Kikusui TOS9300, TOS9302, TOS9301, TOS93 Series, TOS9303LC User Manual

...

TOS9300

TOS9301

TOS9302

TOS9303

TOS9303LC

User’s Manual

Electrical Safety Analyzer

TOS93 Series

DANGER

This product generates high voltage!

Improper operation can lead to serious accidents.

To prevent accidents, be sure to read the section

“Safety Precautions for Testing” in this manual.

Keep this manual close to the product so that the operators

can read the manual at any time.

Part No. IB032282

Dec 2018

Contents 7

Component Names 12

Safety Precautions for Testing 18

Installation 24

Basic Operation 42

Withstanding Voltage and Insulation

Resistance Tests 49

Earth Continuity Test 85

Touch Current Test 102

Protective Conductor Current Test 126

Patient Leakage Current Test 145

Meter Mode 168

Auto Test 182

External Control 199

Memory Function 213

System Settings 219

Maintenance 239

Specifications 245

Appendix 269

Testing is not possible upon opening the package

When you first turn on this product after opening the package, the safety interlock will prevent

you from performing tests. Connect the included SIGNAL I/O plug to the SIGNAL I/O connector

to temporarily release the interlock (p. 204).

When you actually perform tests, design a system that uses the interlock for safety (p. 205).

Notes to the supervisor

• If the operators cannot understand the language used in this manual, translate the manuals

into the appropriate language.

• Make sure that the operators understand the information in this manual before they operate

this product.

• Keep this manual close to the product so that the operators can read the manual at any time.

You will receive a potentially fatal electric shock if:

• You touch an output terminal while output is being generated.

• You touch a test lead that is connected to an output terminal while output is being generated.

• You touch the EUT while output is being generated.

• You touch a location that is electrically connected to an output terminal while output is being

generated.

• You touch a location that is electrically connected to an output terminal immediately after output is turned off after a DC withstanding voltage test or insulation resistance test has been

performed.

DANGER

2 User’s Manual TOS93 Series

This manual provides an overview of the product and

About Manuals

PDFPDF

PaperPaper

PaperPaper

PDFPDF

notes on usage. It also explains how to configure it, operate it, perform maintenance on it, and so on. Read this

manual thoroughly before use, and use the product properly.

Intended readers

These manuals are intended for users of this product and

their instructors. The manuals assume that the reader has

knowledge about electric safety testing.

Manual construction

Copyright

Reproduction and reprinting of this operation manual,

whole or partially, without our permission is prohibited.

Both unit specifications and manual contents are subject to

change without notice.

© Copyright 2018 Kikusui Electronics Corporation

• User’s manual (this manual)

This document is intended for first-time users of this

product. It provides an overview of the product, notes on

usage, and specifications. It also explains how to connect the product, configure the product, operate the

product, perform maintenance on the product, and so

on.

• Communication Interface Manual

This document contains details about remote control.

The interface manual is written for readers with sufficient

basic knowledge of how to control measuring instruments using a PC.

• Setup Guide

This document is intended for first-time users of the

product. It gives an overview of the product, connecting

procedures, safety precautions etc. Please read this

manual before you operating the product.

• Safety Information

This document contains general safety precautions.

Keep them in mind and make sure to observe them.

PDF files are included in the accompanying CD-ROM. You

can view the PDF files using Adobe Reader.

PDFPDF

PDFPDF

Firmware versions that this manual covers

This manual applies to products with firmware versions

1.0X.

For information on how to check the firmware version, see

“Displaying the Device Information” (p. 238).

When contacting us about the product, please provide us

with:

The model (marked in the top section of the front panel)

Firmware version (p. 238)

The serial number (marked on the rear panel)

Trademarks

Microsoft is a registered trademark or trademark of Microsoft Corporation in the United States and/or other countries.

Other company names and product names used in this

manual are generally trademarks or registered trademarks

of the respective companies.

TOS93 Series User’s Manual 3

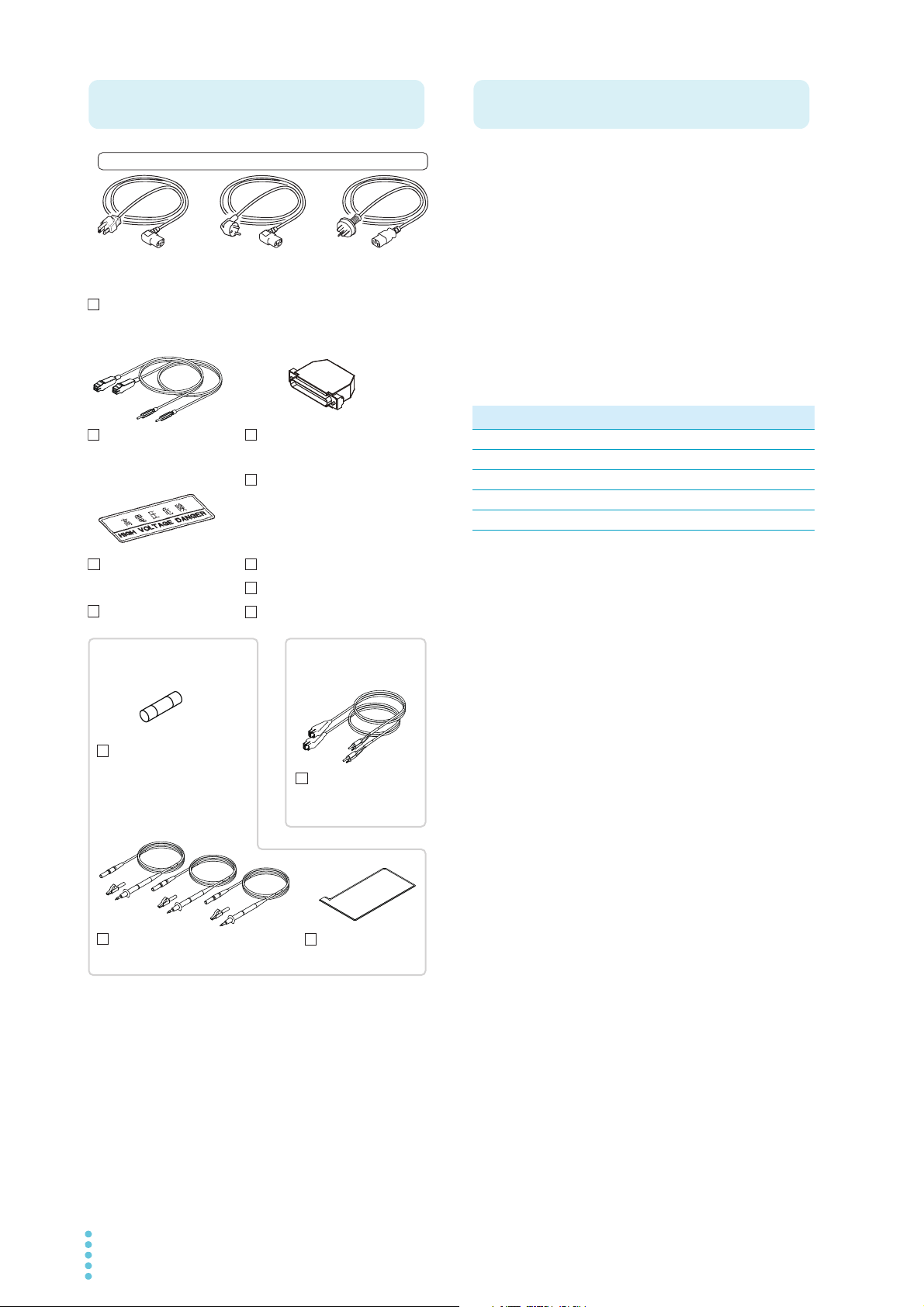

The TOS93 series is a electrical safety analyzer that can

Accessories

High-voltage test lead

TL31-TOS (1 pair)

SIGNAL I/O plug (1 set)

Assembly type D-sub plug unit

Power cord (1 pc.,* length: 2.5 m)

* Two pieces included for the TOS9303LC.

CD-ROM (1 disc)

Setup Guide (1 copy)

Safety Information (1 copy)

Plug: CEE7/7

Rating: 250 Vac/10 A

[85-10-1070]

Plug: GB1002

Rating: 250 Vac/10 A

[85-10-0791]

or or

The attached power cord varies depending on the shipment destination.

High-voltage warning

sticker (1 pc.)

Test leads for earth

continuity test

TL13-TOS (1 pair)

TOS9302, TOS9303,

TOS9303LC only

Test leads for leakage current test

TL22-TOS (2 red, 1 black)

Flat probe

FP01-TOS (1 sheet)

TOS9303LC only

Spare fuse (1 pc.)

15 A, 250V

* Stored in the fuse holder

Plug: NEMA5-15

Rating: 125 Vac/10 A

[85-AA-0003]

Heavy object warning label

(1 pc.)*

Affix this to the product as

necessary.

* Not included with the TOS9300

Cable tie (1 pc.)

Product Overview

perform several types of safety tests on electronic devices

and components. The available types of safety tests

include withstanding voltage test, insulation resistance

test, earth continuity test, leakage current test (touch current test, and protective conductor current test, patient

leakage current test).

Different models are available according to the combination of tests you require, so a single unit is enough to cover

your various safety test needs.

The product is suited to (1) research and development

installations, (2) test facilities for quality assurance testing

and standard certification, and (3) manufacturing lines.

TOS93 Series Lineup

Model

TOS9300 ACW, IR

TOS9301 ACW, DCW, IR

TOS9302 ACW, EC

TOS9303 ACW, DCW, IR, EC

TOS9303LC ACW, DCW, IR, EC, LC

1 ACW: AC withstanding voltage, DCW: DC withstand-

ing voltage, IR: insulation resistance, EC: earth continuity, LC: leakage current

Supported tests

1

Features

Diverse lineup of products

A diverse lineup of products is available for the various

combinations of test required in production lines to

accommodate a variety of needs. Tests can be performed in accordance with the requirements of safety

and electrical standards and ordinances such as IEC,

EN, BS, VDE, UL, CSA, GB, and JIS.

Dielectric breakdown detection sensitivity settings

Safety standards define that corona discharge and partial discharge are not dielectric breakdown. This product

allows you to adjust the detection sensitivity of EUT’s

dielectric breakdown during withstanding voltage testing

to support a wide range of settings from those that do

not detect corona discharge or partial discharge to those

that do. Failure analysis that were not possible with previous Kikusui withstanding voltage testers is now possible.

Support for AC/DC earth continuity test up to 40 A

(TOS9302, TOS9303, TOS9303LC only)

The newly developed amplifier a broad range of tests

from AC earth continuity test of general home electric

appliances to DC earth continuity test of EV-PV systems.

A single unit for safety standard testing

(TOS9303LC only)

A single TOS9303LC, which includes all functions necessary for AC/DC withstanding voltage testing, insulation resistance testing, AC/DC earth continuity testing,

and leakage current testing, can perform the entire set

of safety standard conformance tests.

4 User’s Manual TOS93 Series

Support for touch current, protective conductor

Notations Used in This Manual

9300

9301

9302

9303

9303LC

Safety Precautions

current, and patient leakage current tests

(TOS9303LC only)

Various leakage current tests for medical instruments

are supported in addition to those for general electric

appliances.

