Kimball Cetra, Footprint Assembly Instructions Manual

Cetra®\

Footprint

®

Assembly Instructions

TRAXX

®

Mounted

Worksurface

Installation

Proper product installation, in accordance with these instructions, is the responsibility of the installing agent.

If you have any questions concerning these instructions, please call Kimball Customer Care Teams.

SYSTEMS

Recommended Tools

• Screw Gun with

Torque Option

• #2 Phillips Head Bit

•Tape Measure

Telephone 800.482.1818

Fax 812.482.8300

www.furniture.kimball.com

Form #AISYFP004B-01

#1202060

Printed in U.S.A

© 2001 Kimball International, Inc.

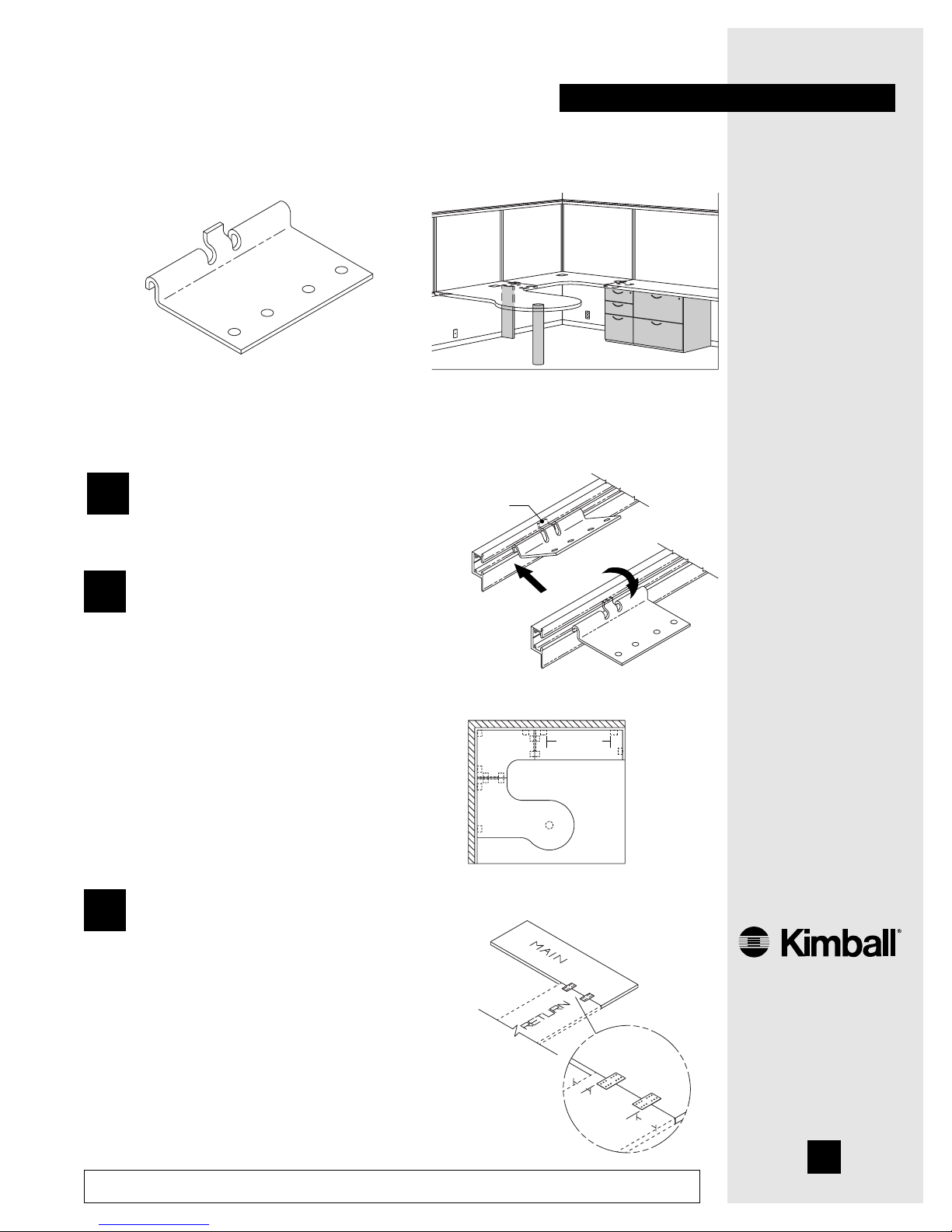

Worksurfaces can be Traxx mounted with worksurface brackets (Figure A) and supported

with pedestals, end panels, and support bases (Figure B).

1

3

2

Push the top of the bracket downward

allowing bracket to hang off of the

Traxx (Figure D).

Figure A

Place worksurface on clean, solid

surface, back side facing up. Install the

flat brackets on the main worksurface,

approximately 2" from front edge and

approximately 6" from back edge of the

adjoining worksurface using the screws

(ASC100) provided (Figure F). Ensure

that the flat bracket attachment does

not interfere with other brackets or

components. Two flat brackets are

required to join surfaces end to end or

at a right angle.

Insert hook on the top of the bracket

into the Traxx at a 45 degree angle

(Figure C).

