Kikusui TOS9213S, TOS9213AS Operation Manual

Part No. Z1-004-642, IB019757

Jul. 2018

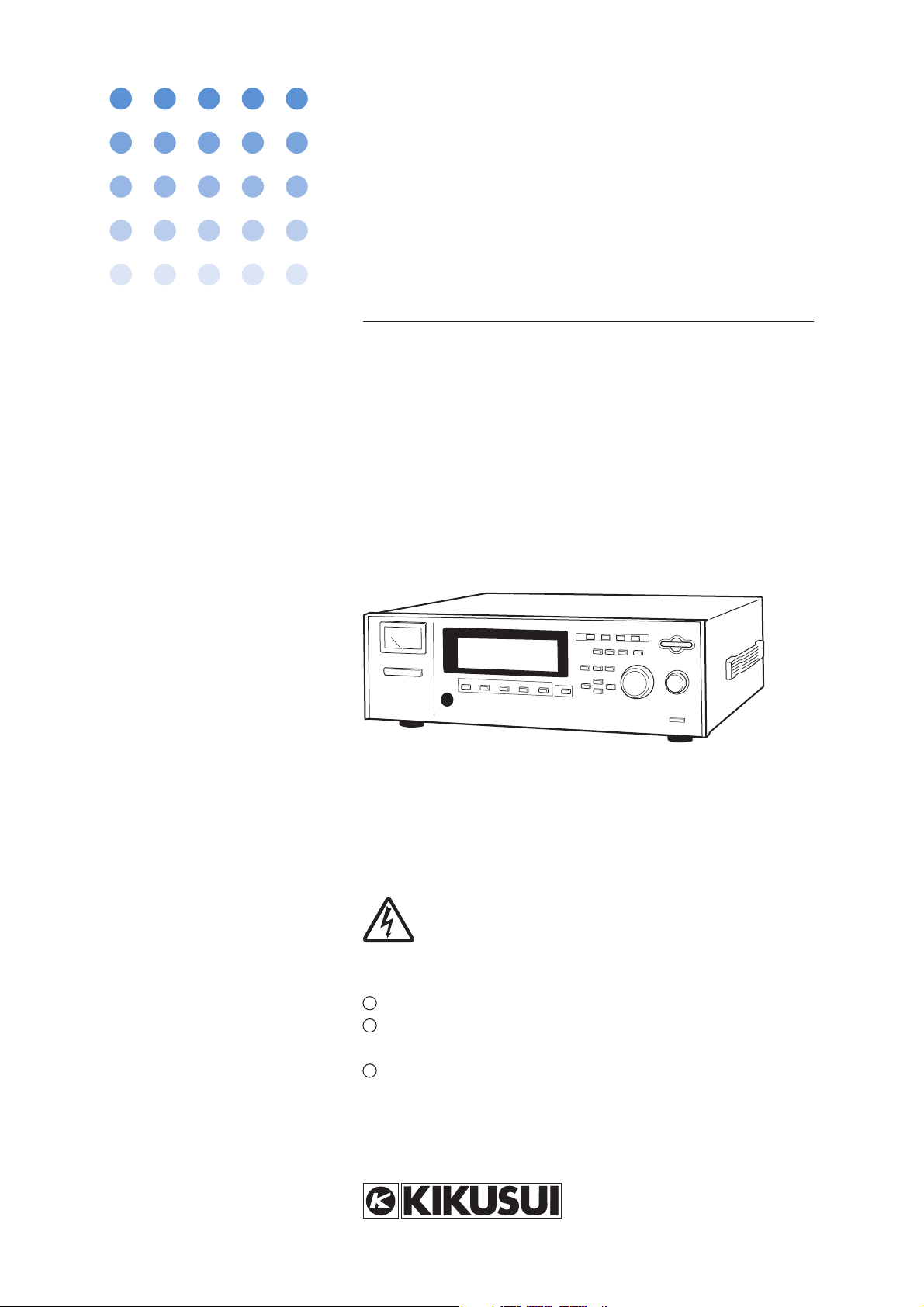

OPERATION MANUAL

DC WITHSTANDING VOLTAGE/

INSULATION RESISTANCE TESTER

TOS9200 Series

TOS9213S

(SPEC80623)

TOS9213AS

(SPEC80767)

DANGER

This Tester generates high voltage.

Any incorrect handling may cause death.

Read Chapter 3 “Precautions on Handling” in

this manual to prevent accident.

Keep this manual near the tester for easy

access of the operator.

Use of Operation Manual

Please read through and understand this Operation Manual before operating the product. After reading, always

keep the manual nearby so that you may refer to it as needed. When moving the product to another location,

be sure to bring the manual as well.

If you find any incorrectly arranged or missing pages in this manual, they will be replaced. If the manual it

gets lost or soiled, a new copy can be provided for a fee. In either case, please contact Kikusui distributor/

agent, and provide the “Kikusui Part No.” given on the cover.

This manual has been prepared with the utmost care; however, if you have any questions, or note any errors or

omissions, please contact Kikusui distributor/agent.

Disposing of used Kikusui products in the EU

Under a law adopted by member nations of the European Union (EU), used electric and electronic products

carrying the symbol below must be disposed of separately from general household waste.

This includes the power cords and other accessories bundled with the products. When

disposing of a product subject to these regulations, please follow the guidance of your

local authority, or inquire with your Kikusui distributor/agent where you purchased the

product.

The symbol applies only to EU member nations.

Disposal outside the EU

When disposing of an electric or electronic product in a country that is not an EU member, please contact your

local authority and ask for the correct method of disposal.

The other company names and product names that appear in this manual are the trademarks or registered

trademarks of the respective manufacturers.

Reproduction and reprinting of this operation manual, whole or partially, without our permission is prohibited.

Both unit specifications and manual contents are subject to change without notice.

Copyright© 2009 Kikusui Electronics Corporation

Interlock Function

The first time the tester is turned on following delivery, the interlock

function activates and testing is disabled.

Before starting a test, read "6.3 INTERLOCK Connector" for the

procedure for starting up the tester using the interlock function.

About this manual

This operation manual describes the withstanding voltage tester

TOS9213S and TOS9213AS.

This manual is applicable to the Tester whose ROM version

number is:

Ver. 1.4x

Yo u can check the version number on the opening screen at turning on the power

or by using the *IDN? message.

For the *IDN? message, see "7.4.1 Register-Related Messages and General Purpose

Messages."

When you contact us for any information about the Tester, please indicate

the ROM version number and serial number of the Tester. The serial number

is shown on the rear panel of the Tester.

The opening screen (Example of ROM version is 1.20)

TOS9213S

DC WITHSTANDING VOLTAGE /

INSULATION RESISTANCE TESTER

Ver. 1.20

KIKUSUI ELECTRONICS CORP.

TOS9213S/ TOS9213AS i

To supervisor in charge of operation

• If the operator does not read the language used in this manual, translate the manual into appropriate language.

• Help the operator in understanding this manual before operation.

• Keep this manual near the tester for easy access of the operator.

For your own safety (to avoid electrification)

While the tester is delivering its test voltage, never touch the following areas, or else, you will be

electrified, and run the risk of death by electric shock.

•the output terminal

• the test leadwires connected to the output terminal

•the Device Under Test (DUT)

• any part of the tester, w hich is electrically connected to the output terminal, and

• the same part as above immediately after the output has been cut off when in the DC mode of

test.

Also, electric shock or accident may arise in the following cases:

• the tester being operated without grounding.

• if the gloves for electrical job are not used.

• approach to any part connected to the output terminal while the power of the tester is turned

on.

• the same action as above immediately after the power of tester has been turn

DC mode of test.

ed off whe

n in the

ii TOS9213S/ TOS9213AS

Power Requirements of this Product

✓

WARNING

Power requirements of this product have been changed and the relevant sections of the Operation

Manual should be revised accordingly.

(Revision should be applied to items indicated by a check mark .)

Input voltage

The input voltage of this product is VAC,

and the voltage range is

Input fuse

The rating of this product's input fuse is A, VAC, and .

•To avoid electrical shock, always disconnect the AC power cord or turn off

the switch on the switchboard before attempting to check or replace the

fuse.

•Use a fuse element having a shape, rating, and characteristics suitable

for this product. The use of a fuse with a different rating or one that short

circuits the fuse holder may result in fire, electric shock, or irreparable

damage.

to VAC. Use the product within this range only.

TOS9213S/ TOS9213AS iii

For the safe use and safe maintenance of this product, the following

symbols are used throughout this manual and on the product. Understand the meanings of the symbols and observe the instructions they

indicate (the choice of symbols used depends on the products).

OR

WARNING

CAUTION

Safety Symbols

Indicates that a high voltage (over 1000 V) is used here. Touch-

ing the part causes a possibly fatal electric shock. If physical

contact is required by your work, start work only after you make

sure that no voltage is output here.

DANGER

Indicates an imminently hazardous situation which, if ignored,

will result in death or serious injury.

Indicates a potentially hazardous situation which, if ignored,

could result in death or serious injury.

Indicates a potentially hazardous situation which, if ignored, may

result in damage to the product and other property.

Shows that the act indicated is prohibited.

Is placed before the sign “DANGER,” “WARNING,” or “CAUTION” to emphasize these. When this symbol is marked on

pro

duct, see the relevant sections in this manual.

the

Indicates a protective conductor terminal.

