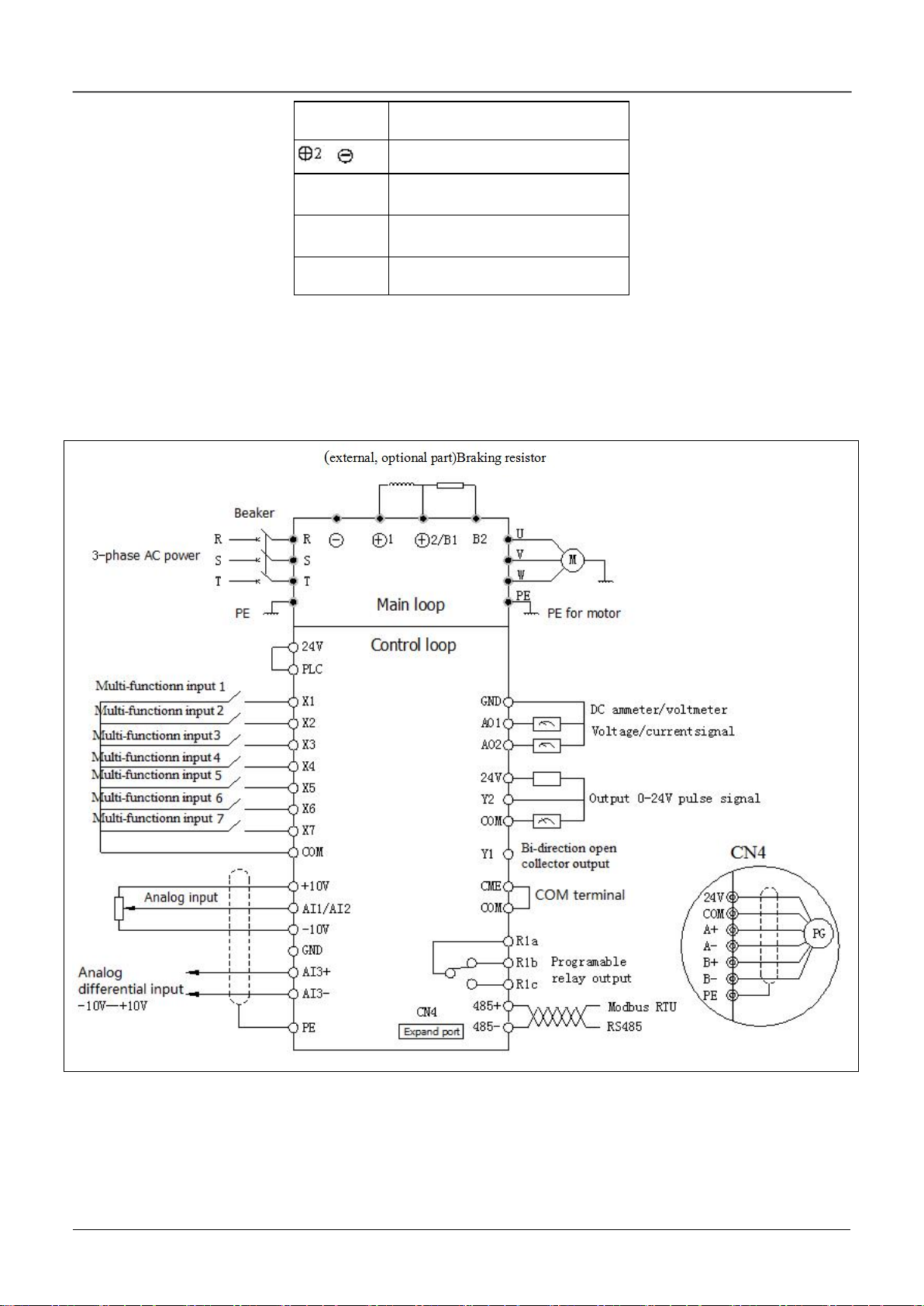

4.1 Wiring and Configuration of Main circuit terminal

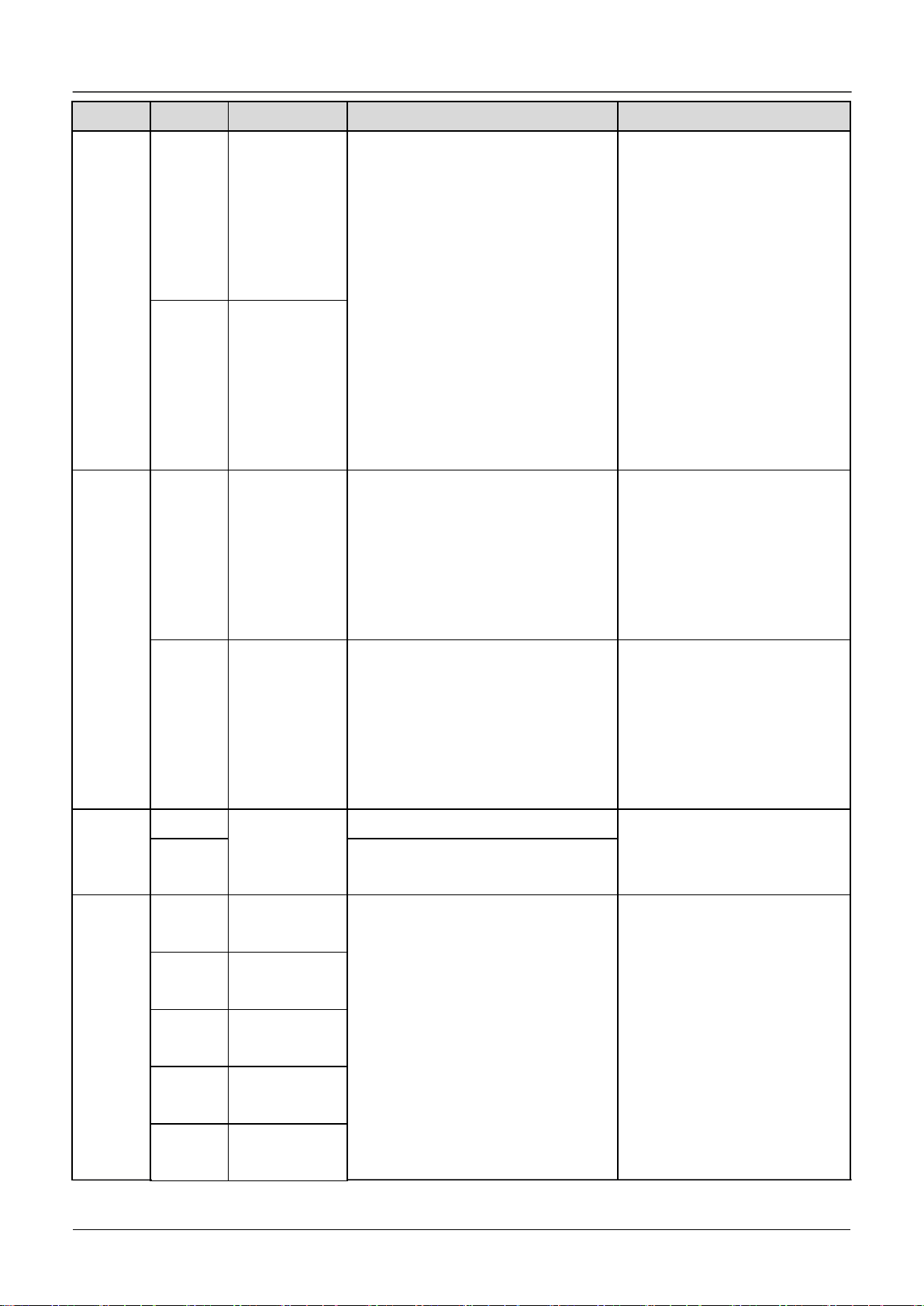

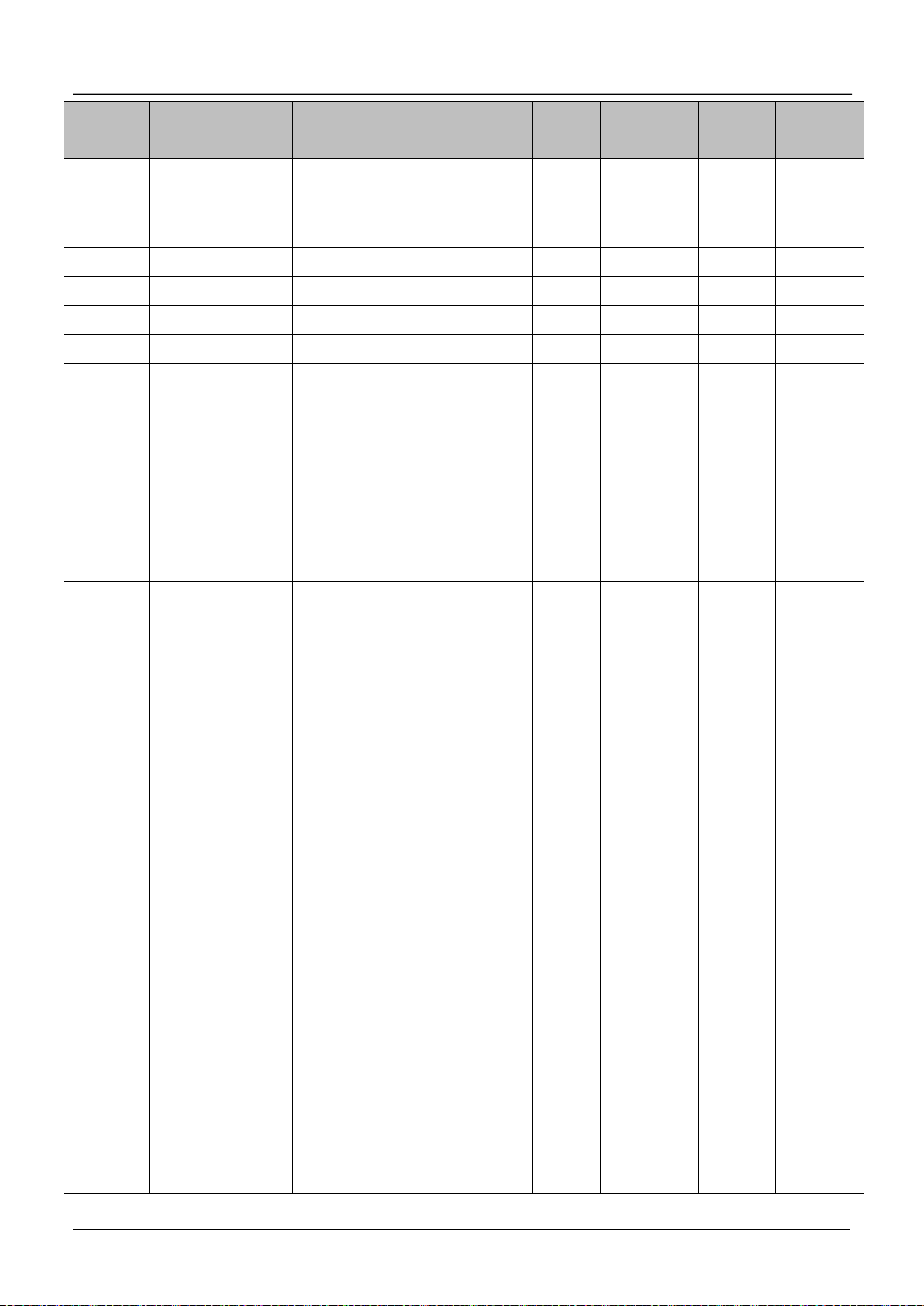

4.1.1 Terminal Type of Main Loop’s Input and Output

Terminal Type

Applicable models: FV100-2S-0004G~FV100-2S-0037G

Application models: FV100-2S-0055G~FV100-2S-0110G

15

12

Application models: FV100-2S-0150G~FV100-2S-0220G

Terminal

name

Function description

L、N

Single phase 220VAC input

terminal

R、S、T

3-phase 380V AC input terminal

DC negative bus output terminal

、

Reserved terminal for external DC

Applicable models:FV100-2T-0004G~FV100-2T-0037G

FV100-4T-0007G/0015L~FV100-4T-0037G /0055L

Applicable models:FV100-2T-0055G~FV100-2T-0110G

FV100-4T-0055G/0075L~FV100-4T-0185G/0220L

Applicable models: FV100-2T-0150G~FV100-2T-0220G

FV100-4T-0220G/0300L~FV100-4T-0370G/0450L

Applicable models:FV100-4T-0450G/0550L~FV100-4T-0750G/0900L

Applicable models:FV100-4T-0900G/1100L~FV100-4T-1320G/1600L

Applicable models:FV100-4T-1600G/1850L~FV100-4T-4000G/4500L

Table 4-1 Description of main loop terminal

16

12

reactor

、

External braking unit

B1、B2

Braking resistor terminal

U、V、W

3-phase AC output terminal

PE

Shield PE terminal

4.1.2 Wiring of VFD for Basic Operation

Applicable model: FV100-4T-0055G /0075L

Fig.4-1 Basic wiring chart

17

12

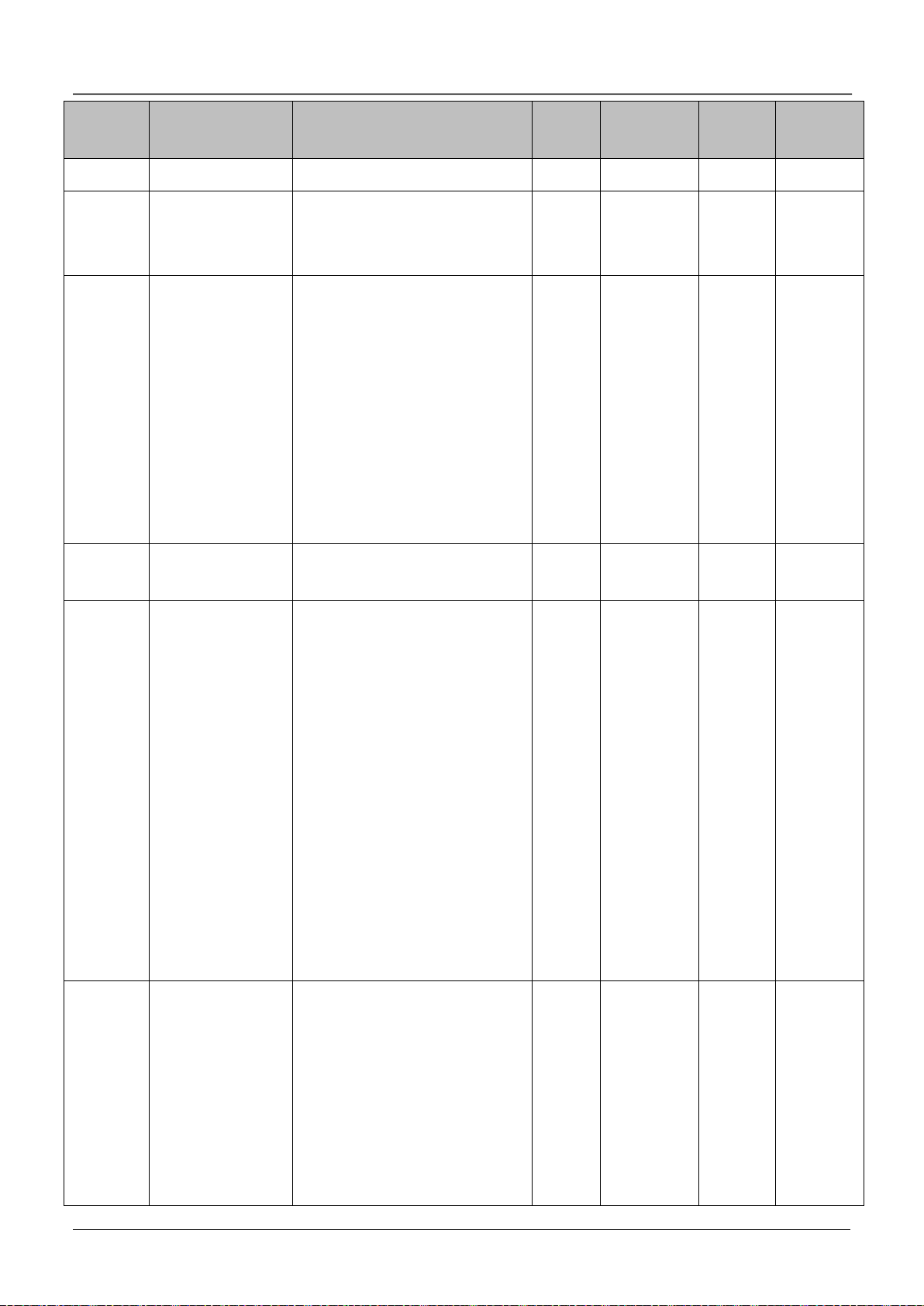

4.2 Wiring and configuration of control circuit

Sequence No.

