Kikusui PWR401L, PWR401MH, PWR401ML, PWR401H, PWR801MH User Manual

...

User’s Manual

PART NO. IB031113

Aug. 2017

400W model

PWR401L PWR401ML

PWR401MH PWR401H

800W model

PWR801L PWR801ML

PWR801MH PWR801H

1200W model

PWR1201L PWR1201ML

PWR1201MH PWR1201H

Regulated DC Power Supply

PWR-01 Series

Component Names 8

Installation and Preparation 13

Connecting the Power Cord 14

Load Considerations 18

Selecting the Load Cables 20

Output Terminal Insulation 22

Connecting to the Output Terminals 24

Turning the Power On 28

Remote Sensing function 30

Basic Features 33

Measured Value Display and Setting Display

34

Panel Operations 36

Output Operation 37

Operation Overview 41

CV Power Supply and CC Power Supply 43

Using the PWR-01 as a CV or CC Power

Supply

Protection functions and Alarms 46

CONFIG Settings 54

Preset Memory function 70

Locking Panel Controls (Key Lock) 71

CONFIG Shortcut function 72

Switching from Remote Mode to Local Mode

Advanced Features 75

Bleeder Circuit function 76

Variable Internal Resistance function 78

Sequence function 79

Synchronized Operation 80

External Control 83

Product Operation 84

About the J1/ J2 Connectors 85

Notes for Connecting External Voltage (Vext)

Output voltage control 90

Output Current Control 92

Controlling the Output On and Off States 94

Controlling Output Shutdown 96

Controlling the Clearing of Alarms 97

External Monitoring 98

Parallel/ Series Operation 101

Master-Slave Parallel Operation 102

Series operation 108

Maintenance 113

Calibration 114

Cleaning 116

Specifications 117

400W model 119

800W model 122

1200W model 125

Common specifications 128

45

73

88

Appendix135

These manuals are intended for users of the Regulated DC

About the PWR-01 Manuals

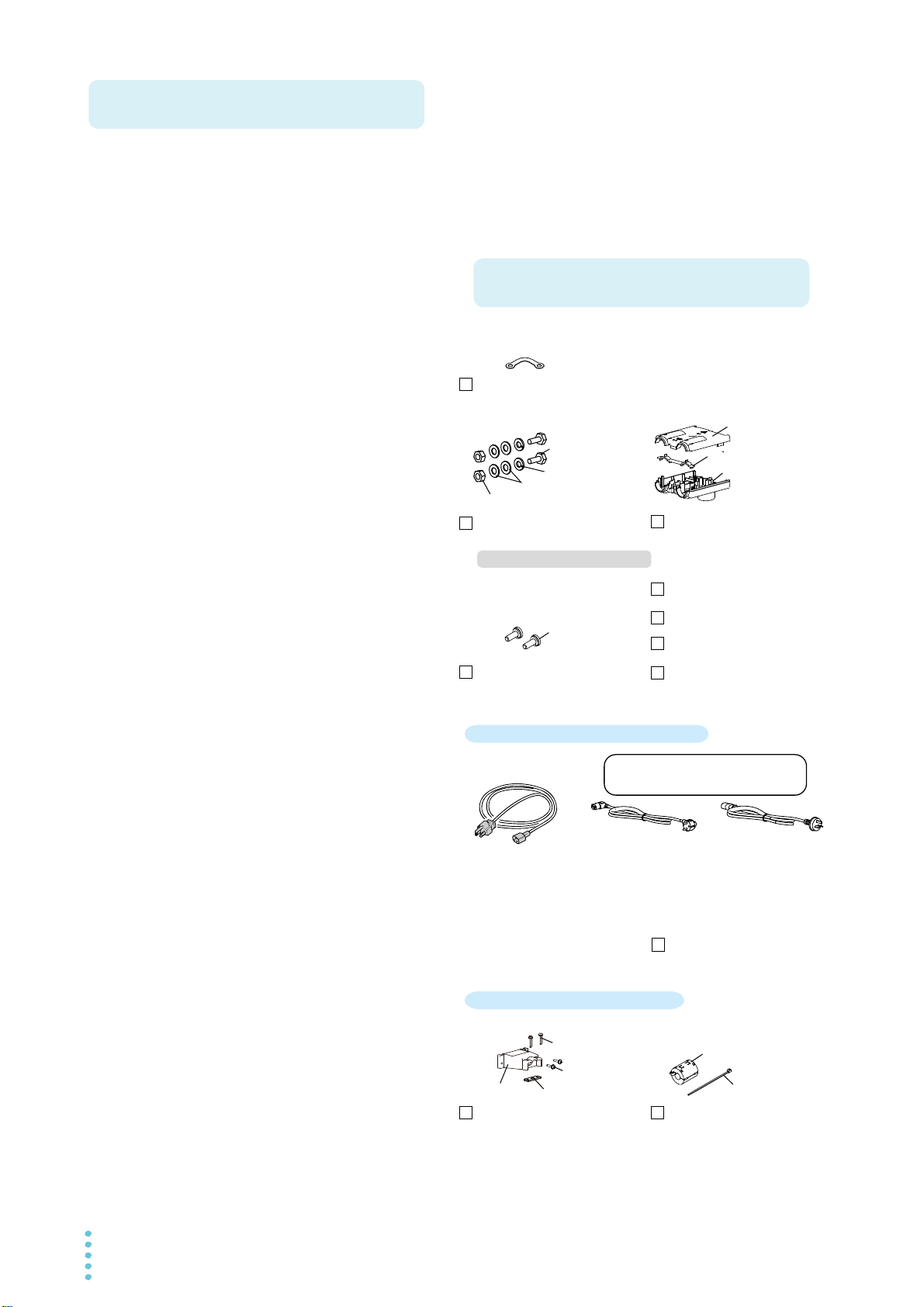

Accessories

Packing list (1 copy)

Safety Information (1 pc.)

CD-ROM (1 disk)

Output terminal M8 bolt set

(2 sets)

Output terminal M4 screws

(2 pcs.)

Chassis connection short bar (1 pc.)

Output terminal cover (1 set)

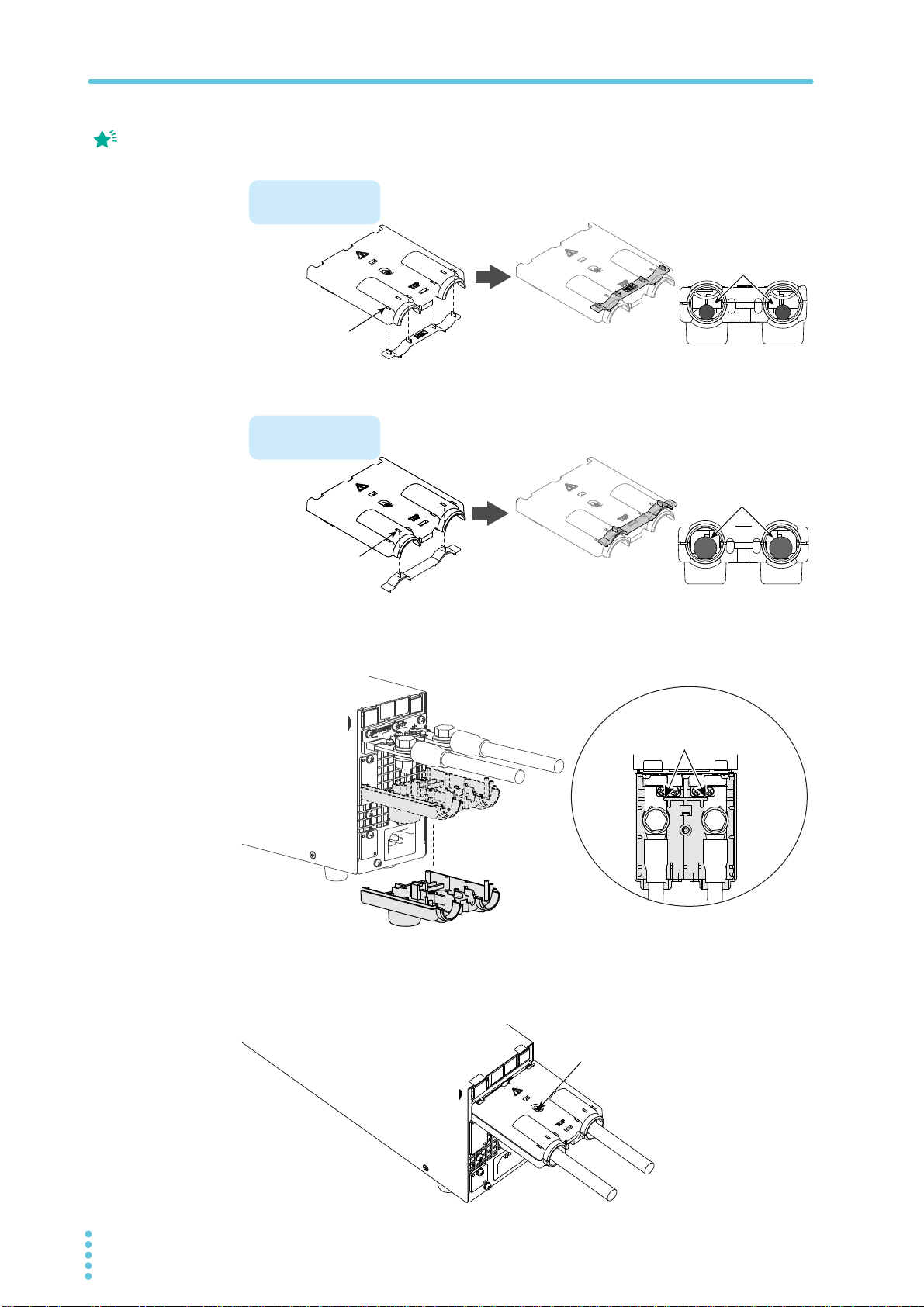

or

or

Included only with the 400W/800W model

Included only with the 1200W model

[E3-300-064]

* Only L type and ML type included.

Quick Reference

(Japanese: 1 pc, English: 1 pc.)

Power cord (1 pc.)

Rating: 125 Vac

Plug: NEMA5-15

Rating: 250 Vac

Plug: CEE7/7

Length: Approx. 2.5 m

[85-10-1070]

Rating: 250 Vac

Plug: GB1002

Length: Approx. 2.5 m

[85-10-0791]

The attached power cord varies

depending on the shipment destination.

Bottom [Q1-500-200]

Top [Q1-500-198]

Adapter [Q1-500-199]

• 400W model:

Length: Approx. 2.5 m

[85-AA-0004]

• 800W model:

Length: Approx. 3.0 m

[85-10-1030]

[M3-112-027]

[M1-100-012]

[M4-100-007]

[M5-100-007]

[M5-101-007]

Input terminal cover (1 set) Ferrite core set (1 set)

[M3-112-018]

[M3-112-015]

[P4-000-551]

[96-01-0370]

[D6-750-001]

[P1-000-410]

Power Supply and their instructors. Explanations are given

under the presumption that the reader has knowledge of the

electrical aspects of regulated DC power supplies.

PWR-01 manual construction

User’s manual (this manual, PDF)

This manual is intended for first-time users of this product. It

provides an overview of the product, notes on usage, and

specifications. It also explains how to configure the product,

operate the product, perform maintenance on the product,

and so on.

Please read this manual before you operate the product.

Communication interface manual (PDF)

This manual describes remote control and multichannel

(Virtual Multi Channel Bus).

The interface manual is written for readers with sufficient

basic knowledge of how to control power supplies using a

PC.

Copyrights

The contents of this document may not be reproduced, in

whole or in part, without the prior consent of the copyright

holder.

The specifications of this product and the contents of this document are subject to change without prior notice.

© 2017 Kikusui Electronics Corporation

Quick Reference

This document briefly explains the PWR-01 panel and the

basic operation of it.

Safety Information

This document contains general safety precautions. Keep

them in mind and make sure to observe them.

PDF files are included in the accompanying CD-ROM.

You can view the PDF files using Adobe Reader.

Firmware versions that this manual covers

This manual applies to products with firmware versions 1.0X.

When contacting us about the product, please provide us with

the following information.

Model (marked in the top section of the front panel)

Firmware version (see page 28)

Serial number (displayed on the top panel).

Trademarks

Microsoft, Internet Explorer, and Windows are registered

trademarks or trademarks of Microsoft Corporation in the

United States and/or other countries.

All company names and product names used in this manual

are trademarks or registered trademarks of their respective

companies.

2 PWR-01

The PWR-01 series is a constant voltage (CV)/constant cur-

Product Overview

rent (CC) automatic crossover power supply that can output a

wide range of voltage and current within rated output power.

The products in this series are divided into the following three

models depending on the output capacity. They are divided

into four types depending on the output voltage.

400W model 800W model 1200W model

L type

(40 V)

ML type

(80 V)

MH type

(240 V)

H type

(650 V)

PWR401L PWR801L PWR1201L

PWR401ML PWR801ML PWR1201ML

PWR401MH PWR801MH PWR1201MH

PWR401H PWR801H PWR1201H

Features

Communication function

RS232C, USB, and LAN interfaces are all installed as standard.

