Kikusui TOS5050A, TOS5051A Operation Manual

Part No. Z1-002-972, IB004839

Aug. 2009

OPERATION MANUAL

WITHSTANDING VOLTAGE TESTER

TOS5000 Series

TOS5050A

TOS5051A

DANGER

This Tester generates high voltage.

• Any incorrect handling may cause death.

• Read “Handling Precautions” in this manual to

prevent accident.

• Keep this manual near the tester for easy access

of the operator.

Use of Operation Manual

Please read through and understand this Operation Manual before operating the product. After reading,

always keep the manual nearby so that you may refer to it as needed. When moving the product to another

location, be sure to bring the manual as well.

If you find any incorrectly arranged or missing pages in this manual, they will be replaced. If the manual

gets lost or soiled, a new copy can be provided for a fee. In either case, please contact Kikusui distributor/

agent, and provide the “Kikusui Part No.” given on the cover.

This manual has been prepared with the utmost care; however, if you have any questions, or note any

errors or omissions, please contact Kikusui distributor/agent.

Disposing of used Kikusui products in the EU

Under a law adopted by member nations of the European Union (EU), used electric and electronic products carrying the symbol

below must be disposed of separately from general household waste.

This includes the power cords and other accessories bundled with the products. When disposing of a product subject to these regulations, please follow the guidance of your local authority, or inquire with your

Kikusui distributor/agent where you purchased the product.

The symbol applies only to EU member nations.

Disposal outside the EU

When disposing of an electric or electronic product in a country that is not an EU member, please contact

your local authority and ask for the correct method of disposal.

Microsoft, and Visual Basic are registered trademarks of the Microsoft Corporation in the U.S. and other

countries.

Reproduction and reprinting of this operation manual, whole or partially, without our permission is prohibited.

Both unit specifications and manual contents are subject to change without notice.

Copyright© 2003-2009 Kikusui Electronics Corporation

Testing is not possible when

you open the package.

If you turn on the power to the tester simply after taking the tester out

from the box, testing is not possible because the interlock function is

activated.

For a description of the interlock function, see section 6.3.3, “Interlock

Function” in this manual. Then, operate the tester appropriately using the

interlock function.

About this manual

This is the operation manual for the TOS5050A/TOS5051A Withstanding Voltage

tester.

NOTE

■

ROM version of the product to which this manual applies

• TOS5050A: Ver.1.0X

• TOS5051A: Ver.1.0X

To check the version number, refer to 5.2 “Checking the tester Operation.”

When you contact us for any information about the tester, please indicate the version number and the serial number of the tester. The serial number is written on the

rear panel of the tester.

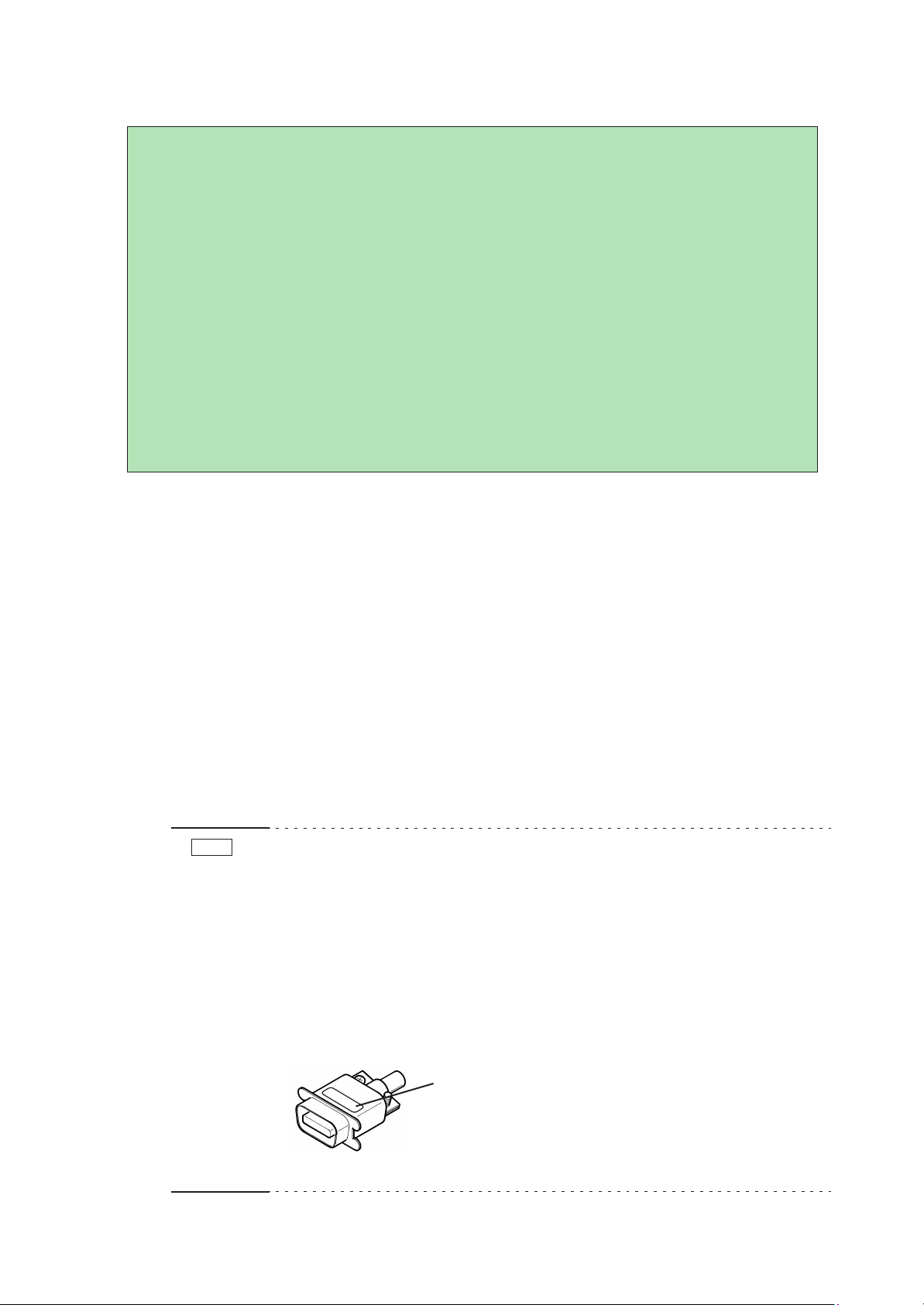

•

To those using the old model TOS5050/5051

The SIGNAL I/O connector on this tester is not compatible with that on the

old model TOS5050/5051 (different pin assignments). Therefore, the 14pin Amphenol plug that is supplied with the tester cannot be shared

between the new and old models.

If you connect the Amphenol plug which you use for the old model to this

tester, testing is not possible because the protection is not released.

To use the Amphenol plug for the old model to this tester, you have to change the

wiring for the interlock function. For details, refer to section 6.3.2 Remote Control through the SIGNAL I/O Connector and 6.3.3 Interlock Function.

TYPE A

The 14-pin Amphenol plug that is supplied with this tester

TOS5051A/5050A I

It is marked “TYPE A” to distinguish

from the plug for the

old model.

To the supervisor in charge of operation

• If the operator does not read the language used in this manual, translate the manual

into the appropriate language.

• Help the operator in understanding this manual before operation.

• Keep this manual near the tester for easy access by the operator.

For your own safety (to avoid electric shock)

While the tester is delivering its test voltage, never touch the following areas, or else,

you will receive electric shock, and run the risk of death.

• the output terminal

• the test leads connected to the output terminal

• the Device Under Test (DUT)

• any area electrically connected to the output terminal.

• any area electrically connected to the output terminal immediately after the output

has been cut off in the DC test mode.

Also, electric shock or accident may occur in the following cases:

• the tester being operated without grounding.

• if the gloves for electrical work are not used.

• approach any part connected to the output terminal while the power of the tester is

turned on.

• approach any part connected to the output terminal immediately after the power of

tester has been turned off in the DC test mode.

II TOS5051A/5050A

Power Requirements of this Product

Power requirements of this product have been changed and the relevant sections of the Operation

Manual should be revised accordingly.

(Revision should be applied to items indicated by a check mark .)

✓

Input voltage

The input voltage of this product is VAC ,

and the voltage range is

to VAC. Use the product within this range only.

Input fuse

The rating of this product's input fuse is A, VAC, and .

WARNING

• To avoid electrical shock, always disconnect the power cord or turn off the

switch on the switchboard before attempting to check or replace the fuse.

• Use a fuse element having a shape, rating, and characteristics suitable

for this product. The use of a fuse with a different rating or one that short

circuits the fuse holder may result in fire, electric shock, or irreparable

damage.

TOS5051A/5050A III

WARNING

Safety Symbols

For the safe use and safe maintenance of this product, the following

symbols are used throughout this manual and on the product. Understand the meanings of the symbols and observe the instructions they

indicate (the choice of symbols used depends on the products).

Indicates that a high voltage (over 1000 V) is used here. Touch-

OR

ing the part causes a possibly fatal electric shock. If physical

contact is required by your work, start work only after you make

sure that no voltage is output here.

DANGER

CAUTION

Indicates an imminently hazardous situation which, if ignored,

will result in death or serious injury.

Indicates a potentially hazardous situation which, if ignored,

could result in death or serious injury.

Indicates a potentially hazardous situation which, if ignored, may

result in damage to the product and other property.

Shows that the act indicated is prohibited.

Is placed before the sign “DANGER,” “WARNING,” or “CAUTION” to emphasize these. When this symbol is marked on the

product, see the relevant sections in this manual.

Indicates a protective conductor terminal.

Indicates a chassis (frame) terminal.

IV Safety Symbols TOS5051A/5050A

Safety Precautions

Operation

Manual

Line

Voltage

The following safety precautions must be observed to avoid fire hazard, electrical shock, accidents, and other failures. Keep them in

mind and make sure that all of them are observed properly.

User

s

• This product must be used only by qualified personnel who understand the contents of this operation manual.

