KILLARK MCX Series Installation, Operation & Maintenance Manual

HUBBELL ELECTRICAL PRODUCTS

A Division of HUBBELL INCORPORATED

CAUTION:

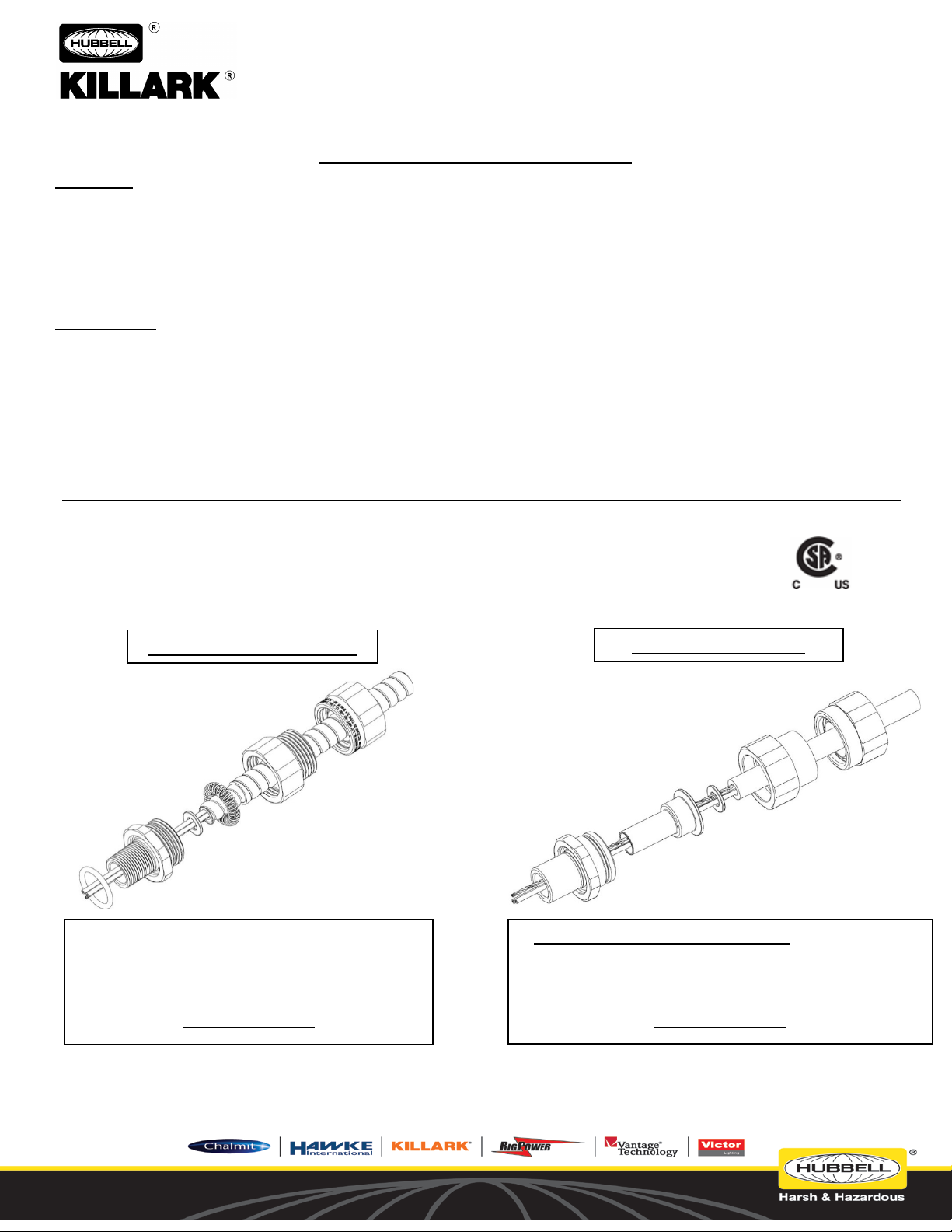

Armored Cable Assembly

Tray Cable Assembly

REMOVE GROUNDING SPRING TO USE WITH

USE FOR TYPE MC, MC-HL, TECK90,

(Delaware)

3940 Martin Luther Kind Drive

St. Louis, Missouri 63113 USA

For use in Zone Classified Hazardous Locations

INSTALLA T ION, OPERATION &

MAINTENANCE D ATA SH E ET

MCX CABLE GLANDS

MCX SERIES CABLE GLANDS

Before installing, make sure you are compliant with area classifications, as failure to do so may result in bodily injury, death and property damage. Do not

attempt installation until you are familiar with the following procedures. All installati on must comply with the applic abl e Electrical Code(s).