The remote interfaces comply with IEEE Std 488.2 1992

and SCPI Specification 1999.0.

The LAN interface complies with the LXI standard. Multichannel (VMCB), which controls up to 31 PWR-01s from a

single PC, can be used to construct a multichannel power

supply system.

Master-slave parallel operation

You can increase the output current by connecting up to

three PWR-01s (two units for the 1200W model) in parallel.

You can set one unit as the master unit, and control the

remaining units as slave units.

If an error occurs in a slave unit, the master unit detects the

alarm and shuts down the output of the entire system.

Setting preset memory function

You can save up to three sets of output settings (the combination of the voltage, current, OVP, OCP, and UVL). You

can simply select a set of output settings that you want to

use rather than having to specify each setting every time.

Automatic output-on setting

You can set the PWR-01 so that when a low AC input protection function (AC-FAIL) is activated and the output is

turned off, the output is automatically turned back on when

the problem that caused the output to turn off is fixed.

Output-on/off delay function

You can set the delay (DELAY TIME) from when the OUTPUT key is turned on or off to when the output actually turns

on or off. This is useful when you want to turn the output on

or off by setting a delay according to the load characteristics.

Set voltage/current limitation function

You can apply limits to the voltage and current settings. This

prevent you from setting an appropriate value by mistake,

which would cause the output to turn off.

Overcurrent protection (OCP) detection time setting

You can set the amount of time that an overcurrent must

persist after the first detection of the overcurrent before the

overcurrent protection (OCP) is activated. If inrush current

from the load causes an excessive current to flow temporarily, you can adjust the delay to prevent the overcurrent protection (OCP) from being activated.

Bleeder circuit function

You can turn the bleeder circuit on and off. Turn the bleeder

circuit off when you do not want the internal bleeder circuit

to sink output current. When you connect a battery, you can

prevent excessive electrical discharges by turning the

bleeder circuit off.

Soft start/ stop function

You can limit the rise time of the load current for loads that

produce inrush current when the output is turned on.

Varia bl e internal resistance function

You can easily simulate rechargeable batteries, solar batteries, fuel cells, and other power supplies that have internal

resistance. By setting the internal resistance value in constant voltage (CV) mode, you can decrease the output voltage according to the output current.

Sequence function

The sequence function recalls conditions set in a program

and runs automatically. If you write a program created on a

PC into the PWR-01, you can execute the program from the

panel.

When a program is written in the PWR-01, you can execute

the program without a PC.

CONFIG setting shortcut function and display

You can register CONFIG setting parameters to the front

panel’s SC keys. Because you do not have to go into the

CONFIG menu to set the parameters, you can perform tests

efficiently by registering CONFIG parameters that you use

frequently. Up to three parameters can be registered.

PWR-01 3

When using this product, be sure to observe the “Safety

Safety Precautions

Precautions Concerning

Installation Location

Notations Used in This Manual

WARNING

CAUTION

DESCRIPTION

Memo

Precautions” in the Safety Information manual.

When installing this product, be sure to observe the

“Precautions Concerning Installation Location” in the Safety

information manual. The following precautions pertain only to

this product.

• In this guide, the suite of products shown on the front cover

is also referred to as the “PWR-01.”

• The term “PC” is used to refer generally to both personal

computers and workstations.

• The illustrations of displays used in this manual may differ

from the actual displays. The illustrations are merely examples.

• The following markings are used in the explanations of this

text.

• When installing this product, be sure to observe the temperature and humidity ranges indicated below.

Operating temperature range: 0 °C to +50 °C (32 °F to

122 °F)

Operating humidity range: 20 %rh to 85 %rh (no condensation)

• When storing this product, be sure to observe the temperature and humidity ranges indicated below.

Storage temperature range: -10 °C to +60 °C (14 °F to

140 °F)

Storage humidity range: 90 %rh or less (no condensation)

Indicates a potentially hazardous situation which, if

ignored, could result in death or serious injury.

Indicates a potentially hazardous situation which, if

ignored, may result in damage to the product or other

property.

Indicates information that you should know.

Explanation of terminology or operation principle.

See

Indicates a reference to detailed information.

Indicates a reference to a manual containing detailed

information.

CFxx: x

“CF” indicates that this is a CONFIG parameter. The two

digits after CF indicate the CONFIG parameter number.

The value after the colon indicates the selected setting.

SHIFT+key name (blue letters)

Indicates an operation that requires you to press a key

indicated in blue characters (below the key) while holding

down SHIFT.

Indicates useful information.

4 PWR-01

Contents

About the PWR-01 Manuals ..................2

Accessories ...........................................2

Product Overview ..................................3

Features ................................................3

Safety Precautions .................................4

Precautions Concerning Installation

Location .................................................4

Notations Used in This Manual ..............4

Component Names.................................8

Installation and Prepara-

1

tion

Connecting the Power Cord ....................... 14

Load Considerations .................................. 18

Selecting the Load Cables ......................... 20

Output Terminal Insulation......................... 22

Connecting to the Output Terminals .......... 24

Turning the Power On................................ 28

Remote Sensing function........................... 30

Basic Features

2

Measured Value Display and Setting Display ..

34

Panel Operations ....................................... 36

Output Operation........................................ 37

Operation Overview ................................... 41

CV Power Supply and CC Power Supply... 43

Using the PWR-01 as a CV or CC Power

Supply ........................................................ 45

Protection functions and Alarms ................ 46

400W model/ 800W model.................. 14

1200W model ...................................... 15

When the output terminal is not grounded

(floating) ..............................................

When the output terminal is grounded 23

Connecting to the rear-panel output

terminals..............................................

Connecting to the front-panel output

terminals..............................................

Turning on the POWER switch............ 28

Turning the POWER switch off............ 29

Output on/off setting at power-on........ 37

Output-on startup state parameter ...... 37

Output-on/ off delay setting ................. 38

Soft start/ stop function........................ 39

Alarm occurrence and clearing alarms 46

Setting the protection functions........... 47

22

24

27

3

4

5

Setting limits ........................................ 52

CONFIG Settings ....................................... 54

CONFIG parameter details.................. 58

Preset Memory function ............................. 70

Saving settings .................................... 70

Recalling settings ................................ 70

Locking Panel Controls (Key Lock) ............ 71

CONFIG Shortcut function ......................... 72

Registering CONFIG shortcuts............ 72

Using CONFIG shortcuts..................... 72

Switching from Remote Mode to Local Mode..

73

Advanced Features

Bleeder Circuit function .............................. 76

Variable Internal Resistance function......... 78

Sequence function ..................................... 79

Writing and executing a sequence

program ...............................................

Synchronized Operation............................. 80

79

External Control

Product Operation ...................................... 84

About the J1/ J2 Connectors ...................... 85

Notes for Connecting External Voltage (Vext).

88

Output voltage control ................................ 90

Control using an external voltage (Vext) ..

90

Control using an external resistance (Rext)

91

Output Current Control............................... 92

Control using an external voltage (Vext) ..

92

Control using an external resistance (Rext)

93

Controlling the Output On and Off States .. 94

Controlling Output Shutdown ..................... 96

Controlling the Clearing of Alarms.............. 97

External Monitoring .................................... 98

Parallel/ Series Operation

Master-Slave Parallel Operation .............. 102

Features ............................................ 102

Connection ........................................ 104

Setting ............................................... 106

Starting master-slave parallel operation ...

107

Series operation ....................................... 108

Features ............................................ 108

Connection ........................................ 110

PWR-01 5

6

7

Setting................................................ 111

Starting series operation .................... 111

Maintenance

Calibration................................................. 114

Calibration overview........................... 114

Calibration procedure......................... 115

Cleaning.................................................... 116

Specifications

400W model.............................................. 119

800W model............................................. 122

1200W model........................................... 125

Common specifications............................ 128

Appe

ndix

A Factory Default Settings.......136

B Options......................................138

C Troubleshooting......................140

6 PWR-01

This page is intentionally blank.

PWR-01 7

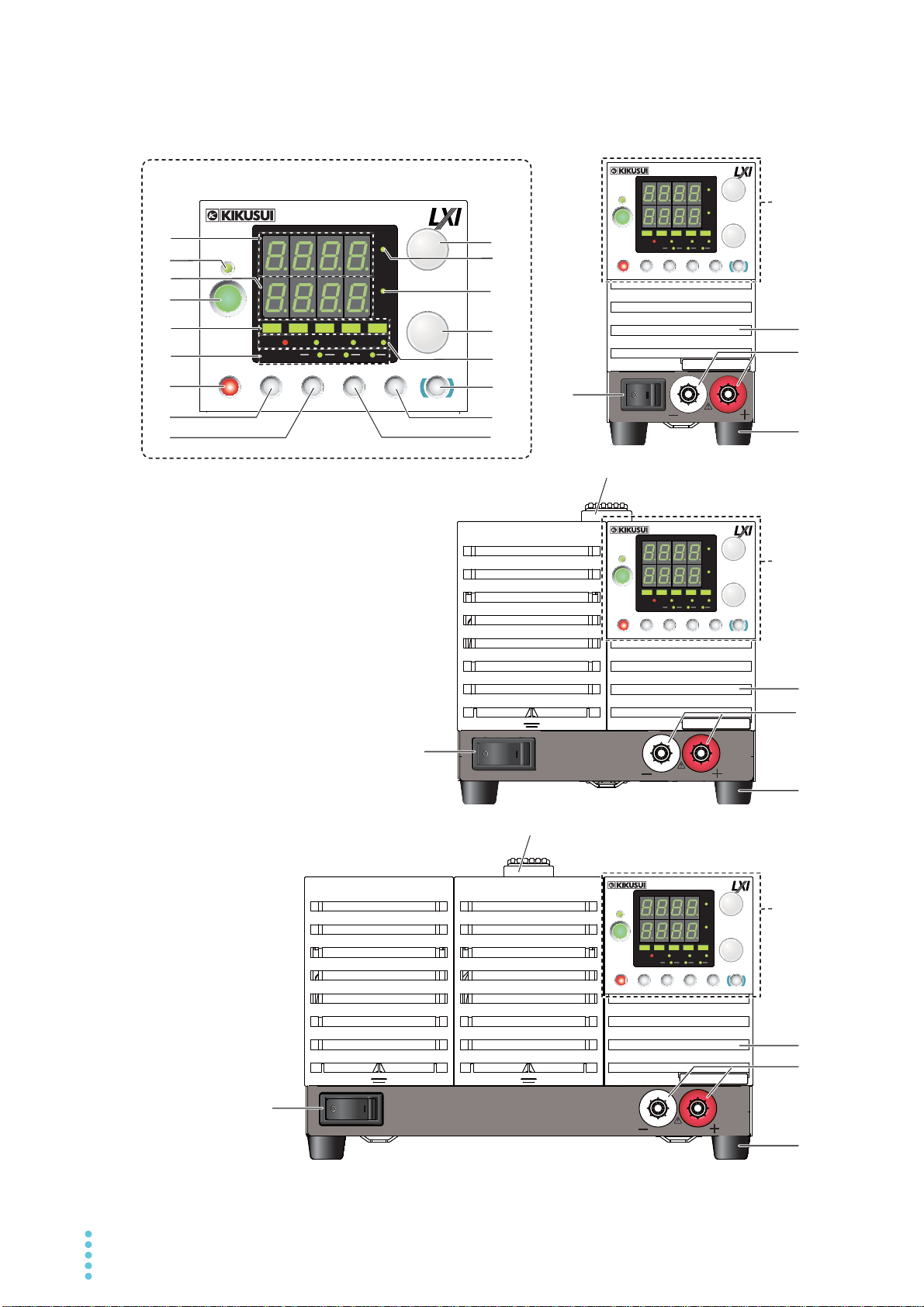

Component Names

CV

CC

/

W

V

A

ALM RMT LOCK LAN

BCA

PRESET

DLY SEQ HBSSVIR

CV

CC

/

W

V

A

ALM RMT LOCK LAN

POWER

MAX10A

DC OUTPUT

POWER

SC2 SC3 LOCKALM CLR SC1

SHIFT

FINE

FINE

REGULATED DC POWER SUPPLY

OUTPUT

VOLTAGE

CURRENT

CONFIG

PWR DSPLMEMORY

LOCALSET OVP•OCP

CV

CC

/

W

V

A

AL M RMT LOCK LAN

BCA

PRESET

DLY SEQ HBSSVIR

CV

CC

/

W

V

A

AL M RMT LOCK LAN

SC2 SC3 LOCKALM CLR SC1

SHIFT

FINE

FINE

REGULA TED DC POWER SUPPLY

OUTPUT

VOLTAGE

CURRENT

CONFIG

PWR DSPLMEMORY

LOCALSET OVP•OCP

CV

CC

/

W

V

A

ALM RMT LOCK LAN

BCA

PRESET

DLY SEQ HBSSVIR

CV

CC

/

W

V

A

ALM RMT LOCK LAN

SC2 SC3 LOCKALM CLR SC1

SHIFT

FINE

FINE

REGULATED DC POWER SUPPLY

OUTPUT

VOLTAGE

CURRENT

CONFIG

PWR DSPLMEMORY

LOCALSET OVP•OCP

CV

CC

/

W

V

A

ALM RMT LOCK LAN

BCA

PRESET

DLY SEQ HBSSVIR

CV

CC

/

W

V

A

ALM RMT LOCK LAN

SC2 SC3 LOCKALM CLR SC1

SHIFT

FINE

FINE

REGULATED DC POWER SUPPLY

OUTPUT

VOLTAGE

CURRENT

CONFIG

PWR DSPLMEMORY

LOCALSET OVP•OCP

MAX10A

DC OUTPUT

POWER

MAX10A

DC OUTPUT

POWER

18

16

17

1

1

1

14

15

19

20

20

20

19

21

21

21

22

22

19

Controls

Controls

Controls

Controls

400W model

800W model

1200W model

PWR

PWR

PWR

7

8

9

6

5

2

3

4

10

11

12

13

Front panel

8 PWR-01

No

See

Name Function

.

