Page 1

FACTORY SEALED CONTROLS - INTRODUCTION

FEATURES-SPECIFICATIONS

SEAL-XM™ SERIES

Class I, Div. 1 & 2, Groups B*, C, D

Class I, Zone 1 & 2, Groups IIB, IIA

Class II, Div. 1 & 2, Groups E, F, G

Class III

NEMA 3, 7 (C,D) 9 (E,F,G)

Certified File 2493125

Contact Factory for other certication details

D2CU

Factory Sealed

Contact Block

R

R

T

T

O

O

N

N

L

L

S

O

S

O

C

C

H

H

C

C

A

A

O

O

Z

Z

L

L

Applications

Seal-XM™ Factory Sealed push button

stations, selector switches, pilot lights and

tumbler switches are used to prevent the

igniting of external hazardous atmospheres by

the enclosed arcing devices in such areas as:

• Hazardous locations due to the

presence of flammable gases or vapors,

combustible dusts or easily ignitable

fibers or flyings

• Installations at petroleum refineries,

chemical and petrochemical plants and

other processing or storage facilities

where similar hazards exist

• Use in conjunction with magnetic starters

or contactors for remote control of motors

Features

• Incorporates Factory Sealed Universal

contact blocks and GOB3 LED pilot light

devices

• External sealing fittings typically not

required, reducing installation time and cost

• No seal plate between the electrical device

and back box allows direct wiring to

contact terminals

• Nema 3 weatherproof

• Grounding boss supplied in the splice box

• Sold as complete units 1/2”, 3/4” Dead

End and thru feed. 1” hubs available on

request

• Standard finish is a grey epoxy powder

baked on for ultimate corrosion resistance

• More wiring room in back box

Material & Groups

FXCS -*-M Groups C, D

Copper free aluminum cover & box

FXCS -*-MB Groups B, C, D

Copper free aluminum cover & box

Copper free aluminum cover & ductile iron back box

Copper free aluminum cover & ductile iron back box

FXCS -*-MBI Groups B, C, D

zinc electroplated

FXCS -*-MI Groups C, D

zinc electroplated

Stainless steel captive cover screws

Operating shafts stainless steel

* Group “B” (-MB & -MBI) versions need not be sealed

within rst 60” of conduit. Sealing tting required

beyond 6 0”

Single Push Button

Double Push Button

CONTACT BLOCK CAT. NO. D2CU

USED ON: DIAGRAM

FXCS -*-M

FXCS -*-MB

FXCS -*-MBI

FXCS -*-MI

Hazardous Rating:

Class I, Division 2, Groups A,B,C,D Class I, Zone

2, Groups IIB+H2, IIA, T6

Terminal Capacity:

22 thru 12 AWG [0.52-2.5mm

stranded conductors. Tightening torque: 7 in-lbs.

(tolerance +3.0/0.0) [~0.8Nm]

Contact Electrical Ratings:

NEMA A600- 7200 VA (Make), 720 VA (Break),

10 Amps Cont. @600V AC (Thermal)

NEMA Q300-69 VA (Make & Break),

2.5 Amps Cont. @250V DC (Thermal)

2

] copper, solid or

LED Pilot Light

LED Pilot Light &

Push Button

Push-Pull Mushroom

Selector Switch

Page 2

R

R

T

T

O

O

N

N

L

L

S

O

S

O

C

C

H

H

A

A

Z

Z

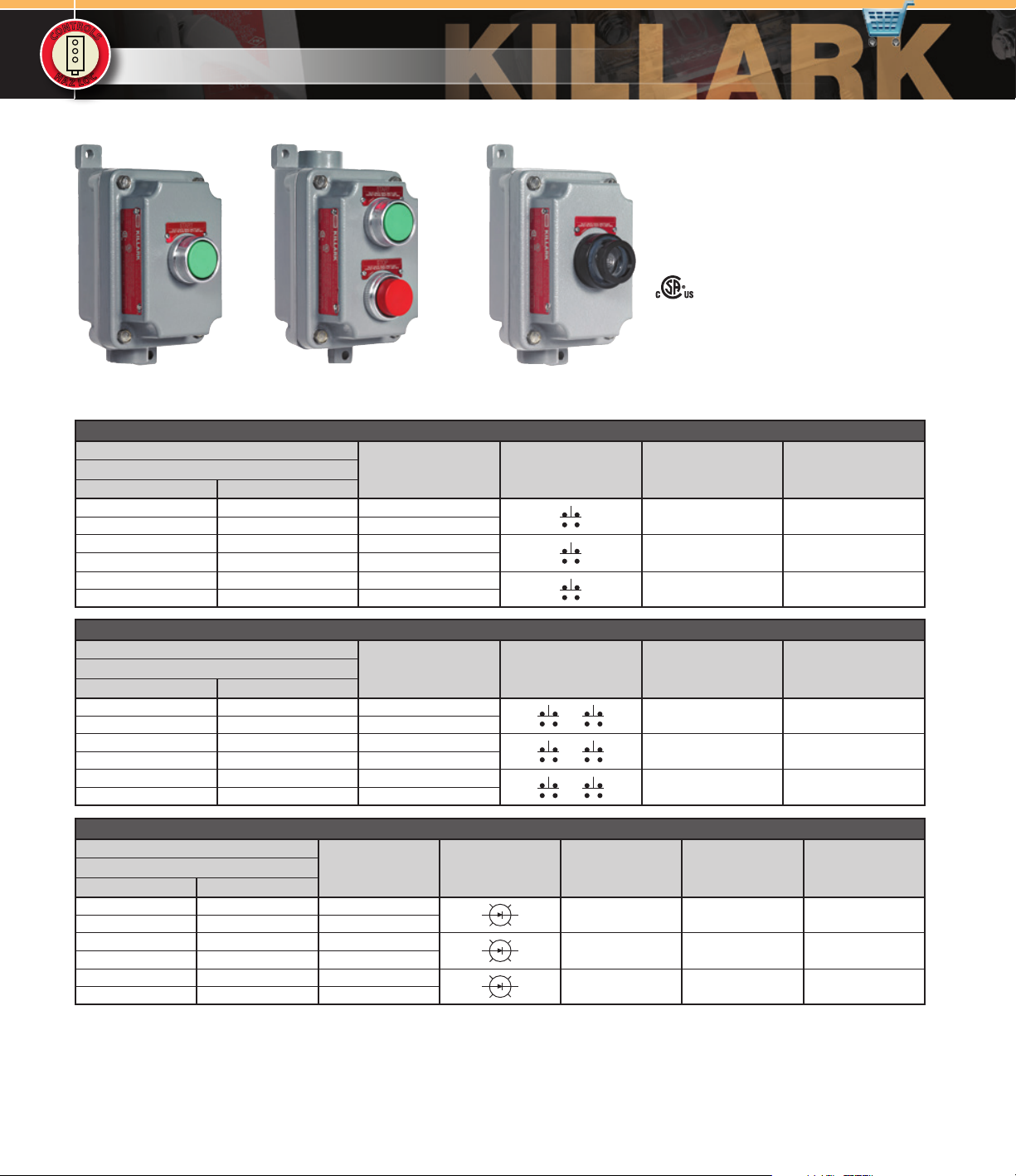

SEAL-XM™ SERIES

C

C

O

O

L

L

FACTORY SEALED CONTROLS - ORDERING INFORMATION 1

Class I, Div. 1 & 2, Groups B*, C, D

Class I, Zone 1 & 2, Groups IIB, IIA

Class II, Div. 1 & 2, Groups E, F, G

Class III

NEMA 3, 7 (C,D) 9 (E,F,G)

