Kikusui PMC18-2A, PMC35-1A, PMC18-3A, PMC35-0.5A, PMC35-2A Operation Manual

...

Part No. Z1-004-632, IA004571

Jun. 2009

OPERATION MANUAL

REGULATED DC POWER SUPPLY

PMC-A SERIES

TYPE I

PMC 18-1A

PMC 18-2A

PMC 18-3A

TYPE II

PMC 18-5A

PMC 35-3A

PMC 70-1A

PMC 110-0.6A

PMC 35-0.5A

PMC 35-1A

PMC 35-2A

PMC 160-0.4A

PMC 250-0.25A

PMC 350-0.2A

PMC 500-0.1A

Use of Operation Manual

Please read through and understand this Operation Manual before operating

the product. After reading, always keep the manual nearby so that you may

refer to it as needed.

If you find any misplaced or missing pages in this manual, they will be

replaced. If the manual gets lost or soiled, a new copy can be provided for a

fee. In either case, please contact Kikusui distributor/agent, and provide the

“Kikusui Part No.” given on the cover.

This manual has been prepared with the utmost care; however, if you have

any questions, or note any errors or omissions, please contact Kikusui dis

tributor/agent.

-

Reproduction and reprinting of this operation manual, in whole or in part,

without written permission is prohibited.

Both unit specifications and manual contents are subject to change without

notice.

Copyright© 2009 Kikusui Electronics Corporation

2 PMC-A

Power Requirements of this Product

✓

WARNING

Power requirements of this product have been changed and relevant sections

of the Operation Manual should be revised accordingly. (Revision should be

applied to items indicated by a check mark .)

Input voltage

The input voltage of this product is Vac,

and the voltage range is to Vac. Use the product

within this range only.

Input fuse

The rating of this product’s input fuse is A, Va c ,

and .

• To avoid electrical shock, always disconnect the

power cord or turn off the switchboard before

attempting to check or replace the fuse.

• Use a fuse element having a shape, rating, and

characteristics suitable for this product. The use of a

fuse with a different rating or one that short circuits

the fuse holder may result in fire, electric shock, or

irreparable damage.

PMC-A 3

4 PMC-A

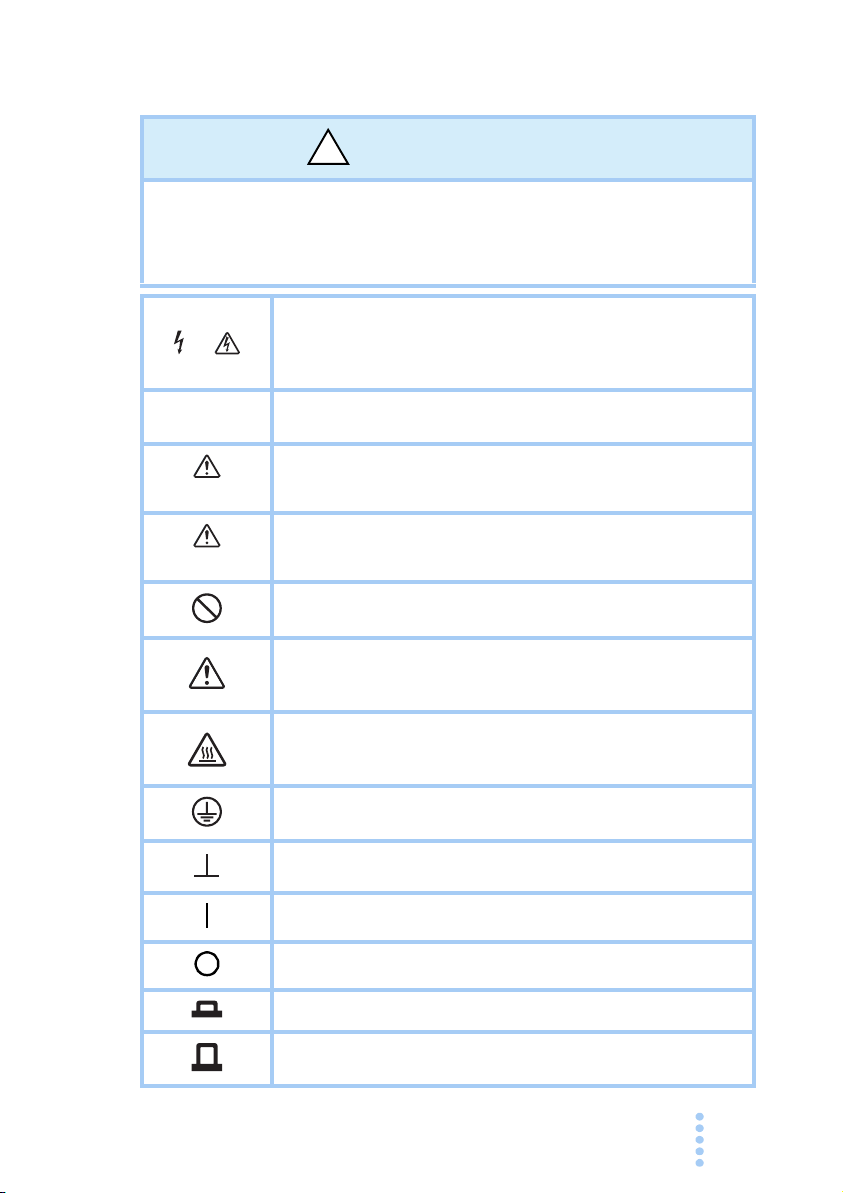

Safety Symbols

!

For the safe use and safe maintenance of this product, the following

symbols are used throughout this manual and on the product. Note the

meaning of each of the symbols to ensure safe use of the product. (Not

all symbols may be used.)

Indicates that a high voltage (over 1 000 V) is used here.

or

To uching the part causes a possibly fatal electric shock. If physical contact is required by your work, star t work only after you

make sure that no voltage is output here.

DANGER

WAR N ING

CAUTION

Indicates an imminently hazardous situation which, if ignored,

will result in death or serious injury.

Indicates a potentially hazardous situation which, if ignored,

could result in death or serious injury.

Indicates a potentially hazardous situation which, if ignored, may

result in damage to the product and other property.

Shows that the act indicated is prohibited.

Indicates a general danger, warning, or caution.

When this symbol is marked on the product, see the relevant

sections in this manual.

Indicates a caution for hot surface of the product.

When this symbol is marked on the product, see the relevant

sections in this manual.

Protective conductor terminal.

Chassis (frame) terminal.