1POWER switch

Press the ( ) side to turn on and the ( ) side to turn off.

p.28, p.29

2 Voltmeter Displays the voltage, alarm, or CONFIG parameter number. p.34, p.54

3OUTPUT LED

Lights green when output is turned on. Blinks orange during output-on delay. Blinks

green during output-off delay.

Blinks orange when output is on and a protection function is activated. p.46

p.37

Lights green during soft start. Blinks green during soft stop. p.39

4 Ammeter

Displays the current, power, or the cause of an alarm, or the value of a CONFIG parameter.

p.34, p.46,

p.54

5 OUTPUT key Used to turn output on and off. p.37

6 VIR/ SS/ DLY/ SEQ/ HB

VIR: Lights when the variable internal resistance function is enabled.

SS: Lights when the soft start/ stop function is enabled and blinks when it is in progress.

DLY: Lights when the output-on/ off delay is enabled and blinks when it is in progress.

SEQ: Lights when a sequence is being executed and blinks the PWR-01 is waiting for a

trigger.

HB: Lights when the hyper bleeder of the bleeder circuit is enabled.

p.78

p.39

p.38

p.79

p.76

A: Lights green when the memory A values are being recalled or saved.

7 PRESET A/ B/ C LED

B: Lights green when the memory B values are being recalled or saved.

p.70

C: Lights green when the memory C values are being recalled or saved.

SET key Used to set and confirm the output voltage and output current (the key has an LED). p.34

8

ALM CLR key Used to release the activated state (alarm) of protection functions (the key has an LED). p.46

OVP•OCP key

9

Used to set and display the overcurrent protection (OCP), overvoltage protection (OVP),

undervoltage limit (UVL) trip points (the key has an LED).

p.47, p.52

SC1 Used to call the CONFIG parameter shortcut (the key has an LED) p.72

CONFIG key Used to configure the various operating conditions (CONFIG) (the key has an LED). p.54

10

SC2 Used to call the CONFIG parameter shortcut (the key has an LED) p.72

VOLTAGE knob Used to set the voltage value or select the value of a CONFIG parameter. p.36, p.54

11

FINE Used to make fine voltage value adjustments. p.36

12 CV LED Lights green during constant voltage mode. p.45

13 CC LED Lights red during constant current mode. p.45

CURRENT knob

14

Used to set the current, change the value of a CONFIG parameter, or set the internal

resistance value.

p.36, p.54,

p.59

FINE Used to make fine current or internal resistance value adjustments. p.36, p.59

Lights red when a protection function is activated. However, when the undervoltage limit

ALM LED

(UVL) is activated, the LED does not light. When the power limit (POWER LIMIT) is acti-

p.71

vated, the LED blinks.

RMT LED Lights green when the PWR-01 is being remotely controlled p.73

LOCK LED Lights green when the keys are locked. p.71

15

Lights and blinks when the LAN interface is running.

• No fault status (green)

LAN LED

LOCAL key

16

• Fault status (red)

• Standby status (orange)

• Identify status (blinking green)

Used to switch between local mode and remote mode (the key has an LED) and switch

the CONFIG parameter display.

Communication Interface

Manual

p.73

SHIFT key Used to enable the functions that are written in blue characters below the key. –

PWR DSPL key Used to display the output power on the ammeter (the key has an LED). p.34

17

LOCK key

Used to lock the operation of all keys other than the OUTPUT key (key lock) (the key has

an LED).

p.71

MEMORY key Used to load and save the value of preset memory A, B, or C (the key has an LED). p.70

18

SC3 Used to call the CONFIG parameter shortcut (the key has an LED). p.72

19 Air inlet (louver) Air inlet for cooling. p.116

20 DC OUTPUT connector Front-panel output terminal. p.27

21 Rubber feet Four locations on the bottom side. p.139

22 Handle Handle for carrying. p.139

PWR-01 9

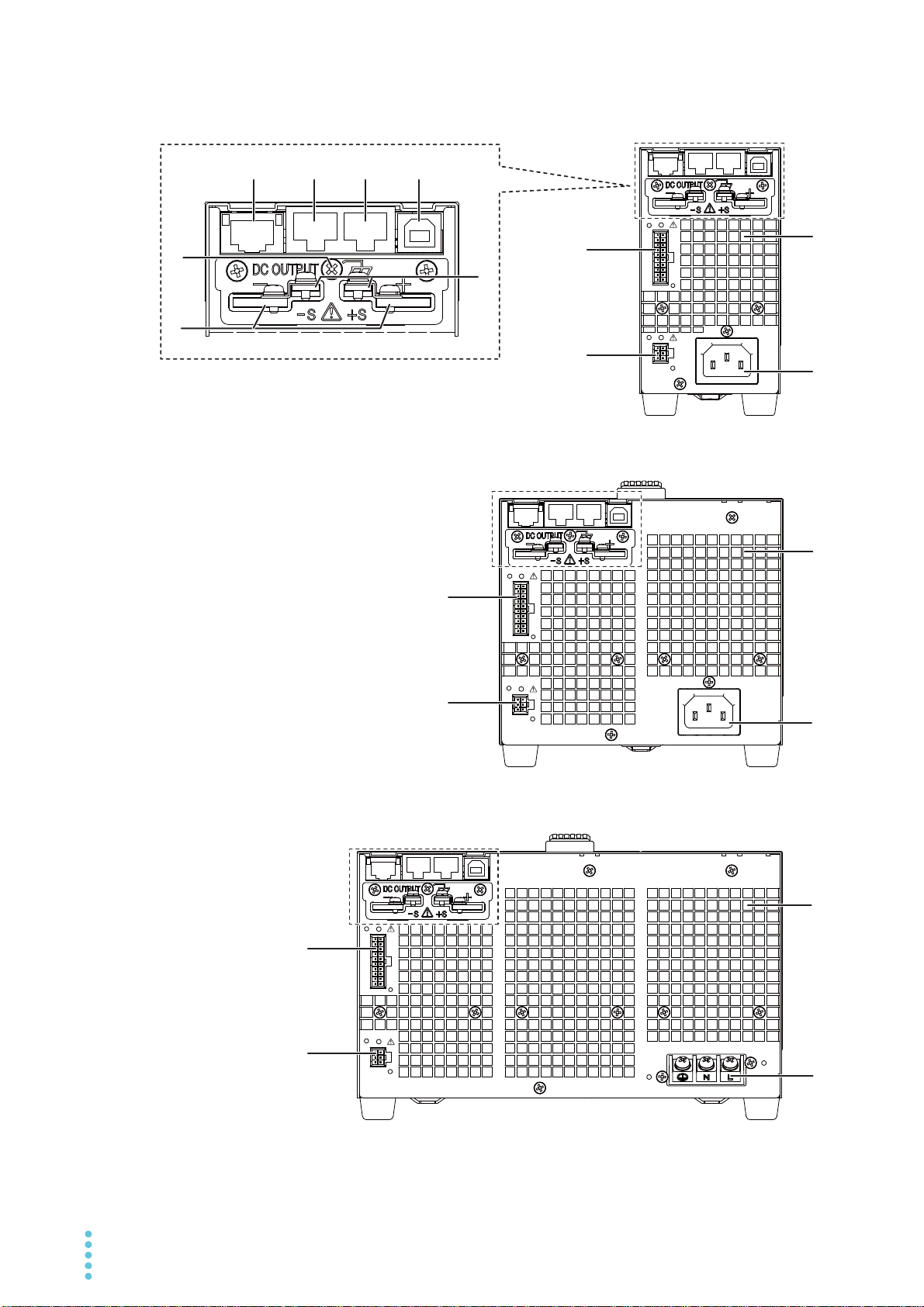

Rear Panel

J1

J2

J2

J1

J2

J1

9

8

10

11

8

8

9

9

400W model

800W model

7

456

1

3

2

10

11

10

11

1200W model

10 PWR-01

No.

See

Name Function

1 DC OUTPUT terminal Rear-panel output terminal. p.24

Chassis terminal A connector for grounding the output. p.24

2

3 LAN port

RS232C/ TRG IN

4

connector

1

1

5 TRG OUT connector

6 USB port

Sensing terminal Terminals to connect the sensing cables to. p.30

7

Air outlet Air outlet for internal cooling. –

8

1

9AC INPUT

10 J1 connector

11 J2 connector

1. A connector cover or terminal cover is attached when the product is shipped from the factory.

1

1

Ethernet port for controlling the PWR-01 remotely.

RS232C port for controlling the PWR-01 remotely.

Trigger signal input connector. The common terminal is connected to the

chassis.

Trigger signal output terminal. The common terminal is connected to the

1

chassis.

USB port for controlling the PWR-01 remotely.

400W model/ 800W model: AC inlet.

1200W model: AC INPUT terminal block.

For external control and master-slave parallel operation. p.85, p.104

External control p.85

Communication

Interface Manual

p.14

p.15

PWR-01 11

12 PWR-01

This page is intentionally blank.

Installation and Preparation

This chapter describes how to turn on the

PWR-01, what kind of load cables to use,

and how to connect cables to the output

terminals.

Connecting the Power Cord

WARNING

This product conforms to IEC Overvoltage Category II (energy-consuming equipment that is

supplied from a fixed installation).

Risk of electric shock.

• This product conforms to IEC Safety Class I (equipment that has a protective conductor terminal). Be sure to earth ground the product to prevent electric shock.

• The product is grounded through the power cord ground wire. Connect the protective conductor terminal to earth ground.

400W model/ 800W model

• Use the included power cord to connect to the AC line.

If the supplied power cord cannot be used because the rated voltage or the plug shape is

incompatible, have a qualified engineer select an appropriate power cord that is 3 m or less

in length.

• The power cord with a plug can be used to disconnect the product from the AC power line

in an emergency. Connect the plug to an easily accessible power outlet so that the plug can

be removed from the outlet at any time. Be sure to provide adequate clearance around the

power outlet.

• Do not use the dedicated power cord with other instruments.

Check that the AC power line meets the nomin al input rating of the prod-

1

uct.

The product can receive a nominal line voltage in the range of 100 Vac to 240 Vac at

50 Hz or 60 Hz.

Check that the POWER switch is turned off.

2

Connect the power cord to the AC inlet on the rear panel.

3

Insert the power plug into a grounded outlet.