Certified File 2493125

Single Push Button LED Pilot Light

Double Push Button

FEATURES-SPECIFICATIONS

SEAL-XM MOMENTARY CONTACT SINGLE PUSH BUTTON

CATALOG NUMBER

BOX COVERj

HUB SIZE DIAGRAM BUTTON COLOR

DEAD-END FE ED-THRU

FXCS-1B1-M FXCS-4B1-M 1/2”

FXCS-2B1-M FXCS-5B1-M 3/4”

FXCS-1B2-M

FXCS-2B2-M

FXCS-1B3- M FXCS-4B3-M 1/2”

FXCS-2B3-M FXCS-5B3-M 3/4”

m

m

FXCS-4B2-M

FXCS-5B2-M

m

m

1/2”

3/4”

SEAL-XM MOMENTARY CONTACT DOUBLE PUSH BUTTON

CATALOG NUMBER

BOX & COVERj

HUB SIZE DIAGRAM BUTTON COLOR

DEAD-END FE ED-THRU

FXCS-1B4-M FXCS-4B4-M 1/2”

FXCS-2B4-M FXCS-5B4-M 3/4”

FXCS-1B5-M FXCS-4B5-M 1/2”

FXCS-2B5-M FXCS-5B5-M 3/4”

FXCS-1B7-M FXCS-4B7-M 1/2”

FXCS-2B7-M FXCS-5B7-M 3/4”

SEAL-XM LED PILOT LIGHT

CATALOG NUMBER

BOX & COVERj

HUB SIZE DIAGRAM

DEAD-END F EED-T HRU

FXCS-1B24 CL-M FXCS-4B24CL-M 1/2”

FXCS-2B24CL-M FXCS-5B24CL-M 3/4”

FXCS-1B24 GL-M FXCS-4B24GL-M 1/2”

FXCS-2B24GL-M FXCS-5B24GL-M 3/4”

FXCS-1B24RL-M FXCS-4B24RL-M 1/2”

FXCS-2B24RL-M FXCS-5B24RL-M 3/4”

j Replace -M with -MB for Group “B” Rating, -MI for Iron Back Box, -MBI for Group “B” and Iron Back Box.

k For other than standard legend plate markings refer to ‘Custom Legend Plates’ on page C59.

l For other than standard 120V lamp, consult factory, or see page C59 to order lamp voltage desired to be changed in eld.

m For lockout on Stop Button, add “-LO” to end of catalog number. i.e. FXCS-1B2-M-LO

* Group “B” (-MB & -MBI) versions need not be sealed within rst 6 0” of conduit. Sealing ttings required beyond 60”.

VOLTl

120V CLEAR SPECIFY

120V GREEN SPECIFY

120V RED SPECIFY

LEGEND PLATE

MARKINGk

GREEN START

RED STOP

BLACK SPECIFY

LEGEND PLATE

MARKINGk

GREEN/RED START/STOP

GREEN/GREEN SPECIFY

BLACK/BLACK SPECIFY

LENS COLOR

LEGEND PLATE

MARKINGk

Page 3

SEAL-XM™ SERIES

FACTORY SEALED CONTROLS - ORDERING INFORMATION 2

Class I, Div. 1 & 2, Groups B*, C, D

Class I, Zone 1 & 2, Groups IIB, IIA

Class II, Div. 1 & 2, Groups E, F, G

Class III

NEMA 3, 7 (C,D) 9 (E,F,G)

Certified File 2493125

R

R

T

T

O

O

N

N

L

L

S

O

S

O

C

C

H

H

C

C

A

A

O

O

Z

Z

L

L

Double LED

Pilot Light

Push Button

LED Pilot Light

FEATURES-SPECIFICATIONS

CATALOG NUMBER

BOX & COVERj

HUB SIZE DIAGRAM

DEAD-END F EED-T HRU

FXCS-1B30 CL-M FXCS-4B30CL-M 1/2”

FXCS-2B30CL-M FXCS-5B30CL-M 3/4”

