Page 1

KILLARK RECEPTACLES

H

H

A

A

Z

Z

ACCEPTOR SERIES

C

C

O

O

L

L

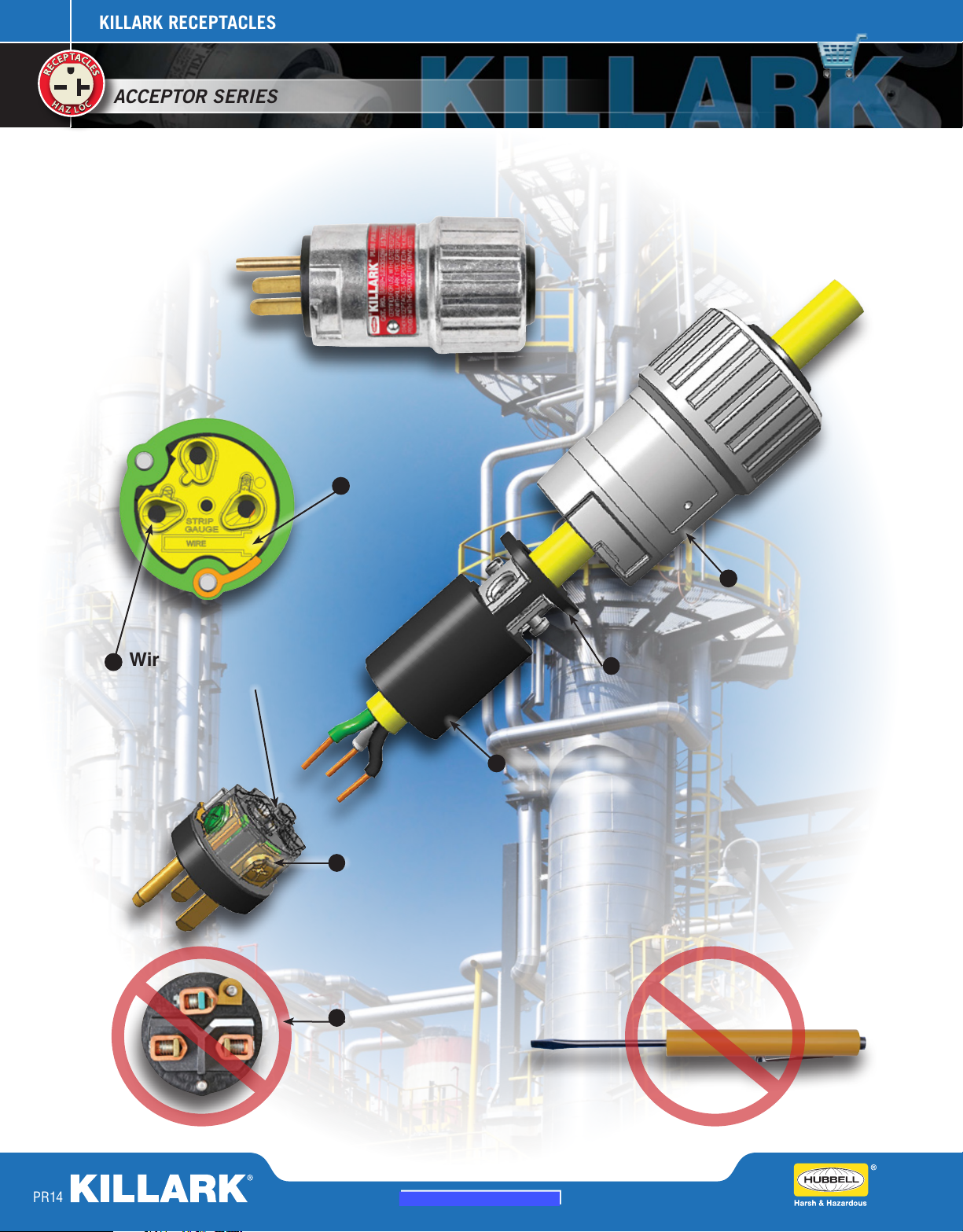

EXCLUSIVE QUICK WIRING PLUG

UGPQW Plug

Wire guides

enables easy

conductor

installation

Built-in wire

strip gauge

Single piece

shell for

fewer parts

Centered

cable grip

Insulator ts

one way only

Side tightening terminals

use full sized #2 screwdriver

(either at or Phillips)

