Killbros 590, 690 Operator's Manual/parts Catalog

OPERATOR’S MANUAL

PARTS CATALOG

PART NO. 106260

Corner Auger Grain Carts

24325 ST. RT. 697W

DELPHOS, OH. 45833

OM02504

590 (After Serial No. D1949-)

690 (After Serial No. D1948-)

PH: 419-695-2060

FAX: 419-695-6875

2

INTRODUCTION

Your new Killbros. Grain Cart is engineered to

meet today's challenging operating standards.

The product you have chosen was designed

to fit these needs and yours, offering numerous operating features that increase your harvesting efficiency for years to come.

A dual auger, along with a rugged design

throughout, will keep maintenance to a minimum. You have also purchased a unit with

many options as your operation may change.

An axle with removable spindles for the addition of an electronic scale package providing

yield per acre and accumulate bushels per

field. An optional Hydraulic Drive Kit eliminates the need for PTO hook up.

The following pages will provide you with information regarding safety, operating and servicing instructions for your new product. Use

this book to familiarize yourself and to get the

maximum use of your grain cart as it was

designed to do. Please provide this booklet to

other operators as well, for their safety and

efficient use. And again, Thank you for your

purchase.

This symbol identifies important

safety messages. When you see it,

read the message that follows and be alert to

the possibility of personal injury.

Remember, safety instructions stated in this

manual are for your protection. Read them

carefully and follow closely when working around

or using the GRAIN CART.

REMEMBER:

THINK SAFETY

A CAREFUL OPERATOR IS THE

BEST INSURANCE AGAINST AN

ACCIDENT!

No accident-prevention program can be successful without the wholehearted cooperation of the

person who is directly responsible for the operation of the equipment.

To read accident reports from all over the country is to be convinced that a large number

of accidents can be prevented only by the operator anticipating the result before the accident is

caused and doing something about it. No power-driven equipment, whether it be transportation or

processing, whether it be on the highway, in the harvest field, or in the industrial plant, can be

safer than the man who is at the controls. If accidents are to be prevented--and they can be

prevented--it will be done by the operators who accept the full measure of their responsibility.

It is true that the designer, the manufacturer, and the safety engineer can help; and they will

help, but their combined efforts can be wiped out by a single careless act of the operator.

It is said that, "the best kind of a safety device is a careful operator." We, at Killbros. ask

that you be that kind of operator.

Thank-You!

Killbros.