Make sure that the circuit is de-energized before starting installation or maintenance.

Verify that the installation is grounded. Failure to ground will create electrical shock hazards, which can cause serious injury and or death.

IMPORTANT:

Please read these instructions carefully before installing or maintaining this equipment. Good electrical practices should be followed at all times and this

data should be used as a guide only.

Technical information, advice and recommendations contained in these documents is based upon information that Killark believes to be reliable. All the

information and advice contained in these documents is intended for use only by persons having been trained and possessing the requisite skill and knowhow and to be used by such persons only at their own discretion and risk. The nature of these instructions is informative only and does not cover all of the

details, variations or combinations in which this equipment may be used, its storage, delivery, installation, check out, safe operation and maintenance.

Since conditions of use of the product are outside of the care, custody and control of Killark, the purchaser should determine the suitability of the product

for his intended use, and assumes all risk and liability whatsoever in connection therewith.

Class I, Division 1, Group s A, B, C, D

Class II, Division 1, Gro u ps E, F, &G; Class III.

Type 3, 4, and 4X, IP66, Operating Temperature Range -50°C +60°C

TECK90-HL, RA90, RA90-HL, AC90, AC90-

HL, ACWU90, & ACWU90-HL CABLE.

SEE PAGES: 2-3

P/N KIL 00921499 FORM NO, K1499 MCX Series Cable Glands Page 1 of 7

TYPE TC-ER-HL, TC, TC-ER, PLTC, PLTC-ER,

ITC, ITC-ER, MV & MARINE SHIPBOARD CABLE.

