Page 1

JUNCTION BOXES

KILLARK ENCLOSURES

B7E SERIES

S

S

U

O

U

O

L

L

R

R

C

C

E

E

N

S

N

S

E

E

H

H

C

C

A

A

O

O

Z

Z

L

L

FEATURES-SPECIFICATIONS

Applications

• Locations made hazardous due to the

presence of flammable gases or vapors,

combustible dust, or easily ignitable fibers

and flyings, and areas which are subject to

corrosion, weather and dampness

• Petroleum Refineries, Chemical and

Petrochemical plants with indoor and

outdoor process

• Applications requiring junction, pull and/

or splice boxes

• Enclosures to house control stations,

relays, starters, circuit breakers, terminal

blocks and other equipment or devices

(Glass viewing windows cannot be added to the Prism

Series Enclosures. Use Killark Quantum Enclosures

when viewing windows are required.)

#UL1203 - E xplosion proof and dustignition-proof electrical equipment for use

in hazardous (classified) locations. File

#E83969

#C22.2 No. 3 0-M1986-Explosion -proof

Enclosure for use in Class I Hazardous

Locations. FILE #LR11716

Features

• Copper-free cast aluminum construction.

High strength, lighter in weight, corrosion

resistant

• Quick Release, Captivated Cover Bolts

of 316 Grade Stainless Steel. Triplelead bolts require only 3-1/2 turns to

disengage. Stainless steel (316 grade) for

maximum protection from corrosion

• Gasketed Flange. Nitrile (BUNA-N) “O”

ring gasket is located inside bolt circle to

prevent water seeping into enclosure

• Ductile Mounting Lugs. Lugs are made

of ductile aluminum alloy to adjust to

irregular mounting surfaces without

damage to enclosure

• Hinged Cover is Standard

Class I, Div. 1 & 2,

Groups B, C, Dj

Class I, Zone 1 & 2

Groups IIB + H2, IIA

Class II, Div. 1 & 2,

Groups E, F, G

Class III, Div. 1 & 2

Enclosure Type 3, 4, 4X

NEMA 3, 4, 4x, 7 (B, C, D), 9 (E, F, G)

• Recessed Flange Notches. Flanges are

notched to allow for easier cover opening

with prying instrument without flange

damage

• Conduit Openings. Conduit openings can

be supplied at factory, or can be field

installed.

Material/Finish

• Enclosure: Cast Copper-free Aluminum

(less than 4/10 of 1%)

• Hinges: Aluminum with stainless steel

hardware

• Cover Bolts: 316 Grade Stainless Steel

• Aluminum Lacquer Paint Finish Standard

on all B7E except B7EP and B7EQ which

are powder epoxy as standard

B7E JUNCTION BOXES AND ENCLOSURES

DIMENSIONS

CATALOG

NUMBER

B7EA 6-1 /2” 13-1/2” 6-11 /16” 11” 18” 9-1 /8” 3-5/8” 16-3/8” 1 1-1/ 2” 1” 4 rows of 2 = 8

B7EB 10” 18-1/2 ” 6-5/8” 14-1 /2” 23” 9-1 /8” 7” 2 1-3/8” 1 1-1/ 2” 1” 7 rows of 3 = 21

B7EC 8” 15-1/2 ” 6-11 /16” 12-1 /2” 20” 9-1 /8” 5” 18-3/8” 1 1-1/2” 1” 5 rows of 2 = 10

B7ED 10” 21” 6-11/ 16” 14-1/ 2” 25-1/2” 9-1 /8” 7” 23 -7/8 ” 1 1-1/2” 1” 8 rows of 3 = 24

B7EE 8” 21-3/4” 8-5/16” 12 -1/ 2” 26 -1/4” 10-3 /4” 5” 24-5/8” 1 2” 2” 8 rows of 2 = 16

B7EF 13” 22-3/4” 8-3/8” 17-7/ 8” 27-1 /4” 11” 10-3 /8” 25-5/8” 1 4” 4” 8 rows of 4 = 32

B7EG 12” 29-3/4” 8-7/ 8” 16 -1/ 2” 34-1/4 ” 11-1/ 2” 9” 32-5/8” 1 5” 4” 8 rows of 3 = 24

