Page 1

KILLARK LIGHTING

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

H

H

A

A

Z

Z

EBS SERIES

C

C

O

O

L

L

EMERGENCY BATTERY SYSTEM – INTRODUCTION

EBS Battery Unit Only

EBS

FEATURES-SPECIFICATIONS

Applications

Where required by the NEC (or local “Life Safety”

code) for safe egress (over doors, aisleways,

stairs, walkways, exit paths, and outer perimeter

walls) to provide illumination during interruption

of normal power to area lighting.

In indoor or outdoor locations made hazardous

by the presence of flammable gas, vapors, or

dusts. Includes refinery/chemical production

and storage, grain processing, waste water

treatment facilities and any area requiring

heavy-duty dependable emergency lighting.

Exclusive Features

• LED Heads provide clear crisp illumination

at 5000° Kelvink

• LED Head L70 value 100,000 hours for

minimal maintenance

• Two head models up to 500% brighter

than competitive conventional unitsl

• Enclosure Type 4 (NEMA 4) for wet and

harsh locations

• Group B is standard when using EBSHK

type heads

• Automatic Safety Disconnect – Removing

main cover disconnects battery power

• Ambient Suitability 0°C to 45°C Battery

Unit; Heads to 55°

• Compact unit requires only two mounting

points

• World Voltage 120-277 VAC 50/60Hz input

Other Features

• High % of lumens maintained during 90

minute egress cycle

• EBSHK type heads are fully adjustable on

unit or remote when ordered with

RFSL Factory Sealed mounting kits

LED

TECHNOLOGY

• EBSEL type heads are factory sealed on

their EZ type mounting boxes

• Heads can be remote mounted over 300’

from battery unit

• Ni-Cad sealed batteries provide 90

minutes of illumination

• Integral base unit LED pilot light indicates

AC power is present

• Choice of Integral or Remote Push-To-Test

station to verify system operation

• Vapor Capsule to inhibit corrosion is

standard with main enclosure unit

• Terminal Blocks identified for incoming

and outgoing connections

Compliances

• UL 1598 Standard for Luminaires

• UL 8750 for LED Lighting

• UL 844 Luminaires for Hazardous

Locations

• UL 1203 Explosion-Proof/Dust-Ignition-

Proof Electrical Enclosures

• UL 924 Emergency Lighting

• CSA C22.2 no. 137-M1981 Luminaires for

Hazardous Locations

• CSA C22.2 no. 30-M1986 C1D1 Enclosures

• CSA 22.2 no. 25-1066 C2D1 EFG Enclosures

• Enclosure Type 4

• NEMA 4, 7BjCD, 9EFG

Materials

• Main Enclosure and Heads Copper Free

Aluminum alloy with Baked Powder epoxy/

polyester finish, electrostatically applied

for complete, uniform corrosion protection

• Attachment fittings copper-free aluminum

• External hardware 316 Stainless Steel

• EBSEL reflectors EXIT accessory

aluminum with white paint

Class I, Div. 1&2, Groups Bj,C,D

Class I, Zone 1&2, Groups llB+H2j, llA

Class II, Div. 1&2, Groups EFG

Class III

Enclosure Type 4 (NEMA 4, 7Bj CD, 9EFG)

File LR11713

Notes

j Main EBS unit is CID1 Grp B (Suitable Zone 1

IIB+H2) with attached EBSHK heads or no heads;

with attached EBSEL heads unit is CID1 Groups CD

(Suitable Zone 1 IIB, IIA)

k See VSL Series Photometry Color Graphs; 5000°

Kelvin is typical (“sunlight ”)