On (supply)

Off (supply)

In position of a bi-stable push control

Out position of a bi-stable push control

PMC-A 5

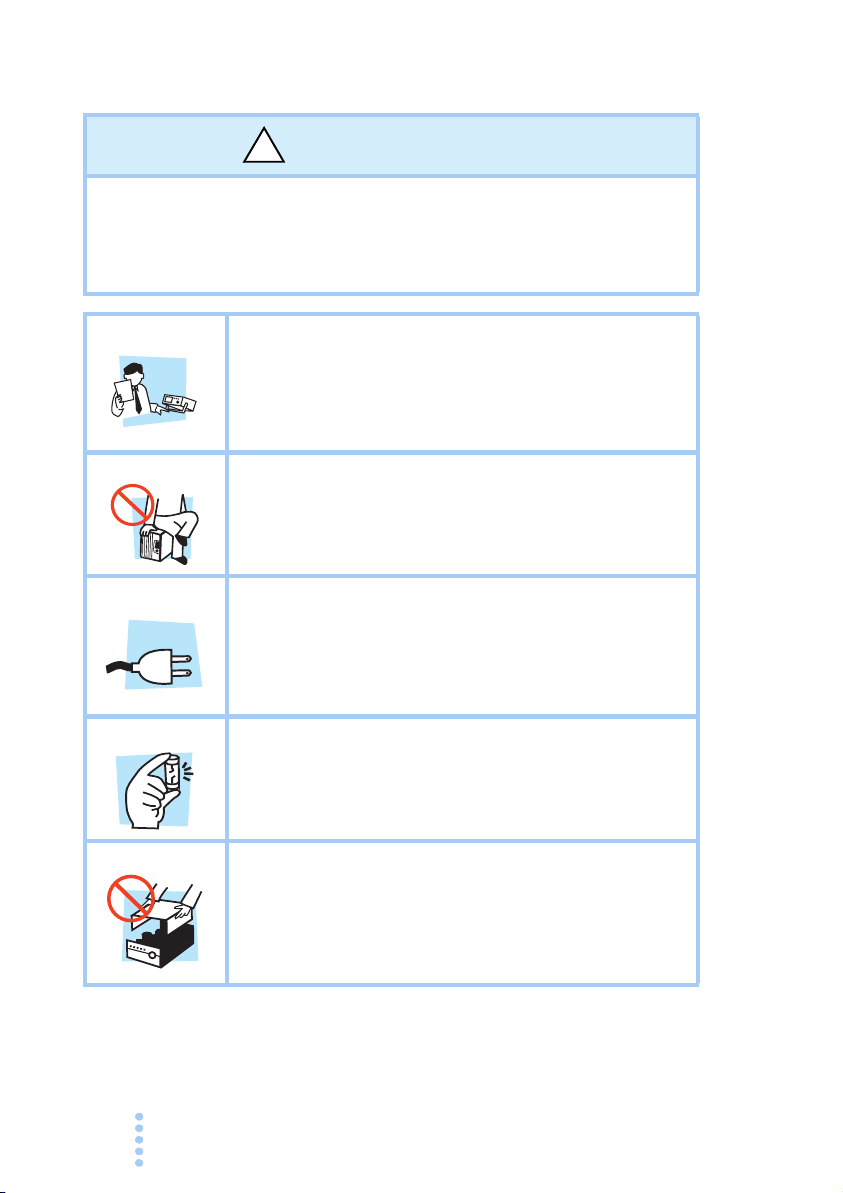

Safety Precautions

!

Line

Voltage

The following safety precautions must be observed to avoid fire hazards,

electric shock, accidents, and other failures. Keep them in mind and make

sure to observe them.

Using the product in a manner that is not specified in this manual may

impair the protection functions provided by the product.

Users

n

o

i

t

ra

e

p

O

Manual

Purpose of use

Input power

Fuse

Cover

• This product must be used only by qualified personnel who

understand the contents of this operation manual.

•If unqualified personnel is to use the product, be sure the

product is handled under the supervision of qualified

personnel (those who have electrical knowledge). This is to

prevent the possibility of personal injury.

• Never use the product for purposes other than the product's

intended use.

• This product is not designed or manufactured for general

home or consumer use.

• Use the product within the rated input power voltage range.

• For applying power, use the power cord provided. For

details, see the respective page in the operation manual.

• This product is designed as an equipment of IEC

Overvoltage Category II (energy-consuming equipment

supplied from the fixed installation).

•The fuse can be replaced with a new one. When replacing a

fuse, use the one which has appropriate shape, ratings, and

specifications. For details, refer to the specification section in

this manual.

• Some parts inside the product may cause physical hazards.

Do not remove the external cover.

• When the product is under the operation, the surface of top

cover may get high temperature. It may cause burn on the

skin.

6 PMC-A

Grounding

Check?

N

G

• This product is an IEC Safety Class I equipment (equipment

L

with a protective conductor terminal). To prevent the

possibility of electric shock, be sure to connect the protective

conductor terminal of the product to electrical ground (safety

ground).

Installation

Relocation

Operation

Maintenance

and

inspection

• This product is designed for safe indoor use. Be sure to use

it indoors.

• When installing this product, be sure to observe the

description in 2.2 Precautions Concerning Installation

Location in this manual.

•Turn off the POWER switch, and disconnect all cables

before relocating the product.

• When relocating the product, be sure to include the manual.

•If a malfunction or abnormality is detected on the product,

stop using it immediately, and remove the power plug from

the outlet. Make sure the product is not used until it is

completely repaired.

• Use cables or wires with sufficiently large current capacity

for output wires and load cables.

• Do not disassemble or modify the product. If you need to

modify the product, contact your Kikusui distributor/agent.

• To prevent the possibility of electric shock, make sure to

unplug the power plug before carrying out maintenance or

inspection. Do not remove the external cover during

maintenance or inspection.

• Check that the insulation coating of the power cord is not

broken and that the plug is not cracked or falling apart.

• If the panel needs cleaning, gently wipe using a soft cloth

with water-diluted neutral detergent.

• To maintain the performance and safe operation of the

product, it is recommended that periodic maintenance,

inspection, cleaning, and calibration be performed.

Service

PMC-A 7

•Kikusui service engineers will perform internal service on the

product. If the product needs adjustment or repairs, contact

your Kikusui distributor/agent.

How to Read This Manual

Preface

Thank you for purchasing the PMC-A Series regulated DC

power supply.

This manual is intended for first-time users of the PMC-A

Series (hereafter abbreviated as: the PMC-A). It gives an

overview of the PM

operation, maintenance, safety precautions, etc.

Read this manual thoroughly to use the functions of the PMC-A

effectively. You can also review this manual; when you are

confused about an operation or when a problem occurs.

How to read this manual

This manual is designed to be read from beginning to end. We

recommend that you read the manual thoroughly from the

beginning before using the PMC-A for the first time.

Intended readers of this manual

This manual is intended for those using the PMC-A of

regulated DC power supply and teaching other users on how to

operate the PMC-A.

It assumes that the reader has knowledge of a regulated DC

power

.

C-A and describes various settings,

8 PMC-A

Notations used in this manual

WARNING

CAUTION

DESCRIPTION

See

The following marks are used with the corresponding

explanations in this manual.

Indicates an imminently hazardous situation which, if

ignored, could result in death or serious injury.

Indicates a potentially hazardous situation which, if

ignored, may result in damage to the product and other

property.

Indicates information that you should know.

Explanation of terminology or operation principle.

Indicates reference to detailed information.