• If it is handled by disqualified personnel, personal injury may result. Be sure to handle it under supervision of qualified personnel (those who have electrical knowledge.)

• This product is not designed or manufactured for general home or consumer use.

Purposes of use

• Do not use the product for purposes other than those described in the operation

manual.

Input po

• Use the product with the specified input power voltage.

• For applying power, use the power cord provided. Note that the provided power

cord is not use with some products that can switch among different input power

voltages or use 100 V and 200 V without switching between them. In such a case,

use an appropriate power cord.

wer

Fuse

• With products with a fuse holder on the exterior surface, the fuse can be replaced

with a new one. When replacing a fuse, use the one which has appropriate shape,

ratings, and specifications.

Cover

• There are parts inside the product which may cause physical hazards. Do not

remove the external cover.

TOS5051A/5050A Safety Precautions V

Installation

Check?

• When installing products be sure to observe “2.2 Precautions Concerning Installation Location” described in this manual.

• To avoid electrical shock, connect the protective ground terminal to electrical

ground (safety ground).

• When connecting the power cord to a switchboard, be sure work is performed by

a qualified and licensed electrician or is conducted under the direction of such a

person.

• When installing products with casters, be sure to lock the casters.

Relocation

• Turn off the power switch and then disconnect all cables when relocating the

product.

• Use two or more persons when relocating the product which weights more than

20 kg. The weight of the products can be found on the rear panel of the product

and/or in this operation manual.

• Use extra precautions such as using more people when relocating into or out of

present locations including inclines or steps. Also handle carefully when relocating tall products as they can fall over easily.

• Be sure the operation manual be included when the product is relocated.

Operation

• Check that the AC input voltage setting and the fuse rating are satisfied and that

there is no abnormality on the surface of the power cord. Be sure to unplug the

power cord or stop applying power before checking.

• If any abnormality or failure is detected in the products, stop using it immediately.

Unplug the power cord or disconnect the power cord from the switchboard. Be

careful not to allow the product to be used before it is completely repaired.

• For output wiring or load cables, use connection cables with larger current capacity.

• Do not disassemble or modify the product. If it must be modified, contact Kikusui

distributor/agent.

Maintenance and c

• To avoid electrical shock, be absolutely sure to unplug the power cord or stop

applying power before performing maintenance or checking.

• Do not remove the cover when performing maintenance or checking.

• To maintain performance and safe operation of the product, it is recommended

that periodic maintenance, checking, cleaning, and calibration be performed.

vice

Ser

hecking

• Internal service is to be done by Kikusui service engineers. If the product must be

adjusted or repaired, contact Kikusui distributor/agent.

VI Safety Precautions TOS5051A/5050A

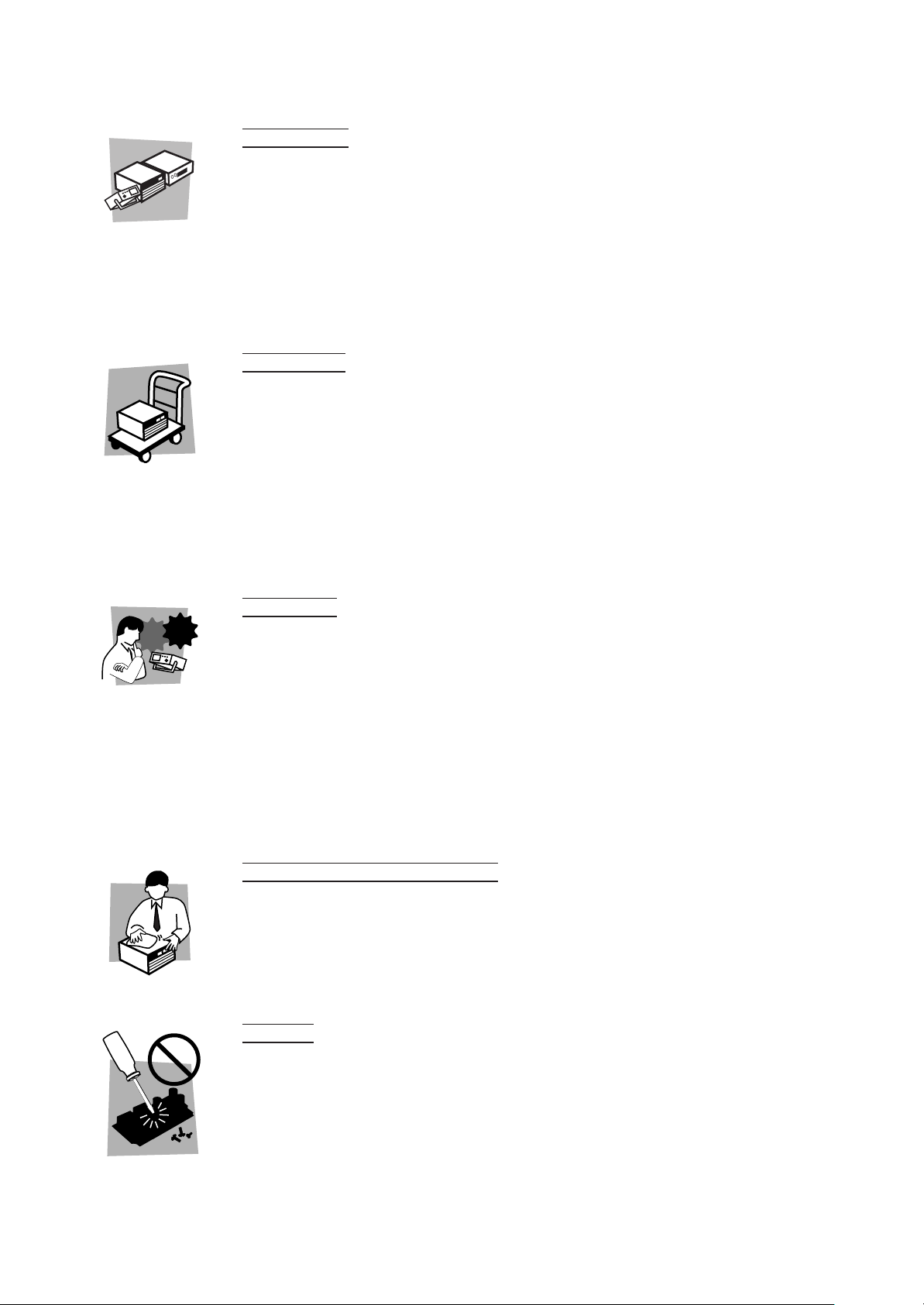

Fr

ont Panel and Rear Panel

• When accessing the panels, be sure to read chapter 3, “Handling Precautions.”

Deflected meter pointer means

hat the tester is in the

“DANGER! HIGH VOLTAGE”

state.

Be sure to read the manual before

controlling the tester remotely.

See section 2.6, “Remote Control.”

Lighted lamp means that the

tester is in the

“DANGER! HIGH VOLTAGE”

state.

Be sure to stop the tester

before changing test

parameters.

Start connecting from

the low voltage test

HIGH VOLTAGE Output Terminal

DANGER!

lead.

Be sure to read the manual before

controlling the tester remotely.*

See section 2.6, “Remote Control.”

RS232C

SIGNAL I O

AC LINE 50 60Hz

800VA MAX

:

7

:

6

:

5

:

4

:

3

:

2

:

1

:

8

:

9

:

10

:

11

:

12

:

13

:

14

READY

L FAIL

U FAIL

PASS

TEST

H.V ON

INTERLOCK

PROTECTION

INTERLOC K

RR START

RR STOP

RR ENABLE

ISOL COM

ISOL COM

+

-

IF THIS CO LUMN IS BLA NK,

THE UNI T IS WIRED I N 100V

SETT ING

LINE VO LTAGE

SUPPLY

STANDARD

100 V

110V

120V

220V

230V

240V

WARNING

TO AVOID ELECTRIC SHOCK, THE POWER CORD PROTECTIVE GROUNDING

CONDUCTOR OR THE PROTECTIVE CONDUCTOR TERMINAL MUST BE

CONNECTED TO GROUND.

DO NOT REMOVE COVERS, REFER SERVICING TO QUALIFIED PERSONNEL.

USE ONLY

BUZZER AND

WARNING LIGH T

.3A MA X

AC100V 0

STATUS OUT

TEST MODE

OFF ON

OFF ON

DOUBLE ACTI ON

PASS HOLD

MOMENTARY

FAIL M ODE

H.V ON

TEST

PASS

U FAIL

L FAIL

READY

PROTECTION

POWER ON

For your safety, be sure to connect to the earth ground.

See section 2.6, “Grounding (Earth).”

Before turning ON the

POWER switch, be certain

that the TEST VOLTAGE

control is in the “0” position.

No

.

KIKUSUI ELECTRONICS CORP.

MADE IN JAPAN

* The SIGNAL I/O connector on this tester is not compatible with that on the old model TOS5050/5051

(different pin assignments). For details, refer to section 6.3.2 Remote Control through the SIGNAL I/O

Connector and 6.3.3 Interlock Function.