FXCS-1B30 GL-M FXCS-4B30GL-M 1/2”

FXCS-2B 30GL-M FXCS-5B30GL-M 3/4”

FXCS-1B30RL-M FXCS-4B30RL-M 1/2”

FXCS-2B30RL-M FXCS-5B30RL-M 3/4”

FXCS-1B30RL-GL-M FXCS-4B30RL-GL-M 1/2”

FXCS-2B30RL-GL-M FXCS-5B30RL-GL-M 3/4”

SEAL-XM MOMENTARY CONTACT PUSH BUTTON AND LED PILOT LIGHT

CATALOG NUMBER

BOX & COVERj

DEAD-END FEED-THRU

FXCS-1B13-C-M FXCS-4B13-C-M 1/2”

FXCS-2B13-C-M FXCS-5B13-C-M 3/4”

FXCS-1B13-O-M FXCS-4B13-O-M 1/2”

FXCS-2B13-O-M FXCS-5B13-O-M 3/4”

FXCS-1B13-U-M FXCS-4B13-U-M 1/2”

FXCS-2B13-U-M FXCS-5B13-U-M 3/4”

HUB SIZE DIAGRAM

Push/Pull

Mushroom

SEAL-XM DOUBLE LED PILOT LIGHT

LA MP VOLT Sm LENS COLORl

LAMP

VOLTSm

120V RED CLEAR STOP SPECIFY

120V GREEN GREEN START SPECIFY

120V BLACK RED SPECIFY SPECIFY

BUTTON

COLOR

LEGEND PLATE

MARKINGk

120V CLEAR SPECIFY

120V GREEN SPECIFY

120V RED SPECIFY

120V RED/GREEN SPECIFY

LENS

COLORl

LEGEND PLATE MARKINGk

BUTTON LENS

SEAL-XM MAINTAINED CONTACT PUSH/PULL MUSHROOM

CATALOG NUMBER

BOX & COVERj

DEAD-END FE ED-THRU

FXCS-1MMG3-M FXCS-4MMG3-M 1/2”

FXCS-2MMG3-M FXCS-5MMG3-M 3/4”

FXCS-1MMR3-M

FXCS-2MMR3-M

FXCS-1MMK3-M FXCS-4MMK3-M 1/2”

FXCS-2MMK3-M FXCS-5MMK3-M 3/4”

j Replace -M with -MB for Group “B” Rating, -MI for Iron Back Box, -MBI for Group “B” and Iron Back Box.

k For other than standard legend plate markings refer to ‘Custom Legend Plates’ on page C59.

l Lens colors other than listed may be supplied - consult factory for special order.

m For other than standard 120V lamp, consult factory, or see page C59 to order lamp voltage desired to be changed in eld.

n For lockout on Stop Button, add “-LO” to end of catalog number. i.e. FXCS-1MMR3-M-LO

Note: Four nameplates supplied; EMERG STOP, START, STOP, BLANK.

Operation - when push button is depressed contacts will change state. Operator remains in depressed position until pulled out to normal position.

* Group “B” (-MB & -MBI) versions need not be sealed within rst 6 0” of conduit. Sealing ttings required beyond 60”.

n

n

FXCS-4MMR3-M

FXCS-5MMR3-M

n

n

HUB SIZE DIAGRAM BUTTON COLOR

GREEN START

1/2”

3/4”

RED STOP

BLACK SPECIFY

LEGEND PLATE

MARKINGk

Page 4

R

R

T

T

O

O

N

N

L

L

S

O

S

O

C

C

H

H

A

A

Z

Z

SEAL-XM™ SERIES

C

C

O

O

L

L

FACTORY SEALED CONTROLS - ORDERING INFORMATION 3

Two Position Selector Switch Three Position Selector Switch

FEATURES-SPECIFICATIONS

SEAL-XM TWO POSITION SELECTOR SWITCH - MAINTAINED CONTACT

CATALOG NUMBER

BOX & COVERj

DEAD-END FEED-THRU

FXCS-1S2A1-M FXCS-4S2 A1-M 1/2”