PMC-A 9

Contents

Contents

Safety Symbols - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5

Safety Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6

How to Read This Manual - - - - - - - - - - - - - - - - - - - - - - - - - - - -8

Contents - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -10

Function index - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -13

Front panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -14

Rear Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -16

Chapter 1 General Description

1.1 About This Manual - - - - - - - - - - - - - - - - - - - - - - - - - - - -17

1.2 Product Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - -17

1.3 Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -18

1.4 Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -19

Chapter 2 Installation and Preparation

2.1 Checking the Package Contents - - - - - - - - - - - - - - - - - -23

2.2 Precautions Concerning Installation Location - - - - - - - - -24

2.3 Precautions to Be Taken When Moving the Product - - - -26

2.4 Rack-mount Adaptor Installation - - - - - - - - - - - - - - - - - -26

2.5 Connecting the Power Cord - - - - - - - - - - - - - - - - - - - - -27

2.6 Ground (Earth) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -28

2.7 Turning On the Power - - - - - - - - - - - - - - - - - - - - - - - - -29

Inrush Current - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -30

Reverse Polarity - - - - - - - - - - - - - - - - - - - - - - - - - - - -30

Chapter 3 Connecting the Load

3.1 Load Considerations - - - - - - - - - - - - - - - - - - - - - - - - - -31

3.1.1 When the Load Current Has Peaks or is Pulse-shaped

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -31

3.1.2 When the Load Generates a Reverse Current to the

Power Supply - - - - - - - - - - - - - - - - - - - - - - - - - - - -32

3.1.3 When the Load Has Accumulated Energy Such As

Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -32

3.2 Connecting the Load - - - - - - - - - - - - - - - - - - - - - - - - - -33

3.2.1 Load Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - -34

Current capacity of the load cable - - - - - - - - - - - - - - - -34

10 PMC-A

Contents

Dependence of allowable cable current on the maximum

allowable insulator temperature - - - - - - - - - - - - - - - - -34

Taking measures against noise - - - - - - - - - - - - - - - - - -35

Voltage rating of the load cable - - - - - - - - - - - - - - - - - -35

3.2.2 Connecting to the Output Terminal - - - - - - - - - - - - -35

Chapter 4 Basic Operation

4.1 Constant Voltage (CV) and Constant Current (CC) Power

Supplies - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 37

Crossover point - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 39

Example of CV/CC mode operation - - - - - - - - - - - - - - -39

4.2 Using the Power Supply as a Constant Voltage Power Supply

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -40

Output Setup Procedure - - - - - - - - - - - - - - - - - - - - - - -40

4.3 Using the Power Supply as a Constant Current Power Supply

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

Output Setup Procedure - - - - - - - - - - - - - - - - - - - - - - -40

4.4 Protection Function - - - - - - - - - - - - - - - - - - - - - - - - - - - 41

4.4.1 Overvoltage Protection (OVP) Function - - - - - - - - -41

Setup procedure of the OVP trip point - - - - - - - - - - - - -41

Clearing alarms - - - - - - - - - - - - - - - - - - - - - - - - - - - - -42

4.4.2 Overheat Protection (OHP) Function - - - - - - - - - - -42

4.4.3 Other Protection Functions - - - - - - - - - - - - - - - - - -42

4.5 Remote Sensing - - - - - - - - - - - - - - - - - - - - - - - - - - - - -43

Handling of SENSING terminals - - - - - - - - - - - - - - - - -43

Connection and setup procedure - - - - - - - - - - - - - - - -44

4.6 Master-Slave Parallel Operation - - - - - - - - - - - - - - - - - - 45

Handling of J1 Terminal - - - - - - - - - - - - - - - - - - - - - - -45

4.6.1 Functions during Master-Slave Parallel Operation - -46

Connection and setup procedure - - - - - - - - - - - - - - - -47

Starting and ending parallel operation - - - - - - - - - - - - -48

4.7 Series Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 51

Maximum number of power supplies connected in series -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -52

