Page 1

UTILITY LIGHT – INTRODUCTION

LED

KILLARK LIGHTING

VSL SERIES

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

H

H

C

C

A

A

O

O

Z

Z

L

L

V SERIES LED

FEATURES-SPECIFICATIONS

Introduction

Killark ‘VSL’ Series LED fixtures are designed

for installations where moisture, dirt, dust,

corrosion and vibration may be present,

or NEMA 3 and 4 areas where wind, water,

snow or high ambients can be expected.

VSL’s are sized to replace “Utility” type

fixtures (incandescent or CFL’s) in hallways,

closets, elevator pits, docks, stairwells,

access tunnels, and mechanical rooms.

These fixtures can be used in locations made

hazardous by the presence of flammable

vapors or gases or combustible dusts as

defined by the NEC. Typical applications

include manufacturing plants, and certain

chemical and petrochemical processing

facilities, sewage treatment plants, off-shore

and dockside installations, and garage areas.

LED Lumminaire Features and

Standards

• Compact in Size with Traditional Industrial

Appearance and Suitability

• Wide variety of optics including glass

globes (clear and tempered, color) plus

polycarbonate globes in clear and colors

• Optional Mounting arrangements including

Pendant, Wall, Ceiling, Stanchion and Adapters

• Fixtures available unit packed, order

option CP

• VSL LED Housings can be retrofitted to

existing V Series splice boxes; upgrade

from CFL or incandescent

• Energy Savings – less than 13 Watts of

Power; less than 16 Watts for VSL1630.

Replaces 75W or higher incandescent

• Long Life – 60,500+ maintenance-free

hours to 70% initial lumens

• Crisp White Light for Excellent Color

Rendering – Chromaticity 5000°K (CCT);

70 CRI

TECHNOLOGY

• Integral driver – maintains fixture’s

compact profile to fit in existing spaces

• Ambient suitability -40°C to 55°Ck

• Instant on – including after power

interruption

• “World Voltage” 120-277VAC 50/60Hz

• Solder-LESS LED Board Connections –

Vibration Resistant

• LM80-08* Measurement of lumen

maintenance for LED light sources

• LM79-08* Certified “Absolute”

Photometry, including Chromaticity Color

for Solid State Lighting

• TM-21* method to project long term

lumen maintenance

• L70 Values – Industry Nomenclature for

Hours of use to 70% of Initial Lumens

Compliances

• UL-8750 for LED lighting

• UL 1598 standard for luminaires

• UL-844 Standard for lighting fixtures for

hazardous locations, Class I, Division 2;

Class II, Division 2; Class III, Division 2

• CSA C22.2 no. 137-M1981 electric

luminaries for use in hazardous locations

• Enclosed and gasketed

• NEMA 3, 4

Materials, Weights

• Body, splice box and guards are corrosion

resistant copper-free aluminum alloy

• Baked powder epoxy/polyester finish,

electrostatically applied for complete,

uniform corrosion protection

• Reflectors – Polypropylene for pendant or

ceiling applications

• Heavy-duty silicone gasketing for NEMA 4

requirements

Class I, Div. 2, Groups A ,B,C,D

Class l, Zone 2, Groups llC,llB,llA

Class II, Div. 2, Groups F,Gj

Class III

Suitable for wet locations

Enclosure Type 4j

Certified - File LR11713

Optic Selection Examples

• Broadest

globe offering for

Hazardous Locations in the industry

• Use as status lights or specialty/

emergency indicators

Clear Glass w/Guard

Red Glass

Red Polycarbonate

* LM-xx & TM-21 are Illumination Engineering Society

Standards designed to promote uniformity in testing

procedures among test labs and manufacturers. For

more information go to www.ies.org

j When mounted (globe down) to V series boxes; not

Class II, Div. 2 or NEMA 4 on VBA, VFPS, VB or VFL

adaptors to sheet metal boxes.

k Glass globe models to 55°C; Polycarbonate suitable

to 40°C.