l Based on published tungsteon/incandescent data

EBSEL Heads 300% brighter; EBSHK Heads 500%

brighter

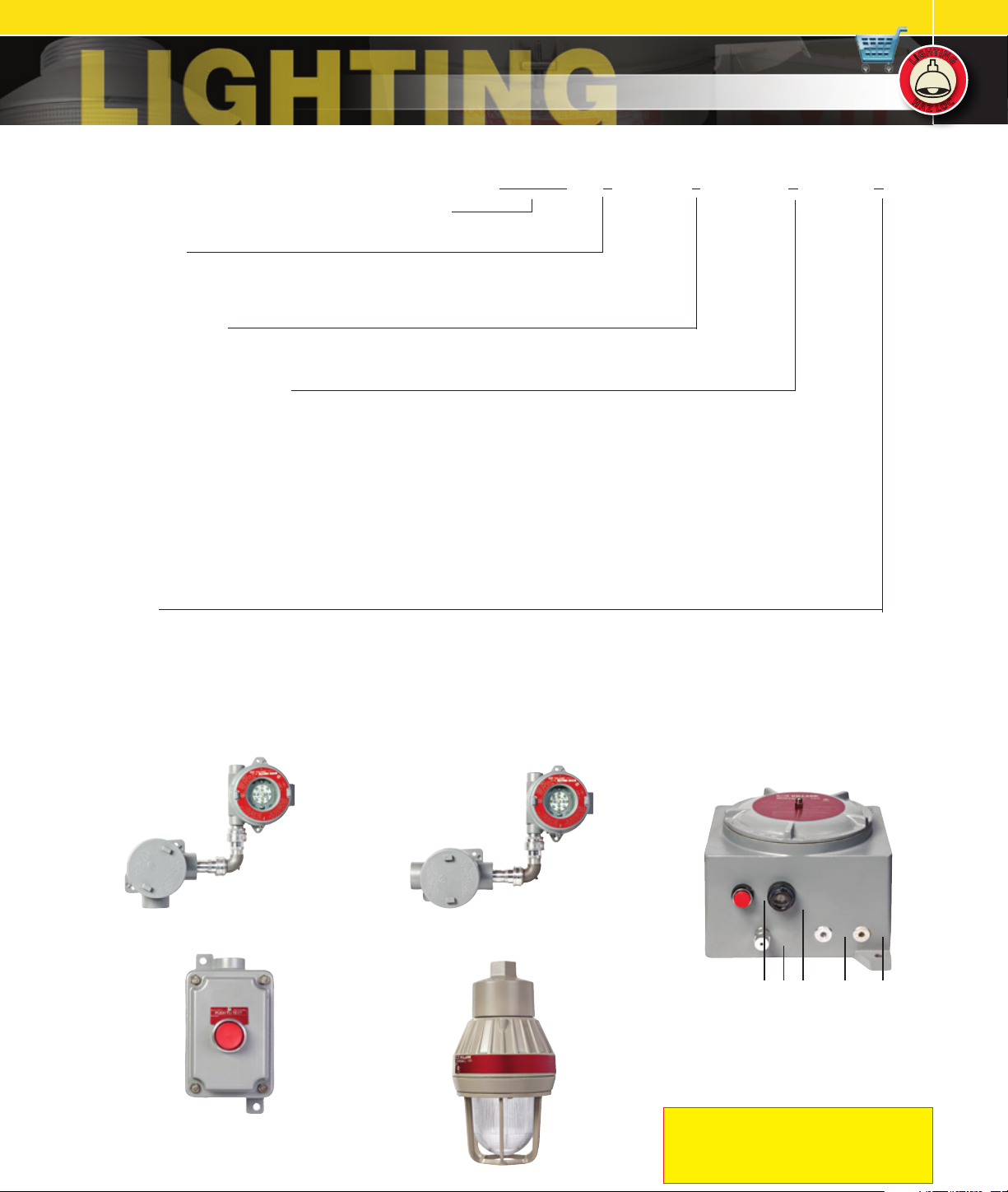

EBS Unit with HK Type Heads and

Integra l Push-To -Test

EBS Unit with EL Type Heads and

Integra l Push-To -Test

EBS Unit with

EL Type Head

and Exit plus

HK Head

with remote

Pus h-To-Tes t

Page 2

KILLARK LIGHTING

EBS SERIES

EMERGENCY BATTERY SYSTEM – LOGIC & COMPONENTS

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

H

H

C

C

A

A

O

O

Z

Z

L

L

Catalog Number Logic

EBS23DH

Series Constant 120-277V 50/60Hz 23W

EBS23DH - P T A D

Dual-Head (Remote or Attached)

Test Options

P Push-To-Test on Enclosure

R Remote Push-To-Test Station (EBS-PTT shipped separately)

N None - ordered separately or breaker controlled

Time Delay Option

T Power Resumption Emergency Time-delay (Factory set approx. 15 min.) 120 thru 277V

N No Time-Delay

Luminaire Head Options jk

N No heads - For Remote Heads Ordered Separately

A 2 EBSHK1030 Heads Factory Attached

B 2 EBSEL1030 Heads (Less Guards) and Fittings for Attachment

BG 2 EBSEL1030 Heads with Guards and Fittings for Attachment

BE 2 EBSEL1030 Heads with 1 Guard and 1 HEXA-100 EXIT and Fittings for Attachment

C 1 EBSHK1030 Head Attached and 1 EBSEL1030 Head (Less Guard) and Fittings for Attachment

CG 1 EBSHK1030 Heads Attached and 1 EBSEL1030 Head with Guard and Fittings for Attachment