4.7.1 Functions during Series operation - - - - - - - - - - - - -52

Connection and setup proced

Starting and ending series operation - - - - - - - - - - - - - -53

ure - - - - - - - - - - - - - - - -53

Chapter 5 External Control

5.1 External Remote Control - - - - - - - - - - - - - - - - - - - - - - -55

PMC-A 11

Contents

J2 connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -56

5.1.1 Remote Control Connection and Setup - - - - - - - - - -59

Controlling the output voltage using external voltage - - -60

Controlling the output voltage using external resistance -61

Controlling the output current using external voltage - - -61

Controlling the output current using external resistance -62

Output on/off control - - - - - - - - - - - - - - - - - - - - - - - - - -63

5.2 Remote Monitoring - - - - - - - - - - - - - - - - - - - - - - - - - - - -63

5.2.1 External Monitoring of the Output Voltage and Output

Current. - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -63

5.2.2 External monitoring of the operating status - - - - - - -64

Chapter 6 Maintenance

6.1 Replacing the Fuse - - - - - - - - - - - - - - - - - - - - - - - - - - -66

6.2 Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -67

Test equipment required for calibration - - - - - - - - - - - -67

Environment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -67

Calibration Procedure - - - - - - - - - - - - - - - - - - - - - - - - -67

Voltage system calibration procedure - - - - - - - - - - - - -68

Current system calibration procedure - - - - - - - - - - - - - -71

Chapter 7 Specifications

7.1 Specifications (Type I) - - - - - - - - - - - - - - - - - - - - - - - - -75

7.2 Specifications (Type II) - - - - - - - - - - - - - - - - - - - - - - - - -80

7.3 Dimension Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - -85

12 PMC-A

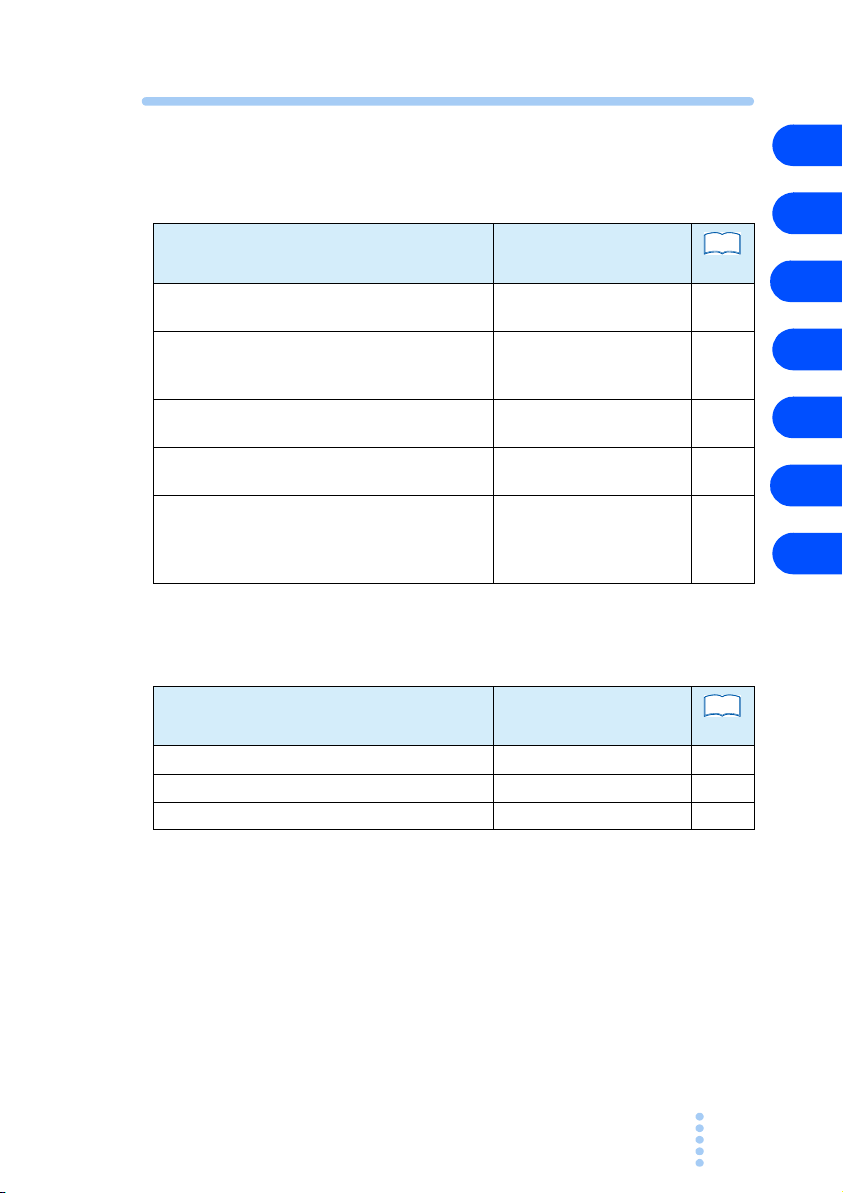

Function index

See

See

Preparation

Usage scenarios Manual sections

Confirming accessories 2 Installation and

Rated input values - quantities 2.5 Connecting the Power

What may be used with power supply

connected to load

Precautions for connecting to remote sensing

lines

Necessary preparations for rack mounting 1.4 Options

Preparation

Cord

7 Specifications

3.2 Connecting the Load

4.5 Remote Sensing

2.4 Rack-mount Adaptor

Installation

7 Specifications

Use

page

23

27

74

34

43

19

26

74

1

2

3

4

5

6

7

Usage scenarios Manual sections

Learning protection details 4.4 Protection Function 41

Learning available function 1.3 Features 18

Clearing alarm conditions immediately. 4.4 Protection Function 41

PMC-A 13

page

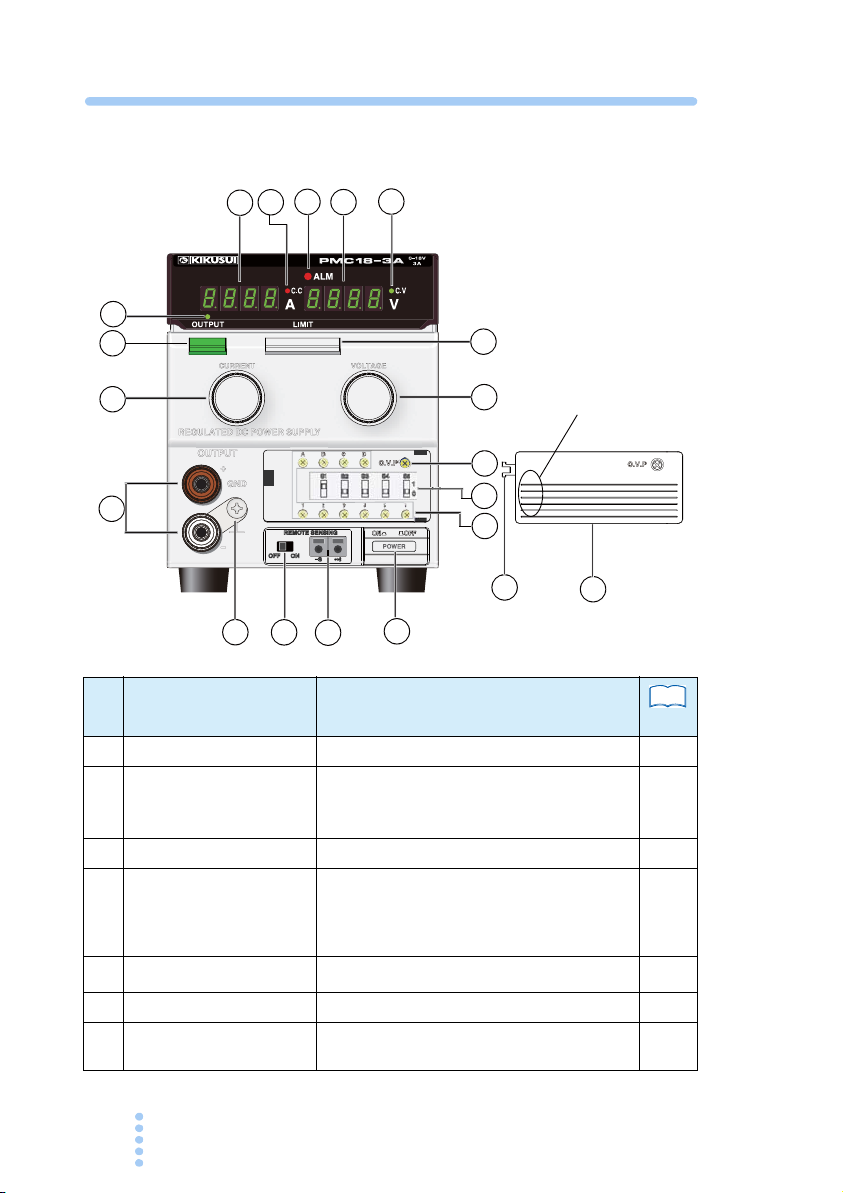

Front panel

1

11

2

3

4

5

6

7

8

9

10

12

13

14

15

16

17

18

19

㧖

275*275*

Press this indicated area

toQRGPVJGEQXGT

No.

1 POWER switch

2 OUTPUT switch

Name Description

Depressed position is ON

Depressed position is ON. When this switch

is turned OFF, the OUTPUT of the power

supply is at high impedance (several k

3 OUTPUT LED

4 LIMIT switch

Lights when the output is ON. (Green)

The voltage and current settings are displayed while this switch is held down.

Ω).

This switch only displays the current setting.

It is not a memory function.

Vol tm eter Displays the voltage.

5

6 Ammeter

7 C.V LED

14 PMC-A

Displays the current.

Lights when operating in constant voltage

(CV) mode. (Green)

See

page

29

40

−

40

−

−

40

No.

See

8 C.C LED

9 VOLTAGE knob

10 CURRENT knob

11 OUTPUT terminal

12 GND terminal

SENSING terminal *1 Remote sensing terminal. 43

13

SENSING switch *1 Enables remote sensing. Turn off the switch

14

15 OVP variable resistor

ALM LED Lights when the overvoltage or overheat

16

S1 to S4 switches Used for analog remote control.