LAN, USB, and RS232C

The product is standard equipped with LXI compatible

LAN, USB 2.0, USB-TMC compatible USB, and

RS232C interface.

Color liquid crystal display

Intuitive display and controls are provided through the 7inch display that shows various test settings, descriptions, and drawings.

• In this manual, the TOS9300, TOS9301, TOS9302,

TOS9303, and TOS9303LC electrical safety analyzer

are also referred to as the TOS93 series.

• The term “PC” is used to refer generally to both personal

computers and workstations.

• The term “EUT” is used to refer generally to an equipment under test.

• Test names may be abbreviated as follows:

AC withstanding voltage: ACW, DC withstanding voltage: DCW, insulation resistance: IR, earth continuity:

EC, leakage current: LC, touch current: TC, protective

conductor current: PCC, patient leakage current: Patient

• The screen captures and illustrations used in this text

may differ from the actual items.

• The following markings are used in this manual.

Indicates an imminently hazardous situation which,

if ignored, will result in death or serious injury.

Indicates a potentially hazardous situation which, if

ignored, could result in death or serious injury.

Indicates a potentially hazardous situation which, if

ignored, may result in slight injury or damage to the

product or other property.

Indicates information that you should know.

Indicates a reference manual (CD-ROM) containing

detailed information.

>

Indicates the hierarchy of items you need to select. The

item to the left of this symbol indicates a higher level

item.

, , , ,

Indicate TOS93 series model names.

9303

When using this product, be sure to observe the precautions in the Safety Information manual. Items specific to

this product are given below.

• This product generates high voltage. Improper operation can lead to serious accidents.

To prevent accidents, be sure to read “Safety Precautions for Testing” (p. 18) in this manual. Keep this manual close to the product so that the operators can read

the manual at any time.

• You will receive a potentially fatal electric shock if:

• You touch an output terminal while output is being

generated.

• You touch a test lead that is connected to an output

terminal while output is being generated.

• You touch the EUT while output is being generated.

• You touch a location that is electrically connected to

an output terminal while output is being generated.

• You touch a location that is electrically connected to

an output terminal immediately after output is turned

off after a DC withstanding voltage test or insulation

resistance test has been performed.

• You may receive a potentially fatal electric shock if:

• You operate the tester without grounding it.

• You operate the tester without using rubber gloves for

electrical work.

• You come close to a location that is electrically connected to an output terminal while output is being generated.

• You come close a location that is electrically connected to an output terminal immediately after output

is turned off after a DC withstanding voltage test or

insulation resistance test has been performed.

• In tests that use test leads, do not touch the tip of

test leads.

Risk of electric shock.

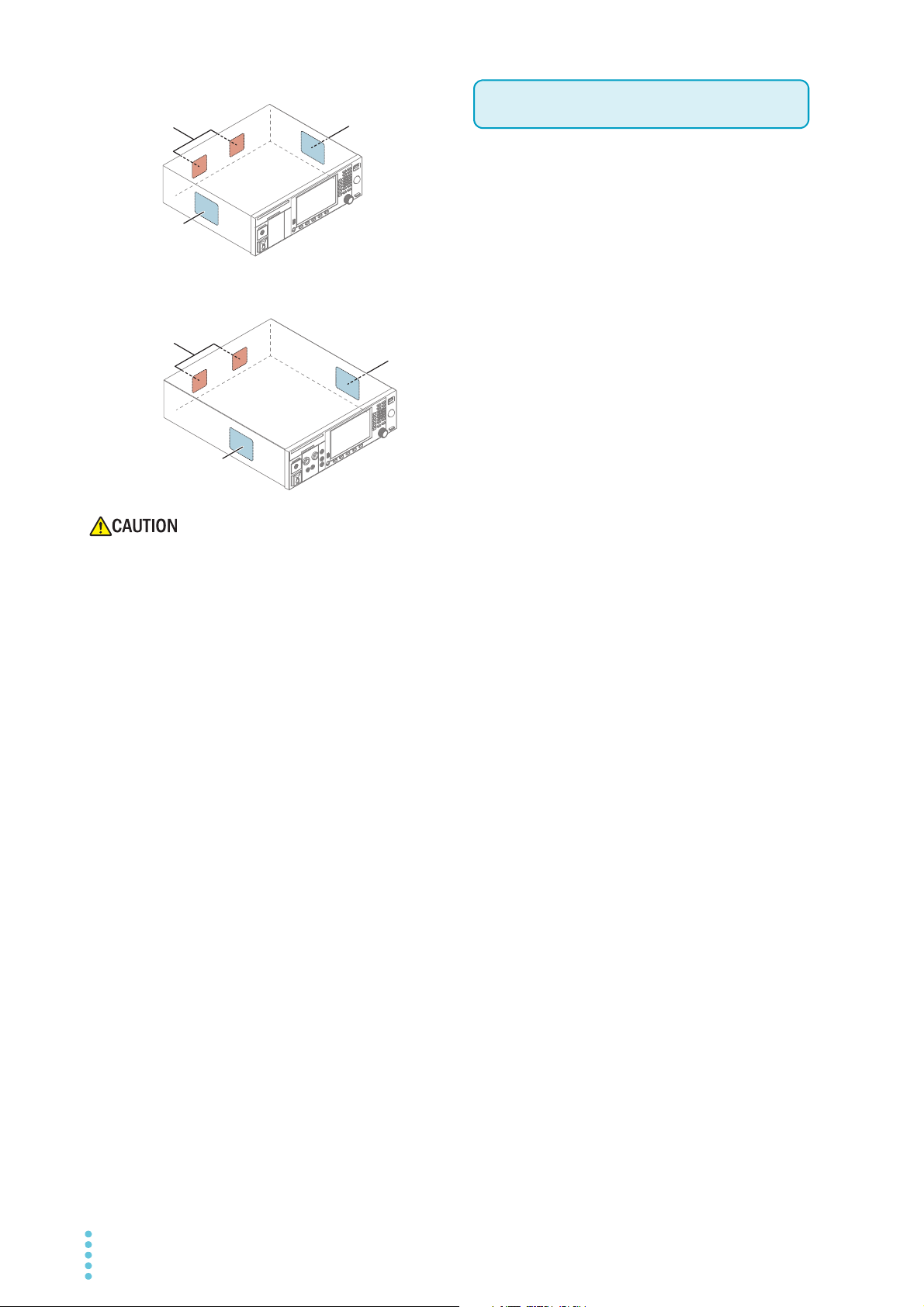

• Do not use the product in a poorly ventilated location.

The product uses forced air cooling. It sucks air through

the inlet holes on its right and left panels and expels air

through its rear panel. Secure adequate space around

the product’s inlet and outlet holes to prevent the possibility of fire caused by accumulation of heat.

Allow at least 20 cm of space between the air inlet/outlet

and the wall (or obstacles). Be careful not to block the

air inlet and outlet when rack mounting the product.

Hot air (approximately 20 °C, 68 °F, hotter than the

ambient temperature) is expelled from the outlet holes.

Do not place objects that are affected by heat near the

air outlet.

TOS93 Series User’s Manual 5

• Do not use this product near highly sensitive mea-

Air outlet

Air inlet

Air inlet

Air outlet

Air inlet

Air inlet

TOS9300, TOS9301

TOS9302, TOS9303, TOS9303LC

Notes on Usage

suring instruments or receivers.

Noise generated by this product may affect other

devices. At a test voltage of 3 kV or greater, the product

may produce corona discharge between its test lead

clips. This will generate a significant amount of broadband RF emission. To minimize this effect, keep the alligator clips away from each other. Also, keep the alligator

clips and test leads away from conducting surfaces,

especially sharp metal edges.

• When installing this product, be sure to observe the temperature and humidity ranges indicated below.

Operating temperature range: 0 °C to 40 °C (32 °F to

104 °F)

Operating humidity range: 20 %rh to 80 %rh (no condensation)

• When storing this product, be sure to observe the temperature and humidity ranges indicated below.

Storage temperature range: -20 °C to 70 °C (-4 °F to

158 °F)

Storage humidity range: 90 %rh or less (no condensation)

6 User’s Manual TOS93 Series

+

Contents

About Manuals ...................................................3

Accessories ........................................................4

Product Overview ...............................................4

Notations Used in This Manual...........................5

Safety Precautions .............................................5

Notes on Usage..................................................6

Component Names ..........................................12

Safety Precautions for

Testing

Lighting of the DANGER LED...........................18

Test Precautions ..............................................18

Pre-test precautions ............................................. 18

Testing precautions .............................................. 19

Precautions when setting test conditions ............. 19

Precautions after Output Has Been Turned Off20

Estimated discharge time ..................................... 20

Remote Control Precautions ............................21

Malfunction Precautions ...................................21

Dangerous malfunctions ....................................... 21

Emergency measures........................................... 21

Protection Functions.........................................22

Installation

Connecting the Power Cord .............................24

Checking Whether the Power Is On or Off .......25

Checking the interlock operation .......................... 25

Turning the power on............................................ 26

Turning the power off............................................ 27

Connection for Withstanding Voltage and Insula-

tion Resistance Tests .......................................28

Connecting the test leads ..................................... 28

Removing the test leads ....................................... 32

Connection for Earth Continuity Tests..............33

Four-terminal wiring and two-terminal wiring ........ 33

Connecting the test leads ..................................... 34

Removing the test leads ....................................... 36

Connection for Leakage Current Tests.............37

Using the insulation transformer........................... 37

Connecting the EUT to the power supply ............. 37

Connecting the test leads..................................... 40

Basic Operation

Basic Panel Operations.................................... 42

Switching menus .................................................. 42

Using the function keys ........................................ 43

Inputting numbers and characters........................ 45

Changing values................................................... 46

Selecting the Test Mode .................................. 47

Selecting the test mode........................................ 48

Withstanding Voltage and

Insulation Resistance Tests

Setting Test Conditions ....................................49

Displaying the setup screen (Home menu) .......... 49

Description of test conditions ............................... 50

Test voltage.......................................................... 51

Limit voltage ......................................................... 52

Start voltage ......................................................... 53

Frequency ............................................................ 54

Upper limit ............................................................ 55

Lower limit ............................................................ 56

Unit of criteria (Judge Type) ................................. 57

Auto setting of the judgment delay (Delay Auto) .. 58

Test time............................................................... 60

Voltage rise time................................................... 61

Voltage fall time.................................................... 62

Discharge time ..................................................... 63

Discharge when interlock is activated (Discharge In-

terlock).................................................................. 64

Current detection response speed (Filter)............ 65

Grounding mode (GND) ....................................... 66

Current measurement mode (Current RMS) ........ 68

Voltage measurement mode (Volt Measure)........ 69

Peak value display (Display Peakhold) ................ 70

Using the low-pass filter ....................................... 71

Offset (Offset Real, Offset Imag).......................... 72

Offset.................................................................... 73

Checking the scanner contact (Contact Check) ... 74

Setting scanner channels (Edit) ........................... 75

Opening the scanner (All Open)........................... 76

TOS93 Series User’s Manual 7

Starting a Test ................................................. 77

Output time limit ....................................................77

Starting a test ........................................................78

Operation after a test starts...................................79

Changing the voltage setting during a test ............82

Finishing the Test and Viewing the Judgment.83

Stopping tests .......................................................83

Conditions that cause a test to end .......................83

Judgment types and operation ..............................84

Clearing the judgment result .................................84

Earth Continuity Test

Setting Test Conditions ................................... 85

Displaying the setup screen (Home menu) ...........85

Description of test conditions ................................86

Test current ...........................................................86

Limit current ..........................................................87

Frequency .............................................................87

Upper limit .............................................................88

Lower limit.............................................................89

Test time ...............................................................90

Current rise time....................................................91

Current fall time .....................................................91

Terminal wiring method (Terminals Wire) .............92

Contact check .......................................................93

Peak value display (Display Peakhold) .................94

Offset.....................................................................95

Starting a Test ................................................. 96

Output time limit ....................................................96

Starting a test ........................................................96

Operation after a test starts...................................97

Changing the current setting during a test ............99

Finishing the Test and Viewing the Judgment100

Stopping tests .....................................................100

Conditions that cause a test to end .....................100

Judgment types and operation ............................101

Clearing the judgment result ...............................101

Touch Current Test

Setting Test Conditions ................................. 102

Displaying the setup screen (Home menu) .........102

Description of test conditions ..............................103

Network ...............................................................104

Polarity of the power supply line .........................105

Single fault mode (Condition) ..............................106

Probe connection destination ..............................107

Output from the 110% terminal (110% OUT) ......108

Upper limit ...........................................................109

Lower limit...........................................................110

Judgment delay (Judge Delay) ...........................111

Test time .............................................................112

Measurement range............................................113

Measurement mode (Measure Mode).................115

Voltmeter band expansion (VoltMeter BandWidth) ...