3

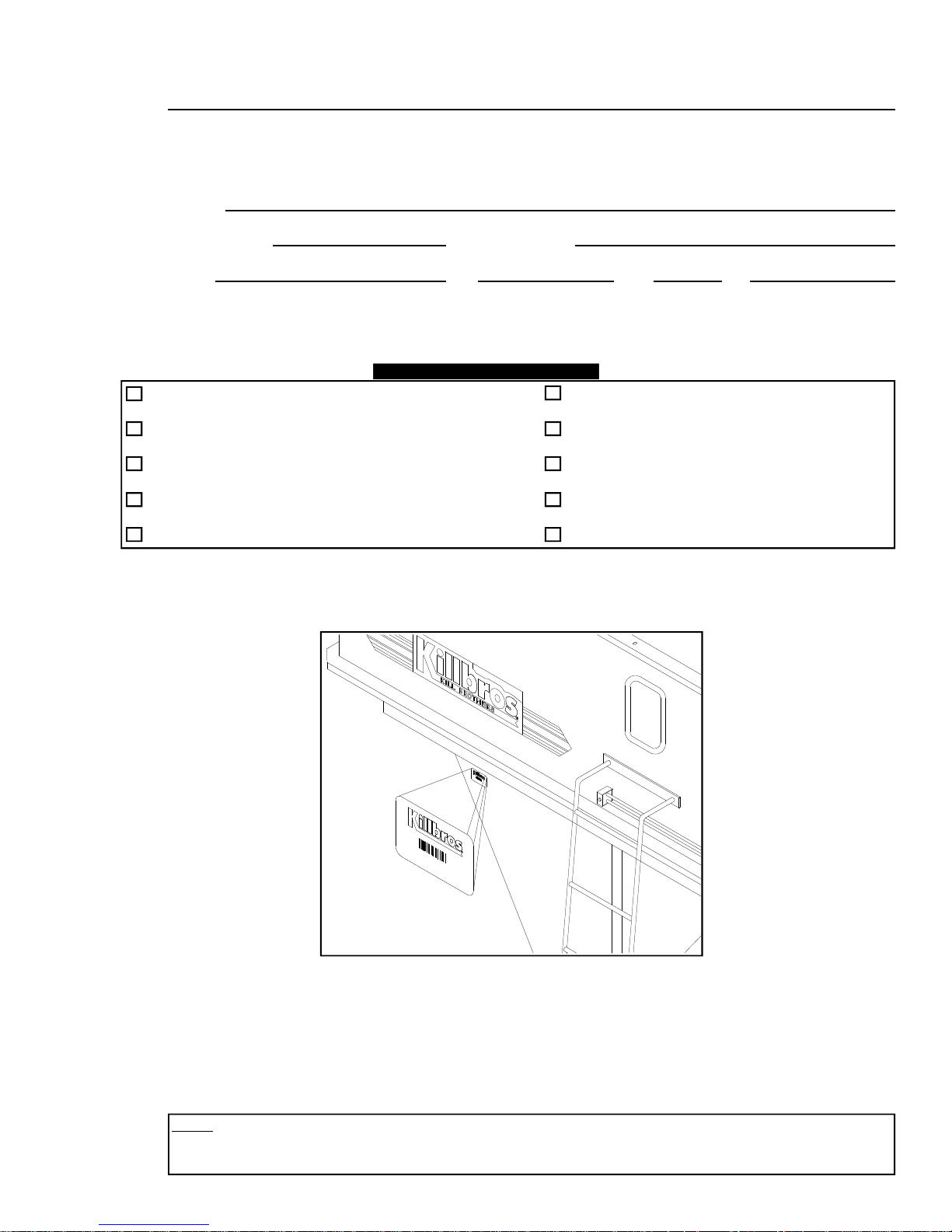

THANK YOU FOR YOUR PURCHASE!

Please fill out and retain this portion for your records. For warranty consideration, please contact

dealer where purchased.

Product:

Serial Number: Date of Purchase:

Dealer: City: State: Zip:

Please supply this information when you have questions or when ordering repair or replacement

parts. Your dealer needs this information to give you prompt, efficient service.

PRE-OPERATION CHECKLIST

Wheel bolts tightened (recheck after initial use) Safety and operating procedures reviewed

Tire Pressure checked Field adjustment information reviewed

Hardware Tightened Lubrication procedures reviewed

Machine lubricated Warranty information reviewed

Guards and shields in place Hydraulic hoses properly routed/fittings tight

NOTE: Due to continuing improvements in the design and manufacture of KILLBROS products,

and normal changes in the marketplace, all specifications contained herein are subject to change

without notice.