White Glass w/Guard

Blue Glass

Clear Polycarbonate

Page 2

KILLARK LIGHTING

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

H

H

A

A

Z

Z

VSL SERIES

C

C

O

O

L

L

UTILITY LIGHT – CATALOG LOGIC

Clear Glass w/Guard White Glass w/

Guard

V SERIES LED Catalog Number Logic

VSL1162303A14S5G6- B7S

VSL Series Constant

Lamp Wattage

13

= 13W LED

16

= 16W LED

Voltag e

30

– 120-277VAC (13W, 16W)

27

– 12-24VDC (13W, 16W)

34

– 120-250VDC (13W)

Mounting Type

NN

– Mounr Ordered Separately

A1

– 1/2” Pendant (VGA-1)

A2

– 3/4” Pendant ( VGA-2)

F1

– 1/2” Ceiling w/Feet & Adapter (VBC-1 w/VBA)

F2

– 3/4” Ceiling w/Feet & Adapter (VBC-2 w/VBA)

X1

– 1/2” Ceiling (VGX-1)

X2

– 3/4” Ceiling (VGX-2)

C1

– 1/2” Ceiling (VGC-1)

C2

– 3/4” Ceiling (VGC-2)

H1

– 1/2” Ceiling Dead End (VGH-1)

H2

– 3/4” Ceiling Dead End ( VGH-2)

D1

– 1/2” Ceiling Deep (VXA-1)

D2

– 3/4” Ceiling Deep (VXA-2)

D4

– 1-1/4” Stanchion ( VD-4)

RA

– Round (Box) Adapter (VBA)

SA

– Square (Box) Adapter ( VFPS)

W1

– 1/2” Wall w/Feet (VBC-1 w/VB-1)

W2

– 3/4” Wall w/Feet (VBC-2 w/VB-2)

V1

– 1/2” Wall Elbow (VB-1)

V2

– 3/4” Wall Elbow (VB-2)

FL

– Elbow for “V” Box (VFL)

Blue Glass Clear Polycarbonate Red Polycarbonate

8

Optic Color (Optic Type)

A

B

R

G

P

BG

W

Guard

G

– Guard (For Glass Globes Only)

N

– No Guard (Standard on Polycarbonate Globes

R

– Guard Red (For Glass Globes Only)

Can Signify Emergency UPS Circuits

Optics**

S

– Standard Globe (Clear)

H

– Heat Resistant (Tempered) Globe (Clear)

P

– Polycarbonate (Clear)

COLORED GLOBE OPTIONS** EXAMPLE VSL1330A1SG-A

SUFFIX AND AVAILABLE COMBINATIONS

COLOR

NUMBER

AMBER A A A

BLUE B B —

RUBY R R R

GREEN G — G

PURPLE P — —

BLUE-GREEN BG BG —

WHITE W W W

** Use tempered glass or poly globe for wet location applications.

j When mounted (globe down) to V series boxes; not Class II, Div.2 or

NEMA 4 on VBA , VFPS, VB or VFL adaptors to sheet metal boxes.

k Reector is held on xture body by VAG-100 guard for glass globe models

or polycarbonate globe’s shoulder. Reectors ship separately.

l CP option includes complete xture in components contained in single

outer carton.

Reector

S

– Standard Reflector (Pendant or Ceiling Use Only)k

CP

– Component Packl

– Amber (S, H, P)

– Blue (S, H)

– Red (S, H, P)

– Green (S, P)

– Purple (S)

– Blue Green (S, H)

– White (S)

