KILLARK KF1L SERIES Installation Operation & Maintenance

Page 1 of 8

3940 Dr. Martin Luther King Drive

St. Louis, MO 63113

P/N KIL00921415 FORM NO. K1415 7/13 ERO-6-019-13_2

INSTALLATION, OPERATION &

MAINTENANCE DATA SHEET

FOR

KF1L SERIES LED LUMINAIRE FLOOD

CLASS I DIVISION 1, CLASS II DIVISION 1, OR CLASS I

ZONE 1 HAZARDOUS LOCATIONS.

KF1L SERIES LED LUMINAIRE FLOOD

CAUTION:

Before installing, make sure you are compliant with area classications, failure to do so may result in bodily

injury, death and property damage. Do not attempt installation until you are familiar with the following

procedures. All installation must comply with the applicable Electrical Code.

Make sure that the circuit is de-energized before starting installation or maintenance.

Verify that the installation is grounded. Failure to ground will create electrical shock hazards, which can cause

serious injury and or death.

Note: Due to the surge protection provided in the xture to protect the internal electronics and LEDs, a branch

circuit with the LED xture may false fail a megohmmeter test (sometimes referred to as a megger test. If a

megohmmeter test is required, the LED xture should be removed from the branch circuit.

Note: Multiple uorescent or LED xtures attached to a single Ground Fault Circuit Interrupter (GFCI) may

cause nuisance tripping of the GFCI. Regulatory agencies allow a small amount of leakage current because

of the circuitry required to mitigate possible issues with electromagnetic compatibility (reference UL8750 and

EN61347). The summation of these leakage currents from multiple xtures may be enough to trip a GFCI.

IMPORTANT:

Please read these instructions carefully before installing or maintaining this equipment. Good electrical

practices should be followed at all times and this data should be used as a guide only.

Technical information, advice and recommendations contained in these documents is based upon information

that Killark believes to be reliable. All the information and advice contained in these documents is intended

for use only by persons having been trained and possessing the requisite skill and know-how and to be used

by such persons only at their own discretion and risk. The nature of these instructions is informative only and

does not cover all of the details, variations or combinations in which this equipment may be used, its storage,

delivery, installation, check out, safe operation and maintenance. Since conditions of use of the product are

outside of the care, custody and control of Killark, the purchaser should determine the suitability of the product

for his intended use, and assumes all risk and liability whatsoever in connection therewith.

Page 2 of 8

3940 Dr. Martin Luther King Drive

St. Louis, MO 63113

P/N KIL00921415 FORM NO. K1415 7/13 ERO-6-019-13_2

Luminaires are designed to be installed in Class

I Division 1, Class II Division 1, or Class I Zone 1

Hazardous locations.

Verify that luminaire is grounded. Failure to ground

will create electrical shock hazards, which can cause

serious injury and or death.

NOTE - For Class I, Division 1 / Class II, Division

1 / Class I, Zone 1 Hazardous Locations, use rigid

conduit or cable and connectors / glands rated for

Class I, Division 1 Groups BCD (or Zone I IIB + H2)

hazardous areas.

The KF1L is factory-sealed and does not require a

sealed entry.