17

S5 switch Used for master-slave parallel control.

Variable resistor for cali-

18

bration

19 Front sub-panel cover

Name Description

Lights when operating in constant current

(CC) mode. (Red)

Sets the output voltage. (10 turns)

Sets the output current. (10 turns)

Red : + (positive) terminal

White : - (negative) terminal

Connect either output terminal to the GND

terminal using the short bar unless your

application requires the power supply output

to be floating.

Since Type II models use a relay switch

system, a relay switch noise may appear at

the rising edge of the output when the input

voltage is low or depending on the load

condition.

Connected to the chassis of the power sup-

ply.

when you are not using remote sensing.

Sets the OVP (Overvoltage Protection) trip

point.

protection circuit strips entering an alarm

status. (Red)

Used to calibrate the output voltage and the

meter.

To open the cover, press the part indicated

as PUSH. You can remove the cover by pull

ing the opened cover. Even if the claw (indi-

cated with ) breaks, the cover can be

attached without problem.

㧖

page

40

−

−

2

3

4

1

35

5

6

−

43

41

41

56

67

-

−

7

*1 Not available on models with rated output of 70 V or higher.

PMC-A 15

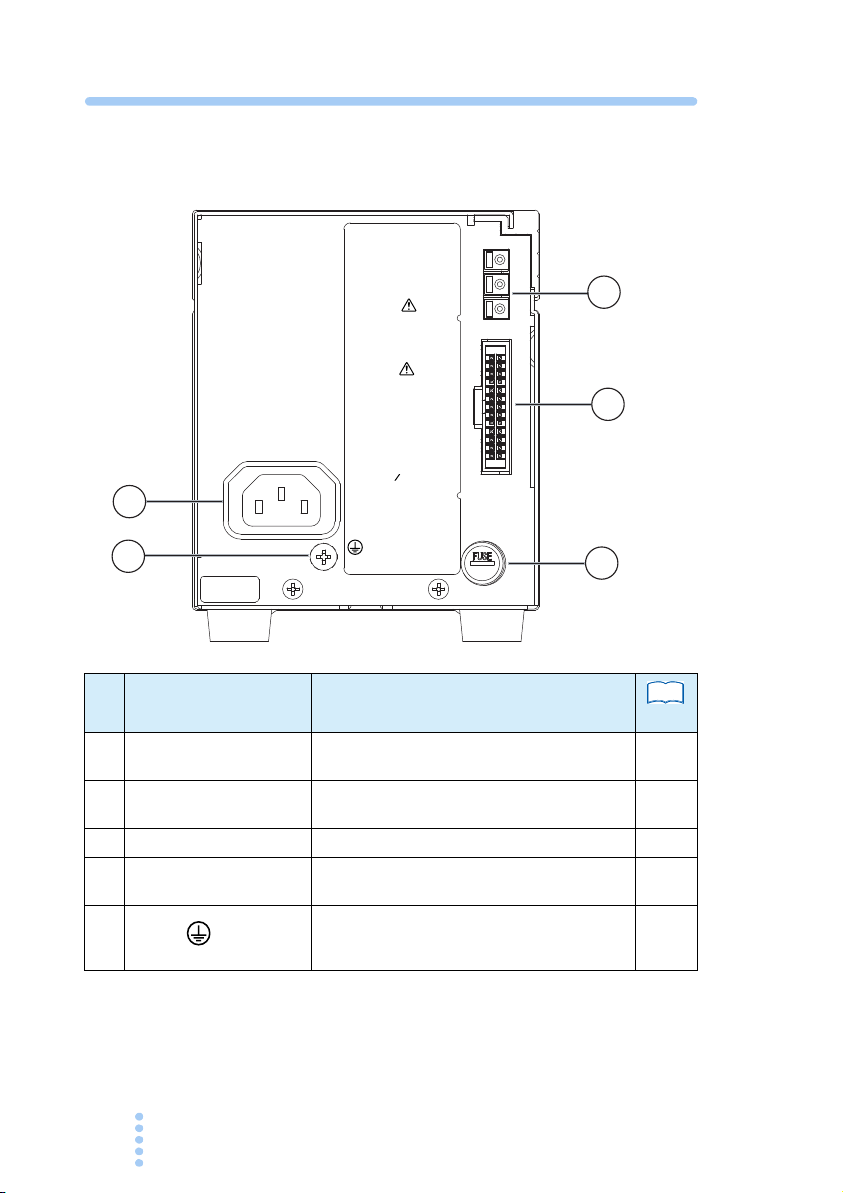

Rear Panel

J

1

J

2

KIKUSUI

ELECTRONICS

CORP.

WARNING

FOR CONTINUED

PROTECTION AGAINST

FIRE HAZARD,

REPLACE ONLY WITH

SAME TYPE AND

RATING FUSE.

CAUTION

TO AVOID ELECTRIC

SHOCK, THE AC POWER

CABLE PROTECTIVE

GROUNDING CONDUCTOR

MUST BE CONNECTED

TO GROUND. DO NOT

REMOVE COVERS,

REFER SERVICING TO

QUALIFIED PERSONNEL.

INPUT

AC100V 50 60Hz

MAX280VA

MADE IN CHINA

FUSE

AC250V

4A (S.B

)

1

2

3

1

2

3

4

5

No.

Name Description

See

page

J1 connector Input/output terminals for master slave par-

1

J2 connector Terminals for analog remote control and

2

Fuse holder Contains an AC input fuse (S.B type) 66

3

INPUT connector Power cord connector for supplying power

4

5

allel operation.

monitoring function.

to the power supply.

Protective conductor terminal.

Always ground the power supply.

43

45

56

27

28

16 PMC-A

General Description

1

This chapter gives an overview and introduces the features of

the PMC-A Series.

1.1 About This Manual

The PMC-A series come in two types depending on the size of

case. This operation manual describes the following models.

■ Type I

PMC18-1A, PMC18-2A, PMC18-3A, PMC35-0.5A,

PMC35-1A, PMC35-2A

■ Type II

PMC18-5A, PMC35-3A, PMC70-1A, PMC110-0.6A,

PMC160-0.4A, PMC250-0.25A, PMC350-0.2A,

PMC500-0.1A

1.2 Product Overview

The PMC-A Series are compact, high-performance, constant

voltage, constant current Series regulated DC power supplies.

The adoption of Series regulated design realizes a highly stable

output with a low level of output noise. In addition, with an

optional power supply controller, it allows to operate via GPIB

systems which offers wide application in the field of R&D,

Manufacturing, Testing, etc.

PMC-A 17

1.3 Features

● Digital display on both voltage and current at the same

time.

The PMC-A series power supply has two bright LED meters

that display the output voltage, output current, and their set

tings.

● High-resolution setting for output voltage and current.

The variable resistors for the output voltage and current set-

tings are 10-turn wire wound type, allowing high-resolution

settings.

● Output ON/OFF by external contact

The output ON/OFF switch is an electronic switch that emits

no chattering or noise. The switch can also be controlled

remotely.