116

Peak value display (Display Peakhold) ...............117

Measurement check (Measure Check) ...............117

Offset .................................................................. 118

Voltage conversion (Conv Voltage) ....................119

Checking the EUT operation (Line OUT) ............ 119

Starting a Test................................................120

Connecting the test leads to the EUT ................. 120

Starting a test...................................................... 121

Operation after a test starts ................................122

Finishing the Test and Viewing the Judgment124

Stopping tests .....................................................124

Conditions that cause a test to end.....................124

Judgment types and operation............................125

Clearing the judgment result ...............................125

Protective Conductor

Current Test

Setting Test Conditions ..................................126

Displaying the setup screen (Home menu) .........126

Description of test conditions ..............................127

Network...............................................................128

Polarity of the power supply line .........................129

Single fault mode (Condition)..............................129

Upper limit...........................................................130

Lower limit...........................................................131

Judgment delay (Judge Delay) ...........................132

Test time .............................................................133

Measurement range............................................134

Measurement mode (Measure Mode).................135

Voltmeter band expansion (VoltMeter BandWidth) ...

136

Peak value display (Display Peakhold) ...............137

Measurement check (Measure Check) ...............137

Offset .................................................................. 138

Voltage conversion (Conv Voltage) ....................139

Checking the EUT operation (Line OUT) ............ 139

Starting a Test................................................140

Starting a test...................................................... 140

Operation after a test starts ................................141

Finishing the Test and Viewing the Judgment143

Stopping tests .....................................................143

Conditions that cause a test to end.....................143

Judgment types and operation............................144

Clearing the judgment result ...............................144

8 User’s Manual TOS93 Series

Patient Leakage Current

Test

Setting Test Conditions ..................................145

Displaying the setup screen (Home menu) ........ 145

Description of test conditions.............................. 146

Network .............................................................. 146

Polarity of the power supply line ......................... 147

Single fault mode (Condition) ............................. 148

Probe connection destination ............................. 149

Output from the 110% terminal (110% OUT) ..... 150

Upper limit .......................................................... 151

Lower limit .......................................................... 152

Judgment delay (Judge Delay) ........................... 153

Test time............................................................. 154

Measurement range ........................................... 155

Measurement mode (Measure Mode) ................ 156

Voltmeter band expansion (VoltMeter BandWidth) ..

157

Peak value display (Display Peakhold) .............. 158

Measurement check (Measure Check)............... 158

Offset .................................................................. 159

Voltage conversion (Conv Voltage) .................... 160

Checking the EUT operation (Line OUT)............ 160

Starting a Test ................................................161

Connecting the test leads to the EUT................. 161

Starting a test ..................................................... 163

Operation after a test starts ................................ 164

Finishing the Test and Viewing the Judgment166

Stopping tests..................................................... 166

Conditions that cause a test to end .................... 166

Judgment types and operation ........................... 167

Clearing the judgment result............................... 167

Meter Mode

Connecting the test leads................................... 179

Taking measurements........................................ 179

Measurement operation ..................................... 180

Measurement example (judgment of the parts that

can be touched).................................................. 180

Auto Test

Auto Test Overview........................................182

Tests that auto test can run................................ 182

Programs and steps ........................................... 182

Main functions .................................................... 183

Program Configuration ...................................184

Displaying the program editing screen ............... 184

Creating a program ............................................ 185

Changing a program name................................. 185

Deleting a program............................................. 186

Setting Steps..................................................187

Displaying the step editing screen...................... 187

Editing steps....................................................... 188

Program Operation Configuration ..................189

Fail judgment operation (FAIL Judgment) .......... 189

Step interval ....................................................... 190

Step start operation (Trigger Source) ................. 191

EUT power supply (Line Break) ......................... 192

Running Auto Tests........................................193

Running an auto test.......................................... 193

Behavior during the test ..................................... 194

Finishing the Test and Viewing the Judgment195

Stopping tests..................................................... 195

Conditions that cause a test to end .................... 195

Judgment types and operation ........................... 196

Clearing the judgment result .............................. 196

Exporting and Importing Programs ................197

Exporting programs to a USB memory device ... 197

Importing programs from a USB memory device 198

Constructing the Measurement Circuit ...........169

Setting Measurement Conditions ...................170

Displaying the setup screen (Home menu) ........ 170

Overview of measurement conditions ................ 170

Network .............................................................. 171

Measuring across terminals A and B (A-B Terminal)

172

SELV setting....................................................... 173

Measurement range ........................................... 174

Measurement mode (Measure Mode) ................ 175

Measurement check (Measure Check)............... 175

Offset .................................................................. 176

Output from the 110% terminal (110% OUT) ..... 177

Polarity of the 110% output ................................ 178

Executing a Measurement ..............................179

TOS93 Series User’s Manual 9

External Control

SIGNAL I/O Connector...................................200

Pin arrangement................................................. 200

I/O signal circuit.................................................. 201

Input signal usage example................................ 202

Output signal usage example............................. 202

Connecting to the SIGNAL I/O connector .......... 203

Activating and Releasing Interlock ................. 204

Interlock activation conditions ............................ 204

Interlock release conditions................................ 204

Examples of how to use interlock....................... 205

Recalling from memory ..................................206

Starting and Stopping Tests .......................... 207

Starting a test ......................................................207

Stopping a test ....................................................207

Monitoring the Test Status............................. 208

Monitoring the test mode.....................................208

Monitoring the test and voltage generation status ....

208

Monitoring the test status ....................................208

Monitoring judgment results ................................209

Monitoring the step execution status of auto tests ....