TOS5051A/5050A Safety Precautions VII

Contents

Power Requirements of this Product ___________________________ III

Safety Symbols ___________________________________________ IV

Safety Precautions _________________________________________ V

Chapter 1 General ________________________________________ 1-1

Chapter 2 Installation and Preparation_________________________ 2-1

1.1 Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.2 Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.3 Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

2.1 Checking the Package Contents - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.2 Precautions Concerning Installation Location - - - - - - - - - - - - - - - - - - - - 2-3

2.3 Precautions When Moving the tester - - - - - - - - - - - - - - - - - - - - - - - - - - 2-4

2.4 AC Line Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-4

2.5 Connecting the Power Cord - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

2.6 Grounding (Earth) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-6

Chapter 3 Handling Precautions _____________________________ 3-1

3.1 Preparative Procedures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.1.1 Wearing Insulation Gloves - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.1.2 Grounding the Tester - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.2 Warnings and Cautions When Operating the Tester - - - - - - - - - - - - - - - - 3-2

3.2.1 Before Turning ON the AC Input Power - - - - - - - - - - - - - - - - - 3-2

3.2.2 Connecting the Low Test Lead - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.2.3 Connecting the High Test Lead - - - - - - - - - - - - - - - - - - - - - - - 3-3

3.2.4 Before Changing Test Parameters - - - - - - - - - - - - - - - - - - - - - - 3-3

3.2.5 Precautions for Pausing Tests - - - - - - - - - - - - - - - - - - - - - - - - - 3-4

3.2.6 Items Charged Up to Dangerous High Voltages - - - - - - - - - - - - 3-4

3.3 Warnings after Turning OFF the Power - - - - - - - - - - - - - - - - - - - - - - - - 3-5

3.3.1 Check Items after Turning OFF the Power - - - - - - - - - - - - - - - - 3-5

3.3.2 Residual High Voltages (TOS5051A Only) - - - - - - - - - - - - - - - 3-5

3.4 Warnings for Remote Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

3.5 Inhibitions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

3.5.1 Inhibition of Rapid ON/OFF Repetitions - - - - - - - - - - - - - - - - - 3-6

3.5.2 Inhibition of Shorting to Earth Ground - - - - - - - - - - - - - - - - - - 3-6

3.6 Actions to Be Taken in Emergency - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-7

3.7 Breakdown - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-7

3.7.1 Stopping the Use of Broken Testers - - - - - - - - - - - - - - - - - - - - 3-7

3.7.2 DANGER Lamp - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-7

3.8 Wattage, Heat, and Other Limiting Conditions of Use - - - - - - - - - - - - - - 3-8

Chapter 4 Description of Front and Rear Panel Items _____________ 4-1

4.1 Description of Front Panel Items - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

VIII Contents TOS5051A/5050A

4.2 Display Items - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-13

4.3 Description of Rear Panel Items - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-19

Chapter 5 Preparative Test Procedures _______________________ 5-1

5.1 Initial Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

5.2 Checking the Tester Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-4

5.3 Checking the Tester before Starting Test Operation - - - - - - - - - - - - - - - 5-6

Chapter 6 Test Procedures _________________________________ 6-1

6.1 AC Withstanding Voltage Test Procedure - - - - - - - - - - - - - - - - - - - - - - 6-2

6.1.1 Selecting an AC Test Voltage Range - - - - - - - - - - - - - - - - - - - - 6-2

6.1.2 Setting the Upper Cutoff Current - - - - - - - - - - - - - - - - - - - - - - - 6-2

6.1.3 Setting the Lower Cutoff Current - - - - - - - - - - - - - - - - - - - - - - - 6-3

6.1.4 Setting the Test Time - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-5

6.1.5 Setting the Test Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-6

6.1.6 Connecting the DUT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-6

6.1.7 Executing a Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-7

6.2 DC Withstanding Voltage Test Procedure (TOS5051A Only) - - - - - - - 6-11

6.2.1 Selecting a DC Test Voltage Range - - - - - - - - - - - - - - - - - - - - 6-11

6.2.2 Setting the Upper Cutoff Current - - - - - - - - - - - - - - - - - - - - - - 6-12

6.2.3 Setting the Lower Cutoff Current - - - - - - - - - - - - - - - - - - - - - 6-13

6.2.4 Setting the Test Time - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-14

6.2.5 Setting the Test Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-15

6.2.6 Connecting the DUT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-15

6.2.7 Executing a Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-16

Chap.1Chap.2Chap.3Chap.4Chap.5Chap.6Chap.7Chap.8Chap.9Chap.10

6.3 Remote Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-20

6.3.1 Remote Control through the REMOTE Connector - - - - - - - - - - 6-20

6.3.2 Remote Control through the SIGNAL I/O Connector - - - - - - - - 6-21

6.3.3 Interlock Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-24

6.3.4 Start/Stop Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-25

6.3.5 Output Signal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-27

6.4 STATUS OUT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-28

6.5 Settings for Special Test Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-29

6.5.1 DOUBLE ACTION Switch - - - - - - - - - - - - - - - - - - - - - - - - - - 6-29

6.5.2 PASS HOLD Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-29

6.5.3 MOMENTARY Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-30

6.5.4 FAIL MODE Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-30

Chapter 7 RS-232C Interface _______________________________ 7-1

7.1 Connecting the Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

7.2 RS-232C Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

7.3 Communication Method - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-3

7.4 Talk Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-3

7.5 Before Using the RS-232C - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-5

TOS5051A/5050A Contents IX

7.6 RS-232C Commands and Responses - - - - - - - - - - - - - - - - - - - - - - - - - - 7-7

7.7 Sample Program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-10

Chapter 8 Operating Principle _______________________________ 8-1

8.1 Block Diagrams - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-2

8.2 Zero-turn-on Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-4

8.3 Delay Time for Pass/Fail Judgment in DC Mode - - - - - - - - - - - - - - - - - 8-5

8.4 Automatic Discharge Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-5

Chapter 9 Maintenance ____________________________________ 9-1

9.1 Cleaning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-2

9.2 Checking the Cord and Leads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-2

9.3 Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-3

9.4 Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-3

Chapter 10 Specifications _________________________________ 10-1

10.1 Basic Performance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-2

10.2 Interface and Other Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-5

10.3 General Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-7

10.4 Outline Drawing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-8

Index ___________________________________________________ I- 1

X Contents TOS5051A/5050A

Chapter 1 General

1

1

Chap.1

General

This chapter gives an overview and introduces the features of the tester.

TOS5051A/5050A 1-1

1.1 Overview

The TOS5051A/5050A is a tester for carrying out withstanding voltage tests on electronic devices and electronic parts. The TOS5051A is capable of carrying out both

AC tests and DC tests; the TOS5050A is capable of carrying out AC tests.

This tester integrates new ideas and technologies with the conventional, consistent

philosophy of providing the highest safety, reliability, and operability to the operator.

WARNING

• The tester is equipped with various safety features to protect the operator

from hazards. However, when the tester is in use, high voltage is applied

to the DUT. Inadvertently touching the DUT, test leads, probes, and output

terminals can cause electric shock.

• Be sure to provide full protective measures around the tester and DUT to

prevent electric shock--such as to enclose the test area with rope fences

to prevent access.

1.2 Features

1. Tests complying with major industrial standards

The tester can carry out withstanding (dielectric strength) tests on electronic

devices and electronic parts in compliance with JIS, UL, CSA, BS, and other

major electrical standards and ordinances.

2. Transformer capacity of 500 VA

The tester is equipped with a transformer, rated 500 VA.

3. Rational layouts of keys and switches

The keys have a slant-plane for easy viewing and convenient operation. The switch

for AC/DC select and test voltage range select and the control for test voltage

adjustment are installed concentrically, allowing you to operate them conveniently

with two concentric knobs. For the adjustment of the pass/fail-judgment limit current and timer, dedicated increment/decrement keys are provided. These keys and

switches, together with the large display easy to view, are laid out rationally and

will assist you to conduct your tests accurately and efficiently.

4. A large color display

The tester has a large color vacuum fluorescent display. The wide viewing angle

and high intensity indicates information in clearly. Various information including

test conditions, instrument status, measured values, and result of pass/fail judgment are indicated using large letters and color assisting you to conduct your tests

accurately and efficiently.

1-2 TOS5051A/5050A

5. An analog voltmeter and a digital voltmeter

The tester is equipped with an analog voltmeter (±5 % FS) and a digital voltmeter (±1.5 % FS)--the former for quick grasp of the voltage and the latter for

more accurate readout--assisting you to conduct your tests rapidly but accurately.

6. A digital ammeter

The digital ammeter can be used to measure the current that flows through the

DUT (device under test).

7. A window comparator for pass/fail judgment

The tester has a window comparator for pass/fail judgment with reference to

both upper (U) and lower (L) criteria (cutoff current). The comparator generates a FAIL signal when the measured current that flows through the DUT is

greater than the preset upper limit criterion or when it is less than the preset

lower limit criterion. The L FAIL detection function contributes to improve the

test reliability by detecting open-circuits and bad contacts of the test leads. The

tester has a separate indicator and signal output for each type of failure (U type

and L type). This allows you to immediately find out whether the failure is a

withstand voltage failure or an open-circuit/bad-contact failure.

You can preset the upper limit and lower limit currents (cutoff currents) independently, within the ranges shown in the following table.

Chap.1

General

Model Preset range of upper and lower limits

TOS5051A 0.1 mA to 110 mAAC 200 steps

0.1 mA to 11 mADC 101 steps

TOS5050A 0.1 mA to 110 mAAC 200 steps

8. A digital timer

The timer allows you to preset the period during which the test voltage is to be

applied to the DUT. The preset range is 0.5 to 999 seconds (in 1895 steps).

When the timer function is ON, the preset period is decreased and the timer

indicates the remaining period; when it is OFF, time is increased and the timer

indicates the elapsed period.

9. Remote control function

The tester has functions for remote start/stop control operation. That is, it has a

5-pin DIN connector (for the optional remote control box or high voltage test

probe) on its front panel and a 14-pin Amphenol connector on its rear panel.

The remote control function, together with the status signal function, will help

you conduct efficient automatic labor-saving tests.

TOS5051A/5050A 1-3

10.Status signals

The tester delivers seven status signals--namely, H.V ON, TEST, PASS, U

FAIL, L FAIL, READY, and PROTECTION--through its 14-pin Amphenol

connector (shared with the remote control signals) on the rear panel. The signal form is open collector. The tester can deliver a 100 VAC output in response

to one of eight states--namely, H.V ON, TEST, PASS, U FAIL, L FAIL,

READY, PROTECTION, and POWER ON. Used in conjunction with the

remote control function, these status signals will help you to conduct still more

efficient automatic labor-saving tests.

11.Compact and light

The tester is compact and light as shown below.

Model Overall dimensions Weight

TOS5051A

320 mm (W) × 132 mm (H) × 300 mm (D)

TOS5050A 15 kg

16 kg

12.Memory backup function

When you turn the tester OFF, the tester stores its existing test state in its nonvolatile memory. When you turn the tester ON the next time, the tester recalls

the stored information and restores the test state that existed when you turned

OFF the power last time.

13.A safer high voltage output terminal

The lead insertion portion of the high voltage output terminal is structured with

a restriction for safer connection.