OM02608

4

Table of Contents

INTRODUCTION ................................................2

SAFETY DECALS ...........................................5

SAFETY ...........................................................6

OPERATIONS

ELECTRICAL HOOK-UP ..................................7

TRACTOR HOOK-UP .......................................7

HYDRAULIC HOOK-UP ................................... 7

OPERATION IN FIELD ....................................8

OPERATING THE PTO...................................8

Coupling the PTO.......................9

Lubrication.................................. 9

Chains........................................9

Dismantling...............................10

ASSEMBLY

INSTALLATION OF 690 SIDEBOARDS.......18

INSTALLATION OF OPTIONAL

HYDRAULIC DRIVE ......................................19

INSTALLATION OF SCALE UNIT .................20

PARTS

AUGER COMPONENTS .................................21

FLOW CONTROL COMPONENTS ................22

POWER TRAIN COMPONENTS ...................23

GEAR BOX DIAGRAM ...................................24

POWER TAKE-OFF SHAFT .........................25

AXLE/HUB COMPONENTS ............................26

SCALE COMPONENTS .................................27

SIDEBOARDS .................................................28

Assembling...............................10

Slip Clutch................................10

IMPORTANT SCALE INFORMATION ............11

OPERATING THE SCALE .............................12

SCALE TROUBLESHOOTING ........................14

SERVICE

LUBRICATION AND MAINTENANCE ............16

SERVICE TIPS ...............................................16

WHEEL NUTS/TIRE PRESSURE .................16

AUGER SYSTEM ...........................................17

FLOW CONTROL GATE ................................17

INDICATOR ARM ............................................17

CART ASSEMBLY..........................................17

LIGHT PACKAGE ...........................................29

MISCELLANEOUS...........................................30

DECALS ..........................................................31

AUXILARY HYDRAULIC DRIVE UNIT ..........32

ADJUSTABLE GEARBOX OPERATION .......18

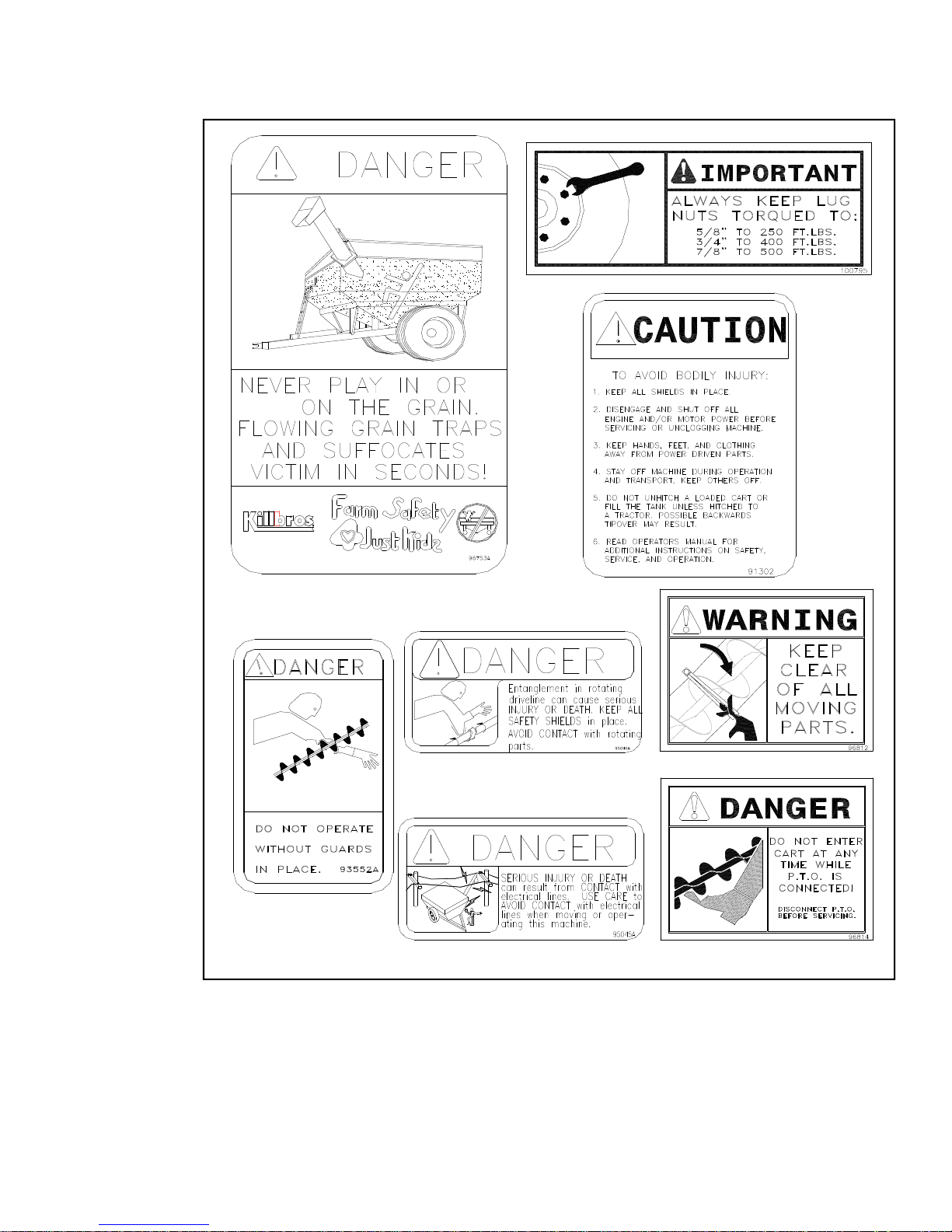

590/690 SAFETY DECALS

5

OM02569

(Refer to pg. 31 for part numbers)

6

SAFETY

AVOID POSSIBLE INJURY

Always use safety precautions. Most accidents are a result of failure to practice safety.

Accidents cause lost time and suffering. Do

not operate the Grain Cart without reading

this manual thoroughly.

Follow all safety precautions as outlined in

this manual.

All machinery should be operated only by

those who are experienced and responsible

and have been delegated to do so.

BEFORE OPERATING

Be sure that all hardware is in place and

properly secured.

Keep safety signs clean and legible at all

times.

Check tire pressure so that it is at the recommended rating during operation.

Check box for any debris or excess grain

before each use.

Keep children and all unauthorized personnel

clear of work area.

Do not allow anyone to ride on the equipment. Make sure everyone is clear before

operating the machine or tractor.

Always shut tractor engine off when working

on the unit.

Be sure that the clean-out doors are closed

and securely latched.

Keep body, hair, and clothing away from

moving parts.