Function

1

Analog input and output terminal, RS232 and RSRS485 communication port

AO1 AO2 AI3+ +10V 24V PLC X4 X5 X6 X7

AI1 AI2 AI3- GND X1 X2 X3 COM

485+

485-

R1a R1b R1c

CME Y1 Y2

Category

Terminals

Name

Function description

Specification

Shield

Shielded PE

PE terminal connected to shielding

layer. 485 communication cable,

Analog signal cable, motor power cable

shield can be connected to this terminal

here

Connected to PE terminal of main

loop inside

Power

supply

+10

+10V Power

supply

Provide +10V power supply

Maximum current output is 5mA

GND

+10V GND of

Power supply

GND for analog signal and 10V power

supply

Isolated from COM and CME

inside

Analog

input

AI1

Signal-ended

input AI1

Can accept analog voltage or current

input, jumper AI1 can select voltage or

current input mode. (Reference ground:

GND)

Input voltage range: -10V~10V

(Input impedance 45KΩ)

Resolution: 1/4000

Input current range : 0mA~20

mA, Resolution: 1/2000(Need

jumper)

AI2

Signal-ended

input AI2

Can accept analog voltage or current

input, jumper AI2 can select voltage or

current input mode. (Reference ground:

GND)

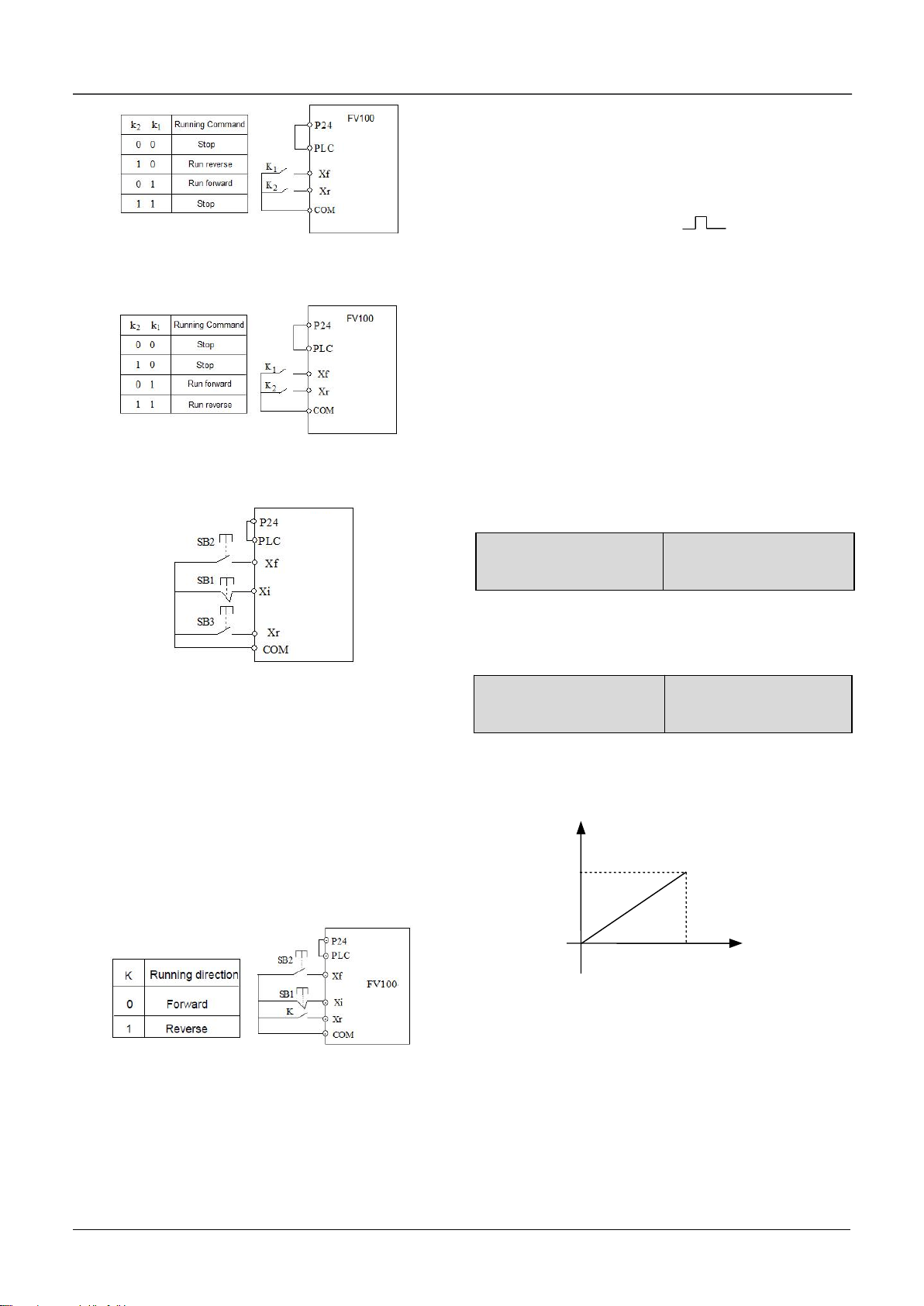

4.2.1 Wiring of control circuit terminal.

Wire the terminals correctly before using the Drive. Refer to the table 4-2 for control circuit terminal function

Table 4-2 Control circuit terminal function

Note

It is recommended to use cables bigger than 1mm2 to connect to the terminals.

Arrangement of control circuit terminals is as follows

Fig.4-2 Arrangement of control terminals

Refer to table 4-3 and 4-4 for description of each terminal

Table 4-3 function list of each list

18

12

Category

Terminals

Name

Function description

Specification

AI3+

Analog voltage

differential input

AI3+ or analog

voltage

single-ended

input

When connected to the analog voltage

differential input, AI3+ is the

same-phase input and AI3- is the

inverted phase input;

when connected to the analog voltage

single-ended input, AI3+ is signal

input,AI3- should connect to GND

(Reference ground: GND)

Input voltage range: -10V~+10V

(Input resistor: 15kΩ)

Resolution: 1/4000

AI3-

Analog voltage

differential input

AI3- or analog

voltage

single-ended

input

Analog

output

AO1

Analog output 1

Providing analog voltage or current

output, they are selected by the jumper

AO1. The default setting is output

voltage, refer to the function code

A6.28 for detail.(Reference ground:

GND)

Voltage output range: 0V~10V

Current output range: 0/4~20mA

AO2

Analog output 2

Providing analog voltage or current

output, they are selected by the jumper

AO2. The default setting is output

voltage, refer to the function code

A6.29 for detail.(Reference ground:

GND)

Voltage output range: 0V~10V

Current output range: 0/4~20mA

Communi

cation

RS485+

RS485

communication

port

485+

Standard RS-485 communication

port, please use twisted-pair cable

or shielded cable.

RS485-

485-

Multi-fun

ction

input

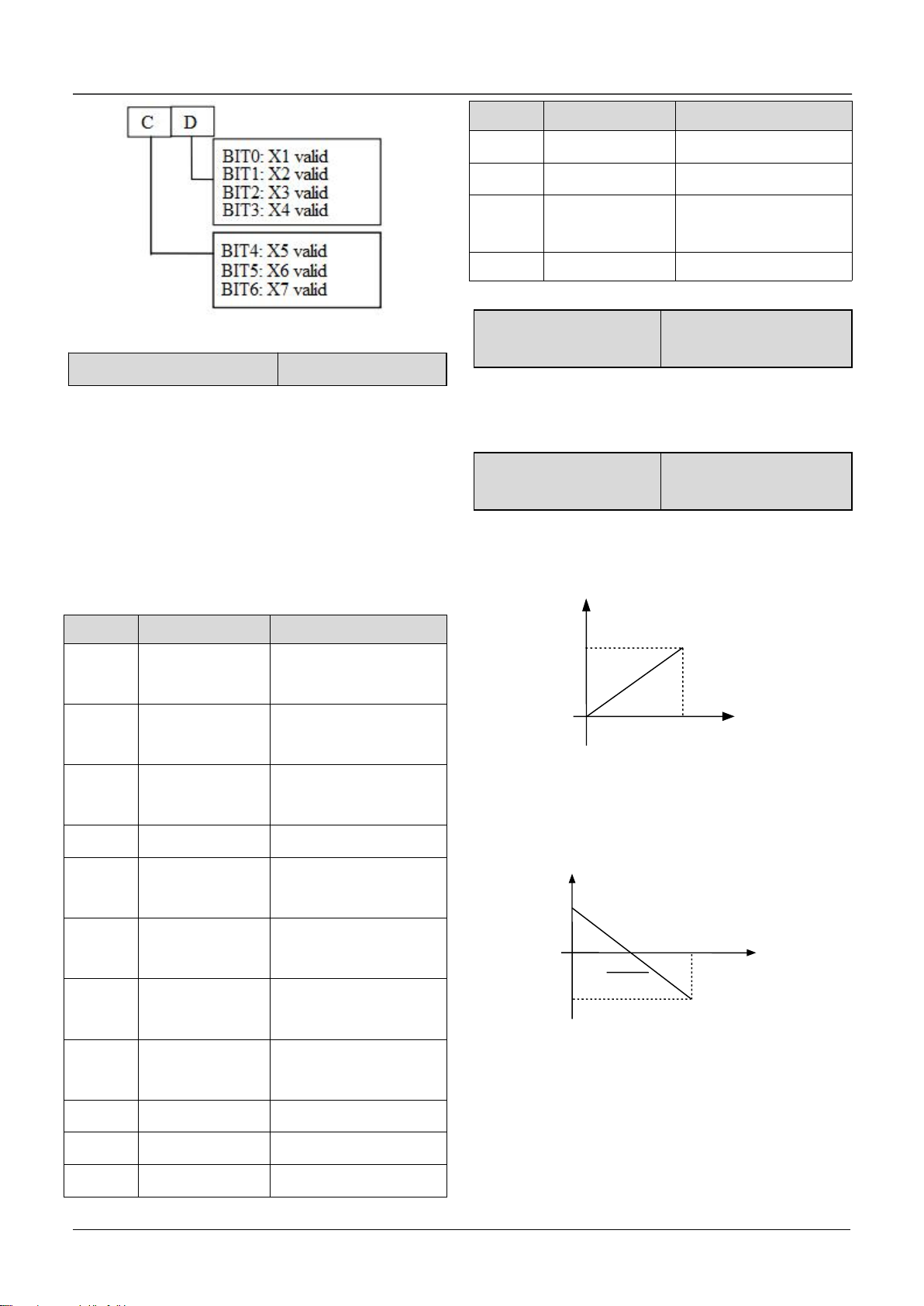

terminal

X1

Multi-function

input terminal 1

Can be defined as multi-function digital

input terminal.(Refer to the A6 group,

form A6.00 to A6.06)

Optocoupler isolation input

Input resistor: R=3.3kΩ

Maximum frequency input of

X1~X6: 200Hz

Maximum input frequency of X7:

100kHz

Input voltage range:2~30v

X2

Multi-function

input terminal 2

X3

Multi-function

input terminal 3

X4

Multi-function

input terminal 4

X5

Multi-function

input terminal 5

19

12

Category

Terminals

Name

Function description

Specification

+24V

X1、。。。X7

PLC

+3.3V

COM

24V

R

X6

Multi-function

input terminal 6

X7

Multi-function

input terminal 7

Multi-fun

ction

output

terminal

Y1

Bi-direction

open-collector

output

Can be defined as multi-function digital

output terminal , refer to the A6.14 for

detail (Com port: CME)

Optocoupler isolation output

Maximum working voltage: 30v

Maximum output current: 50mA

Y2

Open collector

pulse terminal

Can be defined as multi-function pulse

signal output terminal , refer to the

A6.25 for detail(Com port: CME)

Maximum output frequency:

100kHz(Depend on the A6.26)

Power

supply

24V

+24V power

supply

Providing +24V power for others

Maximum output current: 200mA

Common

port

PLC

Common port of

multi-function

input

Common port of Multi-function input

(Short cut with 24V in default)

Common port of X1~X7, PLC is

isolated from 24V internally

COM

Common port of

24V power

supply

Three common ports in all, cooperate

with other terminals

COM is isolated from

CME and GND inside the drive

CME

common port of

Y1output

Common port of multi-function output

terminal Y1

Relay

output

terminal 1

R1a

Relay output

Can be defined as multi-function relay

output terminal(Refer to the A6.16 for

detail)

R1a-R1b:Normally closed,

R1a-R1c:normally open

Contact capacity :

AC250V/2A(COSΦ=1)

AC250V/1A(COSΦ=0.4)

DC30V/1A

Input voltage for overvoltage

class of relay output terminal

is overvoltage class II

R1b

R1c

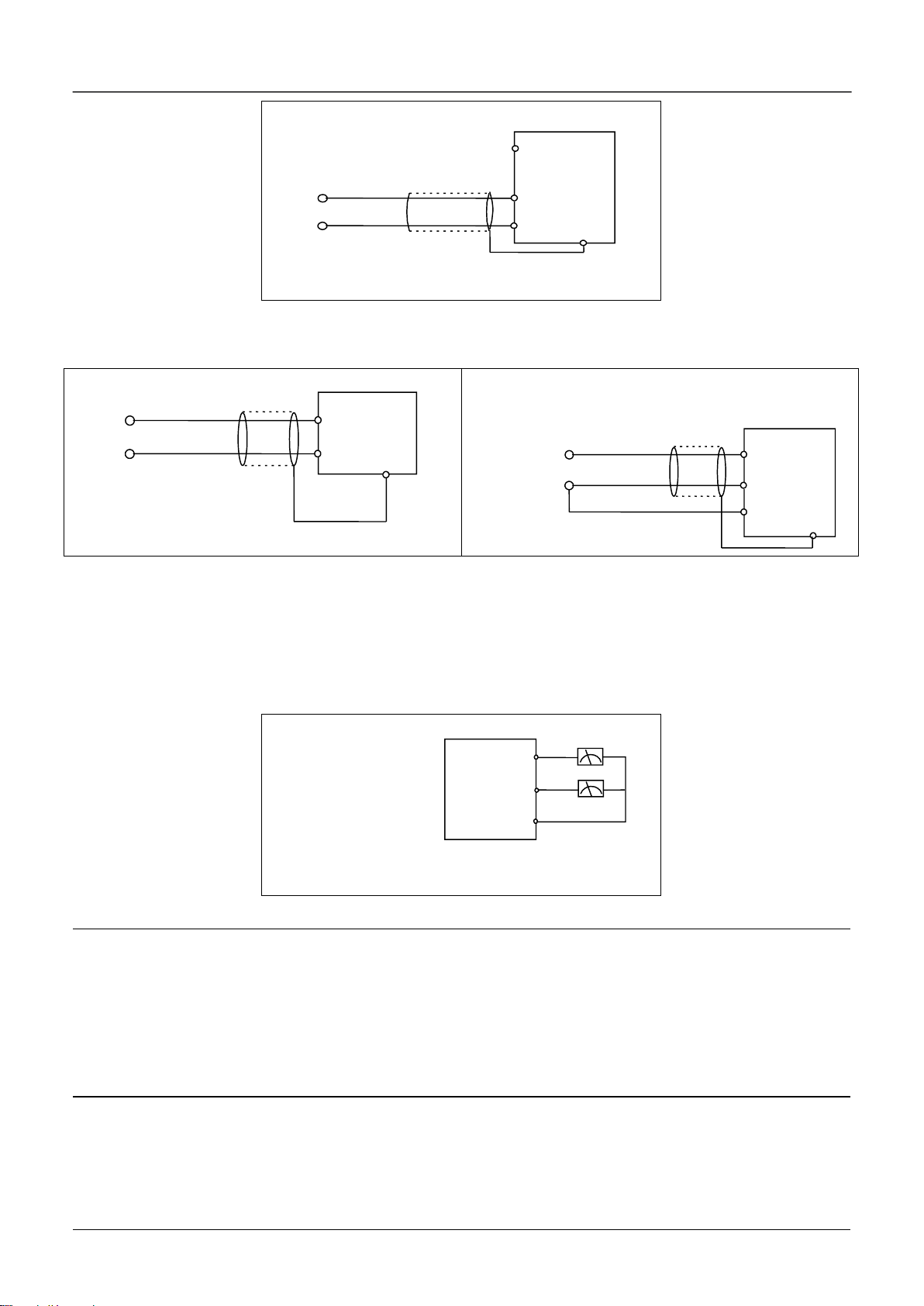

1) AI1, AI2 can be connected to analog voltage or current single-ended input. Use a jumper can select AI1 as Voltage

Wiring of analog input

model and AI2 as current mode. The wiring is as follows:

20

12

Shield cable connect

to PE

AI1,AI2

GND

+10

-10~+10

V

Or

0~20m

A

P

E

FV100

Fig 4-3 AI1,AI2 terminal wiring

2) AI3+,AI3- can be connected to the analog differential or single-ended input , the wiring is as follows:

A

I

+

AI-

P

E

FV100

-0V~+10

V

Analog differential

voltage input

Shield cable

connected to PE

P

E

-10V~+10V

Shield cable connected to PE

GND

AI3+/AI3-

AI3+/AI3-

FV100

Fig 4-4 AI+,AI- differential voltage input wiring

Fig 4-5 AI+,AI- single-ended voltage input wiring

AO1

AO2

GND

FV100

Analog meters

Wiring of analog output terminal

If the analog output terminals AO1 and AO2 are connected to analog meters, then various kinds of physical values can

be measured. The jumper can select current output (0/4~20mA) or voltage output (0/2~10V). The wiring is as follows:

Notes:

1. When using analog input, a filter capacitor common mode inductor can be installed between signal input and GND

2. The analog input voltage is better under 15V.

3. Analog input and output signals are easily disturbed by noise, so shielded cables must be used to transmit these

signals and the cable length should be as short as possible.

