Kilews SKP-BC32HL Operation And Maintenance Manual

電動起子控制器操作手冊

OPERATION AND MAINTENANCE MANUAL

內附零件分解圖與零件表

SKP-BC32HL

CONTROLLER

OF

LOW VOLTAGE METAL ASSEMBLY SCREW DRIVER

KILEWS INDUSTRIAL CO., LTD.

OBR-T09ce

SKP-BC32HL POWER CONTROLLER (E) CE

NOTICE

Metal Assembly Screwdrivers are designed for installing threaded fasteners in light

industrial and appliance manufacturing applications.

KILEWS is not responsible for customer modification of tools for applications on which

KILEWS was not consulted.

WARNING

Important safety information enclosed.

Read all these instructions before placing tool in service or operation this tool and save

these instructions. It is the responsibility of the employer to place the information in this

manual into the hands of the operator. Failure to observe the following warnings could

result in injury. When using electric tools, Basic safety precautions should always be

followed to reduce the risk of fire, electric shock and personal injury, including the

following:

1. General Safety Rules………………………………………………..…….2

2. Operations Cautions…………………………………………………....... 4

3. Main Technical Parameter……………………………………….…….... 5

4. Control Panel Specifications ………………………………………........6

Functions of Keys on Panel …………………………………….7

I/O Inserting Hole Instruction……………………………………8

Dip Switch Functional Instruction……………………………..9

5. System Setting……………………………………………………….…… 10

6. Simulated Learning……………………………………………………..…13

7. Grounding……………………………………………………………..…….13

8. Servicing……………………………………………………………….……13

9. Explosive Drawing for Parts /Spare- Part List………………………..25

一、 重要安全說明事項………………………………………………….. …15

二、操作須知…………………………………………………………………15

三、主要技術參數……………………………………………………………16

四、面板規格…………………………………………………………………17

面板按鍵功能說明……………………………………………..18

I/O 插孔說明……………………………………………………19

功能指撥開關說明…………………………………………..…20

五、 系統設定方式………………………………………………………..…22

六、自動學習設定步驟……………………………………………………….24

七、接地說明……………………………………………………………….…24

八、零件分解圖/零件表………………………………………………………25

1

SKP-BC32HL POWER CONTROLLER (E) CE

1. General Safety Rules

WARNING!

in electric shock fire and/or serious injure. The term “power tool” in all of the warning listed

below refer to your mains operated (corded) power tool or battery operated (cordless)

power tool.

SAVE THESE INSTRUCTIONS

1) Electrical Safety

a) Keep work area clean and well lit. Cluttered and dark areas invite accidents.

b) Do not operate power tools in explosive atmosphere, such as in the presence of

flammable liquids, gases or dust. Power tools creat sparks which may ignite the dust

of fumes..

c) Keep children, and bystanders away while operating a power tool. Distractions can

cause you to lose control.

2) Electrical Safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not

use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

c) Don’t expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord to carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use.

Use of cord suitable for outdoor use reduces the risk of electric shock .

3) Personal Safety

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use power tool while you are tired or under the influence of

drugs, alcohol, or medication. A moment of inattention while operating power tools

may result in serious personal injury.

b) Use safety equipment. Always wear eye protection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c) Avoid accidental starting. Ensure the switch is in the off position before plugging

in. Carrying power tools with your finger on the switch or plugging in power tools that

have the switch on invites accidents.

d) Remove any adjusting keys or wrench before turning the power tool on. A wrench

or a key that is left attached to a rotating part of the power tool may result in personal

injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

f) Dress properly. Do not w ear loose clothing or jewellery. Keep your hair,clothing,

and gloves away from moving parts. Loose clothes, jewellery, or long hair can be

caught in moving parts

Read all instructions Failure to follow all instructions listed below may result

2

SKP-BC32HL POWER CONTROLLER (E) CE

g) If devices are provided for the connection of dust extraction and collection

facilitys, ensure these are connected and properly used. Use of these devices can

reduce dust related hazards.