DURING OPERATION

Keep children and all unauthorized personnel

clear of work area.

Never enter or climb on Grain Cart while the

auger is running.

Do not operate with safety shields removed or

clean-out door open.

Ensure that all personnel are clear before

moving the Cart.

Keep hands, feet, clothing, and objects away

from moving parts.

Do not grease equipment when in operation.

DO NOT allow ANYONE to enter the box at

any time, if entry is necessary, be sure chute

door is closed, P.T.O. is disengaged, and

tractor brakes are locked before entry.

BEFORE TRANSPORT

Make sure that all safety decals and reflectors are clean and in place on the machine.

While attaching cart to tractor be sure you

can see the driver and the driver can see you

at all times to avoid being struck by the

tractor.

Comply with all state and local laws governing

highway safety when moving machinery.

Use accessory lighting and warning lights when

transporting at night to adequately warn operators of other vehicles.

When auger is not in use, be sure to fold to

rest position.

DURING TRANSPORT

Use good judgment when transporting implements on highways. Maintain complete control

at all times. Regulate speed to road conditions.

Be careful when moving unit near electrical

lines with discharge auger up.

Drive at speeds slow enough to insure your

safety as well as others.

Regulate speed during off-road travel. Do not

travel faster than 8 M.P.H. loaded.

Due to the height and width of the implement,

use extra caution on highways, farm lanes,

and when approaching low and narrow clearances.

Follow all regulations concerning weight limitations on roadways, bridges, and overpasses.

Unit is to be towed at tractor speeds only. 20

M.P.H. maximum.

Do not attempt to move any objects away

from moving parts.

COMPLY WITH ALL SAFETY WARNINGS

AND CAUTIONS IN THIS MANUAL!