14.A DANGER lamp

The tester has a large and bright DANGER lamp. This lamp lights when electric charge is remaining on the output terminal, warning you of a possible electric shock hazard.

15.Interlock function

The tester has an interlock function that shuts down the output voltage in synchronization with the external device. When this function is activated, the output is shut down and keeps tests from being executed.

The interlock function operates even if there is open-circuit or bad contact in

the signal line, thereby enhancing further the operation safety.

16.Keylock function

The tester has a keylock function to disable all keys (except the START/STOP

keys) to guard against inadvertent key operation by the operator or an unauthorized person. This improves the reliability of tests.

17.Switches for safer operation

A rotary switch is used for AC/DC test mode selection and test voltage range

selection. The START switch is of a recessed type. These features, together

with the keylock function, enhance operation reliability and safety.

1-4 TOS5051A/5050A

18.Noise-resistant circuits

The internal circuits of the tester are designed to be highly resistant against

noise, thereby enhancing the operation reliability.

19.Automatic discharge function (TOS5051A only)

When the DC test output voltage is turned off, the output circuit is automatically discharged, thereby discharging the charge in the device under test

(DUT). This feature, together with the DANGER lamp, enhances the test operation safety.

20.A DC/DC converter for quality DC test voltage (TOS5051A only)

The tester has a DC/DC converter which generates a quality test voltage of

high stability with less ripple.

21.Equipped with a RS-232C interface for outputting test data

and test results

The measurement results can be output to a PC or printer.

1.3 Options

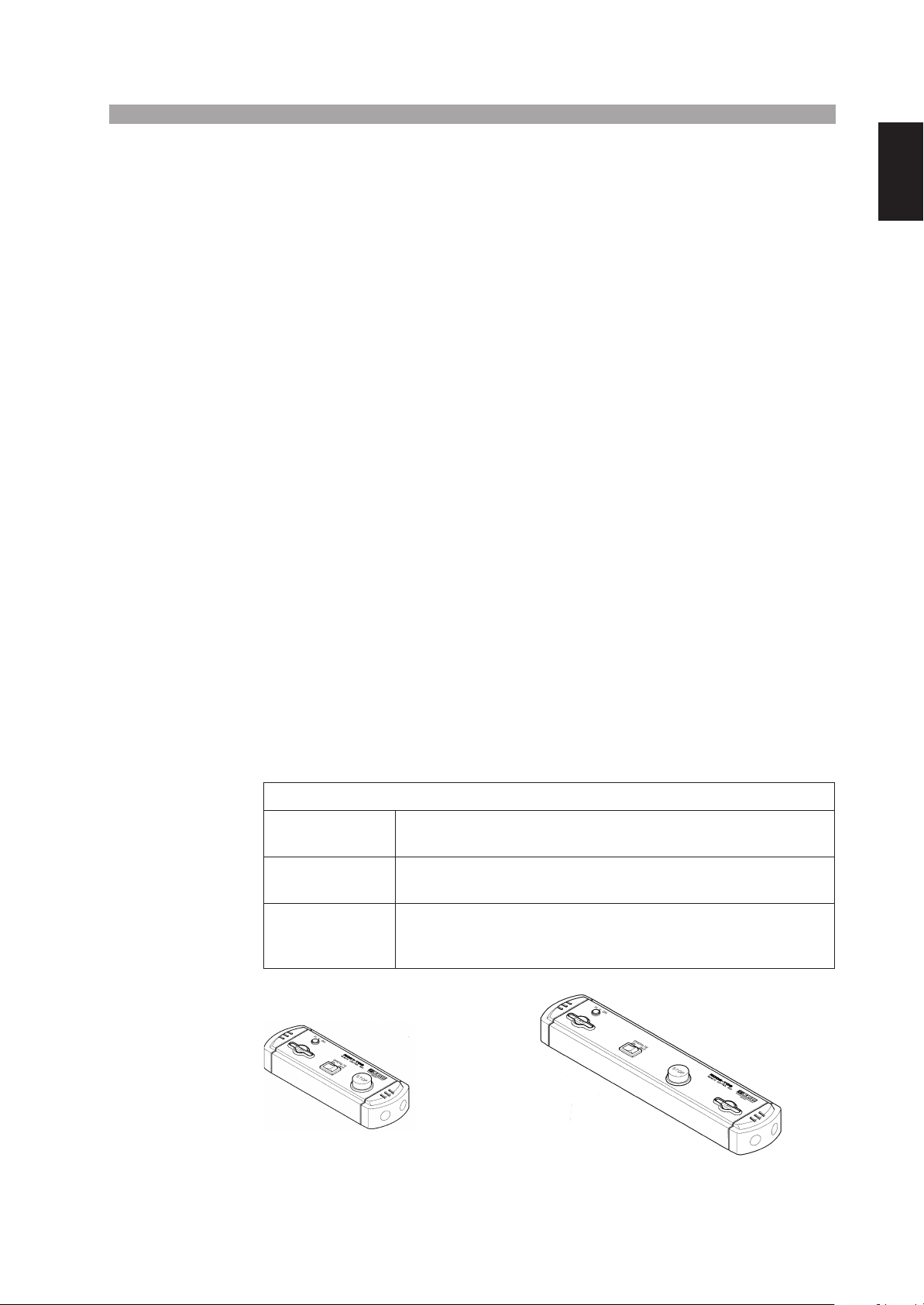

Model RC01-TOS/RC02-TOS remote control box

Chap.1

General

Model RC01-TOS or RC02-TOS remote control box is used to remotely control the

start/stop of test operation of the tester. Connect the Control Box to the REMOTE

connector on the front panel of the tester. The RC01-TOS has one START switch;

RC02-TOS has two START switches. The test starts when you press both switches

at the same time, thereby enhancing the operating safety.

Description of the RC01-TOS/RC02-TOS function

OPERATE switch

START switch

STOP switch

This switch enables (when ON) or disables (when OFF) the START

switch or switches.

The test starts when you press this switch (or switches) if the

OPERATE switch is ON and the tester is in the READY status.

This switch terminates the test (cuts off the test voltage or resets the

tester from the FAIL or other particular status--its functions are the

same with those of the STOP switch on the front panel of the tester.

RC01-TOS RC02-TOS

200(W) × 70(Η) × 39(D) mm 330(W) × 70(Η) × 39(D) mm

TOS5051A/5050A 1-5

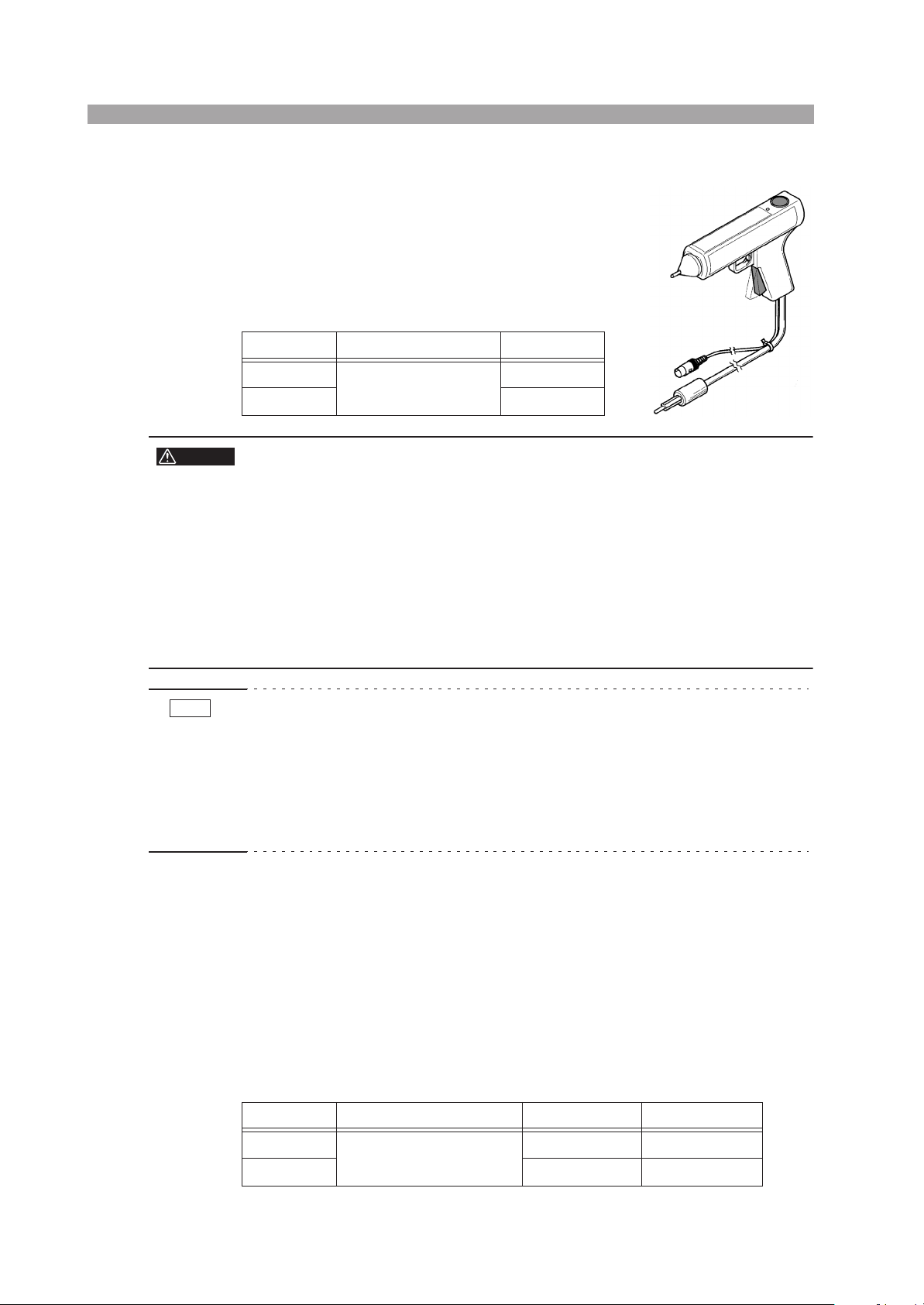

Model HP01A-TOS/HP02A-TOS high voltage test probe

HA01-TOS

The high voltage test probe renders a three-fold operating safety. The test voltage is not delivered unless

you squeeze with one hand the slide lever of the grip

of the probe and pull the trigger while you press with

the other hand the switch on top of the probe. If you

release your hand, the probe immediately delivers a

STOP signal to cut off the test voltage.