4. The analog output terminal can stand the voltage under 15V

Fig.4-6 Wiring of analog output

21

12

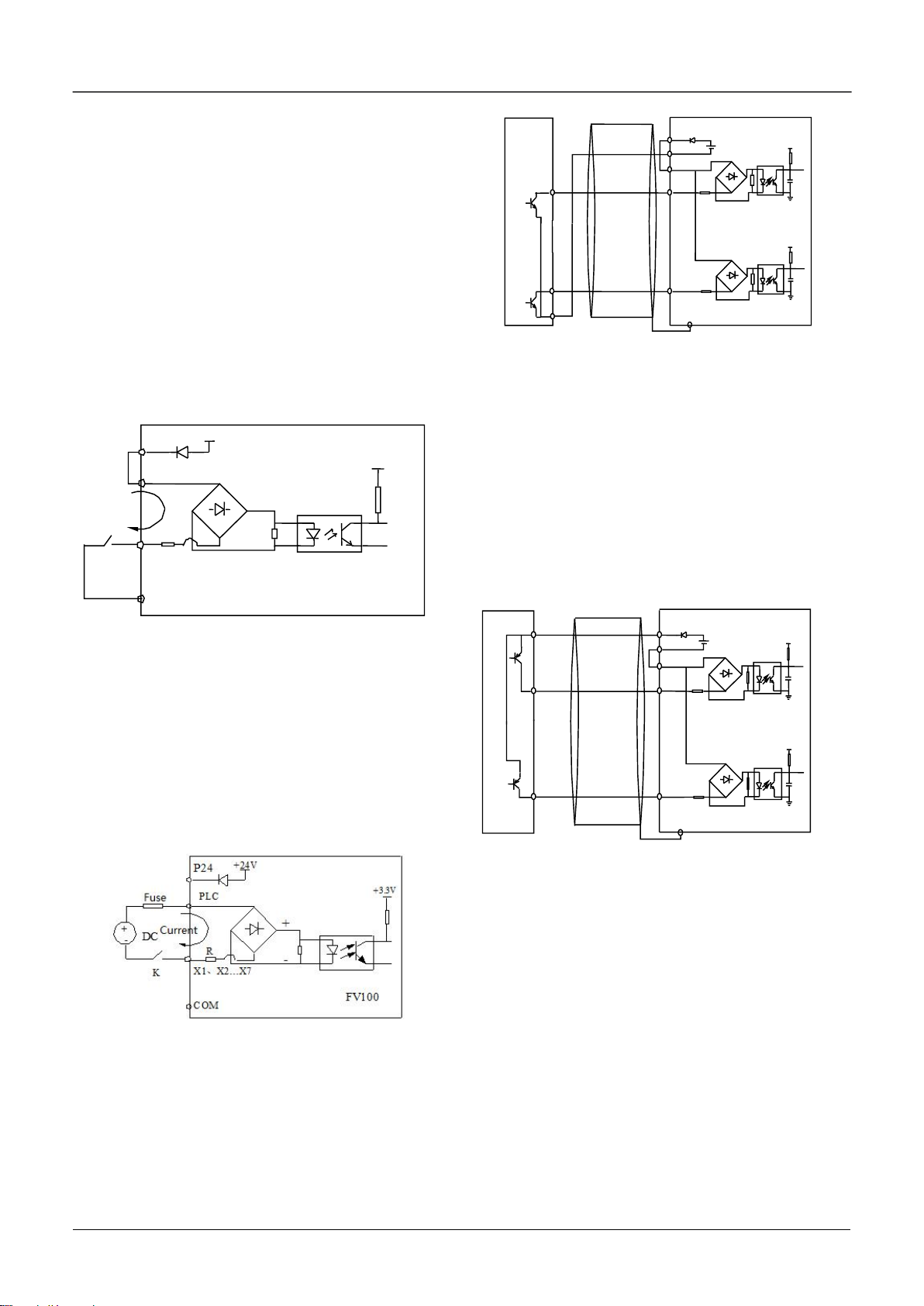

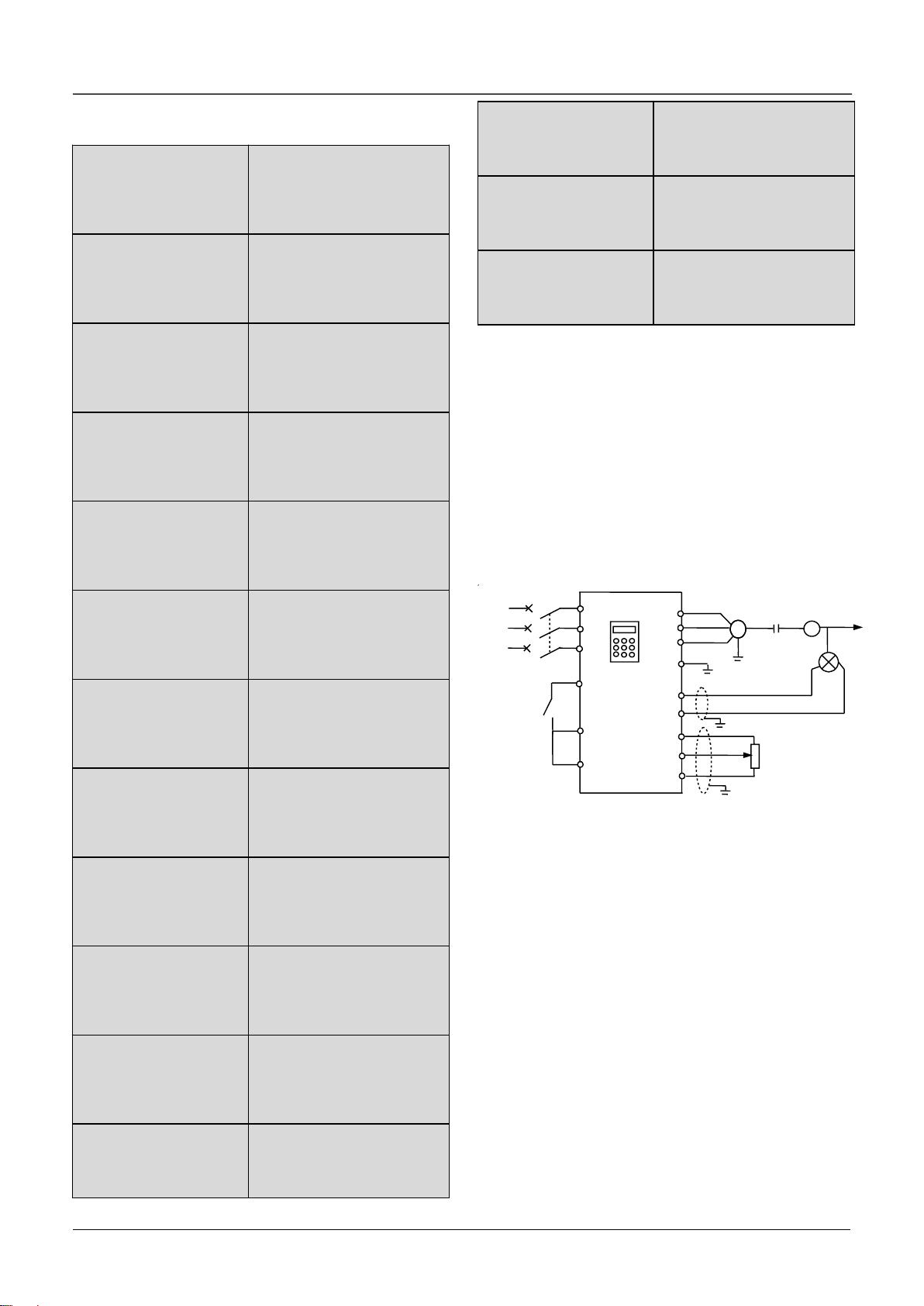

Wiring of multiple function input terminal and

operation terminal

FV100 multi-function input terminal uses a full-bridge

rectifying circuit as shown in Fig.4-7. PLC is the

common terminal of terminals X1~X7, The current

flows through terminal PLC can be pulling current and

the feeding current. Wiring of X1~X7 is flexible and the

typical wiring are as follows:

1. Dry contacts method

1) Use the internal 24V power supply of VFD, the

wiring is as in fig.4-7.

+24V

X1

、

X2...X7

PLC

FV100

+3.3V

COM

24V

R

+

-

K

Current

Fig.4-7 Wiring method of using the internal 24V power

supply

2) Use external power supply, (The power supply must

satisfy the UL CLASS 2 standard and a 4A fuse must be

added between the power supply and terminal), the

wiring is as Fig.4-8 (Make sure the PLC and 24V

terminal is disconnected)

Fig.4-8 Wiring of external power supply

2. Source/drain connection method

1) Use internal +24V power supply of VFD and the

external controller uses NPN transistors whose common

emitter are connected, as shown in the fig.4-9

Shielded cable's end near the drive

should be connected to the PE

COM

¡

FV100

P

E

¡

1

¡

PL

X1

¡

¡

24V

CO

¡

¡

24V

D2

+

-

+3.3V

10

¡X7¡

+3.3

External controller

Fig.4-9 Use internal power supply

for Source connection

2) Use internal +24V power supply and the external

controller uses PNP transistors whose common emitter

are connected, as shown in the fig 4-10(Make sure the

PLC and 24V terminal is disconnected). The wiring is as

shown in fig.4-10

¡ñ

¡ñ

¡ñ¡ñ¡ñ

¡ñ

¡ñ

¡ñ

¡ñ

COM

P

E1PLC

X1

24V

COM

D2

+

-

+3.3V

10

X7

+3.3V

24V DC

Fig 4-10 Use internal power supply

for drain connection

3) Use external power supply for source connection

(Make sure the PLC and 24V terminal is disconnected).

As shown in the fig.4-11

Shielded cable's end near the drive

should be connected to the PE

22

12

¡ñ

¡ñ

¡ñ¡ñ¡ñ

¡ñ

¡ñ

¡ñ

¡ñ

24V

+

-

Shielded cable's end near the drive

should be connected to the PE

FV100

P

E

1

PLC

X1

24V

COM

24V DC

D2

+

-

+3.3V

10

X7

+3.3V

Fig 4-11 Use external power supply

for source connection

4) Use external power supply for drain connection

(Make sure the PLC and 24V terminal is disconnected).

As shown in the fig 4-12

¡ñ

¡ñ

¡ñ¡ñ¡ñ

¡ñ

¡ñ

¡ñ

¡ñ

+

-

24V

FV100

P

E

1

PLCX124V

COM

24V DC

D2

+

-

+3.3V

10

X7

External controller

+3.3V

Fig 4-12 Use external power supply

for drain connection

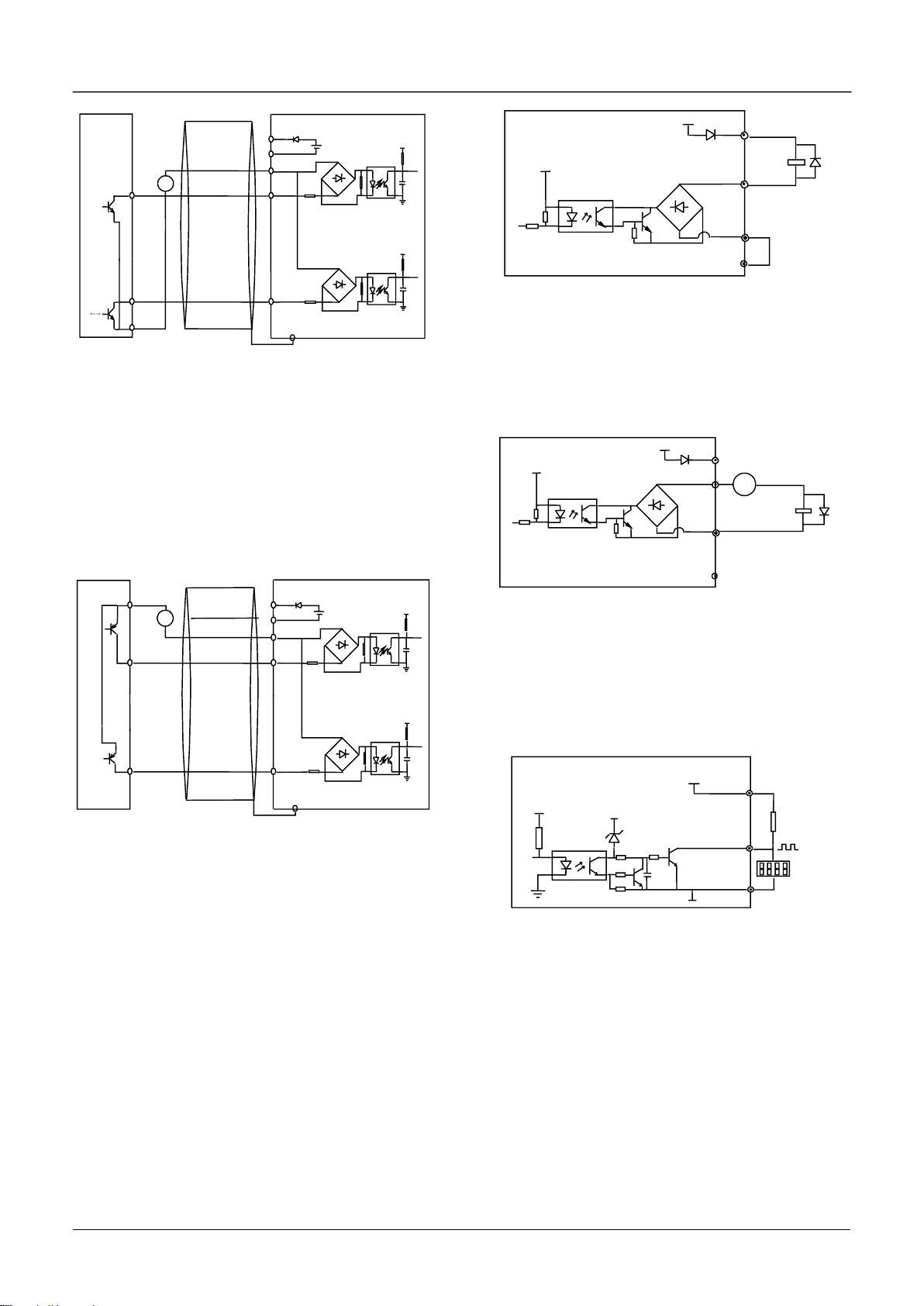

Multi-function output terminal wiring

1. Multi-function output terminal Y1 can use the internal

24 power supply, the wiring is as shown in Fig.4-13

FV100

COM

24V

+5V

+24V

CME

Y1

Relay

Fig 4-13 Wiring method 1 of multi-function

output terminal Y1

2. Multi-function output terminal Y1can use the external

24 power supply too, the wiring is as shown in Fig.4-14.

DC

FV100

COM

Y1

24V

+5V

+24V

+ -

Relay

Fig 4-14 Wiring method 2 of multi-function

output terminal Y1

3. Y2 can also be used as pulse frequency output, If Y2

uses the internal 24V power supply. The wiring is shown

in Fig.4-15.

+24V

FV100

24V

4.7k

Y2

COM

+5V

+24V

Fig 4-15 Wiring method 1 of output terminal Y2

4. When Y2 is used as a digital pulse frequency output, it

can also use the external power supply. The wiring is

shown in Fig.4-16

Shielded cable's end near the drive

should be connected to the PE

Digital

frequency meter

CME

23

12

DC

+24V

24V

4.7k

Y2

COM

+5V

+24V

+

-

FV100

Fig.4-16 Wiring method 2 of output terminal Y2

Wiring of relay output terminals R1a, R1b and R1c

If the drive drives an inductive load (such as

electromagnetic relays and contactor), then a surge

suppressing circuit should be added, such as RC

snubbing circuit (Notice that the leakage current must be

smaller than the holding current of the controlled relay

or contactor) and varistor or a free-wheeling diode (Used

in the DC electric-magnetic circuit and pay attention to

the polarity when installing). Snubbing components

should be as close to the coils of relay or contactor as

possible.