SEE PAGES: 4-7

HUBBELL ELECTRICAL PRODUCTS

A Division of HUBBELL INCORPORATED

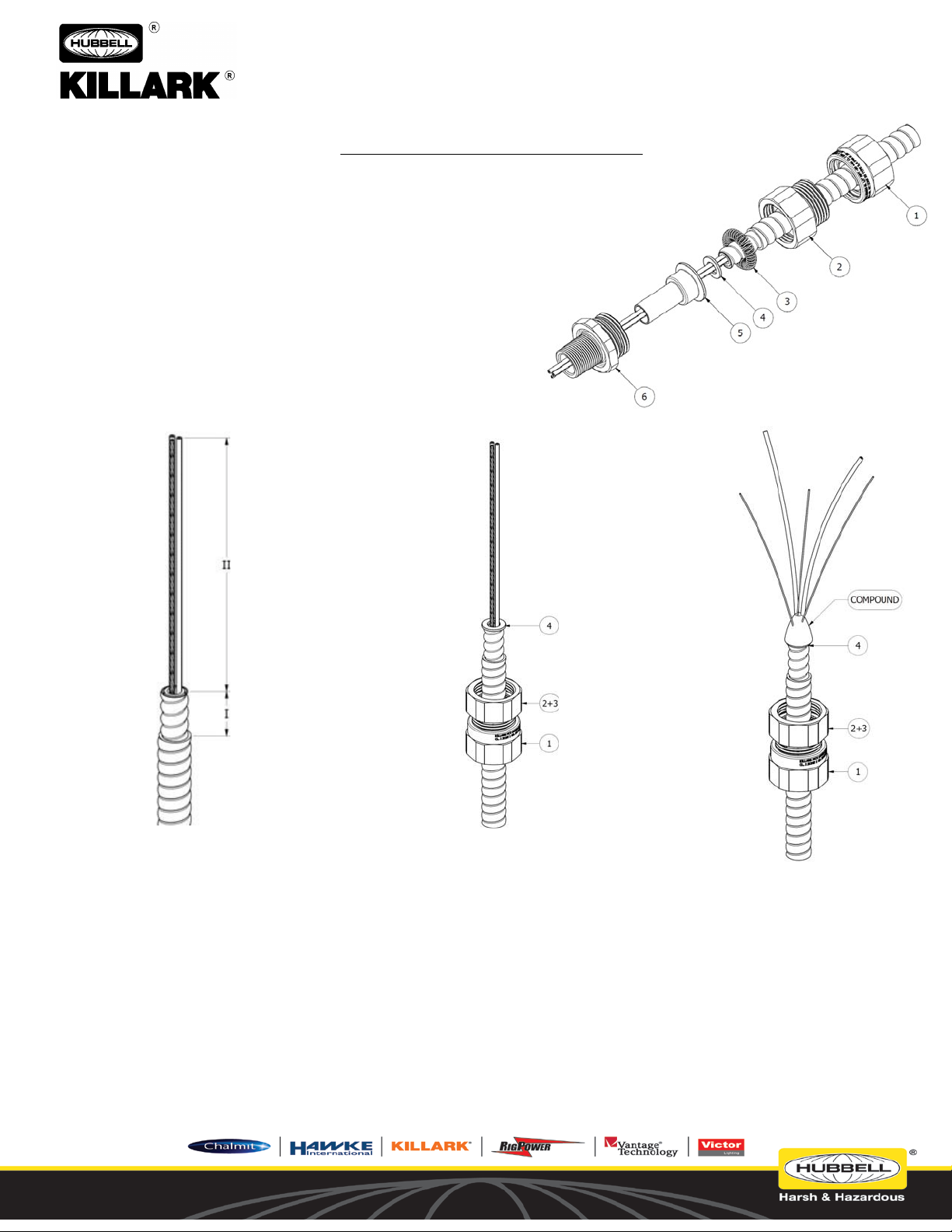

Back Nut

Armored Cable Assembly

Cable Preparation

Cable Gland Preparation

Potted Wire Preparation

(Delaware)

3940 Martin Luther Kind Drive

St. Louis, Missouri 63113 USA

For use in Zone Classified Hazardous Locations

INSTALLA T ION, OPERATION &

MAINTENANCE D ATA SH E ET

1.

2.

Middle Nut

3.

Grounding Spring (Captive in the Middle Nut)

4.

Armor Stop

5.

Potting Chamber

6.

Entry Component

MCX CABLE GLANDS

A)

Strip cable to suit equipment as shown

above, exposing metal armor sheath (I)

and insulated cores (II).

I = 3/4" (19mm) for ½” size glands

I = 13/16" (21mm) for ¾” size glands

I = 1" (25mm) for 1” size glands

I = 1-1/4" (32mm) for 1 ¼” size glands

I = 2-3/8” (60 mm) for 1 ½” size glands

I = 2-5/8” (66mm) for 2” size glands

I = 2-13/16” (71 mm) for 2 ½” size glands

I = 3” (76 mm) for 3” size glands

I = 2-3/4” (70 mm) for 3 ½” size glands

I = 3-1/8” (79 mm) for 4” size glands

II to suit equipment

P/N KIL 00921499 FORM NO, K1499 MCX Series Cable Glands Page 2 of 7

B)

Push the cable through the back

nut (1), middle nut (2), and

grounding spring (3). Locate the

armor stop (4) at the end of the

armor as shown above. If the

conductors are too large to f it

through the armor stop (4) it can be

removed from the assembly. The

entry component (6) has a built in

armor stop for larger cables.

C)

Spread out the cable cores

and the individual strands of

un-insulated conductors for

the packing of the compound.

Pack the compound between

the cores and strands as

shown above. See Page 3 for

compound preparation details.

