Killark-Hubbell Electrical Products KFLH SERIES Catalog Page

C1D2 FLOOD – INTRODUCTION & LOGIC

FEATURES-SPECIFICATIONS

Applications

LED Floods are designed for installations

where moisture, dirt, dust, corrosion and

vibration may be present, or NEMA 3 and

4X areas where wind, water, snow or high

ambients can be expected. They can be used

in locations made hazardous by the presence

of flammable vapors or gases or combustible

dusts as defined by the NEC.

Typical applications include manufacturing

plants, and certain chemical and

petrochemical processing facilities, sewage

treatment plants, off-shore and dockside

installations, garages and storage facilities.

Compliances

• UL-8750 for LED lighting

• ANSI/UL 1598(A)

• UL-844 Standard for lighting fixtures for

hazardous locations, Class I, Division 2;

Class II, Divisions 1 and 2; Class III

• CSA C22.2 no. 137-M1981 electric

luminairies for use in hazardous locations

• Enclosed and gasketed

• NEMA 3, 4X

• IP66

Materials

• Body and lens frame corrosion resistant

copper-free aluminum alloy with

baked powder epoxy/polyester finish,

electrostatically applied for complete,

uniform corrosion protection

• All external hardware – stainless steel

• Thermal shock and impact resistant glass

lens (Polycarbonate available)

• High temperature silicone gasketing

• Trunnion heavy gauge 316 stainless steel

LED

LED Flood Features and Standards

• Crisp White Light for Excellent Color

Rendering – Chromaticity 5000K (CCT);

approx. 70 CRI

• Energy Savings – High lumens per watt

• Long Life – to 100,000+ maintenance free

hours to 70% initial lumens

• Ambient suitability -40°C to 55°C up

to 250Wk to -50°C for non-hazardous

applications

• Instant On – Including after power

interruption

• World Voltage 120 – 277VAC 50/60Hz

• Solder-LESS LED Board Connections –

Vibration Resistant

• LM80-08* Measurement of lumen

maintenance for LED light sources

• LM79-08* Certified “Absolute”

Photometry, including Chromaticity Color

for Solid State Lighting

• L70 Values – Industry Nomenclature for

Hours of use to 70% of initial Lumens –

TM-21* & Calculated

Catalog Number Logic

KFLH - Series Constant

Fixture Wattage

170 210 220 250 300 390 -

170W

210W

220W

250W

300W

390W

Voltage

30

33

34

Options

PL

F

FF

TBL

P1

P2

P3

QD

D20

IEX

– 120 - 277VAC 50/60Hz

– 347 - 48 0VAC 60Hz (170W to 250W)k

– 120 - 250VDC (170W to 250W)

- Polycarbonate Lens

- Single Fusej

- Double Fusej

- Terminal Blocks

- 120V Photocell, factory installed

- 208V-277V Photocell, factory installed

- 347V Photocell, factory installed

- Quick Disconnect

- 2x M20 entries

- IEXEx includes TBL & External ground

KFLH 170 30 XX

KILLARK LIGHTING

KFLH SERIES

Class I, Div. 2, Groups A, B, C, D

Class I, Zone 2, IIC, IIB, IIA

Class II, Div. 1 & 2, Groups E, F, G

Class III

Suitable for wet locations

Marine Rated (US only)

NEMA 3, 4X

IP66

IEC Ex Rated Model (w/ IEX suf fix)

Zone 2 and Zone 21 areas

Ex nA IIC T6…T3, Gc

Ex tb IIC T105°C Db

Tamb -50°C < Ta < + 55°C, IP66

IECEx Certificate

QPS 15.0011

ATEX Certificate

CML 15AT EX4079X (nA)

& CML 15AT EX3080X (tb)

PATENTED

LENS and

REFLECTOR

DESIGN

KFLH

Luminaire

Dark Sk y Visor

KFLH -DARK

* LM-xx & TM-xx are illumination Engineering Society

Standards designed to promote uniformity in testing

procedures among test labs and manufacturers.

