Kikusui TOS6200A, TOS6210 User Manual

USER’S MANUAL

EARTH CONTINUITY TESTER

TOS6200A

TOS6210

Part No. IB028661

Mar. 2015

Use of Operation Manual

There are four TOS6200A/6210 Manuals listed as follows.

• Setup Guide

This manual is intended for first-time users of this product. It provides an overview of the product and

notes on usage. It also explains how to set up the product for testing the DUT. Always read this manual

before using the product.

• Quick Reference

This manual explains Panel description and operation briefly.

• Safety Information

This document contains general safety precautions for this product. Keep them in mind and make sure to

observe them.

• User’s Manual (this manual)

This manual is intended for first-time users of this product. It provides an overview of the product and

notes on usage. It also explains how to configure the product, operate the product, remotely controlling

the product, perform maintenance on the product, and so on.

TOS6200A/6210 Manuals are intended for users of the Earth Continuity Tester and their instructors.

Explanations are given under the presumption that the reader has knowledge about the electrical aspects of

electrical safety testing.

Every effort has been made to ensure the accuracy of this manual. However, if you have any questions, or

find any errors or omissions, please contact your Kikusui agent or distributor.

If you find any misplaced or missing pages in this manual, it will be replaced. If the manual gets lost or

soiled, a new copy can be provided for a fee. In either case, please contact your Kikusui agent or distributor, and provide the “Kikusui Part No.” given on the cover.

After you have finished reading manuals, store them so that you can use it for reference at any time.

Disposing of used Kikusui products in the EU

Under a law adopted by member nations of the European Union (EU), used electric and electronic products

carrying the symbol below must be disposed of separately from general household waste.

This includes the power cords and other accessories bundled with the products. When

disposing of a product subject to these regulations, please follow the guidance of your

local authority, or inquire with your Kikusui distributor/agent where you purchased the

product.

The symbol applies only to EU member nations.

Disposal outside the EU

When disposing of an electric or electronic product in a country that is not an EU member, please contact

your local authority and ask for the correct method of disposal.

The company names and product names that appear in this manual are the trademarks or registered trademarks of the respective manufacturers.

Reproduction and reprinting of this operation manual, whole or partially, without our permission is prohibited.

Both unit specifications and manual contents are subject to change without notice.

Copyright© 2015 Kikusui Electronics Corporation

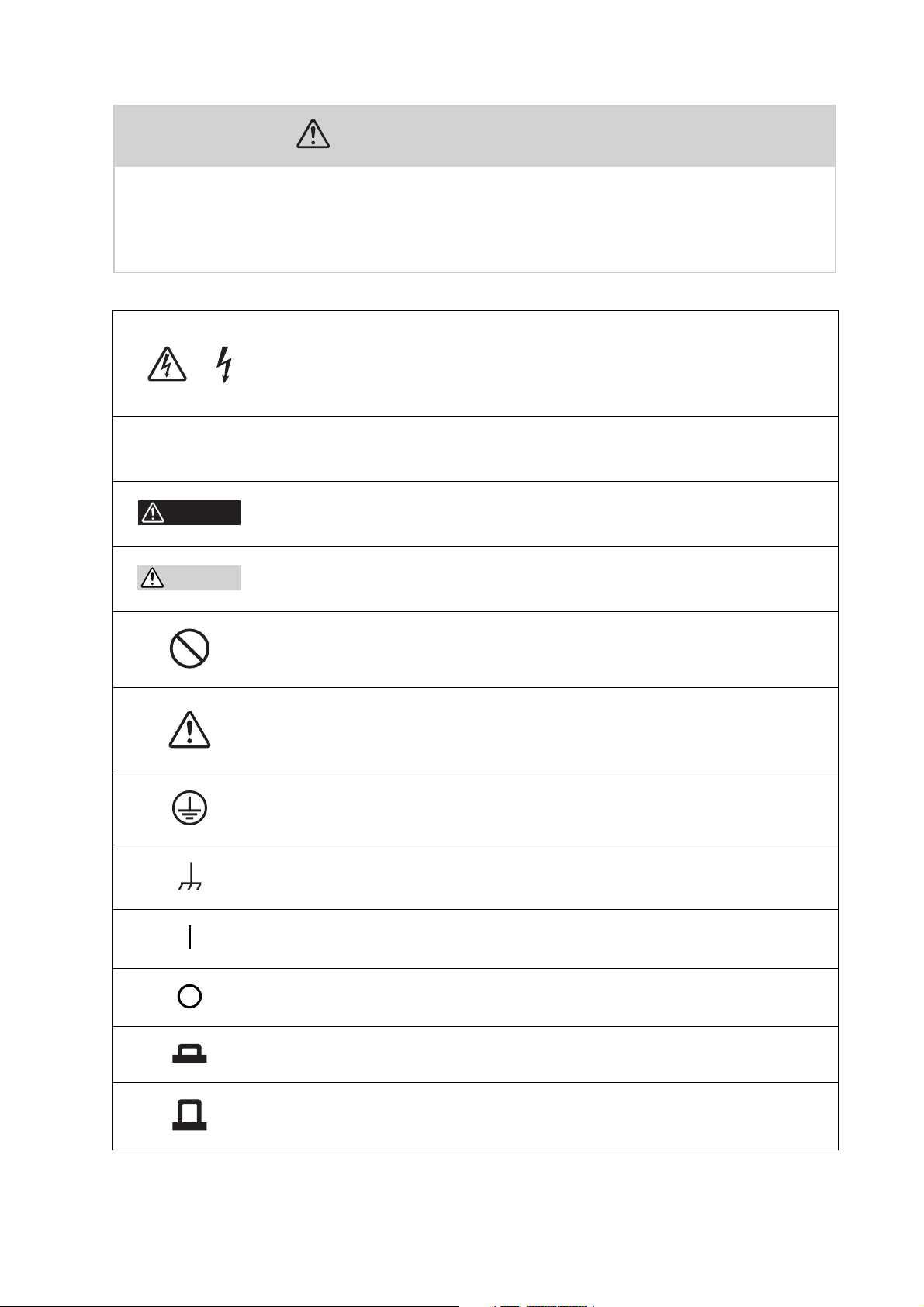

Safety Symbols

For the safe use and safe maintenance of this product, the following

symbols are used throughout this manual and on the product. Understand the meanings of the symbols and observe the instructions they

indicate (the choice of symbols used depends on the products).

Indicates that a high voltage (over 1000 V) is used here. Touching

or

the part causes a possibly fatal electric shock. If physical contact

is required by your work, start work only after you make sure that

no voltage is output here.

DANGER

WARNING

CAUTION

Indicates an imminently hazardous situation which, if ignored, will

result in death or serious injury.

Indicates a potentially hazardous situation which, if ignored,

could result in death or serious injury.

Indicates a potentially hazardous situation which, if ignored, may

result in damage to the product and other property.

Shows that the act indicated is prohibited.

Is placed before the sign “DANGER,” “WARNING,” or “CAUTION”

to emphasize these. When this symbol is marked on the product,

see the relevant sections in this manual.

Protective conductor terminal.

Chassis (frame) terminal.

On (supply)

Off (supply)

