Page 1

KILLARK CONTROLS

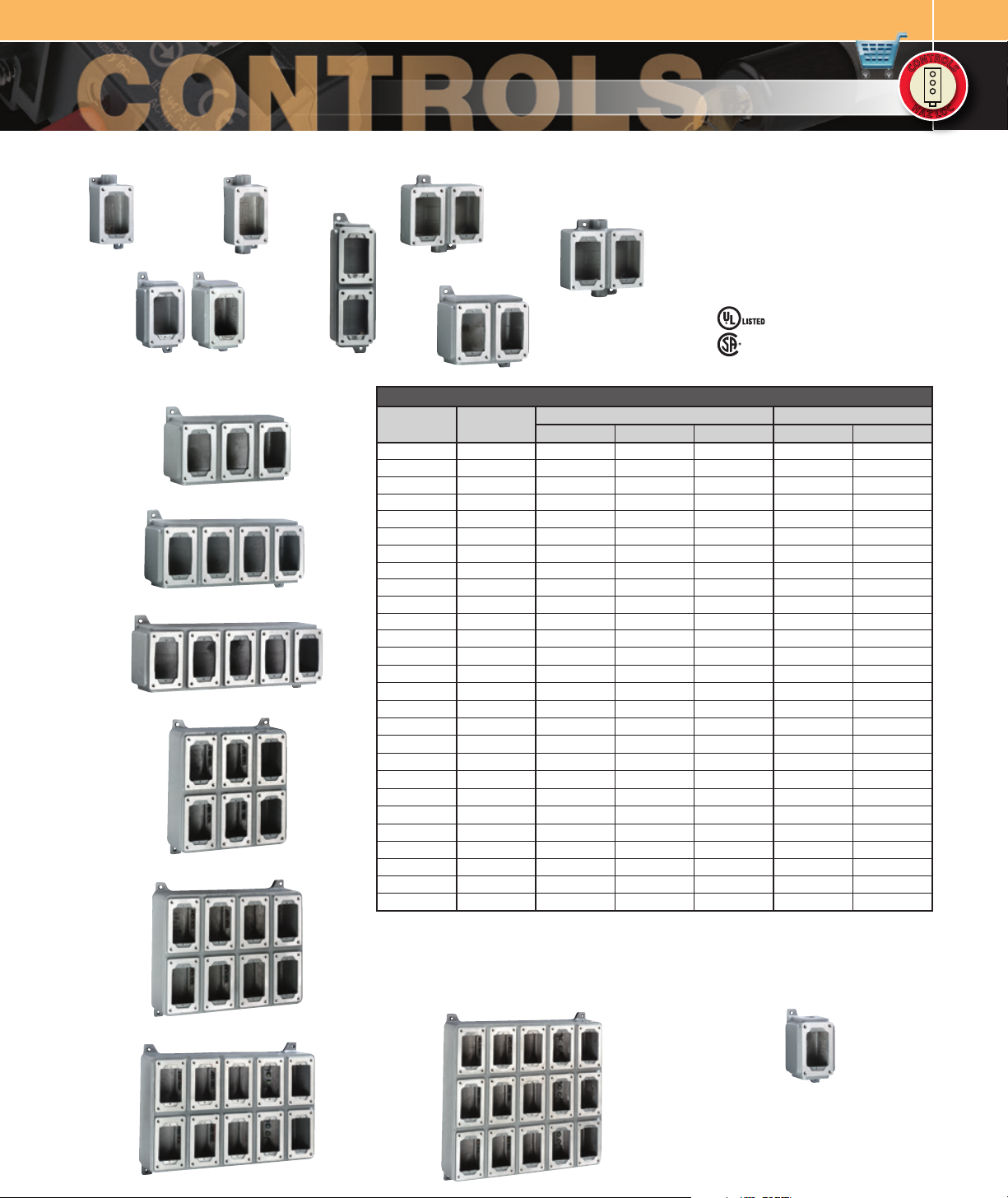

SWB SERIES

DEVICE BODIES FOR USE WITH XCS / XS / XST COVER ASSEMBLIES

R

R

T

T

O

O

N

N

L

L

S

O

S

O

C

C

H

H

C

C

A

A

O

O

Z

Z

L

L

Feed Thru

Dead End

SWB-4-5-6l

SWB -1-2-3l

SWB -13-14

FEATURES-SPECIFICATIONS

SWB -19

SWB-20

SWB-21

SWB-32

Dead End

SWB -7-8- 9l

Class I, Div. 1 & 2, Groups C, D

Class l, Zones 1 & 2, Groups llB, IIA

Class II, Div. 1 & 2, Groups E, F, G

Class Ill

NEMA 7 (C, D) 9 (E, F, G)

SWB -17

Feed Thru

SWB -10 -11-12l

SWB -18

- File E5 336 0

Certified - L R11712

See files for details or call Killark.