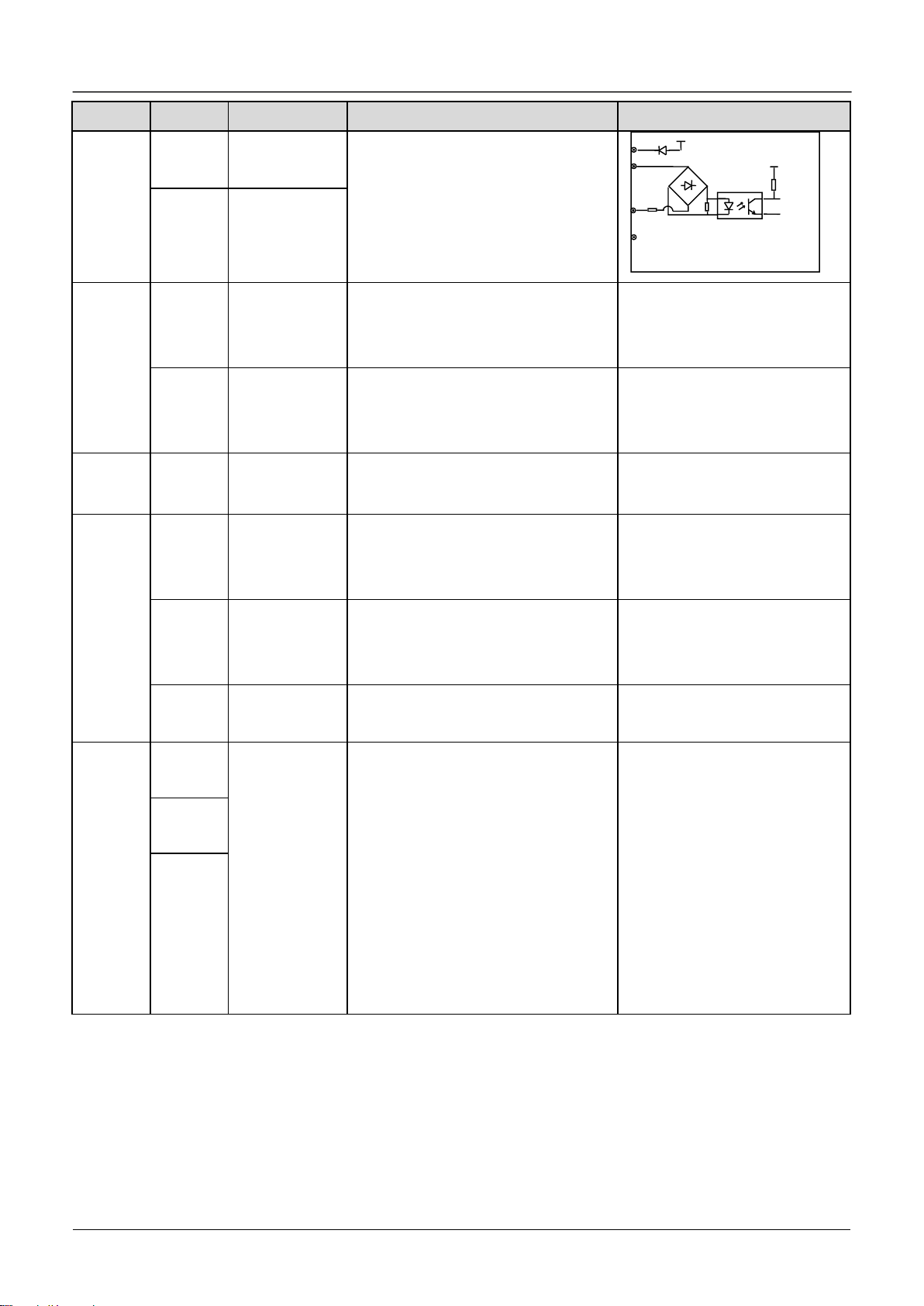

5. Attentions for encoder (PG) wiring

Connection method of PG signal must be corresponding

with PG model. Differential output, open collector

output and push-pull output encoder wirings are shown

in Fig.4-17, 4-18 and 4-19.

Fig 4-17 Wiring of differential output encoder

Fig.4-18 Wiring of open collector output encoder

Fig.4-19 Wiring of push-pull output encoder

Note

1. Don’t short circuit terminals 24V and COM,

otherwise the control board may be damaged.

2. Please use multi-core shielded cable or multi-stranded

cable (above 1mm²) to connect the control terminals.3.

When using a shielded cable, the shielded layer’s end

that is nearer to the drive should be connected to PE.

4. The control cables should be as far away(at least

20cm) from the main circuits and high voltage cables as

possible (including power supply cables, motor cables,

relay cables and contactor cables and so on). The cables

should be vertical to each other to reduce the disturbance

to minimum.

5. The resistors R in Fig. 4-13 and Fig.4-14 should be

removed for 24V input relays, and the resistance of R

should be selected according the parameters of relay for

non-24V relay.

6. Digital output terminal can not stand the voltage

higher than 30V

24

24

Chapter 5 Operation Instructions of Kinco VFD

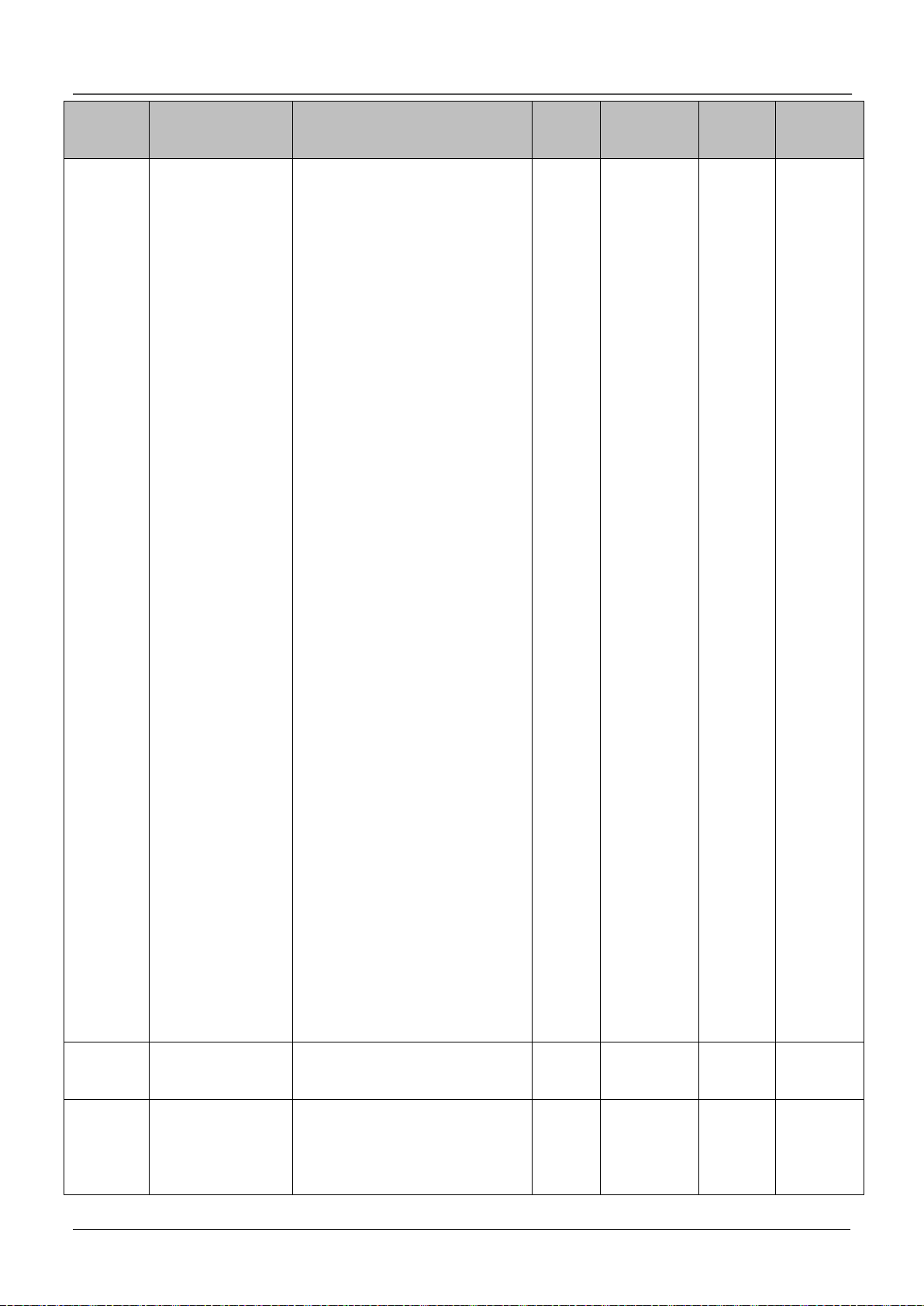

Key

Name

Function

MENU

Program/exit key

Enter or exit programming status

ENTER

Function/data key

Enter next level menu or confirm data

∧

Increase key

Increase data or parameter

∨

Decrease key

Decrease data or parameter

SHIFT

Shift key

In editing status, press this key to select the Bit to be modified. In other

status, this key is used to switch the parameters to display.

M

Multi-function key

Use the b4.01 to configure the function of this key

RUN

Run key

In panel control mode, press this key to run the drive.

STOP/RST

Stop/reset key

Press this key to stop or reset the drive.

In this chapter we introduce the necessary knowledge of Kinco VFD and related operations.

5.1 Using Operation Panel

5.1.1 Operation panel appearance and keys’ function description

Operation panel is used to setup the drive and display parameters, it is LED display. As shown in Fig.5-1

Fig.5-1 Illustration of operation panel

There are 8 keys on the operation panel and functions of each key are shown in Table 5-1.

Table 5-1 Function list of operation panel

25

25

5.1.2 Function Descriptions of LED and Indicators

Indicator

Status

Current status of drive

Operating status

indicator(RUN)

Off

Stop

On

Run

Operating

direction

indicator(FWD)

Off

Forwards

On

Reverse

Operating mode

indicator(MON)

On

Controlled by operation

panel

Off

Controlled by terminals

Flashing

Communicating

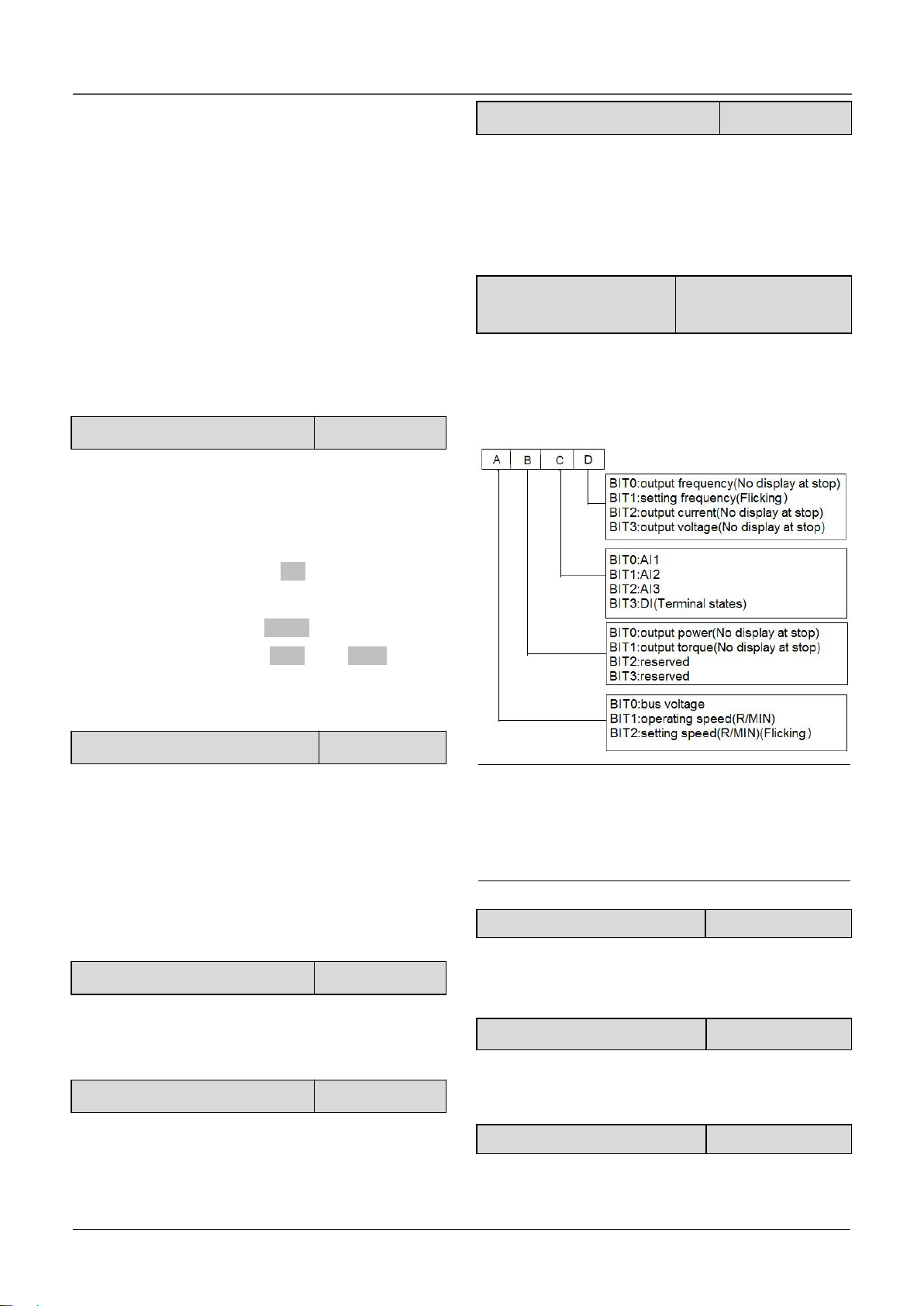

The operation panel consists of a 5-digits eight segments LED display, 3 LED indicators for unit and 3 LED indicators

for status which is as shown in Fig.5-1. The LED display can display the status parameters, function codes and error

codes of the drive. The 3 unit indicators are corresponding to three units, the descriptions of three status indicator are

shown in table 5-2

Table 5-2

5.1.3 Display status of operation panel

FV100 operation panel can display the parameters in stopping, operating, editing and function code..

1. Parameters displayed in stopping status

When the drive is in stop status, the operation panel displays the stop status parameter. Pressing the SHIFT key can

display different stop status parameters in cycle (Defined by function code b4.05)

2. Parameters displayed in operation status

When the drive receives operating command, it starts running and its panel will display the operation status parameters,

the RUN indicator turns on. The status of FWD indicator depends on the operation direction. The unit indicator display

the unit of the parameter, by pressing the SHIFT key can display different operation parameters in cycle (Defined by

function code b4.05)

3. Parameters displayed in error status

When the drive detects a fault signal, the panel will display the flashing fault code..

Press the SHIFT key to display the stop status parameters and error code in cycle. By pressing the STOP/RST, control

terminal or communication command to reset the error. If the error exists still, then the panel keeps displaying the error

code.

4. Parameter edit status

When the drive is in stop, operation or error state, press MENU/ESC can enter edit status (If password needed, please

refer to description of A0.00),. Edit state displays in 2-level menu, they are: function code group or function code

number→function code parameter value. You can press ENTER to enter parameter displayed status. In function

parameter displayed status, press ENTER to save the settings, and press MENU to exit the menu.

26

26

5.1.4 Panel Operation

Various operations can be completed on the operation panel; the following are 5 common examples. Refer to function

code list in chapter 9 for detail function code description.

Example 1:Set parameters

Example: Change the value in A0.03 from 50.00Hz to 30Hz

1. In the stop parameter displaying state, press MENU to enter the first level A0.00;

2. Press ∧ to change A0.00 to A0.03;

3. Press ENTER to enter the second level menu

4. Press the SHIFT to change the marker to the highest bit

5. Press the ∨ to change the 50.00 to 30.00

6. Press the ENTER to confirm above change and back to the fist level menu. Then the parameter is changed

successfully.

The above operations are shown in following picture.

Fig 5-2 Example of setting parameter

In function parameter displaying status, if there is no bit flashing. It means that this function code can not be changed,

the possible reason are:

1. This function code is unchangeable parameter. Like actual detected parameter, operation log parameter and so on

2. This parameter can not be changed when running; you need stop the VFD to edit the parameter

3. The parameters are protected. When the b4.02 is 1, function code can not be changed. It is to protect the VFD from

wrong operation. If you want to edit this parameter, you need set function code b4.02 to 0.

Example 2: Regulate the setting frequency

Press the ∧ or ∨ to change the setting frequency directly when power on VFD

Note:

When the Operating Speed, Setting Speed, Operating Line Speed, and Setting Line Speed is displayed on the panel.

Press ∧ or ∨ is to modify the value of Setting Speed or Setting Line Speed.

Example: changing the setting frequency from 50.00Hz to 40.00Hz.

After the VFD power on (in this example the LED is in voltage display status AI1), Press ∨ to modify the setting

frequency (Holding ∨ can speed up the modification) from 50.00Hz to 40.00Hz. So the setting frequency is

modified.

The above steps are as the following figure:

27

27

Fig 5-3 Modify the setting frequency

After modification, if there are no operations in 5 seconds, The LED will back to display the voltage, it means to

display the status before modification.

Example 3: Set the password

To protect parameters, the VFD provides password protection function. The user needs to input the right password to

edit the parameters if the VFD has been set password. For some manufacturer parameters, it also need to input correct

manufacturer password.

Note:

Do not try to change the manufacturer parameters. if they are not set properly, the VFD may not work or be damaged.

Function code A0.00 is to set user password. Refer to 6.1 A0 group for more information

Suppose the user’s password to be set as 8614, then the VFD is locked, and you can not do any operation to VFD.

Then you can follow the following steps to unlock the VFD.

1 when the VFD is locked, press MENU. The LED will display the password verification status: 0000;

2 Change 0000 to 8614;

3 Press ENTER to confirm. Then the LED will display A0.01. So the VFD is unlocked

Note:

After unlock the password, if there is no operation in 5 minutes, VFD will be locked again.

Example 4: Lock the operation panel

The b4.00 is used to lock the operation panel. Refer to 6.1 A0 group for more information

Example: Lock all the keys of the operation panel Under stop parameter displaying status.

1 press MENU to enter A.00

2 Press ∧ to choose the function code b4.00

3 Press ENTER to enter the second level menu

4 Press ∧ to change the hundreds place from 0 to 1

5 Press ENTER to confirm

6 Press MENU to back to the stop parameter displaying status;

7 Press ENTER and hold, then press MENU, so the key board is locked

Example 5: Unlock the keys of the operation panel

When the operation panel is locked, follow the follow operations to unlock it:

Press the MENU and hold , then press the ∨ once, so the key boar is unlocked

28

28

Note:

Whatever the setting is in b4.00, after the VFD power on, the operation board is in unlock status.