In position of a bi-stable push control

Out position of a bi-stable push control

TOS6200A/6210 Safety Symbols 1

Contents

Safety Symbols ____________________________________________ 1

Chapter 1 General ________________________________________ 1-1

Chapter 2 Installation and Preparation for Use __________________ 2-1

1.1 Overview of the Manual ----------------------------------1-2

1.2 Introduction and Features ---------------------------------1-3

1.3 Options ---------------------------------------------1-6

2.1 Unpacking Checks --------------------------------------2-2

2.2 Precautions for Installation --------------------------------2-3

2.3 Connecting the AC Power Cord -----------------------------2-4

2.4 Connecting the Test Leads --------------------------------2-5

2.4.1 Supplied Test Lead TL11-TOS/TL12-TOS ----------------2-5

2.4.2 Optional Test Probe LP01-TOS/LP02-TOS ----------------2-7

2.4.3 Other Leads -------------------------------------2-8

2.4.4 Measurements Using Four Terminals --------------------2-9

2.4.5 Measurements Using Two Terminals --------------------2-9

2.4.6 Connecting to the DUT ----------------------------2-10

2.5 Preliminary Inspection ----------------------------------2-11

Chapter 3 Part Names and Functions _________________________ 3-1

3.1 Front Panel -------------------------------------------3-2

3.2 Rear Panel -------------------------------------------3-6

Chapter 4 Basic Operation__________________________________ 4-1

4.1 Turning on the power ------------------------------------4-2

4.2 Setting the Test Conditions --------------------------------4-3

4.2.1 Test Current -------------------------------------4-4

4.2.2 Test Frequency -----------------------------------4-5

4.2.3 Upper Reference Value ------------------------------4-5

4.2.4 Lower Reference Value -----------------------------4-8

4.2.5 Test Time -------------------------------------4-11

4.2.6 Offset Canceling Function --------------------------4-12

4.3 Starting and Ending Test --------------------------------- 4-14

4.3.1 Starting a Test ----------------------------------- 4-14

4.3.2 Ending the Test ----------------------------------4-15

4.4 System Setup ---------------------------------------- 4-17

4.5 Interface Setup ---------------------------------------4-22

4.5.1 GPIB Address -----------------------------------4-22

4.5.2 RS-232C Protocol -------------------------------- 4-23

4.6 Panel Memory ----------------------------------------4-24

4.6.1 Storing in the Panel Memory ------------------------4-25

2 Contents TOS6200A/6210

4.6.2 Recalling the Panel Memory ------------------------- 4-26

4.7 Program -------------------------------------------- 4-27

4.7.1 Recalling the Program ----------------------------- 4-28

4.7.2 Creating or Editing the Program ----------------------- 4-28

4.7.3 Running the Program ----------------------------- 4-30

4.7.4 Suspending the Program ---------------------------- 4-30

4.7.5 PASS/FAIL Judgment During Program Execution ---------- 4-30

4.7.6 Ending the Program ------------------------------- 4-31

4.8 Key Lock ------------------------------------------- 4-32

4.9 Checking the Test Conditions ----------------------------- 4-32

4.9.1 Setting Output out of the Operation Range --------------- 4-33

4.9.2 Upper Reference Value <= Lower Reference Value (UP <= LOW) 435

4.10 Protection Fuction ------------------------------------- 4-36

4.10.1 Time Limitation with Respect to Output (OVER HEAT) ----- 4-37

4.10.2 Overheating Protection (OVER HEAT) ----------------- 4-38

4.10.3 Overload Protection (OVER LOAD) ------------------- 4-38

4.10.4 Output Voltage Limitation (VOLT LIMIT) --------------- 4-39

4.10.5 Change in ENABLE Signal (SIGNAL I/O) --------------- 4-40

4.10.6 Output current error (CURR ERROR) ------------------ 4-40

4.11 Initialize ------------------------------------------- 4-41

Chapter 5 REMOTE and SIGNAL I/O _________________________ 5-1

5.1 REMOTE Terminal ------------------------------------- 5-2

5.2 SIGNAL I/O Connector ---------------------------------- 5-3

5.2.1 SIGNAL I/O Connector Specifications ------------------ 5-4

5.2.2 Starting a Test ------------------------------------ 5-6

5.2.3 Recalling a Panel Memory and Program ------------------ 5-7

5.2.4 Examples of Use --------------------------------- 5-8

Chapter 6 GPIB and RS-232C _______________________________ 6-1

6.1 Interface --------------------------------------------6-2

6.1.1 GPIB Interface ----------------------------------- 6-2

6.1.2 RS-232C Interface --------------------------------- 6-2

6.2 Message and Terminator ---------------------------------6-4

6.2.1 Messages --------------------------------------- 6-4

6.2.2 Terminator ------------------------------------- 6-6

6.2.3 Special Symbols and Characters ----------------------- 6-6

6.3 Device Messages --------------------------------------- 6-7

6.3.1 Register-Related and General-Purpose Messages ------------ 6-7

6.3.2 System-Related Messages -------------------------- 6-13

6.3.3 Messages Relating to Test Conditions and Test Execution ---- 6-18

6.3.4 Messages Relating to the Tester Status ------------------ 6-26

6.3.5 Memory-Related Messages ------------------------- 6-29

6.3.6 Program-Related Messages ------------------------- 6-32

TOS6200A/6210 Contents 3

6.4 Registers ------------------------------------------- 6-36

6.5 List of Device Messages --------------------------------- 6-40

Chapter 7 Maintenance ____________________________________ 7-1

7.1 Cleaning --------------------------------------------7-2

7.2 Inspection --------------------------------------------7-2

7.3 Checking and Replacing the Fuse ----------------------------7-3

7.4 Replacing the Cooling Fan and Backup Battery ------------------7-4

7.5 Calibration -------------------------------------------7-4

7.6 In Case of Problems -------------------------------------7-5

Chapter 8 Specifications ___________________________________ 8-1

8.1 Basic Performance --------------------------------------8-2

8.2 Interface and Other Functions ------------------------------8-4

8.3 General Specifications -----------------------------------8-6

8.4 External Dimensions ------------------------------------8-8

Appendix _______________________________________________ A-1

A.1 Operational Principle ------------------------------------A-1

A.2 ASCII Codes 20H to 7EH ---------------------------------A-2

A.3 Initial Settings of the Memory ------------------------------A-3

A.4 Summary of the Safety Standards for Earth Continuity Testing --------A-4

Index ___________________________________________________ I- 1

4 Contents TOS6200A/6210

1

1

Chapter 1 General

Gives an overview of the tester and describes its features and various options.

TOS6200A/6210 1-1

1.1 Overview of the Manual

This operation manual is for the TOS6200A/6210 earth continuity tester.

■ Firmware version of products applied

This Operation Manual applies to products with version 2.0x firmware installed.

The ROM version number is displayed in the opening screen displayed immediately

after power is switched ON. You can also obtain the ROM version number with the

*IDN? message. For information on the *IDN? message, see 6.3.1, "RegisterRelated and General-Purpose Messages."

Before making product inquiries, please have ready the tester ROM version number

and serial number indicated on the rear panel of your tester.

TOS6200A

EARTH CONTINUITY TESTER

Ver. 1.01

KIKUSUI ELECTRONICS CORP.

Fig.1-1 Opening screen for firmware version 1.01

(Example of TOS6200A)

1-2 General TOS6200A/6210

1.2 Introduction and Features

This tester is used to perform earth continuity tests required for class-I devices for

various safety standards, including the IEC, EN, UL, VDE, BS, JIS, and the Electrical Appliance and Material Control Law of Japan.

The tester must be used under the following conditions:

TOS6200A TOS6210

Test current value 3Aac to 30 Aac 6Aac to 60 Aac

Output terminal voltage 5.4 V or less

Resistance value 1.2 or less 0.6 or less

Maximum power 150 VA or less 220 VA or less

• Making test current constant

The test current for earth continuity tests has been made constant. This eliminates

the need to alter the test current, even if the resistance of the DUT (device under

test) changes.

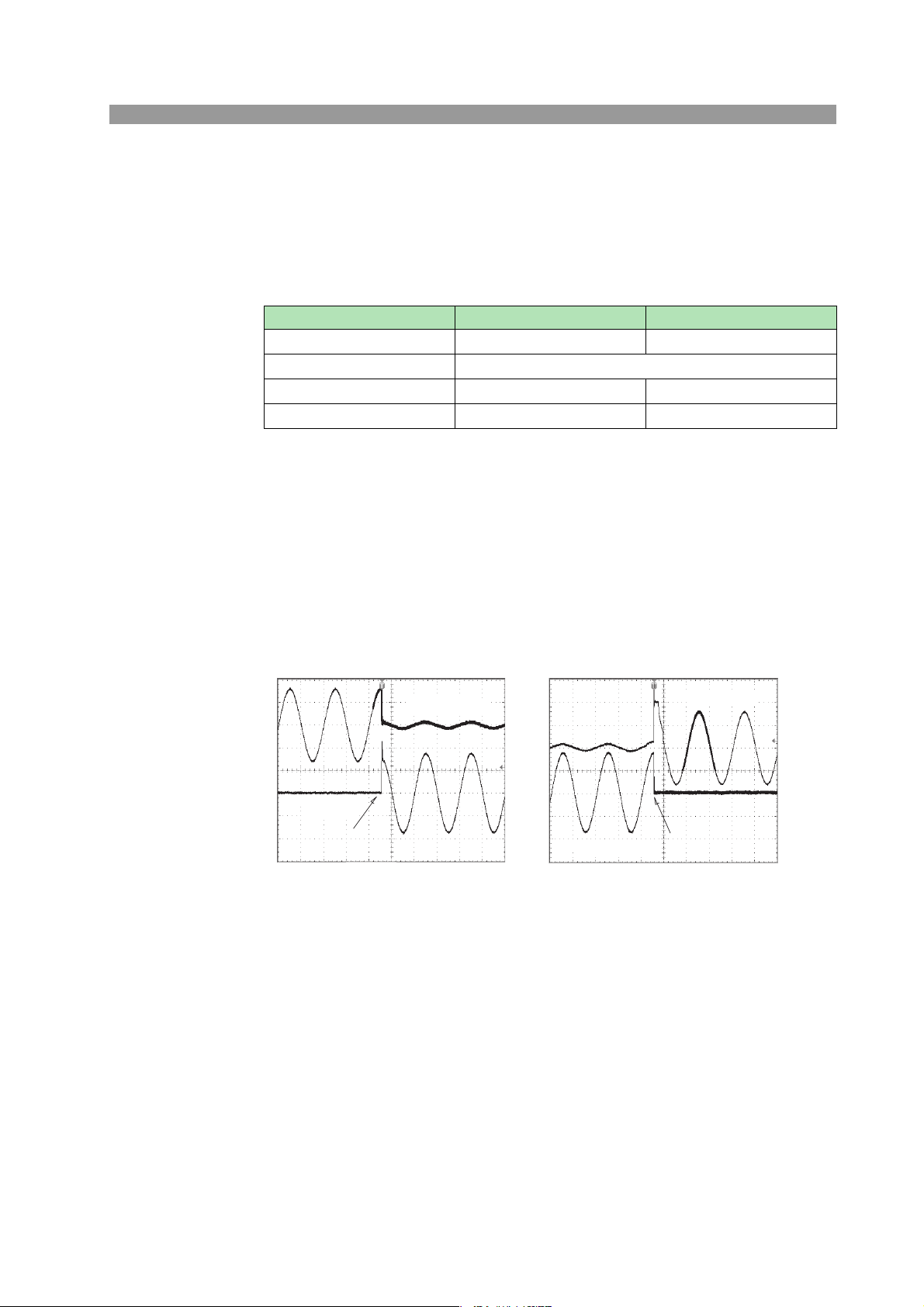

• Safety output voltage

The constant current/constant voltage circuit provides fast response, preventing

generation of excessive output voltage even when output is interrupted during testing. The tester complies with the limitations on no-load output voltages (6 V or

less,

12 V or less, and so on) required by many safety standards.

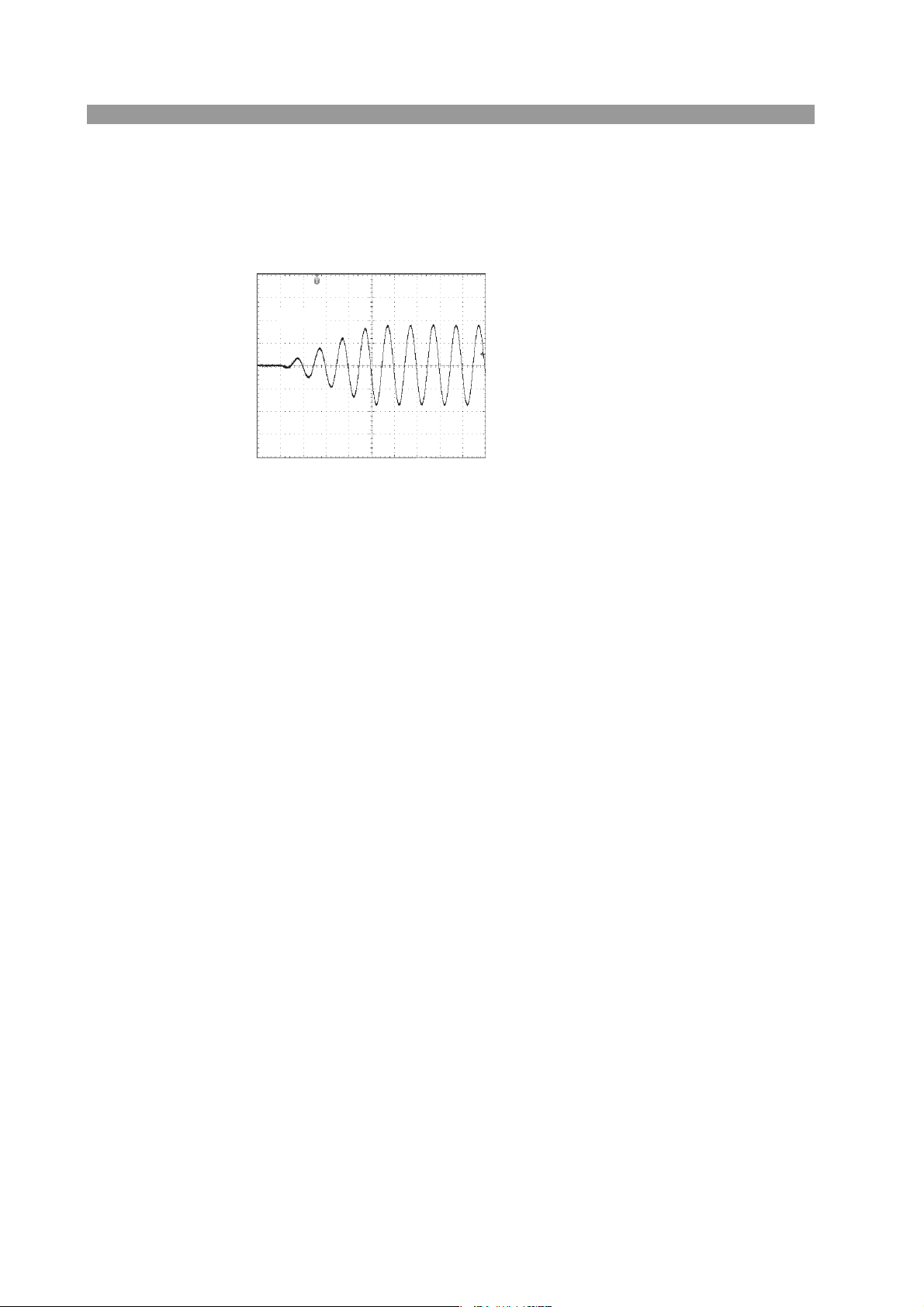

CH1: Voltage waveform

CH2: Current

waveform

Short circuit

CH1: 5 V/div CH2: 50 A/div 10 ms/div

TOS6210

CH1:Voltagewaveform

CH2:Currentwaveform

CH1: 5 V/div CH2: 50 A/div 10 ms/div

Open

TOS6210

TOS6200A/6210 General 1-3

• Reduced cycle time

A test current is a constant current value set within approximately 100 ms.