Indicates a chassis(frame) terminal.

iv Safety Symbols TOS9213S/ TOS9213AS

Safety Precautions

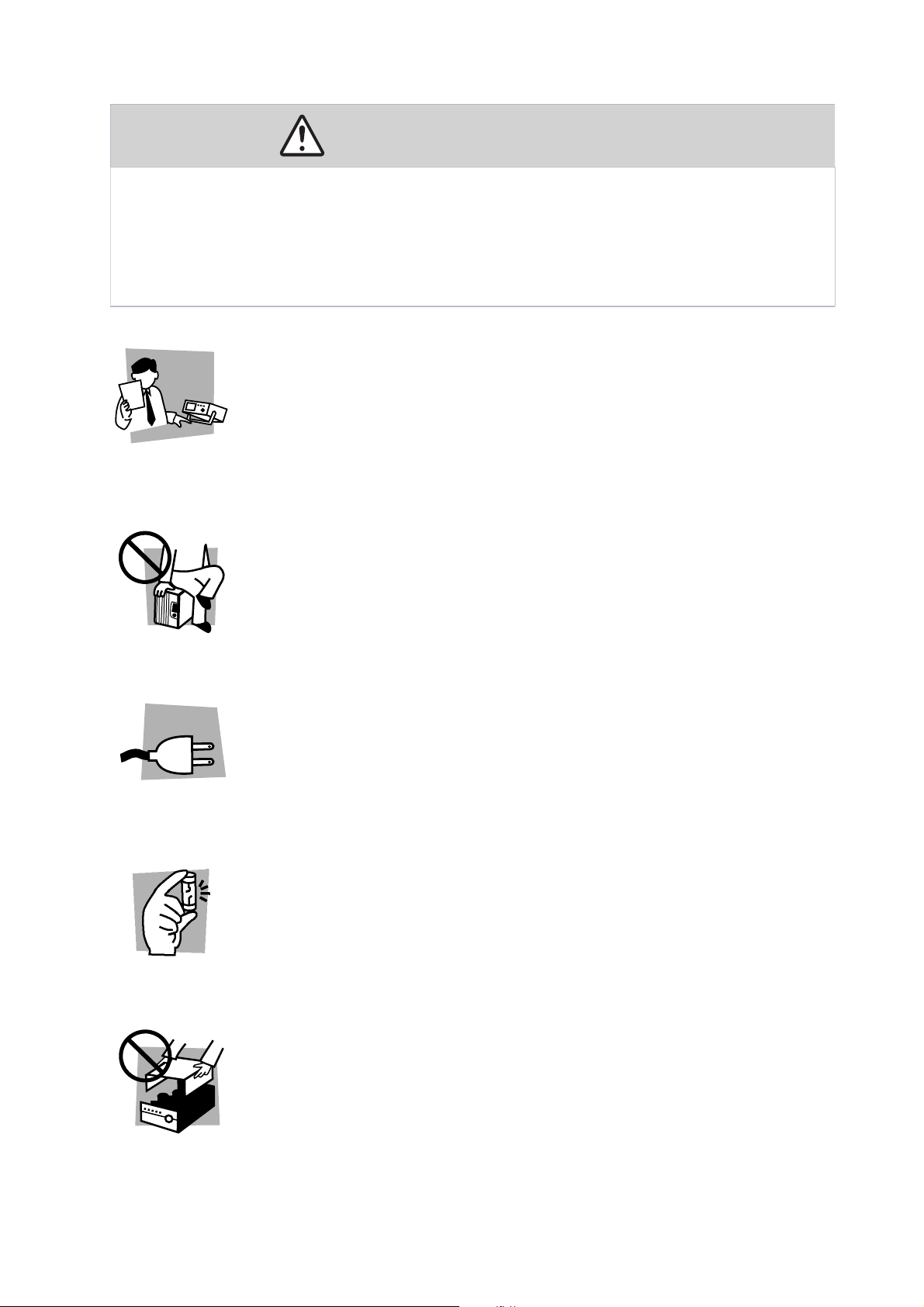

Operation

Manual

Line

Voltage

The following safety precautions must be observed to avoid fire hazard,

electrical shock, accidents, and other failures. Keep them in mind and

make sure that all of them are observed properly. Using the product in a

manner that is not specified in this manual may impair the protection

functions provided by the product.

Users

• This product must be used only by qualified personnel who understand the contents of this operation manual.

• If it is handled by disqualified personnel, personal injury may result. Be sure to handle it under supervision of qualified personnel (those who have electrical knowl-

edge.)

Purposes of use

• Do not use the product for purposes other than those described in the operation

manual.

• This product is not designed or manufactured for general home or consumer use.

Input power

• Use the product with the specified input power voltage.

• For applying power, use the AC power cord provided.

• This product is an equipment of IEC Overvoltage Category II (energy-consuming

equipment supplied from the fixed installation).

Fuse

•The fuse can be replaced with a new one. When replacing a fuse, use the one

which has appropriate shape, ratings, and specifications.

Cover

• There are parts inside the product which may cause physical hazards. Do not

remove the external cover.

TOS9213S/ TOS9213AS v

Grounding

GNL

Check?

• This product is an IEC Safety Class I equipment (equipment with a protective conductor terminal). To prevent electric shock, be sure to connect the protective conductor terminal of the product to electrical ground (safety ground).

Installation

• This product is designed for safe indoor use. Be sure to use the product indoors.

• When installing products, be sure to observe precautions concerning installation

location. For details, see the respective page in the operation manual.

Relocation

•Turn off the power switch and then disconnect all cables when relocating the prod-

uct.

•Be sure the operation manual be included when the product is relocated.

Operation

• If any abnormality or failure is detected in the products, stop using it immediately.

Unplug the AC power cord. Be careful not to allow the product to be used before it

is completely repaired.

• Do not disassemble or modify the product. If it must be modified, contact Kikusui

distributor/agent.

Maintenance and checking

•To avoid electrical shock, be absolutely sure to unplug the AC power cord before

performing maintenance or checking. Do not remove the cover.

• To maintain performance and safe operation of the product, it is recommended that

periodic maintenance, checking, cleaning, and calibration be performed.

Service

• Internal service is to be done by Kikusui service engineers. If the product must be

adjusted or repaired, contact Kikusui distributor/agent.