CE 1 EBSHK1030 Heads Attached and 1 EBSEL1030 Head witn HEXA-100 EXIT and Fittings for Attachment

D 1 EBSHK1030 Only (2nd Head Remote - Ordered Separately)

E 1 EBSEL1030 Only Less Guard and Fittings for Attachment (2nd Head Remote - Ordered Separately)

EG 1 EBSEL1030 Only with Guard and Fittings for Attachment (2nd Head Remote - Ordered Separately)

EE 1 EBSEL1030 Only with HEXA100 EXIT and Fittings for Attachment (2nd Head Remote - Ordered Separately)

Drain l

D Group B Drain for Wet Applications including condensation from heat <> cold cycling

Blank Not included

j Main Enclosure nameplate does not reect heads ordered; unit is Dual Marked with ratings dependent on heads attached. E.g. if No heads or EBSHK only

head(s) attached then unit is C1D1 Groups BCD; if an EBSEL head is attached then unit is Groups CD.

k Units ordered with EBSHK heads are shipped with heads attached; EBSEL heads are shipped separately.

l Drain packed in enclosure with vapor capsule.

Factory Sealed Remote LED

Spot Light - Bottom Feed

Remote Push-To-Test Station

Factory Sealed Remote LED

Spot Light - Side Feed

Remote LED Luminaire

EBS UNIT - BOTTOM DETAIL

A B C D E

A Optional Push-To-Test

B Optional Group B Drain

C Standard Pilot Light

D Entry for Remote P-T-T Station

E Power Entry (also on top)

The EBS23 System is designed to power

2 Heads for operation (total attached

or remote); each Head is approximately

30VDC, 10 Watts.

Page 3

KILLARK LIGHTING

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

H

H

A

A

Z

Z

EBS SERIES

C

C

O

O

L

L

EMERGENCY BATTERY SYSTEM – PRE-CONFIGURED UNITS

LED

TECHNOLOGY

Class I, Div. 1&2, Groups Bj,C,D

Class I, Zone 1&2, Groups llB+H2j, llA

Class II, Div. 1&2, Groups EFG

Class III

Enclosure Type 4 (NEMA 4, 7Bj CD, 9EFG)

File LR11713

ORDERING INFORMATION

Integral Push-To-Test Remote Push-To-Test

EBS System with Two EBSHK Heads kl CID1BCD

Integral PTT,

Two EBSHK

EBS23DH-PNA

Integral PTT, TDR

Two EBSHK

EBS23DH-PTA

Remote PTT,

Two EBSHK

EBS23DH-RNA

Remote PTT, TDR

Two EBSHK

EBS23DH-RTA

EBS System with Two EBSEL Heads with Guards kl CID1CD

Integral PTT, Two

EBSEL Heads w/

Guards

EBS23DH-PNBG

Integral PTT, TDR,

Two EBSEL Heads

w/Guards

EBS23DH-PTBG

Remote PTT,

Two EBSEL Heads

w/Guards

EBS23DH-RNBG

Remote PTT, TDR,

Two EBSEL Heads

w/Guards

EBS23DH-RTBG

EBS System with One EBSHK Head & 1 EBSEL Head with Guard kl CID1CD

Integral PTT, One

EBSHK & One

EBSEL Head

w/Guard

EBS23DH-PNCG

Integral PTT, TDR,

One EBSHK & One

EBSEL Head

w/Guard

EBS23DH-PTCG

Remote PTT, One

EBSHK & One

EBSEL Head

w/Guard

EBS23DH-RNCG

Remote PTT, TDR,

One EBSHK &

One EBSEL Head

w/Guard

EBS23DH-RTCG

EBS System with Two EBSEL Heads One with EXIT kl CID1CD

Integral PTT, Two

EBSEL Heads, One

w/EXIT, One w/

Guard

EBS23DH-PNBE

Integral PTT, TDR,

Two EBSEL Heads

One w/EXIT, One

w/Guard

EBS23DH-PTBE

Remote PTT, Two

EBSEL Heads, One

w/EXIT, One

w/Guard

EBS23DH-RNBE

Remote PTT, Two

EBSEL Heads,

One w/EXIT, One

w/Guard

EBS23DH-RTBE

EBS System with One EBSHK Head & One EBSEL Head with EXIT kl CID1CD

Integral PTT, One

EBSHK Head, One

EBSEL w/EXIT

EBS23DH-PNCE

Integral PTT, TDR,

One EBSHK Head,

One EBSEL w/EXIT

EBS23DH-PTCE

Remote PTT, One

EBSHK Head, One

EBSEL w/EXIT

EBS23DH-RNCE

Remote PTT, TDR,

One EBSHK Head,

One EBSEL w/EXIT

EBS23DH-RTCE

EBS System Only for Remote Heads (order two separately) kl CID1BCD

Integral PTT,

No Heads

EBS23DH-PNN

j Main EBS unit is CID1 Group B (Suitable Zone 1 IIB+H2) with attached EBSHK heads or no heads; with attached

EBSEL heads unit is CID1 Groups CD (Suitable Zone 1 IIB, IIA)

kUse catalog logic for single attached head models and order required remote 2nd head separately. Note, for EXIT

applications EBSEL heads must be ordered without guards.

lPTT = Push-To-Test; TDR = Time Delay Relay (prox 15 minutes after power resumption).