INSTALLATION INSTRUCTIONS

FLOOD LIGHT WITH YOKE MOUNT

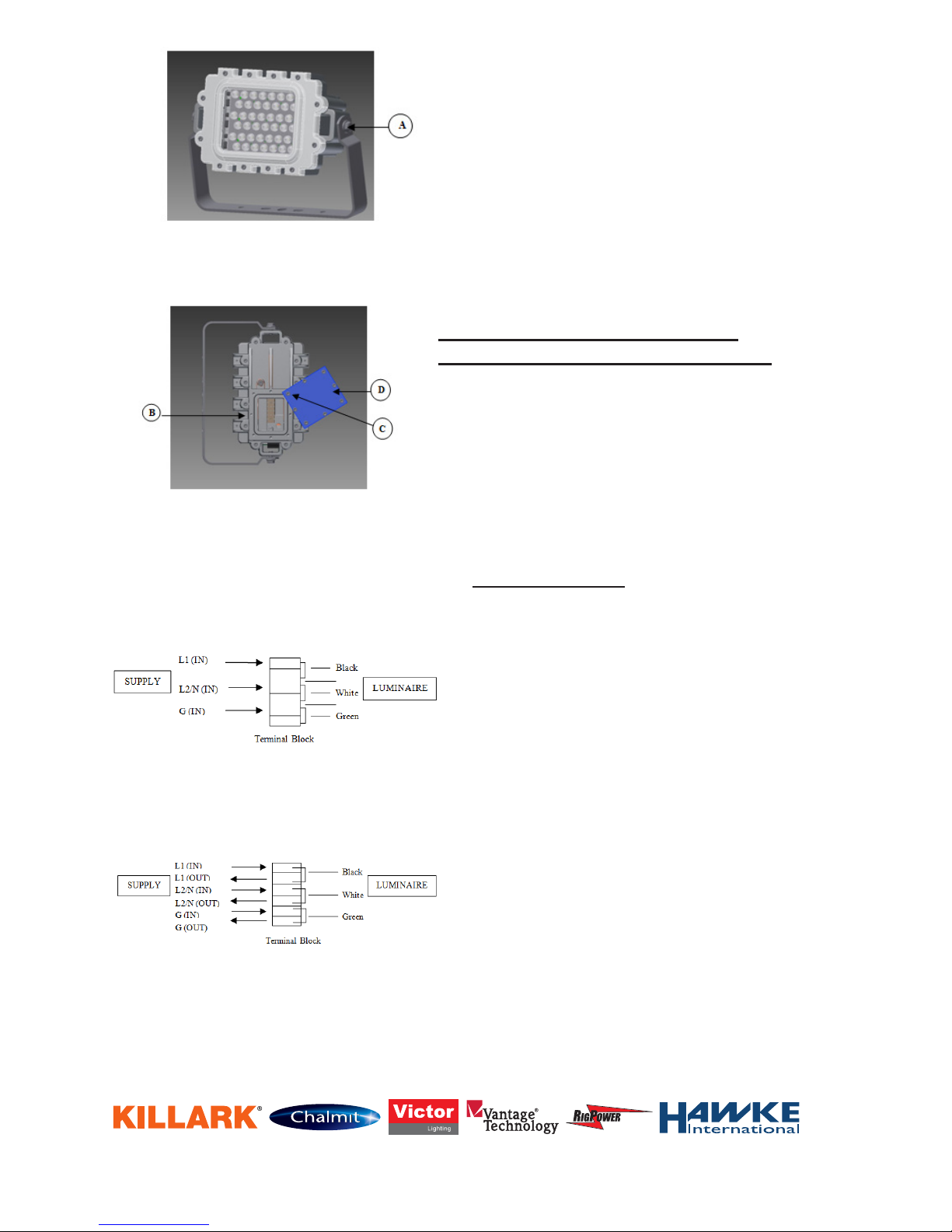

(See Figure 1)

1. For convenience, install the yoke bracket on

the trunnion (swivel point) before mounting the

structure.

2. Loosen bolts (A) - aim the oodlight to the

desired spot.

3. Tighten both bolts (A) securely.

4. Fasten the yoke bracket to the mounting location

using ½” bolts/fasteners.

IMPORTANT NOTE

Turn off electricity to circuit at main fuse or at

circuit breaker.

5. Run supply wire to xture through applicable hub

(B) on the side of the xture. Make watertight

joint using sealing ttings at threaded hub on

the side of the xture. The hub is threaded

¾”-14NPT (North American version) or M20

(International version).

6. Loosen and remove all but one of the access

door captive screws (C). Rotate access door (D)

to allow for access into terminal chamber. See

Figure 2 for more details.

7. CAUTION - Connection as described below

requires the use of a factory installed terminal

block assembly. See diagrams on left.

8. Replace access door (D) and access door

captive screws (C). Securely tighten screws (C).

See Figure 2 for more details.

9. Turn ON electricity to verify xture is operating

properly.

Figure 1

KF1L Series Typical Assembly

Figure 2

KF1L Series Factory Installed Terminal Block

Connection Method

(Insulated Terminal Block Assembly)

Loop In / Loop Out Wiring Method

Connection Method

(Insulated Terminal Block Assembly)