Model Voltage rating Cable length

WARNING

NOTE

HP01A-TOS

HP02A-TOS Approx. 3.5 m

4 kVAC (rms), 50/60 Hz

5 kVDC

Approx. 1.8 m

• The maximum voltage rating of the probe is 4

kVACrms or 5 kVDC. Never apply voltages

exceeding the voltage rating.

• Do not connect the probe to or disconnect it from the DUT while the test

voltage is being delivered. If you do, the DUT may be damaged. If you disconnect the probe from the DUT while the test voltage is being delivered,

the DUT will remain charged at the high test voltage. Before connecting

the probe to the DUT, be sure that the test voltage is OFF (the LED on top

of the probe is OFF); before disconnecting the probe from the DUT, be

sure that the test voltage is OFF (the LED is OFF).

• If you need to perform a test in compliance to the UL Standard by using the probe,

turn the FAIL MODE switch (DIP switch on the rear panel) of the tester to ON. If

this switch is ON, the tester behaves in the following manner and you can accurately confirm the FAIL status. When a test is terminated due to a failure, the FAIL

status on the tester is not reset even when you release the probe. To reset the FAIL

status, you must press the STOP switch on the tester. For details, refer to Section

6.5.4, “FAIL MODE Switch” (page 6-30).

Model PL01-TOS warning light unit

This unit indicates that the tester is in the TEST-ON status (delivering the test voltage).

Model BZ01-TOS buzzer unit

This unit may be used when the sound generated by the buzzer housed in the tester

is insufficient. This unit can be driven by the FAIL status signal of the tester.

High Voltage test leads

Model Voltage rating Cable length Remarks

TL01-TOS

TL02-TOS Approx. 3.0 m

1-6 TOS5051A/5050A

5 kVAC (rms), 50/60 Hz

5 kVDC

Approx. 1.5 m Tester accessory

2

2

Chapter 2 Installation and

Preparation

This chapter describes the procedures from unpacking to preparation before use.

Chap.2

Installation and Preparation

TOS5051A/5050A 2-1

2.1 Checking the Package Contents

When you receive the product, check that all accessories are included and that the

product and accessories have not been damaged during transportation.

If any of the accessories are damaged or missing, contact Kikusui distributor/agent.

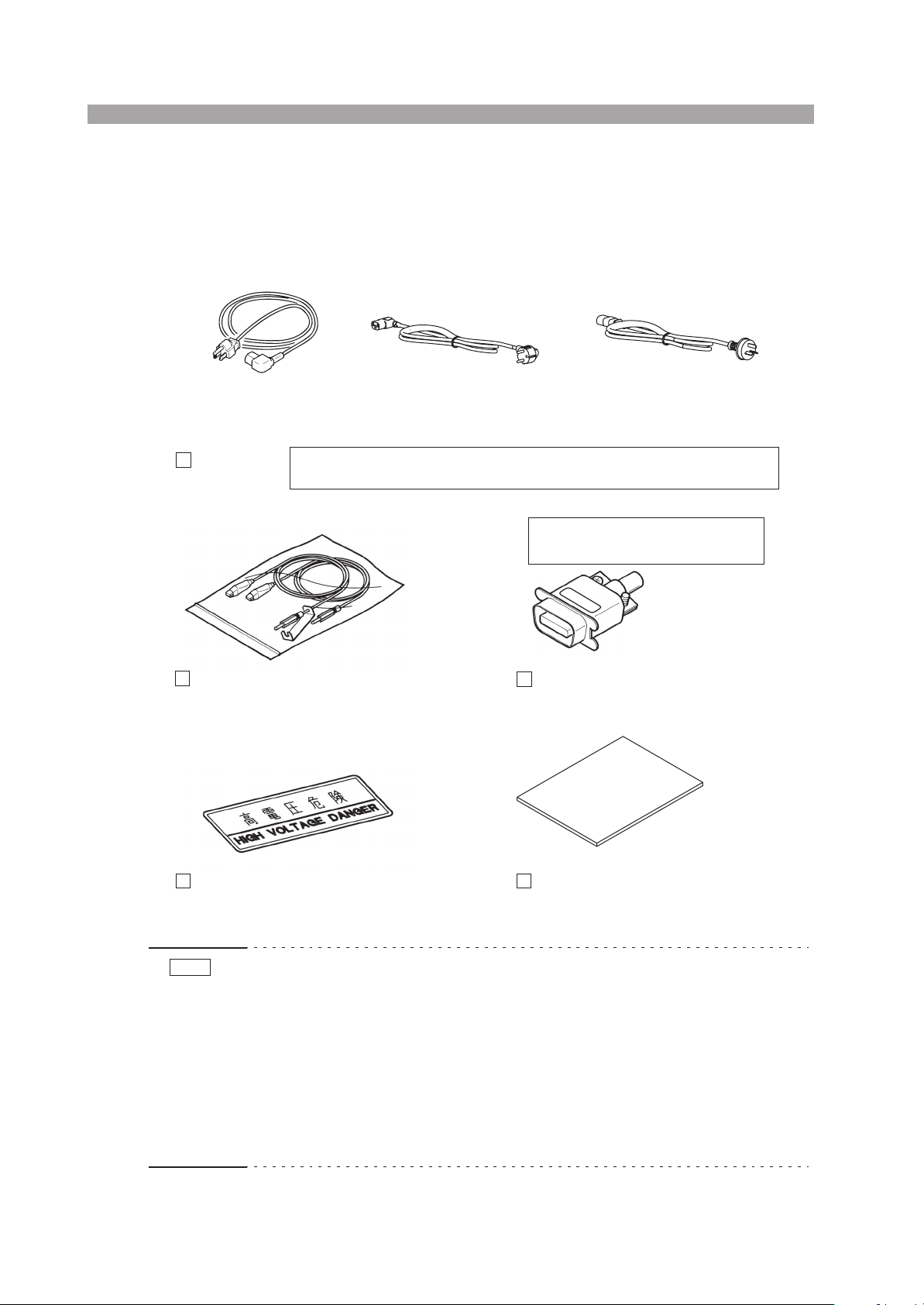

or or

Rated voltage: 125 Vac

PLUG: NEMA5-15

[85-AA-0003] [85-AA-0005]

Power cord 1

(1 piece)

High voltage test leads

TL01-TOS (1.5 meters) (1 set)

The power cord that is provided varies depending on the destination for the product

at the factory-shipment.

[82970]

Rated voltage: 250 Vac

PLUG: CEE7/7

[85-AA-0005]

Rated voltage: 250 Vac

PLUG: GB1002

[85-10-0790]

The plug that is supplied cannot be

shared between the new and old models.

TYPE

A

[83-21-4000]

14-pin Amphenol connector plug* (1 piece)

Assembly type

[A8-210-202]

“HIGH VOLTAGE DANGER” sticker (1 sheet)

Operation manual (1 copy)

[Z1-002-972]

Fig.2-1 Accessories

NOTE

• It is recommended that all packing materials be saved, in case the product needs

to be transported at a later date.

• Attach the “HIGH VOLTAGE DANGER” sticker to a conspicuous place on the

tester or near the installation location.

•*

To those using the old model TOS5050/5051

The SIGNAL I/O connector on this tester is not compatible with that on the old model

TOS5050/5051 (different pin assignments). Therefore, the 14-pin Amphenol plug that

is supplied with the tester cannot be shared between the new and old models.

It is marked “TYPE A” to distinguish the two.

2-2 TOS5051A/5050A

2.2 Precautions Concerning Installation Location

This section describes the precautions to be taken when installing the product. Make

sure to observe them.

■

Do not use the tester in a flammable atmosphere.

To prevent the possibility of explosion or fire, do not use the product near alcohol,

thinner or other combustible materials, or in an atmosphere containing such vapors.

■

Avoid locations where the tester is exposed to high temperature or direct sunlight.

Do not place the product near a heater or in areas subject to drastic temperature changes.

Operating temperature range: 0 °C to +40 °C (+32 °F to +104 °F)

Storage temperature range: -20

■

Avoid humid environments.

Do not place the product in high-humidity locations--near a boiler, humidifier, or

water supply.

Operating humidity range: 20 % to 80 % RH (no condensation)

Storage humidity range: 0 to 80 % RH (no condensation)

Condensation may occur even within the operating humidity range. In such case, do

not use the product until the condensation dries up completely.

°

C to +70 °C (-4 °F to +158 °F)

Chap.2

Installation and Preparation

■

Do not place the tester in a corrosive atmosphere.

Do not install the tester in a corrosive atmosphere or in environments containing sulfuric

acid mist, etc. This may cause corrosion of various conductors and bad contacts of connectors inside the tester leading to malfunction and failure, or in the worst case, a fire.

■

Do not place the tester in a dusty location.

Accumulation of dust can lead to electric shock or fire.

■

Do not use the tester where ventilation is poor.

Secure adequate space around the product so that air can circulate around it.

■

Do not place objects on top of the tester.

Placing objects on top of the tester can cause failures (especially heavy objects).

■

Do not place the tester on an inclined surface or location subject to vibrations.

The tester may fall or tip over causing damages and injuries.

■

Do not use the tester in a location where strong magnetic or electric fields are nearby or a location where large amount of distortion and noise is present on the input power supply waveform.

The product may malfunction.

TOS5051A/5050A 2-3

■

Do not use the tester near highly sensitive measuring instruments or transceivers.

Do not operate the tester near highly sensitive measuring instruments such as communication receivers, because the noise generated by the tester may interfere with

such devices.

Above 3 kV test voltage, the tester may produce corona discharge between its test

lead clips which will generate a significant amount of broadband RF emission. To

minimize this effect, separate the alligator clips and leads away from each other and

from conducting surfaces, especially sharp metal edges.