1

Figure B

Note: The maximum distance between

brackets should be no greater than 48"

(Figure E). The maximum span of an

unsupported worksurface should not

exceed 60" for 1 3/16" worksurfaces and

72" for 1 9/16" worksurfaces. Support is

required within 6" of surfaces butted

end-to-end. This may be a pedestal or

12" deep support panel.

Figure E

Figure F

Worksurface Brackets

Pedestals, End Panels and Support Bases

Figure D

Figure C

Hook

48" or less

2"

6"

Traxx

Mounted

Worksurface

Installation

Proper product installation, in accordance with these instructions, is the responsibility of the installing agent.

If you have any questions concerning these instructions, please call Kimball Customer Care Teams.

SYSTEMS

6

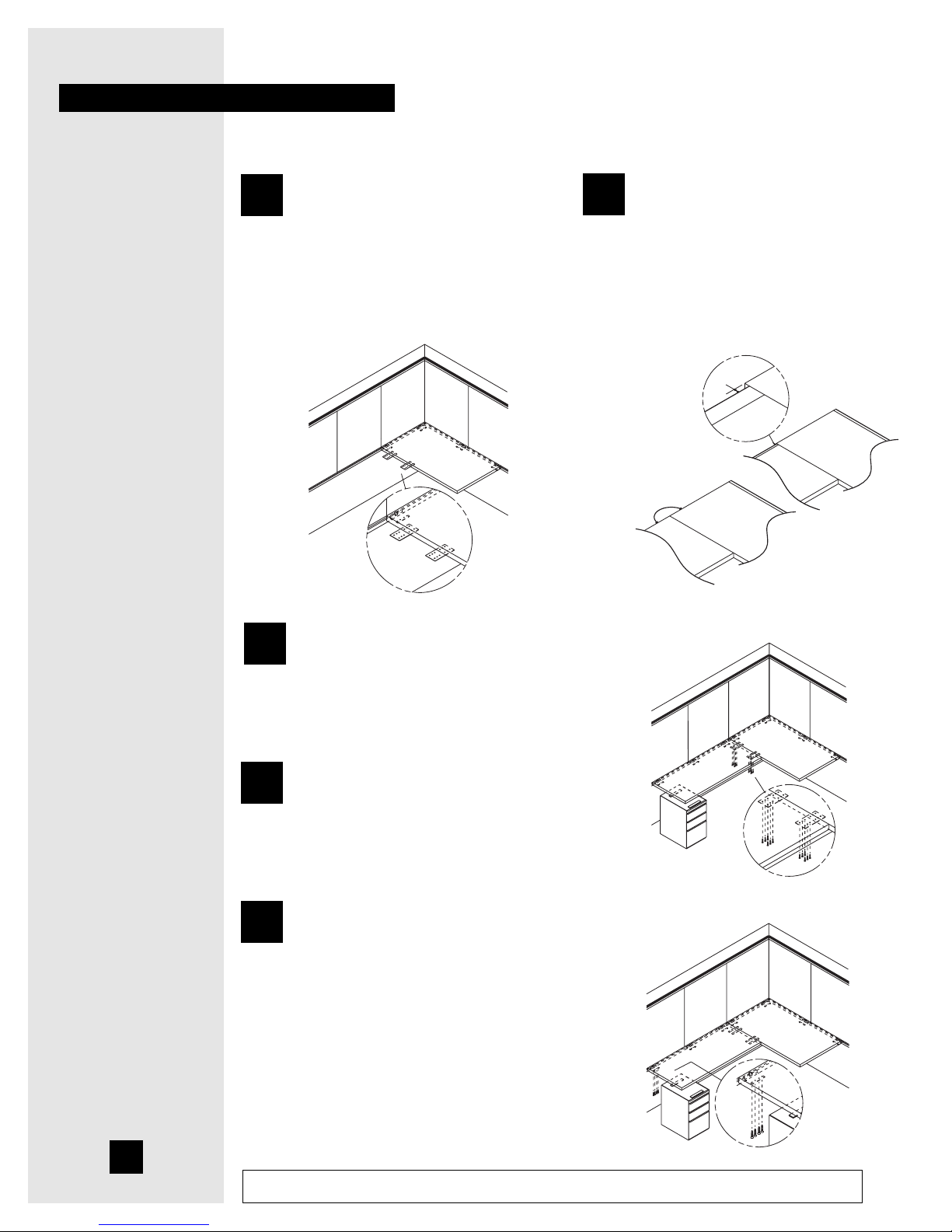

Attach extension or filler worksurface to

the flat brackets with screws (ASC100)

provided (Figure J). Twelve screws are

required per bracket.

Cetra\

Footprint

Assembly Instructions

2

5

Lay extension or filler worksurface onto

brackets.

4

Lay the worksurface on the brackets

(Figure G).

Figure G

Note: When attaching two surfaces at a

right angle, there will be a 1/8" gap

between the wire manager and Traxx

(Figure H). If there is no wire manager,

the surfaces should align (Figure I).

Tip: Use an undersurface component as

additional support until the worksurface

bracket is secured to the surface.

Figure J

Figure K

7

Beginning at one end of the worksurface

layout, apply pressure to the front of the

ganged worksurfaces while controlling

the gaps between the Traxx and back of

worksurface.

8

Attach the worksurfaces to the worksurface

brackets using the screws (ASC100)

provided (Figure K). A minimum of three

screws are required per bracket.

Figure I

Figure H

1/8"

Loading...

Loading...