Page 1

KILLARK LIGHTING

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

H

H

A

A

Z

Z

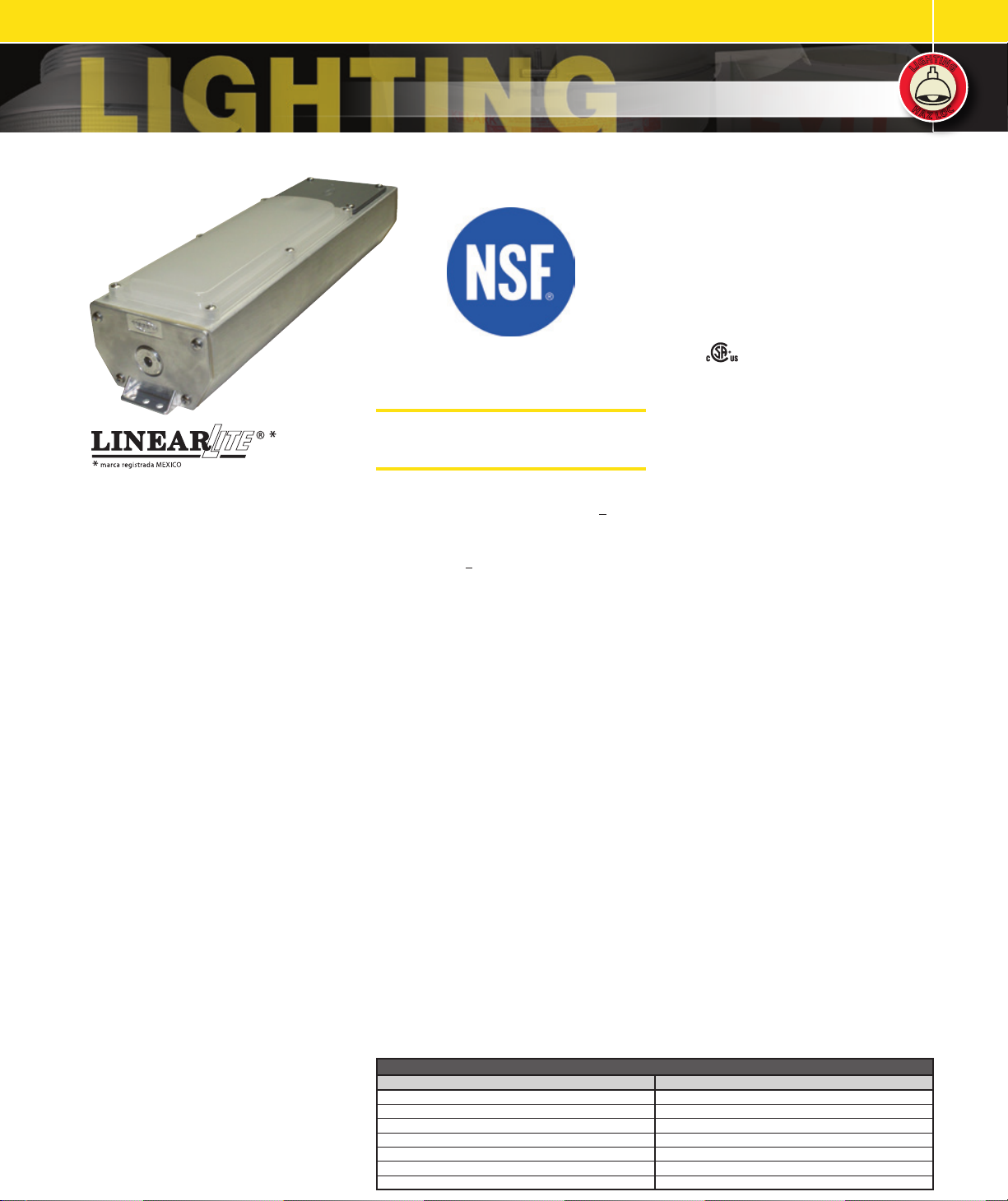

LALFP SERIES

C

C

O

O

L

L

LALFP

• Maintenance free

long-lasting LEDs

• NSF Certied with

Impact Resistant

polycarbonate lens

• All exterior

stainless steel

hardware

Linear LED Food Processing Fixture

• Large wiring

access for ease

of installation

• Extremely durable copper-

free aluminum mounting feet

& access plate with anodized

aluminum housing

• 90 or 180 minute emergency

with Self-diagnostics in

accordance with

NF PA 101® Life Safety Code

Page 2

LINEAR LED TECHNOLOGY

KILLARK LIGHTING

LALFP SERIES

Class I, Div. 2, Groups A, B, C, D

Class l, Zone 2, Groups IIC, llB, llA

Class II, Div. 1 & 2, Groups E, F, G

AEx nAII, Ex nAII

Wet Locations

Type 4X

IP66/IP67

ABS

Typ e Appr ova l

NSF Food Handling

H

H

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

C

C

A

A

O

O

Z

Z

L

L

FEATURES-SPECIFICATIONS

Applications

Linear LED Luminaires are designed for food

processing installations where moisture,

corrosion and vibration may be present, and

Type 3, 4X, IP66/IP67. They can be used in

locations made hazardous by the presence

of flammable vapors or gases or combustible

dusts as defined by the NEC/CEC.

Typical applications include non-food zones,

splash zones, hazardous food processing

areas, high and low ambient areas, and hosedown zones.

NSF (National Sanitation Foundation)

approved for “Food Handling” areas, typically

requiring non-glass lighting.

ABS (American Bureau of Shipping) type

approval for use on decks, vessels, platforms,

barges, ships and boats. Also suitable for

docks and marinas.

Compliances

• UL-8750 for LED lighting

• ANSI/UL 1598(A)

• UL-844 Standard for lighting fixtures for

hazardous locations, Class I, Division 2;

Class II, Divisions 1 and 2; Class III

• CSA C22.2 no. 137-M1981 electric

luminaires for use in hazardous locations

• Enclosed and gasketed

• Type 3, 4X

• IP66/IP67

Approved

Supplemental 20KA /10KV Surge Protection

is standard (for 120-277 VAC models)

10KA/10KV Surge Protection (for 347-480 VAC)

Materials

• Housing – one piece clear anodized < .1%

copper-free aluminum extrusion

• Endcaps & wiring – Access covers are

copper-free (< .4%) aluminum with natural

finish.