Standard Wiring Method

Page 3 of 8

3940 Dr. Martin Luther King Drive

St. Louis, MO 63113

P/N KIL00921415 FORM NO. K1415 7/13 ERO-6-019-13_2

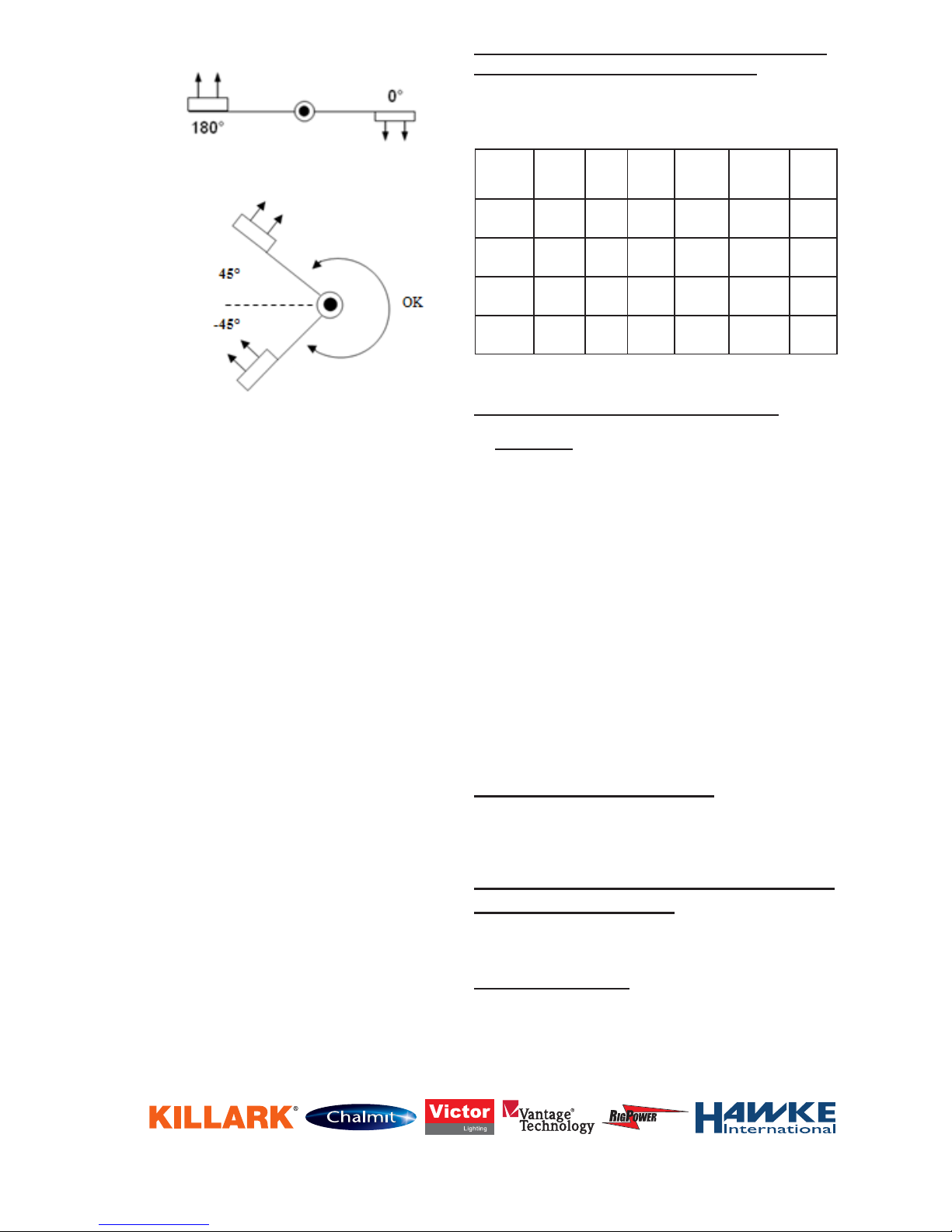

Aiming Designations (Applies to Class and

Division Designated Fixtures Only)

The gures on left refer to nameplate data as

applicable. NOTE: For aiming designation “B”, verify

that the luminaire is not pointed straight up (180°).

Luminaire

Wattage

Ambient

C1 D1

T-Code

C1 D1

Aiming

Range

Diagram

C2 D1

T-Code

Groups

C2 D1

Aiming

Range

Diagram

125 40

55

T6

T5

AAT3C/T3C

T3A/T3C

EFG / EFG

EF / EFG

A / B

A / B

110 40

55

T6

T6

AAT3C / T3C

T3A / T3C

EFG / EFG

EF / EFG

A / B

A / B

105 40

55

T6

T6

AAT3C / T3C

T3A / T3C

EFG / EFG

EF / EFG

A / B

A / B

90 40

55

T6

T6

AAT3C / T3C

T3A / T3C

EFG / EFG

EF / EFG

A / B

A / B

Fig.A

Fig.B

MAINTENANCE INSTRUCTIONS

CAUTION

Disconnect the supplying circuit before opening

xture or removing optics. To maintain maximum

light output, this xture should be cleaned

periodically. Maintenance procedures sometimes

require xtures to be hosed down for good

housekeeping. The supply circuit must be turned

OFF and the xture lens must be allowed to cool

to the ambient room temperature before cleaning.

Only mild, non-abrasive cleaning agents should be

used. The force of water applied by a hose must

not exceed 65 gallons per minute coming from a

1” diameter hose applied at a distance of 10 feet.

These periodic cleaning procedures are important

to prevent the accumulation of dust and dirt which

will impair the light output of the xture. The glass

lens should be regularly inspected for scratches

and chips and, if damaged, must be replaced.

HIGH VIBRATION AREAS

Periodic inspection of lens tightness is required;

recommended every six (6) months.

DIRECTIONS FOR INSTALLATION OF

KF1L ACCESSORIES

NOTE – Reector (KF1L-DARK) and Guard (KF1LG)

cannot be used simultaneously.

KF1L-DARK Reector

IMPORTANT- Before installing, check the xture

nameplate to be sure you have the correct xture.

WARNING- Turn OFF the supplying circuit before

starting installation.

Loading...

Loading...