210

Monitoring the activation status of protection func-

tions.....................................................................210

Monitoring Measurements............................. 211

Monitoring current waveforms .............................211

Monitoring voltage waveforms ............................211

Using Option Products................................... 212

Signal output from the STATUS OUT connector.212

Signal I/O of the REMOTE connector .................212

Initializing the Settings....................................235

Restoring the factory default settings..................235

Restoring the reset settings ................................236

Updating.........................................................237

Displaying the Device Information..................238

Maintenance

Inspection.......................................................239

Pre-inspection for withstanding voltage test and insu-

lation resistance test ...........................................239

Pre-testing the earth continuity test ....................240

Pre-testing the leakage current test ....................241

Replacing Components .................................. 243

Replacing the backup battery .............................243

Replacing the fuse ..............................................243

Periodic Calibration ........................................244

Memory Function

Saving and Recalling Test Conditions........... 213

How to view the setup memory screen ...............213

Saving to the setup memory ...............................214

Checking the setup memory details ....................215

Recalling the setup memory................................216

Saving and Viewing Test Results .................. 217

Displaying a list of test results.............................217

Saving test results to a USB memory device ......218

Clearing the list of test results .............................218

System Settings

Displaying and Changing CONFIG Settings.. 219

Panel settings at startup (Power On) ..................220

Operation when there is no SCPI communication

(Watchdog)..........................................................221

Screen saver .......................................................222

Key lock...............................................................223

Calibration configuration .....................................224

Beep sound (Beeper) ..........................................225

Fail mode ............................................................226

Test start settings................................................227

PASS judgment result hold time .........................228

STATUS OUT setting (Status Output) ................229

Outputting judgment for each step (Step END Judg-

ment) ...................................................................230

Displaying/Changing the Interface Settings... 231

Displaying SCPI Errors.................................. 233

Setting the Date/Time.................................... 234

Specifications

Withstanding voltage test section .......................246

Insulation resistance test section ........................249

Earth continuity test section ................................253

Leakage current test section...............................255

Interface ..............................................................262

Other functions.................................................... 263

General specifications.........................................265

External dimensions............................................266

Appendix

Default Settings and Reset Settings...............269

Withstanding voltage (ACW/DCW), insulation resis-

tance (IR) test conditions ....................................269

Earth continuity (EC) test conditions ...................270

Leakage current (LC) test conditions .................. 270

Auto test (AUTO) settings ...................................272

Memory function .................................................272

CONFIG settings.................................................273

Interface settings.................................................274

Stray Capacitance of AC Withstanding Voltage

Tests...............................................................275

Timing Charts .................................................276

Contact check operation .....................................276

ACW test (PASS judgment) ................................277

ACW test (FAIL judgment) ..................................278

ACW test (interlock) ............................................ 279

Options...........................................................280

High voltage scanner ..........................................280

10 User’s Manual TOS93 Series

Remote control box ............................................ 281

DIN adapter cable............................................... 281

High voltage test probe....................................... 282

Warning light unit ................................................ 282

Multi-outlet .......................................................... 283

Brackets.............................................................. 284

Troubleshooting..............................................285

Index...............................................................287

TOS93 Series User’s Manual 11

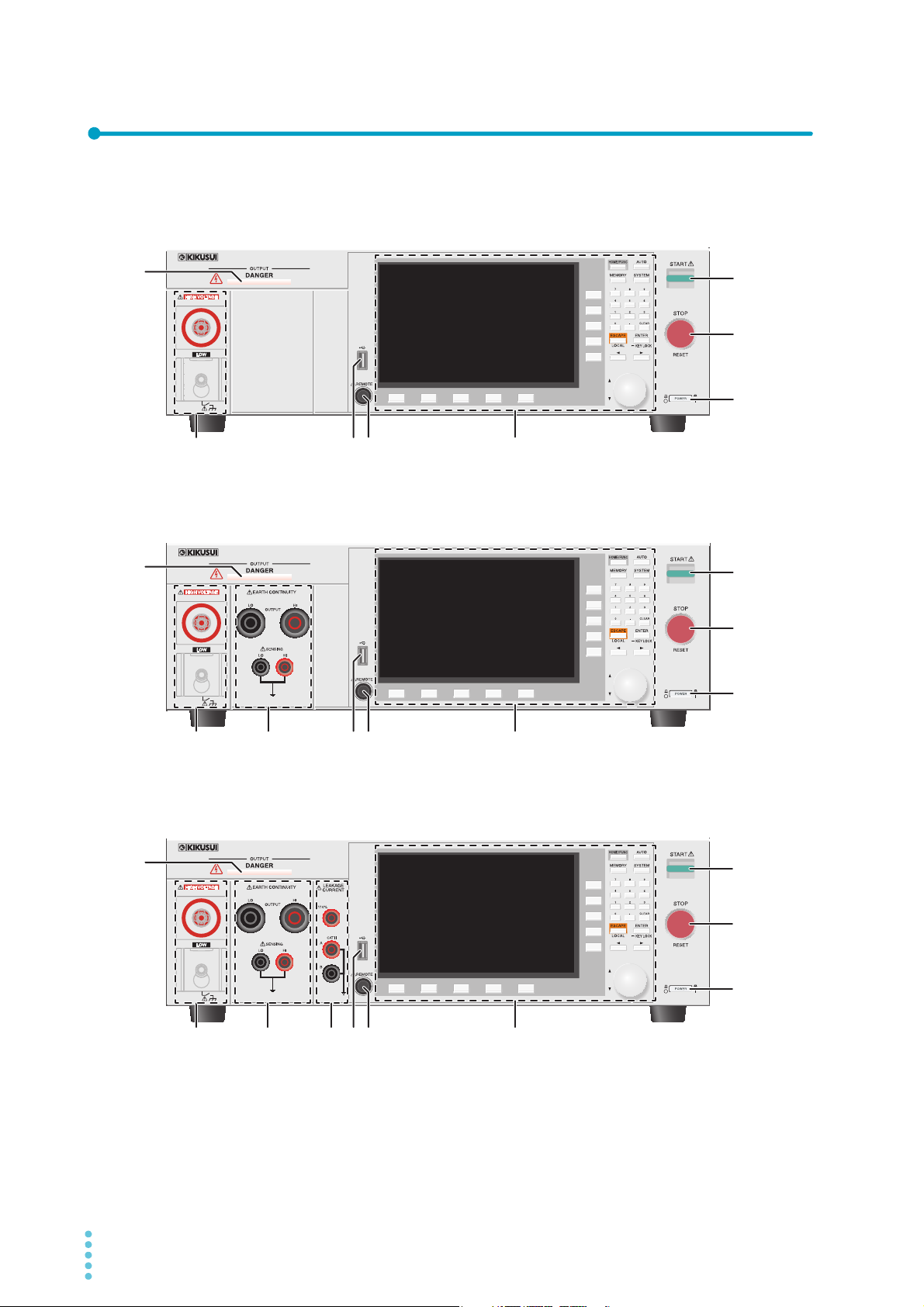

Component Names

56

1

56 7

2

1

1

2

8

9

3

7

8

9

8

9

Front panel

TOS9300, TOS9301

10

TOS9302, TOS9303

TOS9303LC

10

2

3456 7

10

12 User’s Manual TOS93 Series

No. Name Function See

DANGER LED Lights red when the power is turned on, when a test is in progress, when

1

–

a high voltage is being output, or when there is residual voltage at the

output terminals. On the TOS9303LC, the LED also lights red when supply voltage is being supplied to the EUT.

Area for withstanding voltage,

2

–

p.28

insulation resistance

HIGH VOLTAGE terminal Outputs the test voltage of the high voltage side. –

LOW terminal Outputs the test voltage of the low voltage side (with cable lock). –

Area for earth continuity test –

3

p.33

OUTPUT HI terminal Outputs the test voltage of the high voltage side. –

OUTPUT LO terminal Outputs the test voltage of the low voltage side. –

SENSING HI terminal Detects the voltage at the sensing terminal (of the high voltage side)

–

when four-terminal wiring is in use.

SENSING LO terminal Detects the voltage at the sensing terminal (of the low voltage side) when

–

four-terminal wiring is in use.

Area for leakage current test –

4

p.37

110% terminal Outputs 110 % voltage. –

A and B terminals Measurement terminals for connecting test leads and probes. –

USB port (host)

5

REMOTE connector For connecting the optional remote control box or test probes.

6

Controls –

7

START switch Starts a test. –

8

STOP switch Stops testing and clears the current status. Returns to the HOME menu

9

For connecting an external keyboard.

Saves setup memory and test results.

Exporting and Importing Programs.

Updates the firmware.

p.45

p.213

p.197

p.237

p.280

p.14

–

screen.

POWER switch

10

Turns the power on (

) and off( ).

p.26

TOS93 Series User’s Manual 13

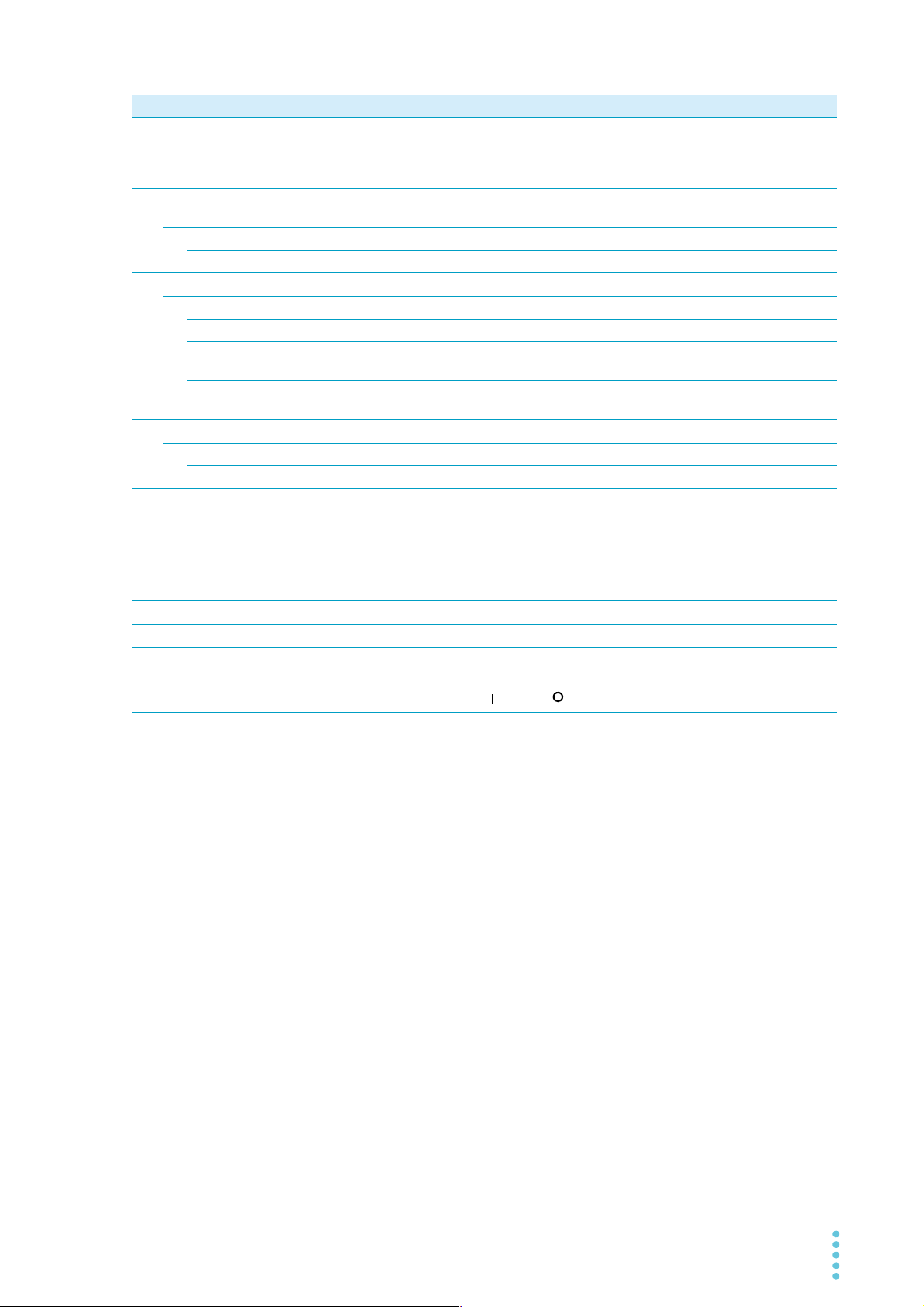

Controls

AUTO

MEMORY

SYSTEM

ENTERESCAPE

879

546

213

0CLEAR

LOCAL

KEY LOCK

HOME/FUNC

1

910

2

3

6

7

8

5

4

No. Name Function See

Display Displays the settings, measured values, and other information.

1

Menu keys Switch the display.

2

HOME/FUNC key Switches between the test setup screen (Home menu) and test selection

screen (Function menu).

AUTO key Displays the auto test screen.

MEMORY key Displays the memory function screen.

SYSTEM key Displays the system setting screen (System Menu).

Numeric keypad Enters values.

3

CLEAR key Deletes numbers/characters.

4

ENTER key Confirms numeric keypad input. Confirmation after selection of setting item.

5

KEYLOCK key Hold down to lock the keys. Hold down when key lock is enabled to unlock.

ESCAPE key Cancels numeric/character input. Closes windows.

6

LOCAL key Returns remote control to panel operation.

←/→ keys Move the cursor left and right. Select the left or right item.

7

Rotary knob Selects an item. Enters numbers and characters.

8

Function keys Executes the item that is displayed above each key (function area).

9

Sub-function keys Executes the item that is displayed to the left of each key (sub-function area).