4

14 PWR-01

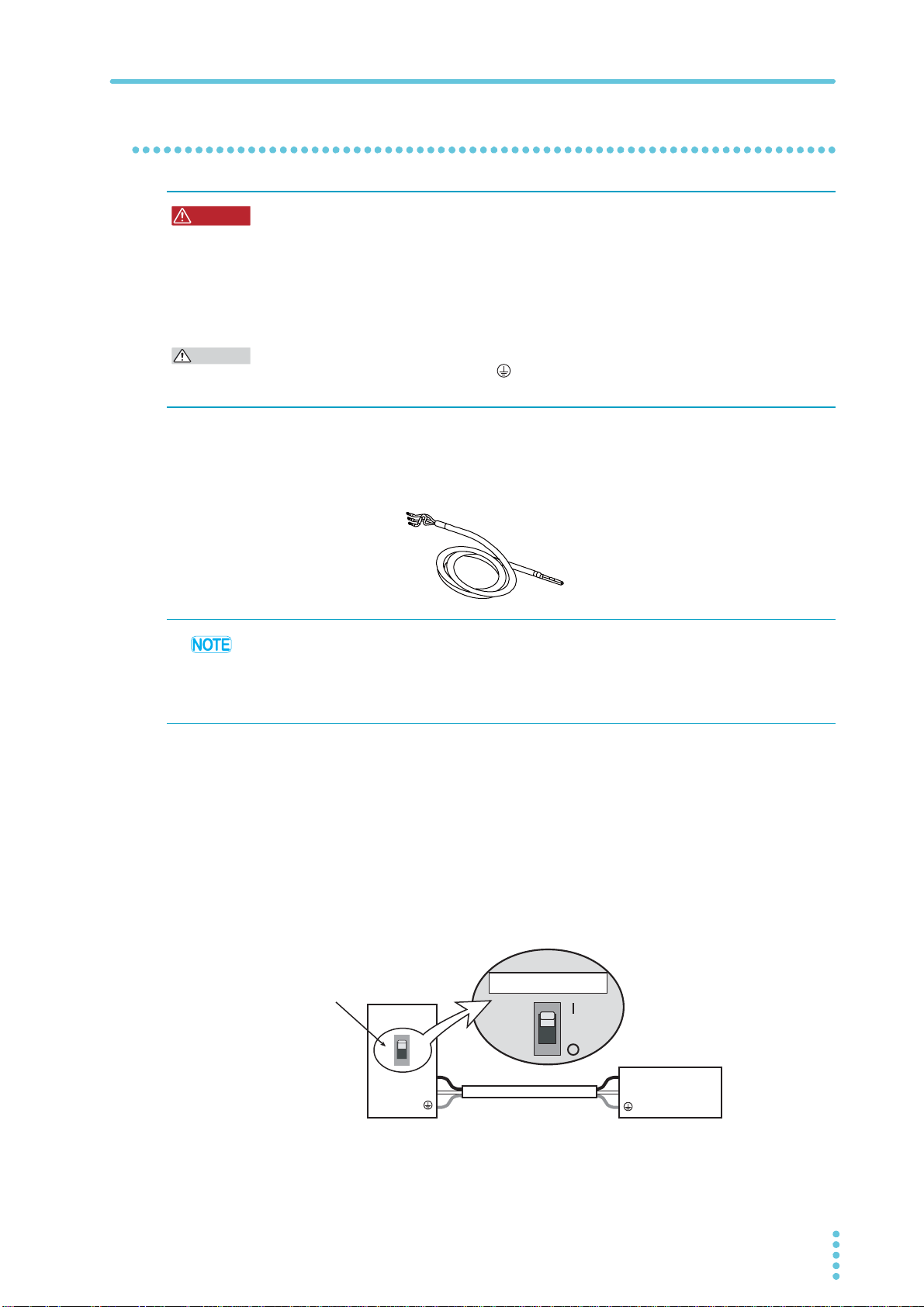

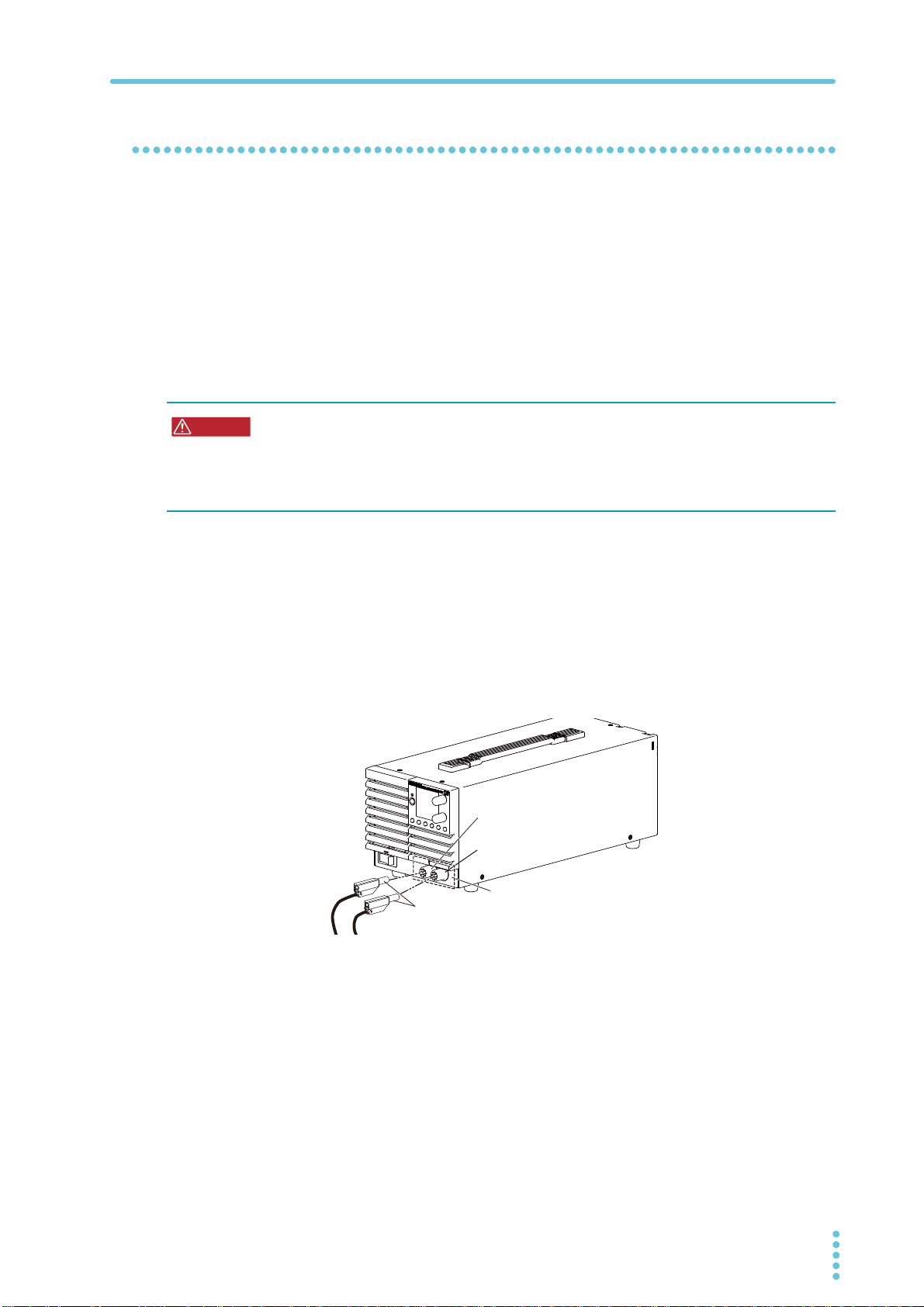

1200W model

WARNING

CAUTION

AC5.5-3P3M-M4C-VCTF

For the 1200W

model

[85-10-1010]

PWR1201L

Switchboard

Circuit breaker indication example

PWR1201L dedicated

PWR1201L

dedicated circuit breaker

N

L

N

L

Risk of electric shock.

• Before you connect the power cable, turn off the switchboard breaker (a switch that

cuts off the power supply from the switchboard).

Risk of fire.

• Be sure to have a qualified engineer make the connection to the switchboard.

• The switchboard breaker must meet the requirements shown below.

Inside the product, protection circuits are connected to match the polarity of the input termi-

nal. Be sure to connect the L, N, and (GND) terminals correctly between the switchboard

and the product.

A power cord is not included with the 1200W model. Use a power cord that conforms to the

rated AC input voltage and current of this product.

The following dedicated power cord is available as an option.

Installation and Preparation | Connecting the Power Cord

• We recommend that you use the optional dedicated power cord to connect to the AC power

line. If you will not use the dedicated power cord, use an appropriate power cord with a

length of 3 m or less that has been selected by a qualified technician.

• In an emergency, turn off the switchboard breaker to separate the product from the AC

power line.

Switchboard breaker requirements

• Rated current: 30 A (100 V system), 15 A (200 V system)

(for safety reasons, circuit breakers exceeding the specified current cannot be used)

• Only use the breaker with this product.

• Keep the breaker readily accessible at all times.

• Indicate that the circuit breaker is dedicated for use with this product and that it is used

to disconnect the product from the AC power line.

PWR-01 15

Installation and Preparation | Connecting the Power Cord

Input terminal cover

N

L

(GND)

AC INPUT terminal block

N: White or blue

L: Black or brown

Lock plate

Lock plate

(GND): Green or

green and yellow

Secure the insulated section

of the power cord in place

with a lock plate.

Power cord

Screw

Input terminal cover

400W model 800W model 1200W model

Protective conductor current

(at 265 Vac, 60 Hz)

Inrush current 25 Amax 50 Amax 75 Amax

Necessary cable

Vinyl cabtire cable (VCTF): Nominal cross-sectional area 5.5 mm

Finished diameter: 12.1 mm or less

Rated voltage: 250 V or higher

Input terminal end: Ring terminal 5.5-4 (5.5 mm

Connection procedure

Check that the AC power line meets the nomin al input rating of the prod-

1

uct.

The product can receive a nominal line voltage in the range of 100 Vac to 240 Vac at

50 Hz or 60 Hz.

1.5 mA 2.5 mA 4.0 mA

2

M4)

2

3core

Check that the POWER switch is turned off.

2

Connect the power cord to the AC INPUT terminal on the rear panel.

3

Pass the power cord through the included INPUT terminal cover, and fix

the cord in place using the lock plate and screws.

Be sure to connect the L, N, and (GND) of the AC input terminal correctly.

Attach the INPUT terminal cover using the screws on the PWR-01 .

4

16 PWR-01

Attach the included ferrite core to the power cord.

5

Installation and Preparation | Connecting the Power Cord

Insert the cable tie

through here.

Firmly apply the cable tie to

attach the core to the power

cord.

Approx. 10 cm

1

2

3

Attach the core as close to the input terminal as possible but not too close as to get in

the way of attaching and removing the INPUT terminal cover.

Use the cable tie to fix the core on to the power cord. Check that the core is locked

and does not move. Cut the cable tie at an appropriate length.

Attach a appropriate crimping terminal to the switchboard end of the

6

power cord.

Turn off the switchboard’s circuit breaker.

7

Connect the L, N, and (GND) wires of the power cord to the matching

8

terminals on the switchboard.

PWR-01 17

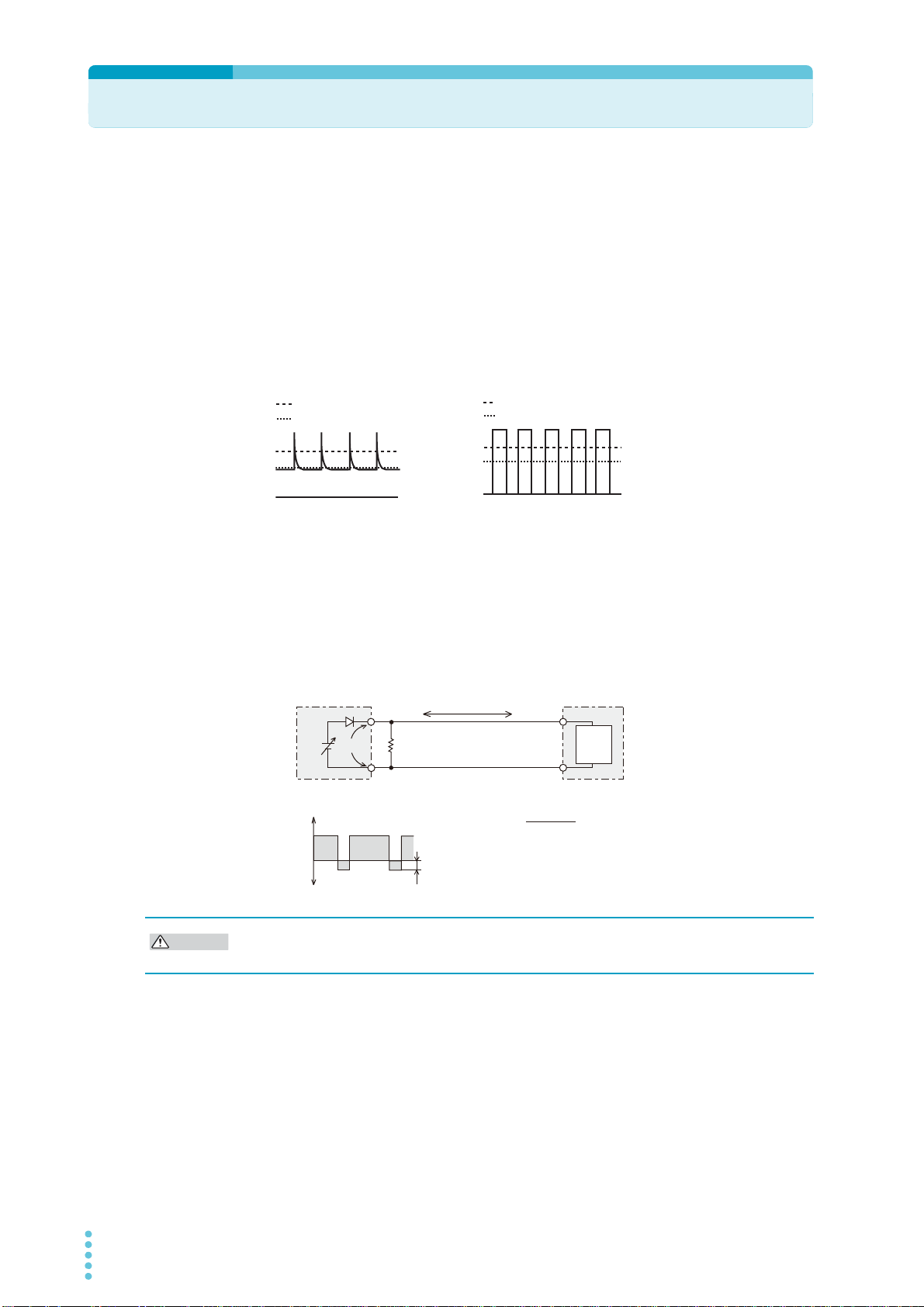

Load Considerations

Constant current setting

Ammeter reading (mean value)

Constant current setting

Ammeter reading (mean value)

O

RD

EO

Equivalent circuit of the PWR-01

Regenerative load

í

0

Reverse current

+IO

+

Irp

RDLQ

RD

EO: Output voltage

Irp: Maximum reverse current

(2LQ9

,USLQ$

Load

CAUTION

Note that the output will become unstable if the following types of loads are connected.