PR14

Old style insulator

requires miniature

screwdriver

Page 2

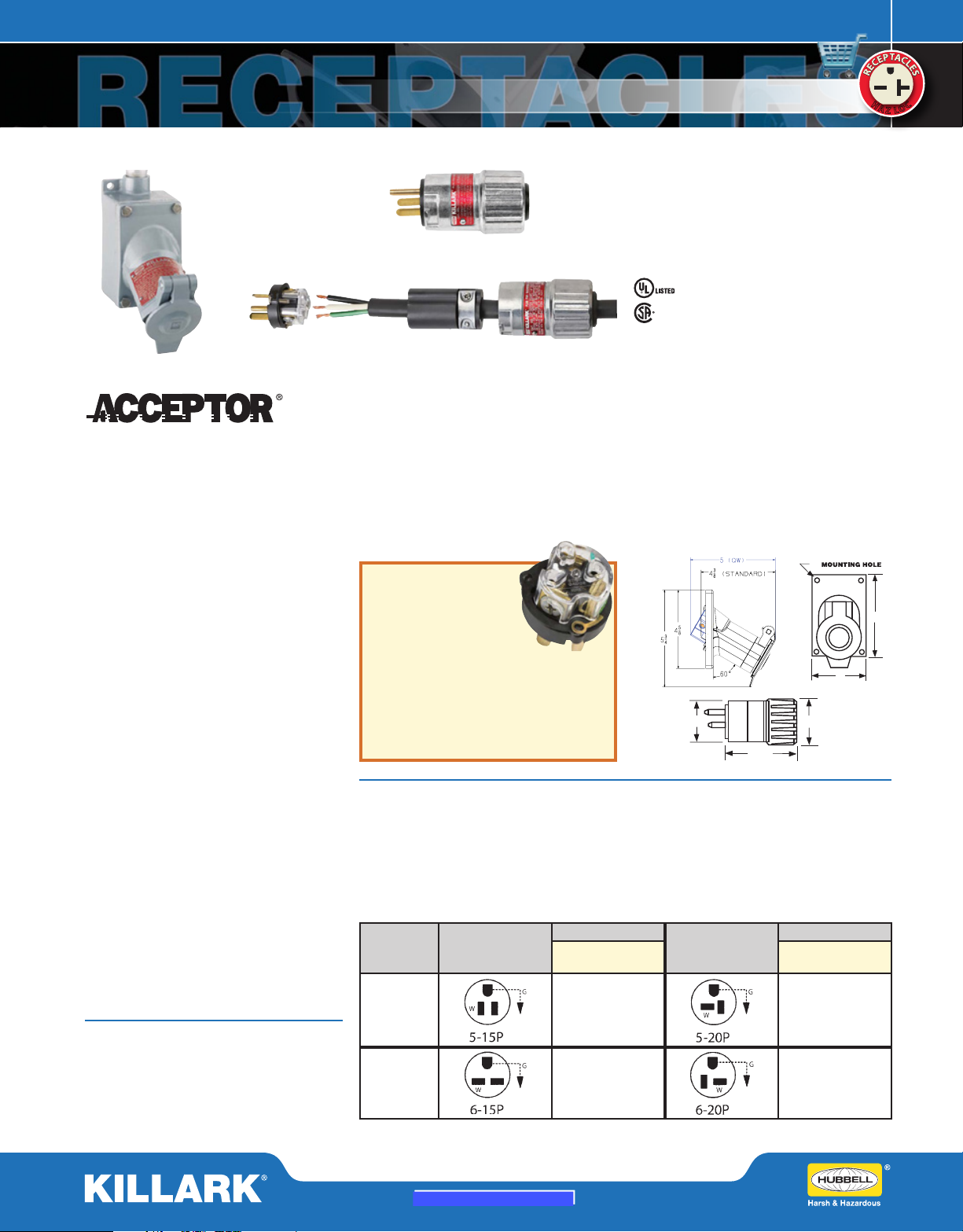

UGR / UGP BLADED RECEPTACLES

1

/4

"