Earth continuity tests can be conducted even at 1-second intervals. This enables

the instrument to perform tests in production lines that require reduced cycle

times.

CH1: Current waveform

TOS6210

CH1: 50 A/div 20 ms/div

• Compact and lightweight

A new high-efficiency power supply (achieving a power conversion efficiency of

65%) and large output (TOS6200A: 150 VA, TOS6210: 220 VA) makes possible a

tester that is remarkably compact and lightweight, about half the size and weight

of our conventional testers.

• Excellent measurement accuracy

The tester is equipped with an ohmmeter of +/-(2% of reading + 0.003 ) that calculates resistance values based on measured current and voltage.

• Offset canceling function

The tester has an offset canceling function that cancels values for contact resistance at alligator clip connections, the contact resistance of measuring leads in

measurements using two terminals, and other resistance components.

• Contact check function

The tester is provided with a contact check function that verifies the connection of

the DUT (by current detection) before initiating testing.

• Voltage judgment function

This function allows either a resistance value or a voltage drop value (voltage

between the SAMPLING terminals) to be selected as the reference value for judgment criteria.

It also allows voltage drop value-based testing to be conducted, which is required

by safety standards such as UL 60950-1 and IEC 60950-1.

• Simple operations

Tester functions are fast and easily controlled, with an intuitive control method

that's easy to pick up, even for first-time users.

For example, test conditions are set simply by selecting an item displayed on the

LCD with the cursor keys and turning the rotary knob to set/select a value.

Any items you wish to set up can be assigned to the function keys.

1-4 General TOS6200A/6210

• Stores up to 100 types of test conditions

The tester allows you to store and name up to 100 test conditions involving parameters such as test current, determined resistance value, and test time. For example,

you can store test conditions for a specific safety standard under the name of the

standard, or store test conditions under the name of the destination of the DUT.

When test conditions need to be modified due to changes in the destination of the

product or revised safety standards, you can recall a set of test conditions simply

by entering a memory number, making necessary modifications to the pre-existing

standard.

Assigning specific names allows test conditions to called up by name. This function is available through both the front panel and the remote control.

• Programming of test conditions

A combination of stored test conditions allows automatic execution of tests consisting of several programs of up to 100 steps each.

Although the total number of steps is limited to 500, 100 types of programs can be

stored and recalled from the front panel or the remote control.

• GPIB and RS-232C interfaces

The tester is provided with standard GPIB and RS-232C interfaces. It is therefore

not necessary to buy additional GPIB and RS-232C boards.

An interface cable and PC or sequencer allows remote control of test conditions

such as test current, determined resistance value, and testing time. Measured values and test results can also be read back.

• Supplied test leads

The tester comes with alligator clip test leads, letting you start testing immediately.

• Memo function

The tester has a memo function that can store up to 20 characters per line on 3

lines, which can be used to store serial numbers, calibration dates, and/or comments.

TOS6200A/6210 General 1-5

1.3 Options

The following options are available for the tester.

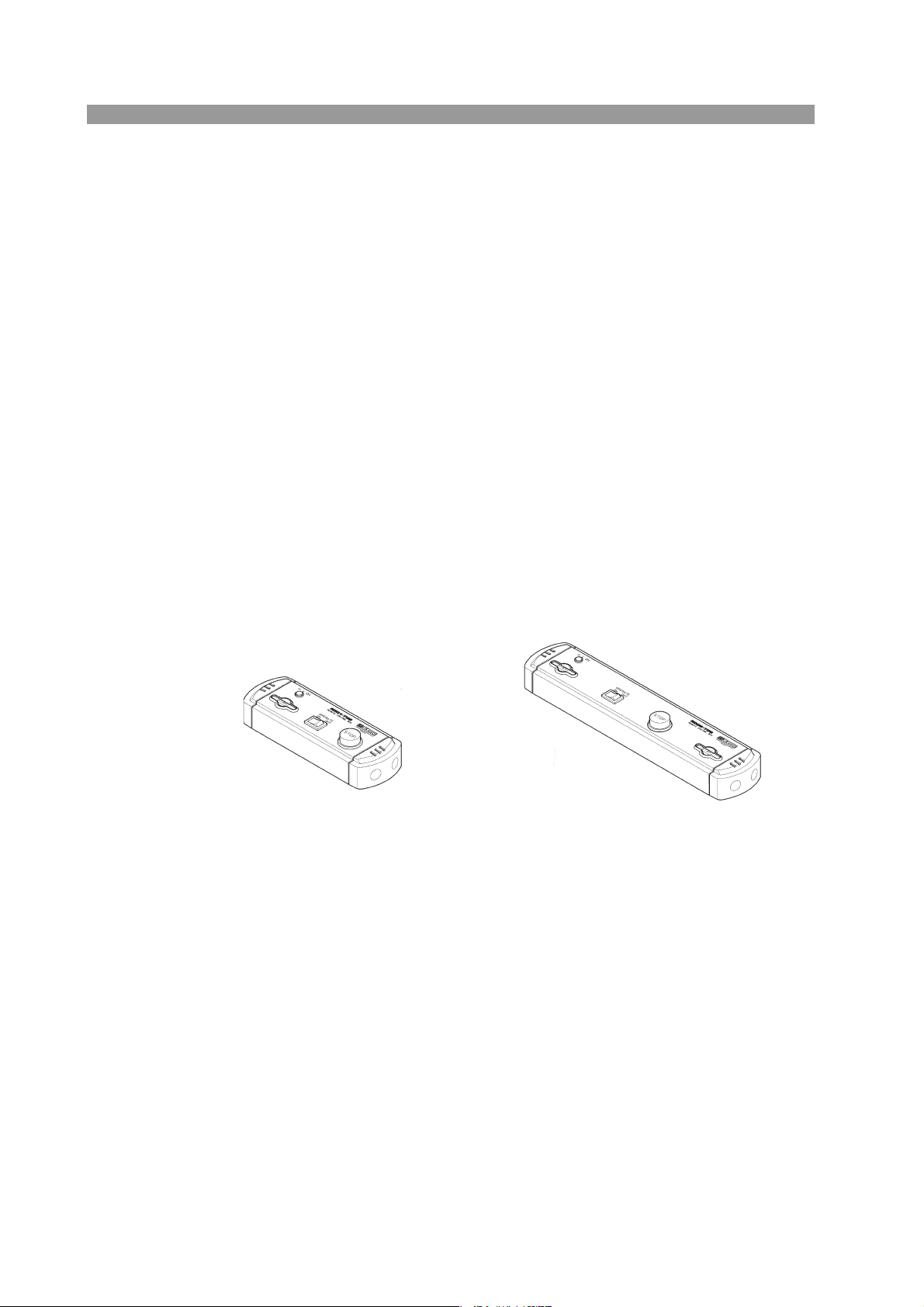

■ RC01-TOS/RC02-TOS Remote Control Box

When connected to the REMOTE terminal on the front panel, remote control boxes

are used to control tester start/stop functions.

The RC01-TOS has one START switch, while the RC02-TOS has two START

switches. For the RC02-TOS, a test starts only when both switches are pressed

simultaneously.

Functions

OPERATE switch

Test switches are enabled only when this switch is set to the ON position.

When it is set to the OFF position, a test in progress will be stopped.

START switch

With the OPERATE switch set to ON and the tester in ready status, press this

switch to start testing.

STOP switch

Used to shut off output voltage or cancel a FAIL status; has the same function

as the STOP switch located on the tester.

RC01-TOS:

200mm(W) x 70mm(H) x 39mm(D)

1-6 General TOS6200A/6210

RC02-TOS:

330mm(W) x 70mm(H) x 39mm(D)

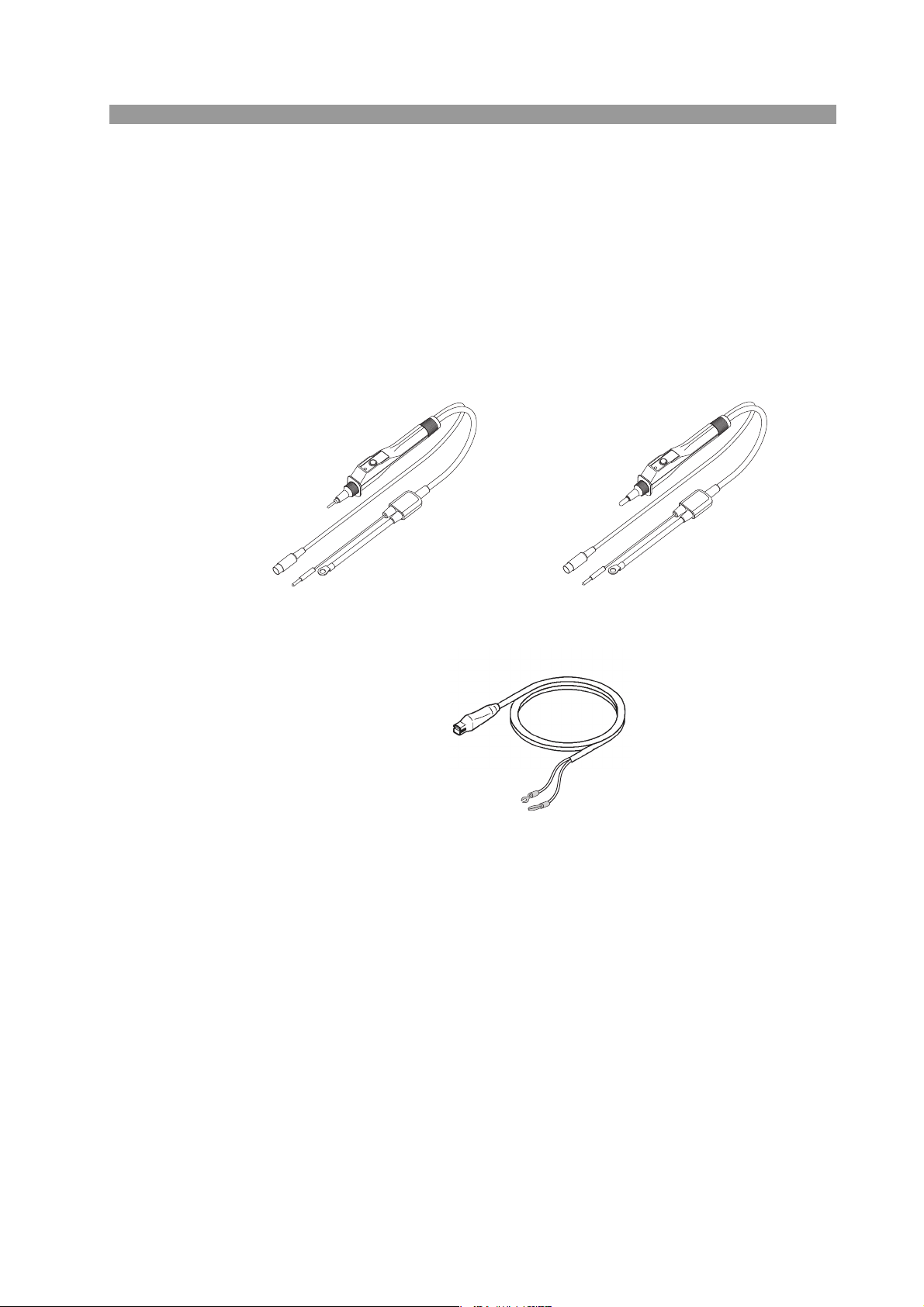

■ LP01-TOS/LP02-TOS Test Probe

This probe lets you use the switches located on the probe to control tester starting

test/stopping test operations. Connect it to the OUTPUT and REMOTE terminals

on the tester's front panel.