Loads with peak current or pulse-shaped current

The PWR-01 only indicates mean values. Even when the indicated value is less than or equal

to the set constant current, the peak values may exceed the set constant current. If this happens, the PWR-01 is instantaneously put into constant-current mode, and the output voltage

drops.

For these types of loads, you must increase the set constant current or increase the current

capacity.

Load current with peaks Pulse-shaped load current

Loads that generate reverse current to the power supply

The PWR-01 cannot absorb reverse current from the load. Therefore, if a regenerative load

(such as an inverter, converter, or transformer) is connected, the output voltage increases

and becomes unstable. This can cause a malfunction.

For these types of loads, connect a resistor (RD) as shown in the following figure to bypass

the reverse current. However, the amount of current to the load decreases by Irp.

I

: Reverse current bypass dummy load

Output current

-IO

Use a resistor with sufficient rated power for RD. If a resistor with insufficient rated power for

the circuit is used, resistor RD will burn out.

18 PWR-01

Installation and Preparation | Load Considerations

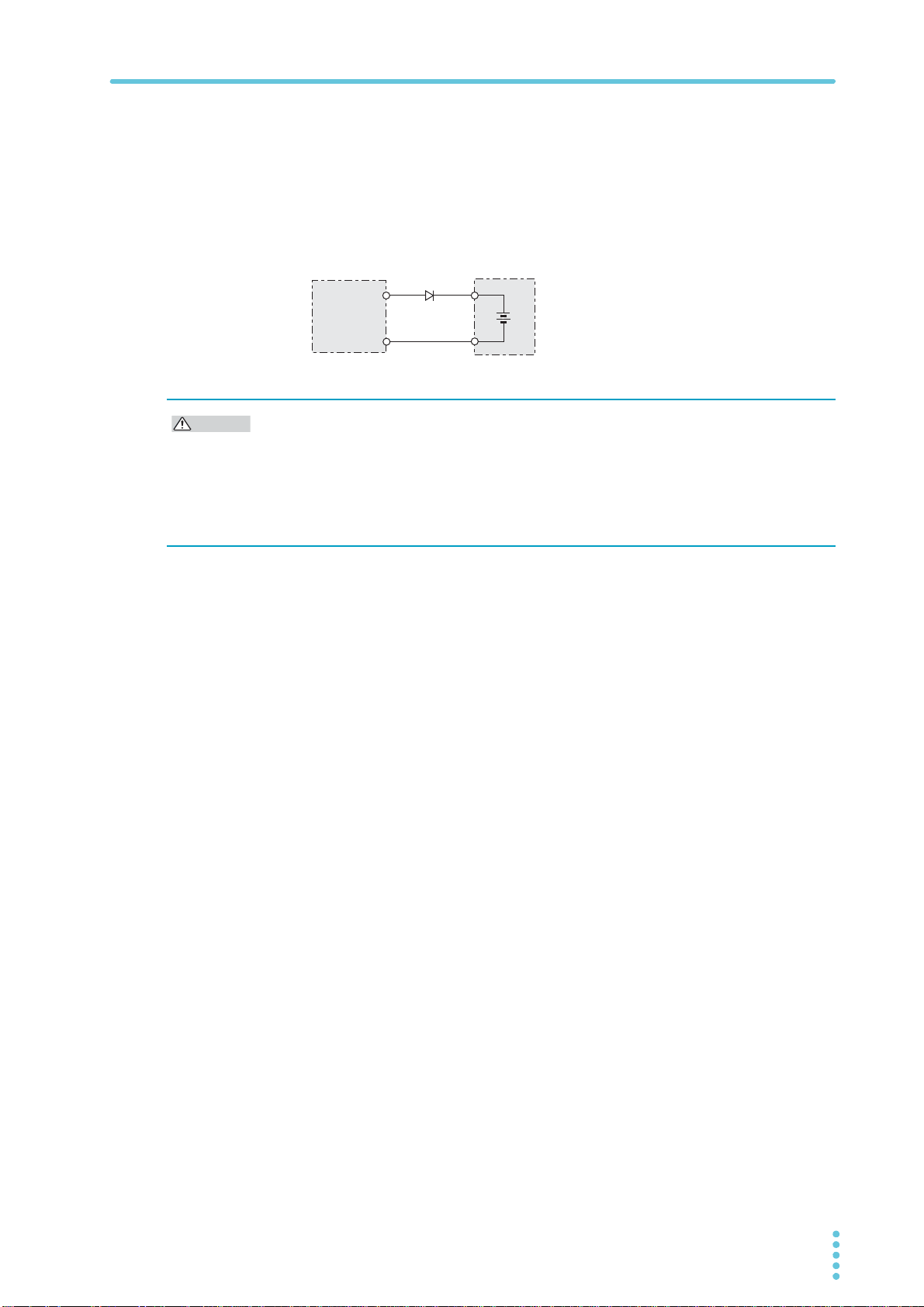

This product

Load with accumulated energy

DRP: Reverse-current-protection diode

D

RP

CAUTION

Loads with accumulated energy

Connecting a load with accumulated energy, such as a battery, to the PWR-01 may cause

current to flow from the load to the internal circuit of the PWR-01. This current may damage

the PWR-01 or reduce the life of the load.

For this type of load, connect a reverse-current-prevention diode (DRP) between the PWR-01

and the load in series as shown in the following figure.

This cannot be used in conjunction with remote sensing.

• To protect the load and the PWR-01, use a DRP that conforms to the following

specifications.

Reverse voltage withstand capacity: At least twice the rated output voltage of the PWR-01.

Forward current capacity: 3 to 10 times the rated output current of the PWR-01.

A diode with small loss.

• Be sure to take into account the heat generated by D

heat dissipation.

RP. DRP will burn out with inadequate

PWR-01 19

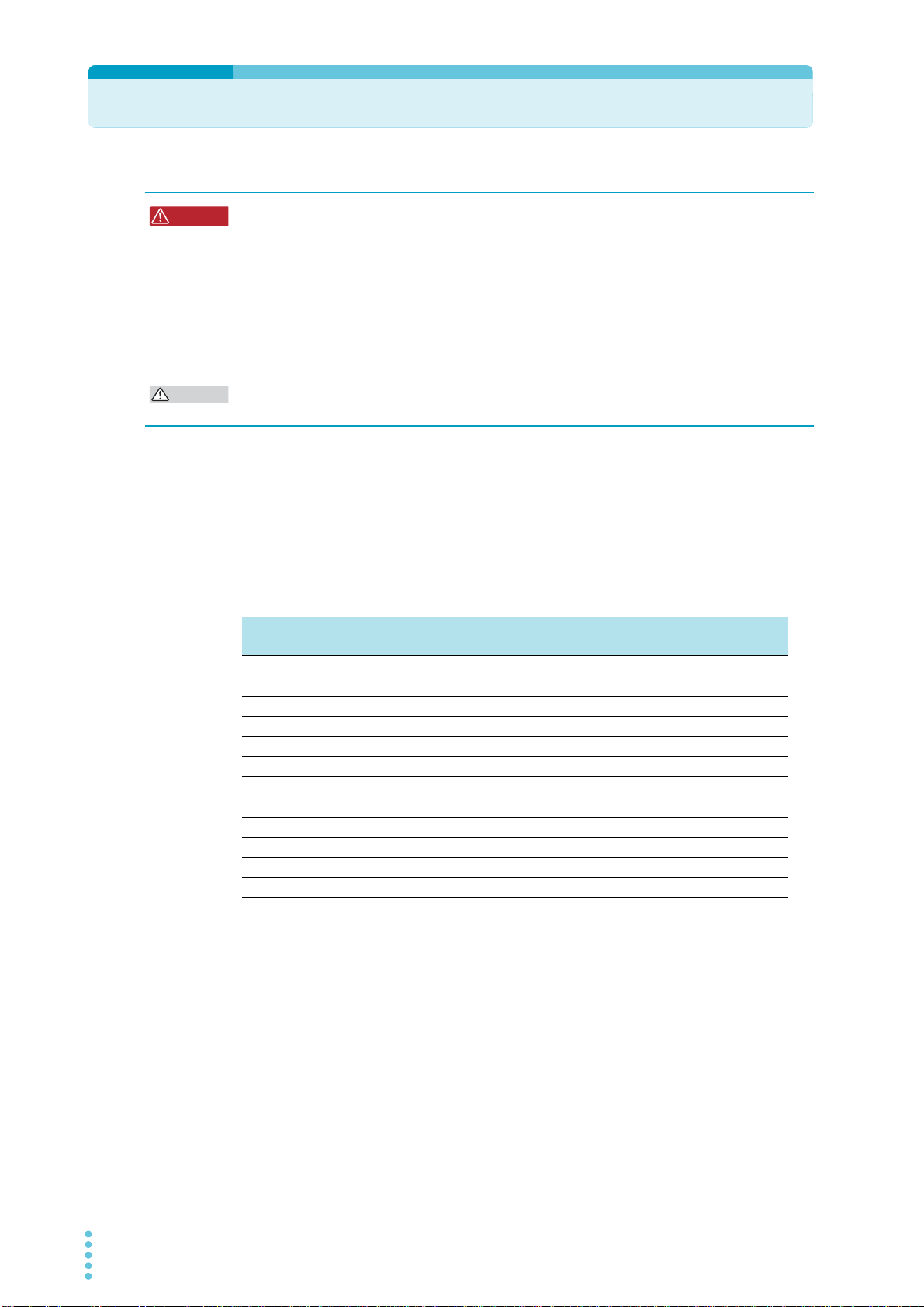

Selecting the Load Cables

WARNING

CAUTION

Risk of fire.

• Use load cables whose capacity is adequate for the PWR-01’s rated output current.

• The output terminal and its surrounding area become very hot. Use cables whose

covers have an allowable temperature of 85 °C or higher.

Risk of electric shock.

• Use load cables with a voltage rating that meets or exceeds the product’s isolation

voltage. For details on the PWR-01’s isolation voltage, see Chap.7 "Specifications"(p.117).

• Use load cables with a core diameter that is appropriate for the amount of current being

used and with sturdy, flame-resistant insulation.

Current capacity of load cables

A cable’s temperature is determined by the resistive loss based on the current, the ambient

temperature, and the cable’s external thermal resistance. The following table shows the current capacity of heat-resistant vinyl cables that have a maximum allowable temperature of

60 °C when one of the cables is separated and stretched out horizontally in air in an ambient

temperature of 30 °C. The current must be reduced under certain conditions, such as when

vinyl cables that have a low heat resistance are used, when the ambient temperature is 30 °C

or greater, or when cables are bundled together and little heat is radiated.

Nominal cross-

sectional area (mm

2 14 (2.08) 27 10

3.5 12 (3.31) 37 -

5.5 10 (5.26) 49 20

8 8 (8.37) 61 30

14 6 (13.3) 88 50

22 4 (21.15) 115 80

30 2 (33.62) 139 -

38 1 (42.41) 162 100

50 1/0 (53.49) 190 -

60 2/0 (67.43) 217 -

80 3/0 (85.01) 257 200

100 4/0 (107.2) 298 -

1 Excerpt from Japanese laws related to electrical equipment.

AWG (reference cross-

2

sectional area; mm

)

2

)

Allowable current1(A)

(Ta = 30 °C)

Kikusui-recommended current (A)

Taking measures against noise

When connecting cables that have the same heat resistance, separating the cables as much

as possible to increase heat radiation enables a greater amount of current to flow. However,

wiring the + (positive) and - (negative) output wires of the load cable side by side or bundling

them together is more effective against unwanted noise. The Kikusui-recommended currents

shown in the above table are allowable currents that have been reduced in consideration of

the potential bundling of load cables. Use these values as a guideline when connecting

cables.

20 PWR-01

Installation and Preparation | Selecting the Load Cables

Limitations of the remote sensing function

All wires have resistance. As the wire becomes longer or the current becomes larger, the voltage drop in the wire becomes greater. This results in a smaller voltage being applied at the

load end. The PWR-01 has a sensing function that compensates for this voltage drop up to

the following values (p.30). If the voltage drop exceeds this level, use cables that have a

greater cross-sectional area.

L type ML type MH type H type

Compensation

voltage

Approx. 1.5 V one

way

Approx. 4 V one

way

Approx. 5 V one

way

Approx. 5 V one

way

PWR-01 21

Output Terminal Insulation

WARNING

CAUTION

+

–

+

+S

–S

–

+

–

16

17

18

19

14

15

20

2

3

4

5

6

13

12

11

10

9

8

7

1

2

3

4

5

6

1

AC

DC

OUTPUT

J1 J2

SENS

L

N

Load

Rext

PWR-01

Vext

Approximately the same

electric potential as the

negative output terminal

All pins of the J1 connector are at

approximately the same electric

potential as the PWR-01’s negative output terminal.