10

p.15

p.42

p.42

p.182

p.213

p.219

p.45

p.45

p.45

p.223

p.45

p.285

p.45

p.45

p.43

p.43

14 User’s Manual TOS93 Series

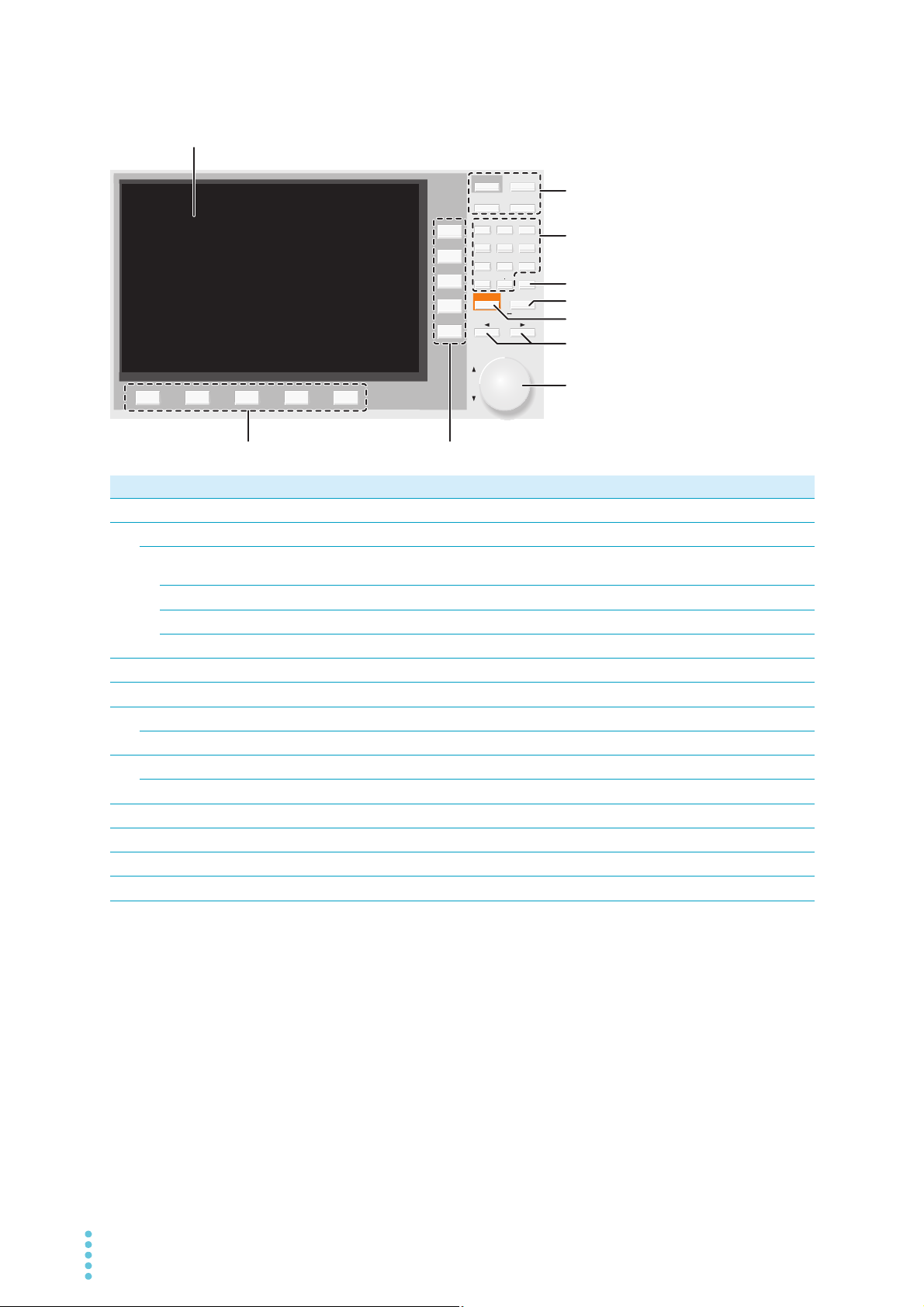

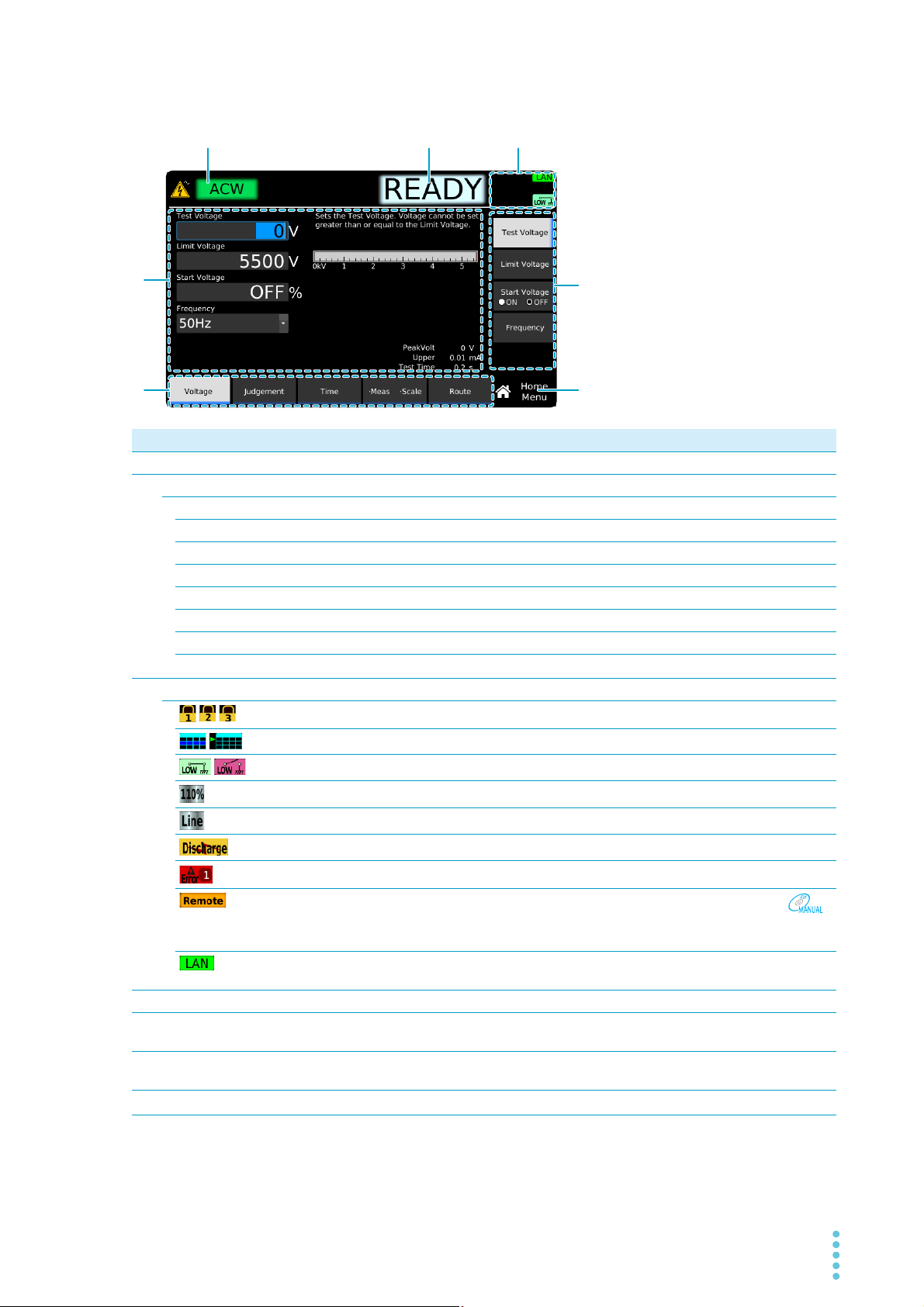

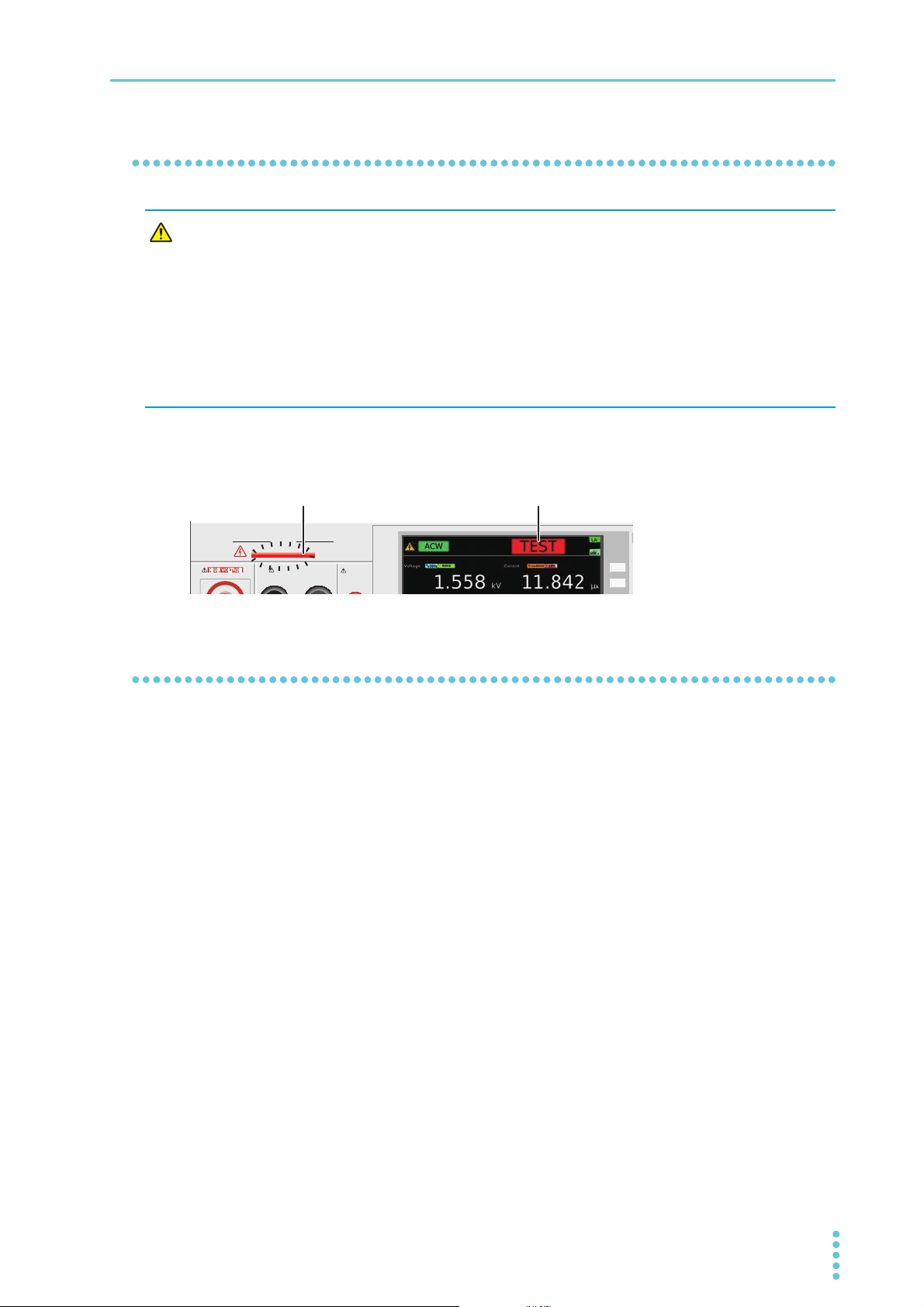

Display

123

4

5

6

7

No. Name Function See

Test mode Selected test type. –

1

Test status. – –

2

READY Ready to start test. –

RISE Voltage or current rising. –

FALL Voltage or current falling. –

TEST Testing. –

PASS Test successful. –

U-FAIL

L-FAIL Test failed because a value less than or equal to the lower limit was detected. –

CHECK Contact check in progress.

Status display icon area.

3

//

/

/

Settings area

4

function area Indicates that execution is possible with the keys (function keys) at the bottom

5

sub-function area Indicates that execution is possible with the keys (sub-function keys) in the

6

Menu name Name of the menu currently displayed.

7

Test failed because a value greater than or equal to the upper limit was detected.

– –

Indicates that key lock is on. The key lock level is displayed numerically.

Auto testing/auto test standby.

GND setting (Low, Guard).

Applying voltage from the 110 % terminal.

Supplying power to the EUT from the AC LINE OUT terminal block.

While discharging.

SCPI error. The number of error incidents (up to 16) is displayed numerically.