■ Secure adequate space around the power plug.

Do not insert the power plug to an outlet where accessibility to the plug is poor.

And, do not place objects near the outlet that would result in poor accessibility to

the plug.

2.3 Precautions When Moving the tester

When moving the tester to the installation location or when transporting the tester,

note the following points.

■ Turn OFF the POWER switch.

Moving the tester with the power ON may result in electric shock or damage.

■ Remove all wiring.

Moving the tester with the cables connected can cause wires to break or injuries due

to the tester falling over.

■ When transporting the tester, be sure to use the original packing materials.

Otherwise, damage may result from vibrations or from the tester falling during

transportation.

2.4 AC Line Requirements

The AC line requirements of the tester are as follows:

Nominal voltage Voltage tolerance Nominal frequency

100 V ±10 % of nominal voltage 50/60 Hz

The standard nominal AC line voltage of the tester is 100 V. The tester normally

operates on an AC line voltage within ±10 % of the nominal voltage. If the line voltage is outside of this range, the tester may not operate normally or may be damaged.

If your AC line voltage is outside of this range, be sure to convert it into within this

range by using an autotransformer or other appropriate means.

2-4 TOS5051A/5050A

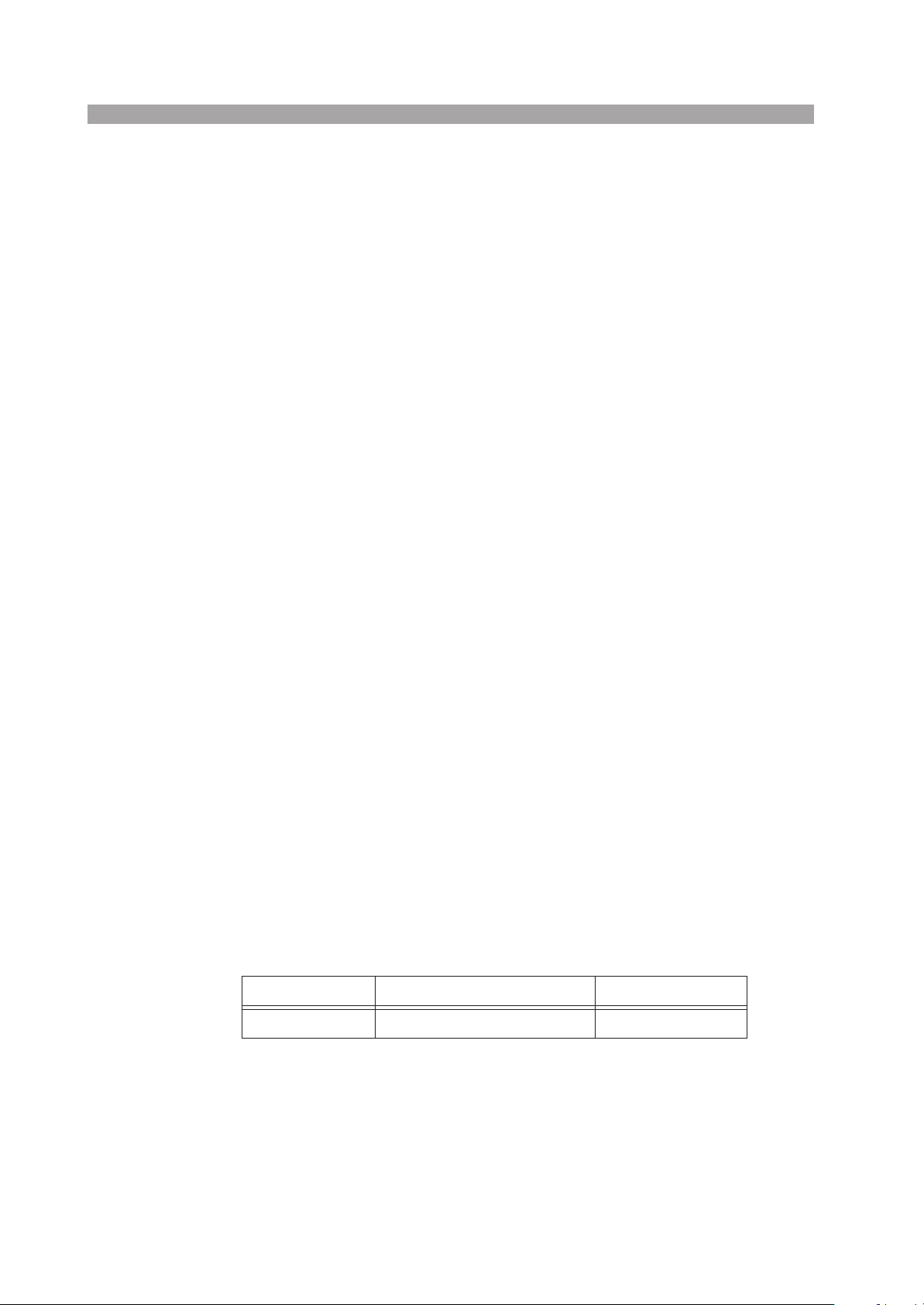

Testers that operate on other AC line voltages as shown below also are available as

factory-modification options.

Optional AC line voltages 110 V 120 V 220 V 230 V 240 V

The following table is printed on the rear panel of the tester. If nothing is marked in

the “SETTING SUPPLY” column, the nominal voltage is 100 V. The change in the

nominal voltage is made at the factory. If a change has been made, a mark is indicated to the left of the corresponding voltage.

Before turning ON the AC input power of the tester, be sure that your AC line voltage conforms with the nominal voltage indicated on the indicator sheet.

SETTING SUPPLY LINE VOLTAGE

STANDARD 100 V

110 V

120 V

Chap.2

220 V

230 V

240 V

WARNING

• Do not modify your tester by yourself. Consult Kikusui distributor/agent to

have your tester modified.

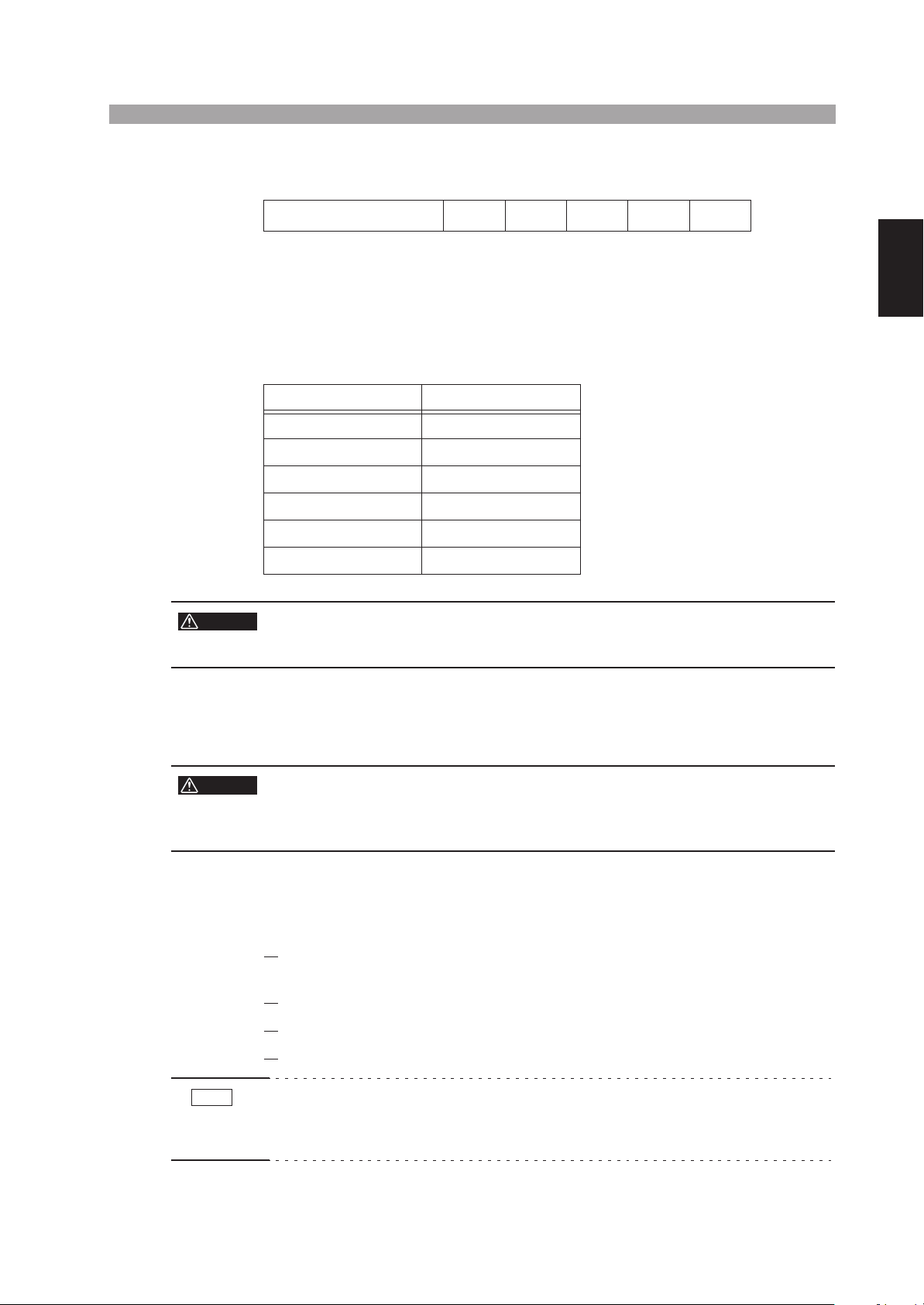

2.5 Connecting the Power Cord

WARNING

• This product is designed to be connected to a power supply classified as

overvoltage category II. Do not connect to a power supply classified as

overvoltage category III or IV.

• Do not use the power cord that comes with the product as a power cord

for other equipment.

1. Check that the AC power supply is within the input power supply range

of the product.

Installation and Preparation

Check that the POWER switch is turned OFF.