vi TOS9213S/ TOS9213AS

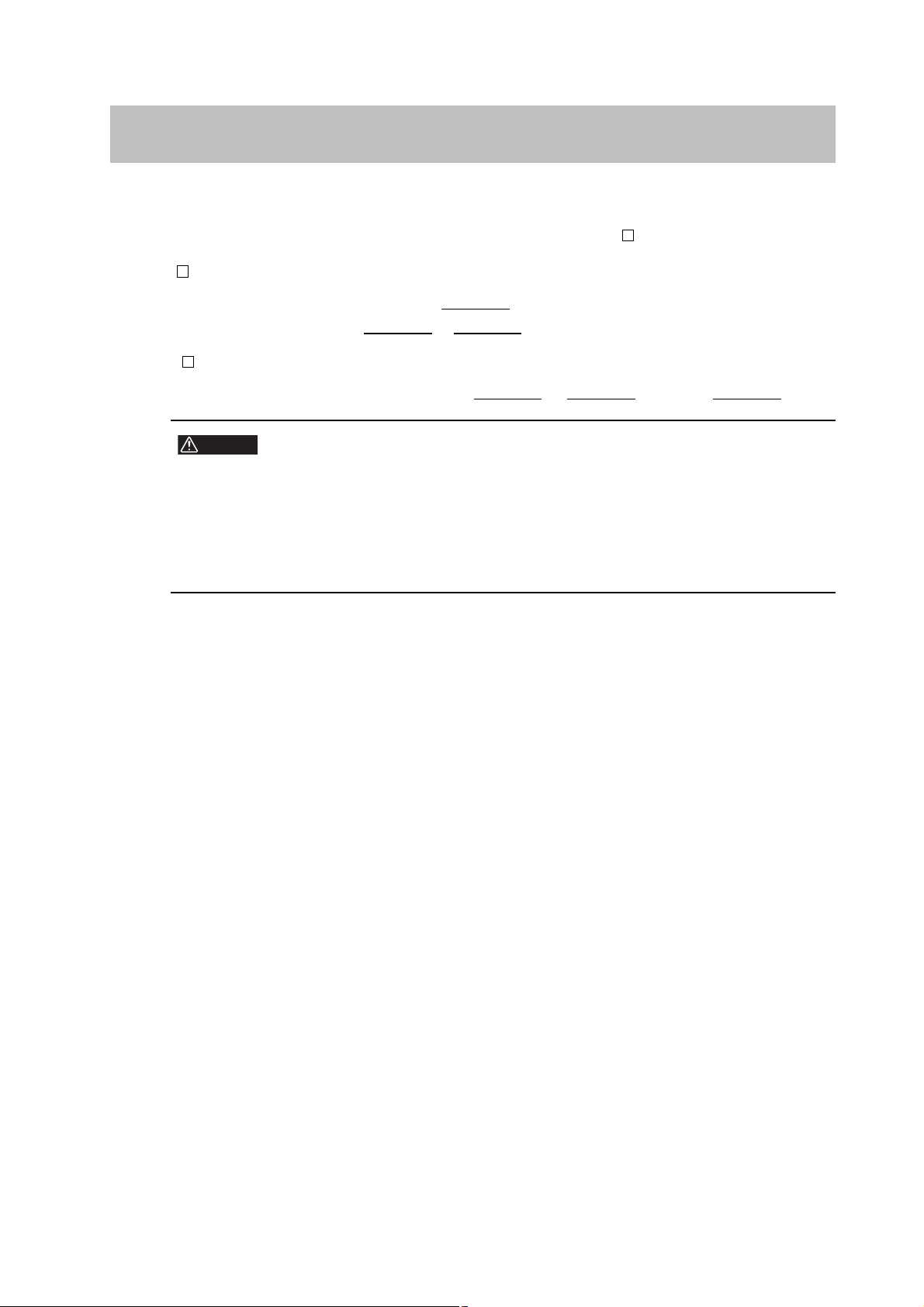

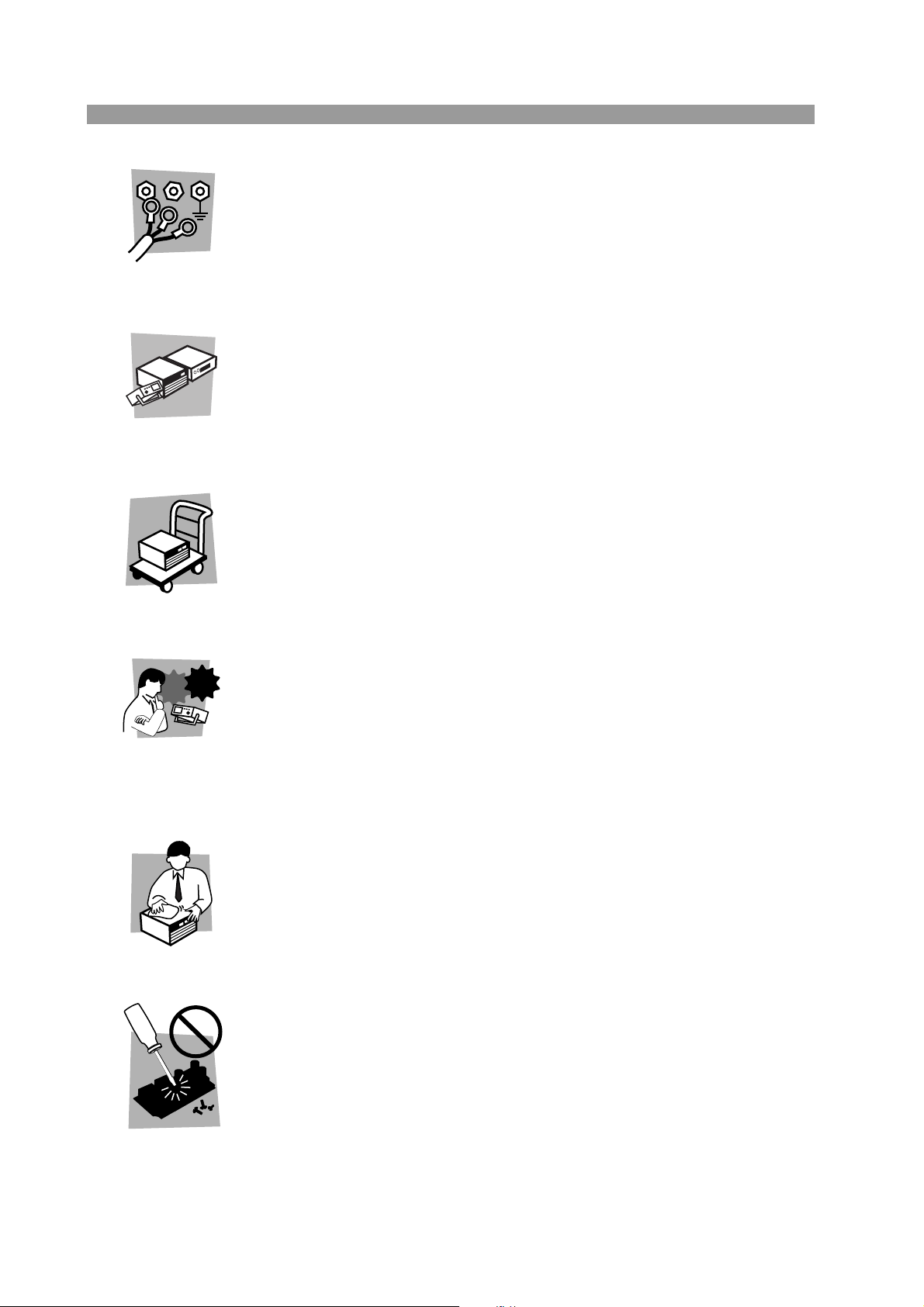

Front panel and Rear panel

OUTPUT

AUTO

RECALL

ENTER

DCW IR SYSTEM LOCAL

TEST

FUNCTION GPIB

PASS FAIL

MEMORY ENTRY

CURSOR

REMOTE

PROTECTION

RMT

FF

5

F

4

F

3

F

2

F

1

PREV NEXT

EDIT

STORE

I

/

F KEY LOCK

SHIFSHIFT

DANGER

DC WITHSTANDING VOLTAGE

/

INSULATION RESISTANCE TESTER

TOS9213S

HIGH VOLTAGE

TERMINAL

LOW

MAX10kV

Before using the remote-control

function, read the Operation Manual.

For connection, begin with the test

leadwire of the low-voltage level.

Deflected meter pointer means that the Tester is in

“DANGER HIGH VOLTAGE” state.

Lighted lamp means that

the Tester is in “DANGER

HIGH VOLTAGE” state.

To ensure safety, be sure to connect to an earth

ground.See “2.5 Connecting the AC Power Cord.”

Before using the remote-control

function, read the Operation Manual.

To change testing conditions,

press the STOP button.

DANGER

HIGH VOLTAGE terminal

• Before using the tester, be sure to read Chapter3 "Precautions on Handling"

TOS9213S/ TOS9213AS vii

Description of Contents

This manual is composed of the following chapters:

Chapter 1 Preface

This section provides an outline of the tester and explains its features and options.

Chapter 2 Setup

This chapter describes the procedures from unpacking to installation to operation

checking.

Chapter 3 Precautions on Handling

This chapter describes the precautions to be followed in the handling of this tester.

When using the tester, take utmost care to ensure safety.

Chapter 4 Part names and Functions

This chapter describes the names and functions of components such as switches,

displays, and connectors on the front and rear panels.

Chapter 5 Basic Operations

This chapter describes the procedures for conducting withstanding voltage and insulation resistance tests.

Chapter 6 Using Terminals and Connectors

This chapter describes the procedures for use of the connectors on the front and rear

panels.

Chapter 7 GPIB/RS-232C Interface

This chapter describes the GPIB and RS-232C interfaces and the device messages.

Chapter 8 Controlling the TOS6200

This chapter describes the procedure for using the tester to control Kikusui’s earth

continuity tester TOS6200 via the RS-232C interface.

Chapter 9 Maintenance

This chapter describes the maintenance, inspection, and calibration of the tester.

Chapter 10 Specifications

This chapter describes the electrical and mechanical specifications for the tester.

Appendix

Appendix describes the operating principle of the tester and ASCII code table (20H

to 7EH).

viii TOS9213S/ TOS9213AS

Contents

Safety Symbols - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - iv

Safety Precautions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - v

Chapter 1 Preface

1.1 Outline - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.2 Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

1.3 Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

Chapter 2 Setup

2.1 Unpacking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.2 Precautions for Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

2.3 Precautions for Moving- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-4

2.4 Checking the Line Voltage and Fuse - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

2.4.1 Switching source voltages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

2.4.2 Checking and replacing fuses - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-6

2.5 Connecting the AC Power Cord - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-7

2.6 Checking Operations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-9

Chapter 3 Precautions on Handling

Chap. 1Chap. 2Chap. 3Chap. 4Chap. 5Chap. 6Chap. 7Chap. 8Appendix Chap. 9Chap. 10

3.1 Prohibited Operations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.2 Action When in Emergency- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.3 Precautions on Testing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

3.4 Warning for Residual High Voltages - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-4

3.5 Dangerous States of Failed Tester - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-5

3.6 To Ensure Long-Term Use Without Failures- - - - - - - - - - - - - - - - - - - - - - - 3-6

3.7 Daily Checking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

Chapter 4 Part names and Functions

4.1 Front Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

4.2 Rear Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-6

Chapter 5 Basic Operations

5.1 Turning on the Power - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

5.2 Pre-Test Zero Adjustment- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

5.3 Structure of LCD Screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-4

5.4 Settings for DC Withstanding Voltage Testing - - - - - - - - - - - - - - - - - - - - - 5-5

5.4.1 Settings on the DCW1 screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-6

5.4.2 Settings on the DCW2 screen - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-10

5.4.3 Settings on the DCW3 screen - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-18

5.5 Settings for Insulation Resistance Testing - - - - - - - - - - - - - - - - - - - - - - - 5-20

5.5.1 Settings on the IR1 screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-21

5.5.2 Settings on the IR2 screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-28

5.5.3 Settings on the IR3 screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-34

5.6 Connecting the Test Leadwire- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-36

TOS9213S/ TOS9213AS ix

5.6.1 Connecting the test leadwire to the tester - - - - - - - - - - - - - - - - - - - 5-36

5.6.2 Connecting a DUT- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-36

5.7 Starting and Ending a Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-38

5.7.1 Starting a test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-38

5.7.2 Ending the test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-40

5.8 System Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-43

5.8.1 SYSTEM 1 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-43

5.8.2 SYSTEM2 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-45

5.8.3 SYSTEM3 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-47

5.8.4 SYSTEM4 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-48

5.9 Interface Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-49

5.10 Panel Memory - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-50

5.10.1Storage in the panel memory - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-50

5.10.2Recalling panel memory - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-51

5.11 Program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-52

5.11.1Creating and editing a program - - - - - - - - - - - - - - - - - - - - - - - - - - 5-53

5.11.2Executing a program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-55

5.11.3Suspending the program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-55

5.11.4Judgement on the program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-56

5.11.5Exiting the program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-56

