Page 1

ALUMINUM CABLE CONNECTORS

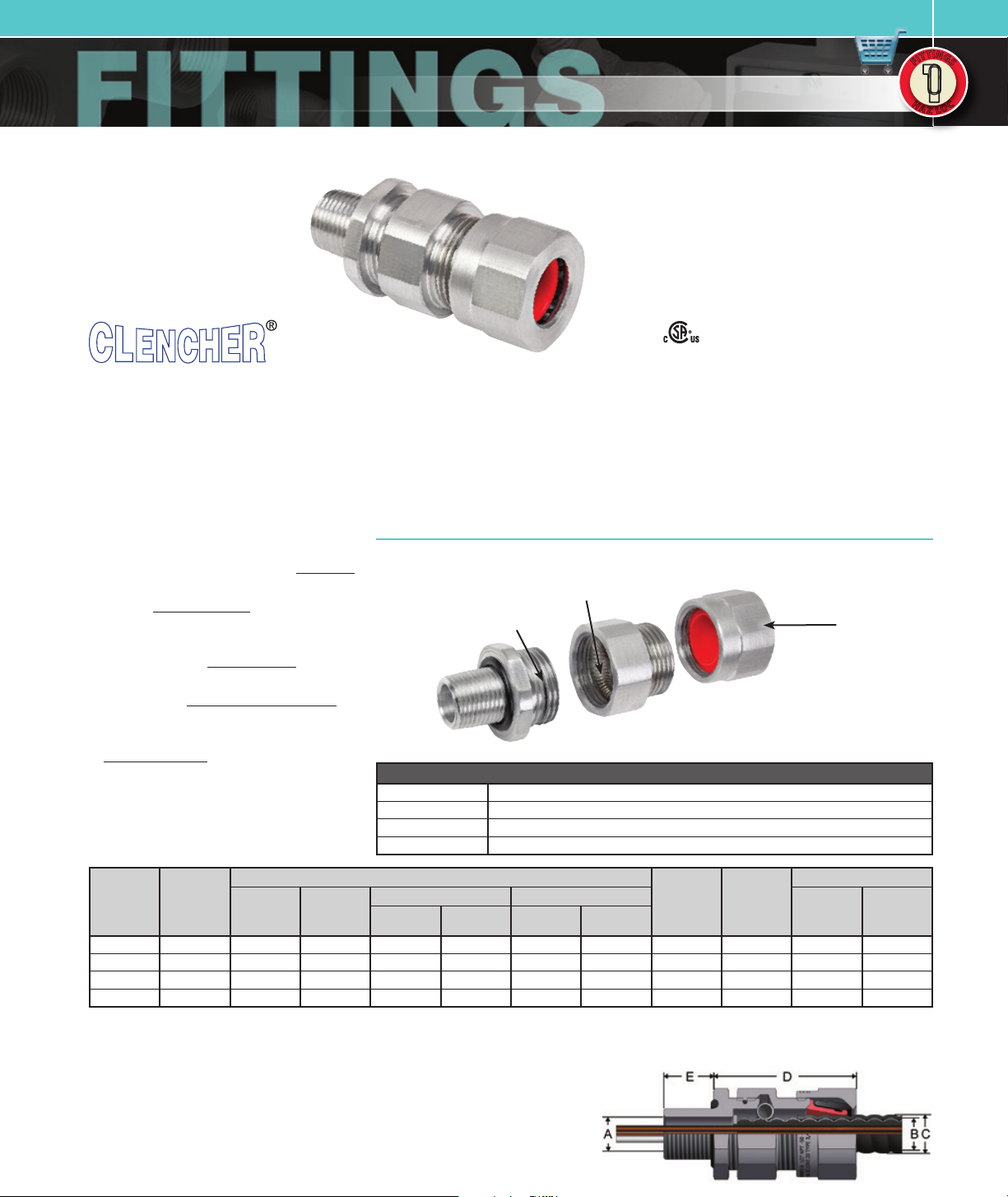

FEATURES-SPECIFICATIONS

Applications

Designed for use with jacketed interlocked,

continuously corrugated and welded armor

cable (all types shown in chart below). Install

where it is essential to provide positive

grounding to the cable and for a Type 3,4

connection.

MC

Materials

• Body – Copper free aluminum (less than

4/10 of 1%)

• Ground Spring – Stainless Steel

• Backnut Seal – Thermoplastic elastomer

(silicone)

KILLARK FITTINGS

MC SERIES

Class I, Div. 2†, Groups A, B, C, D

Class II, Div. 1 & 2, Groups E, F, G

Class III

Class I, Zone 2†, Group IIC, Zone 20

Suitable for wet locations

Types 3, 4

IP66

• Backnut Clamp – Nylon

• Inner and Outer O-rings – Nitrile

Operating Temperature Range

• -50°C to +60°C

N

I

N

I

T

T

G

G

T

T

I

S

I

S

F

F

H

H

C

C

A

A

O

O

Z

Z

L

L

Features

• 360° armor grounding spring is reuseable.

• Robust threads and world class seal

enables easy installation with minimal

torque required.

Construction Details

Inner o-ring seal

Reuseable

Grounding Spring

NEMA 4

Sealing Backnut

• Design meets and exceeds third party

requirements for cable retention.

• Provides sealing back nut plus inner

o-ring seal to prevent moisture ingress to

the cable armor and enclosure.

• Copper free aluminum construction for

hostile, corrosive and certain hazardous

locations

AC- AC90, ACWU90, AC90-HL, ACWU90-HL, ACG90, ACGWU90

MC- MCC, MCI, MCI-A, MC-HL

RA- RA90, RA90-HL

TECK- TECK90, TECK90-HL

CATALOG

NUMBER

MC1C 1/2” 10 0.56” (14.2) 0.52” (13.2) 0.74” (18 .8) 0.60” (15.2) 0.82” (20.8) 2.3” (58) 0. 83” (21.1) 1.42” (36) 1.50 ” ( 38.1)

MC2 3/4” 21 0.80” (20.3) 0.65” (16.5) 0.95 ” ( 24 .1) 0.73” (18.5) 1.03” (26.2) 2.5” (64) 0.84” (2 1.3) 1.61” (41) 1.69” (42.9)

MC3 1” 42 1.04” (26 .4) 0.89” (22.6) 1.23” (31.2) 0.97” (24.6) 1.31” (33.3) 2.6” (66) 1.03” (26.2) 1.97” (50) 2.13” (254 .1)

MC4 1 1/4” 73 1.28” (32.5) 1.15” (29.5) 1.48” (37.6) 1.23” (3 1.2) 1.56” (39.6) 3.1” (79) 1.0 5” (26.7) 2.36” (60) 2.50” (63.5)

Cable armor diameter and cable jacket diameter refer to the dimensions across the crest.

† Where explosion proof/ameproof enclosures are being used the MC must be installed in conjunction with an approved sealing tting. In Division 2 areas the MC can be t ted

directly to an enclosure which has no source of ignition.

* For metric sizes, consult factory.

ENTRY

THREAD

SIZE (NPT)

MAX

NUMBER

OF CORES

THROUGH

DIAMETER

CABLE ACCEPTANCE DETAILS

ARMOR DIAMETER ‘B’ DIAMETER ‘C’

‘A’

MIN. MAX. MIN. MAX.

SUITABLE ARMORED/METAL CLAD CABLE TYPES

MAX

LENGTH

‘D’

NPT

LENGTH

‘E’

HEXAGON DIMENSIONS

ACROSS

FLATS

ACROSS

CORNERS

Loading...

Loading...