STANDARD

GLOBE

TEMPERED

GLOBE

POLYCARBONATE

LED

TECHNOLOGY

Class I, Div. 2, Groups A ,B,C,D

Class l, Zone 2, Groups llC,llB,llA

Class II, Div. 2, Groups F,Gj

Class III

Suitable for wet locations

Enclosure Type 4j

Certified - File LR11713

Page 3

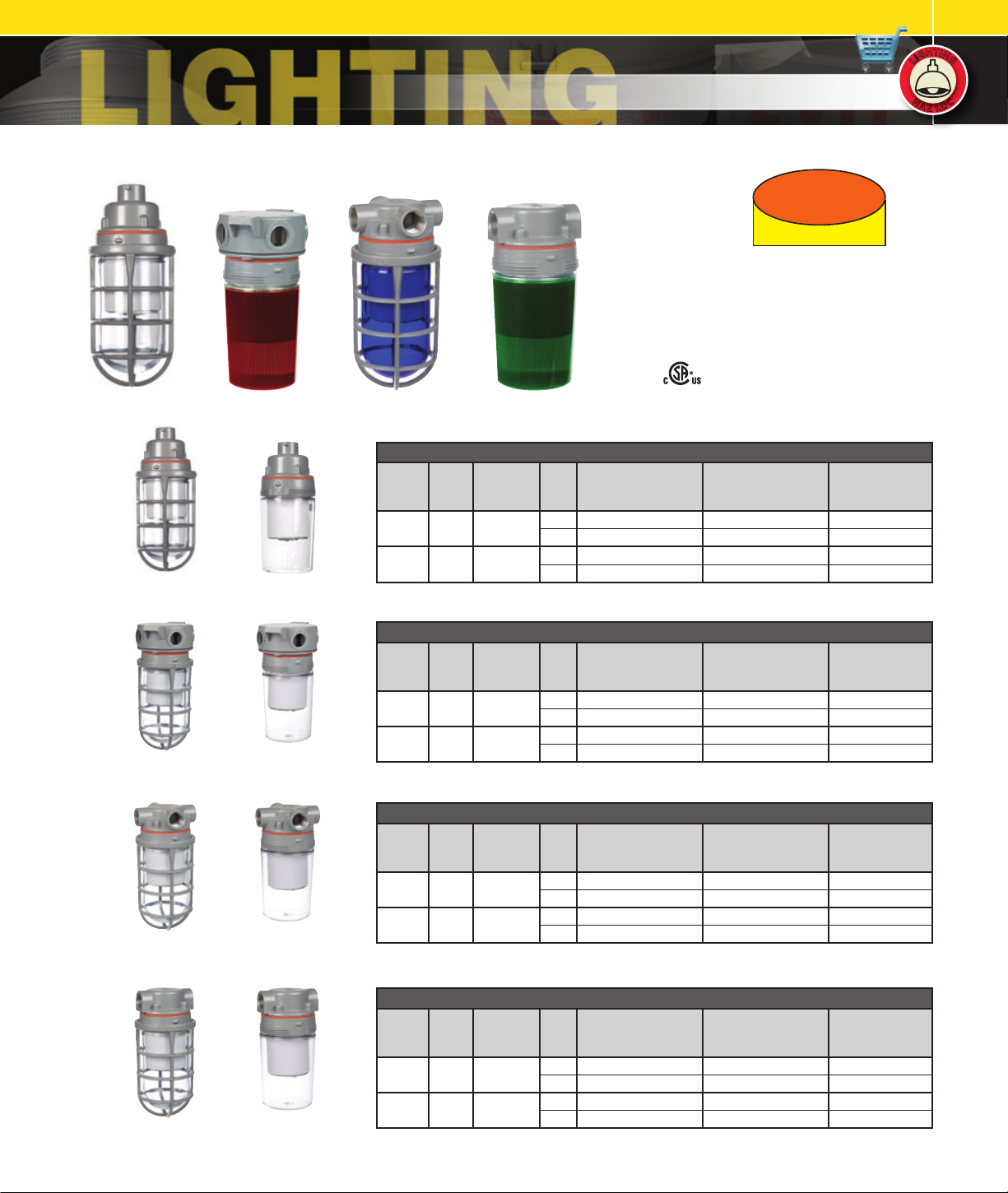

Glass

Globe

UTILITY LIGHT – ORDERING INFORMATION

Class I, Div. 2, Groups A ,B,C,D

Class l, Zone 2, Groups llC,llB,llA

Class II, Div. 2, Groups F,Gj

Class III

Suitable for wet locations

Enclosure Type 4j

ORDERING INFORMATION

PENDANT MOUNT WITH VGA SPLICE BOX 1 – HUB

FIXTURE W/ STANDARD

LED WATTS VOLTAGE

VSL1330 13 120-2 77 VAC

VSL1630 16 120-277 VAC

Poly

Globe

HUB

CLEAR GLASS GLOBE &

SIZE

1/2” VSL1330 A1SG VSL1330 A1HG VSL1330A1PN

3/4” VSL1330A2SG VSL1330A2HG VSL1330A2PN

1/2” VSL1630 A1SG VSL1630 A1HG VSL1630A1PN

3/4” VSL1630A2SG VSL1630A2HG VSL1630A2PN

GUARD**

KILLARK LIGHTING

VSL SERIES

LED

TECHNOLOGY

Certified - File LR11713

FIXTURE W/ TEMPERED

CLEAR GLASS GLOBE &

GUARD**

I

I

L

L

H

H

FIXTURE W/ CLEAR

POLYCARBONATE

GLOBE**

T

T

I

I

H

H

N

N

G

G

G

G

C

C

A

A

O

O

Z

Z

L

L

Glass

Globe

Glass

Globe

Glass

Globe

Poly

Globe