4

5

/8

"

3

"

UGR Receptacle

FEATURES-SPECIFICATIONS

The ACCEPTOR® UGP/UGR Plug and

Receptacle system, with its unique, patented

design, is interchangeable with other

NEMA bladed type explosion-proof and

dust ignition proof devices. The series has

been tested and classified for use with

Crouse-Hinds

U-Line

locations.

versions. See pages PR20-PR21

How The Acceptor System Works

ACCEPTOR receptacles contain an integral

switch which must be closed to energize the

circuit. The design permits only an approved

plug to be energized. To actuate the switch,

the plug must be inserted and rotated

clockwise approximately 45°. The plug will

lock into this position preventing accidental

disengagement. To remove, simply push in

then turn the plug counterclockwise and pull

straight out.

Plugs and receptacles may be used where

interchangeable bladed devices are needed

in locations made hazardous by the presence

of flammable gases or vapors, combustible

dusts or easily ignitable fibers and flyings.

Plug can serve to provide power for portable

equipment used in both hazardous and nonhazardous areas.

Applications

• Petroleum Refineries, Chemical Plants

• Wet/Damp/Corrosive Areas

• Grain Elevators/Feed Mills

®

Ark-Gard®2 and Appleton®

®

plugs and receptacles in hazardous

No w available in GFCI

KILLARK RECEPTACLES

ACCEPTOR® SERIES

Class I, Div. 1 & 2, Groups B, C, D

Class I, Zones 1 & 2, Groups IIB+H2, IIA

UGPQW Plug

Features

• All external hardware is 316 stainless steel

to provide low maintenance and long life

• Factory sealed chamber in UGR receptacle

contains switch’s arcing components

• No additional external seals are required,

except in Group B applications

Quick Wiring Plug

• Single piece shell for

fewer parts

• Transparent wiring

entrance holes for easy

conductor insertion

• Screws tighten from side with “full

sized” screwdriver (slot/Phillips)

• Insulator fits “one way”

• Centered cable grip

PLUG

®

ACCEPTOR

plugs conform to NEMA

configurations and can be used with

standard receptacles in non-hazardous

areas to maximize equipment utilization. The

system’s “turn to engage” feature locks in

VOLTAGE

125VAC UGP -152 31QW UGP-20231QW

NEMA

CONFIGURATION

CATALOG NUMBER

15 AMP PLUG W/QUICK

Class II, Div. 1 & 2, Groups F, G

Class III

NEMA 3, 7 (B, C, D), 9 (F, G)

File No. E91049 and/or E 536 60

Certified File No. LR14667

Wire Size

Suitable for 14 -10 guage SOOW or similar cable

• Receptacles are U.L. Listed as raintight.

Proper sealing against moisture is assured

• Spring loaded receptacle cover closes

when plug is removed to provide

protection when not in use

• Copper-free aluminum (less than 4/10 of

1%) alloy resists corrosion

• Electrostatically applied and baked powder

epoxy/polyester finish

"

1.51

"

2.55

plug and can be used to prevent accidental

disengagement of critical equipment.

Plugs for use with type S, SO, ST or STO

heavy duty cord.

WIRING*

NEMA

CONFIGURATION

20 AMP PLUG W/QUICK

1.69

CATALOG NUMBER

"

WIRING*

H

H

C

C

A

A

O

O

Z

Z

L

L

j Exact models classied for interchangeability are

listed in the information sheet provided with the

products. Ark-Gard® is a registered trademark of

Crouse-Hinds®. U-Line® is a registered trademark of

Appleton Electric Company®.

Plugs Rated Group B when used with properly rated

& installed receptacles. See next page.