Integral PTT, TDR,

No Heads

EBS23DH-PTN

Remote PTT,

No Heads

EBS23DH-RNN

Remote PTT, TDR,

No Heads

EBS23DH-RTN

Page 4

EMERGENCY BATTERY SYSTEM – REMOTE HEADS & ACCESSORIES

EBSEL1030 REMOTE HEADS WITH MOUNT (FACTORY SEALED) CID1CD; C2D1EFG

10W 30VDC

With Guard EBSEL1030A2G EBSEL1030X2G EBSEL1030B2G EBSEL1030D4G

Without Guardl

PENDANT 3/4”j CEILING 3/4”j WALL 3/4”j STANCHION 1-1/2”k

EB SE L10 30A 2 EBSEL1030X2 EBSEL1030B2 EB SEL10 30D4

KILLARK LIGHTING

EBS SERIES

EBSEL

Shown with

Exit Accessory

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

H

H

C

C

A

A

O

O

Z

Z

L

L

EBSEL1030 COMPONENTS & ACCESSORIES – DESCRIPTION

CATALOG NUMBER

EBSEL 10W 30V Head Only with LED’s, Less Mount and Guard EB SE L10 30

Guard EMG1

Red Guard – used to signif y remote fix ture is for Emergency

EXIT Accessor y – 3-sided white painted aluminum

EMG1-Rl

HEXA-10 0l

Dome Reflector ERSD15

Angle Reflector ERA15

Sealed Fittings Set for attachment of Pendant EBSEL to EBS23HD-xx x EBS-AHFS

Replacement Globe and Support Assembly EMGS1

MOUNTING BOXES

CATALOG NUMBER

PENDANT CEILING BRACKET STANCHION

EZA2 EZX2 EZB2 – 3/4”

EZA3 EZX3 EZB3 – 1”

– – –

j For 1” pendant, ceiling and wall hubs, substitute “3” for “2” in catalog number; example: EBSEL1030A3G.

k Stanchion conduit hub size supplied is 1-1/2” with 1-1/2” to 1-1/4” reducer for 1-1/4” mounting.

l Order xture without guard for use with HE XA-100 EXIT Accessory, or to order EMG1-R Red Guard.

m For EBSEL with Mount Dimensions, see EMI15 series in lighting section.

EZD4k

HUB SIZE

1-1/4” / 1-1 /2”

EBSHK1030 10W 30V HEADS, COMPONENTS & ACCESSORIES CID1BCD; C2D1EFG

DESCRIPTION CATALOG NUMBER

EBSHK Head Only with LED’s – Requires Field Sealj

EBSHK Head with ADJUSTABLE FACTORY SE ALED “C” fittings set EBSHK1030-RFSC

EBSHK Head with ADJUSTABLE FACTORY SE ALED “L” fittings set EBSHK1030-RFSL

Sealed Fittings Set for attachment of EBSHK to EBS23DH-x xx EBS-AHFS

j Seal purchased separately appropriate of area of use

EBS23DH SERIES ACCESSORIES – DESCRIPTION

Remote Push-To-Test Station Group B 3/4” Feed-Thru w/Close Up Plugj

Remote Push-To-Test Station with Lock Of f, Group B 3/4” Feed-Thruj

Lock-Off for Integral Push-To-Test GO10502

Sealed Fittings Set for attachment of EBSHK to GEBC-2 or GEBL-2 EBS-AHFS

Replacement Bat ter y Pack and Electronics KLBP01

Replacement Vapor Capsule for corrosion protection EBS-VC

j EBS23DH requires conduit seals (purchased separately) exiting enclosure within 18”; EBS-PTT contains a N.C.

contact and is Factory Sealed for C&D and up to 5’ for Group B.