• External screws are 316 stainless steel

• Lens – Impact resistant polycarbonate lens

available in diffuse or clear

LALFP & LALFPxiE Product Features

• LALFPxiE models have “built-in” battery

backup for 90 or 180 minute battery backup

• Shallow design minimizes profile in work

areas with low ceiling heights

• Diffuse Lens Standard to minimize glare;

Clear Lens available

• Polycarbonate Single Lens L1 & L3; Double

Lens model L5

• Variety of mounting options including

swivel brackets, wall, ceiling brackets, or

beam clamps

• End Caps each have 2 mounting feet

built-in plus a safety strap attachment point

• Standard unit End Caps each have single

a ¾” NPT hub, and fixture is furnished

with one ¾” close-up plug and two ¾” to

½” reducers – provides out of the box ½”

dead-end to ¾” feed-through flexibility.

Metric openings are available.

• Standard LALFPs have one wiring Access

Plate for easy access to terminal block.

INTELLIGENT EMERGENCY SERVICE CODES

INDICATOR STATUS SIGNAL DESCRIPTION OF STATUS SIGNAL

0.5s ON and 0.5s OFF Battery disconnected.

2.5s ON and 2.5s OFF LED load disconnec ted.

4.5s ON and 0.5s OFF Driver in self-diagnostic mode.

1.5s ON and 3.5s OFF Battery needs to be replaced.

0.5s ON and 4.5s OFF Damaged driver. Replace

ON Normal/Charging.

OFF (LED Load ON) Discharging / Emergency Operation

Certified - File LR11713

Electronics Includes:

• Self-diagnostics monitors LED status, LED

driver circuit, battery capacity and charger

function and displays any fault detection by

means of a flashing code

• Self-Test feature automatically runs a 1

minute test once a month and an alternating

30-60 minute test once every 6 months.

Multi-color LED indicator provides visible

fault detection and charging status

• User initiated 1, or 90-minute system test

feature

• 15 minute re-transfer delay

• Automatic unit transfer in brown-out

conditions (below 80% of nominal AC input

voltage)

LED Features and Standards

• Many Midpower LEDs blend light to

simulate fluorescent tubes

• Crisp White Light for Excellent Color

Rendering – Chromaticity 5000K (CCT);

approx. 70 CRI

• LED Array Life – 100,000+ hours with 70%

initial lumens

• Long Fixture Life – 50,000 - 55,000

maintenance free hours

• Ambient suitability -40°C to 65°C (see

tables). -20°C to 50°C Ambient suitability

for Emergency models.