4) Power tool Use and Care

a) Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use power tool if switch does not turn it on or off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source before making any adjustments,

changing accessories, or storing the power tools. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tools

operation. If damaged, have the power tool repaired before use. Many accidents are

cause by poorly maintained power tools.

f) Keep cutting tools sharp and clean, Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g) Use the power tools, accessories and tool bits ect., in accordance with these

instructions and in the manner intended for the particular type of power tool,

taking into account the working conditions and the work to be performed. Use of

the power tool for operations different from intended could result in a hazardous

situation.

5) SERVICE

a) Have your power tool serviced by qualified repair person using only indentical

replacement parts, This will ensure that the safety of the power tool is maintained.

Additional information shall be provide

a) Instruction for putting into use

1. Setting-up or fixing power tool in a stable position as appropriate for power tools which

can be mounted on a support.

2. Assembly

3. Connection to power supply, cabling, fusing, socket type and earthing requirements.

4. Illustrated description of functions.

5. Limitations on ambient conditions.

6. List of contents.

b) Operating Instructions.

1. Setting and testing.

2. T ool changing.

3. Clamping of work.

4. Limits on size of work piece.

5. General instructions for use.

c) Maintenance and servicing.

1. Regular cleaning, maintenance, and lubrication.

2. Servicing by manufacture or agent, list of addresses.

3. List of user-replaceable parts.

4. Special tools which may be required.

3

SKP-BC32HL POWER CONTROLLER (E) CE

2. Operations Cautions

1. Please read the operating manual thoroughly and comply with safety regulation to

operate this Multi-Function Controller.

2. Please grasp the plug of power cord while plugging in or out the plugs of connecting

cord of Electric Screwdriver and power cord.

3. Please fix the power controller to avoid any danger of pulling and dragging t he power

cord.

4. Do not near oil, chemical materials or heated objects, also please be alert not to

scratch the power cord by sharp object.

5. This type of Controller can only be applied to Kilews Electric Screwdriver with Counter.

Do not use Electric Screwdriver Controller on other types of machinery.

6. In case of the Controller is overheated or overloaded with maximum current rating of

fuse, the high-speed fuse will be melt down and cut off the power. If the Controller

continues to jump off or has an abnormal switching reaction, please stop the operation

immediately and send back the Controller for repair.

7. When Electric Screwdriver is running, if slides Forward/Reverse Switch instantly,

device will generate the protection program to force Electric Screwdriver stop.

8. Please do not disassemble Electric Screwdriver casually and try to repair it by self.

9. When Controller is not in use, please turn the main power switch OFF and unplug the

power.

10. Installation shall be installed and protected in accordance with national wiring rules.

*Please arrange to use the whole set of Electric Screwdriver SKD-BC series with the

Multi-Function Controller.

*Please arrange to use together with Kilews SKD-BC series Electric Screwdriver. If

operator uses different brand of Electric Screwdriver and repair tools with parts or

accessories not from Kilews manufacturer, it may cause the Controller

malfunction or poor quality. As a result, all of product guarantees will be void and

no obligation to the manufacturer.

*When Electric Screwdriver is running, if operator slide Forward/Reverse switch

instantly, device will turn on the protection program to force the Electric

Screwdriver stop running.

CAUTION

4

SKP-BC32HL POWER CONTROLLER (E) CE

3. Main Technical parameters

Model No

Input Voltage

Output Voltage

Power Consumption

Counting Numbers

Counting Method

Connecting Sensor

Sensing Switch Mode

Slow-Start Tim e Adj.

Slow-Start Speed Adj.

