Killark-Hubbell Electrical Products CTCA Series, Z Series Sales Brochure

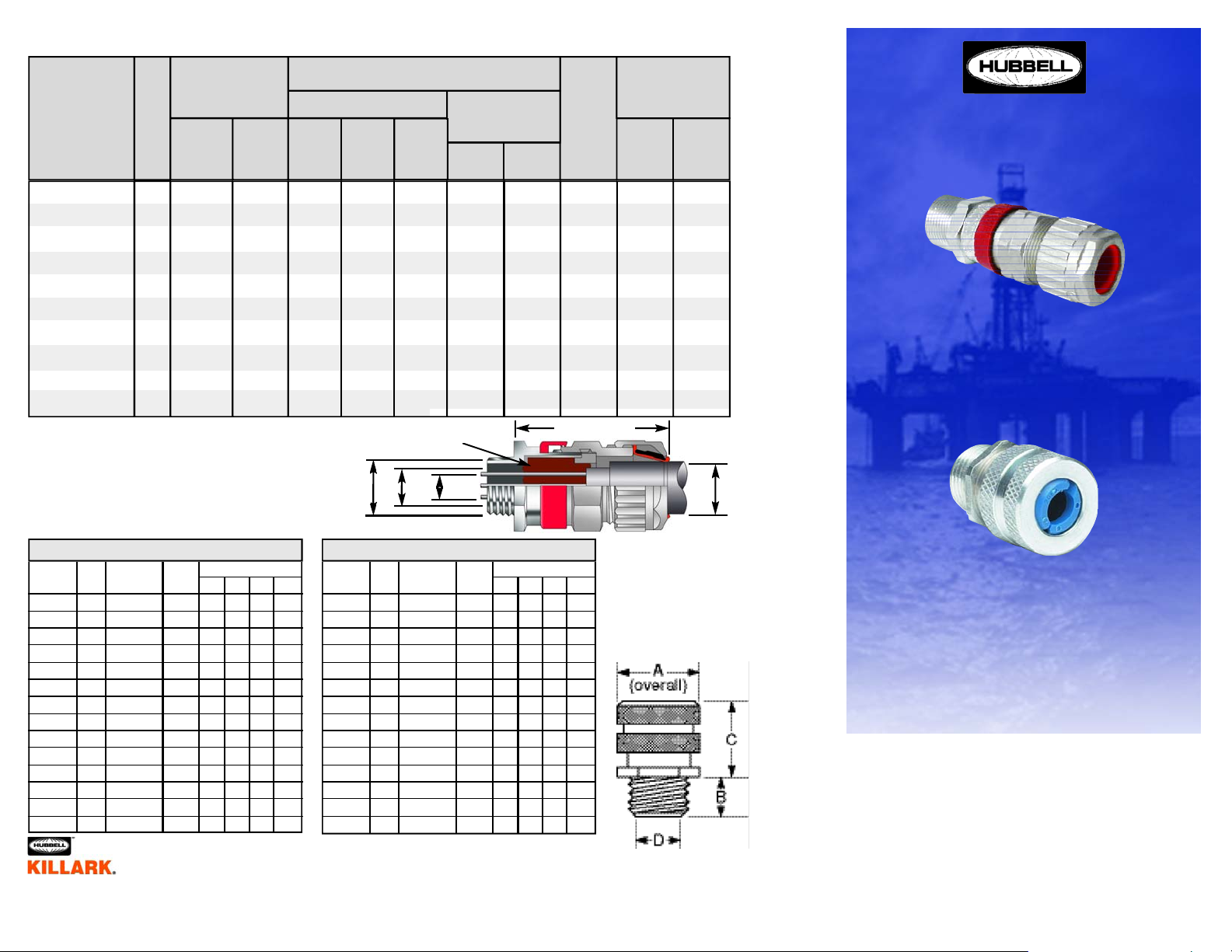

CTCA Series Selector

®

Catalog

Number

CTCAS050S

CTCAO050

CTCAA050L

CTCAB075

CTCAC100

CTCAC2125

CTCAD200

CTCAE250

CTCAF300

CTCAH350

Size

Ref.

Os

O

A

B

C

C2

D

E

F

H

Entry Thread

Size

NPT

std./

option

1

/2”

1

/2”

1

/2”-3/4”

3

/4”-1”

1

/4”

1”-1

1

/4”-11/2”

1

1

/2”

2”-1

1

/2”-2”

2

1

/2”

3”-2

1

/2”

3

Metric

M20

M20

M20

M25

M32

M40

M50

M63

M75

M90

Cable Acceptance Details

Inner Sheath/ Cores

‘D’ Max.

Cores

0.35”

0.35”

0.43”

0.64”

0.86”

1.04”

1.46”

1.88”

2.32”

2.79”

Entry Thread

Over

‘E’ Max

Inner

Sheath

0.39”

0.39”

0.64”

0.93”

1.23”

1.59”

1.96”

2.55”

2.98”

3.12”

‘E’

Max.