● External Remote Control

The output voltage and current can be controlled remotely

using an external analog signal (voltage or resistance). By

connecting a power supply controller such as KIKUSUI's

PIA3200 or PIA4810 via the GPIB interface, the PMC-A

series power supply can be integrated into a system such as

an automated test system.

-

● External monitor function

The monitor output enables to monitor the status output, out-

put voltage, and output current from outside of the PMC-A.

● Remote sensing function

The remote sensing function stabilizes the output voltage

across the load. (equipped with 18 V, 35 V models)

● Equipped with overvoltage protection (OVP) function

as standard.

• To control the PMC-A series power supply using

KIKUSUI's PIA3200 (via the GPIB interface), the ROM

version of the PIA3200 must be 1.03 or later. If not, the

18 PMC-A

ROM needs to be upgraded. To have the ROM upgraded,

contact your Kikusui agent or distributor.

• On Type II models, the internal loss is decreased by

changing the input voltage of the series regulator. The

input voltage is changed by switching secondary taps of

the internal transformer using relays. The relay has three

switch points and changes depending on the input volt

age. If the input voltage fluctuates when the output volt-

age of power supply is used near a relay switch point, you

may hear the sound of the relay switching. This is not a

malfunction. When the relay is switched, a spike volt

age at the output voltage may be generated.

1.4 Options

The following options are available for the PMC-A series.

For details, contact your Kikusui agent or distributor.

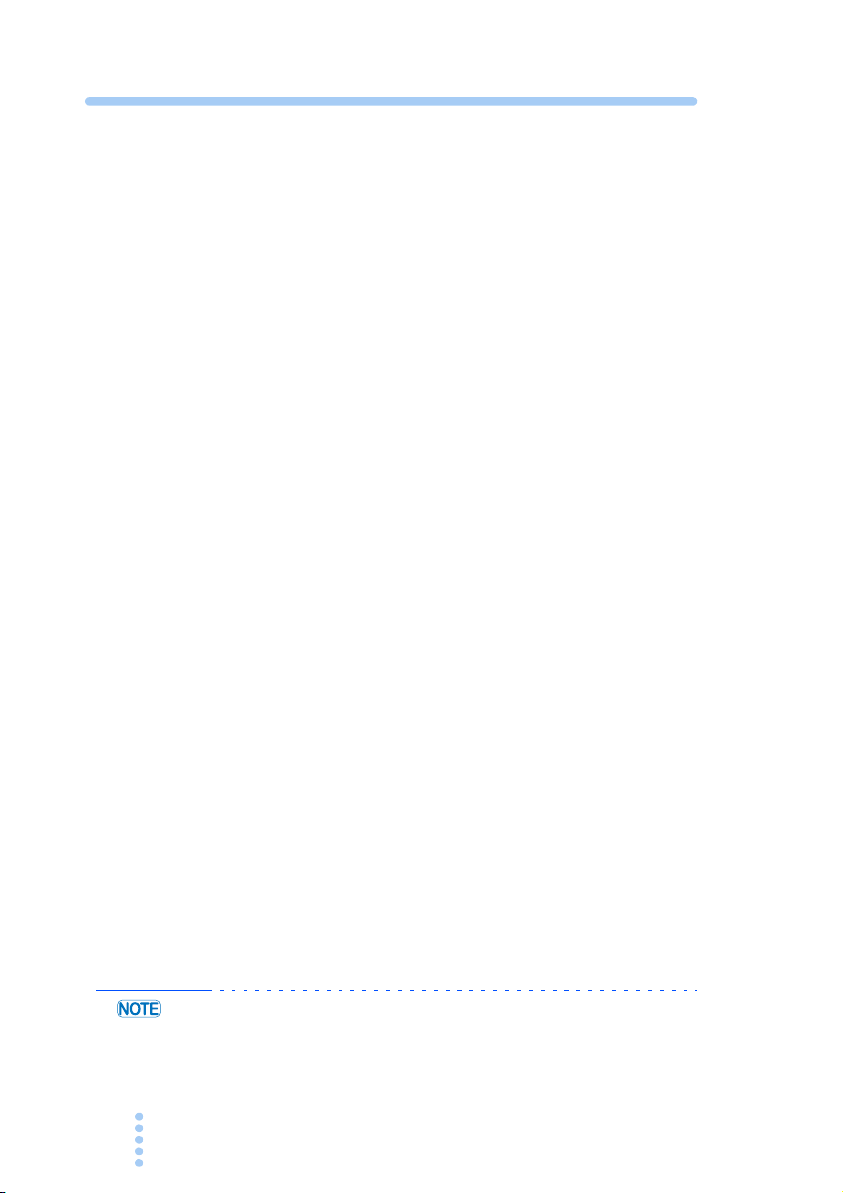

■ Guard cap (GP01-PMC)

-

-

Exchanged with the knob to prevent inadvertent

operation of voltage or current setting.

1

General Description

■ Output terminal cover (OTC01-PMC)

Covers the output terminal to prevent unex-

pected accidents. Applies to models with a

rated output of 70 V or greater.

It is recommended that you use the output ter-

minal cover for your safety.

PMC-A 19

■ Handle (CH01-PMC)

A convenient handle for carrying the

power supply.

Applies to all type II models.

■ Rack mount options

The following options are available for rack mount system.

Name Model Note

Rack adapter

Blank panel

KRA3 inch rack (EIA standard)

KRA150 Milli rack (JIS standard)

KBP3-2

KBP3-4

BP191(-M)

BP1H(-M)

*1

(EIA, JIS common) - 1/2

width

(EIA, JIS common) - 1/4

width

*1

inch rack (EIA standard)

Milli rack (JIS standard)

*1. the model added with “-M” is “mesh” type.

CAUTION

• The PMC-A power supply uses unforced air cooling.

In order to keep a space for cooling intake, at least

one layer of “blank panel” must be installed when

the PMC-A is rack mounted.

JIS standard:50 mm、EIA standard:44.45 mm

*

For details, contact your Kikusui agent or distributor.