2.

Connect the power cord to the AC LINE connector on the rear panel.

3.

Insert the power plug to the outlet.

4.

NOTE

• The tester should be connected to a stable AC power supply.

From the tester’s internal circuit configuration of view in the AC withstanding

voltage test, the output voltage is affected by fluctuations of the AC power supply.

TOS5051A/5050A 2-5

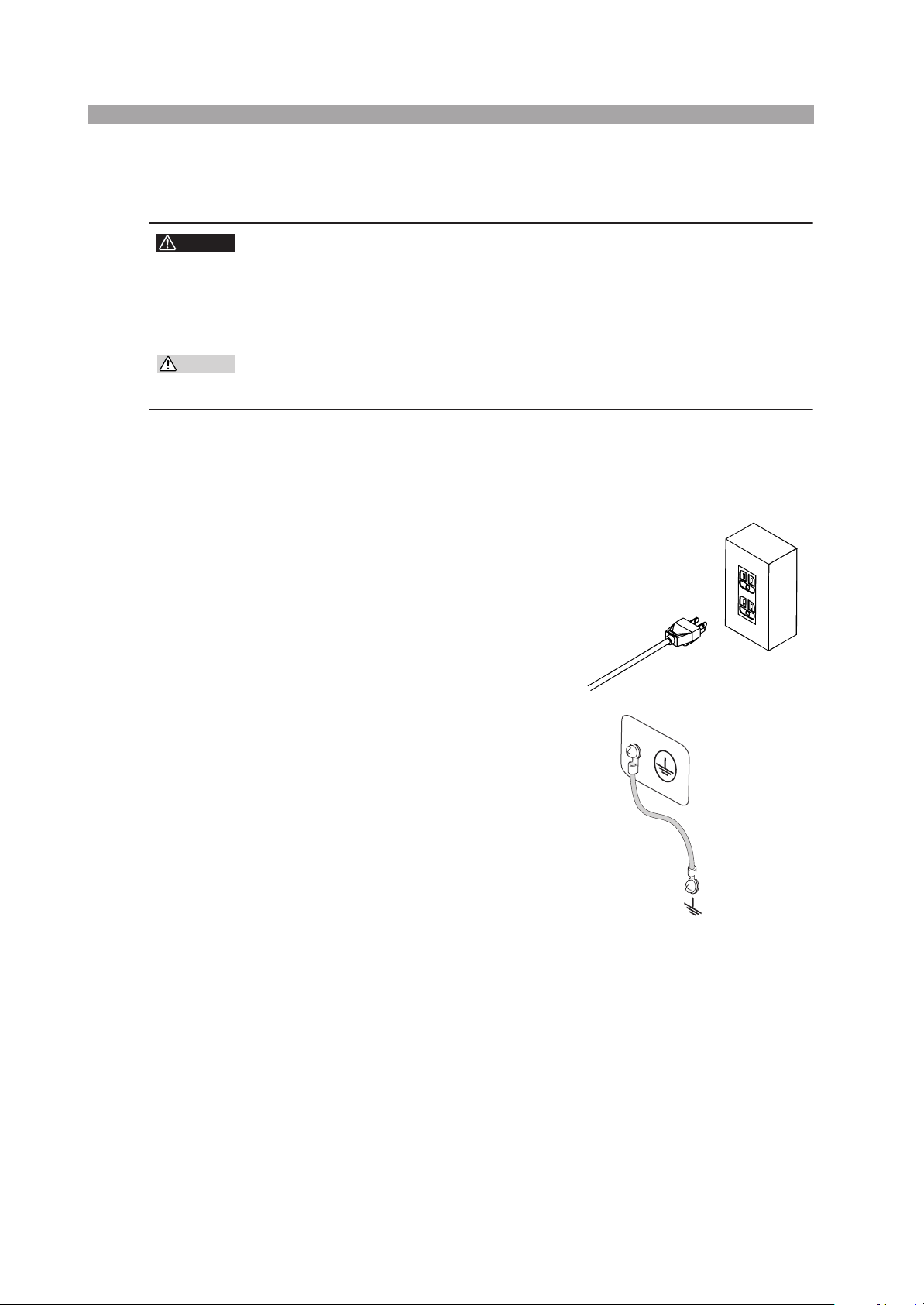

2.6 Grounding (Earth)

WARNING

CAUTION

• Electric shock may occur, if proper grounding is not furnished.

• This product is designed as a Class I equipment (equipment furnished

with electric shock protection through protective grounding in addition to

the basic insulation). Be sure to connect the protective ground terminal to

an appropriate earth ground.

• If you do not ground the product, malfunction may occur due to external

noise, or the noise generated by the product may become large.

Make sure to ground the unit for your safety.

There are two types of methods in grounding the tester. Make sure to ground the

tester using either method.

1. Connect the power cord to a threepin power outlet with proper grounding.

Three-pin outlet with

proper grounding

2. Connect the grounding (earth) terminal on the rear panel to the earth

ground.

A qualified personal shall select and

create the wiring and make the

attachments.

Securely connect the wiring using

appropriate tools.

Appropriate

earth ground

Fig. 2-2 Grounding method

2-6 TOS5051A/5050A

3

3

Chap.3

WARNING

Chapter 3 Handling

Precautions

This chapter gives warnings and cautions you must observe when operating the

tester.

• The tester delivers a 5 kV test voltage which can cause electric shock.

When operating the tester, be extremely careful and observe the cautions,

warnings, and other instructions given in this chapter.

Handling Precautions

TOS5051A/5050A 3-1

3.1 Preparative Procedures

3.1.1 Wearing Insulation Gloves

When handling the tester, be sure to wear insulation gloves in order to protect yourself against high voltages. If you cannot obtain insulation gloves, please contact

Kikusui distributor/agent for them.

3.1.2 Grounding the Tester

Be sure to ground the tester. To do this, connect securely (using a tool) an earth line

to the protective grounding terminal on the rear panel of the tester. Unless the tester

is securely grounded, when the tester output is shorted to an earth line or to a conveyor or other device which is connected to an earth line or when it is shorted to the

AC line*

electric shock.

For a description of the grounding method, see section 2.6, “Grounding (Earth)”

(Page 2-6 ).

1

, the tester chassis can be charged up to the high voltage that can cause

DESCRIPTION

*1 The term “AC line” here means the line on which the tester is operating. That is

the line to whose outlet the power cord of the tester is connected. It may be of a

commercial AC power line or of a private-generator AC power line.

3.2 Warnings and Cautions When Operating the Tester

3.2.1 Before Turning ON the AC Input Power

Before turning on the AC input power, be certain that the TEST VOLTAGE control

knob is at the “0” position (fully counterclockwise position).

3.2.2 Connecting the Low Test Lead

For the connection method of the low test lead to the LOW output terminal of the

tester, see Fig. 3-1. Each time before using the tester, check that the low test lead is

not broken.

3-2 TOS5051A/5050A

When connecting the tester to a DUT (device under test), connect the low test lead

first (and the high test lead next) and be sure that it securely connects the LOW output terminal of the tester to the corresponding terminal (chassis protective grounding terminal) of the DUT. If the connection is inadequate, entire DUT can be

charged up to a hazardous high voltage.

LOW output terminal

Test lead (black) to DUT

Install the lead clamp like this

Fig.3-1 Connecting the low-voltage test lead

Chap.3

3.2.3 Connecting the High Test Lead

Be sure to observe the order of lead connections--the low test lead first and the high

test lead next. To connect the tester to a DUT, proceed as follows:

Press the STOP switch.

1.

Check that the output voltmeter reading is “0”.

2.

Check that the DANGER lamp is OFF.

3.

Connect the high test lead to the HIGH VOLTAGE output terminal.

4.

Short the low and high test leads, and check that high voltage is not

5.

present.

Connect the tester to the DUT, with the low output lead first and high

6.

output lead next.

3.2.4 Before Changing Test Parameters

Before changing test parameters, press the STOP switch and be certain that the

TEST VOLTAGE control knob is at the “0” position (fully counterclockwise).

Handling Precautions

TOS5051A/5050A 3-3

3.2.5 Precautions for Pausing Tests

When you pause a test, be sure to turn the TEST VOLTAGE control knob to the “0”

position (fully counterclockwise) and press the STOP switch. If you are not going to

resume the test soon or if you are leaving the test area, be sure to turn OFF the

switch.