5.2 Operation mode of VFD

In the follow-up sections, you may encounter the terms describing the control, running and status of drive many times.

Please read this section carefully. It will help you to understand and use the functions discussed in the follow chapters

correctly.

5.2.1 Control mode of VFD

It defines the physical channels by which drive receives operating commands like START, STOP, JOG and others,

there are two channels:

1 Operation panel control: The drive is controlled by RUN, STOP and M keys on the operation panel;

2 Terminal control: The drive is controlled by terminals Xi、Xj and COM (2-wire mode), or by terminal Xki (3-wire

mode);

The control modes can be selected by function code A0.04, multi-function input terminal (Function No. 15~17 are

selected by A6.00~A6.06 ).

3 Modbus communication: by using host computer to control the VFD to start or stop.

Note:

Before you change the control mode, make sure that the mode suitable for the application. Wrong selection of control

mode may cause damage to equipment or human injury!

5.2.2 Operating Status

There are 3 operating status: stop, motor parameters auto-tuning, and operating.

1. Stop status: After the drive is switched on and initialized, if no operating command is accepted or the stop command

is executed, then the drive in stop status.

2. Operating status: The drive enters operating status after it receives the operating command.

3. Motor parameters auto-tuning status: If there is an operating command after b0.11 is set to 1 or 2, the drive then

enters motor parameters auto-tuning status, and then enters stopping status after auto-tuning process finishes.

5.2.3 Control mode and operation mode of Kinco VFD

Control mode

FV100 VFD has three control methods, it is set by A0.01:

1. Vector control without PG: it is vector control without speed sensor, need not to install the PG, at the same time it

has very high control performance, it can control the speed and torque of motor accurately. It has the characteristics

like low frequency with high torque and steady speed with high accuracy. It is often used in the applications that the

V/F control mode can not satisfy, but require high robustness.

2. Vector control with PG: The PG is needed, the PG is installed on the shaft of controlled motor to ensure the control

performance. It is used in the applications that require high torque response, and much higher accuracy of torque and

speed control.

29

29

3. V/F control: It is used in the applications that do not require very high performance, such as one VFD controls

multiple motors.

Operation mode

Speed control: Control the speed of motor accurately, related function codes in A5 group should be set.

Torque control: Control the torque of motor accurately, related function codes in A5 group should be set.

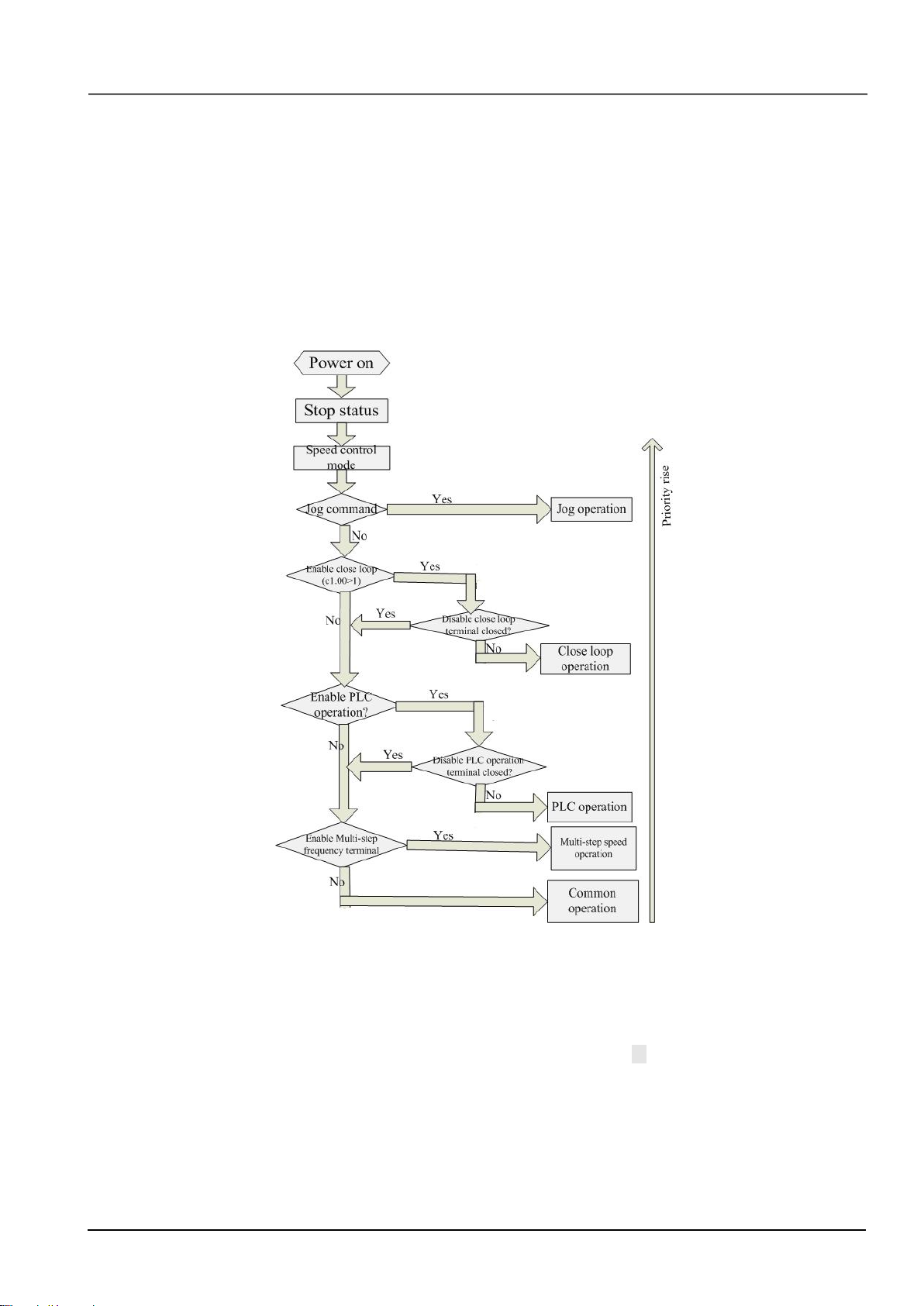

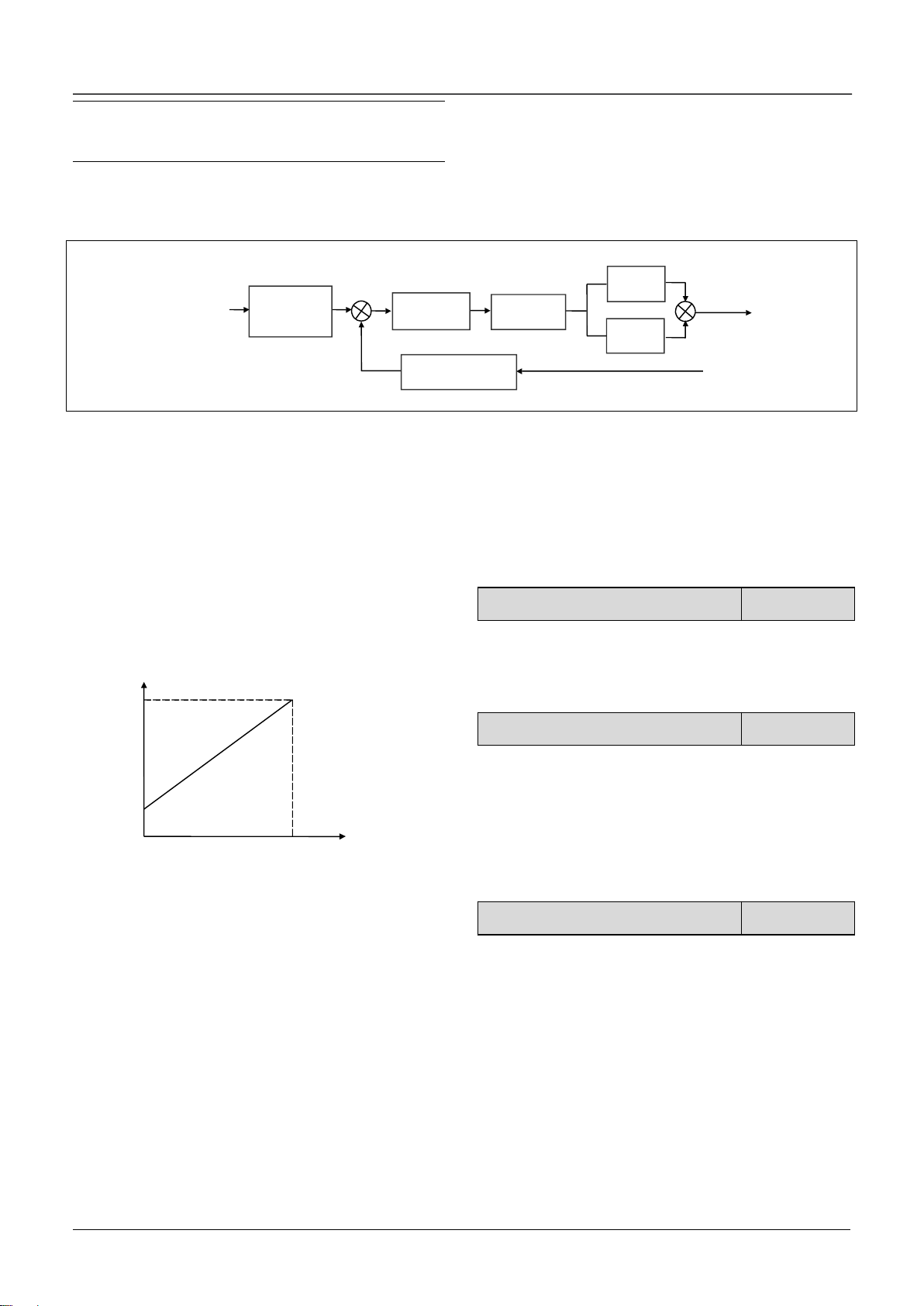

5.2.4 The channels to set the VFD frequency

FV100 supports 5 kinds of operating modes in speed control mode which can be sequenced according to the priority:

Jog>Close loop process operation>PLC operation>Multiple speed operation>simple operation. It is shown as follows:

Fig 5-4 Operating mode in speed control mode

The three operating modes provide three basic frequency source.Two of them can use the auxiliary frequency to

stacking and adjusting (except Jog mode), the descriptions of each mode are as follows:

1) JOG operation:

When the drive is in STOP state, and receives the JOG command (for example the M key on the panel is pressed), then

the drive jogs at the JOG frequency (refer to function code A2.04 and A2.05)

2) Close-loop process operation:

If the close-loop operating function is enabled (C1.00=1), the drive will select the close-loop operation mode, that is, it

will perform closed-loop regulation according to the given and feedback value (refer to function code C1 group). This

mode can be deactivated by the multi-function terminals, and switch to the lower priority mode.

30

30

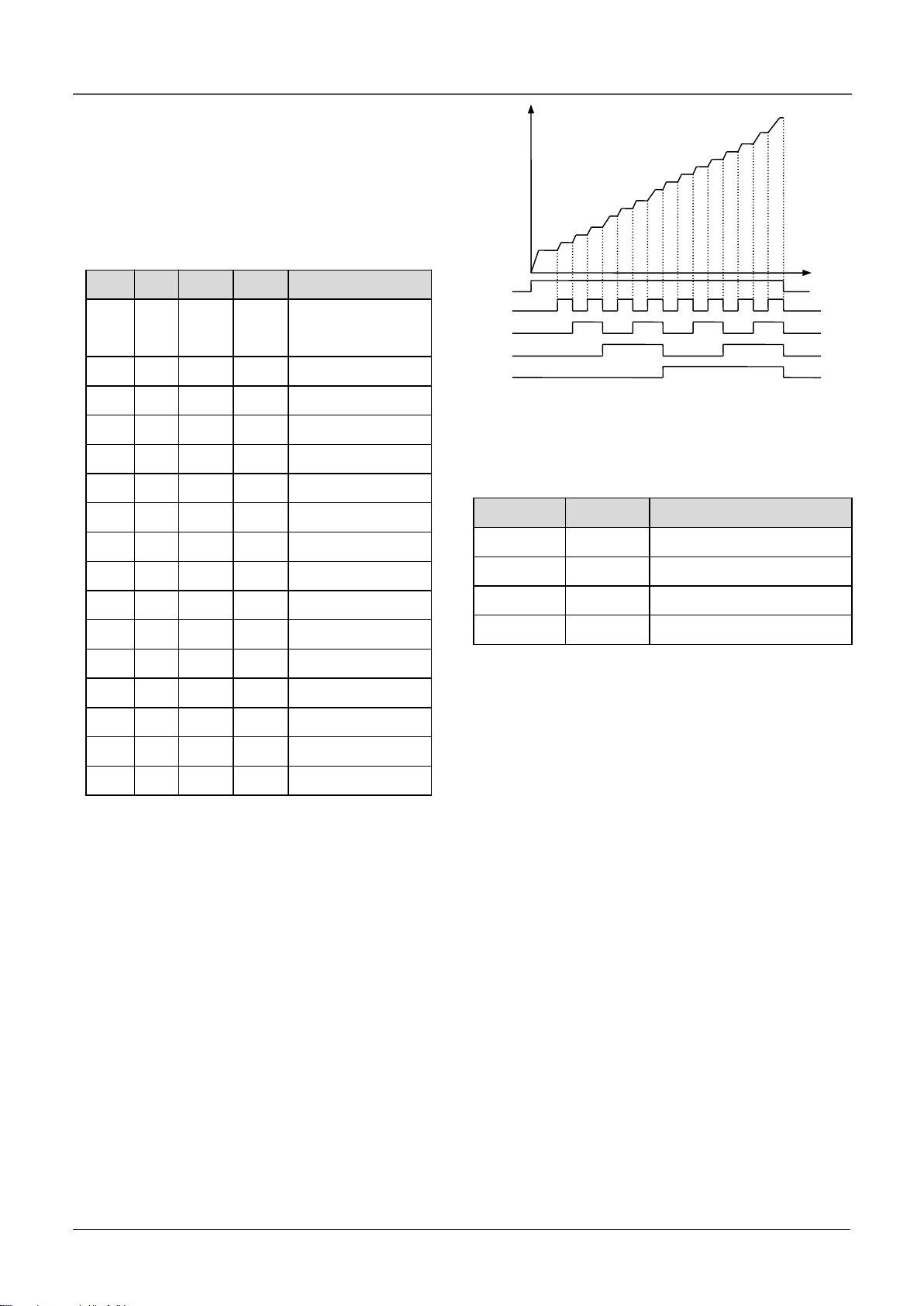

3) PLC operation

N

Y

N

Y

N

Y

N

Y

N

Y

Properly wiring

Power on

Display

8.8.8.8?

.

Contactor closed?

Successful

Check the reason

Start

Check wiring

Check input

voltage

Display frequency?

Failed

Cut off the power

This function is customized, description is omitted.

4) Multi-step (MS) speed operation:

Select Multiple frequency 1~15(C0.00~C0.14)to start Multiple speed operation by the ON/OFF combinations of the

multi-function terminals (No.27, 28, 29 and 30 function). If all the terminals are “OFF”,it is in simple operation.