• Instant On – Including after power

interruption

• World Voltage 120 - 277VAC 50/60Hz

• Solder-LESS LED Board Connections –

Vibration Resistant

Page 3

KILLARK LIGHTING

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

H

H

A

A

Z

Z

LALFP SERIES

C

C

O

O

L

L

CATALOG LOGIC

Weather Rated

W – Weather only

Blank –

Hazardous Location and Weather rated

LALFP – Series Constant

Aluminum Extrusion with Polycarbonate Lens

Fixture Lumen Output

2 –

2000 Lumen Range

4 –

4000 Lumen Range

6 –

6000 Lumen Range

8 –

8000 Lumen Range

11 –

11,000 Lumen Range

16 –

16,000 Lumen Range

Emergency Battery Backup

Blank –

No Emergency

iE05 –

500 Lumen Range during 180 minute emergency

iE1 –

1000 Lumen Range during 90 minute emergency

iE3 –

3000 Lumen Range during 90 minute emergency

(only available on L5 & L6)

LALFPW 16 iE3 30 L5 D FF

Example

= Weather only rated, 16,000 Lumen

output with 3,000 Lumen output during

90 minute emergency operation, 120277 VAC, approximately 5 foot length

Diffuse Lens, 2 fuses

Options

F –

Single Fuse (1 pole)

FF –

Two Fuses (2 pole - 2 hot legs)

S52 –

1 Endcap with 1x1/2” NPT and 1xM20

Entries (3/4” NPT Plugged)

D52 –

2 Endcaps with 1x1/2” NPT and 1xM20

Entries (3/4” NPT Plugged)

D50 –

2x1/2” NPT Entries 1 end cap, 3/4”

plugged; 2nd end cap std. 1x3/4” NPT

D502 –

2x1/2” Entries 2 end caps, 3/4” NPTs

plugged

D20 –

2xM20 Entries 1 end cap, 3/4” plugged;

2nd end cap std. 1x3/4”NPT

D202 –

2xM20 Entries 2 end caps, 3/4” NPTs

plugged

LSP –

Less Surge Protector

GH –

Gray Housing

RH –

Red Housing

TBL –

Terminal Blocks Looping through Wiring

NAP –

QD –

No Access Plate (only available on L1)

Quick Discount

Specials – Contact Factory for custom

congurations and options

Voltage

30 –

120V-277VAC 50/60Hz all models

27 –

12VDC - 24VDC models only L1 Length and 2 & 3 Lumen Range

33 –

347-480VAC LAL 28W & 55W non-emergency models only

34 –

125VDC-250VDC; 120-277VAC 50/60Hz Lumen Range 2, 4, 8, & 16

non-emergency models

Energy Savings

LED VS FLUORESCENT WATTAGE & DELIVERED LUMENS

CATALOG NUMBER LUMENS L/W FLUORESCENT LUMENS L/W

LALFP230CL3 2479 138 40W 1x40W BX 2471 63

LALFP430CL 3 3624 129 55W 1x55W BX 3766 65

LA LFP 630 CL1 5515 122 64W 2x32T8 4772 80

LALFP830CL3 7709 12 8 120W 2x60T12HO 6965 56

LALFP1130CL5 11032 13 8 162W 3x54T5HO 11619 65

Lens

D –

Diffuse Polycarbonate

C –

Clear Polycarbonate

Length

L1 –

Approximately 1 foot (2, 4, 6 Lumen Outputs)

L3 –

Approximately 3 feet (2, 4, 6, 8 Lumen Outputs)

L5 –

Approximately 5 feet (11, 16 Lumen Outputs)