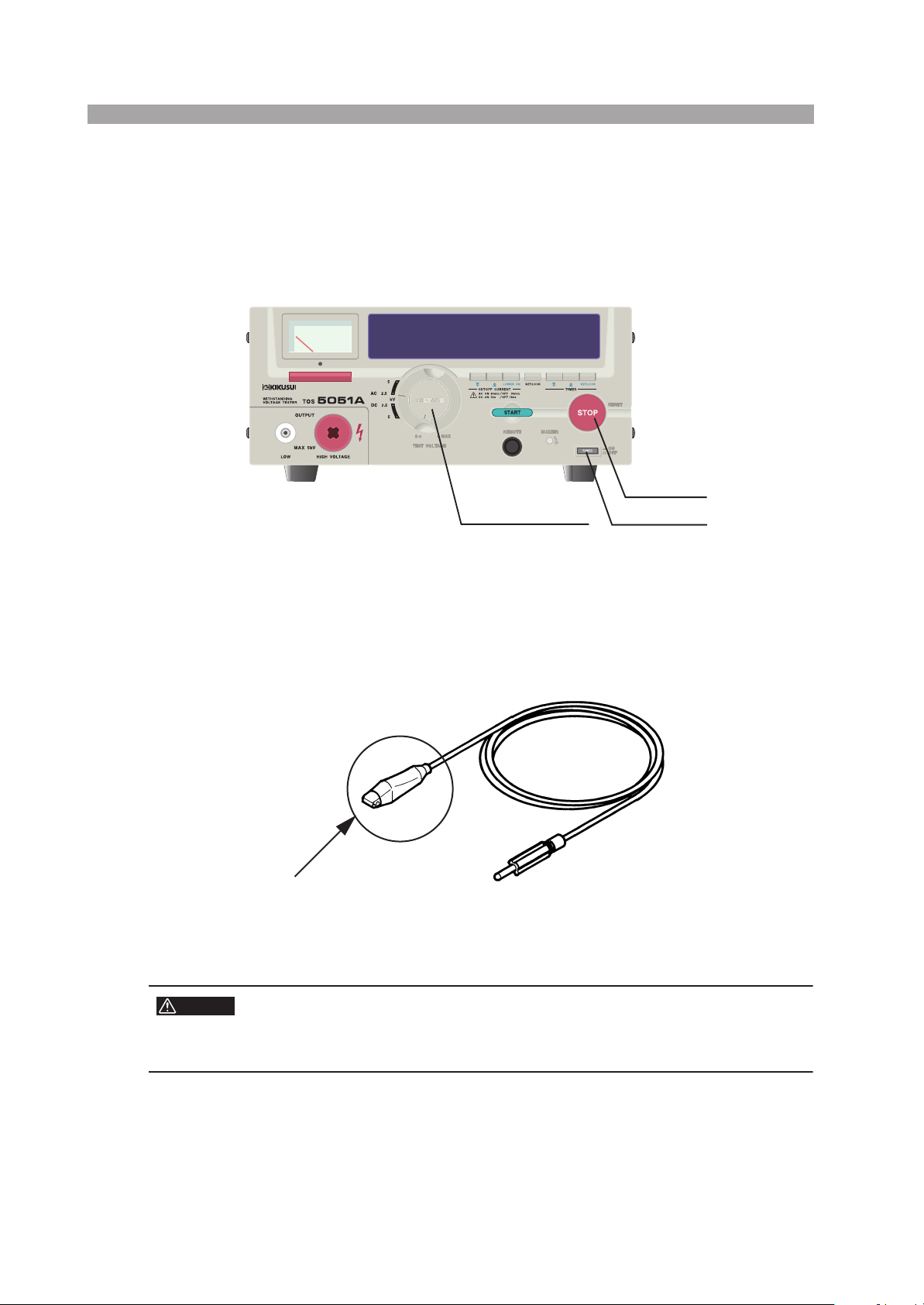

STOP switch

TEST VOLTAGE control

POWER switch

Fig. 3-2 TOS5051A front panel

3.2.6 Items Charged Up to Dangerous High Voltages

WARNING

While the test is in progress (“TEST” is lit), touching a section charged with high

voltage near the DUT, test lead, probe, or output terminal is dangerous.

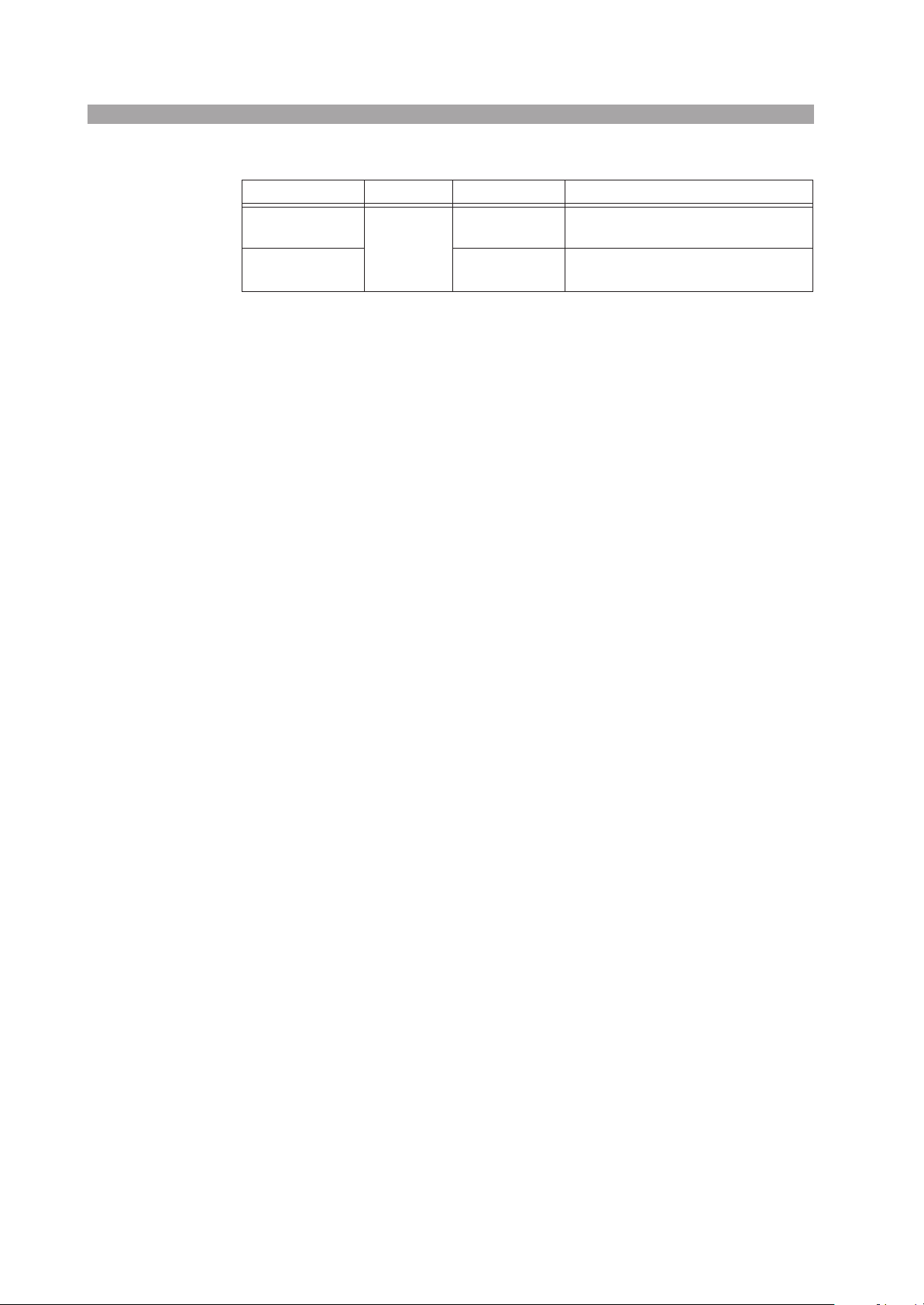

Alligator clip

(Never touch this area when test is in progress.)

Fig. 3-3 Test lead

• The vinyl sheaths of the alligator clips of the test leads which are supplied

with the tester does not have sufficient insulation for the high test voltages.

Never touch them when the test is in progress.

3-4 TOS5051A/5050A

3.3 Warnings after Turning OFF the Power

3.3.1 Check Items after Turning OFF the Power

If you have to touch the DUT, test leads, probes, and/or output terminals and their

vicinities for re-connections or other reasons, be sure of the following two matters:

• The output voltmeter indicates “0.”

• The DANGER lamp has turned OFF.

When you have tested the DUT with the DC output of the tester, the DUT will

remain charged at the high test voltage. For details, see section 3.3.2, “Residual

High Voltages (TOS5051A Only)” on Page 3-5 .

3.3.2 Residual High Voltages (TOS5051A Only)

Warning for Residual High Voltages

When you perform a test with the DC output, the DUT, test leads, probes, and output terminals and their vicinities are charged up to high voltages. Even after you

turn off the DC output, these voltages remain there for a period that depends on the

conditions of the test. Within this period, never touch the DUT, test leads, probes, or

output terminals or their vicinities to avoid electric shock.

When touching a section charged with high voltage, check the following:

Chap.3

Handling Precautions

• The output voltmeter indicates “0”.

• The DANGER lamp has turned OFF.

Checking the Discharge

The time necessary for the residual high voltage to be discharged varies depending

on test conditions--such as the properties of the DUT and the test voltage delivered

by tester.

Table 3-1 indicates the time it takes to discharge the internal capacitor when the

DUT is not connected (on the tester alone).

If a DUT is connected, the discharge time varies depending on the characteristics of

the DUT.

Table 3-1 indicates the time it takes to discharge when a DUT whose capacitance is

0.05 μF is connected to the tester.

TOS5051A/5050A 3-5

Table3-1 Discharge time

Test voltage Discharge time Note

TOS5051A alone

5 kV

DUT Approx. 50 ms

The tester has an internal circuit to discharge the residual high voltage of its output

circuit when the output is turned off. Do not disconnect the DUT from the tester

during a test. If you do, the residual high voltage on the DUT will remain undischarged for a long period.

Approx. 16 ms

Time until the output terminal voltage

of the TOS5051A attenuates to 30 V

Time until the DUT voltage attenuates to 30 V

3.4 Warnings for Remote Control

Be extremely careful when operating the tester in the remote control mode in which

the dangerous high test voltage is turned ON/OFF remotely. Provide protective

means as follows:

• Provide means to assure that the test setup does not output voltage

inadvertently (TEST state).

• Provide means to assure that no one can touch the DUT, test leads,

probes, output terminals and their vicinities when high voltage is being

output (TEST state).

3.5 Inhibitions

3.5.1 Inhibition of Rapid ON/OFF Repetitions

After turning OFF the power switch, be sure to allow several seconds or more

before turning it ON again. Do not repeat the operation of turning ON/OFF the

power switch rapidly. If you do, the protectors of the tester may not be able to render their protective functions properly. Do not turn OFF the power switch without

turning OFF the output switch first. Do this only in case of emergency.

3.5.2 Inhibition of Shorting to Earth Ground

Pay attention so that the high test voltage line is not shorted to a nearby AC line or

nearby devices (such as conveyors) which are connected to an earth ground. If it is

shorted, the tester chassis can be charged up to a hazardous high voltage.

Be sure to connect the protective grounding terminal of the tester to an earth line. If

this has been done correctly, the tester will not be damaged and its chassis will not

be charged up to the high voltage even when the HIGH output terminal is shorted to

the LOW output terminal.

For your safety, be sure to ground the tester. For a description of the grounding

method, see section 2.6, “Grounding (Earth)” (Page 2-6 ).

3-6 TOS5051A/5050A

Loading...

Loading...