Risk of electric shock. For safety reasons, even if the output terminal is grounded,

make sure that the insulation capacity of the output terminal (including the sensing

terminal) is greater than or equal to the isolation voltage of this product.

For details on the isolation voltage of each model, see "Specifications" (p.117).

If you cannot obtain a cable with sufficient rated voltage, secure adequate withstand

voltage by passing the cable through an insulation tube with a withstand voltage

greater than the isolation voltage of the PWR-01.

The signal cable may burn out. If the PWR-01 is to be controlled through an external voltage

(Vext), do not ground the external voltage (leave it floating).

The cable and load that are connected to the output terminal (including the sensing terminal)

must have an insulation capacity that is greater than or equal to the isolation voltage of the

PWR-01 with respect to the chassis. Isolation voltage indicates the maximum allowed voltage

that appears across the output terminal of the power supply unit and the protective conductor

terminal (chassis terminal).

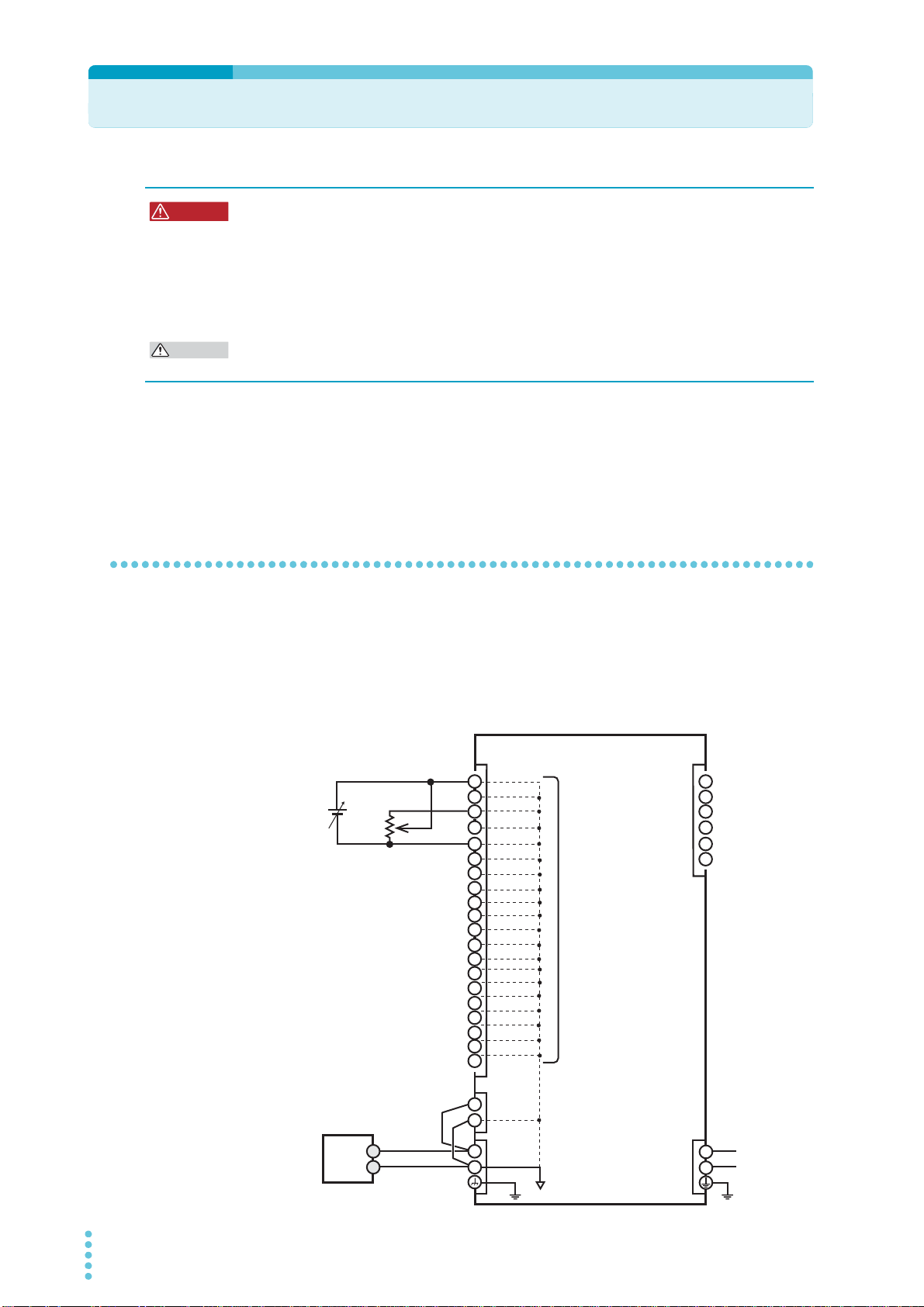

When the output terminal is not grounded (floating)

The output terminal of the PWR-01 is isolated from the protective conductor terminal. If you

connect the GND wire of the power cord to the ground terminal of the switchboard, the chassis of the PWR-01 is set to ground potential.

The J1 connector on the rear panel are at approximately the same electric potential as the

PWR-01’s negative output terminal. Cables and devices that are connected to these pins

must have an insulation capacity greater than or equal to the isolation voltage of the PWR-01.

INPUT

22 PWR-01

Installation and Preparation | Output Terminal Insulation

+

–

+

+S

–S

–

+

–

16

17

18

19

14

15

20

2

3

4

5

6

13

12

11

10

9

8

7

1

2

3

4

5

6

1

AC

INPUT

DC

OUTPUT

J1 J2

SENS

L

N

Load

Rext

PWR-01

Vext

Chassis terminal

Approximately the

same electric potential

as the negative output

terminal

All pins of the J1 connector are

at approximately the same electric potential as the PWR-01’s

negative output terminal.

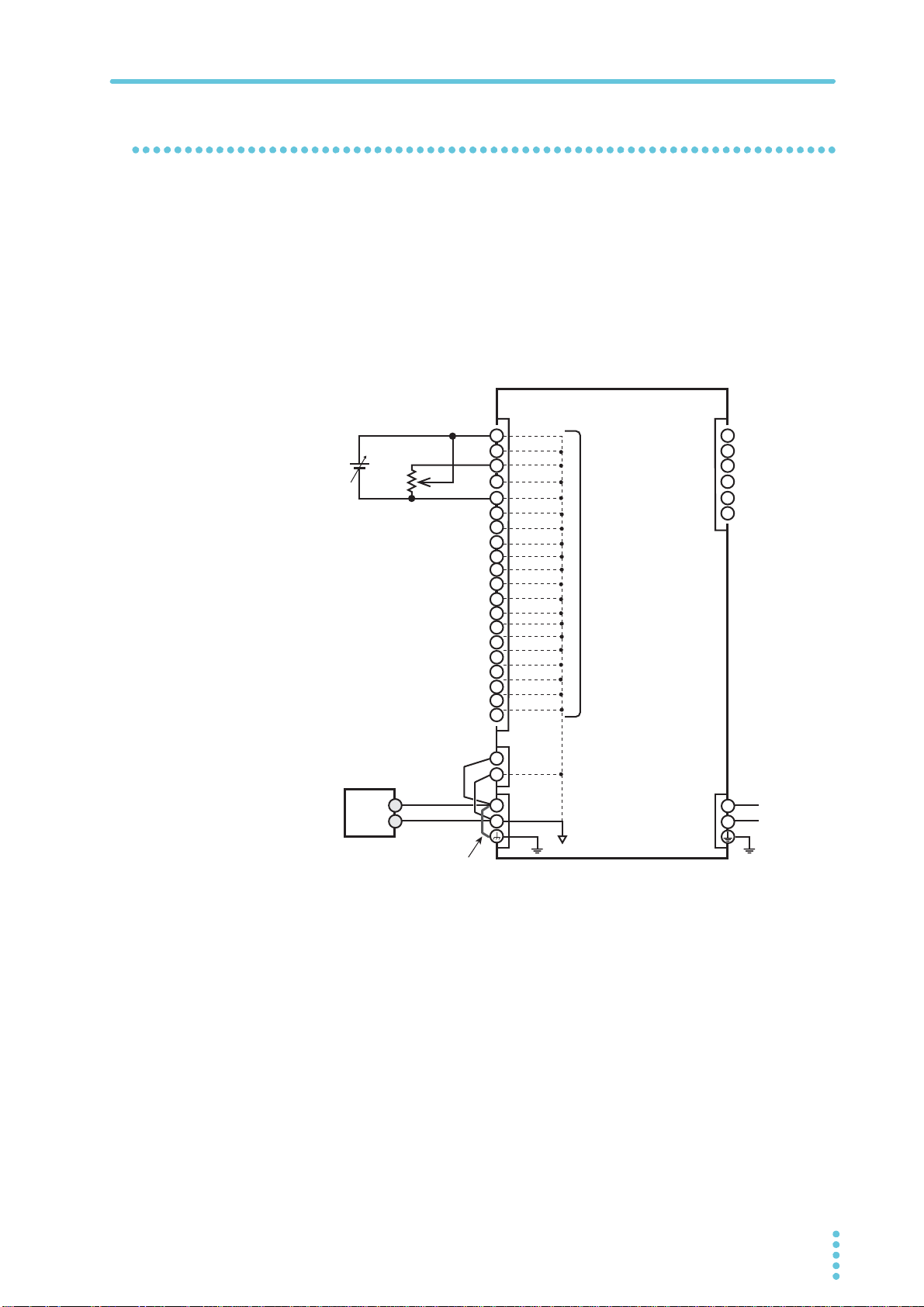

When the output terminal is grounded

If the positive output terminal is connected to the chassis terminal, the positive output terminal is at ground potential. The cable and load that are connected to the output terminal

(including the sensing terminal) will only require an insulation capacity that is greater than or

equal to the maximum output voltage of the PWR-01 with respect to the chassis.

The same holds true when the negative terminal is connected to the chassis terminal. The

cable and load require an insulation capacity that is greater than or equal to the maximum

output voltage of the PWR-01.

For safety reasons, connect one of the output terminals to the chassis terminal unless your

application requires the output terminals to be floating.