Note:

About the frequency setting channel under speed mode, please refer to the chapter 6 for detail information

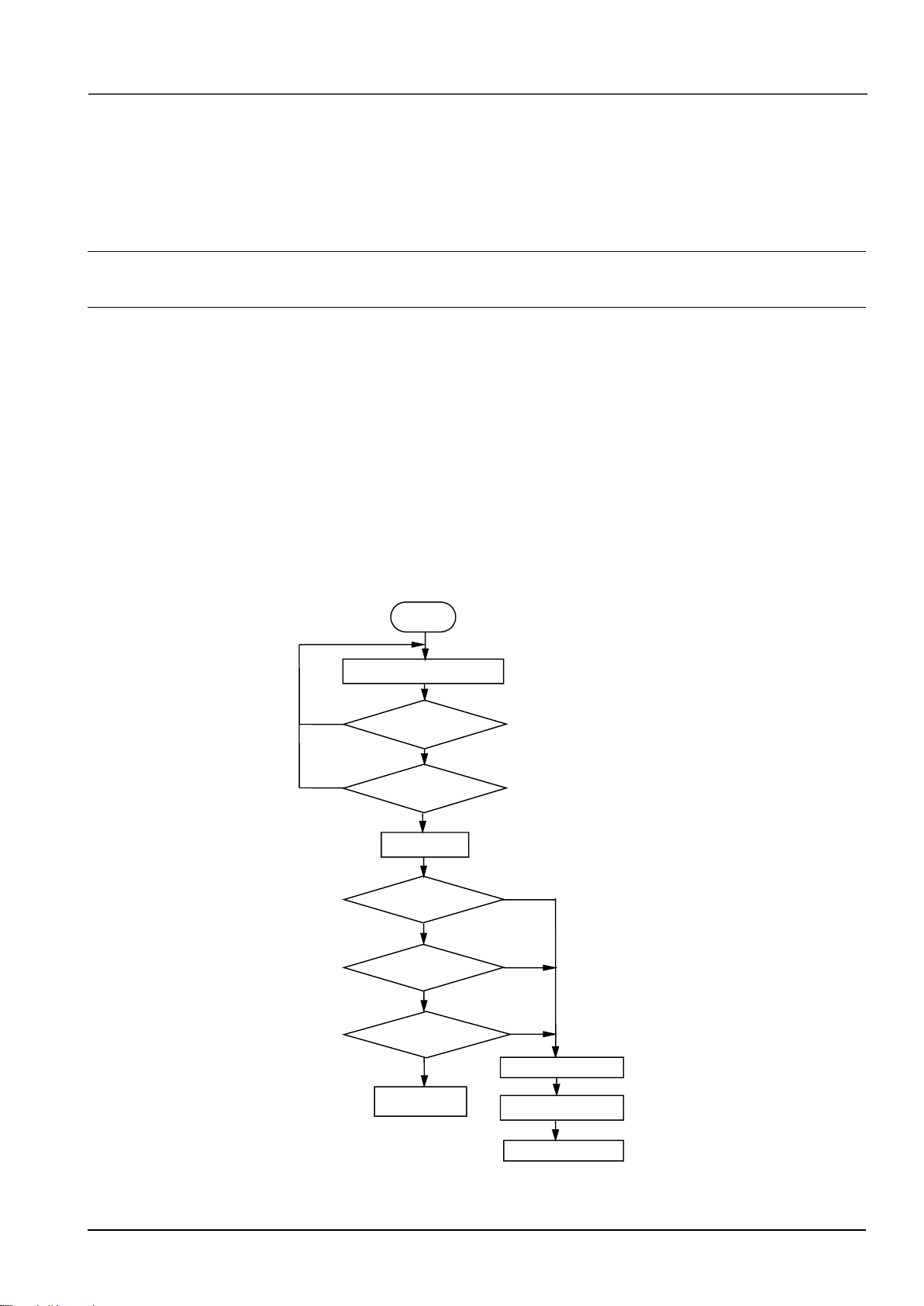

5.3 Power on the Drive for the first time

5.3.1 Checking before power on

Please wire the drive correctly according to chapter 4

5.3.2 Operations when start up the first time

After checking the wiring and AC supply, switch on the circuit breaker of the drive to supply AC power to it. The

drive’s panel will display “8.8.8.8.” at first, and then the contactor closes. If the LED displays the setting frequency,that

is to say the initialization of the drive is completed.

Procedures of first-time start-up are as follows:

Fig.5-5 Procedures of first-time start-up

31

31

Chapter 6 Parameter Introductions

Note:

XX.XX

YYYYYY

N1~N2

【D】

Parameter

No.

Parameter

Name

Range

Default

value

6.1 Group A0

A0.00 User password

00000~65535

【00000】

This function is used to prevent the irrelevant personnel

from inquiring and changing the parameter as to protect

the safety of the VFD parameters.

0000: No password protection.

Set password:

Input four digits as user password, and press ENTER

key for confirmation. After 5 minutes without any other

operation,the password will be effective automatically.

Change password:

Press MENU key to enter into the password verification

status. Input correct password, and it enters parameter

editing status. Select A0.00 (parameter A0.00 displayed

as 00000).Input new password and press ENTER key for

confirmation. After 5 minutes without any other

operation,the password will be effective automatically.

Note:

Please safekeeping the user password.

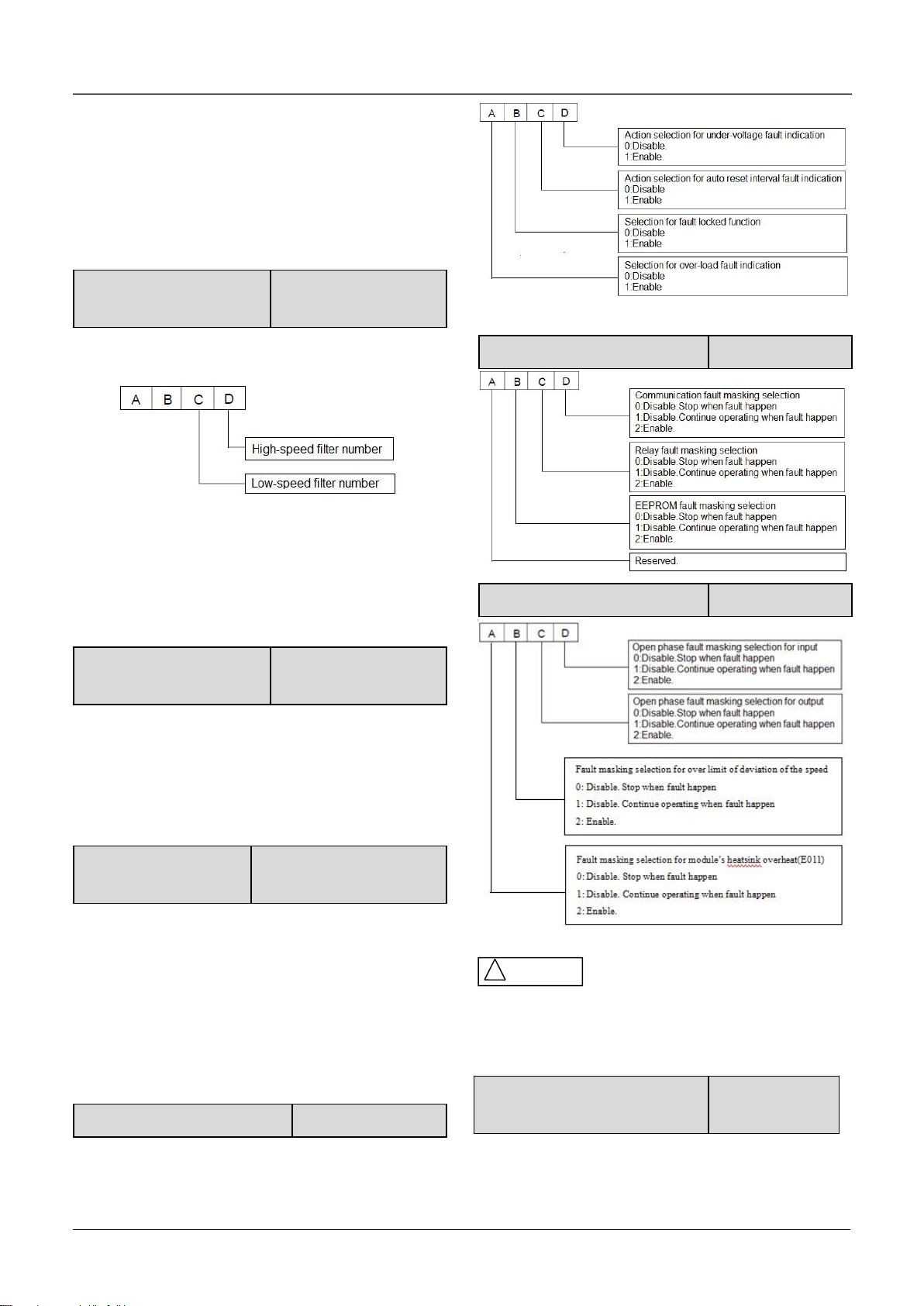

A0.01 Control mode

0~2【2】

0: Vector control without PG (Open loop vector control)

It is a vector control mode without speed sensor

feedback.It is applicable to most applications.

1: Vector control with PG (Closed loop vector control)

It is a vector control with speed sensor feedback.It is

applicable to applications with high accuracy

requirement of speed control precision,torque control

and simple servo control.

2:V/F control

It is used to make the voltage and frequency in a

constant ratio. It is applicable to most application,

especially for the application of one drive to drive

multiple motors.

A0.02 Main reference

frequency selector

0~4【0】

0: Digital setting.

The VFD will regard the value in A0.03 as the initial

reference frequency when power on.

It can be adjusted via ▲ and ▼ key on the panel(panel

control),or adjusted via setting the function of terminal

to be UP/DOWN function(set any two of Xi to be 13 and

14, terminal control )

X1~X7

choose any

two of them

13

Frequency ramp up (UP)

14

Frequency ramp down (DN)

1: Set via AI1 terminal.

The reference frequency is set by analog input via

terminal AI1 and the voltage range is -10V~10V. The

relationship between voltage and reference frequency

can be set in Group A3.

2: Set via AI2 terminal.

The reference frequency is set by analog input via

terminal AI2 and the voltage range is -10V~10V. The

relationship between voltage and reference frequency

can be set in Group A3.

3: Set via AI3 terminal.

The reference frequency is set by analog input via

terminal AI3 and the voltage range is -10V~10V. The

relationship between voltage and reference frequency

can be set in Group A3.

4: Set via X7/DI terminal (PULSE).

Set the reference frequency by the X7 terminal’s

frequency of pulse input .The relationship between pulse

frequency and reference frequency can be set in Group

A3.

5: Reserved.

32

32

A0.03 Set the operating

frequency in digital mode

Range: Lower limit of

frequency ~upper limit

of frequency【50.00Hz】

When the main reference frequency is set in digital

mode(A0.02 = 0), this setting of A0.03 is the drive’s

initial frequency value.

A0.04 Methods of inputting

operating commands

0~2【0】

FV100 has two control modes.

0: Panel control:Input operating commands via panel

Start and stop the drive by pressing RUN, STOP and M

on the panel.

1: Terminal control: Input operating commands via

terminals.

Use external terminals Xi(Set function code

A6.00~A6.06 to 1 and 2),M Forward, M Reverse to start

and stop the drive.

2:Modbus communication.

A0.05 Set running direction

0~1【0】

This function is active in panel control mode , and

inactive in terminal control mode.

0: Forward

1: Reverse

A0.06 Acc time 1

0.0~6000.0s

【6.0s】

A0.07 Dec time 1

0.0~6000.0s

【6.0s】

Default value of Acc/Dec time 1:

2kW or below:6.0S

30kW~45kW:20.0S

45kW or above:30.0S

Acc time is the time taken for the motor to accelerate

from 0Hz to the maximum frequency (as set in A0.08).

Dec time is the time taken for the motor to decelerate

from maximum frequency (A0.08) to 0Hz.

FV100 series VFD has defined 4 kinds of Acc/Dec

time.(Here only Acc/Dec time 1 is defined, and Acc/Dec

time 2~4 will be defined in A4.01~A4.06),and the

Acc/Dec time 1~4 can be selected via the combination

of multiple function input terminals,please refer to

A6.00~A6.07.