Start Detecting Time

Stop Detecting Time

Disqualification Detecting Alarm

Qualification Detecting Alarm

Auto response/Manual response

External Connection Input Confirm key/Reset Key

External Connection Output

Electric Screwdriver Speed Control

Size(mm)

Weight(Kg) 0.9

ON (2 Sensor) / OFF (1 Sensor)

On/ Off/FF/EF with LED Light and Buzzer

On/Off/FF/EF with LED Light and Buzzer

SPEED:HI/LO ;Slow Start

SKP-BC32HL

AC 100-240V 50/60HZ

DC 32V/ 20V 1.8A/3A

60W

1-99

Count forward/Count down

ON / OFF

0.1-9.9 seconds

30%-100% Rated speed

0.01-9.99 seconds

0.1-9.9 seconds

ON/OFF

OK / NG / OK ALL

150 *48*130(mm)

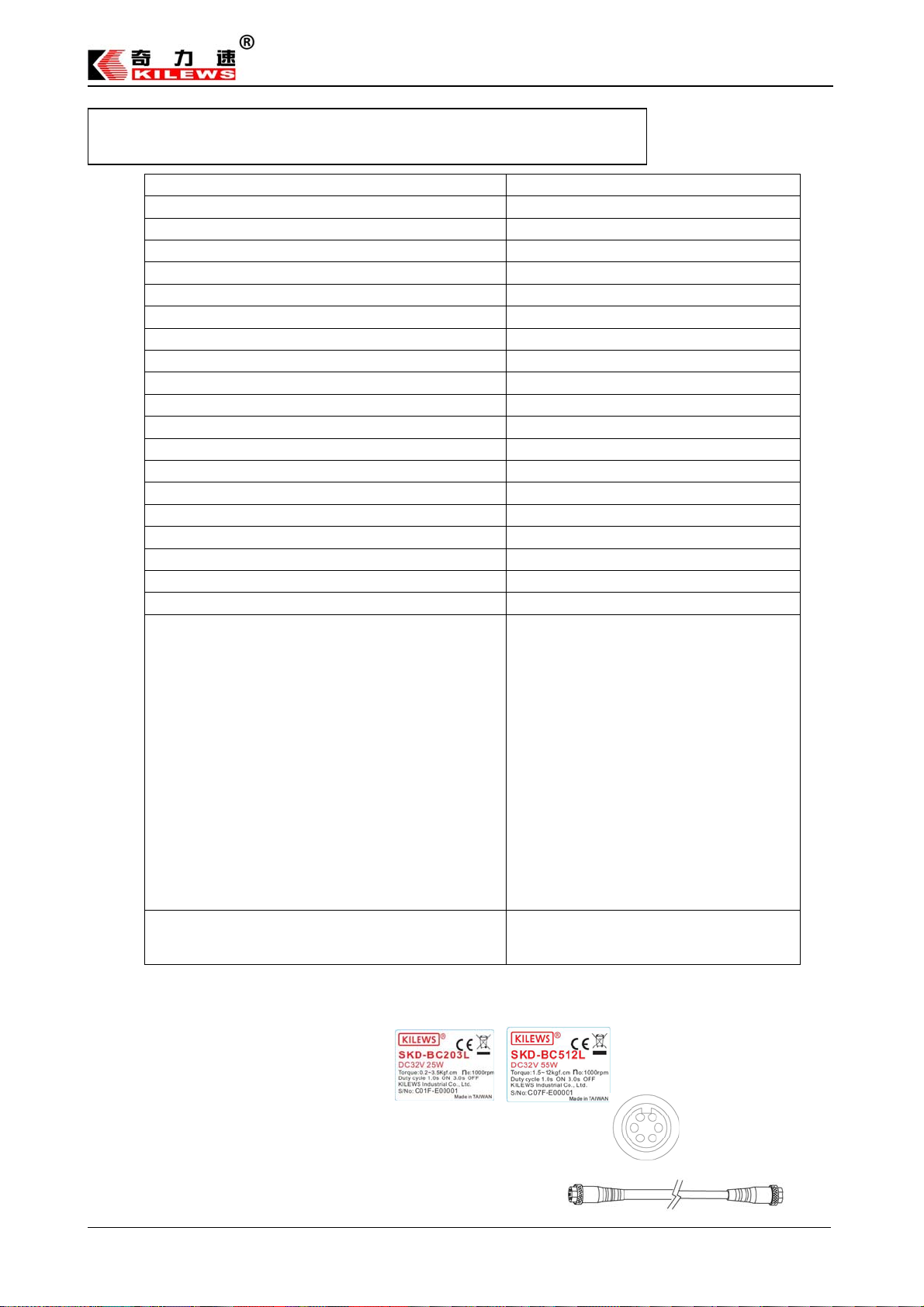

SKD-BC203L

SKD-BC207L

Applicable Electric Screwdrivers

Accessories

SKD-BC512L ; SKD-BC512P

SKD-BC519L ; SKD-BC519P

SKD-BC512LF ; SKD-BC512PF

SKD-BC210L

Power cord*1

Suspension Bail *2

Terminal Block *1

※SKP-BC32HL must match with SIX PIN screwdrivers , please confirm the screwdriver’s type is SKD-BC

and connector is seven PIN when user is using it.

To confirm procedure of screwdriver::

1、To confirm the sticker is “SKD-BC” type.

2、To confirm screwdriver’s CONNECTOR is SIX PIN.

3、To confirm the connect cable between Screwdriver and power controller is SIX wires.