PWR-01 23

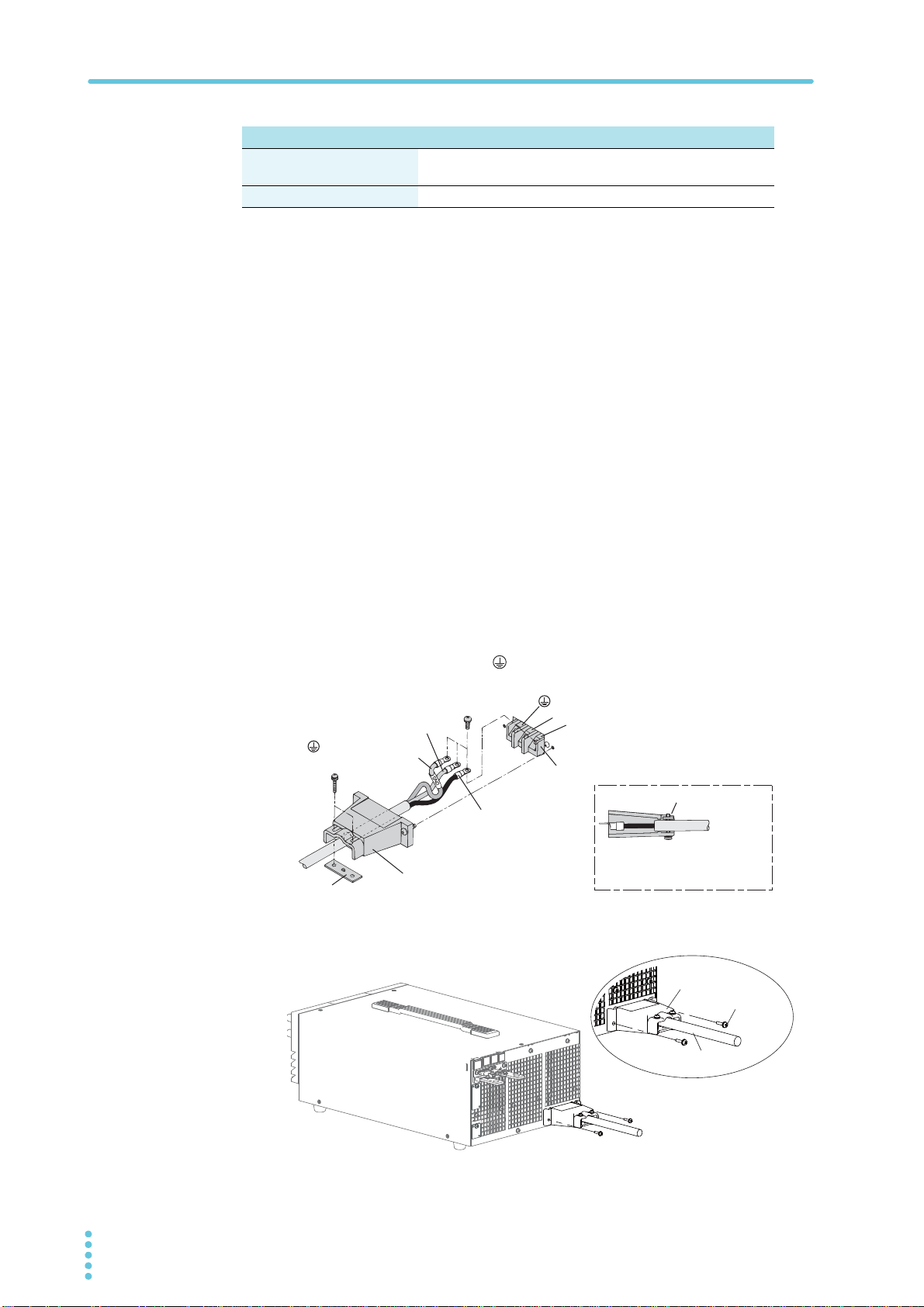

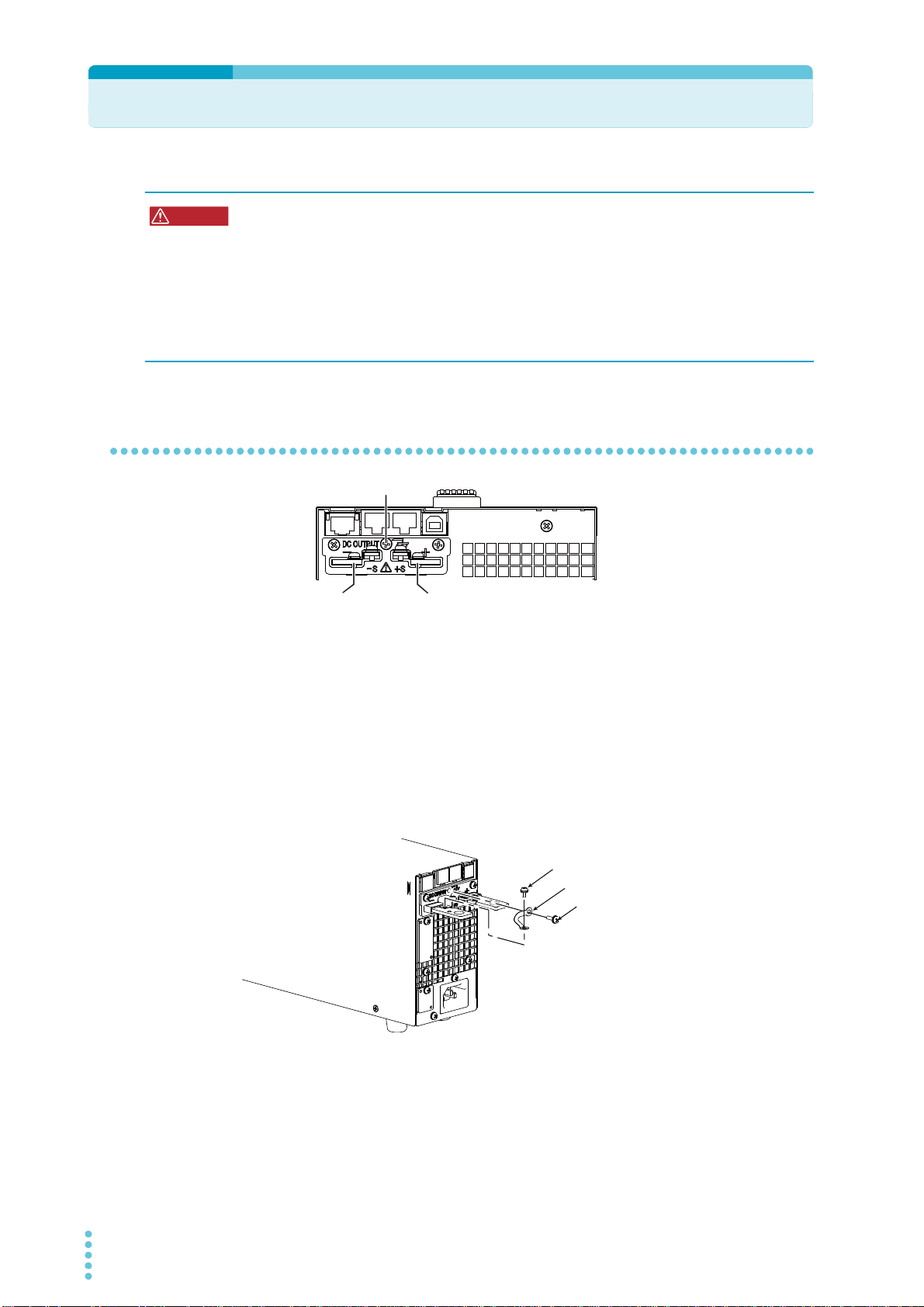

Connecting to the Output Terminals

WARNING

Chassis terminal

íQHJDWLYHWHUPLQDO

SRVLWLYHWHUPLQDO

800W model example

Chassis connection short bar

Screw (M3)

Screw (M3)

400W model

Example of connecting to the negative terminal

Risk of electric shock.

• Turn the POWER switch off before you touch the rear-panel output terminals.

• Even if you turn the out put off or turn the POWER switch off, if the bleeder circuit is

set to off (CF01: DIS), the voltage that was present when the output was on will

remain at the output terminals. Set the bleeder circuit to on (CF01: NORM/ HYP)

before you touch the output terminals.

• Regardless of whether load cables are connected to the output terminals, be sure to

attach the OUTPUT terminal cover before turning the POWER switch on.

Connecting to the rear-panel output terminals

Turn the POWER switch off.

1

Check that there is no residual voltage at the rear-panel output terminals.

Connect one end of the included chassis connection short bar to the

2

chassis terminal and the other end to the negative or positive output terminal.

Use the screw on the PWR-01 to connect the short bar to the chassis terminal. Use the

screw on the rear-panel output terminal to connect the short bar to the output terminal.

If you are not grounding the output terminal (leaving it floating), refer to “Output Termi-

nal Insulation” (p.22) before use.

Attach crimping terminals to the load cables.

3

The rear-panel output terminals have holes for connecting the load cables. Use crimping terminals that are appropriate for the bolts that you are using.

24 PWR-01

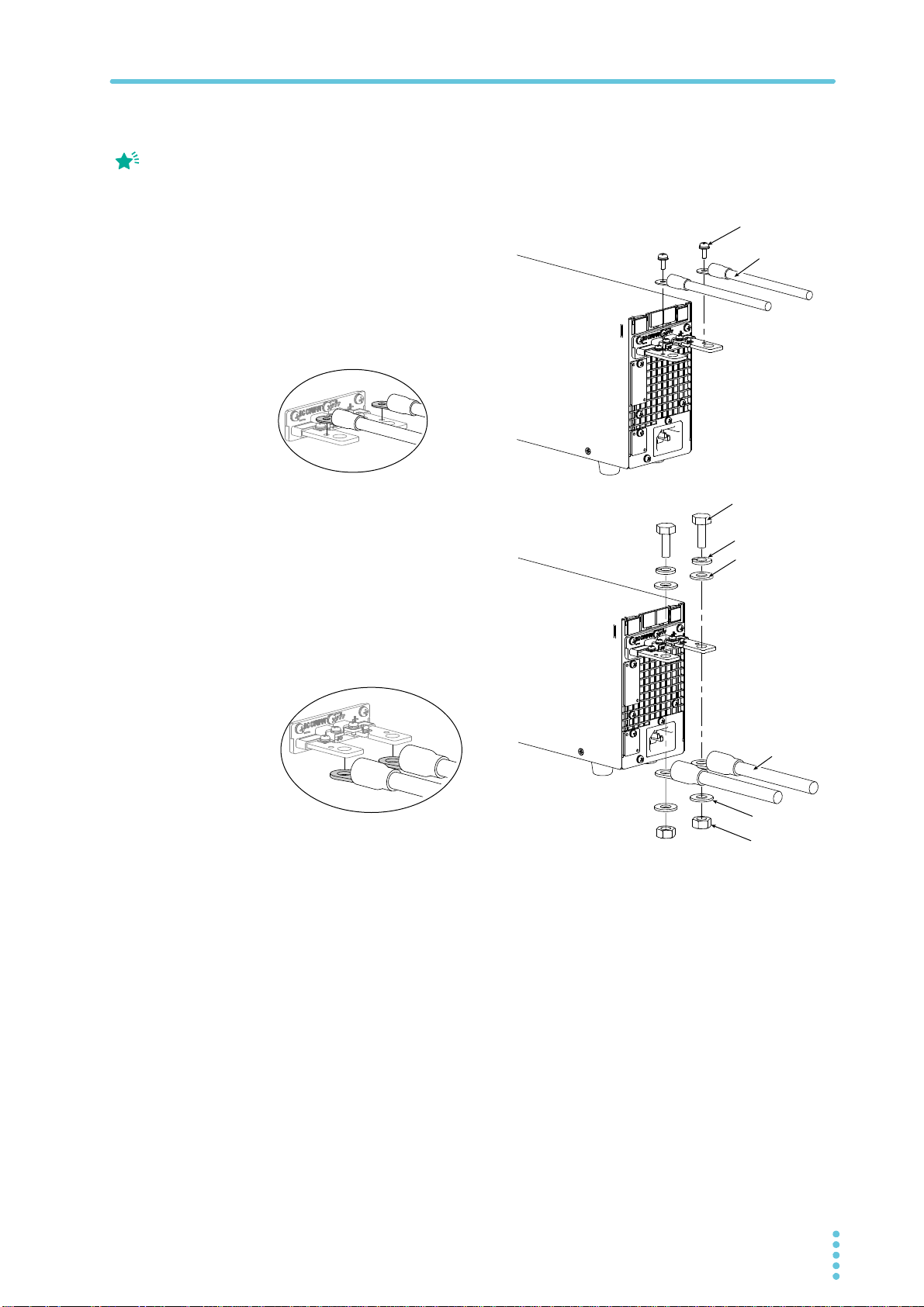

Memo

If you do not connect load

Spring washer

(M8)

Washer (M8)

Washer (M8)

Bolt (M8)

Load cable

Using the M8 bolt set to connect the cables

Cable diameter (including the insulation)

ø8 to ø17

Applicable models

L type, ML type

Screw (M4)

Load cable

Connection using the M4 screw set

Cable diameter (including the insulation)

Up to ø7

Applicable models

All models

400W model example

Bring the ring to the bottom

side, and align to the bottom

of the output terminal.

cables in the correct

orientation, you will not be

able to attach the

OUTPUT terminal cover.

Installation and Preparation | Connecting to the Output Terminals

Connect the load cables to the rear-panel output terminals.

4

Use the included screw set.

To reduce the influence of noise on the output, keep the cables as short as possible. If

possible, twist the positive and negative load cables.

Bring the ring to the bottom

side, and align to the top side

Nut (M8)

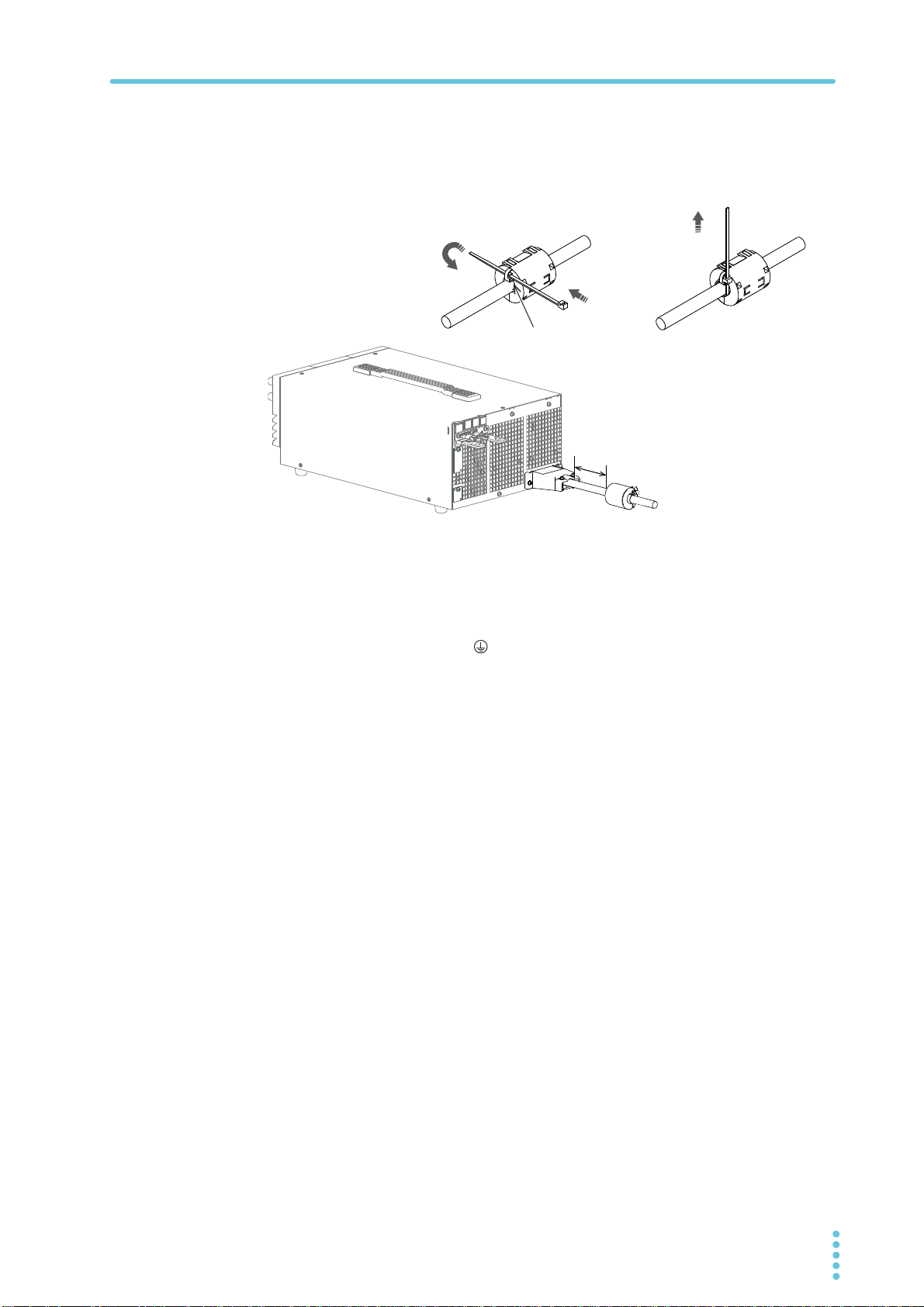

Attaching the OUTPUT terminal cover

You can adjust the diameter of the holes that the load cables pass through by changing the