5.12 Key Lock - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-57

5.13 Invalid Settings- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-57

5.14 Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-58

5.15 Initialization - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-62

Chapter 6 Using Terminals and Connectors

6.1 REMOTE Terminal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

6.2 SIGNAL I/O Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-4

6.2.1 Specifications for the SIGNAL I/O connector - - - - - - - - - - - - - - - - - - 6-5

6.2.2 Example- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-7

6.2.3 Starting a test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-8

6.2.4 Recalling the panel memory and programs - - - - - - - - - - - - - - - - - - 6-10

6.3 INTERLOCK Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-12

6.4 STATUS OUT Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-14

Chapter 7 GPIB/RS-232C Interface

7.1 GPIB Interface - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

7.1.1 Connecting the GPIB cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

7.1.2 Setting the GPIB address- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-3

7.2 RS-232C Interface - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-4

7.2.1 Connecting the RS-232C cable - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-4

7.2.2 RS-232C settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-4

7.2.3 RS-232C flow control- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-6

7.3 Messages and Terminators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-7

7.3.1 Messages- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-7

7.3.2 Terminators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-9

7.3.3 Special symbols and characters - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-9

7.4 Device Messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-10

7.4.1 Register-related messages and general purpose messages - - - - - - 7-10

7.4.2 Messages used exclusively for DC withstanding voltage testing - - - 7-16

x TOS9213S/ TOS9213AS

7.4.3 Messages used exclusively for insulation resistance testing - - - - - - 7-24

7.4.4 Messages common to all tests - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-33

7.4.5 System-related messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-36

7.4.6 Memory-related messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-44

7.4.7 Program-related messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-50

7.5 Registers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-56

7.6 Message List- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-60

7.6.1 Register-related messages and general messages - - - - - - - - - - - - 7-60

7.6.2 Messages for DC withstanding voltage testing - - - - - - - - - - - - - - - 7-61

7.6.3 Messages for insulation resistance testing - - - - - - - - - - - - - - - - - - 7-62

7.6.4 Messages common to all tests - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-63

7.6.5 System-related messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-64

7.6.6 Memory-related messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-66

7.6.7 Program-related messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-68

Chapter 8 Controlling the TOS6200

8.1 Pre-Control Preparation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-2

8.1.1 Connection and startup procedure - - - - - - - - - - - - - - - - - - - - - - - - - 8-2

8.1.2 Settings on the TOS6200 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-2

8.1.3 Settings on the TOS9213S/ TOS9213AS - - - - - - - - - - - - - - - - - - - - 8-3

8.2 Starting a Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-6

8.3 Test Judgement- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-7

8.4 Canceling the TOS6200 Control Mode- - - - - - - - - - - - - - - - - - - - - - - - - - - 8-8

Chap. 1Chap. 2Chap. 3Chap. 4Chap. 5Chap. 6Chap. 7Chap. 8Appendix Chap. 9Chap. 10

Chapter 9 Maintenance

9.1 Cleaning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-2

9.2 Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-2

9.3 Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-3

9.4 Calibration- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-3

9.5 Troubleshooting- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-4

Chapter 10 Specifications

10.1 Withstanding Voltage Test Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-2

10.2 Insulation Resistance Testing Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-5

10.3 Interface and Other Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-8

10.4 General Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -10-11

10.5 Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -10-12

Appendix

A.1 Operating Principle - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-1

A.2 ASCII Code 20H to 7EH - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-3

Index

TOS9213S/ TOS9213AS xi

xii TOS9213S/ TOS9213AS

Chapter 1 Preface

Chap. 1

Preface

This section provides an outline of the tester and explains its features and options.

TOS9213S/ TOS9213AS 1-1

1.1 Outline

The TOS9213S/ TOS9213AS (hereinafter referred to as “the tester”) is withstanding

voltage/insulation resistance tester. The tester can perform DC withstanding voltage

testing and insulation resistance testing. The tester can operate at up to 10 kVDC (at

a maximum output of 50 W for up to 1 minute) in DC withstanding voltage testing.

The tester is capable of performing withstanding voltage testing on electronic equipment and components in accordance with safety standards, including IEC, EN,

VDE, BS, UL, CSA, JIS, and the Electrical Appliance and Material Safety Law (in

Japan.)

The high-voltage block features a high-efficiency switching power supply and a

PWM-based switching amplifier. This ensures high and stable output extremely

resistant to power-supply and load fluctuations.

Because the tester boasts measurement accuracy that enables it to handle high-resolution current measurements and judgements of values as small as tens of µA, it is

ideal for testing solar panels (photovoltaic panels) and other devices.

For insulation resistance testing, TOS9213S is compatible with the test voltage

range of 25 V to 1000 V (at a resolution of 1 V) and the resistance measuring range

of 0.01 M

whereas TOS9213AS is compatible with the test voltage range of 25 V to 1500 V

(at a resolution of 1V) and the resistance measuring range of 0.01 M

(at rated current range of 50nA to 1 mA maximum, or at rated current range of 50

nA to 0.1 mA if the test voltage setting exceeds 1020 V).

Not only can the tester make judgements using insulation resistance values, it can

also make judgments using measurements of the leakage current that flows through

the insulation resistance.

Once connected to a DUT, the tester can not only perform DC withstanding voltage

tests, and insulation resistance tests separately, but can also conduct these tests consecutively using the program function. When combined with the high-voltage scanner TOS9221/TOS9220, each tester can operate using four channels. The tester can

be connected to four scanners, thus permitting the connection of a total of 16 channels. Further, when used together with the earth continuity tester TOS6200, the tester can also be applied to safety tests such as earth continuity tests. (When combined

with the scanner, the output voltage is up to 6 kV.)

The tester is equipped with GPIB and RS-232C as standard features, making them

highly applicable to a variety of automatic testing systems that require greater safety

and reliability.