Maximum rating: LP01-TOS 30 A

LP02-TOS 60 A

Cable length: 2 m

Accessory: LOW Test Lead (LP01-TOS/LP02-TOS) 2 m

LP01-TOS:

28 mm(W) x 45.5 mm(H) x 226 mm(D)

LOW Test Lead

LP02-TOS:

28 mm(W) x 45.5 mm(H) x 226 mm(D)

TOS6200A/6210 General 1-7

1-8 General TOS6200A/6210

2

2

Chapter 2 Installation and

Preparation for Use

Describes the steps from unpacking to installation to preparation required before

switching on POWER.

TOS6200A/6210 2-1

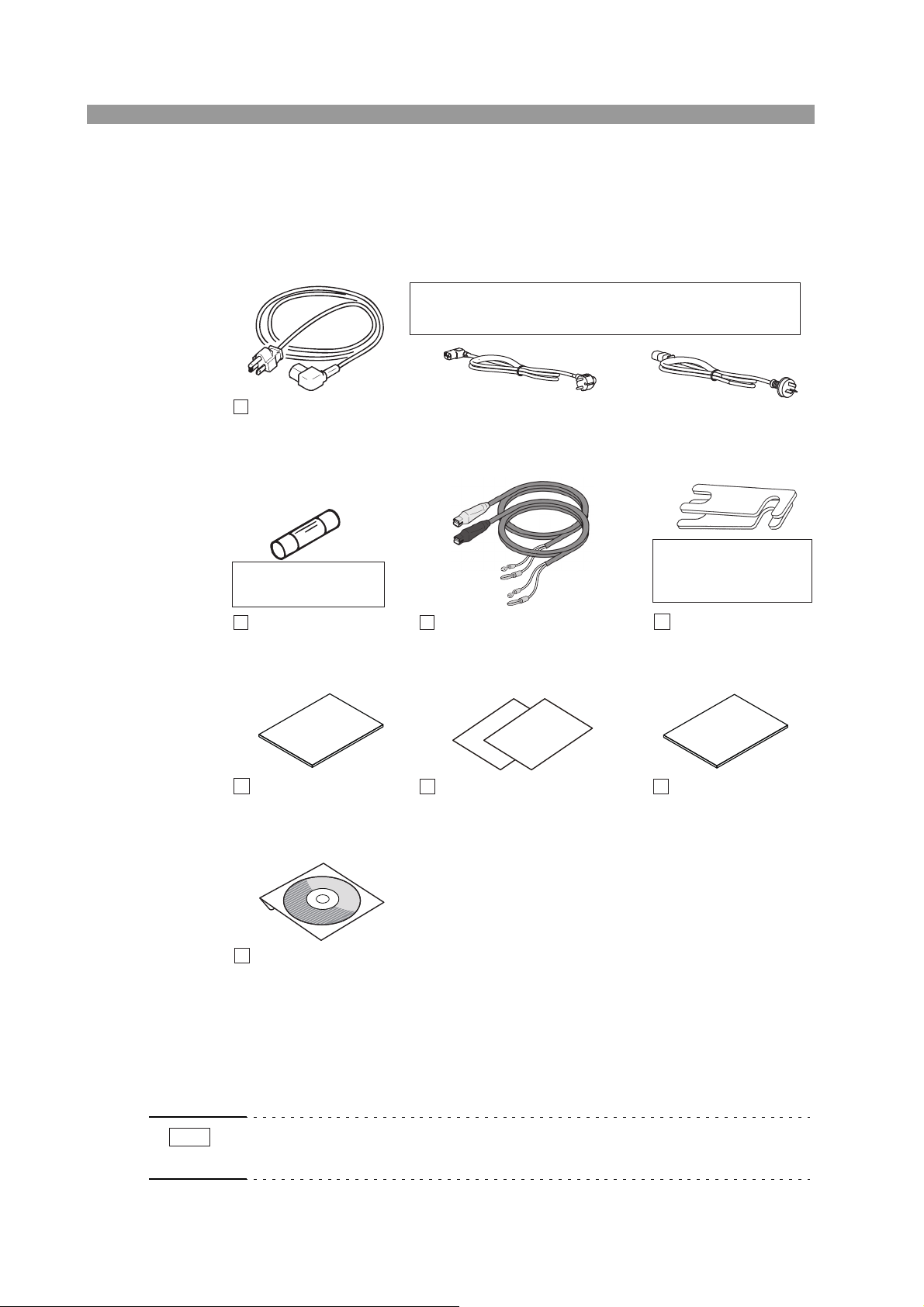

2.1 Unpacking Checks

Upon receiving the product, make sure the package contains the necessary accessories, and that the product has not been damaged during transportation.

If any damage or imperfection is found, contact Kikusui distributor/agent.

The power cord that is provided varies depending on

the destination for the product at the factory-shipment.

or or

AC power cord, 1

Rated voltage: 125 Vac

PLUG: NEMA5-15

[85-AA-0003]

Inserted in the

AC LINE connector

Spare fuse, 1

6.3 A 250 V

[99-02-0019]

Setup Guide (1 pc.)

[Z1-006-310]

Rated voltage: 250 Vac

PLUG: CEE7/7

[85-AA-0005]

Test leads, 1 set

TOS6200A: TL11-TOS 1.5 m

TOS6210: TL12-TOS 1.5 m

Quick Reference

English: 1 pc. [Z1-006-322]

Japanese: 1 pc. [Z1-006-320]

Rated voltage: 250 Vac

PLUG: GB1002

[85-10-0790]

Installed between

the OUTPUT and

SAMPLING terminals

Short-circuit bars, 2

[E3-300-032]

Safety Information

(1 pc.)

[Z1-005-040]

CD-ROM (1 pc.) ᳕SA-6061᳗

Fig.2-1 List of Accessories

SIGNAL I/O, GPIB interface, and RS-232C interface cables are not supplied with

the product and must be purchased separately.

For information on connecting those cables, see 5.2, "SIGNAL I/O Connector” and

6, "GPIB and RS-232C.”

NOTE

• Packing materials may be used for later transport of the product, so it is recommended that they be retained.

2-2 Installation and Preparation for Use TOS6200A/6210

2.2 Precautions for Installation

When installing this product, be sure to observe the precautions provided in "Precautions Concerning Installation Location" in the Safety information manual. Items

specific to this product are given below.

Precautions for installation location

When you install the product, be sure to observe the temperature and

humidity ranges indicated below.

Operating temperature range:5 Cto35C (41 Fto95F)

Operating humidity range:20 %rh to 80 %rh (no dew condensation is allowed)

When you store the product, be sure to observe the temperature and

humidity ranges indicated below.

Storage temperature range:-20 Cto+70C (-4 F to +158 F)

Storage humidity range:90 %rh or less (no dew condensation is allowed)

Use of the feet

CAUTION

Used to raise the front panel of the meter to get a better view of the LCD screen or

improve the operability of the keys.

Pull the provided feet forward onto the floor until you hear them click.

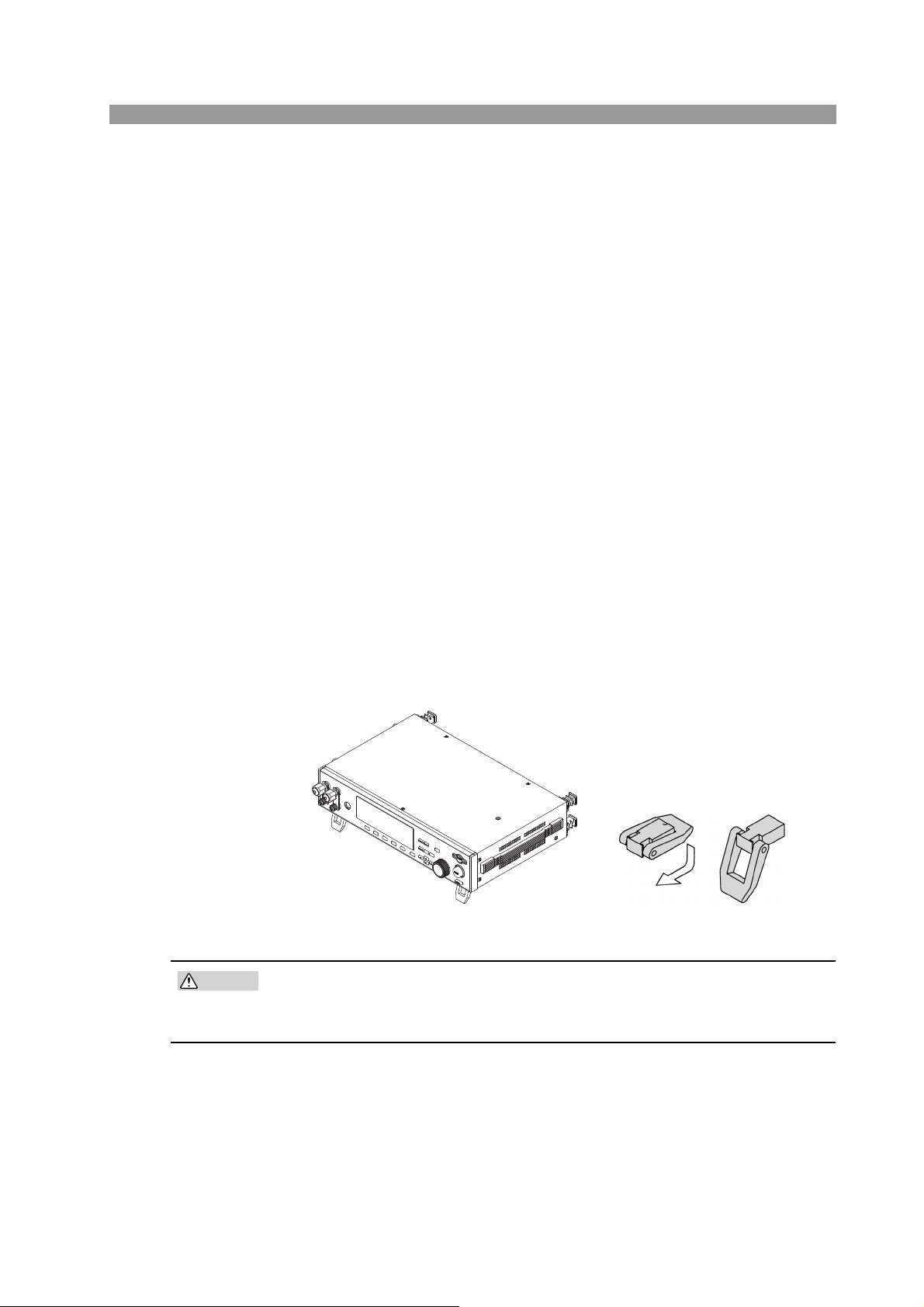

Fig. 2-2 How to use the feet

• Do not use the rubber strips on the sides as feet. Use of the product in an

upright position with a rubber strip at the bottom may cause the product to

fall down, resulting in damage to the tester or injury to the user.