B7EH 17” 29-3/4” 8-11/16 ” 21-1/2” 34-1 /4” 11-7/8” 14” 32-5/8” 1

B7EJ 15-1/ 2” 57-1/ 2” 9-5/16” 20-1/4 ” 62-1/4” 15” 18-1/2” 43 -1/2” 2 5” 5” 18 rows of 4 = 72

B7EK 13” 20” 6-5/8” 17-1/2 ” 24-3/4” 9-1/2” 15 -1/ 4” 13” 2 3” 1-1/2 ” 6 rows of 4 = 24

B7EL 13” 29” 6-5/8” 17-1/2” 33-3/8” 9 -1/2” 15-1/4” 21” 2 3” 1-1 /2” 9 rows of 4 = 36

B7EM 13” 41” 6-5/8” 17-1/2” 45-3/8” 9 -1/2” 15-1/4” 33” 2 3” 1-1/2” 14 rows of 4 = 56

B7EN 13” 50” 6-5/8” 17-1/ 2” 54-3/8” 9-1/2” 15 -1/4” 42” 2 3” 1-1/ 2” 17 rows of 4 = 68

B7EPl

B7EQl

jAll Conduits must be sealed within 18” when used in G roup B Locations.

kOperator spacing is 2-1/2” to except on B7EG & B7EH spacing is 3” to . Internal Mounting Pan Thickness is 1/8”

except on B7EJ it is 3/16” thick. B7EJ Enclosure Cover has an Internal Rib Structure. Consult Killark for drawing details

before layout of cover devices. Maximum number of “G” series control operators permitted in cover, down + across = total.

lB7 COMPACT Series - Details on page E39.

NOMINAL INSIDE OUTSIDE MOUNTING

WIDTH

3-5/8” 5-13/ 16 ” 5 -1/16 ” 5-3/4” 8 -1/ 16” 6-5/16” 3-1/8” 8 -1/ 8” 1 1” 1” 1 row of 2 = 2

4-1/4” 9-3/ 16” 6-5/16” 8 -1/8” 13-1/16” 7-13/16” 6-3/8” 7-1/2 ” 2 1-1/ 2” 1-1/2 ” 1 row of 4 = 4

(A)

LENGTH

(B)

DEPTH

(C)

WIDTH

(D)

LENGTH

(E)

DEPTH

(F)

WIDTH

(G)

LENGTH

DRAWING

FIGURE

(H)