SWB DEVICE BODIES AND DIMENSIONS

CATALOG

NUMBER

HUB SIZE

LENGTH WIDTH DEPTH VERTICAL HORIZONTAL

SWB-1 1/2” 5-7/8”(149) 3”(76) 2-1/4”(57) 5-3/8 ”(137 ) 2-3/ 8”(60)

SWB-2 3/4” 5-7/8”(149) 3”(76) 2-1/4 ”(57 ) 5-3/8”(137) 2-3/8”(60)

SWB-3 1” 5-7/8”(149) 3”(76) 2-1/4”(57) 5-3/8 ”(137 ) 2-3/ 8”(60)

SWB-4 1/2” 5-7/8”(149) 3”(76) 2-1/4 ”(57) 5-3/8”(137) 2-3/8”(60)

SWB-5 3/4” 5-7/8”(149) 3”(76) 2-1/4”(57) 5-3/8”(137 ) 2-3/8”(60)

SWB-6 1” 5-7/8”(149) 3”(76) 2-1/ 4”(57) 5-3/8 ”(137 ) 2-3/ 8”(60)

SWB-7 1/2” 5-7/8”(149) 6-1/2”(165) 2-1/ 4”(57) 5-3/8 ”(137 ) 2-1/2”(64)

SWB-8 3/4” 5-7/8”(149) 6-1/2”(165) 2-1/4”(57) 5-3/8”(137 ) 2-1/2”(64)

SWB-9 1” 5-7/8”(149) 6-1/2”(165) 2-1/ 4”(57) 5-3/8 ”(137 ) 2-1/2”(64)

SWB-10 1/2” 5-7/8”(149) 6-1/2”(165) 2-1/4”( 57 ) 5-3 /8”(137) 2-1/2”(64)

SWB-11 3/4” 5-7/8”(149) 6-1/2”(165) 2-1/4”(57 ) 5 -3/8”(137) 2-1/2”(64)

SWB-12 1” 5-7/8”(149) 6-1/2”(165) 2-1/4”(57 ) 5 -3/8”(137) 2-1/2”(64)

SWB-13

SWB-14

SWB-17

SWB-18

SWB-19

SWB-20

SWB-21

SWB-32

SWB-33

SWB-34

SWB-38

j

k

j

k

k

k

k

k

k

k

k

5-1/4”(133) 3-5/8”(92) 2-1/2”(64) 6-1/8”(156) 2-3/8”(60)

5-1/4”(133) 3-5/8”(92) 3-5/16”(84) 6-1/8”(156) 2-3/8”(60)

10-3/8”(26 4) 3-5/8”(92) 2-1/2”(64) 11-3/ 8”( 28 9) 2-1/ 8” (5 4)

5-1/4”(133) 7-1/ 8”(18 1) 3-5/16”(84) 6”(152) 5-3/4”(146)

5-1/4”(133) 10-5/8”(270) 3-5/16”(84) 6”(15 2) 9-3/16”(233)

5-1/4”(133) 14-1/8 ”(359)

5-1/4”(133) 17-5/8”(448) 3-5/16”(84) 6”(15 2) 16 -3/16”(411)

12”(305 ) 10-5/8”(270) 3-5/16”(84) 11-1/8”(283) 9-3/16”(233)

10-3/8”(26 4) 14-1/ 8”(3 59) 3-5/16”(84) 11-3 /16”(28 4) 12-3 /4”(324)

12”(305 ) 17-3 /4”(451) 3-5/16”(84) 11-5/16”(287) 16-1/4”(413)

17-1/ 8”(4 35 ) 17-3/4”(4 51) 3-5/16”(84) 11-5/16”(287) 16-1/4”(413)

SWB-42 3/4” 5-1/4”(133) 3-5/8” (92) 3-5/16”(84) 6-1/8”(156) 2-3/ 8”(60)

SWB-45 3/4” 5-1/4”(133) 3-5/8”(92) 3-5/16”(84) 6-1/8”(156) 2-3/8”(60)

SWB-48

SWB-49

1/2” k

3/4” k

5-1/4”(133) 3-5/8”(92) 3-5/16”(84) 6-1/8”(156) 2-3/8”(60)

5-1/4”(133) 3-5/8”(92) 3-5/16”(84) 6-1/8”(156) 2-3/8”(60)

jMaximum size drilled and tapped opening 1” – Shallow device bodies.

kMaximum size drilled and tapped opening 1-1/2” – Deep device bodies.

lSWB-1 thru SWB-12 Boxes have cast in conduit hubs. Additional conduit openings can not be included. Use

SWB-13-14 or 18 for custom conduit requirements. See following page for custom conduit information. SWB-13

through SWB-38 boxes are blank without conduit openings and can be factory or eld installed. See following

page for custom conduit information.