Ω to 9.99 GΩ (at rated current range of 50 nA to 1 mA maximum),

Ω to 9.99 GΩ

1-2 TOS9213S/ TOS9213AS

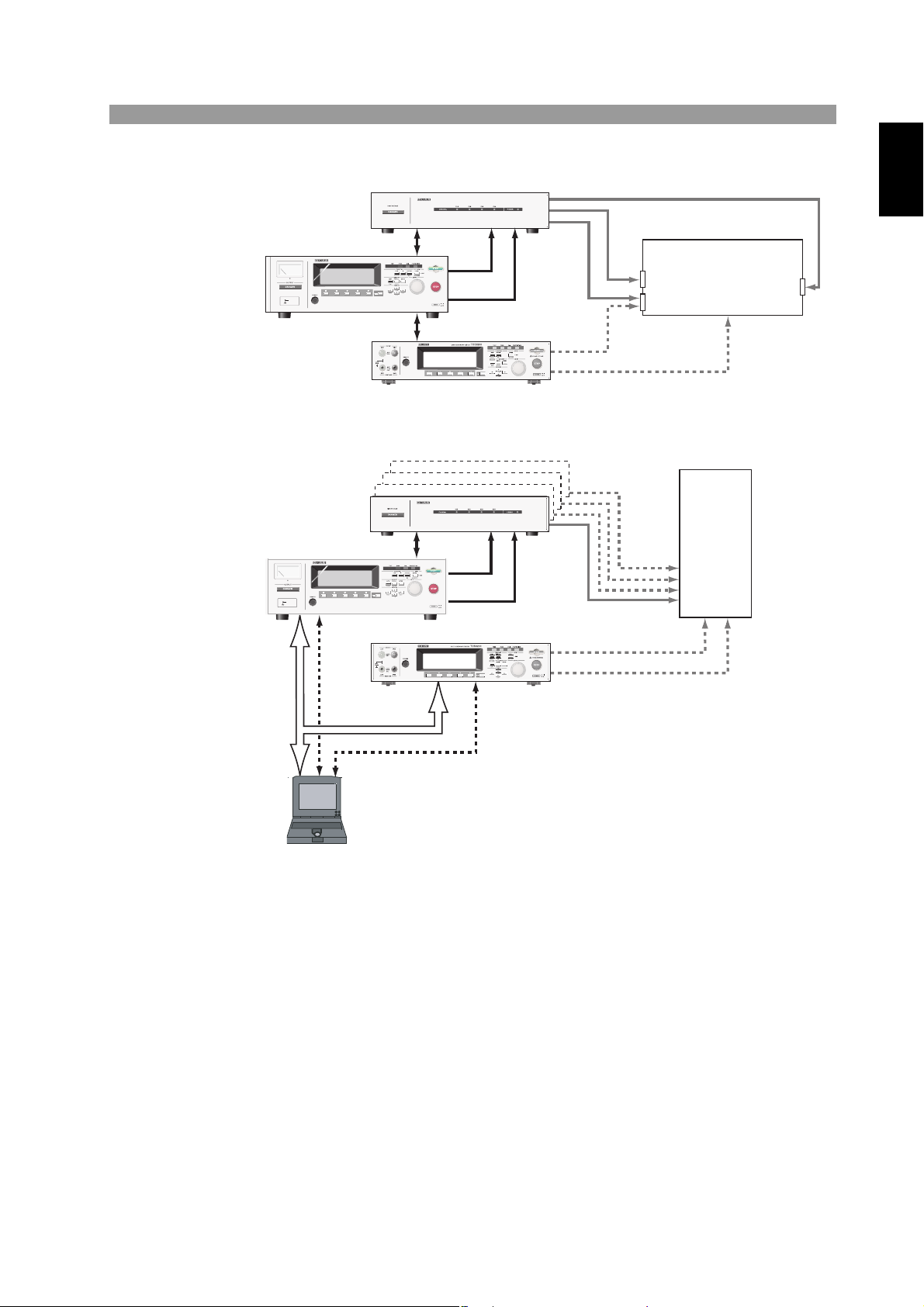

Example of system application 1

SCAN I/F

Maximum of

16 channels

RS-232C

RS-232C

GPIB

H.V

LOW

DUT

TOS9220/9221

TOS9213S/9213AS

TOS6200

DC WITHSTANDING VOLTAGE/

INSULATION RESISTANCE TESTER

TOS9213S

TERMINAL

LOW

TOS9220/9221

Chap. 1

TOS9213S/9213AS

SCAN I/F

H.V

TERMINAL

LOW

DC WITHSTANDING VOLTAGE/

INSULATION RESISTANCE TESTER

TOS9213S

LOW

RS-232C

TOS6200

Example of system application 2

DUT

Switching power supply

Switching

power supply

GND

terminal

Frame

Output

terminal

Preface

TOS9213S/ TOS9213AS 1-3

1.2 Features

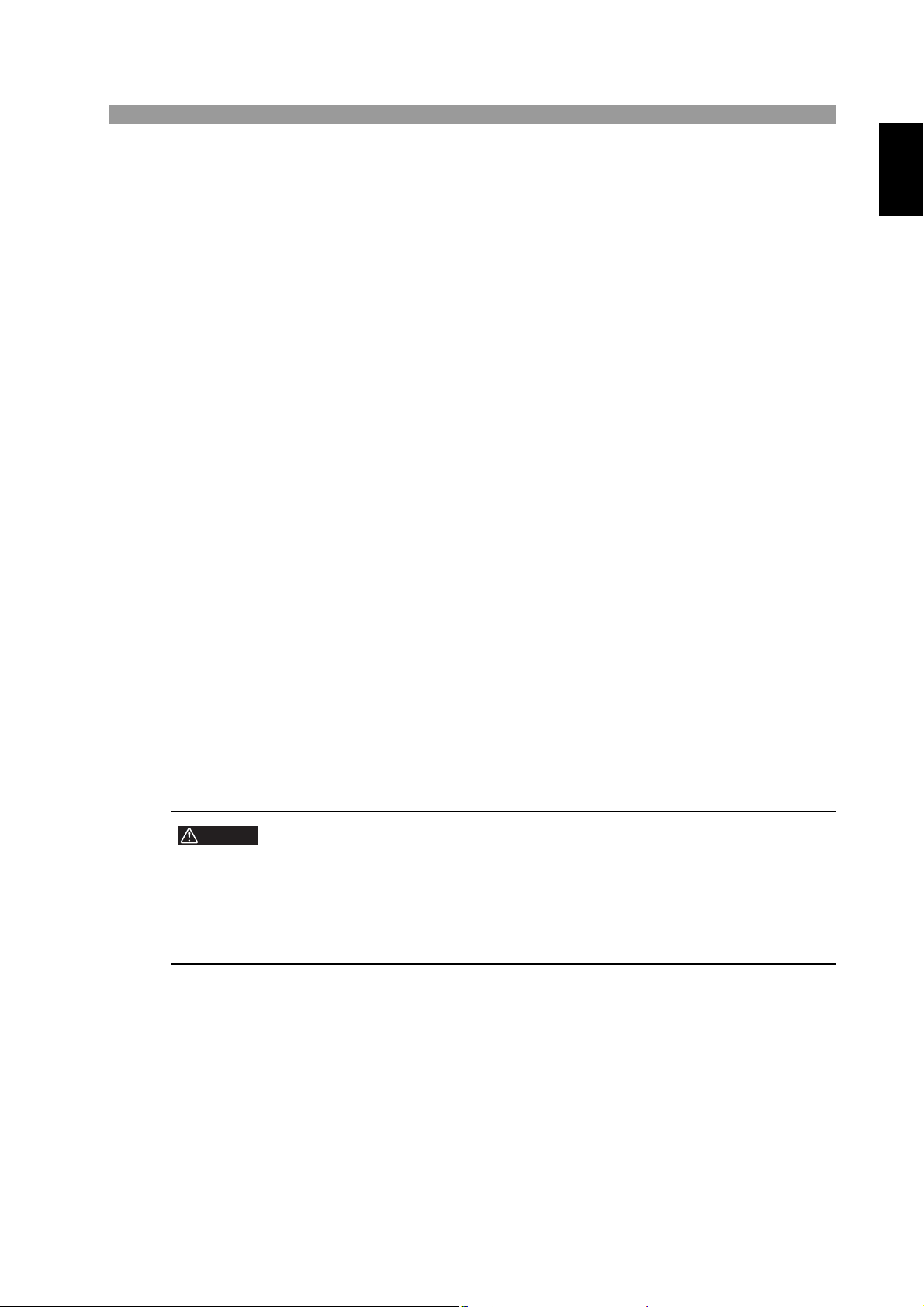

DCW Output Voltage Range

0.00

2.00

4.00

6.00

8.00

10.0

012345

Current [mA]

Voltage [kV]

■ Two testing functions – DC withstanding voltage, and

insulation resistance tests

When connected to a DUT, the tester can perform these two different tests consecutively.

■ DC withstanding voltage test at 10 kV

(maximum output of 50 W)

The tester can perform DC withstanding voltage tests for a wide voltage range of up

to 10 kV (maximum output of 50 W and maximum duration of 1 minute). The tester

is equipped with a stable, low-ripple DC/DC converter with a voltage regulation of 1

% or less.

■ Improved measurement accuracy

The tester is equipped with a digital voltmeter for withstanding voltage testing with

an accuracy of ±(1 % of the reading +20 V), and another for insulation resistance

testing with an accuracy of ±(1 % of the reading +1 V). The two voltmeters display

measured values not only during a test but also during execution of a program.

The tester is equipped with an ammeter for withstanding voltage testing that features

accuracy of ±(3 % of the reading +5 μA

olution tests, such as those that are required for PV panels. The two ammeters display

measured values not only during a test but also during execution of a program.

■ Insulation resistance test at 25 V to 1500 V (resolution of 1 V) /

0.01 MΩ to 9.99 GΩ (at rated current range of 50 nA to 1 mA

maximum *2)

*1

). Thus, it is capable of performing high-res-

*1: 0 to 2mA range

TOS9213S allows you to conduct an insulation resistance test at test voltage

range of 25 V to 1000 V (resolution of 1 V) with resistance measuring range of

0.01 MΩ to 9.99 GΩ. Whereas, TOS9213AS allows you to conduct a test at

test voltage range of 25 V to 1500 V (resolution of 1 V) with resistance measuring range of 0.01 MΩ to 9.99 GΩ.

*2: For TOS9213AS, if the test voltage setting exceeds 1020 V, the resistance

measuring range is valid at rated current range of 50 nA to 0.1 mA.

1-4 TOS9213S/ TOS9213AS

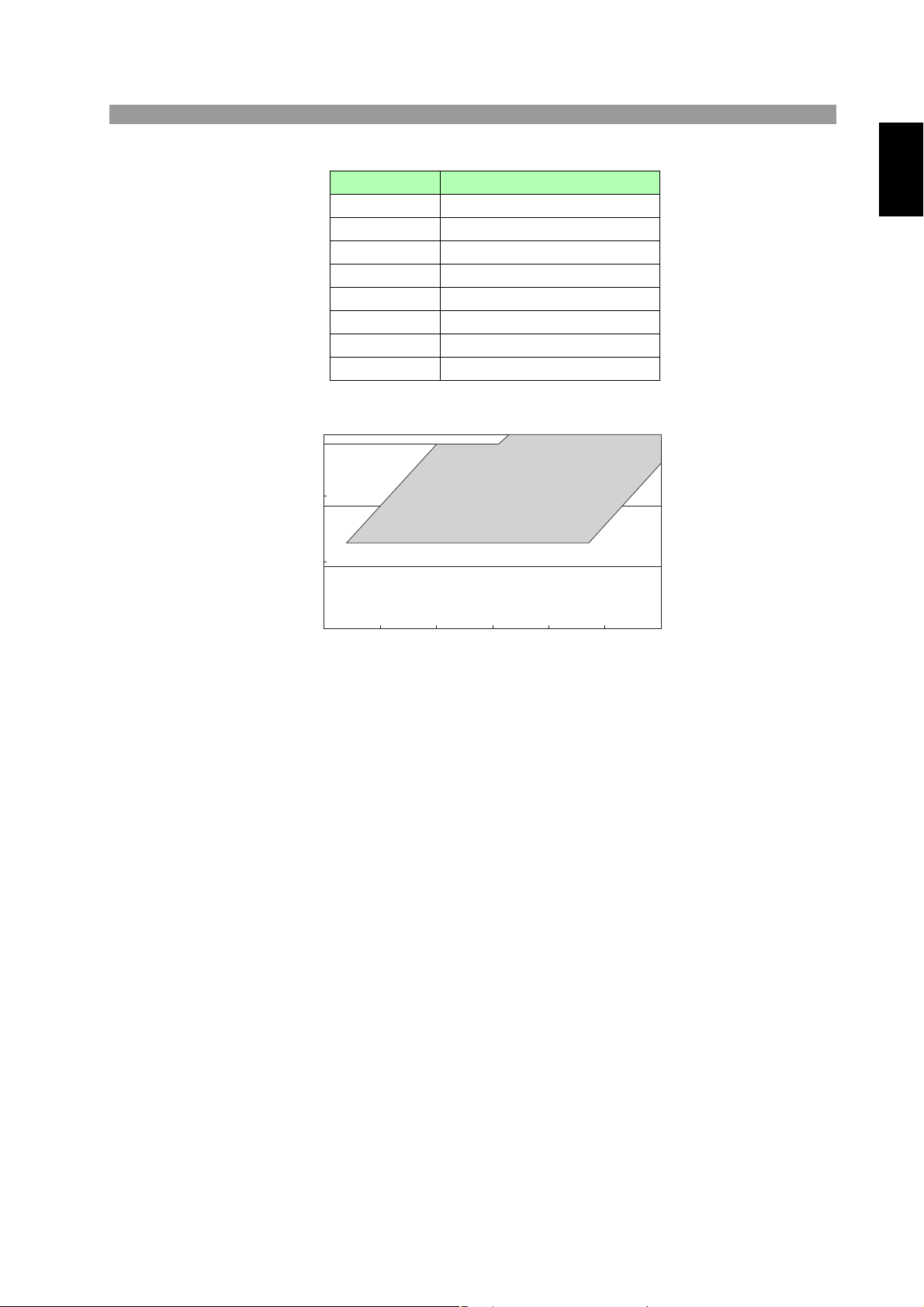

Test voltage Resistance measuring range

1

10

100

1000

0.01 0.1 1 10 100 1000 10000

Voltage [V]