250VAC UGP -152 32QW UGP-20232QW

*For Old Style plug remove QW from Catalog Number

PR15

Page 3

KILLARK RECEPTACLES

H

H

A

A

Z

Z

ACCEPTOR® SERIES

C

C

O

O

L

L

One or two

conductors

per phase

EXCLUSIVE QUICK WIRING RECEPTACLE

Side tightening

terminals use

full sized #2

screwdriver (either

at or Phillips)

2nd conductor

set feeds next

receptacle in circuit

Wire Guides enable

easy conductor

insertion

PR16

Old Style Terminals

• Recessed – Difficult to attach conductors

• Conductor must be curled – Full engagement uncertain

• Flat Screwdriver only

• Designed for one conductor – required jumper or “double wiring”

Page 4

KILLARK RECEPTACLES

ACCEPTOR® SERIES

UGR0 QUICK WIRING SELECTION INFORMATION

H

H

C

C

A

A

O

O

Z

Z

L

L

SWB-1, 2, 3

FEATURES-SPECIFICATIONS

NEMA RATING &

CONFIGURATION

20 Amp

125 Volt

2 POLE

3 WIRE

15 Amp

125 Volt

2 POLE

3 WIRE

20 Amp

250 Volt

2 POLE

3 WIRE

15 Amp

250 Volt

2 POLE

3 WIRE

5-20R

5-15 R

6-20R

6-15 R

ENCLOSURE STYLE HUB SIZE

RECEPTACLE ONLY — UGR0-20231QW UGR0-20231QW —

DEAD END

FEED-THRU

RECEPTACLE ONLY — UGR0C-15231QW UGR0C-15231QW —

DEAD END

FEED-THRU

RECEPTACLE ONLY — UGR0-20232QW UGR0-20232QW —

DEAD END

FEED-THRU

RECEPTACLE ONLY — UGR0C-15232QW UGR0C-15232QW —

DEAD END

FEED-THRU

SWB- 4, 5, 6 Single Gang Double Gang

RECEPTACLES AND ASSEMBLIES

SINGLE GANG

GROUPS C, D, F, & G*

1/2” UGR1-20231QW UGR7-20231QW UGRB1-20231QW

3/4” UGR2-20231QW UGR8-20231QW UGRB2-20231QW

1” UGR3-20231QW UGR9-20231QW UGRB3-20231QW

1/2” UGR4-20231QW UGR10-20231QW UGRB4-20231QW

3/4” UGR5-20231QW UGR11-20231QW UGRB5-20231QW

1” UGR6-20231QW UGR12-20231QW UGRB6-20231QW

1/2” UGR1C-15231QW UGR7C-15231QW UGRB1C-15231QW

3/4” UGR2C-15231QW UGR8C-15231QW UGRB2C-15231QW

1” UGR3C-15231QW UGR9C-15231QW UGRB3C-15231QW

1/2” UGR4C-15231QW UGR10C-15231QW UGRB4C-15231QW

3/4” UGR5C-15231QW UGR11C-15231QW UGRB5C-15231QW

1” UGR6C-15231QW UGR12C-15231QW UGRB6C-15231QW

1/2” UGR1-20232QW UGR7-20232QW UGRB1-20232QW

3/4” UGR2-20232QW UGR8-20232QW UGRB2-20232QW

1” UGR3-20232QW UGR9-20232QW UGRB3-20232QW

1/2” UGR4-20232QW UGR10-20232QW UGRB4-20232QW

3/4” UGR5-20232QW UGR11-20232QW UGRB5-20232QW

1” UGR6-20232QW UGR12-20232QW UGRB6-20232QW

1/2” UGR1C-15232QW UGR7C-15232QW UGRB1C-15232QW

3/4” UGR2C-15232QW UGR8C-15232QW UGRB2C-15232QW

1” UGR3C-15232QW UGR9C-15232QW UGRB3C-15232QW

1/2” UGR4C-15232QW UGR10C-15232QW UGRB4C-15232QW

3/4” UGR5C-15232QW UGR11C-15232QW UGRB5C-15232QW

1” UGR6C-15232QW UGR12C-15232QW UGRB6C-15232QW

DOUBLE GANG

GROUPS C D, F, & G*

SINGLE GANG

GROUPS B, C, D, F & G*

j Items in this column are suitable for Class I, Group B in addition to Class I, Groups C, D. Also suitable for Class I, Zone 1, Groups IIB+H2, IIA.

k Seals must be installed within 6 inches of conduit opening.

Items in this column may also be used in Class I, Zone 1, Groups IIB, IIA. Assembly numbers not rated for Group B are shipped as receptacle & back box components.

m Refer to Killark full-line catalog Section C for additional SWB Series Back Box congurations.

n Canada only conguration

oCanadian Codes now allow “T” combination slots for 15A or 20A plugs. Check breaker and wire feed size for proper application ratings.