EXTERNAL MOUNTING

3-5/16”(84) 6”(15 2) 12 -11/ 16”(3 22)

SWB-33

SWB-34 SWB-38

SWB- 42

(3/4” Dead End)

SWB-45

(3/4” Feed Thru)

SWB- 48

(Two 1/2”on Bottom)

SWB- 49

(Two 3/4”on Bottom)

Page 2

KILLARK CONTROLS

R

R

T

T

O

O

N

N

L

L

S

O

S

O

C

C

H

H

A

A

Z

Z

SWB SERIES

C

C

O

O

L

L

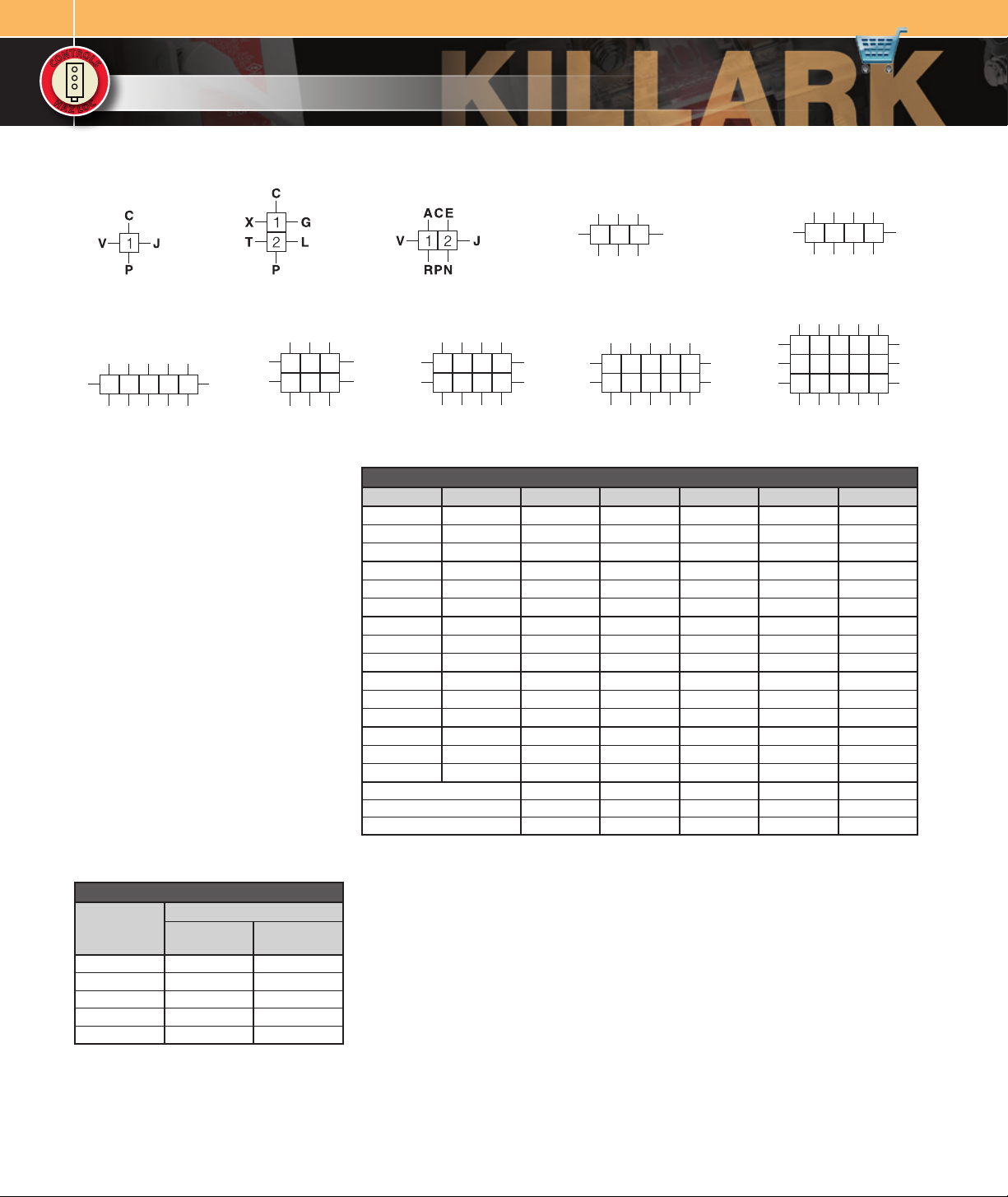

Conduit Opening Location Charts

SWB -13-14 SWB -17 SWB -18 SWB -19 SWB-20

A B C D E

1 2 3 4 5

R Q P O N

SWB-21

JV

A C E

X

1 2 3

T L

4 5 6

R P N

SWB-32

CONDUIT OPENING DATA

A C E

R P N

A B D E

G

X

1 2 3 4

T

5 6 7 8

R Q O N

SWB-33

G

L

X

T

1 2 3

JV

A B C D E

1 2 3 4 5

6 7 8 9 10

R Q P O N

SWB-34

A BCD E

1 2 3 4

JV

R QPO N

A B C D E

X

G

L

1 2 3 4 5

6 7 8 9 10

T

11 12 13 14 15

G

JV

L

N O P Q R

SWB-38

FEATURES-SPECIFICATIONS

To specify conduit openings select the

letter on these sketches which indicates

the position desired. All conduit openings

will be evenly spaced and located in the

area indicated on the location chart. When

they are to be more accurately located,

submit a sketch with spacing dimensions.

Specific conduit openings must be located

dimensionally from box centerlines to

conduit centerlines and from outside back

surface of box to conduit centerline.

Ordering Instructions:

(1) Select the letter on location chart which

indicates conduit opening position

desired.

(2) Select symbol number from chart which

indicates conduit opening type and size.

(3) Combine the conduit location letter, size

and type number, and add as a suffix to

SWB box catalog number.

Example: SWB-18-C1-J1-P1-V1

SYMBOL NUMBERS

CONDUIT OPENINGS

CONDUIT SIZE