TOS6200A/6210 Installation and Preparation for Use 2-3

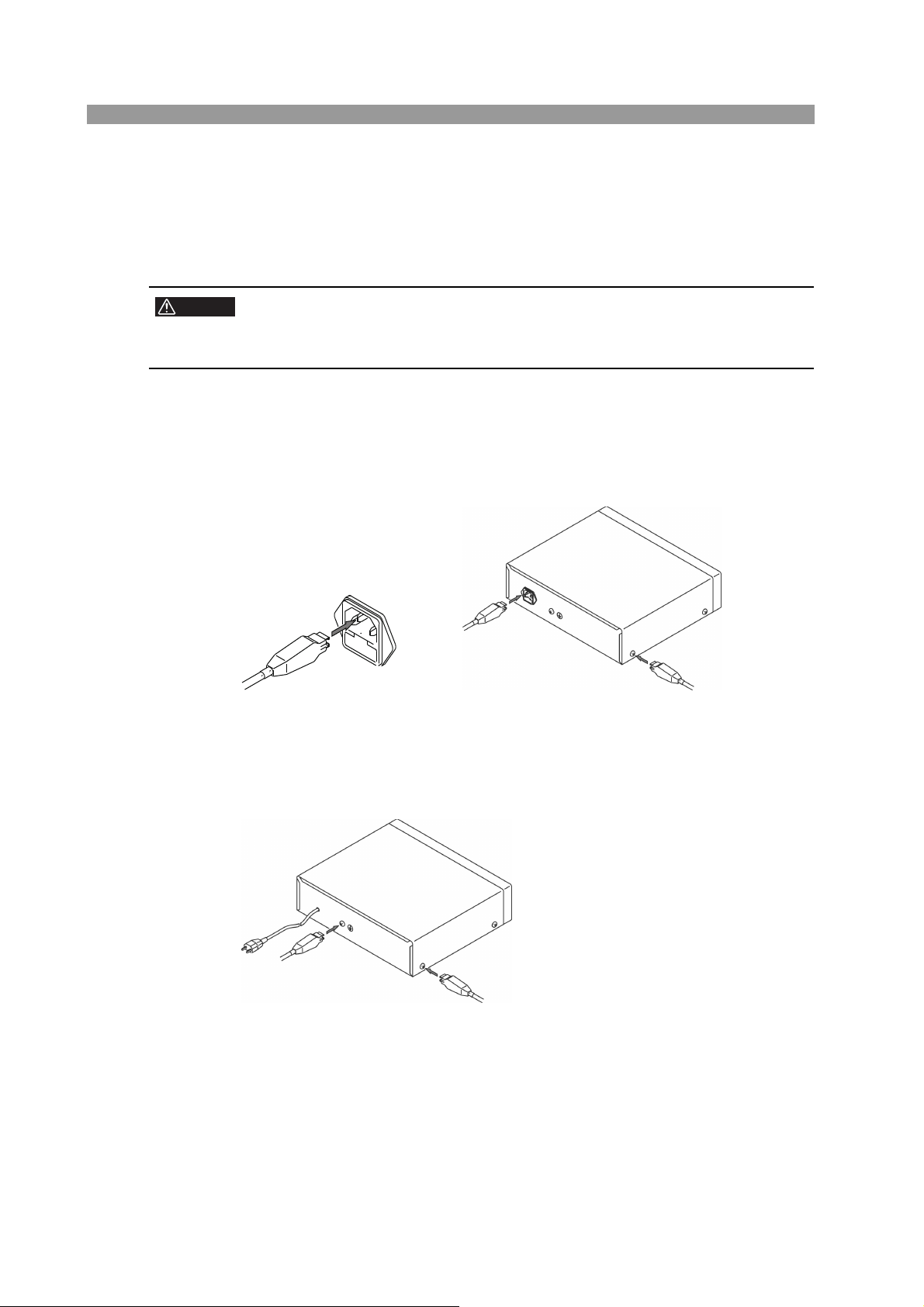

2.3 Connecting the AC Power Cord

WARNING

NOTE

• This product is a piece of equipment that conforms to IEC Safety Class I

(equipment that has a protective conductor terminal). Be sure to earth

ground the product to prevent electric shock.

The product is grounded through the power cord ground wire. Connect the

protective conductor terminal to earth ground.

• Use the supplied power cord to connect to the AC line.

If the supplied power cord cannot be used because the rated voltage or the plug

shape is incompatible, have a qualified engineer replace it with an appropriate

power cord that is 3 m or less in length. If obtaining a power cord is difficult, contact your Kikusui agent or distributor.

• The power cord with a plug can be used to disconnect the product from the AC

line in an emergency. Connect the plug to an easily accessible power outlet so that

the plug can be removed from the outlet at any time. Be sure to provide adequate

clearance around the power outlet.

• Do not use the supplied power cord for other devices.

This product is a piece of equipment that conforms to IEC Overvoltage Category II

(energy-consuming equipment that is supplied from a fixed installation).

Procedure

1. Check that the POWER switch is turned off.

2. Check whether the AC power line is compatible with the input rating of

the Tester.

The product can receive a nominal power supply voltage in the range of 85 Vac

to 250 Vac at a frequency of 47 Hz or 63 Hz.

The input voltage range is also indicated under LINE VOLTAGE RANGE on

the rear panel.

3. Connect the power cord to the rear-panel AC inlet, and then connect

the power plug to an outlet that has a ground terminal.

2-4 Installation and Preparation for Use TOS6200A/6210

2.4 Connecting the Test Leads

WARNING

CAUTION

• This product carries a maximum current flow of 30 A or 62A. Always check

to make sure that no connections are loose. Loose connection will result in

overheating of the OUTPUT terminals or the DUT (Device Under Test),

which may then result in burns or injury.

• Never connect the voltage measurement cable (thin wire) of the supplied

test leads or optional test probe to the OUTPUT terminals. The nominal

sectional area of this wire is inadequate for such currents, and burning

may result.

• This product carries a large current and consequently generates a strong

magnetic field. Make sure that no articles that may be affected by magnetic fields are located near the test leads or current output lines.

For example, images on a CRT positioned close by may be significantly

distorted.