Poly

Globe

Poly

Globe

CEILING MOUNT WITH FEET USING VBC SPLICE BOX AND VBA ADAPTER 4 – HUBS

LED WATTS VOLTAGE

VSL1330 13 120-2 77 VAC

VSL1630 16 120-277 VAC

FIXTURE W/ STANDARD

HUB

CLEAR GLASS GLOBE &

SIZE

1/2” VSL1330F1SG VSL1330F1HG VSL1330F1PN

3/4” VSL1330F2SG VSL1330F2HG VSL1330F2PN

1/2” VSL1630F1SG VSL1630F1HG VSL1630F1PN

3/4” VSL1630F2SG VSL1630F2HG VSL1630F2PN

GUARD**

FIXTURE W/ TEMPERED

CLEAR GLASS GLOBE &

GUARD**

FIXTURE W/ CLEAR

POLYCARBONATE

GLOBE**

CEILING MOUNT WITH VGX SPLICE BOX 4 – HUBS

LED WATTS VOLTAGE

VSL1330 13 120-2 77 VAC

VSL1630 16 120-277 VAC

FIXTURE W/ STANDARD

HUB

CLEAR GLASS GLOBE &

SIZE

1/2” VSL1330X1SG VSL1330X1HG VSL1330X1PN

3/4” VSL1330X2SG VSL1330X2HG VSL1330X2PN

1/2” VSL1630X1SG VSL1630X1HG VSL1630X1PN

3/4” VSL1630X2SG VSL1630X2HG VSL1630X2PN

GUARD**

FIXTURE W/ TEMPERED

CLEAR GLASS GLOBE &

GUARD**

FIXTURE W/ CLEAR

POLYCARBONATE

GLOBE**

CEILING MOUNT WITH VGC SPLICE BOX – FEED THROUGH 2 – HUBS

FIXTURE W/ STANDARD

LED WATTS VOLTAGE

VSL1330 13 120-2 77 VAC

VSL1630 16 120-277 VAC

j When mounted (globe down) to V series boxes; not Class II, Div.2 or NEMA 4 on VBA, VFPS, VB or VFL adaptors

to sheet metal boxes.