For more information go to www.ies.org

Supplemental surge protection included as

standard for AC models only

Construction Note:

Standard with two

3/4” NPT entries with

one plugged

Models for dual

metric entries have

slip holes with

metric locknuts and

certified blanking

plugs

Looping

jFusing not for Canadian or Marine

Installations

k 347V-480V +40°C Max

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

H

H

C

C

A

A

O

O

Z

Z

L

L

KILLARK LIGHTING

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

H

H

A

A

Z

Z

KFLH SERIES

C

C

O

O

L

L

C1D2 FLOOD – ORDERING INFORMATION & TECHNICAL DATA

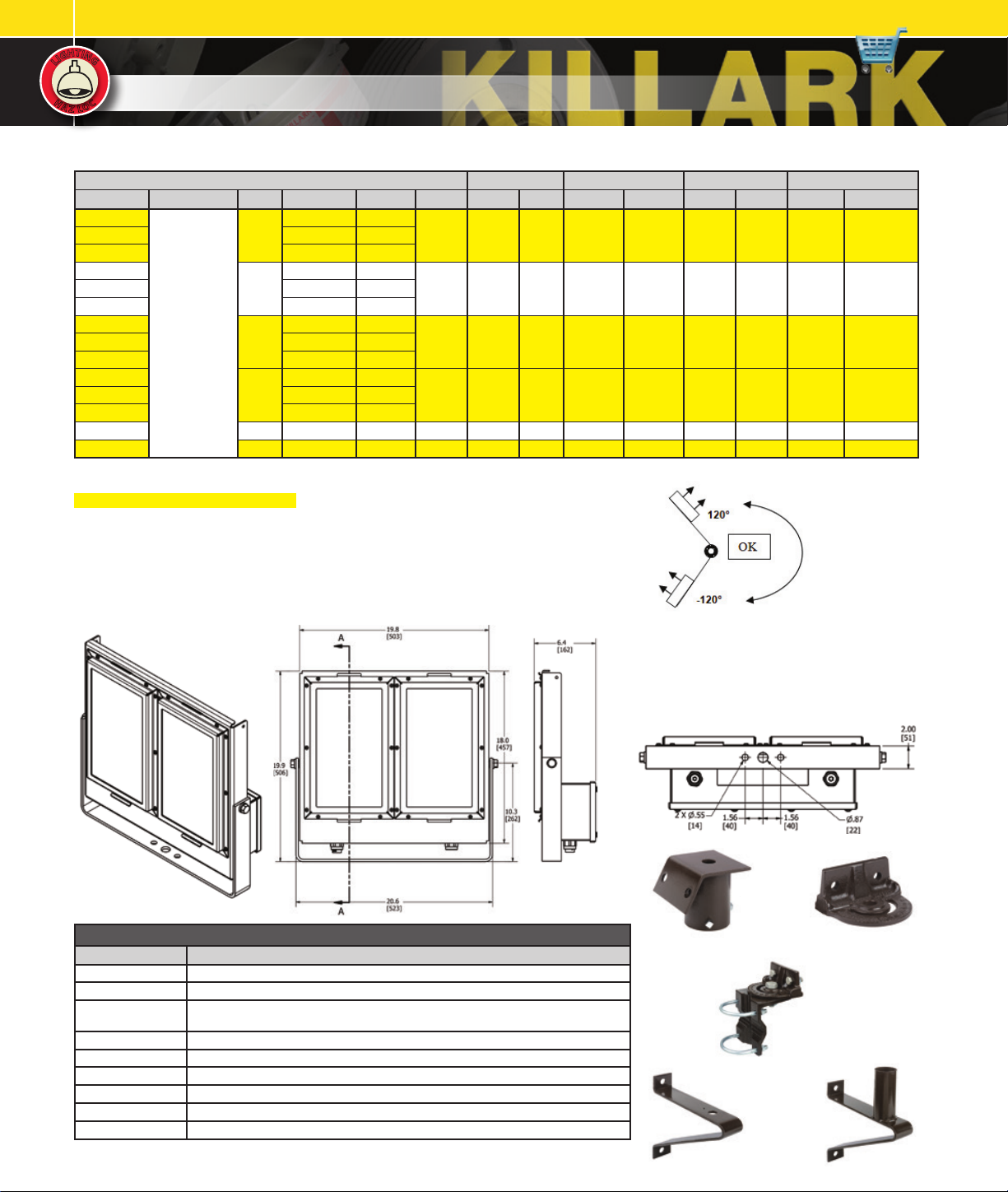

ORDERING INFORMATION AND AMBIENT SUITABILITY C1D2 (C1Z 2) C1D2 SIMULTANEOUS C2D1 L70

CATALOG NO. WEIGHT LBS./KG WATTS VOLTAGE AMPS LUMENS 40°C 55°C 40°C 55°C 40°C 55°C TM-21 CALCULATED

KFLH170 30

KFLH170 34 120-250VDC 1.46- 0. 56

KFLH21030

KFLH21034 120-250VDC 1.75-0.68

KFLH22030

25.00 / 11.3

KFLH22034 120-250VDC 1.88-0.73

KFLH25030

KFLH25033 347-480VAC 0.75-0.54

KFLH25034 120-250VDC 2.17- 0.8 5

KFLH30030 300 120-27 7VAC 2.48-1.07 37030 T4 A ( T4) T4 - - - - 60300 107000

KFLH39030 390 120 -277 VAC 3. 3 0-1.43 40410 T4 A ( T4) T4 - - - - 60300 190000

j Cat. Nos. are 120 through 277VAC 50 /60Hz; see logic for 347-480V or 125-250VDC input

k Amperage measured at 120VAC; 277VAC calculated

l Extra High Lumens per Watt LED Models

m Use 75°C Supply Wire @ 40°C Ambient; 90°C Wire @ 55°C Ambient

n 55°C only for 170W through 250W at 120-277VAC 50/60Hz or 125-250VDC; not 480VAC

o For Dust Applications, limit aiming angle bet ween 120° and -120° to minimize buildup - see gure at right

p L70 is time in hours to 70% of initial lumens remaining. TM -21 based values require very long duration testing and