Under remote control.

LAN connection status. Green: Communication enabled, Orange: Preparing for

communication, Red: Not connected.

Displays settings and descriptions. Displays measured values during testing.

of the display.

right side of the display.

–

p.93

p.223

p.182

p.66

p.177

p.242

p.63

p.233

Interface

Manual

–

–

p.43

p.43

p.42

TOS93 Series User’s Manual 15

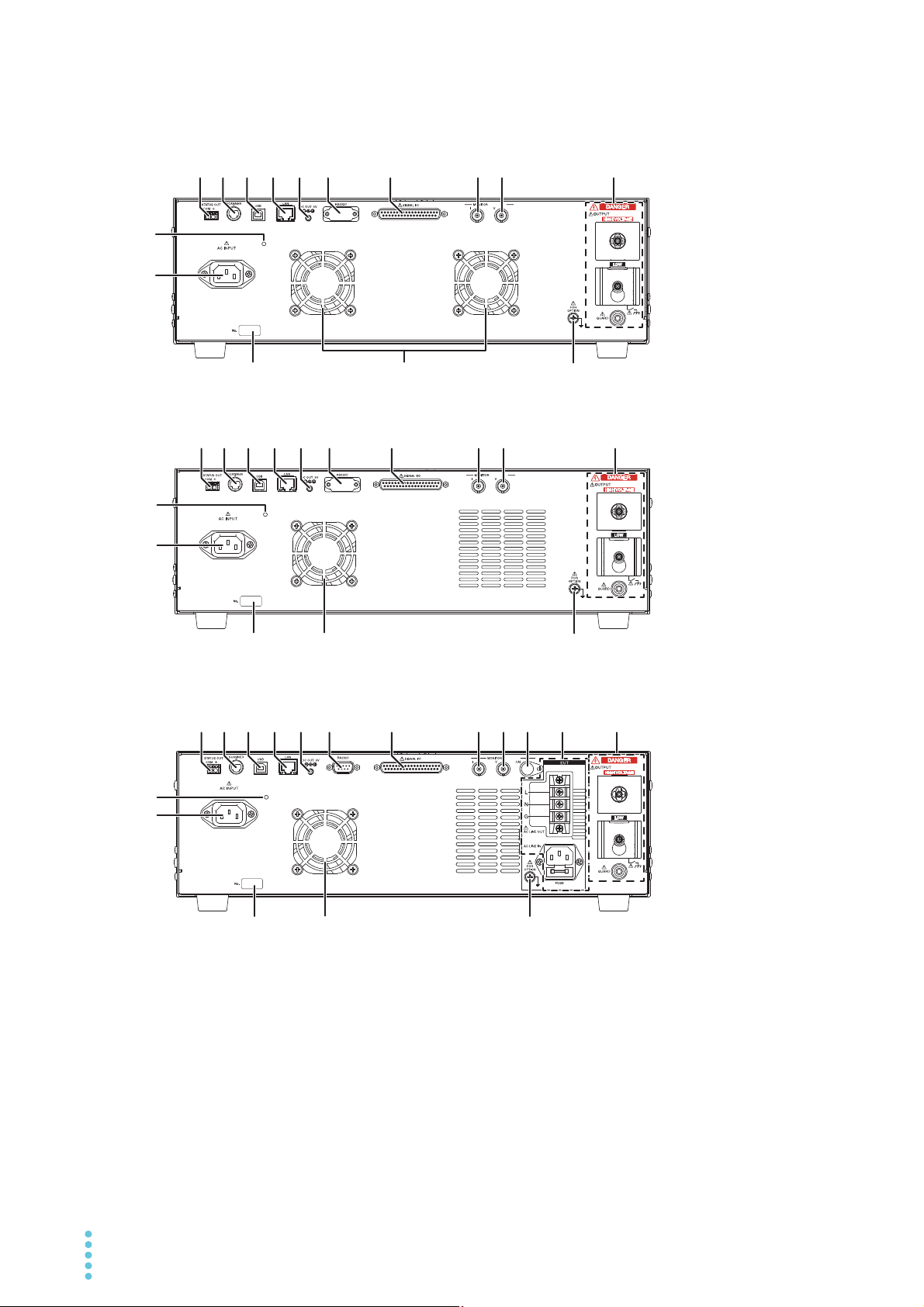

Rear panel

123 4 567 98

14

14

14

123 4 56 7 10 11 12

12

12

13

15

15

15

123 4 567

16 17

1716

16 17

89

89

13

13

TOS9302, TOS9303

TOS9303LC

TOS9300, TOS9301

16 User’s Manual TOS93 Series

No. Name Function See

STATUS OUT connector Connect option products.

1

SCANNER connector Connect to the high voltage scanner option.

2

USB port USB port for remote control.

3

LAN port LAN port for remote control.

4

RS232C port RS232C port for remote control.

5

DC OUT 5 V terminal Connect option products. –

6

SIGNAL I/O connector A I/O signal connector for controlling this product from an external

7

p.212

p.280

Interface

Manual

p.199

device.

I terminal Signal output terminal for monitoring the current waveforms of with-

8

p.211

standing voltage tests.

V terminal Signal output terminal for monitoring the voltage waveforms of with-

9

p.211

standing voltage tests.

CAL terminal Not used. –

10

Area for leakage current test –

11

AC LINE OUT terminal block Connect the EUT here. Power applied to the AC LINE IN inlet is

p.37

–

supplied.

AC LINE IN inlet Connect a power cord for supplying power to the EUT. –

FUSE Input fuse holder for the EUT power supply.

Area for withstanding voltage,

12

–

p.243

p.28

insulation resistance

HIGH VOLTAGE terminal Outputs the test voltage of the high voltage side. –

LOW terminal Outputs the test voltage of the low voltage side (with cable lock). –

GUARD terminal Connect the chassis connection wire of the shield box when a shield

box is used.

Cable tie attachment hole Hole for attaching the included cable tie (for USB cables). –

13

AC INPUT inlet Connect a power cord for supplying power to this product.

14

Serial number Serial number. –

15

Air outlet Vent for cooling this product. –

16

FOR OPTION terminal Connect the ground wire of option products. –

17

p.31

p.24

TOS93 Series User’s Manual 17

Safety Precautions for Testing

WARNING

Lighting of the DANGER LED

The DANGER LED lights when the product is in any of the following conditions.

• At power on

• When a test is running

• When high voltage is being output

• When voltage remains at the output terminals

• When supply voltage is being supplied to the EUT (TOS9303LC only)

Check whether the DANGER LED lights at power on. If it does not, stop using the product, and contact

your Kikusui agent or distributor.

Test Precautions

Pre-test precautions

Risk of electric shock. In a AC withstanding voltage test, the TOS93 series generates a

maximum voltage of 5.0 kVac. In a DC withstanding voltage test, the TOS9301,

TOS9303, and TOS9303LC generate a maximum voltage of 7.2 kVdc. Handling the

product improperly may lead to a fatal accident. To prevent accidents, strictly follow

the precautions and always pay the utmost attention to safety concerns when you

operate the product.

Check the following items before you start testing, and always follow the precautions.

• The power cord is connected to a properly grounded outlet.

• There is no damage such as tears or breaks in the test lead insulation.

• When the POWER switch is turned on, the DANGER LED lights.

• While the DANGER LED is lit, do not touch the items that are charged to a high voltage: the EUT,

the test leads, and the areas near the output terminals.

• When the DANGER LED is lit, do not turn the POWER switch off except in an emergency.

18 User’s Manual TOS93 Series

Testing precautions

WARNING

OUTPUT

DANGER

110%

LEAKAGE

CURRENT

HIGH VOLTAGE

EARTH CONTINUITY

OUTPUT

LOW HIGH

H

Lit Test status

Risk of electric shock.

• While the DANGER LED is lit, it is dangerous to touch the items that are charged to

a high voltage: the EUT, the test leads, the probes, and the areas near the output terminals.

• The alligator clip vinyl insulation of the supplied tests do not have dielectric

strength. Never touch these while the DANGER LED is lit.

• When performing a withstanding voltage test, be sure to wear rubber gloves for

electrical work. If obtaining these gloves is difficult, contact your Kikusui agent or

distributor.

During testing, the DANGER LED lights, and the display shows “TEST.” Be careful because high voltage

may be being output when the DANGER LED is lit.

Safety Precautions for Testing | Test Precautions

Precautions when setting test conditions

Before you set the test conditions or other settings, press the STOP switch, and then be sure to check the

following items to ensure safety.

• The DANGER LED is off.

• The voltmeter is displaying “0.”

TOS93 Series User’s Manual 19

Safety Precautions for Testing

WARNING

Precautions after Output Has Been Turned Off

Risk of electric shock.

• For a while after the output has been turned off, do not touch the items that have

been charged to a high voltage, such as the EUT, the test leads, the test probes, and

the areas near the output terminals.

• After the output has been turned off, the internal discharge circuit goes into operation and discharges the output voltage. During testing and before this discharge

completes, do not disconnect the tester from the EUT.

The EUT, test leads, test probes, and the area around the output terminals are all charged to a high voltage. After the output has been turned off, be sure to check the following before you touch the items that

have been charged to a high voltage.

• The DANGER LED is off.

• “RISE,” “TEST,” or “FALL” is not shown on the display.

• The voltmeter is displaying “0.”

If you will not use the product for some time or if the operator will be away from the product, be sure to turn

the POWER switch off.

Estimated discharge time

The time required to discharge the built-up electrical charge varies according to the test voltage and the

properties of the EUT.

The time that this product requires to discharge the voltage from its internal capacitors down to 30 V is as

follows:

• When an EUT is not connected: 16 ms for a DCW test, 1.5 ms for an IR test

• When an EUT with a input capacitance of 0.05 μF is connected: 50 ms for a DCW test, 6 ms for an IR

test

20 User’s Manual TOS93 Series

Safety Precautions for Testing

WARNING

Remote Control Precautions

If you are performing remote control at a location away from the product, to prevent accidents, follow the

safety measures given below.

• Make sure that high voltages are not generated unintentionally.

• Make it impossible to touch the EUT, test leads, test probes, and the areas near the output terminals when high voltages are being generated.

Malfunction Precautions

Risk of electric shock.

• Until you get the product fixed, make sure that nobody can use it.

• For repairs, contact your Kikusui agent or distributor.

Dangerous malfunctions

If the product is in one of the states explained below, it may be malfunctioning in a very dangerous manner—it may not be possible to turn off the high voltage that is being generated.

• Even when you press the STOP switch, the DANGER LED remains lit.

• Even though a voltage is indicated on the voltmeter, the DANGER LED does not light.

If the tester is not operating properly, it may be generating a high voltage irrespective of the settings made

by the operator. Immediately turn the POWER switch off, and disconnect the power cord from the outlet.

Stop using the product immediately, and contact your Kikusui agent or distributor.

Emergency measures

There are two actions that you must carry out if, due to a malfunction in the product or the EUT, there is a

possibility of an emergency occurring such as electric shock or damage to the EUT.

• Turn the POWER switch off.

• Remove the power cord plug from the outlet.