1/2” 1 11

3/4” 2 12

1” 3 13

1-1/4” 4 14

1-1/ 2” 5 15

DRILLED AND

TAPPED

UNIONM

MINIMUM HUB CENTERS FOR DRILLED AND TAPPED AND UNION HUBS

SIZE FORM 1/2” 3/4” 1” 1-1/4” 1-1/2”

1/2”

1/2”

1/2”

3/4”

3/4”

3/4”

1”

1”

1”

1-1/4”

1-1/4”

1-1/4”

1-1/ 2”

1-1/ 2”

1-1/ 2”

LOCKNUT BUSHING CONDUIT 1-1/8”(29) 1-3/ 8”(3 5) 1-11/16”(43) 2-3/16”(56) 2-7/16 ”(6 2)

LOCKNUT BUSHING CONDUIT 1”(2 5) 1-1/ 4”(32 ) 1-1 /2 ”(38 ) 1-7/8”(4 8) 2-1/8”( 54)

LOCKNUT BUSHING CONDUIT 7/8”(22) 1-1/ 16”(2 7) 1-3/8 ”(35) 1-11/16”(43) 1-15/16”(49)

jMinimum spacing required to provide clearance over locknuts and bushings.

kPreferred – more liberal spacings between centers of conduits to be used whenever possible.

lGU – spacing required for GU Series unions.

mUnion hubs are supplied by using a drilled and tapped opening with GUM Series Union.

† Consult factory for special or additional conduit sizes, locations, and combinations required but not illustrated.

jMIN

kPRE

lGU

jMIN

kPRE

lGU

jMIN

kPRE

lGU

jMIN

kPRE

lGU

jMIN

kPRE

lGU

1-3/16”(46) — — — —

1-3/8”(35) — — — —

1-5/8”(41) — — — —

1-3/8”(35) 1-1/ 2”(3 8) — — —

1-1/ 2”(3 8) 1-5/8”(41) — — —

1-3/4”(44) 1-13/16”(46) — — —

1-1/ 2”(3 8) 1-3/4”(44) 1-13/16”(46) — —

1-3/4”(44) 1-7/8 ”(48) 2”(51) — —

1-7/8 ”(4 8) 2”(51) 2-1/8 ”(54 ) — —

1-11/16”(43) 1-15/16”(49) 2-1/16”( 52 ) 2-5/16”(59) —

1-15/16”(49) 2 -1/16”(5 2) 2-1/4 ”(57 ) 2-1/2”(64) —

2-1/16 ”(52) 2-1/ 4”(57) 2-5/16”(59) 2-1/2”(64) —

1-15/16”(49) 2 -1/16”(5 2) 2-3/ 16”(5 6) 2-1/2”(64) 2-5/8”(67)

2-1/8”(5 4) 2 -1/4”( 57 ) 2-3/ 8”(60) 2-5/8”(67) 2-3/4”(70)

2-3/16”(56) 2-9/32”(58) 7/16”(11) 2-5/8”(67) 2-3/4”( 70)

Loading...

Loading...