** Use tempered glass or poly globes for wet location applications. See logic page for available globe colors.

HUB

CLEAR GLASS GLOBE &

SIZE

1/2” VSL1330 C1SG VS L13 30C1HG VSL1330C1PN

3/4” VSL1330C2SG VSL1330C2HG VSL1330C2PN

1/2” VSL1630 C1SG VS L16 30C1HG VSL1630C1PN

3/4” VSL1630C2SG VSL1630C2HG VSL1630C2PN

GUARD**

FIXTURE W/ TEMPERED

CLEAR GLASS GLOBE &

GUARD**

FIXTURE W/ CLEAR

POLYCARBONATE

GLOBE**

Page 4

KILLARK LIGHTING

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

H

H

A

A

Z

Z

VSL SERIES

C

C

O

O

L

L

UTILITY LIGHT – ORDERING INFORMATION

LED

TECHNOLOGY

Class I, Div. 2, Groups A ,B,C,D

Class l, Zone 2, Groups llC,llB,llA

Class II, Div. 2, Groups F,Gj

Class III

Suitable for wet locations

Enclosure Type 4j

Certified - File LR11713

ORDERING INFORMATION

CEILING MOUNT WITH VGH SPLICE BOX – DEAD END 1 – HUB

Glass

Globe

Poly

Globe

LED WATTS VOLTAGE

VSL1330 13 120-2 77 VAC

VSL1630 16 120-277 VAC

FIXTURE W/ STANDARD

HUB

CLEAR GLASS GLOBE &

SIZE

1/2” VSL133 0H1SG VSL13 30H1HG VSL1330H1PN

3/4” VSL1330H2SG VSL1330H2HG VSL1330H2PN

1/2” VSL163 0H1S G VSL16 30H1HG VSL1630H1PN

3/4” VSL1630H2SG VSL1630H2HG VSL1630H2PN

GUARD**

FIXTURE W/ TEMPERED

CLEAR GLASS GLOBE &

GUARD**

FIXTURE W/ CLEAR

POLYCARBONATE

GLOBE**

Glass

Globe

Glass

Globe

Poly

Globe

Poly

Globe

CEILING MOUNT WITH VXA DEEP SPLICE BOX 5 – HUBS

LED WATTS VOLTAGE

VSL1330 13 120-2 77 VAC

VSL1630 16 120-277 VAC

FIXTURE W/ STANDARD

HUB

CLEAR GLASS GLOBE &

SIZE

1/2” VSL1330D1SG VSL1330D1HG VSL1330D1PN

3/4” VSL1330D2SG VSL1330D2HG VSL1330D2PN

1/2” VSL1630D1SG VSL1630D1HG VSL1630D1PN

3/4” VSL1630D2SG VSL1630D2HG VSL1630D2PN

GUARD**

FIXTURE W/ TEMPERED

CLEAR GLASS GLOBE &

GUARD**

FIXTURE W/ CLEAR

POLYCARBONATE

GLOBE**

CEILING MOUNT WITH VBA ADAPTER FOR ROUND OUTLET BOX 0 – HUBSj

FIXTURE W/ STANDARD

LED WATTS VOLTAGE

VSL1330 13 120-2 77 VAC – VSL1330RASG VSL1330RAHG VSL1330RAPN

VSL1630 16 120-277 VAC – VSL1630RASG VSL1630RAHG VSL1630RAPN

HUB

CLEAR GLASS GLOBE &

SIZE

GUARD**

FIXTURE W/ TEMPERED

CLEAR GLASS GLOBE &

GUARD**

FIXTURE W/ CLEAR

POLYCARBONATE

GLOBE**

CEILING MOUNT WITH VFPS ADAPTER FOR SQUARE OR OCTAGON OUTLET BOX 0 – HUBSj

FIXTURE W/ STANDARD

LED WATTS VOLTAGE

VSL1330 13 120-2 77 VAC – VSL1330SASG VSL1330 SAHG VSL1330SAPN

VSL1630 16 120-277 VAC – VSL1630SASG VS L16 30SAHG VSL1630SAPN

HUB

CLEAR GLASS GLOBE &

SIZE

GUARD**

FIXTURE W/ TEMPERED

CLEAR GLASS GLOBE &

GUARD**

FIXTURE W/ CLEAR

POLYCARBONATE

GLOBE**

Glass

Globe

Poly

Globe

j When mounted (globe down) to V series boxes; not Class II, Div.2 or NEMA 4 on VBA, VFPS, VB or VFL adaptors

to sheet metal boxes.