TOS93 Series User’s Manual 21

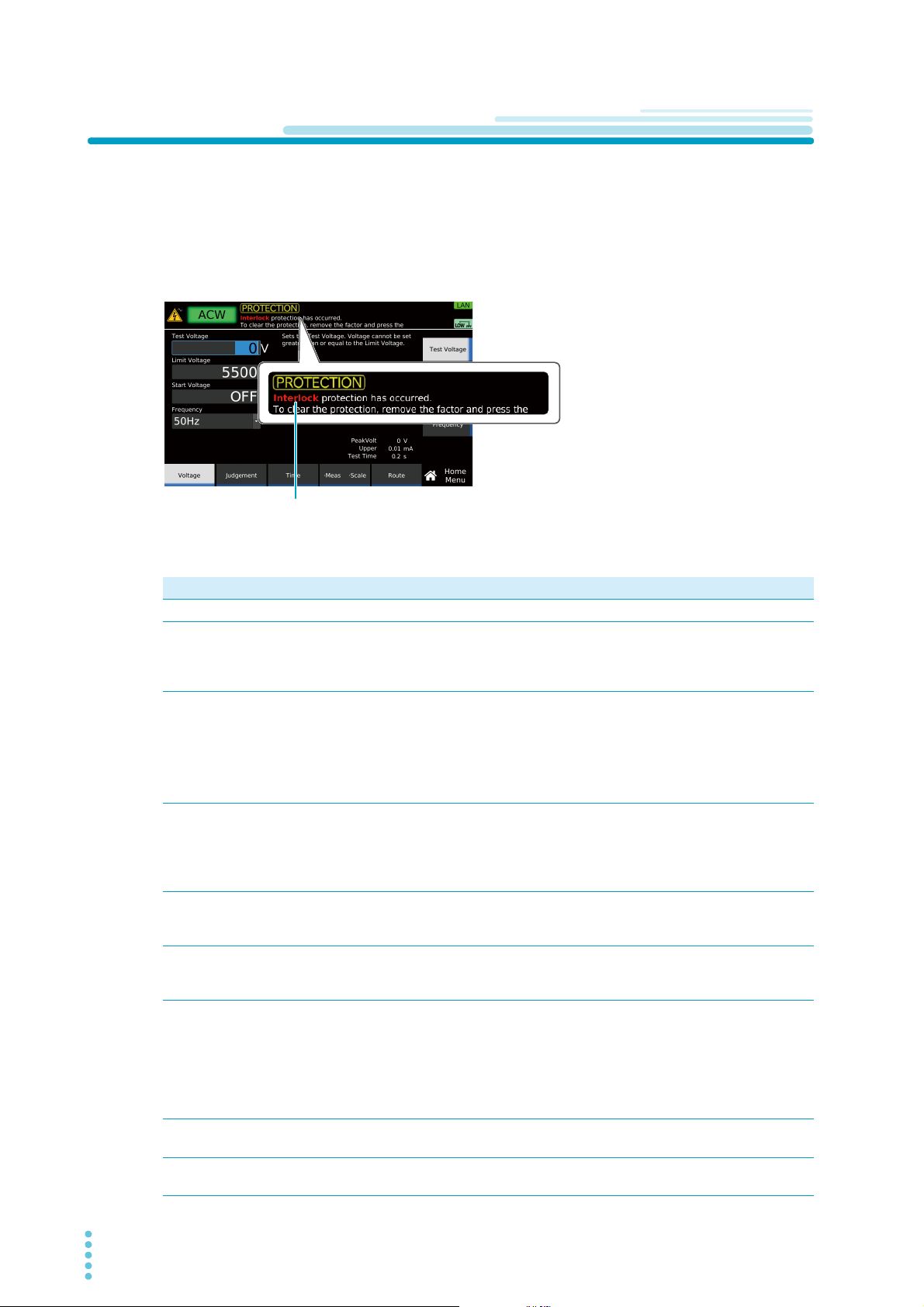

Safety Precautions for Testing

Protection Functions

When one or more protection function activation conditions are met, the protection function will be activated, and you will no longer able to perform test in this state (PROTECTION mode).

When a protection function is activated, the word “PROTECTION” is indicated on the display along with

the type of protection. If a PROTECTION mode occurs during a test, the output is shut off and the test is

stopped immediately. If a leakage current (LC) test is in progress on the TOS9303LC, the power supply to

the EUT is stopped, and the A and B terminals are opened.

Type of protectionType of protection

Use the following table to check the type of protection function, activation condition, and remedy, and

release PROTECTION mode.

Type of protection Activation condition Remedy

Interlock Interlock is activated. Release the interlock (p.204).

Power Supply There is an error in the power supply section. Pressing STOP releases the PRO-

TECTION mode, but the product

needs to be repaired. Contact your

Kikusui agent or distributor.

Output Error An output voltage outside of the following range

is detected.

ACW, DCW, IR test: ±(10 % of setting + 10 V)

EC test: ±(10 % of setting + 5 A)

This error may also occur when the output

changes suddenly.

Over Load An output power outside of the following range is

detected.

ACW: 550 VA, DCW: 110 W, EC: 240 VA,

LC: AC LINE OUT current at approx. 15.75 A or

power at 1600 VA

Over Heat The internal temperature of the product is abnor-

mally high.

Over Rating During a withstanding voltage test, an output

current is generated for a length of time that

exceeds the output time limit (p.77).

Cal The preset calibration period is exceeded. Setting Protection under Calibration

Remote The REMOTE connector is connected or discon-

nected.

Signal I/O There is a change in the SIGNAL I/O connec-

tor’s ENABLE signal.

Eliminate the cause of the error, and

press STOP.

Eliminate the cause of the error, and

press STOP.

(TOS9303LC only) Disconnect the

EUT from AC LINE OUT, and press

STOP.

Confirm that the internal temperature

of the product has decreased, and

then press STOP.

Press STOP, and wait the necessary

rest time.

(p.224) to Disable and pressing

STOP releases the PROTECTION

mode, but the product needs to be

calibrated. To have your product calibrated, contact your Kikusui agent or

distributor.

Check the REMOTE connector, and

then press STOP.

Press STOP.

22 User’s Manual TOS93 Series

Safety Precautions for Testing | Protection Functions

Type of protection Activation condition Remedy

Communication An internal communication error is occurring. Repair is necessary. Turn the power

off, and contact your Kikusui agent or

distributor.

No SCPI communication took place for more

than the specified time when the watchdog

(p.221) was enabled.

Backup There is an error in the backup data due to a

dead battery or the like.

Over Range A value exceeding the maximum value of the

measurement range is detected.

Measure There is an error in the LC test measurement

check (p.241).

Short A relay operation error is detected in an LC test. Repair is necessary. Turn the power

Earth Fault When the grounding mode (GND) is set to

Guard, abnormal current flows from the high

voltage output of this product to ground.

Scan I/F While scanning, the interface cable is discon-

nected.

The channel-assigned scanner is not detected. Check the scanner connection, and

Check the SCPI communication status.

Repair is necessary. Turn the power

off, and contact your Kikusui agent or

distributor.

Eliminate the cause of the error, and

press STOP.

Press STOP, and check whether the

test leads are broken. If you perform

another measurement check and

“Measure” still appears, repairs are

necessary. Contact your Kikusui

agent or distributor.

off, and contact your Kikusui agent or

distributor.

Set the grounding mode to Low.

Connect the interface cable, and

press STOP.

then press STOP.

TOS93 Series User’s Manual 23

Installation

WARNING

To a properly grounded outlet

Connecting the Power Cord

Risk of electric shock.

• This product is IEC Safety Class I equipment (equipment with a protective conductor terminal). To prevent electric shock, be sure to connect the protective conductor

terminal of the product to electrical ground (safety ground).

• The product is grounded through the power cord ground wire. Connect the protective conductor terminal to earth ground.

• Use the supplied power cord to connect to the AC line.

If the supplied power cord cannot be used because the rated voltage or the plug shape is

incompatible, have a qualified engineer replace it with an appropriate power cord that is 3

m or less in length. If obtaining a power cord is difficult, contact your Kikusui agent or distributor.

• Do not use the supplied power cord with other instruments.

• The power cord with a plug can be used to disconnect the product from the AC power line

in an emergency.

• Secure adequate space around the power plug. Do not insert the power plug to an outlet

where accessibility to the plug is poor. And, do not place objects near the outlet that would

result in poor accessibility to the plug.

This product is designed as an equipment of IEC Overvoltage Category II (energy-consuming equipment

supplied from a fixed installation).

Turn off ( ) the POWER switch on the front panel.

1

Check that the AC power line meets the nominal input rating of the product.

2

The product can receive a nominal power supply voltage in the range of 100 Vac to 120 Vac or

200 Vac to 240 Vac. The supported frequencies are 50 Hz and 60 Hz. (Frequency range: 47 Hz to

63 Hz)

Connect the power cord to the AC INPUT inlet on the rear panel.

3

Connect the power cord plug to an outlet with a ground terminal.

4

This completes the connections.

24 User’s Manual TOS93 Series

Installation

Checking Whether the Power Is On or Off

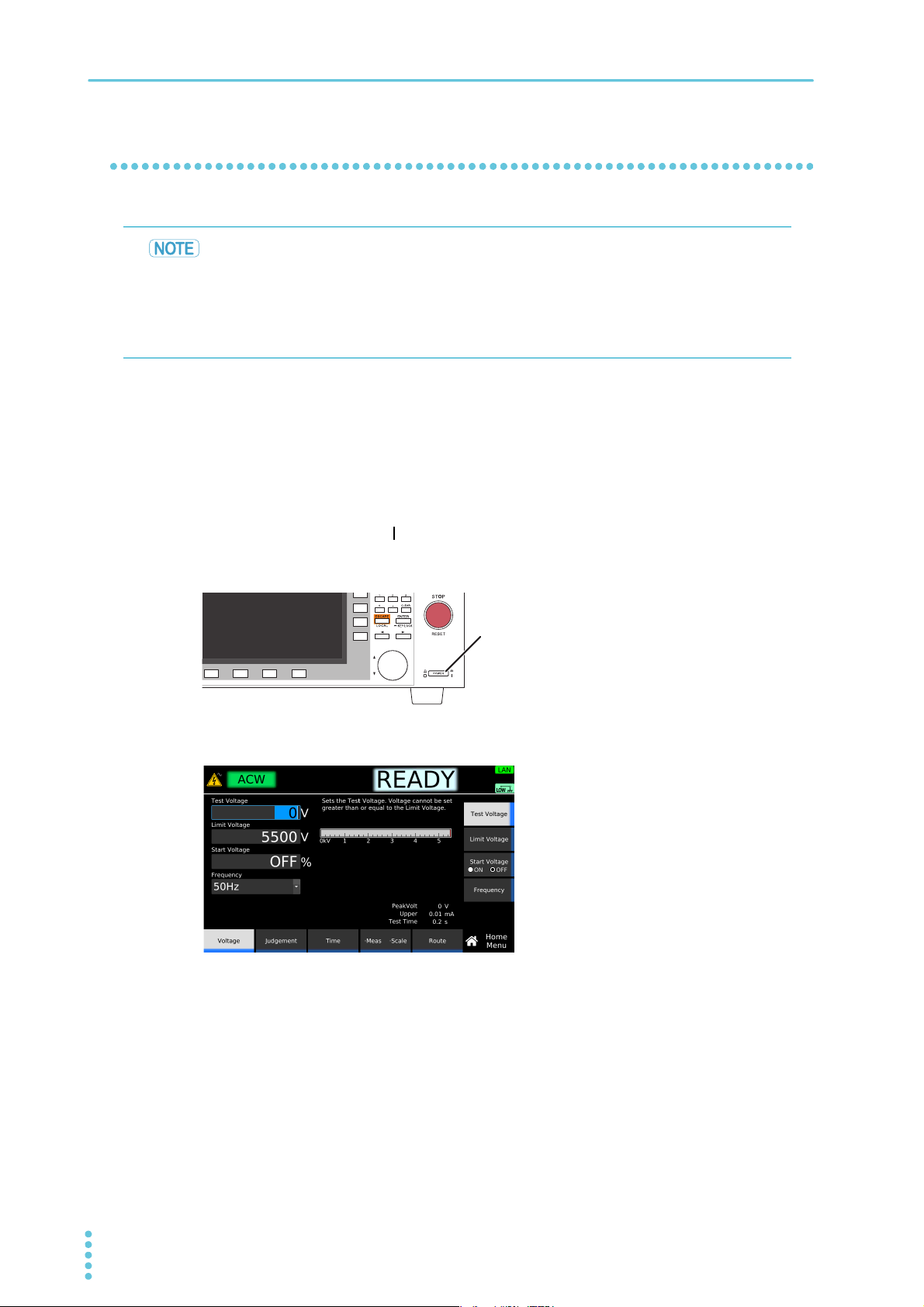

Checking the interlock operation

When this product is turned on for the first time after purchase, it starts in PROTECTION mode in which