NOTE: For replacement receptacle cover and hinge, order KIT-173. For dimension see PR15.

* For Old Style plug remove QW from Catalog Number

PR17

Page 5

KILLARK RECEPTACLES

H

H

A

A

Z

Z

ACCEPTOR® SERIES

C

C

O

O

L

L

Connector with Breech-Lock Cap

UGRC CONNECTORS

“3rd Hand” Plug Operation

Class I, Div. 1 & 2, Groups B, C, D

Class I, Zones 1 & 2, Groups IIB+H

Class II, Div. 1 & 2, Groups F, G

, IIA

2

Class III

NEMA 3, 4X*

Certified File No. LR14667

Certified File No. LR14667

Wire Size

Suitable for 14 -10 guage SOOW or similar cable

FEATURES-SPECIFICATIONS

CONNECTORS

The ACCEPTOR® UGRC Connector

complements UGP/UGR Plugs and

Receptacles, as well as Ground Fault

Protected UGFI and UGRGF Models.

Used with Acceptor plugs, connectors can

extend the reach for hazardous location

rated portable equipment such as hand

lamps. Connectors eliminate the need

for user-created corded box mounted

receptacles. UGRC Connectors are

interchangeable and classified for use with

other NEMA bladed type explosion-proof and

dust ignition proof plugs, including Crouse-

®

Hinds

Ark-Gard®2 and Appleton® ULine®.

Features

• Available with the exclusive Breech-Lock

Cap (see PR5 for more info) – patented

notch provides “3rd hand” plug operation

(holds lid open while one hand operates

plug, and other holds connector).

• Factory Sealed Construction

• Copper-free aluminum (less than 4/10 of

1%) alloy resists corrosion

• Electrostatically applied and baked

powder epoxy/polyester finish

• Dead Front Construction with integral

switch – requires Hazardous Rated

NEMA Bladed plug for operation

Ark-Gard® is a registered trademark of Crouse-Hinds®

U-Line® is a registered trademark of Appleton Electric

Company®

Industrial Applications

• Petroleum Refineries

• Chemical/Petrochemical Plants

• Oil Rigs & Platforms

• Wet/Corrosive Environments

• Grain Elevators

Dimensions

3.69

Breech cap model shown, Flip cap model

NEMA CONFIGURATION 125V CONNECTOR CAP STYLE CATALOG NUMBER*** WEATHER RATING

20 Amp

125 Volt

2 POLE

3 WIRE

5-20R with T-slots

20 Amp

250 Volt

2 POLE

3 WIRE

6-20R with T-slots

* Breech cap models N4X with lid closed and turned, N3 When Plug inserted Hinge Up (see page PR3)

** Flip Lid models N3 with hinge in UP position with or without plug

Replacement Cap and Hinge Kits: Breech KIT-173B, Flip KIT-173

CSA certi ed Class I Div.I for Canada and/or other jurisdictions accepting CSA.

CCSAUS Class II, Groups F & G for US and Canada.

Remove QW in catalog number for Standard Wiring type plug.

125V 15A only (no T-slot) receptacles are available. See 5 -15R Canadian conguration page PR17.

Order numbers UGRC-15231B or UGRC-15231F.