FXCS-2S2A1-M FXCS-5S2A1-M 3/4”

FXCS-1S2A 5-M FXCS-4S2A5-M 1/2”

FXCS-2S2A5-M FXCS-5S2A5-M 3/4”

SEAL-XM THREE POSITION SELECTOR SWITCH - MAINTAINED CONTACT

CATALOG NUMBER

BOX & COVERj

HUB SIZE LEFT POSITION CENTER POSITION RIGHT POSITION

DEAD-END FE ED-THRU

FXCS-1S3C 4-M FXCS-4S3C4-M 1/2”

FXCS-2S3C4-M FXCS-5S3C4-M 3/4”

FXCS-1S3C 5-M FXCS-4S3C5-M 1/2”

FXCS-2S3C5-M FXCS-5S3C5-M 3/4”

SEAL-XM TWO POSITION SELECTOR SWITCH - SPRING RETURN

CATALOG NUMBER

BOX & COVERj

DEAD-END FEED-THRU

FXCS-1S2L 3F-M FXCS-4S2L3F-M 1/2”

FXCS-2S2L3F-M FXCS-5S2L3F-M 3/4”

SELECTOR SWITCH OPERATION - SPRING RETURN TO LEF T FROM RIGHT - MAINTAINED IN LEFT.

SEAL-XM THREE POSITION SELECTOR SWITCH - SPRING RETURN

CATALOG NUMBER

BOX & COVERj

DEAD-END FE ED-THRU

FXCS-1S3M6G-M FXCS-4S3M6G-M 1/2”

FXCS-2S3M6G-M FXCS-5S3M6G-M 3/4”

SPRING RETURN TO CENTER FROM LEFT AND RIGHT - MAINTAINED CENTER

FXCS-1S3L6G-M FXCS-4S3L6G-M 1/2”

FXCS-2S3L6G-M FXCS-5S3L6G-M 3/4”

SPRING RETURN TO CENTER FROM RIGHT - MAINTAINED CENTER AND LEFT

FXCS-1S3R 6G-M FXCS-4S3R6G-M 1/2”

FXCS-2S3R6G-M FXCS-5S3R6G-M 3/4”

SPRING RETURN TO CENTER FROM LEFT - MAINTAINED CENTER AND RIGHT

j Replace -M with -MB for Group “B” Rating, -MI for Iron Back Box, -MBI for Group “B” and Iron Back Box.

* Group “B” (-MB & -MBI) versions need not be sealed within rst 6 0” of conduit. Sealing ttings required beyond 60”.

For other than standard marking, see page C59 and order separately or as modi ed products.

STANDARD NAMEPLATE MARKINGS — 2 Positions — BLANK & OFF-ON — 3 Positon — BLANK or HAND- OFF-AUTO

HUB SIZE LEFT POSITION CENTER POSITION RIGHT POSITION

HUB SIZE LEFT POSITION RIGHT POSITION

HUB SIZE LEFT POSITION RIGHT POSITION

Class I, Div. 1 & 2, Groups B*, C, D

Class I, Zone 1 & 2, Groups IIB, IIA

Class II, Div. 1 & 2, Groups E, F, G

Class III

NEMA 3, 7 (C,D) 9 (E,F,G)

Certified File 2493125

Page 5

SEAL-XM™ SERIES

FACTORY SEALED CONTROLS - ORDERING INFORMATION 4

Class I, Div. 1 & 2, Groups B*, C, D

Class I, Zone 1 & 2, Groups IIB, IIA

Class II, Div. 1 & 2, Groups E, F, G

Class III

NEMA 3, 7 (C,D) 9 (E,F,G)