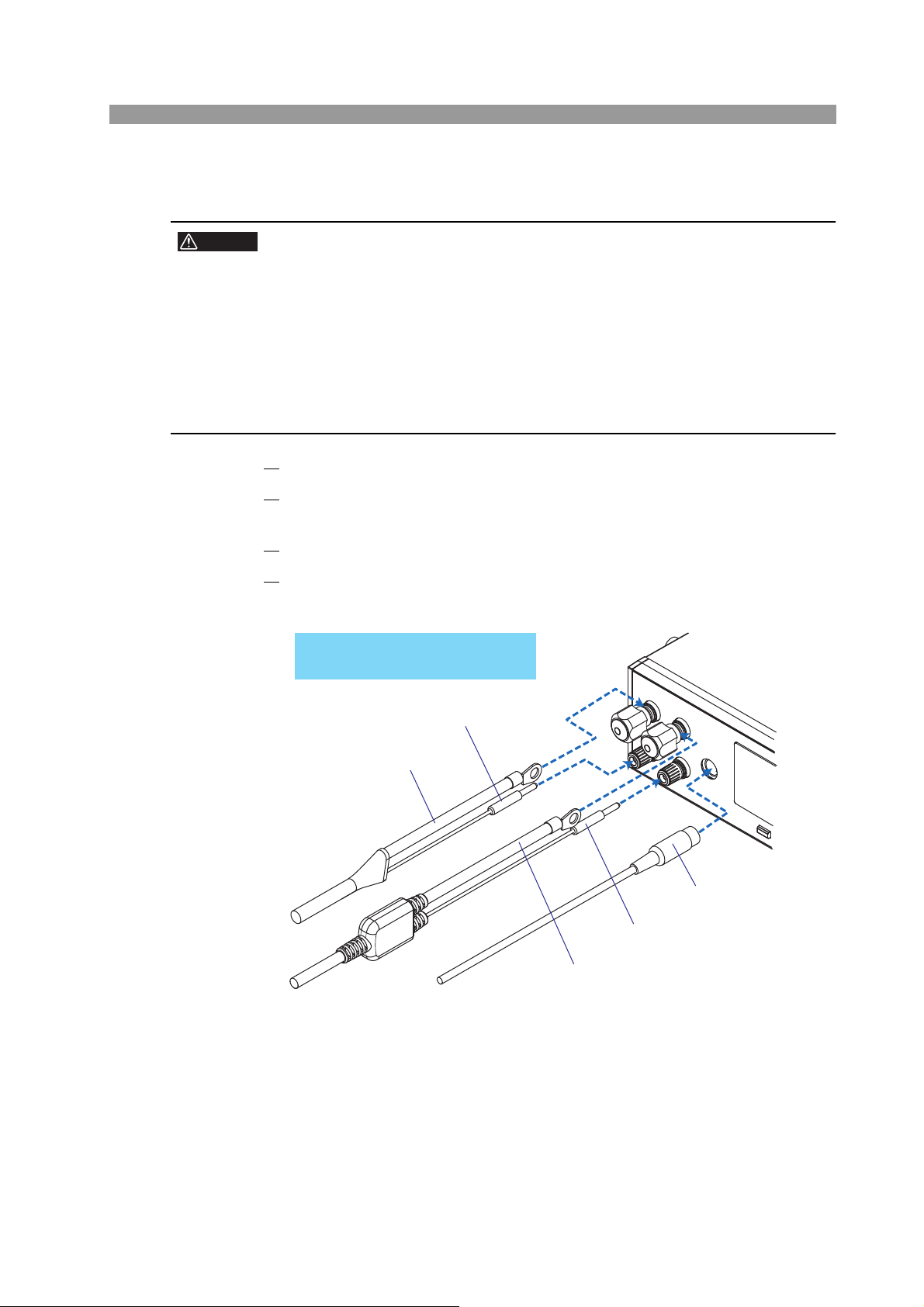

2.4.1 Supplied Test Lead TL11-TOS/TL12-TOS

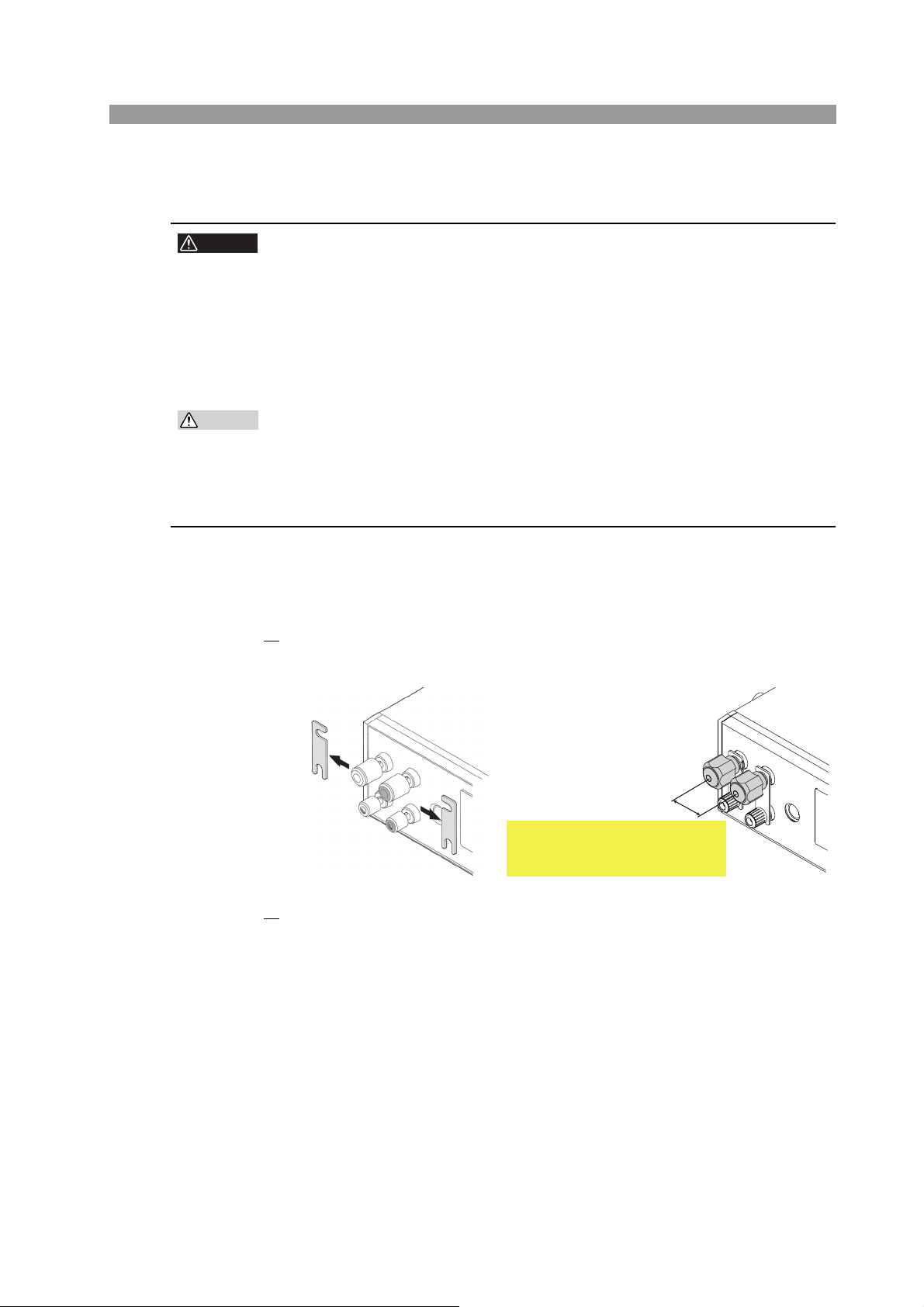

1. Remove the short-circuit bars connecting the OUTPUT and SAMPLING

terminals.

TOS6200A

Take care not to get your finger

caught between the output

terminals when turning the knobs.

TOS6210

2. Connect the current output line on the crimp terminal side of the test

lead (black or white) to the LOW side of the OUTPUT terminals; connect the voltage measurement line on the banana plug side to the LOW

side of the SAMPLING terminals. Check that the connections are

secure.

TOS6200A/6210 Installation and Preparation for Use 2-5

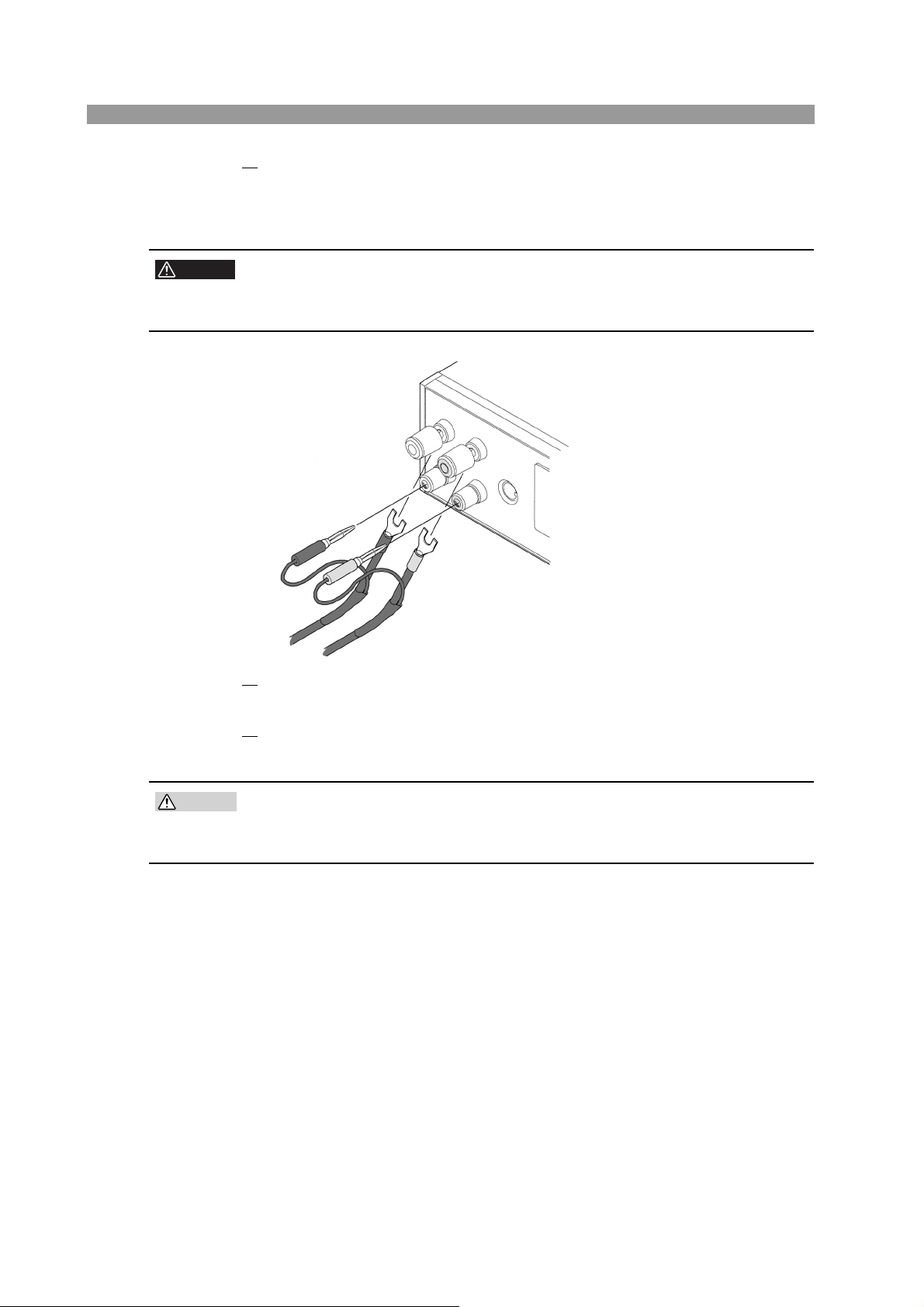

3. Connect the current output line on the crimp terminal side of the test

lead (red) to the HIGH side of the OUTPUT terminals; connect the voltage measurement line on the banana plug side to the HIGH side of the

SAMPLING terminals. Check that the connections are secure.

WARNING

• Improper terminal connections can result in inaccurate measurements and

burns or injury resulting from heat generated by contact resistance at the

terminals.

Connecting example of TOS6200A

4. Connect the alligator clip of the test lead (black or white) to the protec-

tive conductor terminal of the DUT.

CAUTION

5. Connect the alligator clip of the test lead (red) to a test point of the DUT.

For details, see 2.4.6, "Connecting to the DUT”

• Make sure that the alligator clip connections are secure.

Improper connections may result in clip disconnection, causing sparking

and potentially damaging the DUT.

2-6 Installation and Preparation for Use TOS6200A/6210

2.4.2 Optional Test Probe LP01-TOS/LP02-TOS

WARNING

• Never connect the voltage measurement cable (thin wire) of the optional

LP01/LP02-TOS test probe to the OUTPUT terminals. Its nominal sectional area is inadequate for such currents, and burning may occur.

• The rated current of the LP01-TOS and LP02-TOS test probes are up to

30 A and 60 A, respectively. Do not attempt to pass a current exceeding

the rated current.

• Improper terminal connections can result in inaccurate measurements and

burns or injury resulting from heat generated by contact resistance at the

terminals.

1. Turn off the POWER switch of the Tester.

2. Remove the short-circuit bars connecting the OUTPUT and SAMPLING

terminals.

3. Connect the LOW test lead to the LOW terminal of the Tester.

4. Connect the each cable of the test probe to the HIGH and REMOTE ter-

minal of the Tester.

Figure shows connections of the

TOS6210 with the LP02-TOS.

TOS6210

To OUTPUT

LOW terminal

To SAMPLING

LOW terminal

To the REMOTE terminal

To SAMPLING

HIGH terminal

To OUTPUT

HIGH terminal

TOS6200A/6210 Installation and Preparation for Use 2-7

2.4.3 Other Leads

WARNING

CAUTION

• If you use a lead wire other than those supplied with the product, select

wires of the nominal sectional areas meeting the test current.

• To avoid generating excessive heat at the connections, use crimp terminals appropriate for the sectional area of the current output line.