the interlock function (p.204) prevents tests from being executed. Check that the interlock is working properly.

Check that the power cord is connected properly.

1

Check that nothing is connected to the SIGNAL I/O connector on the rear panel.

2

Turn on ( ) the POWER switch on the front panel.

3

Check that PROTECTION mode is activated.

4

After the startup screen, when the product enters PROTECTION mode, the following screen

appears.

Thiscompletesthecheckingoftheinterlockoperation.

Toreleasetheinterlocktemporarily,connecttheincludedSIGNALI/OplugtotheSIGNAL

I/Oconnector,andpressSTOPonthefrontpanel.Whenyouareactuallyperformingtests,

constructasystemthatusestheinterlocktoensuresafety(p.205).

TOS93 Series User’s Manual 25

Installation | Checking Whether the Power Is On or Off

POWER switch

Turning the power on

• When the power is turned on for the first time after purchase, the interlock function sets

the product in PROTECTION mode and prevents tests from being performed. Temporarily

connect the included SIGNAL I/O plug to the SIGNAL I/O connector to release the PROTECTION mode (p.204).

• When you actually perform tests, design a system that uses the interlock for safety

(p.205).

By factory default, the panel settings immediately before the POWER switch is turned off are saved. When

you turn the power on, the product starts in the same state as it was in the last time it was turned off. (However, the output is off.)

The panel setting state at startup can be changed (p.220).

Check that the power cord is connected properly.

1

Turn the POWER switch ( ) on.

2

The DANGER LED lights, but no voltage is generated. If it does not, stop using the product, and

contact your Kikusui agent or distributor.

After the startup screen is displayed, the home screen of the test that was in use before the power

was turned off the last time appears.

The power is now on.

26 User’s Manual TOS93 Series

Turning the power off

WARNING

Turning the POWER switch off ( )

1

The power is turned off.

Risk of electric shock.

• If you want to turn the POWER switch back on, wait at least 10 seconds. It is dangerous to do otherwise, because the protective functions of the product may not

work effectively. This may cause the product to malfunction or reduce the life of the

POWER switch and internal parts such as the fuses.

• Except in an emergency, do not turn the power off while output is being generated.

Installation | Checking Whether the Power Is On or Off

TOS93 Series User’s Manual 27

Installation

9300

9303LC

WARNING

WARNING

Never touch these while

the DANGER LED is lit.

After the test leads are connected

Connection for Withstanding Voltage and Insulation Resistance Tests

Applicable models for withstanding voltage test: All models

Applicable models for insulation resistance test: , , ,

Risk of electric shock. While the DANGER LED is lit, never touch the HIGH VOLTAGE

terminal, test leads, or EUT.

Connecting the test leads

Risk of electric shock.

• Parts of the included test leads near the alligator

clips protrude from the vinyl insulation when the

wires are connected. These parts are dangerous.

Never come close to these parts while the DANGER

LED is lit.

• If connections are incomplete, the entire EUT may be

charged to a high voltage. This is dangerous, so be

sure to connect the EUT correctly.

• Be sure to connect the low-voltage test lead (black) first.

9301

9303

Connect the supplied high voltage test lead TL31-TOS to this product.

Before starting work, check that the covering of the test leads are not torn and that the wires are not broken (p.239).

The following procedure uses the TOS9303LC as an example.

28 User’s Manual TOS93 Series

Installation | Connection for Withstanding Voltage and Insulation Resistance Tests

Check that the POWER switch is off and that the DANGER LED is off.

1

Raise the LOW terminal’s cable lock, and then connect the low-voltage test lead

2

(black).

Lower the cable lock.

3

Check that the connection is secure.

Connect the low-voltage test lead (black) to the EUT.

4

Connect the high-voltage test lead (red) to the EUT.

5

Connect the high-voltage test lead (red) to the HIGH VOLTAGE terminal.

6

This completes the connections.

TOS93 Series User’s Manual 29

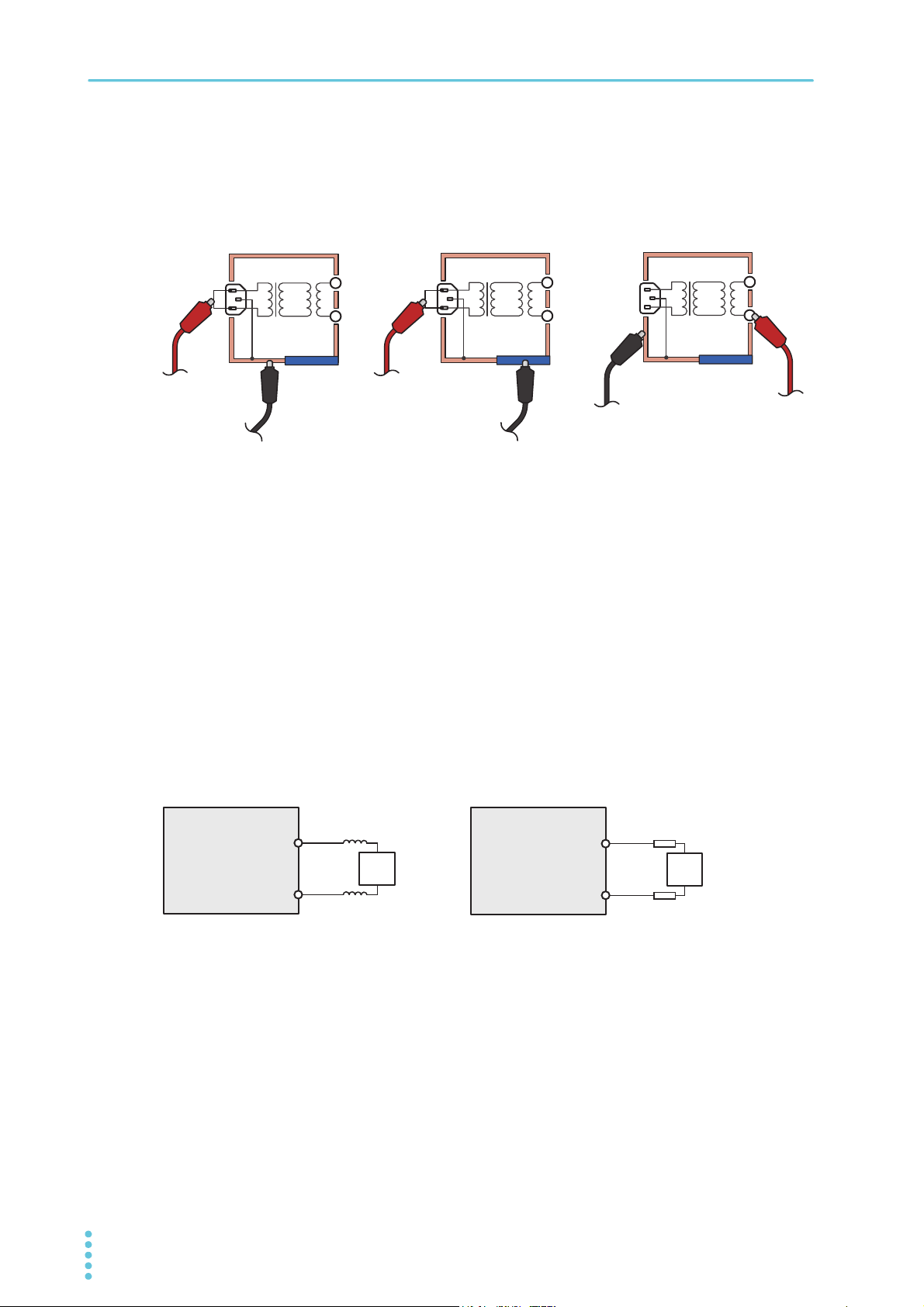

Installation | Connection for Withstanding Voltage and Insulation Resistance Tests

To the HIGH

VOLTAGE

terminal

To the HIGH

VOLTAGE

terminal

To the LOW

terminal

To the HIGH

VOLTAGE

terminal

To the LOW

terminalTo the LOW

terminal

EUT EUTEUT

Ex: Between the power supply

(primary) and grounded

enclosure

Ex: Between the power supply

(primary) and ungrounded

enclosure

Ex: Between the insulation

connection area and

enclosure

470 ȍ, 3

470 ȍ, 3

Toroidal core

Toroidal core

HIGH VOLTAGE

LOW

TOS93TOS93

HIGH VOLTAGE

LOW

EUT

EUT

Examples of how to connect test leads to the EUT

Reducing the effect of noise

Electronic devices in the surrounding area may malfunction due to the effect of noise produced by short

circuits across outputs or a dielectric breakdown of the EUT. To reduce the effect of noise, connect a toroidal core or a resistor of approximately 470 Ω between the tips of the high- and low-voltage test leads and

the EUT. Connect the toroidal core or resistor as close to the EUT as possible.

If you are connecting a toroidal core, it is effective to wrap the test leads two to three times around a type

of core that can be snapped on and that is often used with power cords. This type of core is usually

approximately 20 mm in diameter.

If you are connecting a resistor, pay close attention to the power rating of the resistor. When the upper limit

is 10 mA or less, connect a resistor of approximately 470 Ω (3 W, 30 kV impulse withstanding voltage).

Because connecting the resistor causes the voltage to fall, the voltage that is actually applied to the EUT is

slightly lower than the voltage that is generated from the product’s output terminals (when a 10 mA current

flows, the voltage falls approximately 10 V).

These methods are extremely useful in reducing the effect of noise.

W

W

When connecting toroidal cores When connecting resistors

30 User’s Manual TOS93 Series

Loading...

Loading...