IR Measurement Range

25 V 0.03 MΩ - 500 MΩ

50 V 0.05 MΩ - 1.00 GΩ

100 V 0.10 MΩ - 2.00 GΩ

125 V 0.13 MΩ - 2.50 GΩ

250 V 0.25 MΩ - 5.00 GΩ

500 V 0.50 MΩ - 9.99 GΩ

1000 V 1.00 MΩ - 9.99 GΩ

1500 V 15.00 MΩ - 9.99 GΩ

Chap. 1

Preface

■ Leakage current judgement (insulation resistance testing)

For insulation resistance testing, in addition to the conventional judgement method

using resistance values, the tester can also perform judgements using the value of

the leakage current that flows through the insulation resistance.

■ Fully programmable GPIB and RS-232C interfaces as a

All functions except for the POWER switch, KEYLOCK, and program execute

(AUTO) functions, are remote-controllable. Test conditions such as the test voltage,

judgement value, and test time can be controlled remotely in DC withstanding voltage and insulation resistance tests. Measured values and measurement results can

also be read back by remote control. The GPIB and RS-232C interfaces provided as

a standard feature smoothly interface the tester with a PC, sequencer, and other

devices.

■ Flexible control function realized by a high-voltage scanner

When combined with the optional high-voltage scanner TOS9220 (5 kVAC/6

kVDC), the tester can test multiple points in withstanding voltage and insulation

resistance tests. Using the tester panel, each channel can be set to a HI/LO/OPEN

voltage. One scanner can operate up to four channels. Up to four scanners can be

connected to the tester, enabling the simultaneous operation of a total of 16 channels. The TOS9221 is equipped with a function for detecting connections between

the high-voltage test leadwire and the DUT, thus ensuring highly reliable testing.

standard feature

TOS9213S/ TOS9213AS 1-5

■ Rise-time control function

In DC withstanding voltage testing, and insulation resistance testing, a voltage can

be slowly increased until it reaches a required test value, instead of applying the

required test voltage to the DUT immediately after the start of a test. The voltage

rise time can be set to 0.1 s through 99.9 s at a resolution of 0.1 s, and to 100 s

through 200 s at a resolution of 1 s. The start voltage, which is applied at the start of

a test, can be set to 0 % to 99 % of the test voltage at a resolution of 1 %. Thus, the

tester conforms to the requirement for the type certification test under the UL standard and the withstanding voltage test under the IEC standard that less than half of

the test voltage be applied initially and slowly increased for a specified period of

time before the test voltage is reached.

■ Discharge function

Generally, DUTs contain capacitive elements. Therefore, DUTs remain charged

immediately after a DC withstanding voltage test or insulation resistance test has

been conducted, resulting in the danger of electric shock. The tester has a function

for forcibly discharging the DUT upon completion of DC withstanding voltage test

or insulation resistance test. You can set the discharge time to a value between 0 and

300 s.

■ Enhanced safety

To enhance safety, the tester is equipped with a number of devices and safety functions, including safe output terminals, a discharge function, and an analog voltmeter

that constantly monitor the output-terminal voltages. Such safety measures also

include a danger lamp that constantly monitors output-terminal voltages even when

no test is under way and lights up when a voltage is detected, in addition to an interlock function that cuts off output in coordination with an external device.

■ Voltage hold function

During judgement, this function allows the tester to retain measured voltages

recorded upon completion of a test, while it is still outputting the judgement results.

Combined with the rise-time control function, the voltage hold function enables

detection of the dielectric breakdown voltage.

■ Output voltage monitoring function

When the output voltage deviates from ± (10 % of the setting +50 V), the monitor-

ing function activates to suspend the test, ensuring highly reliable testing.

■ High operability

The tester is easy to operate, allowing the operator to start using it without difficulty.

The tester displays the primary test conditions on the first page of the menu, with

the secondary test conditions shown on the following pages. To set test conditions,

simply use the cursor key to choose from among the items displayed on the LCD,

and then turn the rotary knob. The function keys allow you to jump to items to be

set. During a test, the output voltage can be changed using the rotary knob.

1-6 TOS9213S/ TOS9213AS

■ Saving 100 test conditions for each test

WARNING

One hundred test conditions, such as the test voltage, judgement value, and test

time, can be set and named for each test of the DC withstanding voltage, and insulation resistance. For example, the name of the applicable safety standard and the

shipment destination of the DUT can be saved. Even when a change is made to the

destination of a product or the name of the applicable safety standard, there is no

need to change the preset test conditions. To recall these test conditions, simply set

the memory number. If such test conditions have their own name, they can be confirmed using that name. Test conditions can even be recalled from outside.

■ Programmed test conditions

By configuring the test conditions saved for each test, 100 test steps can be performed consecutively.

When used together with the earth continuity tester TOS6200, the tester integrates

the test conditions saved in the earth continuity tester to perform continuous tests.

Tests can be performed easily, such as on the insulation resistance, DC withstanding

voltage, and earth continuity, in that order.

Up to 500 steps can be configured, with 100 programs storable, permitting recalls

even from outside.

■ Remote-control function and signal output function

Used exclusively for options, the DIN connector on the front panel enables the

remote control of start/stop operations, like its conventional counterpart. Using the

SIGNAL I/O connector on the rear panel, start/stop operations can be conducted and

the panel memory or program memory can be recalled.

Seven signals are output by the open collector through the SIGNAL I/O connector –

HV ON, TEST, PASS, UPPER FAIL, LOWER FAIL, READY, and PROTECTION.

These signals can be used together with the remote-control function to automate

testing and save labor.

Chap. 1

Preface

• This tester handles a high voltage of 10 kVDC. Therefore, do not touch the

DUT or cables, as electric shock may result.

Around the DUT, provide full safety measures such as an enclosure to

keep workers away. In addition, to ensure safety, exercise extreme care to

prevent the output of a high voltage due to improper connections and operations.

TOS9213S/ TOS9213AS 1-7

1.3 Options

The following options are available for this tester:

■ RC01-TOS/RC02-TOS remote-control box

This remote-control box is used for remote control of the start/stop operations of

this tester. It is connected to the REMOTE terminal on the front panel.

The RC01-TOS has one START switch. The RC02-TOS has two START switches,

and starts operation only when both are pressed simultaneously.

Function

OPERATE switch

The TEST-switch operation is effective only when the OPERATE switch is on.

Operation is forcibly stopped when the switch is turned off.

START switch

This switch starts a test only when the OPERATE switch is on and in the ready

status.

STOP switch

This switch is used to cut off the output voltage and cancel the FAIL status.

It performs the same function as the STOP switch on the front panel.

RC01-TOS:

200 mm(W) x 70 mm(H) x 39 mm(D)

1-8 TOS9213S/ TOS9213AS

RC02-TOS:

330 mm(W) x 70 mm(H) x 39 mm(D)

■ High-voltage test probe HP01A-TOS/HP02A-TOS

WARNING

CAUTION

This test probe is connected to Kikusui’s withstanding voltage tester to output a test

voltage. It is designed to prevent the unintended output of a test voltage.

To output a test voltage, hold the slide lever on the test-probe grip and pull the trigger with one hand, then press the switch on top of the probe using the other hand.

When you release either hand, the STOP signal is output and the test voltage is cut

off.

Maximum working voltage

4 kVAC (rms) 50 Hz/60 Hz

5 kVDC

Cable length

HP01A-TOS: Approximately 1.8 m

HP02A-TOS: Approximately 3.5 m

• This probe is designed for a maximum working voltage of 4 kVAC/5 kVDC.

It is dangerous to apply a voltage exceeding this level. Be sure to use this

probe at a test voltage below the maximum working voltage.

• Do not connect this probe to the DUT when a test voltage is being output

from the probe. In addition, do not cut off the connection to the DUT when

a test voltage is being output from the probe.

If the connection between the probe and the DUT is cut off while a high

voltage is being output from the probe, the DUT may be damaged. In addition, the DUT remains charged, making it extremely dangerous.

Therefore, connect the probe to a DUT before staring a test, be sure to

confirm that th

e LED on the probe is off before ending a test, and then dis-

connect the DUT from the probe.

Chap. 1

Preface

• To conduct a test under the UL standard using this probe, turn on the FAIL

MODE function on the tester. When this function is on, the tester performs

the next action to allow the FAIL status to be checked.

When the test ends in the FAIL status, the status is not cancelled even

when you release your hand from the probe. To cancel the FAIL status,

press the STOP switch on the tester. For settings, see “FAIL MODE” in "5.8

System Settings".

TOS9213S/ TOS9213AS 1-9

■ High-voltage scanner

WARNING

The high-voltage scanner TOS9220/TOS9221 has a function to distribute a test voltage supplied by the tester among multiple test points.