MAXIMUM CONDUIT

SIZE

TOP &

BOTTOM

5” 4” 9 rows of 5 = 45

SIDES

MAXIMUM NUMBER

OF OPERATORSk

Page 2

KILLARK ENCLOSURES

S

S

U

O

U

O

L

L

R

R

C

C

E

E

N

S

N

S

E

E

H

H

A

A

Z

Z

B7E SERIES

C

C

O

O

L

L

FEATURES-SPECIFICATIONS

JUNCTION BOXES

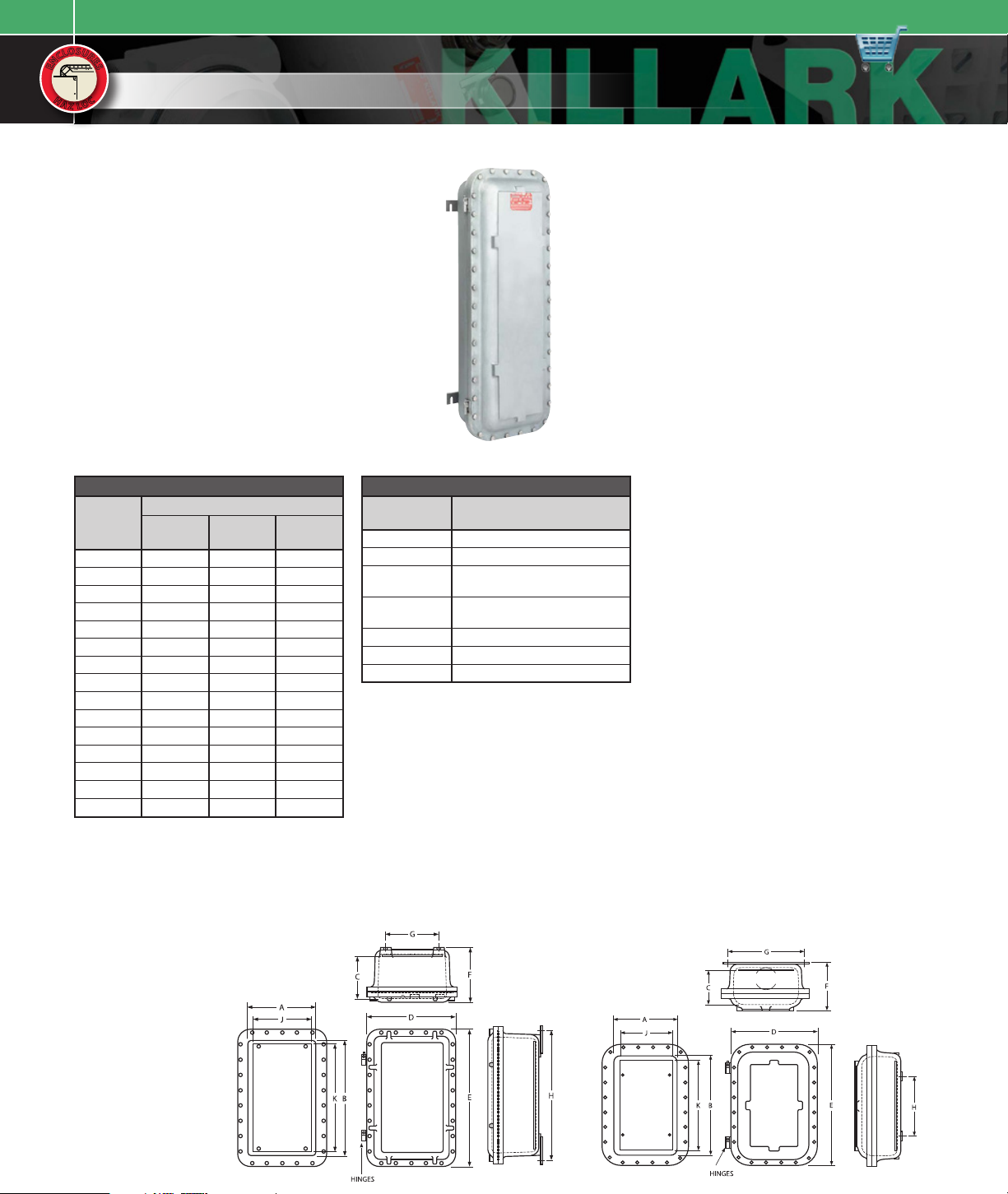

B7E JUNCTION BOXES AND ENCLOSURES

CATALOG

NUMBER

CATALOG

NUMBER

B7EA 19919 5” 11-3/4”

B7EB 199 20 8-1 /4” 16-3/4”

B7EC 18245 6-1/4 ” 13-3 /4”

B7ED 19921 8-3/8” 19-3/8”

B7EE 19923 6-3/8” 20-3/8”

B7EF 18 472 11-5/8” 21-1/4”

B7EG 19924 10” 28”

B7EH 19925 15-3/ 8” 28-3/8”

B7EJ 18279 13-1/2 ” 54”

B7EK 199 26 11” 18”

B7EL 19927 11” 27”

B7EM 199 28 11” 39”

B7EN 19929 11” 47”

B7EPk

B7EQk

— N/A N/A

— N/A N/A

jInternal Mounting Pan Thickness is 1/8” except on

B7EJ it is 3/16” thick.

kB7 COMPACT Series - Details on page E39.

Dimensions

PANj

WIDTH (J)

Figure 1 Figure 2

LENGTH

(K)

(See page E37)

MODIFICATIONS

SUFFIX

NUMBER

KIT-251 100 amp ground lug

KIT-252 225 amp ground lug

SU3B4X

SU94

SU9 Special paint finish

SU14 Fungus proofing of enclosure

SU93 Do not paint enclosure

DESCRIPTION

Drain & breather installed

(GRPs B, C & D T YPE 4X )

“Drill, tap & plug for future”

drain & breather

Loading...

Loading...