** Use tempered glass or poly globes for wet location applications. See logic page for available globe colors.

Page 5

Glass

Globe

UTILITY LIGHT – ORDERING INFORMATION

Class I, Div. 2, Groups A ,B,C,D

Class l, Zone 2, Groups llC,llB,llA

Class II, Div. 2, Groups F,Gj

Class III

Suitable for wet locations

Enclosure Type 4j

ORDERING INFORMATION

WALL MOUNT WITH FEET USING VBC SPLICE BOX AND VB ELBOW 4 – HUBS

FIXTURE W/ STANDARD

LED WATTS VOLTAGE

VSL1330 13 120-2 77 VAC

VSL1630 16 120-277 VAC

Poly

Globe

HUB

CLEAR GLASS GLOBE &

SIZE

1/2” VSL133 0W1S G VS L13 30W 1HG VSL1330W1PN

3/4” VSL1330W2SG VSL1330W2HG VSL1330W2PN

1/2” VSL163 0W1S G VS L1630 W1HG VSL1630W1PN

3/4” VSL1630W2SG VSL1630W2HG VSL1630W2PN

GUARD**

KILLARK LIGHTING

VSL SERIES

TECHNOLOGY

Certified - File LR11713

FIXTURE W/ TEMPERED

CLEAR GLASS GLOBE &

GUARD**

LED

FIXTURE W/ CLEAR

POLYCARBONATE

GLOBE**

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

H

H

C

C

A

A

O

O

Z

Z

L

L

Glass

Globe

Glass

Globe

Poly

Globe

Poly

Globe

WALL MOUNT WITH VB ELBOW TO MOUNT TO 4” OUTLET BOX 0 – HUBSj

LED WATTS VOLTAGE

VSL1330 13 120-2 77 VAC

VSL1630 16 120-277 VAC

FIXTURE W/ STANDARD

HUB

CLEAR GLASS GLOBE &

SIZE

1/2” V SL1330V1SG VSL1330 V1HG VSL1330V1PN

3/4” VSL1330V2SG VSL1330V2HG VSL1330V2PN

1/2” V SL1630V1SG VSL1630 V1HG VSL1630V1PN

3/4” VSL1630V2SG VSL1630V2HG VSL1630V2PN

GUARD**

FIXTURE W/ TEMPERED

CLEAR GLASS GLOBE &

GUARD**

FIXTURE W/ CLEAR

POLYCARBONATE

GLOBE**

NECK

WALL MOUNT – WITH VFL ELBOW FOR DIRECT MOUNT TO V SERIES SPLICE BOXES 0 – HUBSj

FIXTURE W/ STANDARD

LED WATTS VOLTAGE

VSL1330 13 120-2 77 VAC – VSL1330FLSG VSL1330FLHG VSL1330FLPN

VSL1630 16 120-277 VAC – VSL1630FLSG VSL1630FLHG VSL1630FLPN

HUB

CLEAR GLASS GLOBE &

SIZE

GUARD**

FIXTURE W/ TEMPERED

CLEAR GLASS GLOBE &

GUARD**

FIXTURE W/ CLEAR

POLYCARBONATE

GLOBE**

STANCHION MOUNT FOR 1-1/4” THREADED PIPE 1 – HUB

FIXTURE W/ STANDARD

LED WATTS VOLTAGE

VSL1330 13 120-2 77 VAC 1-1/4” VSL1330D4SG VSL1330D4HG VSL1330D4PN

VSL1630 16 120-277 VAC 1-1/4” VSL1630D4SG VSL1630D4HG VSL1630D4PN

HUB

CLEAR GLASS GLOBE &

SIZE

GUARD**

FIXTURE W/ TEMPERED

CLEAR GLASS GLOBE &

GUARD**

FIXTURE W/ CLEAR

POLYCARBONATE

GLOBE**

Glass

Globe

Poly

Globe

j When mounted (globe down) to V series boxes; not Class II, Div.2 or NEMA 4 on VBA, VFPS, VB or VFL adaptors

to sheet metal boxes.