7

OPERATIONS

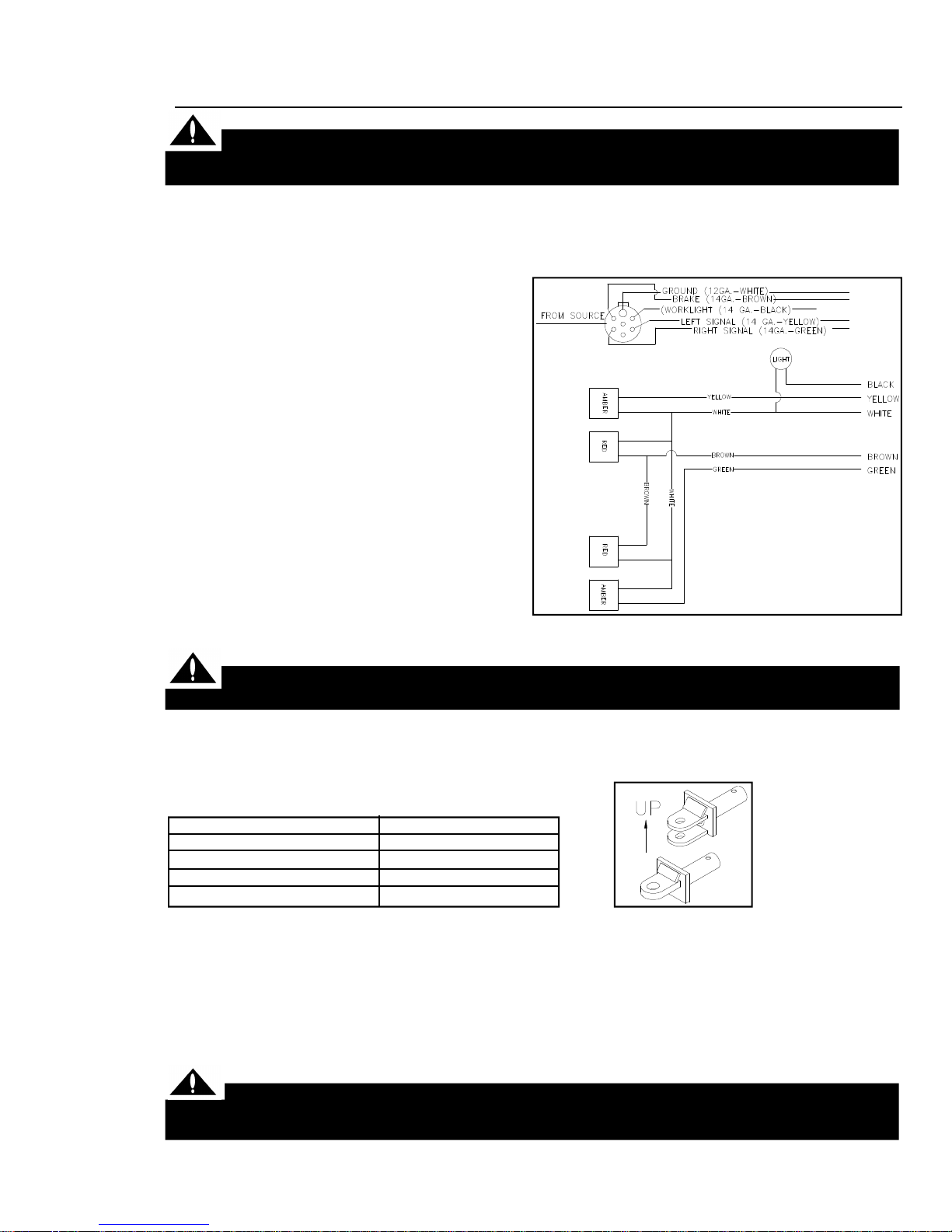

ELECTRICAL HOOK-UP

DO NOT attempt to install, attach, or repair any electrical applications on the cart if work

area is wet. Allow area to dry before any work is to be done. Electrical shock or electrocution may

result if work area is not dry.

Your Grain Cart is supplied with a seven-point SAE connector plug, which will adapt to the

receptacle found on several new tractors on the market today. If not available, an SAE J S60A

seven-point outlet socket can be purchased from your Killbros dealer (order #104838).

SAE SEVEN POINT

CONNECTOR PLUG

Grain Cart Wires

White..... Ground

Green..... Right amber flashing lamp

Yellow.... Left amber flashing lamp

Brown.....Tail Light

Note: it may be necessary to install a switch

in the tractor to operate the auger light.

The following schematic complies with ANSI/

ASAE Standard S279.9/SAEJ137 for new production tractors. NOTE: Wiring specifications

may be different for older tractor models.

Consult your tractor operator’s manual or dealer

for proper wiring and installation. (Fig. 1)

Fig. 1

OM02482

TRACTOR HOOK-UP

Make certain that you can see the driver and the driver can see you at all times to avoid

being struck by tractor while attempting to hook up the Cart.

--Make sure sufficient counterweight is used on the tractor’s front-end.

--Move draw bar into shortest position.

Selecting the proper hitch pin size for your tractor!

Tractor Size

Category 4 (250-400 H.P.)

Category 3 (110-250 H.P.)

Category 2 (65-110 H.P.)

Category 1 (Under 65 H.P.)

Information gathered from: ISO/TC2/SC2 N4123

--With cart hitched to tractor, hook up P.T.O. (see pg. 9-C), following all safety precautions.

--Hook up 7-point electrical plug connection to tractor.

--Be sure hitch is positioned as shown. Gusset should be to top.

Hitch Pin Diameter

2”

1-1/2”

1-1/4”

1”

OM02548

HYDRAULIC HOOK-UP

CAUTION! When coupling hyd. hoses to ports on tractor, be sure that coupler ends are

clean of dust, dirt and debris. Failure to do so could contaminate hydraulic system resulting in

excessive wear and possible failure.

-- Properly identify the hoses for the auger fold and the flow control operation.

8

-- It is advisable to use the hydraulic control lever closest to the operator (most commonly known

as control lever No. 1) to activate the flow control.

-- Once everything has been hooked up, test for any possible needed adjustments:

-Are tires inflated to proper pressure?

-Do Augers run smoothly?

-Does Dump Auger fully extend?

-Does P.T.O. operate properly?

-Is Slip Clutch set too loose or too tight?

-Do Flow Control Gates operate properly?

-Is Indicator Arm working properly?

-Are all lights working properly?

If any one of these is not adjusted properly please read the SERVICE section outlined in the

manual or contact your nearest KILLBROS dealer for further information.

With everything in good operating condition, be sure to close flow control gates before use.

OPERATION IN FIELD

The Grain Cart is not insulated. Keep away form all electrical lines and devices. Electro-

cution can occur without direct contact.

1. Make sure the flow control door is in the closed position before loading into the cart.

2. Engage PTO at a low RPM; and open flow control gate.

3. Increase speed to approximately 850 RPM for optimum unloading performance.

4. Use the flow control opening to slow the rate of the flow rather than the tractor’s RPM.

NOTE: If overload causes the clutch to slip (standard PTO drive) or motor to stall (hydraulic drive),

stop auger immediately. Excessive heating of the clutch will require replacement of internal parts.

Close flow control door and relieve auger unloaded pressure by opening bottom pit dump door to

remove some grain from auger.

5. Do not disengage the auger with the flow control open. Excessive start-up torque may result,

putting stress on the cart driveline and your tractor.