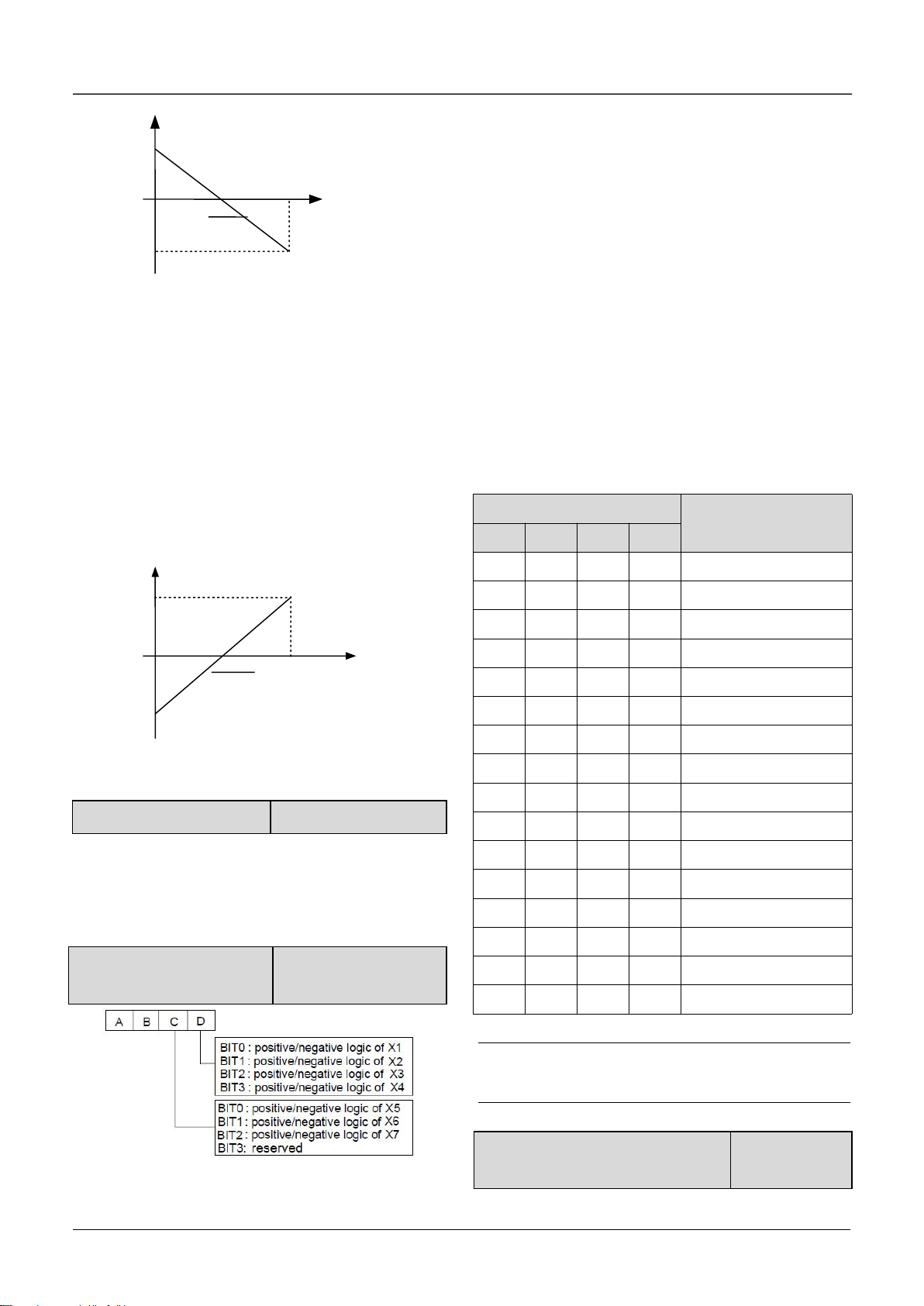

A0.08 Max. output

Frequency

Max{50.00,A0.11 upper limit of

frequency}~300.00Hz【50.00】

A0.09 Max. output

Voltage

0~480V【VFD’s rating values】

A0.10 Upper limit

of frequency

A0.11~A0.08【50.00】

A0.11 Lower limit

of frequency

0.00~A0.10【00.00】

A0.12 Basic

operating frequency

0.00~300【50.00】

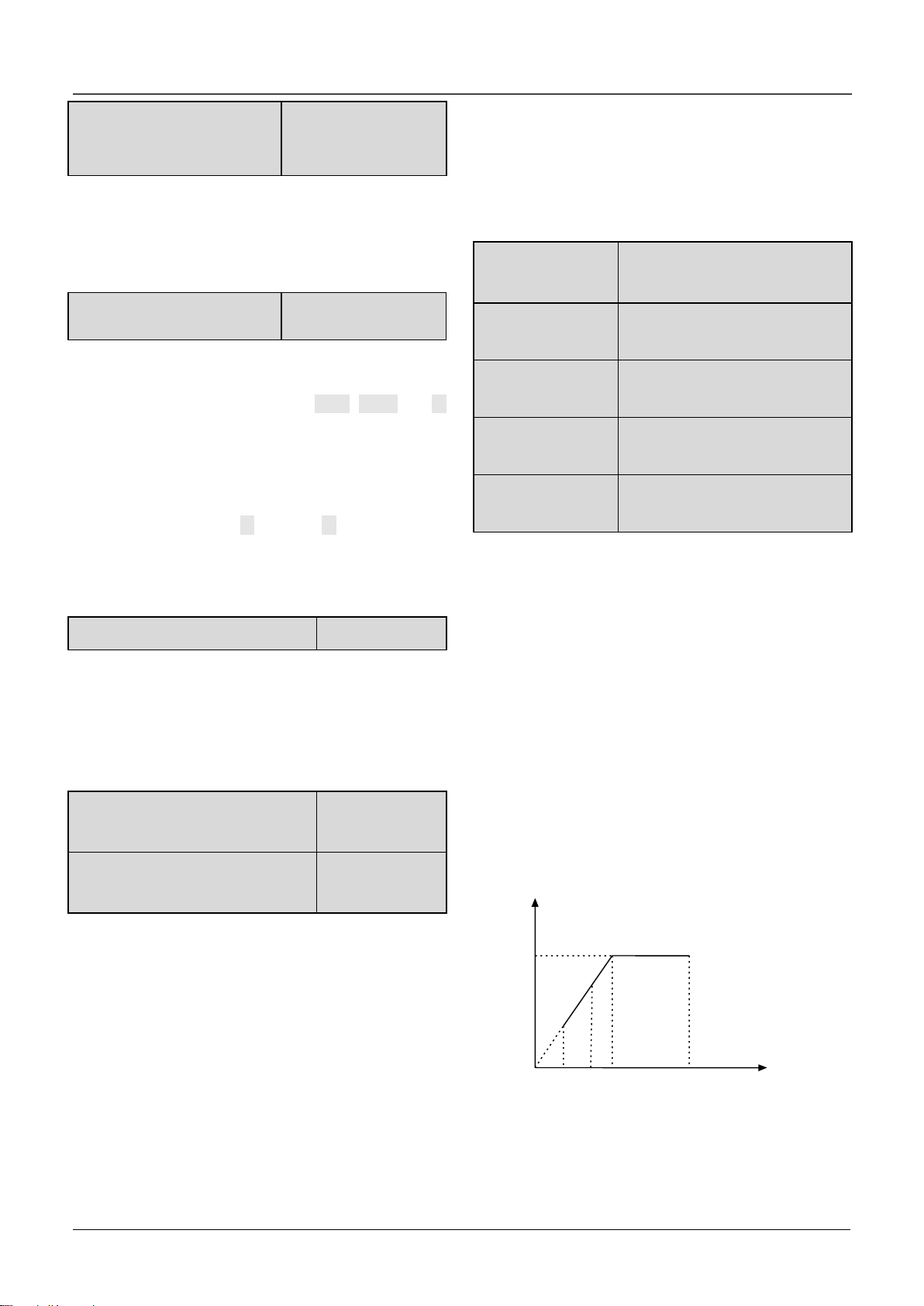

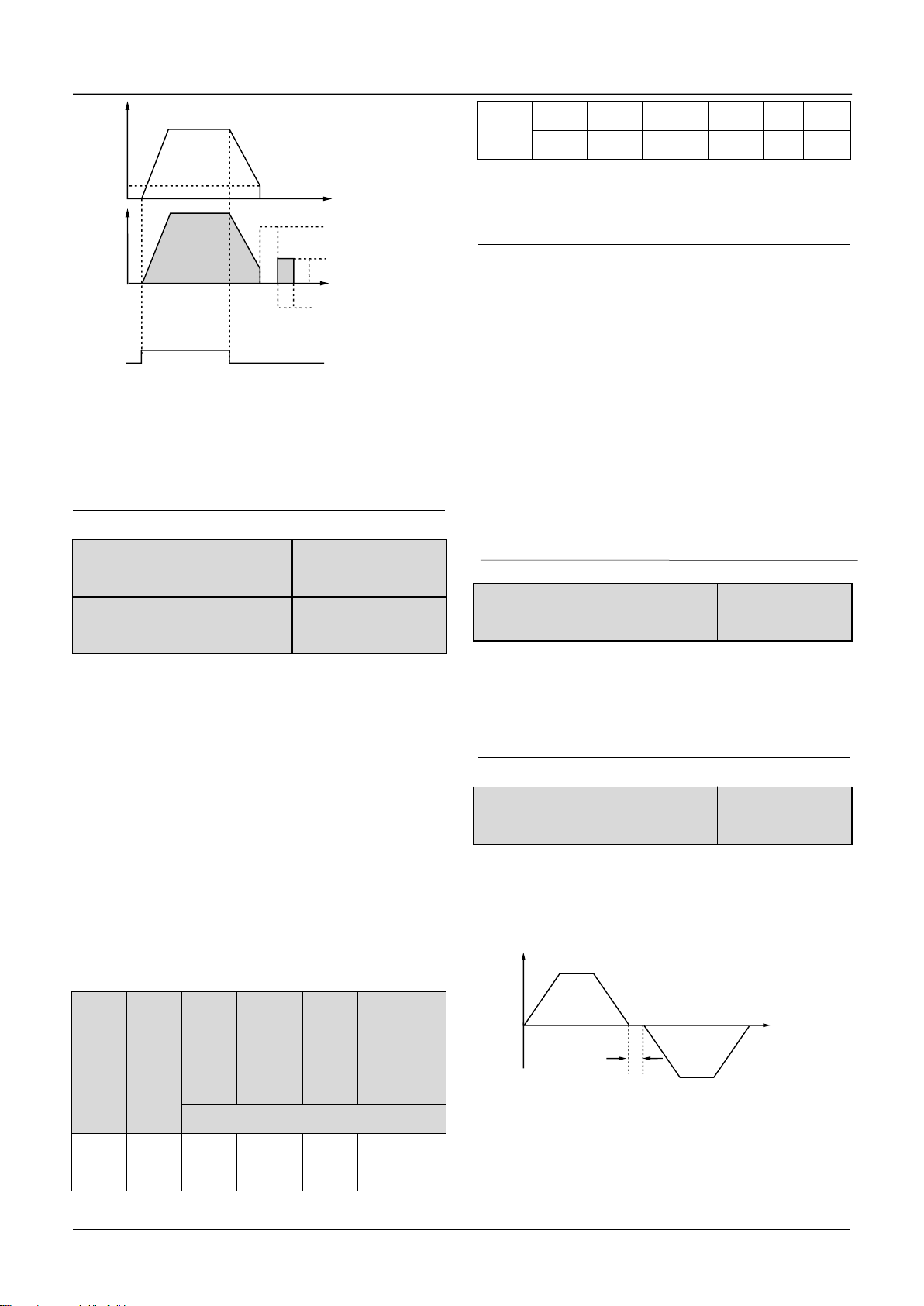

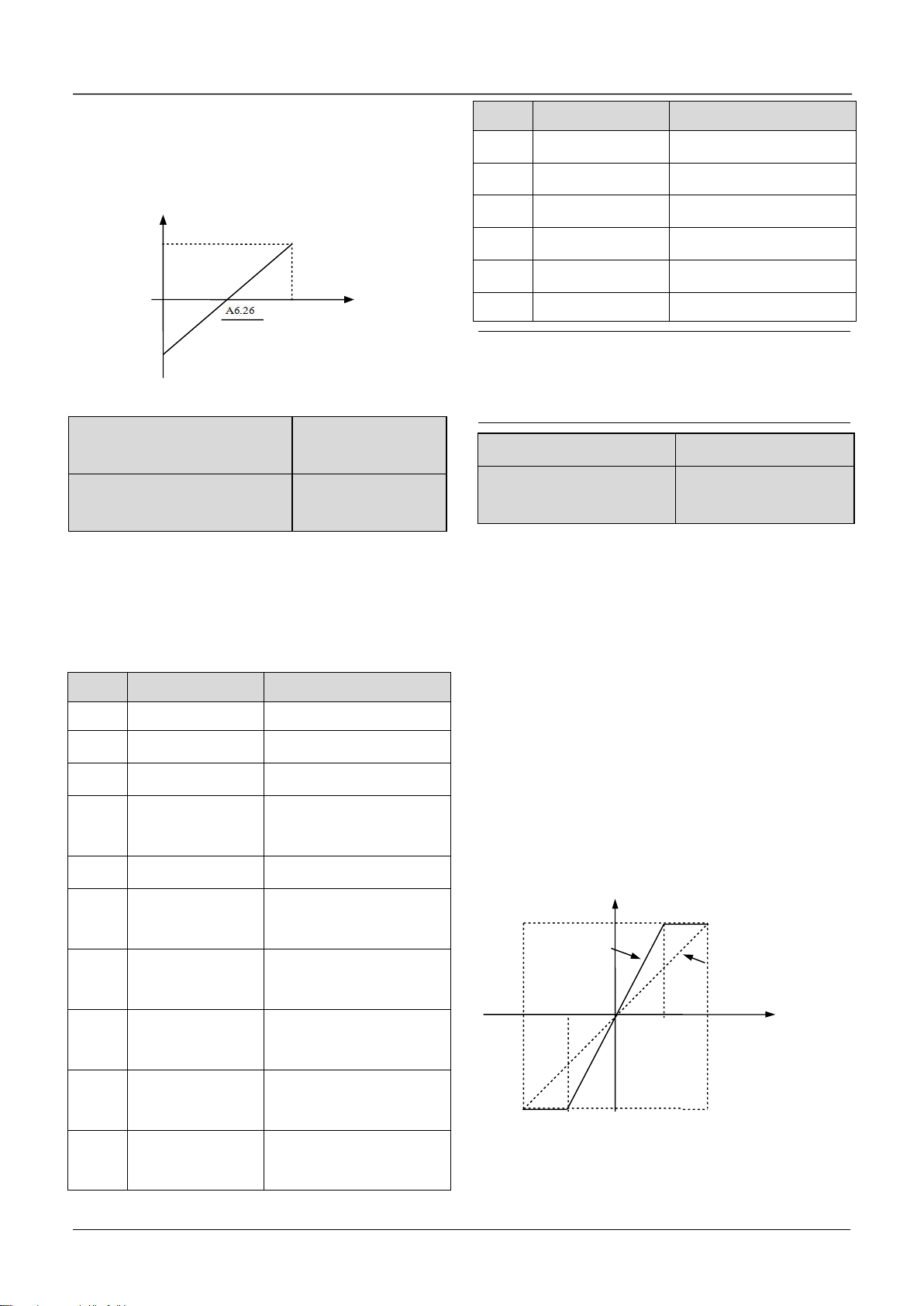

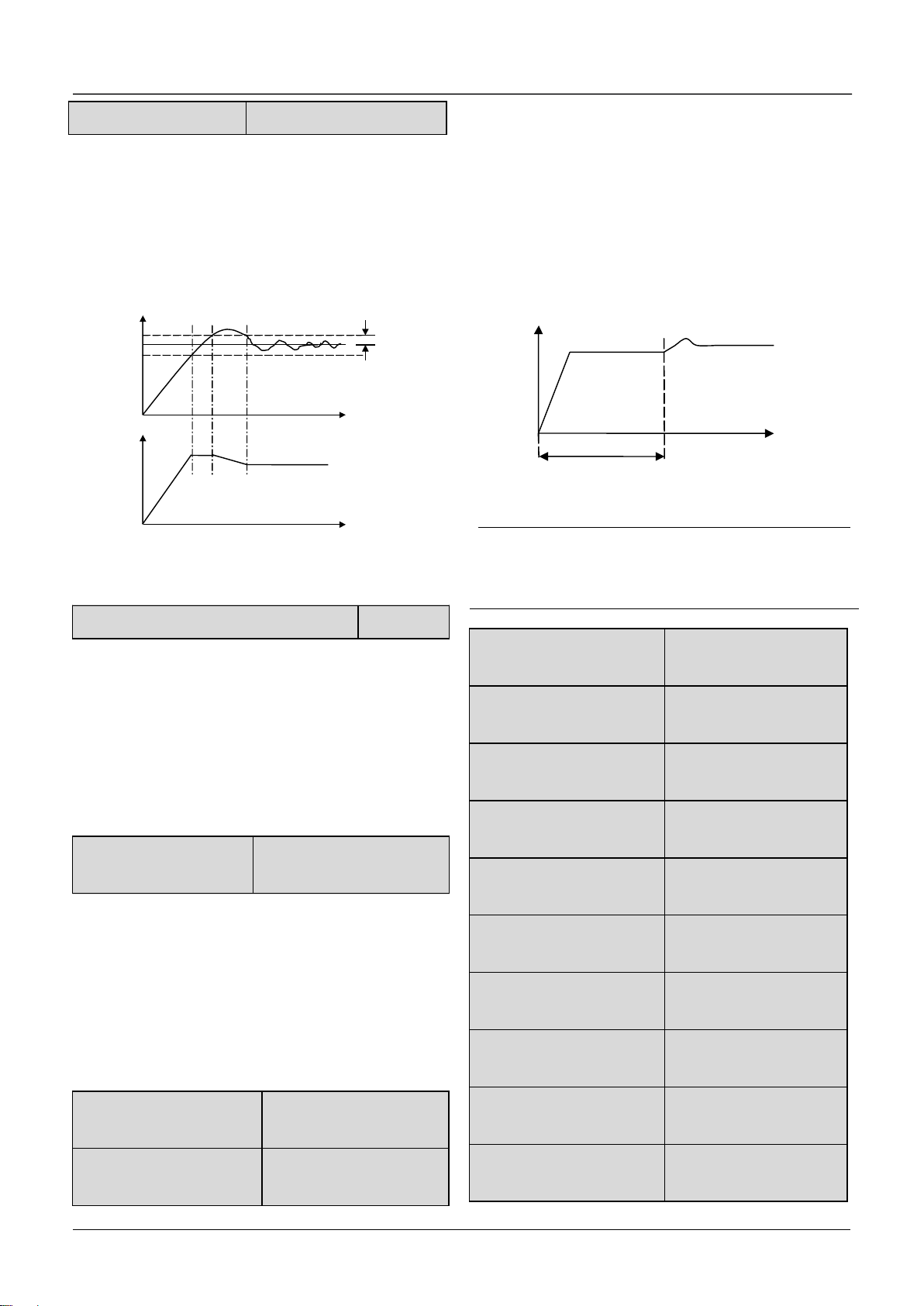

Max output frequency is the highest permissible output

frequency of the drive, as shown in Fig. 6-1 as F

max

;

Max output voltage is the highest permissible output

voltage of the drive, as shown in Fig. 6-1 as V

max

Upper limit of frequency is the highest permissible

operating frequency of the user setting, as shown in Fig.

6-1 as F

H.

Lower limit of frequency is the lowest permissible

operating frequency of the user setting,as shown in

Fig.6-1 as FL.

Basic operating frequency is the Min. frequency when

the drive outputs the max voltage in V/F mode, as shown

in Fig. 6-1 as F

b

FLF

H

F

b

F

max

V

max

Output

Voltage

Output frequency

Fig.6-1 Characteristic parameters

33

33

Note:

1 . Please set Fmax, FHand FLcarefully according to

motor parameters and operating states.

2. FHand FLis invalid for JOG mode and auto tuning

mode.

3.Besides the upper limit of frequency and lower limit

of frequency,the drive is limited by the setting value of

frequency of starting,starting frequency of DC braking

and hopping frequency.

4.The Max. output frequency,upper limit frequency and

lower limit frequency is as shown in Fig.6-1.

5.The upper/lower limit of frequency are used to limit

the actual output frequency.If the preset frequency is

higher than upper limit of frequency,then it will run in

upper limit of frequency.If the preset frequency is lower

than the lower limit of frequency,then it will run in lower

limit of frequency.If the preset frequency is lower than

starting frequency,then it will run in 0Hz.