Page 4

ORDERING INFORMATION

KILLARK LIGHTING

LALFP SERIES

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

H

H

C

C

A

A

O

O

Z

Z

L

L

ORDERING INFORMATION AND AMBIENT SUITABILITY

CATALOG NUMBER WATTS

LA LFP 230 L1D 15 18.73 / 476

LENGTH

IN / MM

VOLTAGE AMPS

0.15-0.06 1503 / 1640 T5 T4A - T4A T4 A -

LUMENS

DIFFUSE/CLEAR

C1D2 A,B,C,D/

ZONE 2 IIC, IIB, IIA

40°C 55°C 65°C 40°C 55°C 65°C 40°C 55°C 65°C

C1D2 E, F, G

SIMULTANEOUS

C2D1 E, F, G

LALFP230L3D 18 32.6 / 828 0.15 - 0.06 2272 / 2479 T6 T6 T6 T4A T4A T4A T4A T4A T4A

LA LFP43 0L1D 35 18.73 / 476 0.30-0.13 3261 / 3558 T5 T4A - T4A T4A - T4A T4A -

LALFP430L3D 28 32.6 / 828 0.23 - 0.10 3321 / 3624 T6 T6 T5 T4A T4A T4A T4A T4A T4A

LA LFP 630 L1D 45 18.73 / 476 0.38-0.17 5136 / 5604 T5 T4A - T4A T4 A - T4 A T4A -

LALFP630L3D 45 32.6 / 828 0.38 - 0.16 5054 / 5 515 T6 T5 - T4A T4A - T4A T4 A -

120/277

VAC 50/60

Hz

LALFP830L3D 60 32.6 / 828 0.50 - 0.22 7064 / 7709 T6 T5 - T4A T4A - T4A T4 A -

LALFP1130L5D 80 57.9 / 1471 0.67 - 0.29 10110 / 11032 T6 T5 - T4A T4A - T4A T4 A -

LALFP1630L5D 120 57.9 / 1471 1.00 - 0.43 15090 / 16467 T6 T5 - T4A T4A - T4A T4 A -

ORDERING INFORMATION AND AMBIENT SUITABILITY

CATALOG NUMBER WATTS

WL ALF P23 0L1D 15 18.73 / 476

LENGTH

IN / MM

VOLTAGE AMPS

0.15-0.06 1503 / 1640

WLALFP230L3D 18 32.6 / 828 0.15 - 0.06 2272 / 2479

WL ALF P4 30L1D 35 18.73 / 476 0.30-0.13 3261 / 3558

WLALFP430L3D 28 32.6 / 828 0.23 - 0.10 3321 / 3624

WL ALF P63 0L1D 45 18.73 / 476 0.38-0.17 5136 / 5604

WLALFP630L3D 45 32.6 / 828 0.38 - 0.16 5054 / 5515

120/277

VAC 50/60

Hz

WLALFP830L3D 60 32.6 / 828 0.50 - 0.22 706 4 / 7709

WLALFP1130L5D 80 57.9 / 1471 0.67 - 0.29 10110 / 11032

WLALFP1630L5D 120 57.9 / 1471 1.00 - 0.43 15090 / 16467

LUMENS

DIFFUSE/CLEAR

Page 5

KILLARK LIGHTING

18.37 [467]

32.25 [819]

57.55 [1462]

12.62 [321]

13.37 [340]

13.87 [352]

Ø.28 TYP

(6) HOLES

3.75 [95]

[123]

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

H

H

A

A

Z

Z

LALFP SERIES

C

C

O

O

L

L

DIMENSIONS

17.87 [454]

17.12 [435]

LALFP-L1 Single Access Panel

31.75 [806]

31.00 [787]

1.46

[37]

LALFP-L3 Single Access Panel

57.05 [1449]

56.30 [1430]

LALFP-L5 Single Access Panel

.25

.63

End View

2.41

[61]

4.83

.56 TYP

.56 TYP

Page 6

KILLARK LIGHTING

LALFP SERIES

ACCESSORIES AND REPLACEMENT PARTS

ACCESSORIES AND REPLACEMENT PARTS

LAL-SB

LZCB Ceiling Bracket Set with Stainless Steel Bolts to at tach to LAL(C) “slots”

LZWB Wall Bracket Set with Stainless Steel Bolts to attach to L AL(C) “slots”

LAL-BC Steel/malleable Iron with Zinc electroplate for corrosion resistance; includes Stainless Steel Bolts to at tach to LAL(C) “slots”

LAL-EB Eyebolt Set with Stainless Steel Bolts to attach to LAL(C) “slots”

VMSC10 10’ Stainless Steel Safety Cable with loop grip

LALG Stainless Guard for 1 L AL Lens, order two for 2 lens models

LALCG LALC Stainless Guard

LAL-LE NSC LR Single Clear Lens with Gasket for LAL Series

LAL-LE NSDIF Single Diffuse Lens with Gasket for L AL Series

LALC-LENSCLR Single Clear Lens with Gasket for LALC Series

LALC-LENSDIF Single Diffuse Lens with Gasket for L ALC Series

Swivel Bracket Set w/ Adjustable Height; includes 5/16” bolts/nuts/ lock-washers for att achment to L AL(C) “slots; can also be at tached to

end cap mounting feet with FBO bolts.

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

H

H

C

C

A

A

O

O

Z

Z

L

L

LAL-SB Dimensions – ex tended shown

VMSC10 Safety Cable

Ceiling Bracket Set

Part Number LZCB

Stainless Steel (natural nish)

-18

[23.8]

[3 8 .1]

LAL-BC Beam Clamp

Loading...

Loading...