6. Properly identify the tractor remotes for proper hook-up of the flow control and auger fold. A

mix-up can damage the auger drive system.

7. Under any circumstance, DO NOT enter the cart with the auger or tractor running.

8. It is strongly advised that the unloaded auger always be returned to the transport position when

not in use.

Operating the PTO

When finishing operation of PTO driven equipment, shift PTO control to neutral, shut off

the engine and wait until the PTO stops before getting off the tractor and disconnecting

the equipment.

Do not wear loose clothing when operating

the power take-off, or when near rotating equipment.

speed for the particular equipment in use.

PTO drive shafts must only be used for their

intended purpose.

PTO drive shafts, clutches and freewheels are

designed for specific machine types and power

requirements. They must not be replaced by

other models.

To avoid injury do not clean, adjust, unclog,

or service PTO driven equipment when the

tractor engine is running.

Never exceed the recommended operating

NOTE: See the tractor and implement manufacturers’ operating instructions.

Ensure that the PTO shaft is securely connected.

9

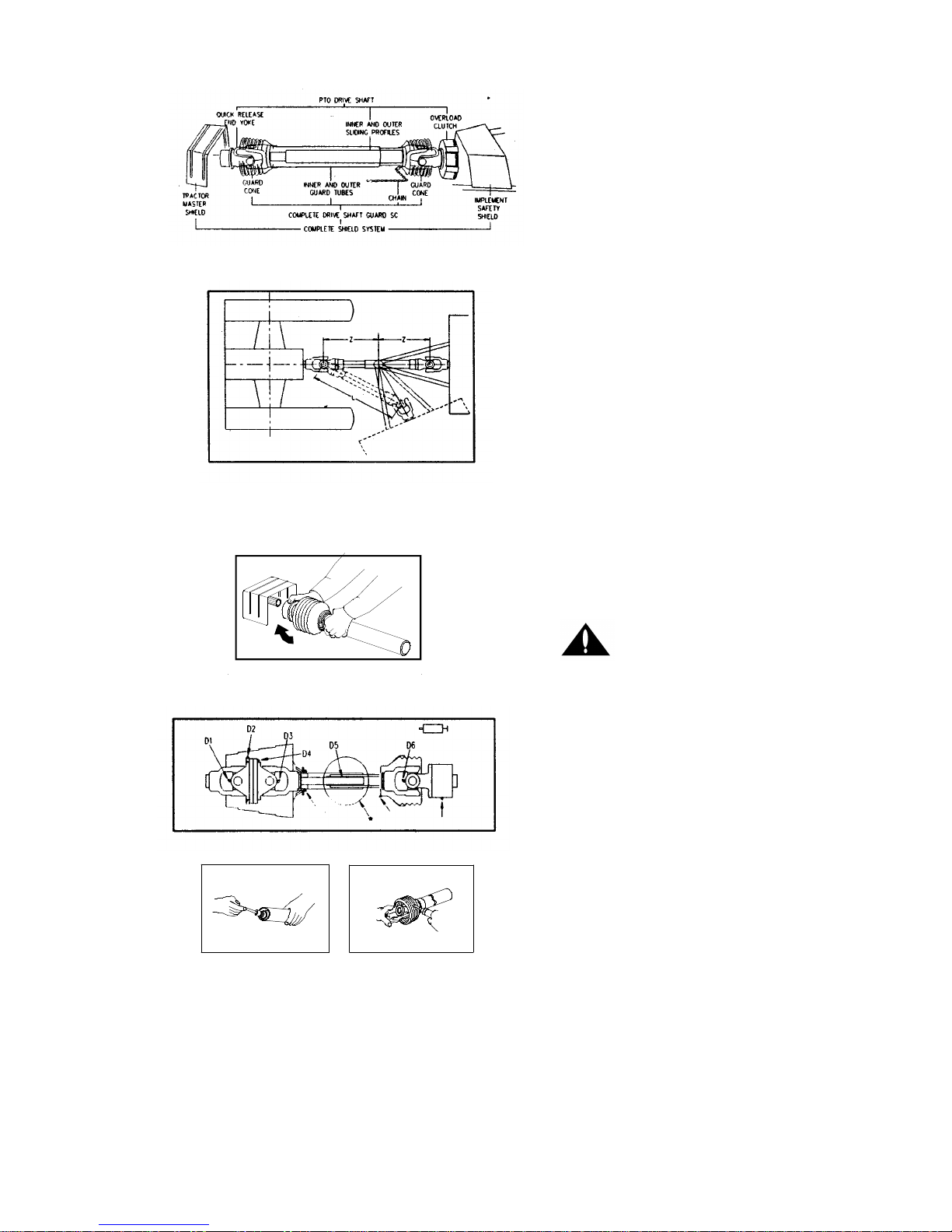

B1

A. Only use a completely shielded drive sys-

tem:

PTO drive systems with complete shielding,

include the tractor master shield and implement shielding installed all the time. If any

component of the shield system has been

removed for any reason it, or an identical

replacement part, must be installed before

operation.