5

SKP-BC32HL POWER CONTROLLER (E) CE

4. Control panel specifications

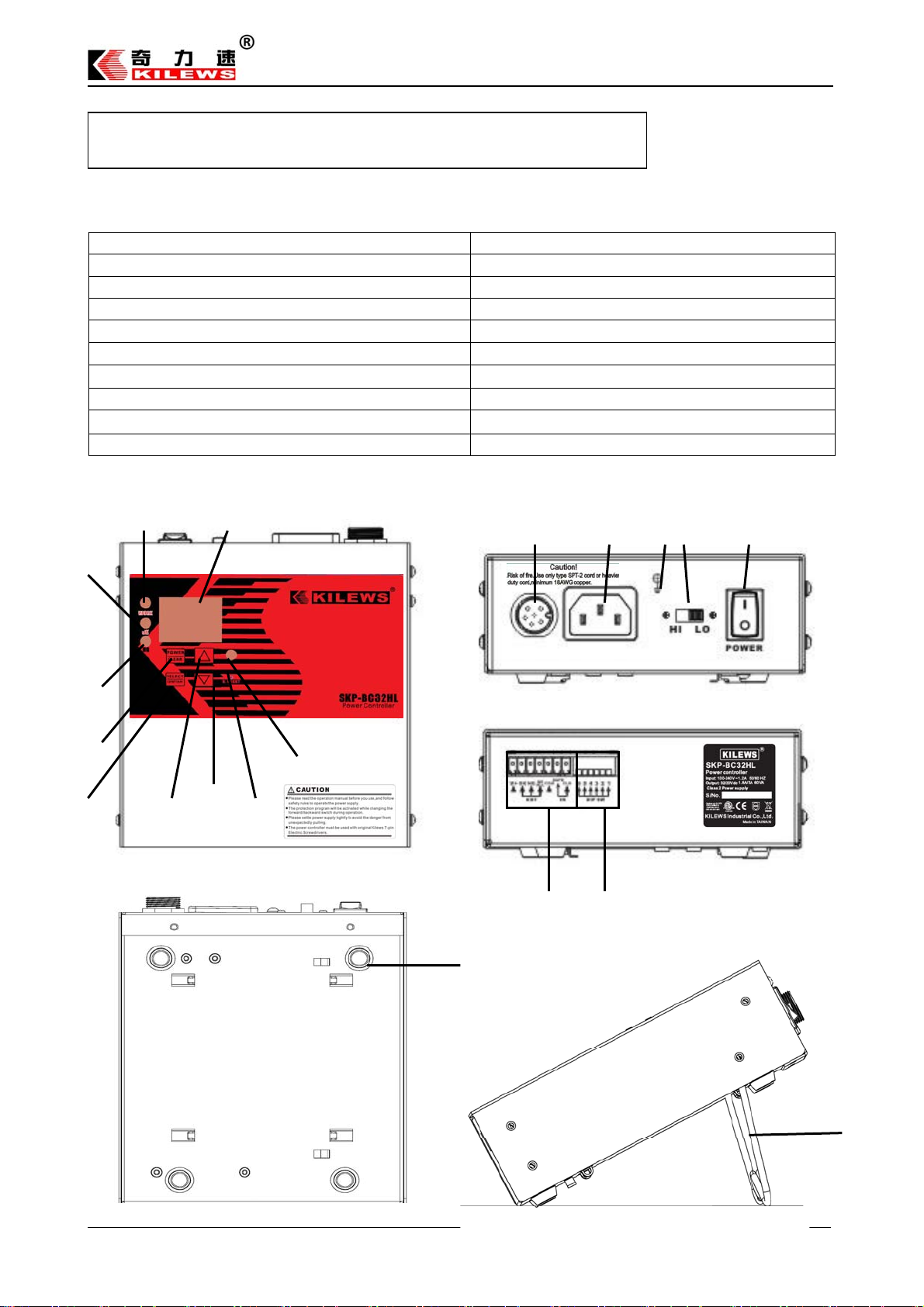

① LED Indicator ⑪6Pin Connector

②WORK Light ⑫ Power Plug

③OK Light ⑬ Grounding Wire

④NG Light ⑭ HI/LO Speed Switch

⑤POWER/CLEAR Key ⑮ POWER SWITCH

⑥Functional Selection/Confirm Key ⑯ I/O Inserting Hole * Instruction

⑦Up-Selecting Key ⑰ Functional Dip Switch * Instruction

⑧Down-Selecting Key ⑱ Rubber shim

⑨System Build-in Reset Key

⑩Power Indicator

○19 Suspension bail

3

○

4

○

5

○

6

○

2

○

7 ○8

○

1

○

9

○

10

○

18

○

11

○

○16○

12

○

17

13

○

14

○

15

○

19

○

6

SKP-BC32HL POWER CONTROLLER (E) CE

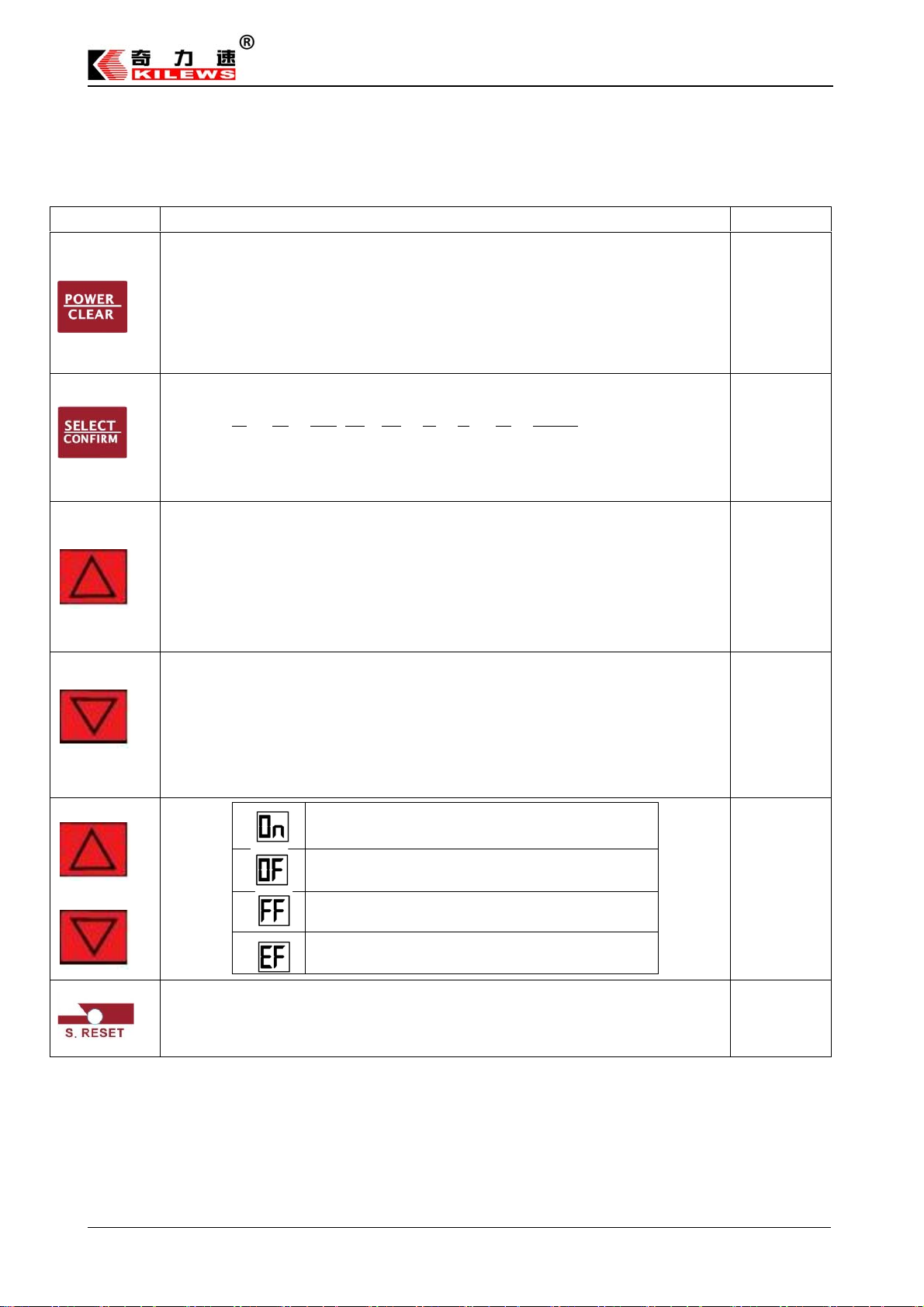

Functions of Keys on Panel:

Key Description of function. Remarks

POWER: Power Switch