is denoted “official repor ted” and is based on at least 6,0 00 minimum, to 12,000 hours testing (at time of printing).

“Calculated” values by the major chip vendors utilized predict L70 life up to 278,000 hours.

120-27 7VAC 1.46-0.63

170

120-27 7VAC 1.75-0.75

210

120-27 7VAC 1.88-0.81

220

120-27 7VAC 2.17-0.94

250

21620 T4A ( T4) T4 T4 T3C T4 T3C 72600 278000KFLH17033 347-480VAC 0.51-0.36

21220 T4A (T4) T4 T4 T3C T4 T3C 60100 270000KFLH21033 347-480VAC 0.61-0.43

26970 T4A (T4) T4 T4 T3C T4 T3C 72600 278000KFLH22033 347-480VAC 0.65-0.47

30950 T4A ( T4) T4 T4 T3C T4 T3C 72600 278000

p Dust A iming

Angles

KFLH MOUNTS AND ACCESSORIESj

CATALOG NUMBER DESCRIPTION

KFS-6 Steel Slipfi tter for 2” Pipe (2-3 /8” o.d.) Tenon. Slips 3.75” Over Pipe.

KFCB Heav y Dut y Cast-Iron Crossarm F itting for Horizont al Trunnion

KFWB

K4040 Heav y Dut y Steel Wall Bracket. (Must be with

4041 Heav y Dut y Steel Wall Bracket 2” Pipe (2-3/8” o.d.) Tenon Fitting. Use with KFS-6.

KFLG Wire Guard, 316 Stainless S teel (order 2 per fixture)

VMSC10k

KFLH-DARKl

KFLH-DOOR Replacement Internal Reflector and Lens Assembly (order 2 per fixture as required)

j Fittings available to adapt trunnion mount oodlights to crossarms, poles and walls. Must be ordered separately.

k Drop limit 1’. Attaches to luminaire cable provision and to mounting structure.

l Designed to eliminate uplight when aimed at 45°.

Heav y Dut y Wall Mount and/or Pipe Clamp Fitting Clamps 2” Pipe (2-3/8” o.d.) Through

2-1/2” Pipe (2-7/8” o.d.)

KFCB

Crossarm Fitting).

10’ Stainless Steel Safety Cable with loop grip

Dark Sk y Visor, White Painted Aluminum

KFS-6

Sliptter

Wall/Pipe Bracket

K4040

Wall Bracket

KFWB

KFCB

Cross Arm Mount

4041

Tenon Fitting

Loading...

Loading...