• A single high-voltage scanner distributes an output to four channels. Each

channel can be set to a different electric-potential level – HIGH, LOW, or

OPEN. AC/DC testing and insulation resistance testing can be conducted at

any of four test points.

• Up to four scanners can be connected to one tester, enabling expansion to a

maximum of 16 channels.

• The contact between the output on each channel and a test point can be

checked (the contact check function is provided for the TOS9221 scanner

only).

These features ensure highly reliable, labor-saving withstanding voltage and insulation resistance tests on electric and electronic devices and components having multiple test points.

Maximum working voltage

5 kVAC (rms)

6 kVDC

• This high-voltage scanner is designed for a maximum working voltage of 5

kVAC/6 kVDC. It is dangerous to apply a voltage exceeding this level. Be

sure to use this scanner at a test voltage below the maximum working volt-

age.

1-10 TOS9213S/ TOS9213AS

Chapter 2 Setup

This chapter describes the procedures from unpacking to installation to operation

checking.

Chap. 2

Setup

TOS9213S/ TOS9213AS 2-1

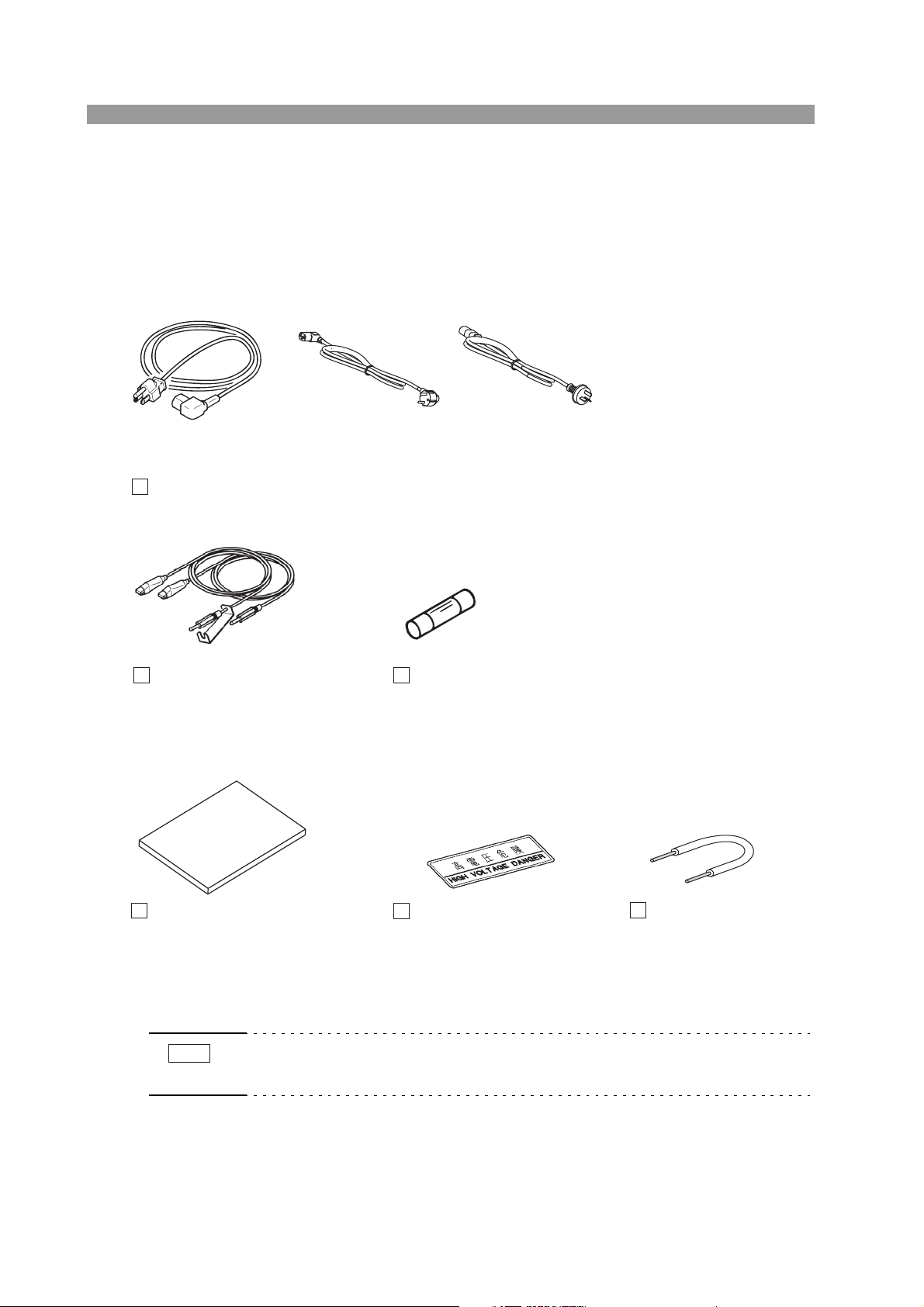

2.1 Unpacking

The power cord that is

provided varies depending

on the destination for the

product at the

factory-shipment.

The fuse that is provided varies

depending on the destination for

the product at the

factory-shipment.

AC Power cord (1 pc.)

TL01-TOS High-voltage

test leadwires (1 set)

1.5 m

[82970]

"HIGH VOLTAGE DANGER"

sticker (1 sheet)

[A8-210-202]

Interlock jumper (1 pc.)

[91-82-1511]

Spare fuse (1 pc.)

10 A, 250 V [99-02-0031]

or 6.3 A, 250 V [99-02-0019]

Operation Manual (1 copy)

[Z1-004-642]

PLUG: NEMA5-15

[85-AA-0003]

PLUG: CEE7/7

[85-10-1070]

or

PLUG: GB1002

[85-10-0790]

or

NOTE

Upon receiving the product, confirm that the necessary accessories are included and

have not been damaged in transit. Should any damage or shortage be found, please

contact Kikusui distributor/agent.

Retain the packing material for future transport.

• Place the "HIGH VOLTAGE DANGER" sticker in a visible location near the tester or installation site.

The product does not include a SIGNAL I/O cable, GPIB interface cable, or RS232C interface cable. Users are requested to procure them on their own.

Fig.2-1 List of accessories

2-2 TOS9213S/ TOS9213AS

2.2 Precautions for Installation

Be sure to observe the following precautions when installing the tester.

■ Do not use the tester in a flammable atmosphere.

To prevent explosion or fire, do not use the tester near alcohol, thinner, or other

combustible materials, or in an atmosphere containing such vapors.

■ Avoid locations where the tester is exposed to high

temperatures or direct sunlight.

Do not locate the tester near a heater or in areas subject to drastic temperature

changes.

Operating temperature range: +5 °C to +35 °C (+41 °F to +95 °F)

Storage temperature range: -20 °C to +70 °C (-4 °F to +158 °F)

■ Avoid humid environments.

Do not locate the tester in a high-humidity environment—near a boiler, humidifier,

or water supply.

Operating humidity range: 20 % to 80 % rh

(no dew condensation permitted)

Storage humidity range: 90 % rh or less

(no dew condensation permitted)

Condensation may occur even within the operating humidity range. In that case, do

not start using the tester until the location is completely dry.

■ Do not place the tester in a corrosive atmosphere.

Chap. 2

Setup

Do not install the tester in a corrosive atmosphere or one containing sulfuric acid

mist or the like. This may cause corrosion of various conductors and imperfect contact with connectors, leading to malfunction and failure, or in the worst case, a fire.

■ Do not locate the tester in a dusty environment.

Dirt and dust in the tester may cause electrical shock or fire.

■ Do not use the tester where ventilation is poor.

This tester features a forced-air cooling system. Provide sufficient space for the air

inlet on the lateral side and the air outlet on the rear side to allow air to flow.

■ Do not place the tester on a tilted surface or in a location

subject to vibrations.

If placed on a non-level surface or in a location subject to vibration, the tester may

fall, resulting in damage and injury.

■ Do not use the tester in locations affected by strong magnetic

or electric fields.

Operation in a location subject to magnetic or electric fields may cause the tester to

malfunction, resulting in electrical shock or fire.

TOS9213S/ TOS9213AS 2-3

■ Do not use the tester in locations near a sensitive measuring

instrument or receiver.

Operation in a location subject, may cause such equipment may be affected by noise generated by the tester.

ated to produce substantial amounts of RF broadband emissions between grips on

the test leadwire. To minimize this effect, secure a sufficient distance between alligator clips.

In addition, keep the alligator clips and test leadwire away from the surfaces of conductors (particularly sharp metal ends).

At a test voltage exceeding 3 kV, corona discharge may be gener-

■ Use the product in an industrial environment.

This product may cause interference if used in residential areas. Such use must be

avoided unless the user takes special measures to reduce electromagnetic emissions

to prevent interference to the reception of radio and television broadcasts.

2.3 Precautions for Moving

When moving the tester to the installation site or otherwise transporting it, take the

following precautions:

■ Before moving the tester, turn off the power switch.

Transporting the tester with its POWER switch on can lead to electric shock and

damage.

■ When moving the tester, Disconnect all wires from it.

Moving the tester without disconnecting the cables may result in breakage of the

wire or injury due to the tester tipping over.

■ For transportation, use the special packing material for the

tester.

Transport the tester in its original package to prevent vibration and falls, which may

damage the tester. If you require packing material, contact Kikusui distributor/agent.

■ Be sure to include this manual.

2-4 TOS9213S/ TOS9213AS

2.4 Checking the Line Voltage and Fuse

CAUTION

Before turning on the POWER switch, be sure to check ratings of the AC power line

and fuse.