20 PMC-A

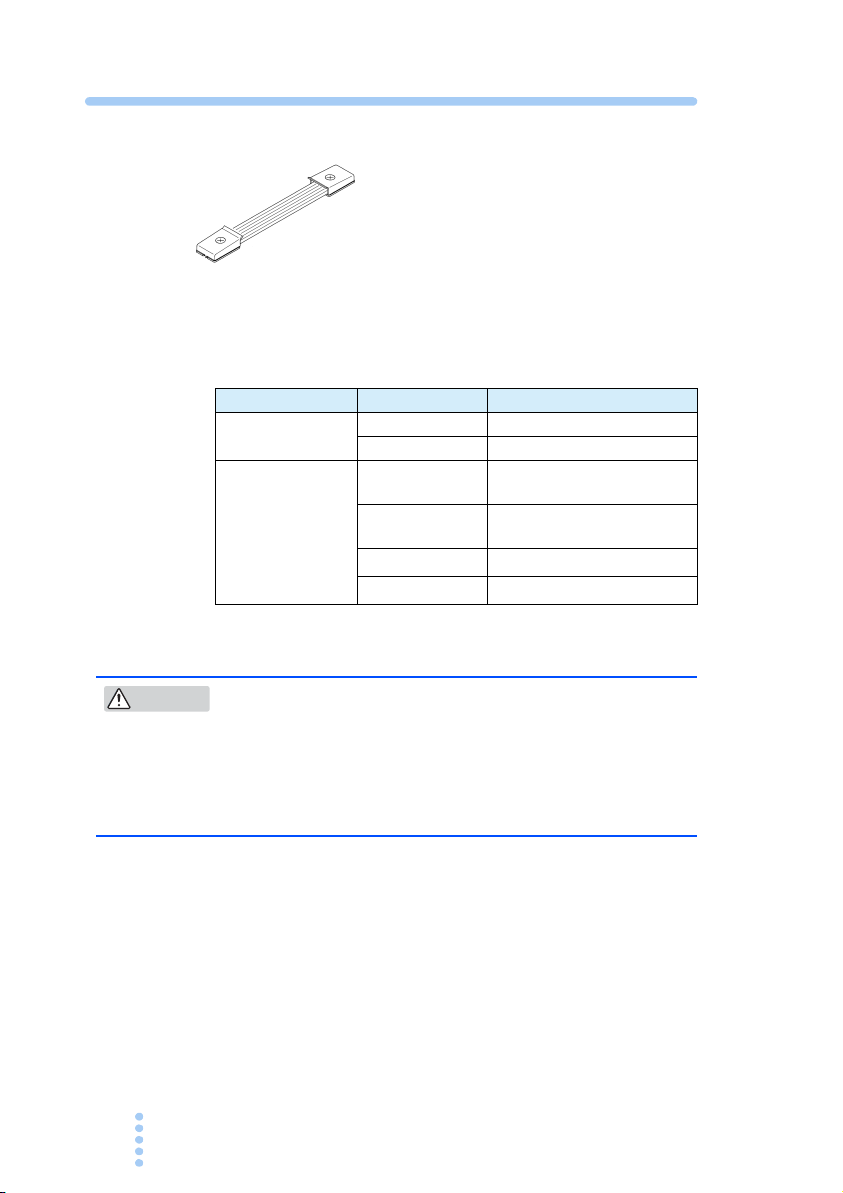

132.5 (5.22)

57 (2.24)

37.75

(1.49)

460 (18.11)

482 (18.98

)

260 (10.24)

Blank panel KBP3-4

Blank panel KBP3-2

149

100

460

480

260

24.5

Rack adapter KRA3

Inch rack EIA standard unit: mm (inch)