No. Of

Cores

6

6

10

21

42

60

80”

100

120

-

Compound

‘D’

Outer Jacket ‘B’

Min. Max.

0.22”

0.37”

0.49”

0.66”

0.87”

1.10”

1.42”

1.81”

2.24”

3.07”

0.47”

0.63”

0.81”

1.02”

1.30”

1.61”

2.07”

2.57”

3.07”

3.52”

‘G’

2.81”

2.81”

2.84”

2.95”

3.11”

3.26”

3.36”

3.56”

3.76”

3.54”

Max. Length

Hexagon

Dimensions

Across

Flats

0.94”

0.94”

1.18”

1.42”

1.81”

2.17”

2.56”

3.15”

3.74”

4.18”

Across

Corners

1.09”

1.09”

1.36”

1.64”

2.09”

2.50”

2.96”

3.64”

4.31”

4.84”

®

KILLARK

Barrier Seal

Connectors

for Tray Cable

‘B’

Z Series Selector**

Z CORD CONNECTORS — STRAIGHT

CATALOG NPT CORD COLOR DIMENSIONS

NUMBER SIZE RANGES CODE

ZS001-EX

ZS002-EX

ZS003-EX

ZS004-EX

ZS006-EX

ZS007-EX

ZS101-EX

ZS102-EX

ZS103-EX

ZS105-EX

ZS108-EX

ZS109-EX*

ZS110-EX*

ZS111-EX*

T

w

H ®

3/8"

3/8"

3/8"

3/8"

3/8"

3/8"

1/2"

1/2"

1/2"

1/2"

1/2"

1/2"

1/2"

1/2"

.062-.125

.125-.187

.187-.250

.250-.312

.312-.375

.375-.437

.062-.125

.125-.187

.187-.250

.250-.375

.375-.500

.500-.625

.625-.750

.750-.875

Green

Orange

Red

Black

White

Blue

Green

Orange

Red

White

Blue

Brown

Yellow

Purple

A B C D

.90

.425

.99

.90

.425

.99

.90

.425

.99

.90

.425

.99

.90

.425

.99

.90

.425

.99

1.10

.55

1.13

1.10

.55

1.13

1.10

.55

1.13

1.10

.55

1.13

1.10

.55

1.13

1.10

.55

1.13

1.50

.55

1.40

1.50

.55

1.40

Z CORD CONNECTORS — STRAIGHT

CATALOG NPT CORD COLOR DIMENSIONS

NUMBER SIZE RANGES CODE

ZS201-EX

.453

.453

ZS202-EX

ZS203-EX

.453

ZS205-EX

.453

.453

ZS208-EX

ZS209-EX

.453

ZS210-EX

.635

.635

ZS211-EX*

ZS308-EX

.635

ZS309-EX

.635

.635

ZS310-EX

ZS311-EX

.635

ZS312-EX

.635

.635

ZS313-EX*

**See Killark Catalog for additional configurations

*Cable Jacket may have to be stripped to pass through

connector body on these sizes

and sizes

3/4"

3/4"

3/4"

3/4"

3/4"

3/4"

3/4"

3/4"

1"

1"

1"

1"

1"

1"

1.000-1.125

.062-.125

.125-.187

.187-.250

.250-.375

.375-.500

.500-.625

.625-.750

.750-.875

.375-.500

.500-.625

.625-.750

.750-.875

.875-1.000

Green

Orange

Red

White

Blue

Brown

Yellow

Purple

Blue

Brown

Yellow

Purple

Gray

Pink

A B C D

1.10

.55

1.29

1.10

.55

1.29

1.10

.55

1.29

1.10

.55

1.29

1.10

.55

1.29

1.10

.55

1.29

1.50

.55

1.40

1.50

.55

1.40

1.60

.71

1.81

1.60

.71

1.81

1.60

.71

1.81

1.60

.71

1.81

1.60

.71

1.81

1.70

.66

2.31

.635

.635

.635

.635

.635

.635

.815

.815

1.015

1.015

1.015

1.015

1.015

1.015

Increased Safety Cord

Connectors

For

Wet, Harsh & Hazardous

Locations

Distributed by:

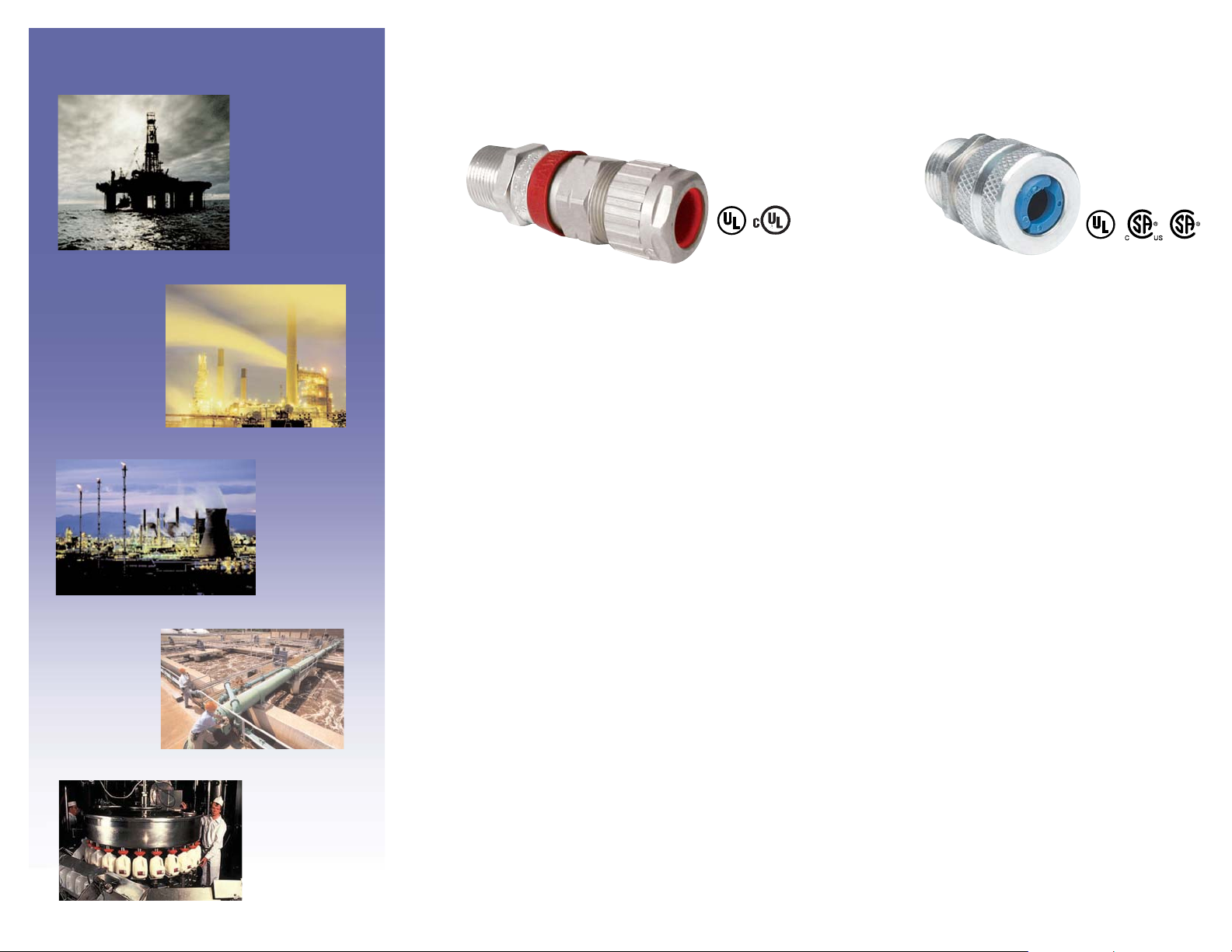

Typical Applications CTCA Series

Barrier Seal Connectors

for Tray Cable

Z Series

Increased Safety

Cord Connectors

Suitability

•

Class I, Div. 2, Groups A,B,C,D

• Class II, Div. 1 & 2, Groups E,F,G

• Class III, Div. 1 & 2

• Class I, Zone 2. Gas Groups IIA,IIB,IIC

• Type 4X

Applications

• Outdoor or Indoor use.

• For use with non armored cable, as permitted

by the NEC.

Features

• Provides a barrier seal between the individual

insulated conductors within the cable and prevents

entry of the products of an explosion into the cable.

• Assembly of the cable gland compresses and

distributes the compound evenly to effect a barrier

seal at the point of entry into the enclosure.

• Provides an outer deluge seal to prevent moisture

ingress to the cable armor and enclosure. Deluge

seal is colored red to indicate Hazardous Area

product.

• Provides a cable retention and low smoke and fume,

zero halogen seal onto the cables outer sheath.

®

Suitability

•

Zone 1, Ex e.

• Listed by CSA as a nationally recognized test lab

(NRTL) for Class I, Div. 2, Class I, Zone 2 in the

United States.

• Type 4 when installed with a proper gasket

Applications

• Use to secure and seal cords or cables entering

sheet steel, stainless steel, FRP and increased

safety enclosures or raceways.

• Z Series connectors are also suitable

forhazardous locations per NEC articles 501-4(b),

502-4(a&b), 503-3(a&b), 505-15(c); CEC 18-106,

18-122, 18-156, 18-218, 18-252, 18-302, 18-352;

IEC 60079-7 Increased Safety (Ex e II). Consult

these articles for appropriate installation

requirements.

Features

• Aluminum construction resists corrosion.

• Neoprene grommet seals out oil and moisture

• Nylon retention ring ensures superior holding

power.

• Wide range of sizes and configurations.

• For non-metallic or standard location connectors,

contact factory.

®

R

R

Offshore Drilling

Petro Chemical

Power Generation

Wastewater Treatment

Food Processing

Loading...

Loading...