orientation of the adapter attached to the OUTPUT terminal cover. There are two available

orientations. Use the appropriate orientation for the load cables (including the insulation) that

you are using.

• Cable diameter (including the insulation) up to ø7: Attach the adapter of the OUTPUT

terminal cover so that the hole diameter is small.

• Cable diameter (including the insulation) from ø8 to ø17: Attach the adapter of the

OUTPUT terminal cover so that the hole diameter is large.

PWR-01 25

Installation and Preparation | Connecting to the Output Terminals

Memo

Top half of the cover

For thin load cables

Cable diameter

(including the insulation)

ø8 to ø17

Cable diameter

(including the insulation)

Up to ø7

For thick load cables

Top half of the cover

Example of the load

cable position

Example of the load

cable position

Insert the adapter

tabs into the two

cuts in the top half

Insert the adapter

tabs into four two

cuts in the top half

Align the cover to the cut-out in

the rear-panel output terminal.

400W model example

After you have lined up the top and

bottom halves of the cover, use the

screws to fix the cover in place.

Screw (M3)

400W model example

Attach the adapter to the top half of the OUTPUT terminal cover.

1

The top and bottom

halves of the OUTPUT

terminal cover have

different shapes.

Insert the adapter tabs into the cuts in the OUTPUT terminal cover.

2

3

Align the bottom half of the OUTPUT terminal cover to the rear-panel

output terminals.

Place the top half of the OUTPUT terminal cover over the bottom half,

and screw them together.

Make sure that the screws are securely fastened.

26 PWR-01

Installation and Preparation | Connecting to the Output Terminals

WARNING

Front-panel output terminal.

- (negative) terminal

+ (positive) terminal

Safety plugs

800W model example

Connecting to the front-panel output terminals

The specifications of the PWR-01 apply to the rear-panel output terminals. The front-panel

output terminals may not meet the specifications.

There is no grounding terminal on the front-panel output terminals. To ground one side of the

output, connect the rear-panel chassis terminal to either the negative output terminal or the

positive output terminal.

If you are not grounding the output terminal (leaving it floating), refer to “Output Terminal

Insulation” (p.22) before use.

If the output current of the front-panel output terminals exceeds 10 A (typical value), the front-

panel output terminal overcurrent protection (FOCP) will be activated (p.50).

• Risk of electric shock. The front-panel output terminals are designed to be used with

safety plugs. Do not use connectors that have bare conductive parts (such as

banana plugs) to connect to the front-panel output terminals.

• Risk of heat buildup or fire.

Do not run current higher than 10 A through the front-panel output terminals.

Necessary cables and plugs (recommended)

Polyvinyl chloride insulation cable: Nominal cross-sectional area of 0.33 mm2 (AWG22) to

0.82 mm

Rated voltage: 1000 V or higher

Length: Less than 3 m

Output terminal plugs: Safety plugs

Safety plugs TL41 and TL42 are available as options (p.139).

1

2

(AWG18)

Attach safety plugs to the load cables.

Connect the load cables with safety plugs to the front-panel output ter-

2

minals.

To reduce the influence of noise on the output, keep the cables as short as possible.

Twist the positive and negative load cables.

PWR-01 27

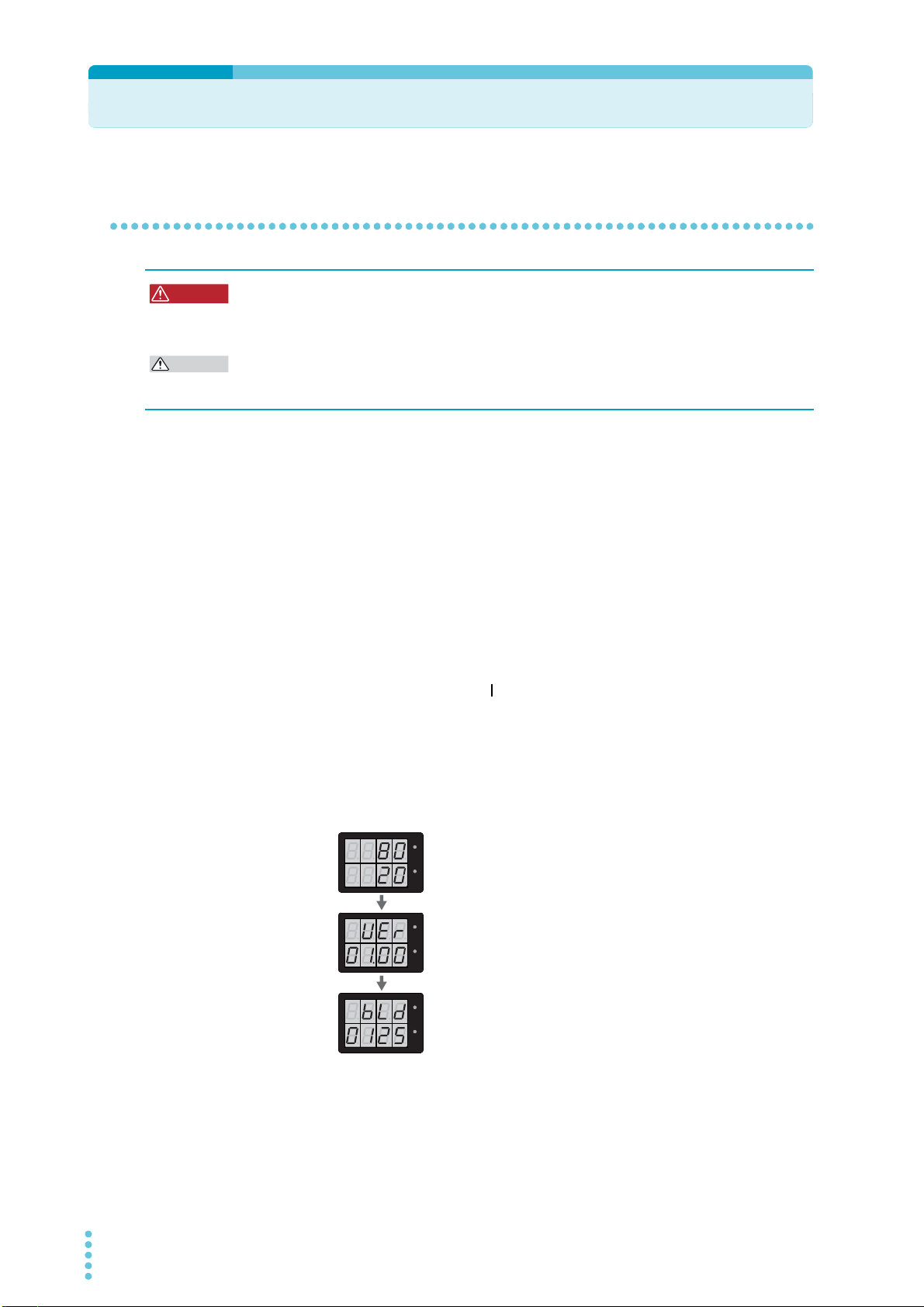

Turning the Power On

WARNING

CAUTION

Firmware version display

(Version 1.00 in this example)

Rated voltage and rated current display

(PWR401ML example)

Build number display

(Build number BLD 0125 in this example)

CV

CC

/

W

V

A

CV

CC

/

W

V

A

CV

CC

/

W

V

A

CV

CC

/

W

V

A

CV

CC

/

W

V

A

CV

CC

/

W

V

A

Turning on the POWER switch

Risk of electric shock. Regardless of whether load cables are connected to the output

terminals, be sure to attach the OUTPUT terminal cover before turning the POWER

switch on.

Risk of damage to load.

If the PWR-01 is configured to turn on the output when the POWER switch is turned on in

CONFIG settings, set an appropriate OVP or OCP value before connecting a different load.

If the POWER switch is turned on for the first time after purchase, the PWR-01 starts in the

factory default condition (p.136). Subsequent times that you turn the PWR-01 on, it starts with

the panel settings (excluding the output on/off setting) that were in use immediately before

the POWER switch was turned off.

You can use the CONFIG settings (CF45) to select the output state of the PWR-01 when the

POWER switch is turned on (p.65).

Check that the power cord is connected correctly.

1

Check that the OUTPUT terminal cover is attached (p.25).

2

When the product is shipped from the factory, the OUTPUT terminal cover is not

attached.

Turn the POWER switch on ( ).

3

All the indicators light, and then the voltmeter and the ammeter display the following

sequence of information: the rated voltage and rated current, the firmware version

number, and then the build number. Each item is displayed for approximately 1 second.

After a few seconds, the PWR-01 enters the operation standby state (the measured

value is displayed).

28 PWR-01

Installation and Preparation | Turning the Power On

CAUTION

Turning the POWER switch off

Turn the POWER switch off ( ).

The PWR-01 saves the panel settings (except the output on/off setting) that were in use

immediately before the POWER switch was turned off.

You can use the CONFIG settings (CF45) to select the output state of the PWR-01 when the

POWER switch is turned on (p.65).

If the POWER switch is turned off immediately after the settings have been changed, the last

settings may not be stored.

After you turn the POWER switch off, wait at least 10 seconds after the panel display turns

off before you turn the POWER switch back on. Repeatedly turning the POWER switch on

and off at short intervals can cause damage to the inrush current limiter. Furthermore, this

will shorten the service life of the POWER switch and the internal input fuse.

PWR-01 29

Remote Sensing function

E3-200-546

WARNING

Remote sensing is a function that stabilizes the output voltage across the load by reducing

the influence of voltage drops and other effects caused by the load cable resistance.

The PWR-01 remote sensing can compensate up to the values shown below. Select a load

cable that has sufficient current capacity to prevent the voltage drop in the load cable from

exceeding the compensation voltage.

When you perform remote sensing, set the voltage of the sensing point (across the load) so

that it does not exceed the rated output voltage. If you are performing remote sensing with

the voltage close to the maximum output voltage, the output is limited by the maximum output

voltage (105 % of the rated output voltage). Electrolytic capacitors may be required at the

sensing point (across the load).

To reduce the effect of noise, use twisted-pair cables or 2-core shielded cables. When you

use shielded cables, connect the shield to the PWR-01 or the load grounding terminal.

L type ML type MH type H type

Compensation

voltage

When the product is shipped from the factory, a sensing short bar

is connected across the sensing terminals and DC OUTPUT terminals. When the sensing terminals are not used, connect the sensing short bar.

If the short bar is damaged or lost, contact your Kikusui agent or

distributor.

Approx. 1.5 V one

way

Approx. 4 V one

way

Approx. 5 V one

way

Approx. 5 V one

way

Connecting the sensing cables

Risk of electric shock and damage to internal circuits.

• Never wire the sensing terminals while the POWER switch is turned on.

• For sensing cables, use cables with a voltage rating that is higher than the PWR-01’s

isolation voltage. Protect the uncovered sections of the shielded cable by using

insulation tubes whose withstand voltage is greater than the PWR-01’ isolation voltage.

• Even if you turn the out put off or turn the POWER switch off, if the bleeder circuit is

set to off (CF01: DIS), the voltage that was present when the output was on will

remain at the output terminals. Set the bleeder circuit to on (CF01: NORM/ HYP)

before you touch the sensing terminals.

• Be sure to attach the OUTPUT terminal cover before turning the POWER switch on.

30 PWR-01

Loading...

Loading...