Milli rack JIS standard unit: mm

Blank panel KBP3-4

Blank panel KBP3-2

Rack adapter KRA150

1

General Description

Fig. 1-1 Example of installation for rack mount

options

PMC-A 21

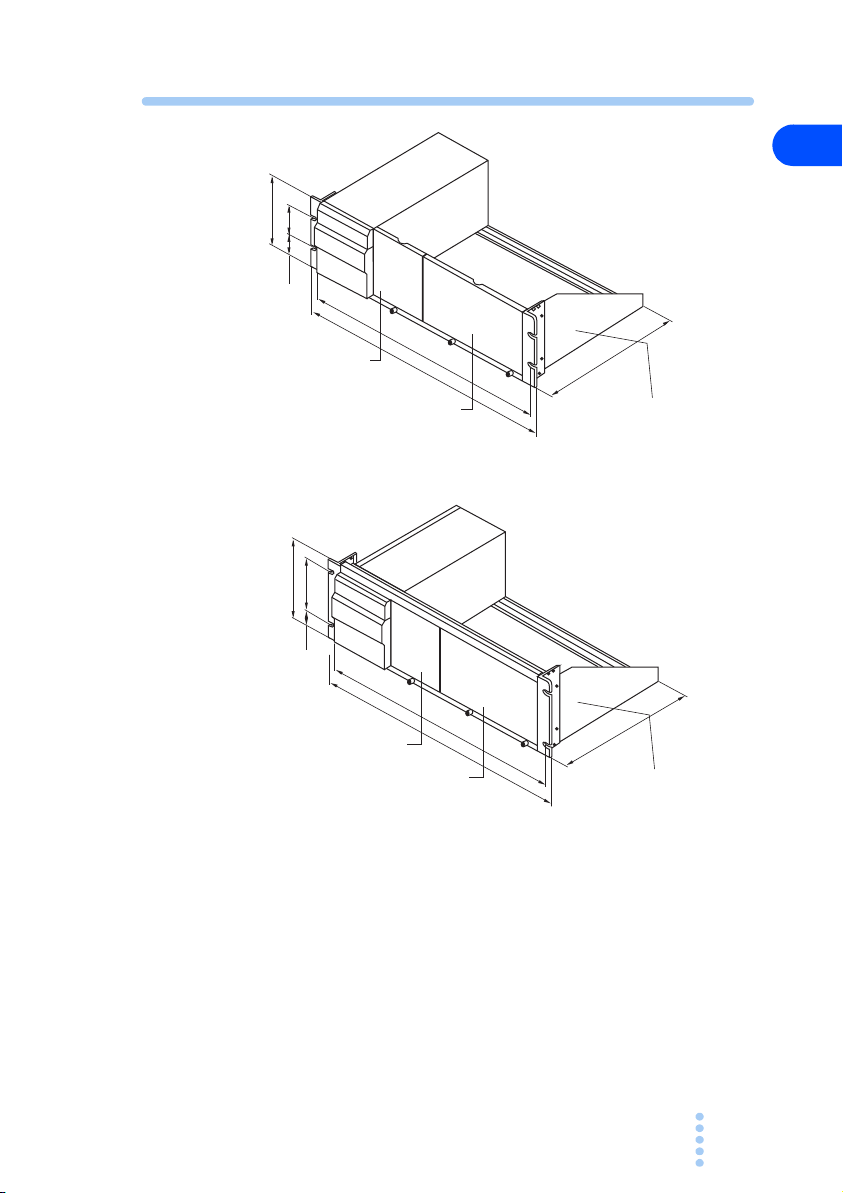

KRA150

KBP3-4

BP1H

KBP3-2

Fig. 1-2 Rack mounting example

22 PMC-A

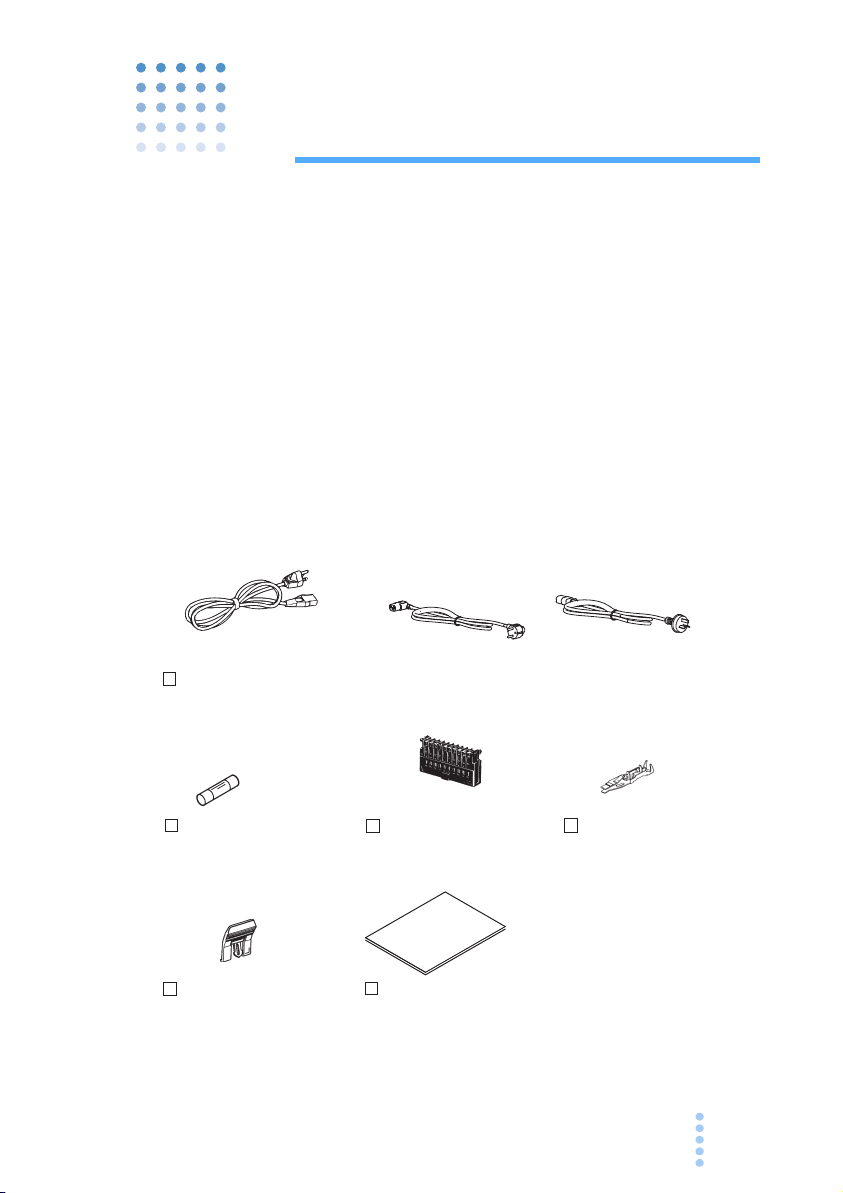

Installation and Preparation

Operation Manual (1pc.)

[Z1-004-632]

Power cord (1pc.)

Fuse (1pc.)

Fuse rating varies

depending on the model.

For details, see Chapter

7, “Specifications.”

[84-49-0100]

Analog remote control

plug (1pc.)

*Attached to the J2 connector on

the rear panel.

[

84-49-0110]

[83-06-5060]

Analog remote

control contact ( 20 pcs.)

[85-AA-0004]

*

The power cord that is

provided varies depending

on the destination at the

factory shipment.

Lock Lever for J2 connector

(1pc.)

*Attached to the J2 connector on

the rear panel.

[85-AA-0005]

PLUG:CEE7/7

[85-10-0790]

PLUG:GB1002

PLUG:NEMA5-15

X 20

2

This chapter explains how to prepare the PMC-A for use from

unpacking to installation.

2.1 Checking the Package Contents

When you receive the PMC-A, check that all accessories are

included and that the accessories have not been damaged dur

ing transportation.

If any of the accessories are damaged or missing, contact your

Kikusui agent or distributor.

We recommend that all packing materials be saved, in case the

PMC-A needs to be transported at a later date.

-

PMC-A 23

Fig. 2-1 Accessories

2.2 Precautions Concerning Installation Location

Be sure to observe the following precautions when installing

the

PMC-A.

● Do not use the product in a flammable atmosphere.

To prevent the possibility of explosion or fire, do not use the

product near alcohol, thinner or other combustible materials,

or in an atmosphere containing such vapors.

● Avoid locations where the product is exposed to high

temperature or direct sunlight.

Do not place the product near a heater or in areas subject to

drastic temperature changes.

Operating temperature range: 0 °C to 40 °C (32 °F to 104 °F)

Storage temperature range: -10 °C to 60 °C (14 °F to 140 °F)

● Avoid humid environments.

Do not place the product in high-humidity locations-near a

boiler, humidifier, or water supply.

Operating humidity range: 10 %rh to 80 %rh

(no condensation)

Storage humidity range: less than 90 % rh

(no condensation)

Condensation may occur even within the operating relative

humidity range. In such cases, do not use the product until

the condensation dries up completely.

● Be sure to use it indoors.

The PMC-A is designed for safe indoor use.

● Do not place the product in a corrosive atmosphere.

Do not install the product in a corrosive atmosphere or in

environments containing sulfuric acid mist, etc. This may

cause corrosion of various conductors and bad contacts of

connectors leading to malfunction and failure, or in the

worst case, a fire.

24 PMC-A

However, operation in such environments may be possible

through alteration. If you wish to use the product in such

environments, consult your Kikusui agent or distributor.

● Do not place the product in a dusty location.

Accumulation of dust can lead to electric shock or fire.

● Do not use the product where ventilation is poor.

The power supply uses unforced air cooling. The air flows

form the bottom panel to the top panel. Do not block the bot

tom and top panels.

The top cover of the product may get high temperature, it

may cause burn on the skin.

Do not install the power supply with the side or front panel

facing up or down.

● Do not place objects on top of the product.

Placing heavy objects on the product may cause malfunction

of the power supply.

Do not stack the power supplies.

● Do not place the product on an inclined surface or loca-

tion subject to vibrations.

The product may fall or tip over causing damages and inju-

ries.

● Do not use the product in a location where strong mag-

netic or electric fields are nearby or a location where

large amount of distortion and noise is present on the

input power supply waveform.

The product may malfunction and cause electric shock or

fire.

-

2

Installation and Preparation

● Do not use the product near highly sensitive measuring

instruments or transceivers.

The noise generated by the product may affect them.

PMC-A 25

2.3 Precautions to Be Taken When Moving

See

the Product

When moving the product to the installation location or when

transporting the product, note the following points.

● Turn off the POWER switch.

Moving the product while the power is turned on can cause

electric shock or damage to it.

● Remove all wiring.

Moving the product with the cables connected can cause

wires to break or injuries due to the product falling over.

● When transporting the product, be sure to use the orig-

inal packing materials.

Otherwise, damage may result from vibrations or from the

product falling during transportation.

● Make sure this manual has been included.

2.4 Rack-mount Adaptor Installation

p.19

26 PMC-A

Before installing the rack-mount adaptor, remove the plastic

feet. How to remove plastic feet is illustrated in

Concerning installation, refer to the KRA3 or the KRA150

installation instructions.

Fig. 2-2.

Loading...

Loading...