*** For O ld Style plug remove QW from Catalog Number

dimensions are similar

8.25

UGRC Connector

UGP Plug

Breech-Lock with Notch

250V CONNECTOR CAP STYLE

Breech-Lock with Notch

2.88

Flip Type

Killark 125V Plugs

20 Amp

15 Amp

Flip Type

Killark 250V Plugs

20 Amp

15 Amp

Connector shown with Acceptor UGRP

receptacle mounted in explosion proof

Quantum

UGRC-20231BQW

UGRC-20231FQW

UGP-20231QW

UGP -152 31QW

UGRC-20232BQW

UGRC-20232FQW

UGP-20232QW

UGP -152 32QW

®

enclosure

Flip Cap

N4X*

N3**

N4X*

N3**

PR18

Page 6

UGRP PANEL RECEPTACLES

KILLARK RECEPTACLES

ACCEPTOR® SERIES

Class I, Div. 1 & 2, Groups B, C, D

Class I, Zones 1 & 2, Groups IIB+H2, IIA

Class II, Div. 1 & 2, Groups F, G

Class III

NEMA 3, 4X*

Certified File No. LR14667

Wire Size

Suitable for 14 -10 guage SOOW or similar cable

H

H

C

C

A

A

O

O

Z

Z

L

L

Flip Cap

FEATURES-SPECIFICATIONS

PANEL RECEPTACLES

The ACCEPTOR

®

UGRP Panel Receptacle

complements UGP/UGR Plugs and

Receptacles, as well as Ground Fault

Protected UGFI and UGRGF Models.

Used with Acceptor plugs, panel receptacles

provide local power for hazardous location

rated portable equipment such as hand

lamps. Units are suitable for Class I Div. 1

or Class I Div.2 depending on the enclosure

type used.

UGRP Panel Receptacles are interchangeable

and classified for use with other NEMA

bladed type explosion-proof and dust

ignition proof plugs, including Crouse-

®

Hinds

Ark-Gard®2 and Appleton® ULine®.

Features

• Available with the exclusive Breech-Lock

Cap (see PR5 for more info) – patented

notch provides “3rd hand” plug operation

(holds lid open while one hand operates

plug, and other holds connector).

• Factory Sealed Construction

• Copper-free aluminum (less than 4/10 of

1%) alloy resists corrosion

• Electrostatically applied and baked powder

epoxy/polyester finish

• Dead Front Construction with integral

switch – requires Hazardous Rated

NEMA Bladed plug for operation

Ark-Gard® is a registered trademark of Crouse-Hinds®

U-Line® is a registered trademark of Appleton Electric

Company®

Industrial Applications

• Petroleum Refineries

• Chemical/Petrochemical Plants

• Oil Rigs & Platforms

• Wet/Corrosive Environments

• Grain Elevators

Typical InstallationBreech Cap Model

• UGRP Receptacles are available

“Factory Installed” in the following series:

Enclosures

» Series EXB, B7E

Distribution Equipment

» Series D2L, B7L Lighting Panelboards

• Contact factory for ordering information

Typical CLI Div. I

application

Typical CLI Div. 2

application

2-3/8” K.O.

Dimensions

Breech Lid

NEMA CONFIGURATION 125V PANEL RECEPTACLE CAP ST YLE CATALOG NUMBER**** WEATHER RATING

20 Amp

125 Volt

2 POLE

3 WIRE

5-20R with T-slots

250V PANEL RECEPTACLE CAP STYLE

20 Amp

250 Volt

2 POLE

3 WIRE

6-20R with T-slots

* Breech cap models N4X with lid closed and turned, N3 When Plug inserted Hinge Up

** Flip Lid models N3 with hinge in UP position with or without plug

*** See PR17 for Plug NEMA Diagram and Dimensions

Replacement Cap and Hinge Kits: Breech KIT-173B, Flip KIT-173

jClass I Div.1 B,C,D in enclosures certi ed to 325 explosive PSI (2”-11½ NPSM threads). Class I Div. 2 in standard

location enclosures using only non-arcing components.

CSAUS Certi ed for United States, Canada, and other jurisdictions accepting the mark.

k

C

lRemove QW in catalog number for Standard Wiring type plug.

125V 15A only (no T-slot) receptacles are available. See 5 -15R Canadian conguration page PR17.

Order numbers UGRP-15231B or UGRP-15231F.

**** For Old Style plug remove QW from Catalog Number

Flip Cap

Breech-Lock with Notch

Flip Type

Killark 125V Plugs

20 Amp

15 Amp

Breech-Lock with Notch

Flip Type

Killark 250V Plugs***

20 Amp

15 Amp

Breech Cap model shown.