** Use tempered glass or poly globes for wet location applications. See logic page for available globe colors.

Page 6

KILLARK LIGHTING

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

H

H

A

A

Z

Z

VSL SERIES

C

C

O

O

L

L

UTILITY LIGHT – COMPONENTS

VSL Fixture Bodies Only

Fixture bodies contain the LED driver and array, heat sink plus gaskets, and are threaded to

accept globes, guards and reflectors. Users with KILLARK “V” Series vapor tight fixtures

RETROFIT

FOR ENERGY

from the 1960’s onward can up-grade to the latest technology and, in many cases, reuse

existing mounts, globes and guards. VSL bodies are designed for metallic boxes and mount

directly to V Series splice boxes or adapters as indicated.

SAVINGS

VSL Body

CATALOG

NUMBER

VSL1330 13W 120-277 VAC 50/60Hz Body with LEDs and Driver

VSL1630 16W 120-277VAC 50/60Hz Body with LEDs and Driver

VSL FIXTURE BODIES

DESCRIPTION

VSL Splice Boxes

For use with VSL Series fixture bodies.

VSL SPLICE BOXES

VGHVGA

VGXVGC

VBCVXA

CATALOG

NUMBER

VGA-1 1/2” 1 A1

VGA-2 3/4” 1 A2

VGH -1 1/2” 1 H1

VGH-2 3/4” 1 H2

VGC -1 1/2” 2 C1

VGC-2 3/4” 2 C2

VGX-1 1/2” 4 X1

VGX-2 3/4” 4 X2

VX A-1 1/2” 5 D1

VXA-2 3/4” 5 D2

VBC-1* 1/ 2” 4 F1

VBC-2* 3/4” 4 F2

VXAB – – – Blank close-up plate (less gasket)

*Volume cu. in. is 18

HUB SIZE Q T Y.

LOGIC

CODE

DESCRIPTION

Pendant mount

Ceiling mount

Ceiling mount

Ceiling mount

Ceiling mount, deep box

Ceiling mount, with 3 close-up plugs (requires VBA Adapter)

or wall mount with VB elbow

VFPSVBA

VFLVB VD

VSL Adapters

VSL ADAPTER MOUNTING PLATES

CATALOG

NUMBER

VBA Adapts fixture body to VB, VJ or steel 3-1/2” & 4” splice boxes. Supplied with gasket.

VFPS Adapts fixture body to steel 4” square outlet boxes or 3-1/2” or 4” oct agon boxes

DESCRIPTION

VSL Wall/Stanchion Mounts

VSL MOUNTING BRACKETS

CATALOG

NUMBER

VB-1 1/2” 1 Wall mount to VJ or VB boxes

VB-2 3/4” 1 Wall mount to VJ or VB boxes

VFL – – Wall mount to V boxes directl y or to VJ, VB boxes with VBA adapter

VD-4 1-1/4 ” 1 Stanchion mount

HUB SIZE Q T Y. DESCRIPTION

Page 7

Glass

Globe

Glass Color

Globe

UTILITY LIGHT – COMPONENTS, RATINGS & WEIGHTS

VSL Globes

VSL GLOBES – ORDERING INFORMATION AND SUFFIX GRID**

TEMPERED

GLASS

OPTIC LOGIC POLYCARBONATE OPTIC LOGIC

Poly

Globe

Poly Color

Globe

COLOR GLASS OPTIC LOGIC

Clear VCG-100 S* VCGP-100 H* VPLCG-100 P*

Amber AMG-100 A VAMGP-100 A VPLCG-100A A

Blue VBG-100 B VBGP-100 B – –

Ruby (Red) VRG-100 R VRGP-100 R VPLCG-100R R

Green VRSG-100 G – – VP LC G-10 0G G

Purple VPG-100 P – – – –

Blue-Green VGG-100 BG VGGP-100 BG – –

White VWG-100 W VWGP-100 W VP LC G-10 0W W

* See Pre- congured ordering tables for complete xtures.