EBSHK1030

CATALOG NUMBER

EBS-PTT

EBS-PTT-LO

EMG1

EBSEL1030

EMG1-R

ERS D15

ER A15

EMGS1

EBSHK1030

EBSHK1030-RFSL

EBSHK1030-RFSC

EBS-PTT

Page 5

KILLARK LIGHTING

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

H

H

A

A

Z

Z

EBS SERIES

C

C

O

O

L

L

EMERGENCY BATTERY SYSTEM – ELECTRICAL & TEMPERATURE DATA

LED 10W EBSHK1030

with

Remote

Options

ZONAL LUMEN SUMMARY

ZONE LUMENS FIXT%

0-30 254 27.9 %

EBS System with

SINGLE HEAD

or with or with

0-40 423 46.3%

0-60 781 85.5%

0-90 913 100.0 %

90 -120 0 0.0%

90 -130 0 0.0%

90 -150 0 0.0%

90 -180 0 0.0%

0-180 913 100.0%

Absolute Photometry

Total Luminaire Efficiency = N.A.%

Spacing to Mounting Height Ratio 2.1

EMERGENCY MODE LUMENS

05 Min. 99.1% 905 Lumens

45 Min. 99.4% 871 Lumens

90 Min. 95.3% 871 Lumens

EXIT SIGNLUMINAIRESPOTLIGHT

EBS23DH ELECTRICAL DATA

CATALOG

NUMBER

EBS23DH 120-27 7 VAC 7. 5 .1 A 33VDC 23 700mA

** Figures nominal. Current is 350mA to each of 2 heads (2 heads are required for proper operation, remote or attached).

VOLTAGE WATTS CURRENT VOLTAGE WATTS CURRENT

INPUT** OUTPUT**

THERMAL PERFORMANCE DATA

CATALOG NUMBER AMBIENT CID1 CIID1 SUITABILITY SUPPLY WIRE

EBS23DH 45°C T6 EFG 0-45°C 75°C

EB SE L10 30 55°C T6 EFG -40 to 40°C 75°C

EBSHK1030 55°C T6 EFG -40 to 40°C 75°C

4 Head EBS option:

EBS units are designed for 2 head operation

and will provide the lumens noted at right.

However, 4 heads can be connected and will

operate for 90 Minutes at half the published

lumen values. The EBSHK1030 would

provide 456 lumens; the EVSEL1030 540

lumens. Instructions for wiring are included

with the main EBS unit.

LED 10W EBSEL1030

ZONAL LUMEN SUMMARY

ZONE LUMENS FIXT%

0-30 180 16.7%

0-40 344 31.8%

0-60 758 70.1%

0-90 106 7 98.7%

90 -120 11 1.0%

90 -130 13 1. 2%

90 -150 14 1. 3%

90 -180 14 1. 3%

0-180 10 81 100%

Absolute Photometry

Total Luminaire Efficiency = N.A.%

Spacing to Mounting Height Ratio 2.1

EMERGENCY MODE LUMENS

5 Min. 94.4% 102 Lumens

45 Min. 91.3 % 987 Lumens

90 Min. 89.3% 966 Lumens

EBSHK Heads can be aimed up to 45 above

horizontal – if ush on wall will require spacing out.

Page 6

KILLARK LIGHTING

EBS SERIES

EMERGENCY BATTERY SYSTEM – DIMENSIONS & WEIGHTS

Dimensions - EBS with HK Heads

T

T

I

I

H

H

N

N

G

G

G

G

I

I

L

L

H

H

C

C

A

A

O

O

Z

Z

L

L

Dimensions - EBS with EL Heads Dimensions - EBS with EL-EXIT & HK Heads

9.47

10.47

3.40

3.40

10.80

8.51

14.64

5.09

Dimensions Factory Sealed

Remote HK Head

For EBSEL

with mounting

11.94

Dimensions,

see EM/15 in

10.95

lighting section.

3.69

6.19

2.25

4.54

Dimensions - Remote Test Station

WEIGHTS (SHIPPING) INDIVIDUAL AND

COMBINATIONSj

EGS23DH Main Unit Only 36.6

EBSEL1030 Pendant Head Only w/ Fittings Set 12.3

EBSHK1030 Head Only w/ Fittings Set 5.0

EBSHK1030-RFSC (or RFSL) 11.0

EBS-PTT 3.0

EBS-AHFS Factory Sealed Fittings Set 0.6

EBS23DH & 1 EBSHK w/ Fittings 41.6

EBS23DH & 2 EBSHK w/ Fittings 46.6

EBS23DH & 1 EBSEL w/ Fittings 48.9

EBS23DH & 2 EBSEL w/ Fittings 61.2

EBS23DH & 1 EBSEL & 1 EBSHK w/ Fit tings 53.9

j EBSEL Heads ship separately

6.71

LBS.

Dimensions - EBS Main Unit

Loading...

Loading...