Flip Cap model dimensions are similar

UGRP-20231BQW

UGRP-20231FQW

UGP-20231QW

UGP -152 31QW

UGRP-20232BQW

UGRP-20232FQW

UGP-20232QW

UGP -152 32QW

N4X*

N3**

N4X*

N3**

PR19

Page 7

KILLARK RECEPTACLES

H

H

A

A

Z

Z

ACCEPTOR® SERIES

C

C

O

O

L

L

UGRS / UGRGF RECEPTACLES

Class I, Div. 2, Groups B, C, D

Class I, Zone 2, Groups IIB+H2, IIA

Class II, Div. 1 & 2, Groups F, G

Class III

NEMA 3, 4X

Certified File No. LR14667

Flip Cap

Breech Cap Model

FEATURES-SPECIFICATIONS

Dimensions

SQUARE RECEPTACLE

UGRS Receptacles utilize VERSAMATE

®

30A

mounting boxes and are designed to provide

“ROTATABLE” design enables cover hinge

location to be in most convenient position

for application. May also be utilized with

sheet metal enclosures which contain no

arcing devices.

NEMA CONFIGURATION 125V SQUARE RECEPTACLE CAP STYLE CATALOG NUMBER

20 Amp

125 Volt

2 POLE

3 WIRE

5-20R with T-slots

20 Amp

250 Volt

2 POLE

3 WIRE

6-20R with T-slots

* Breech cap models N4X with lid closed and turned, N3 When Plug inserted Hinge Up

** Flip Lid models N3 with hinge in UP position with or without plug

*** See PR15 for Plug NEMA Diagram and Dimensions

C D ReceptacleE

Breech-Lock with Notch*

Flip Lid Type**

Killark 125V Plugs***

20 Amp

15 Amp

250V SQUARE RECEPTACLE CAP STYLE

Breech-Lock with Notch*

Flip Lid Type**

Killark 250V Plugs***

20 Amp

15 Amp

Breech Cap model shown.

Flip Cap model dimensions are similar

UGRS-20231BQW

UGRS-20231FQW

UGP-20231QW

UGP -152 31QW

UGRS-20232BQW

UGRS-20232FQW

UGP-20232QW

UGP -152 32QW

UGRS RECEPTACLE & BACKBOXES

E TYPE DEAD END

20A 125V UGRS-20231BE2QW UGRS-20231BC2QW UGRS-20231BD2QW UGRS-20231BQW

20A 250V UGRS-20232BE3 QW UGRS-20232BC3 QW UGRS-20232BD3QW UGRS-20232BQW

Receptacles listed are with Breech cap; for Flip Cover change B to F.

Boxes listed are for 3/4”; for 1/2” change last digit to 1, for 1” change last digit to 3 .

CCSAUS Certi ed for United States, Canada, and other jurisdictions accepting the mark.

125V 15A only (no T-slot) receptacles are available. See 5 -15R Canadian conguration page PR17.

Order numbers UGRS-15231BQW or UGRS-15231FQW.

*** For O ld Style plug remove QW from Catalog Number

C TYPE FEED THRU

D TYPE ANGLED FEED THRU

RECEPTACLE ONLY

UGRGF

Class I, Div. 1 & 2, Groups C, D

Class l, Zones 1 & 2, Groups llB, llA

Class lI, Div. 1 & 2, Groups F, G

Class III

NEMA 3, 7 (C, D) 9 (F, G)

Certified LR11714

See files for details or call Killark.

GFI PROTECTED RECEPTACLE

Utilizes FXS GFI and ACCEPTOR® receptacle

to interrupt a circuit, when a ground fault

is detected on equipment which may be

handled by personnel in hazardous locations.

Features

• Factory Sealed

• Test and Reset push buttons are provided

on cover assembly, with optional pilot light

available Unit should be tested monthly

• Includes new GFCI to meet latest UL943

GFCI standards revisions

• Exterior gasket provides NEMA 3

weatherproof protection

• Ground boss for grounding in the splice box

• Color coded wiring and stainless steel

cover bolts

• Receptacle used is UGRO-20231. See

page PR17

NEMA RATING &

CONFIGURATION

20A, 125V, 2P,

3W

ENCLOSURE

STYLE

Dead End 1/2” UGRGF107

Dead End 3/4” UGRGF108

Dead End 1” UGRGF109

Feed Thru 1/2” UGRGF110

Feed Thru 3/4” UGRGF111

Feed Thru 1” UGRGF112

HUB

SIZE

CATALOG

NUMBER

Electrical Rating

GFI units are rated at 20A, 120 VAC,

60Hz. Class A.