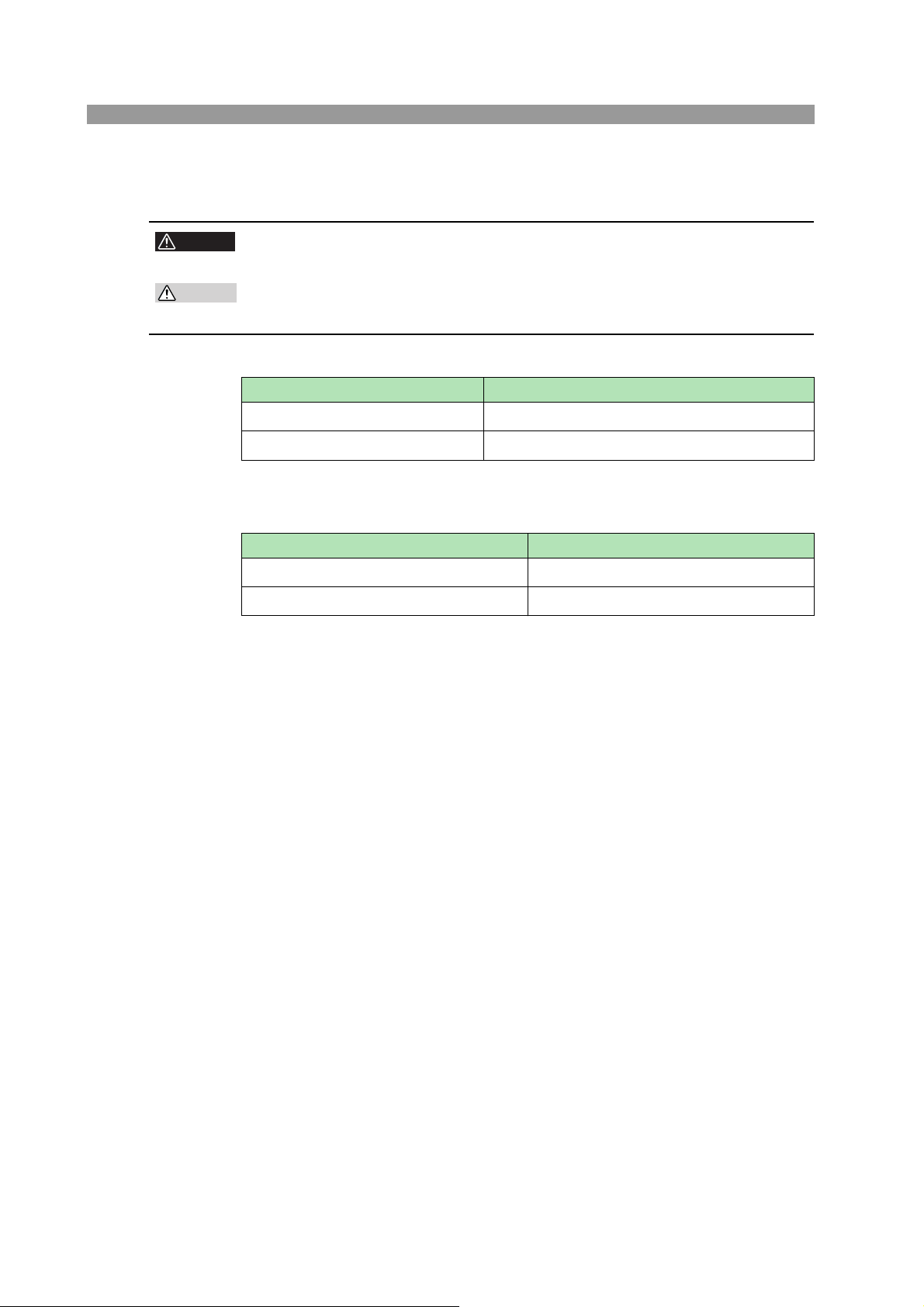

Select wires on the basis of the following criteria.

Test Current (I) Required Nominal Sectional Areas of Wire

I30 A

30<I60 A

5.5 mm2or more

2

14 mm

or more

Resistance values with respect to the nominal sectional areas of wires are as follows:

Use lead wires within a total lead length of 10 m or less.

Nominal Sectional Areas of Wire Resistance Value per Meter

5.5 mm

14 mm

2

2

3.5 m

1.5 m

2-8 Installation and Preparation for Use TOS6200A/6210

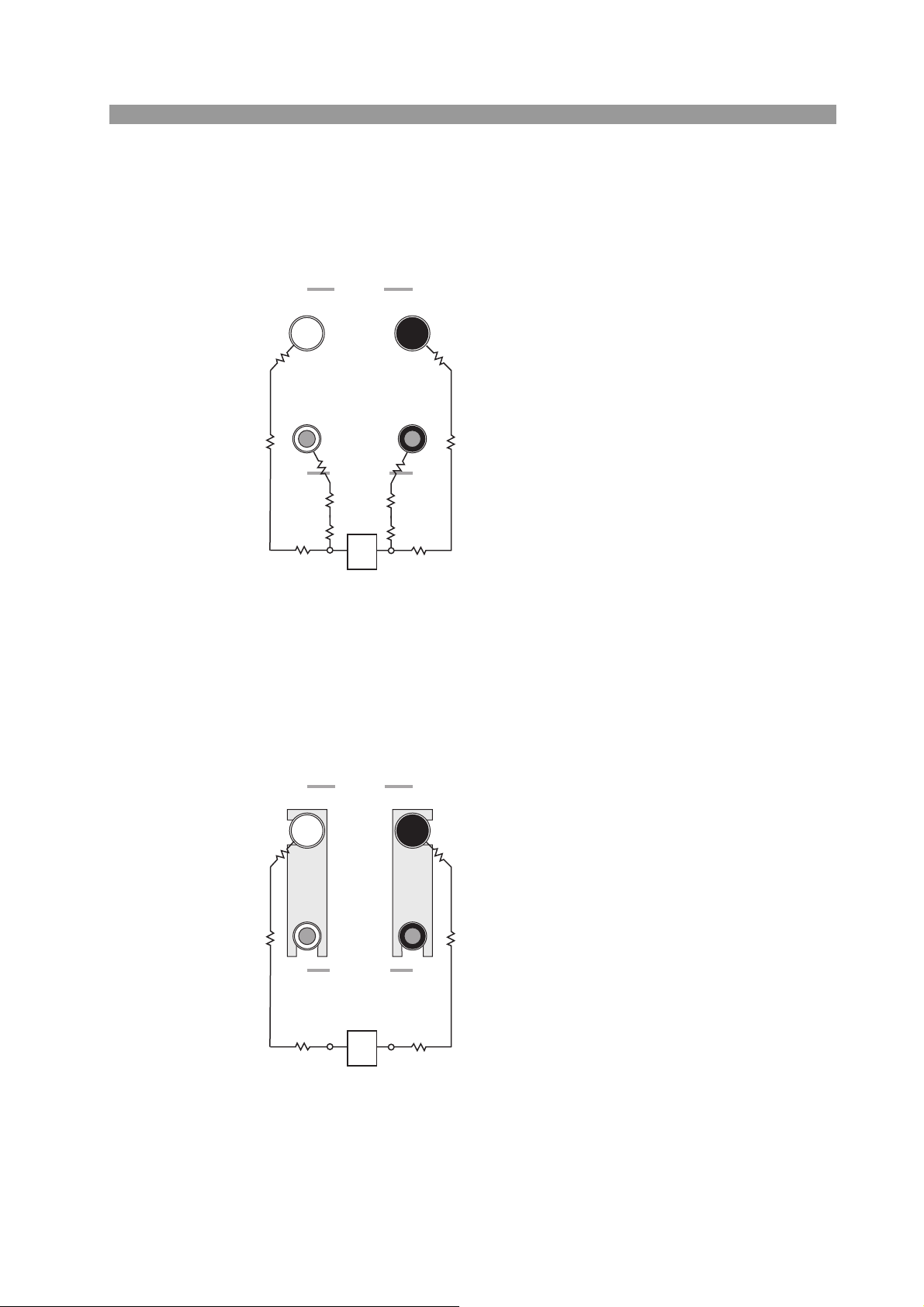

2.4.4 Measurements Using Four Terminals

Four-terminal measurements allow the tester to measure the resistance of the DUT,

excluding the minute resistance of the leads, contact resistance of the OUTPUT terminals, and other non-essential characteristics.

OUTPUT

LOW HIGH

r1

R1

r5 r6

LOW HIGH

SAMPLING

R3 R4

r7 r8

r3

AB

DUT: Device Under Test

r2

R2

r4

Fig. 2-3 Four-Terminal Connection

Remove the short-circuit bars connecting the OUTPUT and SAMPLING terminals and connect the

leads.

Sampling the voltage between A and B allows the

tester to measure the resistance between A and B

without interference from the effects of contact resistance r1 to r8 and resistance components R1 to R4 of

the leads.

r1 to r8: Contact resistance

R1 to R4: Resistance of the leads

2.4.5 Measurements Using Two Terminals

Perform two-terminal measurements if four-terminal measurements can't be made.

Note that measurements using two terminals will include the resistance components

of the leads and the contact resistance of the OUTPUT terminals.

OUTPUT

LOW HIGH

r1

R1 R2

LOW HIGH

SAMPLING

r3 r4

AB

DUT: Device Under Test

r2

Fig. 2-4 Two-Terminal Connection

Install the short-circuit bars between the OUTPUT

and SAMPLING terminals and connect the leads.

The tester measures the total resistance value of contact resistance r1 to r4, resistance components R1

and R2 of the leads, and the resistance between A

and B.

r1 to r4: Contact resistance

R1 to R2: Resistance of the leads

Two-terminal measurements can be performed with the resistance components (R1,

R2) of the leads and the contact resistances (r1 to r4) of the OUTPUT terminals subtracted beforehand. For more information, see 4.2.6, "Offset Canceling Function.”

TOS6200A/6210 Installation and Preparation for Use 2-9

2.4.6 Connecting to the DUT

Connect to the DUT when the tester status is either of the following:

• Ready (“READY” displayed on the LCD)

• Waiting during a contact check (TEST LED blinking)

WARNING

• To avoid burns, do not inadvertently touch the testing point or the end of

the test probe or lead during the test or immediately after test, since they

are at high temperature.

■ Testing from the protective conductor terminal of the AC

power inlet

Connect one of the test leads to the protective conductor terminal of the AC power

inlet of the DUT; connect the other test lead to a test point.

■ Testing from the protective conductor terminal on the enclo-

sure

Connect one of the test leads to the protective conductor terminal of the DUT; connect the other test lead to a test point.

2-10 Installation and Preparation for Use TOS6200A/6210

■ Testing from the ground contact of the AC power cord

Connect one of the test leads to the ground contact of the AC power cord of the

DUT; connect the other test lead to a test point.

NOTE

• Some safety standards specify excluding the resistance value of the AC power

cord protective ground wire from testing. Check the appropriate safety standard

to determine if this is the case.

2.5 Preliminary Inspection

Always inspect the following four points before testing.

• Check that the test lead covers are free of cracks or tears.

• Check that there are no breaks in the test leads.

• Short-circuit the ends of the test leads and test at a specified current to check for

abnormalities.

• Perform the test with the OUTPUT terminals opened. This test must result in a

FAIL judgement.

TOS6200A/6210 Installation and Preparation for Use 2-11

2-12 Installation and Preparation for Use TOS6200A/6210

3

3

Chapter 3 Part Names and

Functions

Gives the names and functions of switches, keys, indications, connectors, and other

parts on the front and rear panels.