To press for six seconds, the system will shut down functions , LED Display light and

WORK light will be shut off.

To return counting function under shutting down counter condition, push three seconds to

open the counter.

CLEAR: Clear Switch

In the middle of counting, push this key for three seconds back to initial.

+

SELECT:

To push this key three seconds any time to enter system. That is:

----- SC-----At------Rc-----SP-----Ht-----Lt------LL-----CHECK

SL

CONFIRM:

When DIP SW3 ON, reaching set up number , the system will ask the operator to

confirm.

UP:

When entering system, this key can increase the number.

This key will point out user set-up number and unit during the process :

U1: No.1 setting number.

U2: No.2 setting number.

U3: No.3 setting number.

U4: No.4 setting number.

U5: No.5 setting number.

DOWN:

When entering system, this key can decrease number.

This key will point out user set-up number and group during the process :

U1: No.1 setting number.

U2: No.2 setting number.

U3: No.3 setting number.

U4: No.4 setting number.

U5: No.5 setting number.

S.RESET:SYSTEM RESET

Because of voltage or operation cause system abnormal , push this key back to the initial number.

When fastening screw, completing work and if mistaken

operation, the buzzer sound will be on.

Wrong operation will be buzzed.

Work completed and wrong operation will cause buzz.

As one screw is fastened and work is completed, buzzer will

be on; wrong operation will be no sound.

Refer to

CONFIRM mode

7

Loading...

Loading...