B. Maximum Joint Angles:

1. Joint (Standard Type)

Continuous operation - 25 degrees

Short duration - 45 degrees

Stationary - 90 degrees

Check shaft articulation and clearance zone!

Joint articulations of more than 45 degrees

lead to damage. Contact between PTO drive

shaft and tractor or implement (e.g. three point

hitch, drawbar) lead to damage.

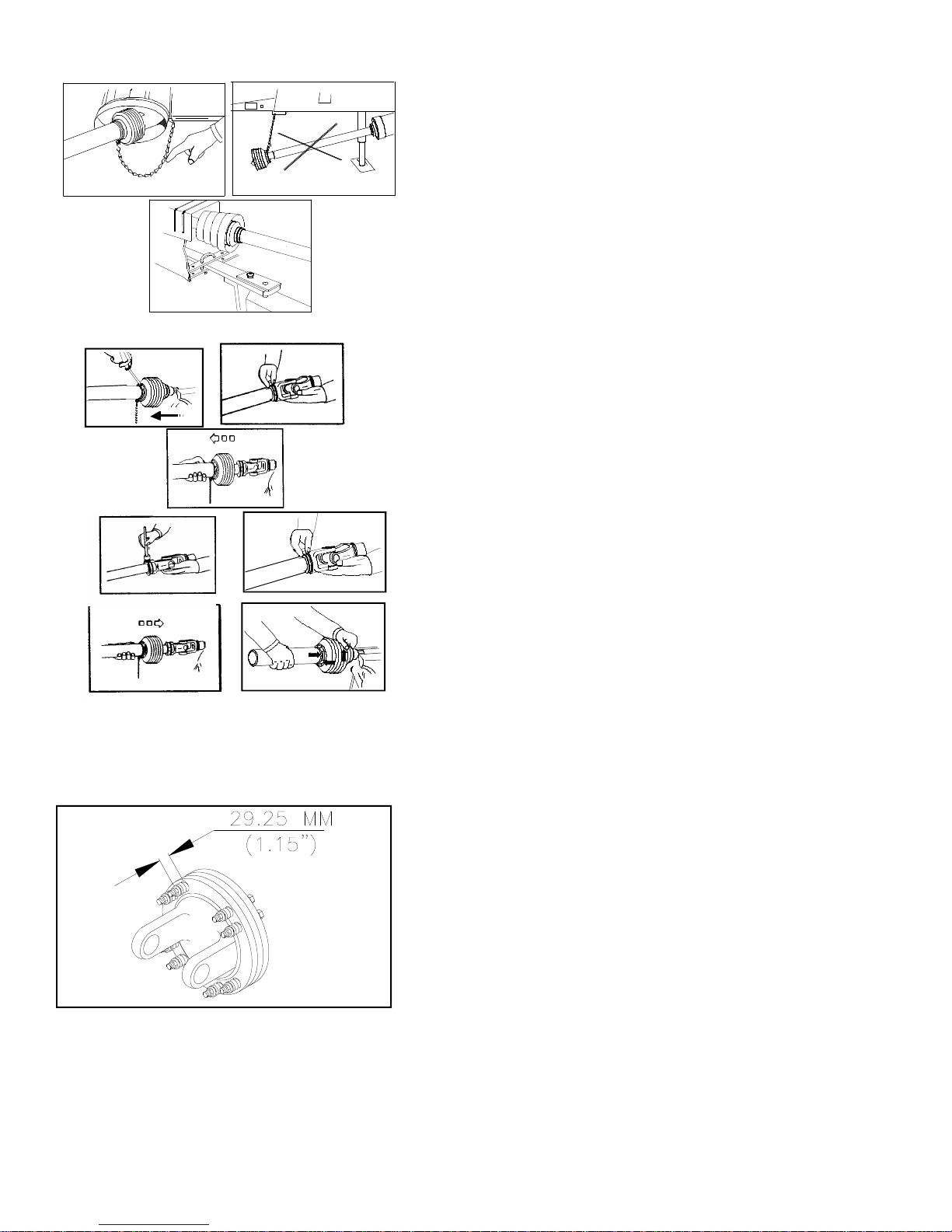

C. Coupling the PTO drive shaft (Fig. C1)

Twist Lock

1. Twist locking collar and simultaneously

push PTO drive shaft onto PTO shaft until

the locking device engages.