Certified File 2493125

R

R

T

T

O

O

N

N

L

L

S

O

S

O

C

C

H

H

C

C

A

A

O

O

Z

Z

L

L

FEATURES-SPECIFICATIONS

SEAL-XM TWO POSITION KEYED SELECTOR SWITCH - MAINTAINED CONTACT

CATALOG NUMBER

BOX & COVERj

DEAD-END FEED-THRU

FXCS-1K2A1-M FXCS-4K2A1-M 1/2”

FXCS-2K 2A1-M FXCS-5K2A1-M 3/4”

FXCS-1K2A5-M FXCS-4K2A5-M 1/2”

FXCS-2K2A5-M FXCS-5K2A5-M 3/4”

SEAL-XM THREE POSITION KEYED SELECTOR SWITCH - MAINTAINED CONTACT

CATALOG NUMBER

BOX & COVERj

HUB SIZE LEFT POSITION CENTER POSITION RIGHT POSITION

DEAD-END FE ED-THRU

FXCS-1K3C 4- M FXCS-4K3C4-M 1/2”

FXCS-2K3C4-M FXCS-5K3C4-M 3/4”

FXCS-1K3C 5-M FXCS-4K3C5-M 1/2”

FXCS-2K3C5-M FXCS-5K3C5-M 3/4”

SEAL-XM TWO POSITION KEYED SELECTOR SWITCH - SPRING RETURN

CATALOG NUMBER

BOX & COVERj

DEAD-END FEED-THRU

FXCS-1K2L3F 22D-M FXCS-4K2L3F22D-M 1/2”

FXCS-2K2L3F22D-M FXCS-5K2L3F22D-M 3/4”

SELECTOR SWITCH OPERATION - SPRING RETURN TO LEF T FROM RIGHT - MAINTAINED IN LEFT.

Keyed Selector Switch

HUB SIZE LEFT POSITION RIGHT POSITION

HUB SIZE LEFT POSITION RIGHT POSITION

SEAL-XM THREE POSITION KEYED SELECTOR SWITCH - SPRING RETURN

CATALOG NUMBER

BOX & COVERj

DEAD-END FE ED-THRU

FXCS-1K3M6G32D-M FXCS-4K3M6G32D-M 1/2”

FXCS-2K3M6G32D-M FXCS-5K3M6G32D-M 3/4”

SELECTOR SWITCH - OPERATION - SPRING RETURN TO CENTER FROM LEFT AND RIGHT - MAINTAINED IN CENTER

FXCS-1K3L6G32D-M FXCS-4K3L6G32D-M 1/2”

FXCS-2K3L6G32D-M FXCS-5K3L6G32D-M 3/4”

SELECTOR SWITCH - OPERATION - SPRING RETURN TO CENTER FROM RIGHT - MAINTAINED CENTER AND LEFT

FXCS-1K3R6G32D-M FXCS-4K3R6G32D-M 1/2”

FXCS-2K3R6G32D-M FXCS-5K3R6G32D-M 3/4”

SELECTOR SWITCH - OPERATION - SPRING RETURN TO CENTER FROM LEFT - MAINTAINED CENTER AND RIGHT

j Replace -M with -MB for Group “B” Rating, -MI for Iron Back Box, -MBI for Group “B” and Iron Back Box.

* Group “B” (-MB & -MBI) versions need not be sealed within rst 6 0” of conduit. Sealing ttings required beyond 60”. Randomly Keyed. For keyed alike Maintained Contact

Switch add “A” to cat. No. ie. FXCS-1K2A1A-M. For keyed alike Spring Return Switch replace “D” with “A” in cat. No. ie. FXCS-1K2L3F22A-M

For other than standard marking, see page C59 and order separately or as modi ed products.

STANDARD NAMEPLATE MARKINGS — 2 Positions — BLANK & OFF-ON — 3 Positon — BLANK or HAND- OFF-AUTO

HUB SIZE LEFT POSITION CENTER POSITION RIGHT POSITION

Loading...

Loading...