HUBBELL ELECTRICAL PRODUCTS

A Division of HUBBELL INCORPORATED

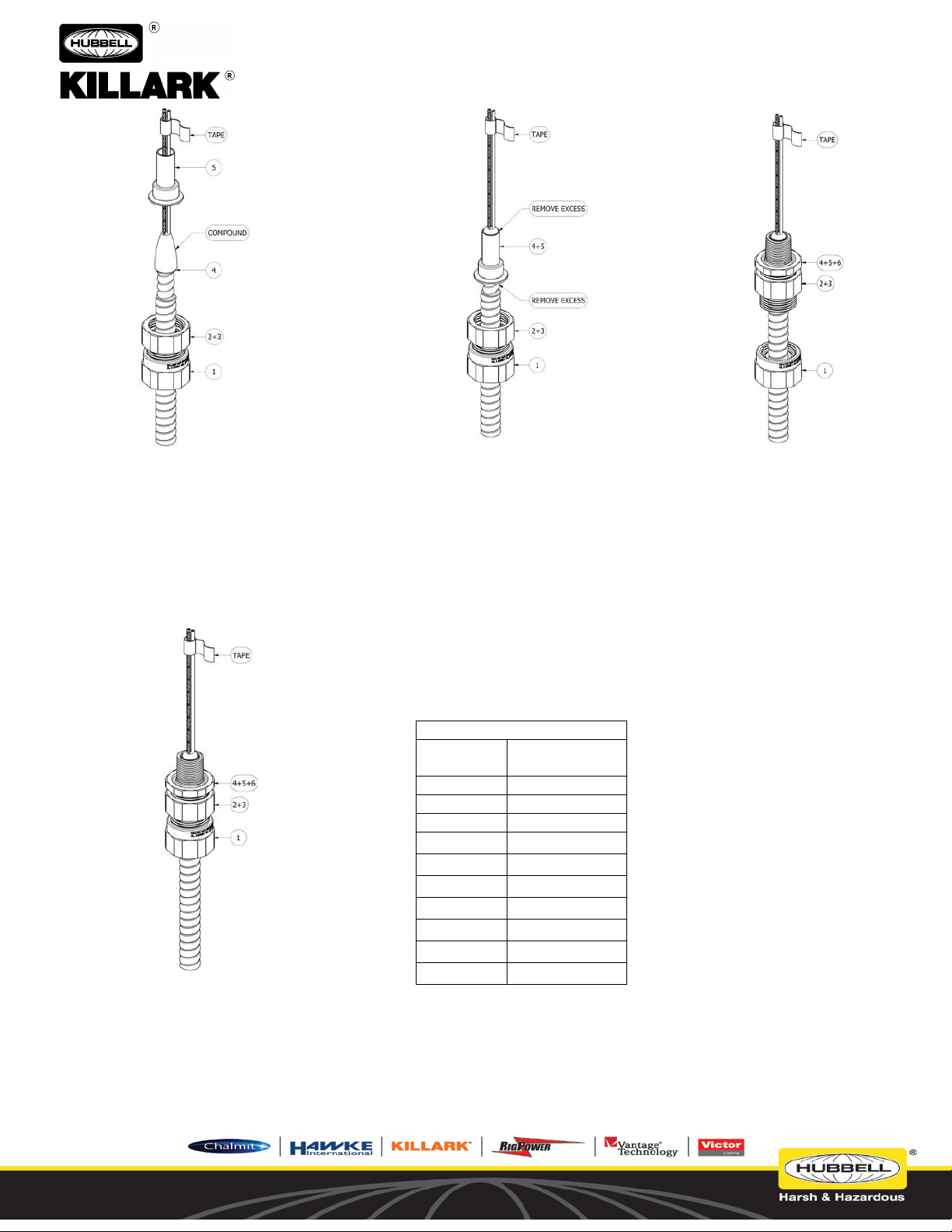

Table A

Assembly

Torque (l bf-ft)

½”

20

¾”

20

1”

30

1 ¼”

40

1 ½”

136

2”

136

2 ½”

158

3”

181

3 ½”

181

4”

181

the circuit.

(Delaware)

3940 Martin Luther Kind Drive

St. Louis, Missouri 63113 USA

INSTALLA T ION, OPERATION &

MAINTENANCE D ATA SH E ET

For use in Zone Classified Hazardous Locations

MCX CABLE GLANDS

D)

With all gaps and voids filled, bring the

conductors back together and pack more

compound around the outside of the

conductors. Tape the conductors together to

prevent disturbance of the compound. Press

the potting chamber (5) over compound until

it hits the armor stop (4) or the end of the

armor. Do not twist the potting

chamber (5) while pressing it over the

compound. Twisting may create voids in

the seal.

G)

Thread the back nut (1) onto the middle nut

(2) to the torque show in Table A

(Approximately hand tight +1 turn). This

will compress the seal inside the back nut

(1) to grip the jacket of the cable for

mechanical retention and the formation of

an environmental seal. Allow the

compound to fully cure before energizing

E)

Ensure that the entire potting

chamber

(5) is filled with compound then

remove any excess compound from

the potting chamber (5). Ensure that

all of the compound is removed from

the tapered surface of the potting

chamber (5) that contacts the

grounding spring. (3) Failing to

remove compound from this surface

will interfere with the compression of

the spring and may impede the

grounding path of the gland.

Gland Size

F)

IMPORTANT NOTE:

THE CONDUCTORS MUST

NOT BE MOVED FOR A

MINIMUM OF FOUR HOURS.

TAKE CARE DURING STEPS F

AND G TO ENSURE THAT THE

CONDUCTORS DO NOT MOVE.

If the gland is to be installed in a

threaded opening first thread the

entry component (6) into the

enclosure to prevent twisting of

the cable. When installing the

entry component (6) into a NPT

entry the component should be

installed hand tight and then one

additional turn with a wrench.

If the entry component (6) is

installed with a locknut it should

tighten to the torque shown in

Table A. (Approximately hand

tight +1 turn)

Slide the potting chamber (5) into

the entry component (6). Take

care to prevent compound from

adhering to the inside of the entry

component (5).

Thread the middle nut (2) onto the

entry component (6) to the torque

show in Table A (Approximately

hand tight +1 turn). This will

compress the grounding spring (3)

to grip the armor for grounding.

P/N KIL 00921499 FORM NO, K1499 MCX Series Cable Glands Page 3 of 7

Loading...

Loading...