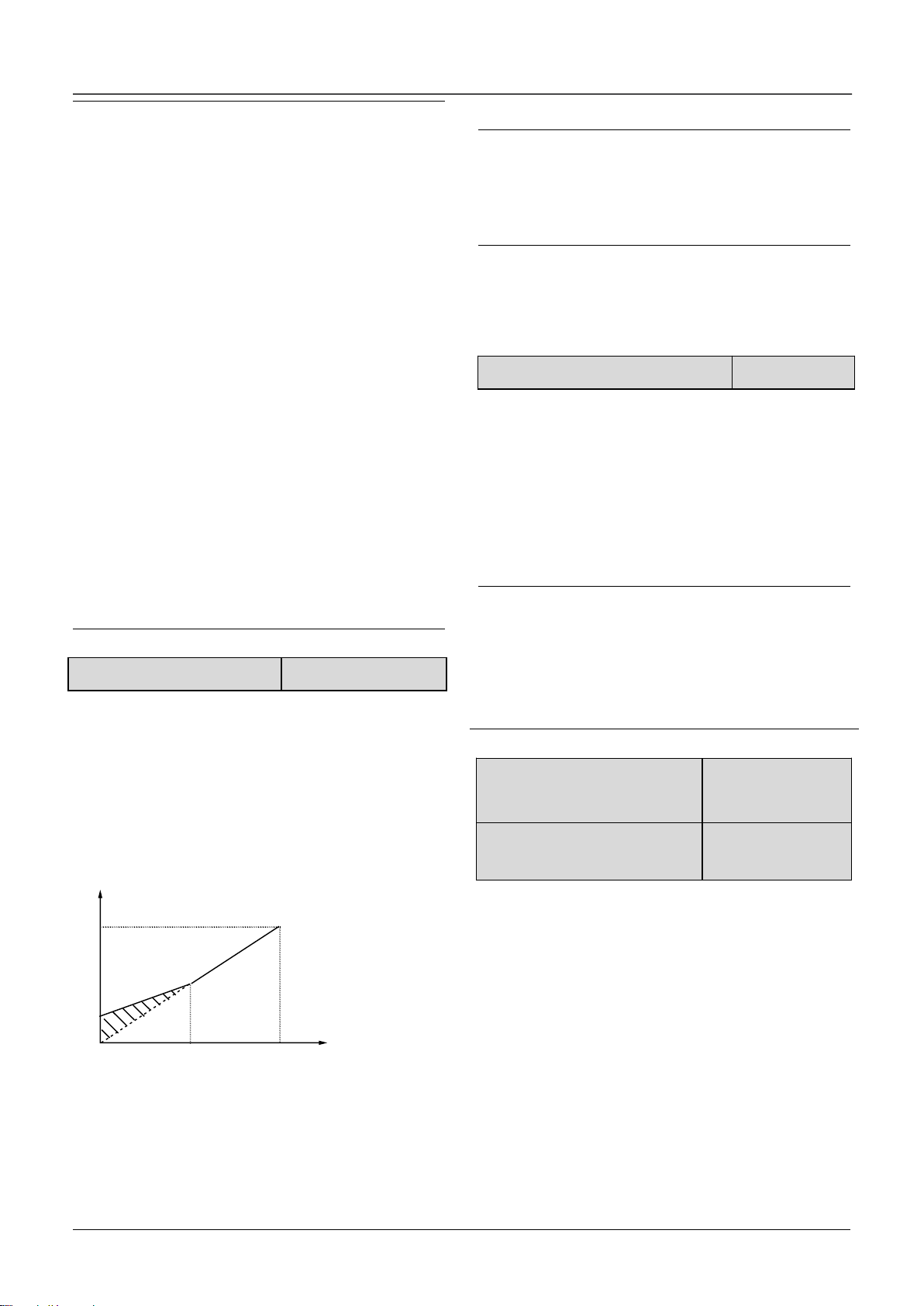

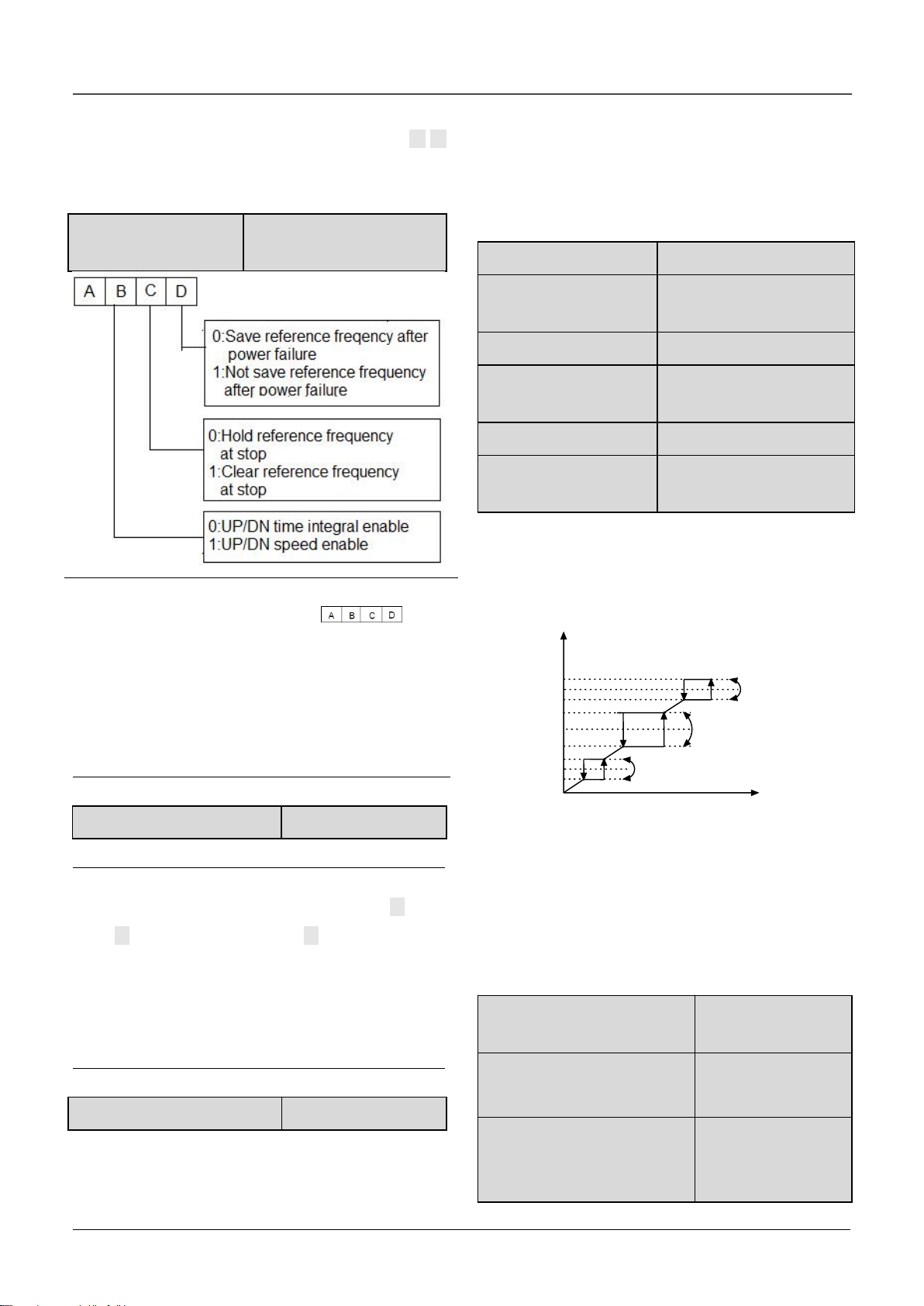

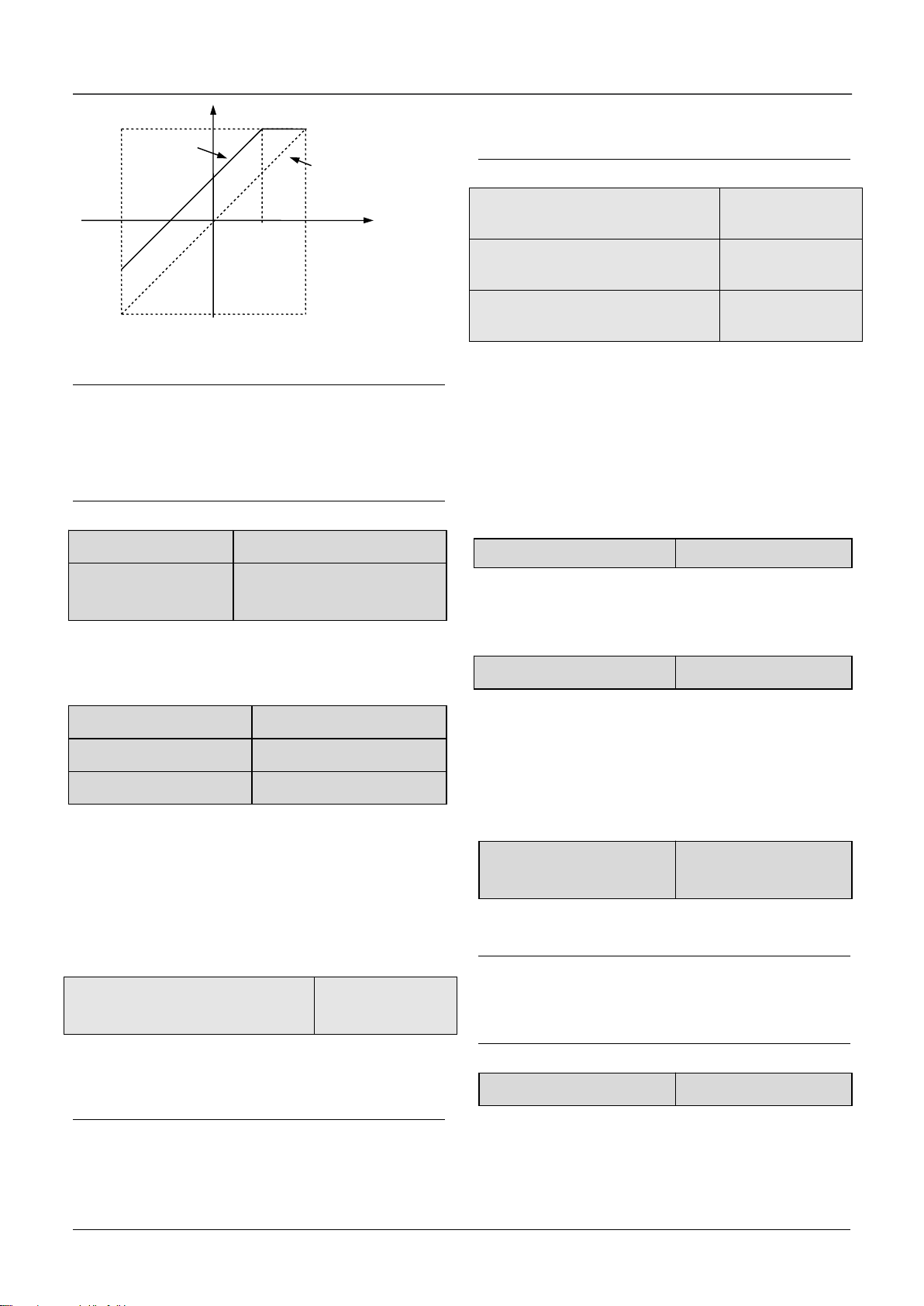

A0.13 Torque boost of motor 1

0.0~30.0%【0.0%】

In order to compensate the torque drop at low frequency,

the drive can boost the voltage so as to boost the torque.

This function code is corresponding to maximum output

voltage.

If A0.13 is set to 0, auto torque boost is enabled and if

A0.13 is set non-zero, manual torque boost is enabled,

as shown in Fig. 6-2.

Vb:Manual torque boost Vmax: Max. output voltage

Fz:Cut-off frequency for torque boost Fb:Basic operating frequency

Output

voltage

F

b

V

b

V

max

Output frequency

F

z

Fig.6-2 Torque boost(shadow area is the boostedvalue)

Note:

1. Wrong parameter setting can cause overheat or

over-current protection of the motor.

2. Refer to b1.07 for definition of fz.

6.2 Group A1

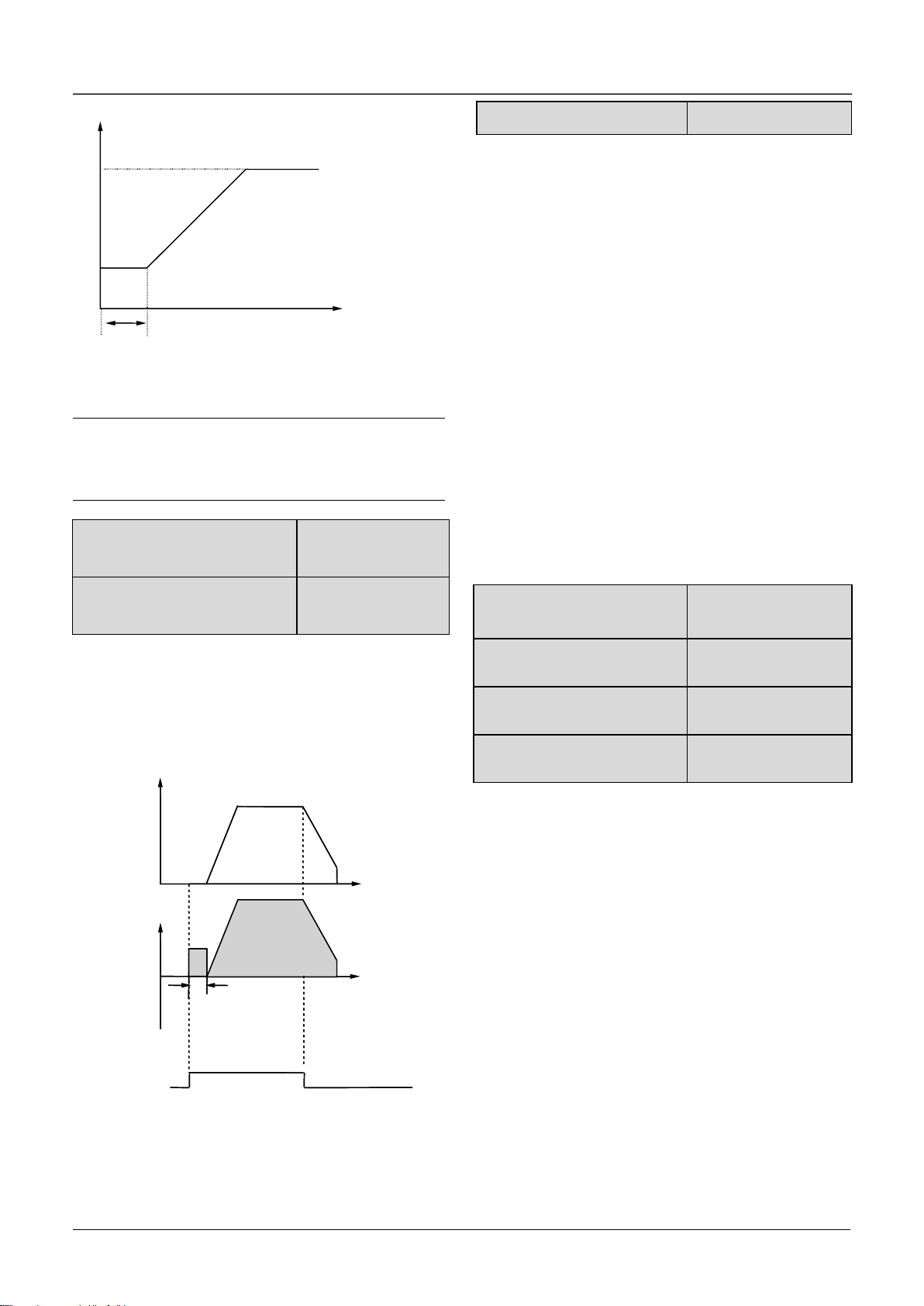

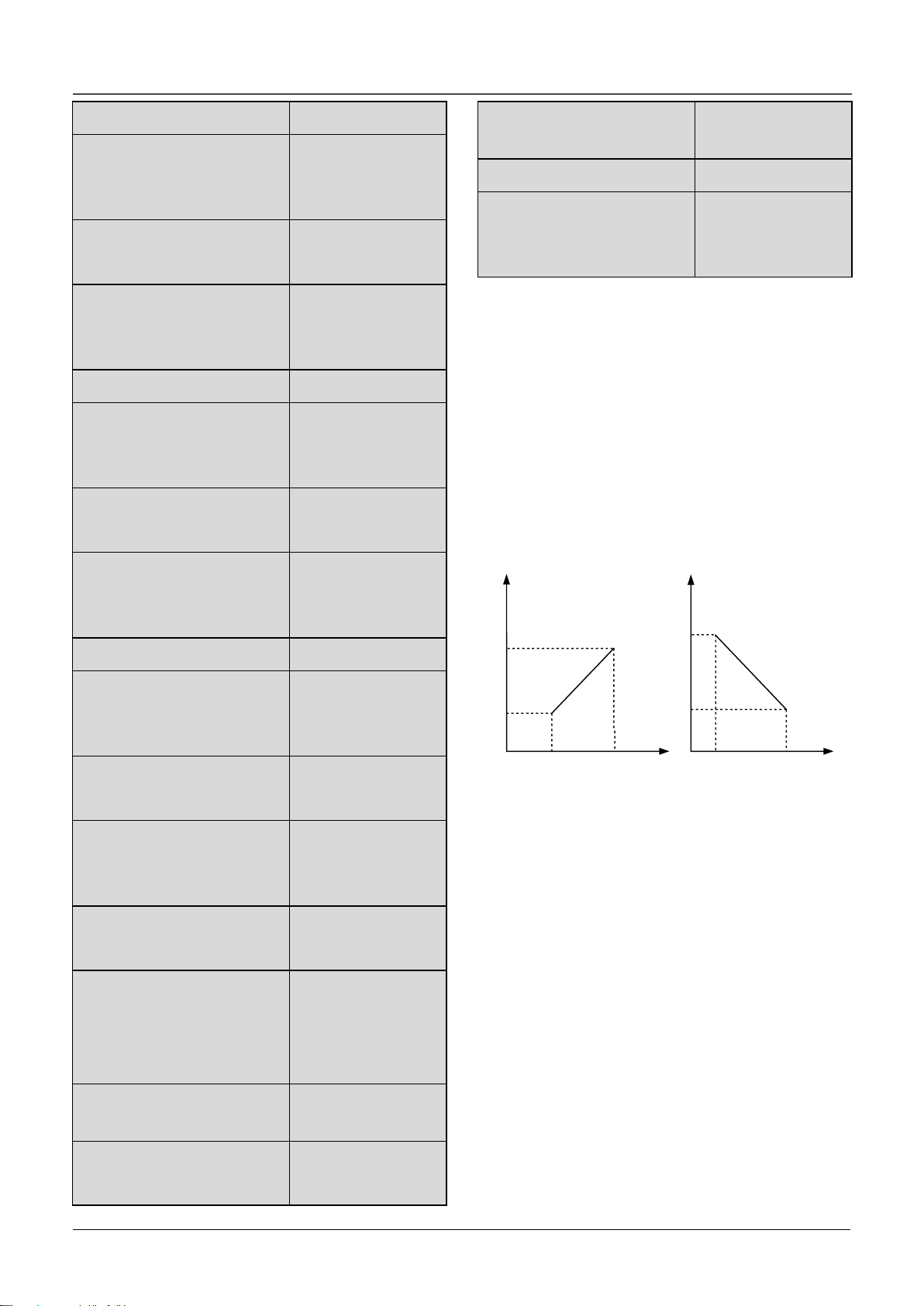

A1.00 Starting mode

0、1、2【0】

0.Start from the starting frequency

Start at the preset starting frequency (A1.01) within the

holding time of starting frequency (A1.02).

1.Brake first and then start

Brake first(refer to A1.03 and A1.04), and then start in

mode 0.

2.Speed tracking

Notes:

Starting mode 1 is suitable for starting the motor that is

running forward or reverse with small inertia load when

the drive stops. For the motor with big inertial load, it is

not recommended to use starting mode 1.

A1.01 Starting frequency

0.00~60.00Hz

【0.00Hz】

A1.02 Holding time of starting

Frequency

0.00~10.00s【0.00s】

Starting frequency is the initial frequency when the drive

starts, as shown in Fig. 6-3 as FS; Holding time of

starting frequency is the time during which the drive

operates at the starting frequency, as shown in Fig. 6-3

as t

1

34

34

Fig.6-3 Starting frequency and starting time

Note:

Starting frequency is not restricted by the lower limit of

frequency.

A1.03 DC injection braking

current at start

0.0~100.0%【0.0%】

A1.04 DC injection braking

time at start

0.00~30.00s【0.00s】

A1.03 and A1.04 are only active when A1.00 is set to 1

(starting mode 1 is selected), as shown in Fig. 6-4.