** Use tempered glass or polycarbonate globes for wet location applications.

VSL Components

VSL COMPONENT PARTS AND ACCESSORIES

CATALOG

NUMBER

VAG-100 Aluminum Guard for use with Glass Globe

VTG-S V TGG1- SVAG-100

VAG-100 R Red Aluminum Guard for use with Glass Globe

VTG-S Body to Splice Box Gasket – Silicone

VTGG1-S Globe Gasket – Silicone

VPRSD-100 White polypropylene for pendant & ceiling applications. Not for use with wall or stanchion models.

DESCRIPTION

KILLARK LIGHTING

VSL SERIES

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

H

H

C

C

A

A

O

O

Z

Z

L

L

Typical Weights (lbs.) w/Standard Globe and Guard – VSL Series

VPR SD -10 0

16-3/8” Dia. 5- 5/8” High

Pendant 7.03 Ceiling 7.51 Wall 8.09 Stanchion 7.61

VSL Thermal Ratings

VSL THERMAL PERFORMANCE DATA INCLUDING VPRSD-100 REFLECTOR

CATALOG

NUMBER

VSL1330 40°C T6 T5 T5 ( F,G) T5 ( F,G) 90° 60,500 100,000+

VSL1330 55°C T5 – – – 90° 60,500 100,000+

VSL1630 40°C T5 – T5 (F,G) – 90° 60,500 100,000+

AMBIENT

GLASS GLOBE POLY GLOB E GLASS GLOBE P OLY GLOBE WIRE TM-21 CALCULATED

C1D2 C2D2 SUPPLY

L70l

VSL Electrical Ratings

VSL LED BODY WITH DRIVERSJAND LEDS – ELECTRICAL RATINGS

CATALOG

NUMBER

VSL1330 120 -277 VAC 12.42 .10 8/.0 47 1300 5.0

VSL1630 120 -277 VAC 15.64 .15 6/.0 67 1625 5.0

j Driver THD<20%, Powerfactor >90% @ 120V; Line regulation 2%; Load regualtion 5%; Protected against Over-voltage and Overcurrent.

k CIL = Calculated Initial Lumens of LED component based on mfg. data and driver current INSIDE the optic. This value is provided as a reference only for comparison to

traditional light sources such as Incandescent, HID, or uorescent which use initial values in “relative” photometry. KILL ARK LED luminaires are tested using the Absolute

photometry method (LM79-08), which calculates delivered lumens only. KILL ARK’s LED luminaires provide very bright white 5000o K (CCT) color and can appear brighter

than traditional light sources with higher lumen values under both photopic and scotopic conditions.

l “TM-21 based values require very long duration testing. The L70/TM-21 “official repor ted” value is based on 10,0 00 hours testing at 1000mA drive current (“repor ted L70” is a

factor of test duration). KILL ARK’s VSL utilizes lower 450mA maximum drive current - “calculated” values by the chip vendor predict L70 life substantially in excess of 100,000

hours even at 1000mA .”

VOLTAGE

50/60HZ

WATTAGE

AMPS

120/ 277

CILk

WEIGHT

LBS.

VSL TOTAL LUMEN OUTPUT

WATTAGE

13W 1211 1104 905

16W 1328 13 08 1072

W/ GLOBE

VCG-100

W/GLOBE

VPLCG-100

W/GLOBE

VWG100

Page 8

KILLARK LIGHTING

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

H

H

A

A

Z

Z

VSL SERIES

C

C

O

O

L

L

UTILITY LIGHT – DIMENSIONS

VSL Body

VSL Body w/Globe &

Guard, No Splice Box

w/Polycarbonate Globe,

No Splice Box

Glass Globe Polycarbonate Globe

VGA

VBC-1 & VBC -2

VXA

VGC or VGX

*VGH is 3-5/8” (92)

Side View

Top Vi ew

VSL Pendant Fixture

w/Globe & Guard

VSL Pendant Fixture

w/Polycarbonate Globe

VSL Ceiling Fixture

w/Globe & Guard

VSL Ceiling Fixture

w/Polycarbonate Globe

VB

VSL Wall Mount ed Fixtu re

w/Globe & Guard

VFL

VSL Stanchion Fixture

w/Globe & Guard

Loading...

Loading...