4-6 miliamp trip setting

Trip Time-UL Curve

mFor Red LED pilot light indicator of live circuit, add

“-PL” to catalog number. Example – UGRGF107-PL.

PR20

Page 8

UGFI GROUND FAULT PROTECTOR

• Adapter Unit

Class I, Div. 2, Groups B, C, D

Class I, Zone 2, Groups IIB+H2, IIA

Class II, Div. 1 & 2, Groups F, G

Class III, Div. 1 & 2

• Hard-Wired Unit

Class I, Div. 1 & 2, Groups B, C, D

Class I, Zones 1 & 2, Groups IIB+ H2, IIA

Class II, Div. 1 & 2, Groups F, G

File No. E91049

Certified File No. LR14667

Class III, Div. 1 & 2

NEMA 3 ENCLOSURE T YPE

(Adapter or Hard-Wired units)

KILLARK RECEPTACLES

ACCEPTOR® SERIES

H

H

C

C

A

A

O

O

Z

Z

L

L

Adapter Unit

The GFCI protected ACCEPTOR® is the

solution to OSHA’s requirements for GFCI

protection when using portable equipment

in hazardous and wet locations. For use

with 125V, or 125/250V 15 or 20 amp

receptacles without GFCI protection, the

Adapter Unit provides GFCI and circuit

protection to connected apparatus by simply

being plugged into an existing receptacle.

The Hard-Wired Unit provides the same

protection and is used directly as a GFCI

protected device. Units are feed-through

with one close-up plug.

Typical Application with

XHL Series Hand Lamp

FEATURES-SPECIFICATIONS

Adapter Unit

• No need to permanently alter existing

installations; Portable Unit can be

temporarily hung using included strap

near an existing receptacle wherever

protection is required

• Factory Sealed Unit

• Acceptor® plug and cord set included with

Adapter Unit. Cord is 36”

Hard-Wired Unit

• provides GFCI and circuit protection in

new installations, or as an upgrade or

replacement for non-GFCI receptacles

• Factory Sealed, except Group B

Adapter and Hard-Wired Unit

• GFCI device also provides circuit

protection, for connected apparatus,

against current overload and short circuits

• Acceptor® receptacles and plugs are

intermateable with both Crouse-Hinds

®

Gard

2 and Appleton® U-Line® products

®

Ark-

• Amber pilot light provides indication that

the receptacle is energized.

• Units can be Padlocked OFF for

maintained safety

• Fully gasketed GFCI compartment

prevents moisture from damaging

electronic components

• Same high quality materials as the

standard ACCEPTOR

j Hard-Wired assemblies in Group B areas require

sealing within 6” of enclosure.

k125VAC & 250 VAC devices are CCSAUS certied;

125VAC devices are also UL Listed.

l 2P 250V units are for 2 “hot line” applications and

include 2P 5mA GFI breakers. 2P Units are for

120/240V or 120/208Y Grounded Power Supply

Systems ONLY. Do NOT use with Delta supply

systems.

Ark-Gard® is a registered trademark of Crouse-Hinds®

U-Line® is a registered trademark of Appleton Electric

Compa ny®.

®

GFCI RECEPTACLE ADAPTER (W/CORD SET)

20A

125V

15A

125V

20A

250V

15A

250V

UGFI20AD

5-20R

UGFI15AD

5-15R

UGFI202AD

6-20R

UGFI152AD

6-15R

HARD WIRED (PERMANENTLY MOUNTED)

GFCI RECEPTACLE

20A

125V

15A

125V

20A

250V

15A

250V

5-20R

5-15R

6-20R

6-15R

1/2” HUB

3/4” HUB

1” HUB

1/2” HUB

3/4” HUB

1” HUB

1/2” HUB

3/4” HUB

1” HUB

1/2” HUB

3/4” HUB

1” HUB

UGFI20C1

UGFI20C2

UGFI20C3

UGFI15C1

UGFI15C2

UGFI15C3

UGFI202C1

UGFI202C2

UGFI202C3

UGFI152C1

UGFI152C 2

UGFI152C 3

Hard-Wired Unit

PR21

Loading...

Loading...