TOS6200A/6210 3-1

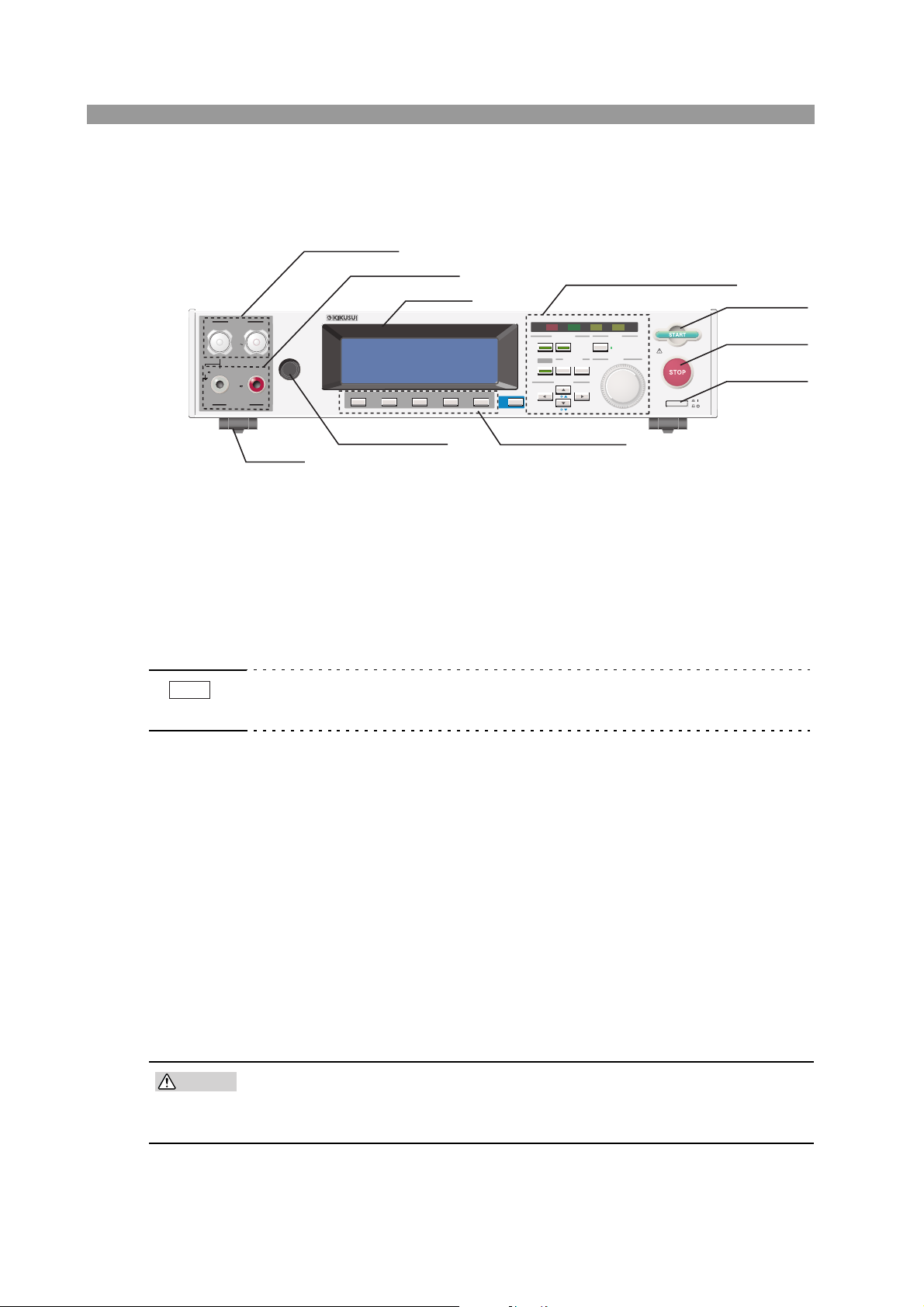

3.1 Front Panel

[4] OUTPUT

OUTPUT

HIGH

LOW

MAX

60A

MAX

20V

MAX

10V

LOW

SAMPLING

REMOTE

HIGH

[5] SAMPLING

[6] LCD

EARTH CONTINUITY TESTER TOS6210

F1 F3

F2

F1 F3

F2

Setup keys (see Fig. 3-2)

[3] START

TEST PASS

FAIL

PROTECTION

FUNCTION GPIB

MAIN SYSTEM LOCAL

OFFSET I / F KEY LOCK

MEMORY ENTRY

AUTO

RECALL

STOREEDIT

F5

F4

F5

F4

SHIFT

CURSOR

RMT

ENTER

ON 10min / OFF 10min

POWER

[2] STOP

[1] POWER

[1] POWER

NOTE

[2] STOP

[3] START

[8] REMOTE

[9] Function keys

[7] Feet

Fig.3-1 Front Panel (example of TOS6210)

Turns the tester power ON/OFF. When power is turned ON ( | ), the tester starts

under the test conditions set when power was turned OFF(O).

Turning the power ON with the SHIFT key held down initializes the tester to factory-set settings. For initialization, see 4.11, "Initialize,” and for turning the power

ON, see 4.1, "Turning on the power.”

• Initializing clears the contents of all panel memories and programs stored. Check

all data in memories and programs before initializing.

This switch is used to stop a test.

Press this switch to cancel a PASS, FAIL, or PROTECTION status.

Pressing this switch places the tester in ready status.

This switch is used to start a test.

Press this switch when "READY" is displayed on the LCD to begin testing.

During testing, the TEST LED indicator lights and a "TEST" indication appears on

the LCD.

[4] OUTPUT

These current output terminals are used to connect current output wires for testing.

CAUTION

3-2 Part Names and Functions TOS6200A/6210

• The maximum input voltage between the OUTPUT terminals and chassis

is 20 Vac/ 20 Vdc or less. Do not apply an external voltage exceeding this

limit.

[5] SAMPLING

These voltage input terminals are used to connect voltage measuring wires for fourterminal measurements.

CAUTION

• The maximum input voltage between the SAMPLING terminals is 10 Vac/

10Vdc or less. Do not apply external voltage exceeding this limit.

[6] LCD

Displays information, including the range of set values and measured values.

[7] Feet

Used to raise the front panel of the tester to get a better view of the LCD screen or

improve the operability of the keys.

For usage of the feet, see 2.2, "Precautions for Installation.”

[8] REMOTE

This terminal is used to connect an optional remote control box or dedicated test

probe.

[9] Function keys

Provide functions corresponding to the F1 to F5 menus displayed on the LCD.

TOS6200A/6210 Part Names and Functions 3-3

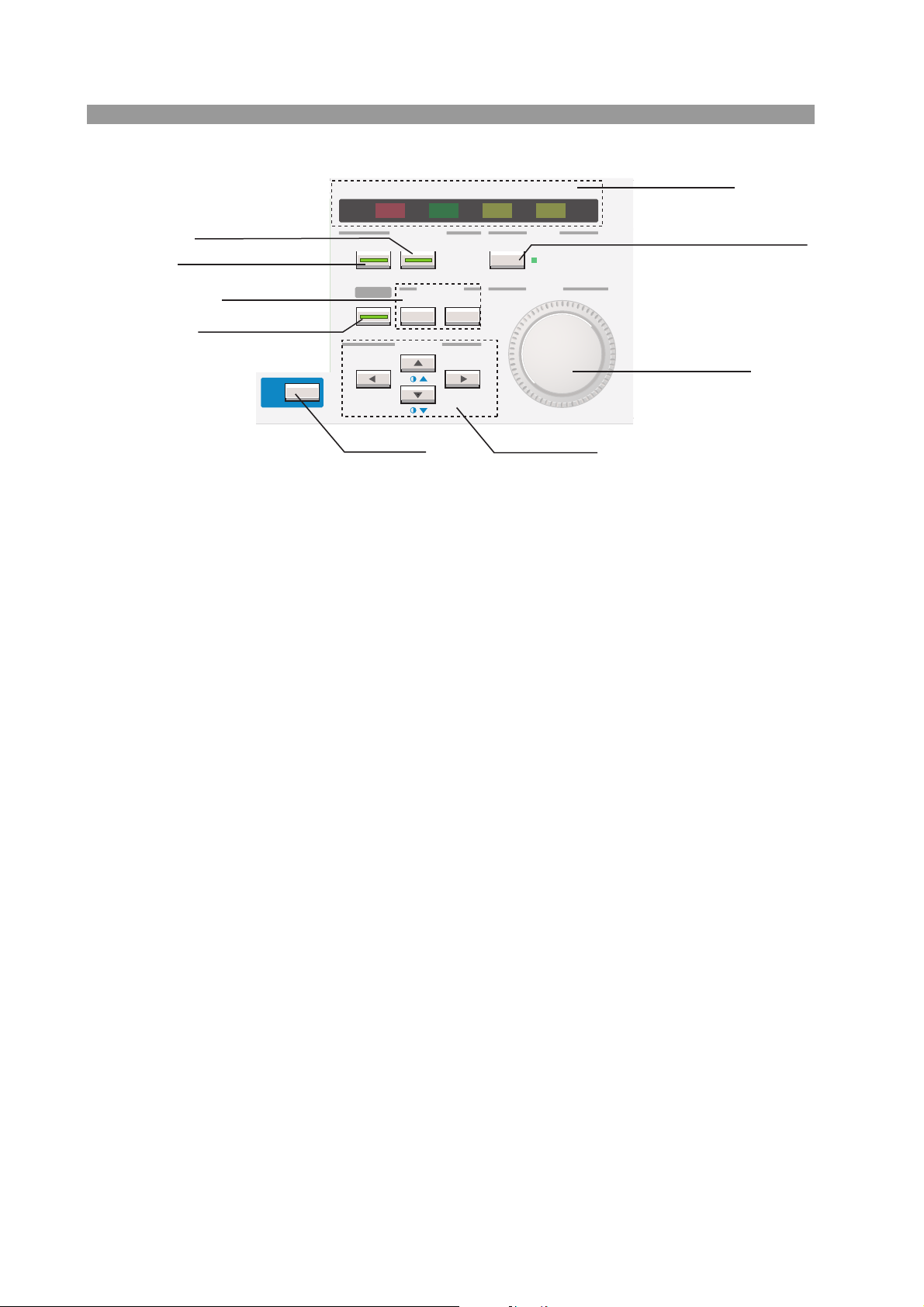

TEST PASS

FAIL

PROTECTION

MAIN SYSTEM LOCAL

RMT

ENTER

RECALL

STOREEDIT

OFFSET I / F KEY LOCK

SHIFT

AUTO

FUNCTION GPIB

MEMORY ENTRY

CURSOR

[16] Indicators

[10] SYSTEM / I/F

[11] MAIN / OFFSET

[12] MEMORY

[13] AUTO / EDIT

Fig. 3-2 Setup keys (example of TOS6210)

[10] SYSTEM / I/F

This key is used to make the system settings of the tester.

Pressing this key causes its LED lights up and displays the system setup screen on

the LCD (SYSTEM).

Pressing this key with the SHIFT key held down displays the interface setup screen

(INTERFACE) on the LCD.

[11] MAIN / OFFSET

[14] SHIFT

[17] LOCAL / KEYLOCK

[18] Rotary knob

[15] CURSOR

Pressing this key causes its LED lights up and displays the test conditions setup

screen (MAIN) on the LCD. Generally, testing is performed from this screen.

Pressing this key with the SHIFT key held down displays the offset measurement

screen (OFFSET).

[12] MEMORY

• RECALL/STORE key

• ENTER key

Press this key to recall panel memory.

Change the memory number using the rotary knob, then press the ENTER key

next to this key. This recalls the contents of the specified memory number.

Pressing this key with the SHIFT key held down enables test conditions to be

stored to memory. The procedure is the same as for recall.

Used to accept an entered memory number when recalling panel memory or

when saving test conditions to panel memory.

3-4 Part Names and Functions TOS6200A/6210

Loading...

Loading...