D2

C1

D3

D1

Check to insure all the locks are secure before engaging the PTO drive shaft.

D. Lubrication (Fig. D1-D3)

Lubricate with quality grease before starting

work every 8 operating hours. Clean and

grease PTO drive shaft before each prolonged

period of non-use.

Molded nipples on the shield near each shield

bearing are intended as grease fittings and

should be lubricated every 8 hours of operation. Telescoping members must be lubricated

to operate successfully regardless of whether

a grease fitting is provided for that purpose.

Telescoping members without fittings should

be pulled apart and grease should be applied

manually. Check and grease guard tubes in

winter to prevent freezing.

E. Chains (Fig. F1-F3)

NOTE: The chain is intended to prevent the

shield from rotating against non-moving parts,

thereby preventing shield damage. A properly

installed chain will increase the service life of

the shield.

10

E1 E2

E3

F1

F2

1. Chains must be fitted to allow sufficient

articulation of the shaft in all working positions. Care must be taken to be sure

that chain does not become entangled with

drawbar hitch or other restrictions during

operation or transport of machine.

2. The PTO drive shaft must not be suspended from the chain when PTO is not

in use or unattached from drive unit.

3. If chain should become unattached, do

not attempt to reattach it with the PTO

engaged. Turn off PTO and tractor engine

before making any repairs. If chain is

missing, replace it before use.

F. Dismantling guard:

1. Keep cone pressed downward and release

collar tabs by pushing with a screwdriver.

Push cone off tube.

2. Spread collar to remove from tube.

G1

G3

F3

G2

G4

OM02520

3. Slide tube off the shaft.

G. Assembling guard:

1. Grease collar groove and inner profile tube.

2. Fit shield tube into collar by centering the

slots over the collar teeth.

3. Align cone, centering grease nipple to

grease filling hole on collar. Press downward to connect.

4. Make sure the three collar tabs are properly engaged by tapping on cone.

H. Slip Clutch - preset at factory

Damage may occur to other parts of the grain

cart if the spring tension is not set properly.

Correct operating procedure of the slip clutch

is to have it slip slightly with each use.

1. If adjustment is necessary, length from

flange surface to under side of nut should

be 29.25 MM (1.15”).

2. Tighten nuts following an alternating cross

pattern until reaching the height specified.

Check that height is constant for all

springs.

3. If too much slippage occurs, only tighten

each nut a quarter of a turn at a time.

This quarter turn will increase the torque

approximately 500-750 inch lbs.

4. After extended time without use, the slip

clutch may “freeze up”. It is very important at the beginning of each season to

loosen the nuts, slip the clutch, and retighten the nuts to the correct length.

11

PLEASE READ THE

FOLLOWING INFORMATION

BEFORE USING YOUR SCALE!

THE FOLLOWING STEPS MUST BE CONSIDERED WHEN USING YOUR SCALE AND TO REALIZE ITS BEST PERFORMANCE. DIGI-STAR SCALES ARE MANUFACTURED TO PROVIDE 1/2%

MAXIMUM ERROR. A GOOD INSTALLATION AND PROPER USE ARE REQUIRED IN ORDER TO

OBTAIN ADVERTISED ACCURACY.

A GOOD INSTALLATION REQUIRES THAT ALL LOAD CELLS ARE PROPERLY INSTALLED WITH

“TOP” ACCURATELY POSITIONED.

OPERATION

TO INSURE + OR -1/2% MAXIMUM ERROR, THE UNIT MUST BE USED AS A STATIONARY

LOAD-OUT WEIGH HOPPER FROM BIN TO TRUCK, FOR EXAMPLE, THE GROUND MUST BE

SMOOTH AND LEVEL WITH MAXIMUM 5” SLOP PER 10 FEET.

TO INSURE + OR -1% MAXIMUM ERROR, THE UNIT MUST BE USED SO THAT ALL WEIGHT

MEASUREMENTS OCCUR ON FLAT SMOOTH GROUND (MAXIMUM OUT OF LEVEL 10” IN 10

FEET) IDEALLY, ALL WEIGHT MEASUREMENTS FOR A FIELD WOULD OCCUR IN THE SAME

SPOT.

WARNING!

ALWAYS DISCONNECT CABLES

FROM SCALE INDICATOR BEFORE

JUMP STARTING ENGINE.

Loading...

Loading...