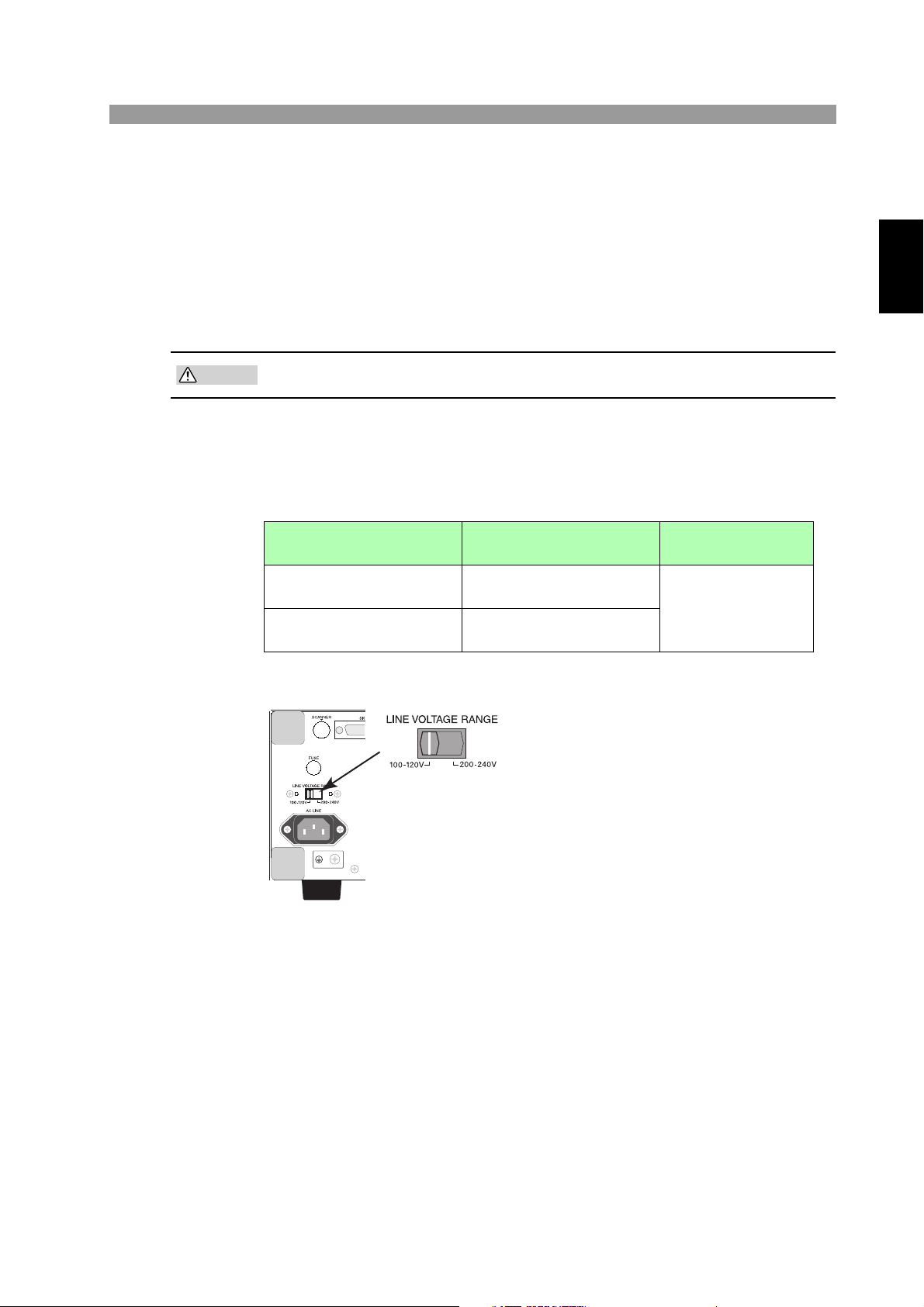

2.4.1 Switching source voltages

• To prevent malfunctions, be sure to operate within the line-voltage range.

The input rating of the tester is shown in Table 2-1. You can change the input voltage with the LINE VOLTAGE RANGE switch on the rear panel. Set the LINE

VOLTAGE RANGE switch for the AC power line that you will use.

Table2-1 Input rating

LINE VOLTAGE RANGE

switch setting

100 - 120 V

200 - 240 V

Nominal voltage range

(Allowable voltage range)

100 VAC to 120 VAC

(85 VAC to 132 VAC)

200 VAC to 240 VAC

(170 VAC to 250 VAC)

Chap. 2

Setup

Allowable frequency

range

47 Hz to 63 Hz

Fig.2-2 LINE-VOLTAGE RANGE switch

TOS9213S/ TOS9213AS 2-5

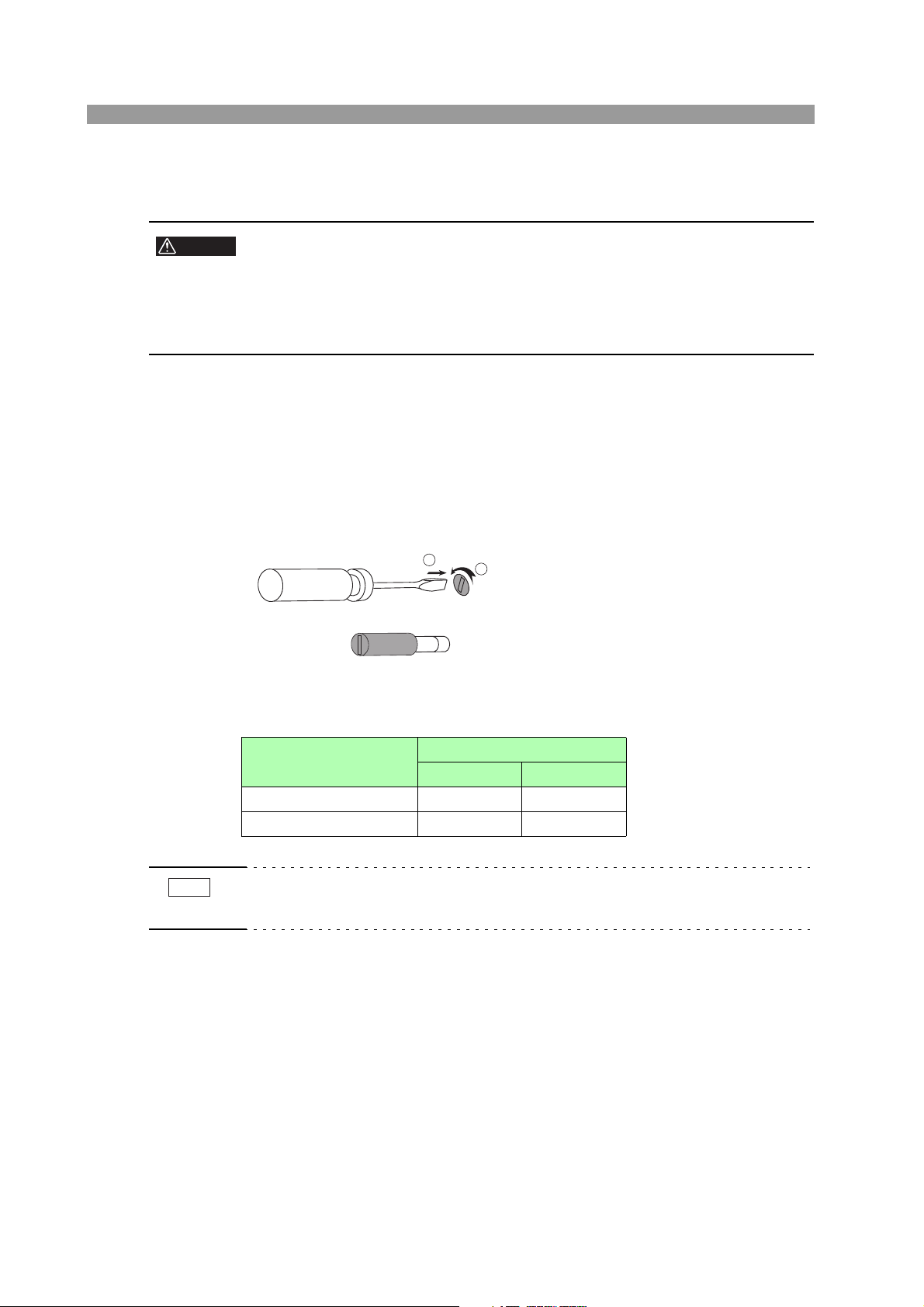

2.4.2 Checking and replacing fuses

WARNING

NOTE

• To prevent electric shock, before checking or replacing the fuse, be sure to

turn off the POWER switch and unplug the AC power cord.

•Make sure that the fuse used conforms to the instrument specifications,

including shape, rating, and characteristics. Using a fuse with different rating or short-circuiting, the fuse holder will damage the instrument.

1. Turn off the POWER switch, and unplug the AC power cord.

2. On the rear panel, remove the fuse holder, as shown in Fig. 2-3, by

pushing it inward and unscrewing it counterclockwise using a screwdriver.

3. In accordance with the fuse rating as shown in Table 2-2, check the fuse

type and replace the fuse.

4. Following the above steps in the reverse order, reinstall the fuse holder.

1

2

Fig.2-3 Removing the fuse holder

Ta ble2-2 Fuse rating

LINE VOLTAGE

RANGE switch setting

100 - 120 V 10 A SLOW –

200 - 240 V – 6.3 A(T)

FUSE (250 V)

UL198G IEC60127

• The pre-arcing time-current characteristic of fuses are named differently in the UL

and IEC standards. Use fuses conforming to both or either of the standards.

2-6 TOS9213S/ TOS9213AS

Loading...

Loading...